#top steel company in india

Photo

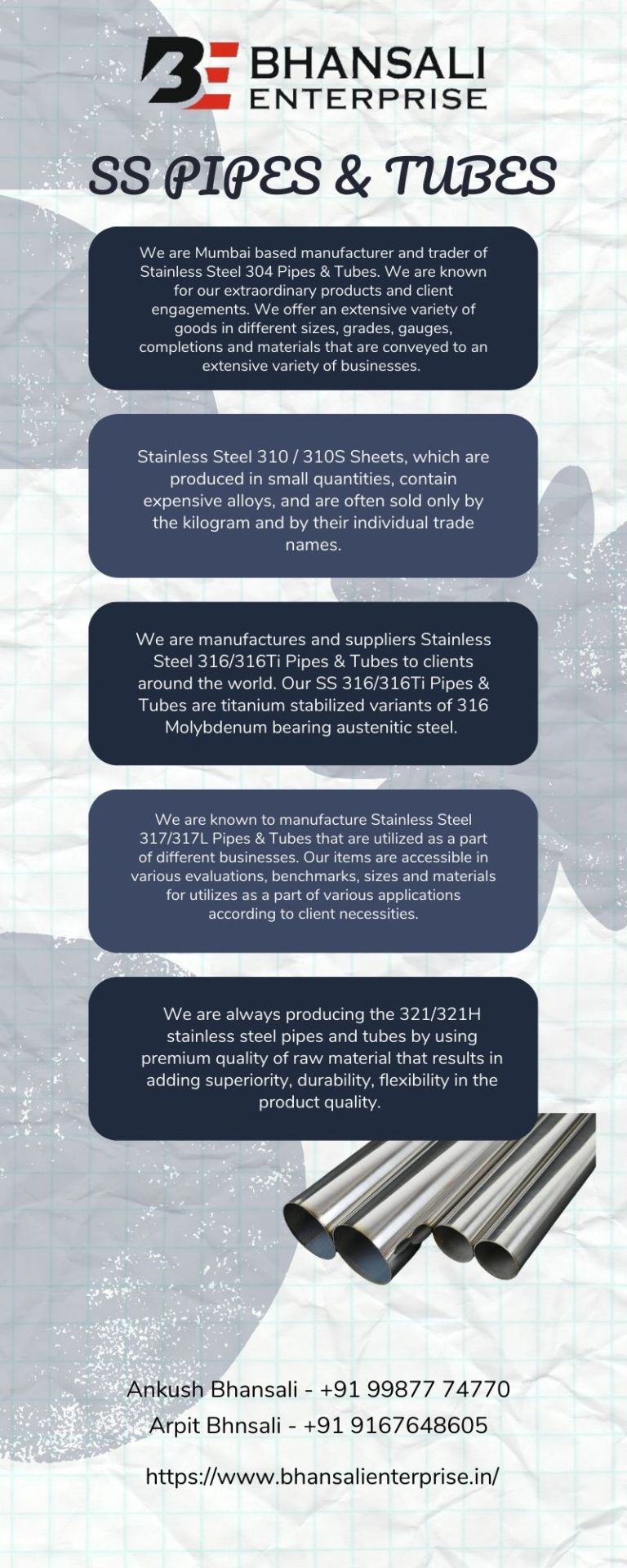

"SS Pipes & Tubes Manufacturer."

We are Mumbai based manufacturer and trader of SS 304 Pipes & Tubes. We are known for our extraordinary products and client engagements. We offer an extensive variety of goods in different sizes, grades, gauges, completions and materials that are conveyed to an extensive variety of businesses. Our SS 304 Pipes are stounding products with an exceptional finishing that we have on offer. We are suppliers, stocks and trades an extensive variety of goods to its clients around the world. Our group of experts monitor the changing market trends and demands to devise products as needs be. We are manufactures and suppliers Stainless Steel 316/316Ti Pipes & Tubes to clients around the world. Our SS 316/316Ti Pipes & Tubes are titanium stabilized variants of 316 Molybdenum bearing austenitic steel. We are known to manufacture Stainless Steel 317/317L Pipes & Tubes that are utilized as a part of different businesses. Our items are accessible in various evaluations, benchmarks, sizes and materials for utilizes as a part of various applications according to client necessities. We are a reliable supplier with a straightforward motive of supplying the high quality of product and maintain good market value. We are always producing the 321/321H stainless steel pipes and tubes by using premium quality of raw material that results in adding superiority, durability, flexibility in the product quality.

#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor

1 note

·

View note

Text

Prime Gold TMT Bars continuously emerge as essential threads, weaving strength, sustainability, and technological power into the urban industry. We are recognized as the best quality TMT bars and the preferred choice of TMT bars suppliers in Delhi by successfully contributing towards the future, where our cities stand not just as architectural marvels but as enduring symbols of progress and resilience.

#TMT Bar#TMT Bars#Quality TMT Bars manufacturers#Top 10 manufacturer of TMT#Best TMT Bars#Best TMT Bar#best tmt bars supplier#best quality TMT Bars in India#best tmt bars manufacturer in India#manufacturer of steel#Best quality TMT Bars#Price of TMT bars#Price of TMT steel#Best TMT Bar Company#Best TMT Bar For House Construction#Best TMT Bar In Delhi#Best TMT Bars For Construction#Best TMT Bars In India#total steel supplier#TMT Bars Company#TMT Bars Manufacturers In India#Top 10 TMT Bar#Top 10 TMT Bar In India#TMT Bars Suppliers#Top TMT Bar

0 notes

Text

Leading and Top Steel Structure Companies in India - MAK Buildings

Explore the top steel structure companies in India for the best in quality and reliability. MAK Buildings provides innovative designs and robust constructions. Trust us for your projects, ensuring timely delivery and exceptional service for all your structural needs.

0 notes

Text

LEADING THE INDUSTRY: THE TOP 10 LARGEST STEEL COMPANIES IN INDIA FOR 2024

The manufacturing landscape is undergoing a significant transformation, and the steel industry is no exception. As digitalization takes center stage, the need for effective digital marketing strategies has become paramount. This blog post delves into the top 10 largest steel companies in India for 2024 and explores how they’re leveraging innovative digital marketing initiatives to stay ahead of the curve.

These industry titans are redefining the digital marketing landscape within the manufacturing sector, from search engine optimization (SEO) to social media engagement. By partnering with a specialized digital marketing agency for manufacturers, these steel giants are amplifying their reach, forging stronger customer relationships, and driving significant business growth.

0 notes

Text

#top stainless steel pipe manufacturer#top stainless steel tube manufacturer#stainless steel manufacturing company in india#Stainless Steel Pipe#Stainless Steel Pipes

0 notes

Text

Top Steel Producers - IBEF India

The top steel producers in the world are key players in the global steel industry, commanding significant market share and driving innovation. With state-of-the-art facilities, advanced technology, and a skilled workforce, these producers consistently deliver high-quality steel products to meet diverse industry demands. Their extensive product portfolios cater to various sectors, including construction, automotive, and infrastructure. To get more information on tata steel india, visit the India Brand Equity Foundation website.

#largest steel plants in the world#top steel producers#world biggest steel company#tata steel india#world's largest steel companies#iron manufacturing companies

1 note

·

View note

Text

plastic kitchenware manufactures in india | best kitchen gadgets in india | kitchen accessories manufacturers | latest kitchenware

Paar Kitchen is a leading manufacturer of plastic and stainless steel kitchenware manufacturer in India. As one of the best kitchenware manufacturers in India, they provide the latest kitchenware and best kitchen gadgets to their customers. They are also among the top stainless steel kitchenware manufacturing companies in Mumbai and India, offering top-quality products that are both durable and stylish. Paar Kitchen is known for producing a wide range of kitchen accessories that cater to different needs and preferences. As a trusted name in the industry, they are also one of the best kitchenware manufacturers in Mumbai. Their products are among the top-rated in the market, making them a go-to choice for customers looking for high-quality kitchenware companies in India.

#plastic kitchenware manufactures in india#best kitchen gadgets in india#kitchen accessories manufacturers#latest kitchenware#Top Stainless Steel kitchenware Manufacturing Companies in Mumbai#top stainless steel kitchenware companies in India#kitchenware companies in India#kitchenware manufacturers in mumbai

0 notes

Text

The best TMT bar supplier in Jalna is Kalika Steel

With reliable steel products from Kalika Steel, the premier TMT bars supplier in Jalna, Jalna's skyline will rise to new heights. Precise steel products will sustain every construction.

#best tmt bars manufacturers#best tmt bars manufacturers in india#best tmt bars supplier#best tmt bars manufacturer#best tmt bars company#best tmt bars company in india#best tmt bar manufacturers in india#top tmt dealers in jalna#steel manufacturers in jalna#tmt bar manufacturers in jalna

0 notes

Text

#best stainless steel supplier in india#top 10 metal companies in india#stainless steel manufacturing industry#stainless steel cold rolled coils#cold rolled coil

0 notes

Text

What is hot-rolled steel? -AMNS INDIA

When it comes to metals, one of the most common is hot-rolled steel. This type of metal is used in a wide range of products and industries, from construction to automotive. If you’re looking to learn more about hot rolled steel, or want to be prepared for what it can do, read on! You’ll find everything you need to know about this common metal. From its composition to its uses, read on to learn everything you need to know about hot-rolled steel.

What is hot-rolled steel?

A hot rolled sheet is a type of steel that is heated up to a high temperature and then rolled into sheets. The high temperature makes the metal harder, so it can be used in things like beams and windows.

Types of hot rolled steel

There are three types of hot rolled steel - round, flat, and square. The round hot rolled coil is the most common type and is usually used for structural applications. The flat is less common but more flexible than round steel and is commonly used in sections that need to be bent or curved. Square steel is the most unusual type and has a higher strength-to-weight ratio than round or flat steel.

Advantages and Disadvantages of Hot Rolled Steel

Hot rolled steel is a type of steel that is produced by Rolling the steel around a critic. The benefits of hot rolled steels include high strength and ductility, which make them well-suited for many uses including construction and engineering. One disadvantage of these steels is that they can be more difficult to work with than other types of steel, making them more expensive.

Applications for Hot Rolled Steel

Hot rolled steel is a type of steel that's produced by rolling heated sheets of metal around a series of long, thin dies. The resulting products are usually thinner and have a more consistent thickness than cold-rolled steel, making them ideal for applications where strength and flexibility are important.

The main advantages of hot-rolled steel over cold-rolled steel include:

-Thinness: Hot-rolled steel is typically about half as thick as cold-rolled steel. This makes it easier to work with and allows for more flexible design options.

-Shrinkage: Hot-rolled steel shrinks less than cold-rolled steel when exposed to heat or moisture. This makes it a better choice for applications where durability is critical, like in the automotive industry.

-Consistency: Hot-rolled steels are often more consistent in thickness than cold-rolled steels, which can help reduce costs and simplify manufacturing processes.

Conclusion

Hot-rolled steel is a type of steel that has been heated-treated to improve its toughness and wear resistance. It is used for various applications, including vehicle frames, bridges, and buildings.

#hot rolled steel#steel#steel companies in india#steel company in india#steel manufacturer#top steel brand in india

0 notes

Video

undefined

tumblr

"Copper Bars Manufacturers."

Bhansali Enterprise is known around the world as a trustworthy business with a lot of customers. Copper Round Bars are offered by us because we are focused on our customers. We supply the bars in a variety of widths and wall thicknesses to meet the specifications of our customers. In addition, we provide prompt shipping by ordering consignments that are in good condition and meet your material requirements. Copper Round Bars are manufactured using alloy of superior quality at our well-functioning manufacturing unit. The entire scopes of bars are created under the severe direction of expert specialists alongside the viable utilization of accessible most recent innovation and present day devices. Bhansali Enterprise manufactures industrial Copper Square Bars of a high quality. We have a lot of ferrous and non-ferrous bars, which are popular in a variety of engineering fields. We are making square bars here in a variety of specifications, standards, designations, and non-standard sizes. The high-quality copper used in the processing of square bars further ensures their functionality. It is well-known for its greater strength and toughness. Additionally, it can be found in both magnetic and non-magnetic forms.

#stainless steel round bar#manufacturer of stainless steel in india#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor#polished stainless steel#stainless steel manufacturers in india

0 notes

Text

How do we improve the hot dip galvanizing process?

Hot dip galvanizing is a process that's been around for a long time and it's still one of the most popular ways to coat metal surfaces with a protective coating. Now, we will provide everything you need to know about how we improve the hot dip galvanizing process.

What is Hot Dip Galvanizing?

Hot dip galvanizing is a popular method for improving the appearance and protection of metal surfaces. It is a relatively simple process that uses a metal coating to increase the lifespan of a surface.

The main ingredients in hot dip galvanizing are zinc and iron. The zinc reacts with the iron to create a protective layer that prevents corrosion. The process is simple: first, the metal object is cleaned and prepared by sanding or roughening the surface. Then, the zinc coat is applied using a sprayer or brush. Finally, the iron coat is applied in layers until it covers the zinc layer.

What factors to consider when choosing hot dip galvanizing as a technique?

There are several important factors to consider when choosing hot dip galvanizing as a protection technique for metal objects: location, climate, material, and application methods. Location is key because weather conditions affect how long the zinc coating lasts. In cold climates, for example, zinc will not corrode as quickly, so it may be more effective to use this approach in areas where outdoor exposure is limited.

Climate can also affect how neighborhoods treat their roadways – if they are treated regularly with hot-dipped galvanizing, this will help protect them from weathering and degradation over time.

What material you choose for your project is also important – metals such as steel tend to corrode more easily than other materials such as aluminum. Hence, it's important to pick an appropriate coating for your project. Finally, application methods are also critical – using the wrong technique can lead to uneven coverage.

What are the Benefits of Hot Dip Galvanizing?

The benefits of hot dip galvanized steel are many and varied. Primarily, it provides a durable finish for metal surfaces. It also helps protect against corrosion and other damage. It can also make metal objects more weather-resistant, making them ideal for outdoor use. Finally, hot dip galvanizing is an effective way to change the color of metal surfaces.

What is the Hot Dip Galvanizing Process?

The Hot Dip Galvanizing Process is a manufacturing process used to improve metal surfaces' appearance and corrosion resistance. The process involves dipping a piece of metal in molten zinc, forming a protective coating on the surface.

What are the Advantages of Using Hot Dip Galvanizing?

There are many advantages to using hot dip galvanizing in a manufacturing process. One of the main benefits is that the hot dip galvanized plant is environmentally friendly and does not use harsh chemicals. It also has high corrosion resistance, making it an ideal choice for products exposed to salt water or other corrosive substances. Additionally, hot dip galvanizing can provide a protective layer over metal surfaces, helping them to resist wear and tear.

Conclusion

The hot dip galvanizing process is a cost-effective way to improve metal surfaces' appearance and corrosion resistance. It can also be used to create durable coatings for areas prone to moisture exposure, such as external hardware and electrical components.

#steel companies in india#steel company in india#steel manufacturer#production of steel in india#no 1 steel company in india#integrated steel plants in india#best steel brand in india#top steel brand in india#steel#sheet#coil

0 notes

Text

What is Pre painted Galvanized Iron (ppgi) ?

Galvanized iron is a popular material for fencing, gates, and other structures. It's strong and durable, making it a good choice for outdoor projects. But what are the benefits of buying pre-painted galvanized iron? Now, we will explore the benefits of pre-painting galvanized iron. From saving time on painting to ensuring consistent color throughout the structure, read on to learn everything you need to know about this popular material.

What is galvanized iron?

Galvanized iron is a rust-resistant material that has been coated in a layer of zinc. This coating makes galvanized iron difficult to rust and makes it resistant to corrosion. One can easily look to buy stainless steel sheet online at affordable prices.

Types of galvanized iron

Pre-painted galvanized iron (ppgi) is a great option for homeowners and businesses who want to update their exterior without doing any of the painting themselves. PPGI can be used on roofs, balconies, doors, windows, and more. Some of the benefits of using PPGI include the following:

-No painting required: PPGI is pre-painted and comes in various colors and designs, so you don't have to worry about the paint job afterward.

-Uniform finish: Thanks to its pre-painted finish, you'll get a uniform look across your entire frame.

-Durable: PPGI is made from durable steel that will last for years.

If you're looking for an affordable way to update your exterior look, then gp sheet is the perfect option. With so many colors and designs available, there's sure to be one that suits your needs.

Benefits of buying ppgi

Pre-painted galvanized iron (PPGI) is a great option for DIYers and homeowners who want to protect their property from the elements. Here are some of the benefits of buying PPGI:

-PPGI is weatherproof so that it can withstand harsh weather conditions.

-It's affordable, so you can buy as much or as little as you need.

-PPGI is easy to install, so that you can install it quickly and easily.

-PPGI has a long lifespan, so that it will last for years.

-ppgi is durable and can last for many years.

-ppgi is easy to maintain and requires little maintenance.

-ppgi has a matte finish that looks great and makes it resistant to corrosion.

Disadvantages of using ppgi

There are a few disadvantages to using ppgi in your construction project. The main disadvantage is the price - ppgi is usually more expensive than other types of metal. Additionally, ppgi is not corrosion resistant, so it requires special care when painting and protecting it from weathering. Finally, ppgi is less strong than other metals, so it may not be suitable for use in high-traffic areas or structures that need to support heavy loads.

Conclusion If you are looking for a cost-effective way to protect your property from the elements, then pre-painted galvanized iron (ppgi) might be the right solution.

#steel companies in india#steel company in india#steel manufacturer#production of steel in india#no 1 steel company in india#integrated steel plants in india#best steel brand in india#top steel brand in india#largest steel producer state in india#crca sheet manufacturers in india#cold rolling mill manufacturers in india#gc sheets manufacturers in india

1 note

·

View note

Text

Christmas Punch

Some point to the ancient Hindustani word "paanstch", which means five: a great drink prepared from five key elements - sweet, sour, alcohol (arrak), water and spices. Some, however, attribute it to English merchant sailors who, though they did not invent the punch, very much drank it. Men working on British East India Company ships used it as a beer alternative in the 17th century. The sailors were known to consume large quantities of beer on their voyages, but when the ships reached the warmer waters of the Indian Ocean, the beer in the cargo bays became rancid and stale. Once the ships reached the coast, the sailors created new drinks from ingredients native to their destination: Arrack, citrus fruits and spices. Back at sea or at home, rum or brandy or other wines were more likely to be used.

Naval Officers and a Bowl of Punch by Thomas Rowlandson c.1790 (x)

The sailors brought punch back with them to Britain. With its exotic flavours and expensive ingredients, it became a fixture in the elite homes of 17th-century England and then a staple. Some parties, however, tended to get out of hand. Like the celebration of Edward Russel, captain-general and commander in chief in the Mediterranean. On 25 October 1694 he had a garden party for 6000 guests in his villa, and had his marble fountain filled with punch. For this, 4 hogsheads (c. 960l) of brandy, 8 hogsheads of water, 25000 lemons 75l of lime juice. 560kg of sugar, 3kg of nutmeg, 300 toasted biscuits and a pipe of dry mountain Malaga. The punch was served by a ship's boy who rowed through the fountain in a small boat.

Sailors sharing both punch and wenches. Taken from “Grog on Board” by Thomas Rowlandson, 1789 (x)

Punch entered the middle class as ingredients became more affordable during the 18th century. Punch was ubiquitous in the British Atlantic world and spread to the American colonies. So why is it considered more of a Christmas drink. It was because many of the merchants stayed at home during the winter months and made punch for the family on Christmas Day with the spices they had bought for themselves locally. This made it something special and is therefore often associated with the Christmas season, even though it was served all year round, especially when the spices became affordable for many.

And if you want to make now your own punch here is a nice recipe.

Bombay Presidency Punch in Bombay Government, August 13, 1694

Servings: 2

Prep Time: 5 minutes

2 Tbsp sugar

2 Tbsp lime or lemon juice

1/2 cup rum

3/4 cups water

nutmeg

In a non-reactive bowl or pitcher, mix together the sugar and the juice and stir until dissolved. (Please use a glass, pottery, or stainless steel bowl or pitcher. Copper, cast iron, and aluminum will react with the acid in the lemon juice.)

Remove any seeds that may have made their way into the bowl. Blend in the rum, and then the water.

Add ice. Then grate nutmeg over the top.

Enjoy your tipple!

73 notes

·

View notes

Text

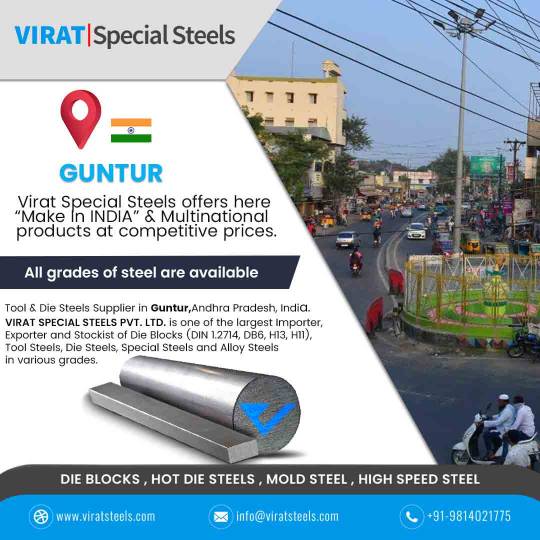

Exploring the top-notch Tool and Die Steel Supplier in Guntur, Andhra Pradesh?

Tool and Die Steel Supplier in APIIC Guntur Industrial Area. Look no further! Virat Special Steels delivers excellence.

Whether it’s tool steel, die steel, mold steel or any other steel requirement, Virat Special Steels stands out as a trusted supplier in Andhra Pradesh!

A significant part of this industrial development is the tool and die steel sector. Tool and die steel are crucial components in manufacturing, used to create a variety of tools, dies, molds, and other essential parts for industries like Forging and Stamping Companies, Metal Fitting, Automotive, Aerospace, and Medical devices.

For tool and die steel requirements in APIIC Guntur, you can consider suppliers like VIRAT SPECIAL STEELS PVT. LIMITED , INDIA . They offer a wide range of tool and die steels, including:

Die Steel (HH 370 – 410 BHN) (DB6 / DIN-1.2714 / AISI L6)

Hot Work Steels (DIN 2343, 2344 / AISI H11, H13)

Plastic Mould Steels (DIN 2738, 2311 / AISI P20)

High Speed Steels (DIN 3243, 3343 / AISI M2, M35)

Cold Work Steels – HCHCr (DIN 2379, 2080 / AISI D2, D3)

Alloy Steels (EN-Series, etc.)

With a state-of-the-art plant in Gurugram and Ludhiana, they ensure quality and reliability. Their strong distribution network across India makes them accessible to customers nationwide.

You can explore their offerings here:

https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-guntur/

Any further queries feel free to contact us :

🌐https://www.viratsteels.com 📨 [email protected] 📞 +91 98140-21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#steel#andhrapradesh#guntur#APIIC#DieSteels#ToolSteel#SteelTrades#H11Steel#H13Steel#DB6Steel#DIN2714

2 notes

·

View notes

Text

Alloy wheels and steel wheels.

When talking about the wheels of a car, the most commonly used term is what we call “the alloys." The alloy wheel type created a massive impact on the automotive sector, especially on the durability, weight, and most importantly, the performance of a car. The invention of these wheel types made way for the origin of several manufacturing companies focusing especially on the alloy wheel type.

Moreover, there is another wheel type known as steel wheels, which are older wheel types. Though the weight of these wheel types decreases acceleration and fuel efficiency, they have an advantage over alloy wheels in that they are resistant to impact cracks.

What is an alloy?

Before discussing the advantages of alloy wheels, we should know about the term "alloy." Technically, alloy means the mixture of one or more metals to form a strong compound. When it comes to automobiles, alloying a wheel means the blending of aluminum and nickel to form a certain type of compound that has certain properties, such as heat resistance, resistance to corrosion, and most importantly, light weight, which enhances the fuel efficiency and acceleration of a car compared with steel wheels.

Currently, Uno Minda is the top-tier alloy wheel manufacturer in India. They make the top-quality alloy wheels for most of the cars produced in India.

Advantages of alloy and steel wheels.

Both alloy wheels and steel wheels have their own advantages and disadvantages. Some of the major advantages of alloys over steel wheels are mainly their light weight, anti-rusting properties, high heat resistance capacity, etc. As a result of these three properties, there is a hike in the performance of the car. The major disadvantage of this wheel type is the high manufacturing and maintenance costs.

Steel wheels have comparatively high durability and a low cost of maintenance and manufacturing compared to alloy wheels. These wheel types are recommended for winter usage and for high-power vehicles running in low-temperature areas.

2 notes

·

View notes