#monel metal composition

Photo

"Monel Alloy 400 Manufacturer."

Monel Alloy 400 is almost immune to chloride associated ion pressure corrosion cracking in ordinary environments. Although, its corrosion resistance is very good in reductive environments, it’s far taken into consideration to be bad in oxidative conditions. Monel Alloy 400 Rod is known to have great mechanical properties at even at subzero temperatures. The alloy can be used in temperatures up that go to 1000° F. Monel 400 has a high melting point, it melts between the temperature range of 2370° F – 2460° F. Since alloy 400 has low strength in an annealed condition , a variety of tempering techniques may be used to increase the tensile strength.

#stainless steel round bar#manufacturer of stainless steel in india#stainless steel round bar manufacturer in india#ss round bar#monel metal composition#monel 400#monel metal#polished stainless steel#stainless steel manufacturers in india#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor

0 notes

Text

Humming a tune, walking into the empty Stark Laboratory, whistling a tune as I settle down...

'J.A.R.V.I.S, come in, it's playtime...'

Monitor system buzzing, activating processing units...

Evening Ma'am. Feeling Creative, I see. How would you like your ambience, Miss Grace?

'What can I say, J, I'm in the mood for work tonight, Aren't you too? Smiles...Just play whatever Mister Stark has on his playlist...'

Noted. Now Playing- Paint it Black by The Rolling Stones

Going into Creative, Miss Grace...

'Restore all of the last few browsings and display into list, please.'

LAST BROWSINGS:

What are the fundamental principles for designing high-entropy alloys with superior strength, ductility, and corrosion resistance for specific applications?

How can we optimize the microstructure of metallic materials to achieve a balance between strength, toughness, and fatigue resistance for specific applications, such as aerospace and automotive?

How can we ensure the long-term durability and safety of nuclear power plant components, considering the harsh radiation and temperature environments?

What are the environmental impacts of metal extraction, processing, and recycling, and how can we develop sustainable strategies to minimize these impacts?

How can we effectively integrate advanced characterization techniques to understand the degradation mechanisms of metallic components in service, and use this knowledge to improve component life and reliability?

Smiles...

'Thank you, I'll be needing that next...Now give me....sustainable microfibre alloy proportions...'

Very Well. You will now need narrowing down from your records.

Iron-based alloys: Often used in machinery due to abundance and cost-effectiveness.

Nickel-based alloys: Known for high-temperature strength and corrosion resistance, suitable for nuclear components.

Titanium alloys: Lightweight and corrosion-resistant, but expensive. High-entropy alloys: Emerging class of alloys with potential for unique properties.

'Now give the proportions we've considered the last time we looked into our simulators, Only for....the Nickel Based Alloys, make a list...'

Looks over thoughtfully as the list is being formulated...scrolls down the list, switching screens on the holograms...

Monel: A nickel-copper alloy known for corrosion resistance. 63% nickel, between 29% and 34% copper, between 2% and 2.5% iron, and between 1.5% and 2% manganese.

Inconel: A family of nickel-chromium-based alloys, often used in high-temperature applications. 61% nickel, 22% chromium, and 9% molybdenum

Hastelloy: A group of nickel-based alloys with exceptional corrosion resistance in various media. Hastelloy C276, also known as UNS N10276, has the following chemical composition: Nickel (Ni): 57%, Molybdenum (Mo): 15–17%, Chromium (Cr): 14.5–16.5%, Iron (Fe): 4–7%, Tungsten (W): 3–4.5%, Manganese (Mn): 1% maximum, Cobalt (Co): 2.5% maximum, Vanadium (V): 0.35% maximum and Silicon (Si): 0.08 maximum

Incoloy: Nickel-iron-chromium alloys designed for high-temperature applications and resistance to oxidation. Nickel: 38–46%, Chromium: 18–22%, Iron: Balance, Aluminum: 0.3–0.7%, Titanium: 0.15–0.6%, Manganese: 1.5% max, Silicon: 1% max, Carbon: 0.05% max, Sulfur: 0.015% max and Phosphorus: 0.02% max

Smirks, clapping my hands twice, the data reducing to 17 little fragments of hologram, flicking away the unnecessary bits that remain of the non highlighted data...

Data Compiled, Miss.

'Yeah, good... you've been writting down what I've been saying while I was in the simulation unit the other day and today, haven't you...?'

Yes Ma'am.

'Turn all of that, into that research booklet we were asked for, so we can give him what....roughly, an estimated idea of the whole entire suit, merits and demerits, budgeting and assemblance...give him the blueprints too, at the end of it...I have a feeling this one will not... disappoint...'

Working on it, Ma'am.

Runs hands on my face tiredly, waiting for it to compile, drumming fingers onto the table, cracks neck, shifts head...

Report Compiled, Ma'am.

'Good boy, J. You've been a darling, tonight, great help, I can never thank you enough... sometime when you're human, or if...Imma owe you big time.'

No worries, Ma'am. You've been quite amazing to work with as well.

Smiles...

'Let's call it a night, J.A.R.V.I.S...Thank you...Good Night...'

Hologram goes off...

Goodnight Ma'am.

______________________________________

( @tony-starkinator @the-loss-of-my-life )

2 notes

·

View notes

Text

All You Need to Know: Cupronickel and Hastelloy Steel Grades

For industries like marine engineering, petrochemical, chemical processing, or aerospace, where materials are exposed to extreme conditions, understanding steel grades ensures the longevity and reliability of structures, machinery, and piping systems. Different grades offer unique combinations of strength, corrosion resistance, temperature tolerance, and other key factors that directly influence their suitability for various environments.

What are Steel Grades?

Steel grades are classifications based on the properties of the metal and its alloying elements. For Cupronickel and Hastelloy, grades are determined by their composition, mechanical strength, and resistance to corrosion, oxidation, and temperature.

Cupronickel Grades: Marine-Grade Material for Extreme Conditions

Cupronickel (Cu-Ni) is an alloy primarily made of copper and nickel. It contains trace elements such as iron and manganese to boost its corrosion resistance, particularly in seawater.

Grades of Cupronickel:

1. Cupronickel 90/10 (C70600):

Composition: 90% copper and 10% nickel.

Properties: High corrosion resistance in seawater, good thermal conductivity.

Applications: Marine hardware, desalination plants, and heat exchangers.

2. Cupronickel 70/30 (C71500):

Composition: 70% copper and 30% nickel.

Properties: Greater strength and corrosion resistance than 90/10, especially in high-velocity seawater.

Applications: Offshore oil and gas platforms, seawater cooling systems, and condensers.

Key Properties of Cupronickel Grades:

1. Corrosion Resistance: Both 70/30 and 90/10 grades are resistant to biofouling and seawater corrosion.

2. Mechanical Strength: 70/30 offers higher mechanical strength than 90/10.

3. Thermal Conductivity: Both grades provide excellent thermal conductivity, making them ideal for heat exchangers and piping systems.

Hastelloy Steel Grades: Superalloys for Extreme Chemical Resistance

Hastelloy is a superalloy made of nickel, molybdenum, and chromium. It’s known for its ability to withstand extreme conditions, such as exposure to aggressive chemicals, high temperatures, and oxidation.

Common Grades of Hastelloy:

1.Hastelloy C-276:

Composition: High nickel, molybdenum, and chromium content with a small amount of tungsten.

Properties: Exceptional resistance to a wide range of severe chemicals and oxidizing agents.

Applications: Petrochemical industry, chemical processing, pollution control, and pulp and paper production.

2. Hastelloy B-3:

Composition: High nickel and molybdenum with limited iron content.

Properties: Excellent resistance to hydrochloric acid at all temperatures and concentrations.

Applications: Chemical reactors, distillation equipment, and piping systems in petrochemical and chemical industries.

Key Properties of Hastelloy Grades:

1. Corrosion Resistance: Hastelloy alloys can withstand acidic environments that would corrode most other materials.

2. High-Temperature Stability: Hastelloy maintains its strength and resistance at high temperatures, making it ideal for industries with extreme heat and corrosive conditions.

3. Oxidation Resistance: It resists oxidation in both static and dynamic conditions, raising its longevity in industrial settings.

Comparing Cupronickel and Hastelloy Steel Grades

Though both Cupronickel and Hastelloy are known for their durability, they serve different industries based on their distinct properties.

Cupronickel 90/10 & 70/30 / Hastelloy C-276 & B-3

Corrosion Resistance Excellent in seawater, Exceptional in aggressive chemicals

Temperature Tolerance Moderate, High (up to 1000°C for some grades)

Applications Marine, Oil & Gas, Chemical processing, aerospace

Understanding the role of advanced alloys of best steel grades and classifying between them accordingly like Cupronickel or Hastelloy and Inconel 600 or Monel Fasteners helps businesses make informed decisions. Choosing the right alloy guarantees your application is protected, reduces costs, and improves performance, even in tough environments.

At Online Fittings, we offer a comprehensive range of Cupronickel and Hastelloy steel grades, ensuring you get the best material for your industrial needs. Explore our products today to find the perfect solution for your next project!

0 notes

Text

Ultimate hints for excessive-performance composites

If you're looking for top-notch alloy products, Siddhagiri Metals and Tubes has been given you protection. With such a lot of products to be had, in addition to SS 304 tube fittings, Inconel 625 round bars, hastelloy c276 plate, and more, this newsletter may be your go-to useful resource for finding statistics and choosing a product that works nicely approximately. It's a totally effective combination of substances to fit your needs.

Inconel 625 flanges are designed to provide a watertight and durable connection underneath hot temperature rise and corrosive situations. Siddhagiri Metals and Tube gives a choice of Inconel 625 flanges designed to fulfil enterprise needs and specifications.

Hastelloy C276 tube fittings from Siddhagiri Metals and Tubes provide super resistance to pitting, crevice corrosion, and strain corrosion cracking, making them best for important packages in medicine, sewage remedy, and different fields.

Duplex 2205 is a low-rate, bendy duplex stainless steel that is evidence of corrosion in hundreds of conditions.Siddhagiri Metals and Tubes offers a complete line of Duplex 2205 Tube Fittings designed for excessive overall performance and long-term reliability.

Super Duplex 2507 tube fittings are recognized for their robust tensile energy and advanced corrosion resistance below excessive situations. Siddhagiri Metals and Tubes offers a huge variety of Super Duplex 2507 Tube Fittings for bundle necessities in oil and gas, chemical production, and plenty of other industries. Copper-nickel filters are acknowledged for their excessive resistance to saltwater corrosion and fouling, making them an excessive first-class desire for marine and offshore applications. Siddhagiri Metals and Tubes gives fantastic copper-nickel tube fittings which can withstand harsh marine situations.

Selecting the Right High-Performance Alloy Products Selecting precise, high-standard performance alloy products is critical to the success and persistence of your packages.When combining materials such as titanium grade 2 round bar, Monel 400 plate, and chrome steel 304 pipe, the following factors must be kept in mind: Corrosion Resistance All of the above high-performance alloys boast extremely high corrosion resistance properties. do, ensuring overall reliable performance. bad environment Whether you need Inconel 625 Round Bar or Hastelloy C276 flanges, you should not forget that Siddhagiri alloys and tubes offer the trade-off with advanced corrosion resistance.

Mechanical Strength From Monel four hundred spherical bars to Duplex 2205 tube fittings, the mechanical strength of high-normal overall performance alloy merchandise is a key consideration. Siddhagiri Metals and Tubes ensures that all products meet stringent mechanical strength requirements, presenting the sturdiness and reliability wanted for numerous business programmes.

High-performance alloys are engineered to go through excessive temperatures and demanding thermal situations. When deciding on items that include Inconel 625 tube fittings or Super Duplex 2507 tube fittings, it's crucial to test their temperature resistance tendencies to assure maximum typical overall performance in high-temperature applications.

Each excessive-standard overall performance alloy product is designed to fulfil precise commercial enterprise requirements and necessities. Whether you want Hastelloy C276 tube fittings or Titanium Grade 2 plate, Siddhagiri Metals and Tubes assures that each product meets relevant industry necessities, ensuring compatibility and conformity with requirements.

Siddhagiri Metals and Tubes is a reliable and appeared company of high-ordinary overall performance alloy items at the side of Inconel 625 plate, Stainless Steel 304 spherical bar, Hastelloy C276 plate, and masses more. Siddhagiri Metals and Tubes is your one-prevent save for immoderate-performance alloy solutions, emphasising fantastic, dependability, and adherence to business enterprise standards. Siddhagiri Metals and Tubes no longer gives anything short of excellence in excessive-overall performance alloy products.

0 notes

Text

Monel 400 Pipes & Tubes Manufacturers In India

Introduction: Monel 400 Pipe contains a nickel mix that has ordinarily 67% nickel in the composition. The material is incredibly well protected against ocean water. Navneet Metal Corporation is an essential supplier and manufacturer of the Monel 400 Pipe products in more prominent totals and from different viewpoints.

Main Features:

Corrosion Resistance: Monel 400 is known for its excellent resistance to corrosion, making it suitable for harsh environments such as marine and chemical industries.

High Strength: Maintains mechanical properties at high temperatures and under extreme conditions, ensuring reliability in demanding applications.

Versatility: Widely used across various sectors including aerospace, oil & gas, chemical processing, and more.

Durability: Offers long-term durability and minimal maintenance, reducing lifecycle costs.

Benefits:

Quality Assurance: Manufacturers adhere to stringent quality standards, ensuring products meet international specifications and industry requirements.

Customization: Ability to provide tailored solutions and specifications based on customer needs, enhancing flexibility in project design.

Local Support: Access to technical expertise and responsive customer service for efficient project management and support.

Cost-Effectiveness: Competitive pricing and local manufacturing efficiencies contribute to overall cost savings.

Why Choose Monel 400 Pipes & Tubes Manufacturers in India? Choosing Monel 400 Pipes & Tubes manufacturers in India offers several advantages:

Proximity: Easy access to manufacturers for inspections, quality control, and ongoing support.

Expertise: Manufacturers have experience in producing Monel 400 products for diverse industrial applications, ensuring product reliability and performance.

Supply Chain Efficiency: Streamlined logistics and supply chain management for timely delivery and reduced lead times.

Industry Compliance: Manufacturers comply with local regulations and standards, ensuring compliance with environmental and safety requirements.

Conclusion: Monel 400 Pipes & Tubes manufacturers in India play a crucial role in providing high-quality, reliable solutions for various industrial applications. Whether for new projects or maintenance requirements, choosing local manufacturers ensures access to superior products and support.

Contact Us: For inquiries or to explore Monel 400 Pipes & Tubes manufacturers in India, contact us today:

Phone: +91-9029896819

Email: [email protected]

Website: https://www.navneetcorp.com

#Monel 400 Pipes & Tubes Manufacturers In India#Monel 400 Pipes & Tubes Suppliers In India#Monel 400 Pipes & Tubes Stockists In India#Monel 400 Pipes & Tubes Exporters In India

0 notes

Text

What is the ASTM grade of Monel 400?

In the realm of metallic materials, Monel 400 holds a distinct position as a nickel-copper alloy with exceptional corrosion resistance and high strength. Therefore, understanding the ASTM grade of Monel 400 is very important for its application in various industries, especially those involving harsh environmental conditions.

What is the ASTM grade of Monel 400?

Monel 400, also known by its UNS number N04400, is a nickel-copper alloy primarily composed of approximately 63% to 70% nickel and 28% to 34% copper, with minor additions of iron, sulfur, carbon, silicon, and manganese. This composition gives it remarkable resistance to corrosion in a wide range of environments, including seawater, hydrogen fluoride, fluorine, sulfuric acid, and alkaline media.

The ASTM grade of Monel 400 is specified in several ASTM standards, including ASTM B127, ASTM B163, ASTM B164, and ASTM B165. These standards define the chemical composition, mechanical properties, and other characteristics of the alloy, ensuring its consistent performance across different applications.

The chemical composition specified in these ASTM standards ensures that Monel 400 maintains its corrosion resistance and mechanical properties. The high nickel content, in particular, confers immunity to chloride-induced stress corrosion cracking, a common failure mode in many other alloys. Additionally, the alloy’s ductility and toughness allow it to be easily formed and processed into various shapes and sizes.

Mechanically, Monel 400 exhibits high strength and toughness over a broad temperature range. Its yield strength and tensile strength, as defined by the ASTM standards, are sufficient to withstand significant loads and stresses in demanding applications. Furthermore, its ductility enables it to absorb deformation without fracturing, enhancing its reliability and durability.

Physically, Monel 400 has a density of approximately 8.80 grams per cubic centimeter and a melting range of 1300-1350 degrees Celsius. Its thermal conductivity and specific heat capacity are also within the range specified by the ASTM standards, ensuring consistent thermal performance.

The processing characteristics of Monel 400 are also addressed in the ASTM standards. It can be easily processed using traditional machining operations, making it suitable for a wide range of manufacturing processes. Its soft nature allows for hot forming into almost any shape, while cold working is typically performed on annealed material to optimize its mechanical properties.

Conclusion

In conclusion, the ASTM grade of Monel 400 is defined by a set of standards that ensure its consistent chemical composition, mechanical properties, and processing characteristics. These standards are the foundation for its widespread use in various industries, where its corrosion resistance and high strength are paramount.

Thank you for reading our article and we hope it can help you to have a better understanding of the ASTM grade of Monel 400. If you are looking for Monel Alloy suppliers and manufacturers online now, we would advise you to visit Huaxiao Alloy.

As a leading supplier of Monel Alloy products from Shanghai China, Huaxiao Alloy offers customers high-quality Monel alloy products such as Monel 400 and Monel K500 at a very competitive price.

0 notes

Text

Monel 400 Stud Bolt Stockists

Chhajed Steel and Alloys is one of the renowned exporters of Monel 400 Stud shock, which are created utilizing a nickel-copper compound and show top notch, toughness and extraordinary disintegration assurance over a wide temperature expand. Monel 400 Threaded Rods is used all through a wide grouping of circumstances, particularly the marine and blend and toward the ocean undertakings. Monel 400 Threaded Bars is ideally a short metallic hung bar. Twofold end stud screw with strings on either end can verify two spines even more capably. Monel 400 Tie Rods is made in consistence with the set present day benchmarks. Monel 400 Tie Bars is commonly perceived for its high-strength, versatility, dimensional exactness, utilization insurance, etc. We produce premium quality standard and changed of Monel 400 Double Ended Studs from various metals and metal mixes as indicated by ASTM/ASME/DIN/DIN Standards and Specifications.

Each bit of our Alloy 400 Threaded Rods is conveyed in our sound framework utilizing top review rust proof steel to give the customers long life advantage. We offer Alloy 400 Threaded Bars that will by and large keep the procedure running with our tolerable and five star things. Impervious to both steam and seawater, Alloy 400 Tie Rods strength and against ruinous properties sway it to ideal for huge duty applications, for example, exchange (pipe) occupying utilized as a bit of oil preparing plants. Composite 400 Tie Bars is routinely utilized as a bit of Sulfuric damaging and hydrofluoric ruinous alkylation plants, Pickling bat warming turns, and so on. Purchase Alloy 400 stud dash at sensible rates from us. We also offer at balanced sizes and shapes to our customers.

For More Information:

Visit Our Website: https://www.chhajedfasteners.com/

Contact No: +91-982-151-3630

E-Mail ID: [email protected]

0 notes

Text

Unveiling the Strength and Versatility of Metal Jacketed Gaskets

Metal jacketed gaskets, the unsung heroes of industrial sealing solutions, play a crucial role in ensuring the integrity of pipelines, machinery, and various industrial applications. These specialized gaskets are engineered to withstand extreme temperatures, pressures, and corrosive environments, making them indispensable components across diverse sectors such as oil and gas, petrochemical, aerospace, and manufacturing. Let's delve deeper into the world of Metal Jacked Gaskets to understand their significance and versatility.

Understanding Metal Jacketed Gaskets

Metal jacketed gaskets are composite sealing materials consisting of a metallic outer shell and a soft filler material, typically graphite, PTFE, or non-asbestos materials. The combination of a robust metal jacket and a compressible filler provides an effective seal against leakage, even under demanding operating conditions. Common metals used for the jacket include stainless steel, carbon steel, and alloys like inconel or monel, chosen based on the application's requirements.

Key Features and Benefits

Resilience to Extreme Conditions: Metal jacketed gaskets excel in environments with high temperatures, extreme pressures, and aggressive chemicals where conventional gaskets may fail. The metal jacket provides structural integrity, while the filler material ensures a tight seal, preventing leaks and minimizing downtime.

Versatility: Metal jacketed gaskets are available in various configurations, including spiral wound, double jacketed, and Kammprofile Gaskets catering to diverse sealing requirements. They can accommodate flanges with irregularities, making them suitable for a wide range of applications.

Enhanced Durability: Unlike traditional gaskets that may degrade over time due to exposure to harsh conditions, metal jacketed gaskets offer exceptional durability and long-term reliability, reducing maintenance costs and downtime.

Conformance to Industry Standards: Metal jacketed gaskets adhere to stringent industry standards and certifications, ensuring compliance with safety and quality regulations. This makes them the preferred choice for critical applications where reliability is paramount.

Applications Across Industries

Oil and Gas: Metal jacketed gaskets are extensively used in pipelines, valves, and flange connections within the oil and gas industry, where they seal joints in refineries, offshore platforms, and petrochemical plants, withstanding the rigors of hydrocarbon processing.

Aerospace: In aerospace applications, where components are subjected to extreme temperatures and pressures, metal jacketed gaskets provide reliable sealing solutions for engine assemblies, fuel systems, and hydraulic systems, ensuring aircraft safety and performance.

Manufacturing: Metal jacketed gaskets find applications in various manufacturing processes, including chemical processing, food and beverage, pharmaceuticals, and pulp and paper, where they seal equipment and machinery, preventing contamination and ensuring product integrity.

Power Generation: Within power generation facilities such as thermal power plants and nuclear reactors, metal jacketed gaskets seal joints in boilers, turbines, and heat exchangers, withstanding high temperatures and pressures inherent in energy production.

0 notes

Photo

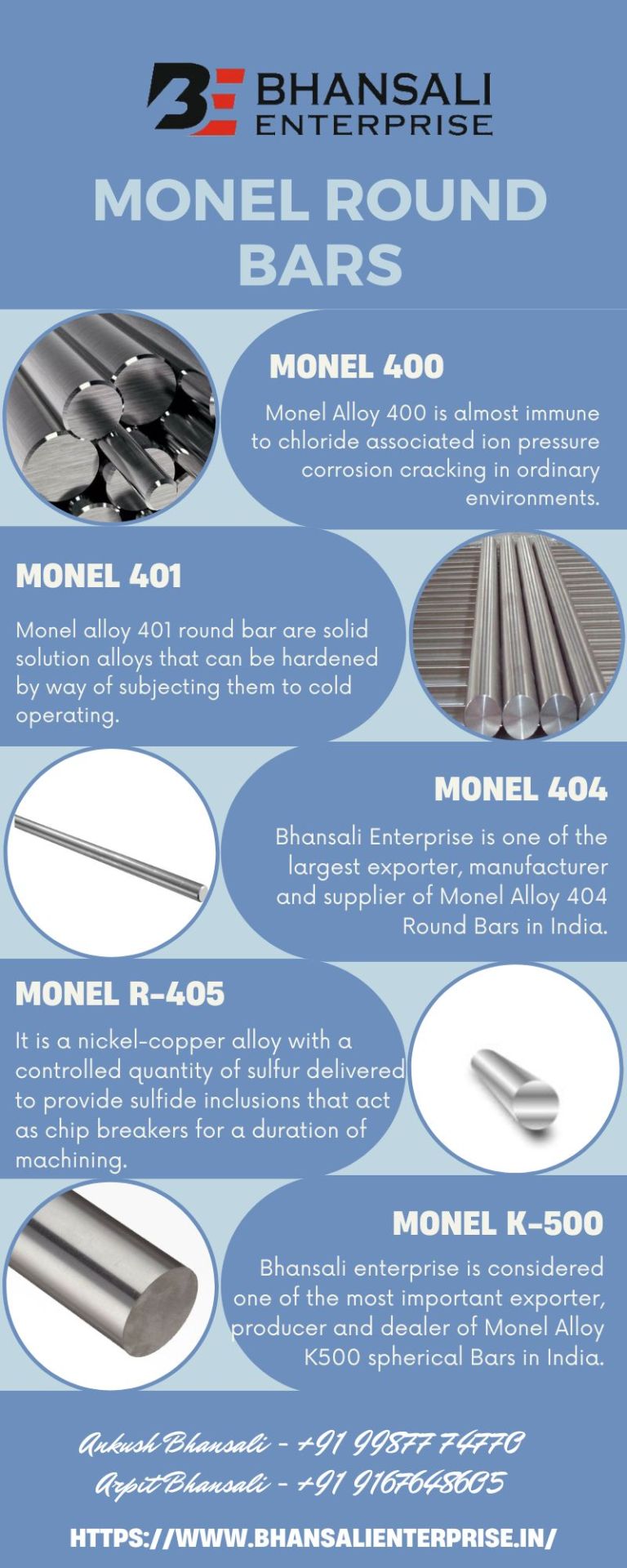

"Monel Round Bars."

Monel Alloy 400 Rod is known to have great mechanical properties at even at subzero temperatures. The alloy can be used in temperatures up that go to 1000° F. Monel 400 has a high melting point, it melts between the temperature range of 2370° F – 2460° F. Since alloy 400 has low strength in an annealed condition , a variety of tempering techniques may be used to increase the tensile strength. MONEL 401 is designed to be used in unique electric powered and digital applications. The common kinds of MONEL 401 alloy are strip and wire. This datasheet will look at the chemical composition, properties and applications of MONEL 401 alloy. Bhansali Enterprise is one of the largest exporter, manufacturer and supplier of Monel Alloy 404 Round Bars in India. Monel 404 Round Bars is more resistant to nickel under reducing environments and more resistant than copper under oxidizing environments, where it does exhibit however improved resistance to reducing media than oxidizing. Monel Alloy 404 Rods is a Nickel-Copper alloy, resistant to sea water and steam at elevated temperatures, in addition to caustic and salt solutions. Monel Alloy R-405 is the unfastened machining model of Monel 400. It is a nickel-copper alloy with a controlled quantity of sulfur delivered to provide sulfide inclusions that act as chip breakers for the duration of machining. Bhansali enterprise is considered one of the most important exporter, producer and dealer of Monel Alloy K500 spherical Bars in India.

#stainless steel round bar#manufacturer of stainless steel in india#stainless steel round bar manufacturer in india#ss round bar#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor#monel metal composition#monel metal#stainless steel manufacturers in india#polished stainless steel

0 notes

Text

Buy Super Duplex S32760 Flanges | Bhagyalaxmi Industrial

In the area of metallurgy, in which precision, sturdiness, and reliability are paramount, the name "Super Duplex S32760" stands proudly as a testament to engineering brilliance. As industries continue to evolve, the demand for superior materials that could resist the most hard environments is on the rise. Enter Super Duplex S32760 flanges—the unsung heroes that ensure seamless connectivity and structural integrity in essential programs.

Understanding Super Duplex S32760 Flanges

The Manufacturing Marvel

Super Duplex S32760 flanges are made from a unique alloy that blends chromium, molybdenum, and nitrogen to create a material with high-quality corrosion resistance and mechanical energy. These flanges play a pivotal role in connecting pipes and facilitating the clean flow of fluids in industries ranging from oil and fuel to chemical processing.

Key Features of Super Duplex S32760 Flanges

Corrosion Resistance: The alloy composition of Super Duplex S32760 offers extraordinary resistance to corrosion, making it a perfect choice for harsh environments.

High Strength: These flanges boast superior mechanical energy, ensuring toughness and reliability in annoying programs.

Versatility: Super Duplex S32760 flanges locate programs in diverse industries, which include offshore oil rigs, chemical processing plants, and desalination facilities.

The Role of Bhagyalaxmi Industrial

Amidst the myriad of picks to be had in the market, Bhagyalaxmi Industrial emerges as an extraordinary participant as a Super Duplex S32760 Flanges Manufacturer, Super Duplex S32760 Flanges Supplier, Super Duplex S32760 Flanges Stockist, Super Duplex S32760 Flanges Exporter, Super Duplex S32760 Flanges Dealer. Specializing in an intensive variety of ferrous and non-ferrous metals, Bhagyalaxmi Industrial has carved a spot for itself as a reliable issuer of extremely good commercial additives.

Bhagyalaxmi Industrial Advantage

Diverse Product Range: Bhagyalaxmi Industrial offers a complete array of merchandise, together with pipes, tubes, pipe fittings, cast fittings, flanges, sheets, plates, coils, bars, rods, and fasteners, among others.

Material Expertise: The agency deals in diverse metals, such as stainless steel, duplex, and splendid duplex metallic alloy steel, carbon metallic, titanium, Inconel, Hastelloy, monel, nickel, cupro nickel, etc.

Quality Assurance: All products from Bhagyalaxmi Industrial are made from advanced high-quality uncooked substances, adhering to international requirements. Customization options ensure that clients obtain products tailored to their precise specs.

Competitive Pricing: Despite supplying top-notch first-class, Bhagyalaxmi Industrial keeps a commitment to affordable pricing, ensuring accessibility without compromising on excellence.

Super Duplex S32760 Flanges: Applications and Industries

The versatility of Super Duplex S32760 flanges extends throughout various industries, gambling a vital position in ensuring the efficient and dependable operation of critical strategies.

1. Offshore Oil and Gas

In the cruel conditions of offshore drilling rigs, Super Duplex S32760 flanges provide the durability and corrosion resistance required for seamless operations. These flanges contribute to the integrity of the pipeline community, ensuring the safe extraction and transportation of oil and gasoline.

2. Chemical Processing

Chemical processing flora calls for materials that can withstand corrosive chemicals and intense temperatures. Super Duplex S32760 flanges excel in such environments, ensuring the sturdiness and reliability of the difficult piping systems vital to chemical production approaches.

3. Desalination Facilities

As the worldwide call for freshwater increases, desalination facilities play a vital role in providing a sustainable answer. Super Duplex S32760 flanges, with their corrosion-resistant residences, contribute to the performance and longevity of desalination plants, wherein exposure to saltwater is a constant task.

Ensuring Quality and Satisfaction

The credibility of vendors is an important aspect of the industrial delivery chain, and Bhagyalaxmi Industrial places a robust emphasis on keeping the best standards. The continuous effort to stabilize and improve quality guarantees that clients acquire products that no longer best meet but exceed their expectations.

Customization for Client Satisfaction

Recognizing the various needs of customers, Bhagyalaxmi Industrial offers customization options for Super Duplex S32760 flanges. This guarantees that the products align with the unique necessities of each assignment, contributing to more desirable purchaser pride.

Conclusion: Connecting Excellence with Bhagyalaxmi Industrial

In the ever-evolving landscape of industrial additives, Super Duplex S32760 flanges have become a symbol of excellence. Bhagyalaxmi Industrial, with its commitment to quality, diversity, and customer delight, stands as a reliable accomplice for industries seeking top-notch merchandise.

As industries push the boundaries of what's viable, the selection of substances becomes increasingly vital. Super Duplex S32760 flanges from Bhagyalaxmi Industrial provide a robust answer, combining power, sturdiness, and corrosion resistance.

For those seeking to elevate their commercial approaches with the quality-in-magnificence Super Duplex S32760 flanges, Bhagyalaxmi Industrial is the name to trust. Contact them today and enjoy the difference that first-rate and commitment can make for your operations. Bhagyalaxmi Industrial – Connecting Excellence in Every Flange!

#Super Duplex S32760 Flanges Manufacturer#Super Duplex S32760 Flanges Supplier#Super Duplex S32760 Flanges Stockist#Super Duplex S32760 Flanges Exporter#Super Duplex S32760 Flanges Dealer

0 notes

Text

Inconel 600 Flanges Manufacturers in UAE

Inconel 600 Flanges are involved in a material that has carbon, manganese, silicon, sulfur, copper, iron, nickel and chromium. This is a nickel chromium composite as it contains 72% nickel and 14% chromium. Meraki Star Metals Oil & Gas Equipment Trading L.L.C. is a principal Supplier and manufacturers of the Inconel 600 Flanges in different shapes, types and scales. The flanges come in different arrangements, for instance, GOST Flanges, JISB2220, BS1560-3.1, and so on. The strains of shouting of the Flanges vary from class 1500 to class 600.

The Inconel 600 Outwardly weakened Flanges is one kind of the Flanges used to close a line affiliation. It is presented close to the completion of a line to close it forever with welding or with strings for straight forward departure upon upkeep tasks. There are different sorts, for instance, the UNS N06600 Weld Neck Flanges which goes with a welded neck and holding the lines set up can be used. The weld neck flanges are more typical in greater expansiveness directing systems. There are different rules to manage the distances across the Flanges and the ANSI B16.5 Mix 600 Slip on Flanges range from 1⁄2 killjoys to 24 slithers in apparent drag size.

The slip on Flanges are great for fitting drawn consistent lines since they permit the lines to slip onto them for exact association area change. The ASTM B564 Inconel 600 Composite Line Flangess have a place with the particular that determines the nickel compounds, Inconel, monel and hastelloy Flanges. The material has a high return strength of 310MPa and high elasticity of 655MPa. The material likewise has an extremely high liquefying point of 1413 degrees Celsius. These properties permit the Flanges to be utilized in high pressure, high temperature funneling applications like intensity exchangers and boilers. Kindly reach us for more item types like the Inconel 600 Opening Spine and others with their costs.

For More Information:

Visit Our Website: https://www.merakimetals.ae

Contact No: +971-523973687

E-Mail ID: [email protected]

0 notes

Text

Become an Expert on Copper Nails by Watching These 5 Videos

Marine fasteners play a crucial function in the world of seafaring, making sure the security as well as integrity of ships, watercrafts, offshore structures, as well as aquatic devices. These important components protected different components of vessels, offering a durable connection that can withstand the severe conditions of the open sea. In this article, we look into the value of aquatic bolts, their various kinds, materials, as well as applications, along with the obstacles faced in guaranteeing their performance in maritime environments.

The Significance of Marine Fasteners

Marine fasteners function as the anchors of the maritime market. They are accountable for holding with each other critical elements such as hulls, decks, poles, rigging, as well as numerous mechanical systems aboard ships and also watercrafts. Offered the extreme conditions faced mixed-up, consisting of deep sea direct exposure, high humidity, constant vibrations, and also considerable mechanical stress and anxiety, aquatic fasteners should be extremely sturdy, corrosion-resistant, and reputable.

Sorts Of Marine Fasteners

Bolts and also Nuts: Bolts and also nuts are amongst the most typically used fasteners in aquatic applications. They are designed Copper Nails to supply a strong, detachable link as well as can be located safeguarding machinery, frameworks, and equipment aboard ships.

Screws: Screws are made use of when a strong long-term link is needed. They are commonly utilized to attach wood, metal, or composite products in various aquatic applications.

Rivets: Rivets are fasteners that create a permanent connection between two or even more elements by flawing the tail end of the rivet after installation. They are widely utilized in shipbuilding and fixing.

Washing machines: Washers are utilized with screws as well as nuts to disperse the pressure and also prevent damages to the connected products.

Pins and also Clips: These fasteners are made use of to protect rigging and also various other parts that require regular disassembly and reassembly.

Products Used in Marine Fasteners

Marine bolts are made from materials that display extraordinary resistance to corrosion and also wear and tear in aquatic settings. Some common products include:

Stainless-steel: Marine-grade stainless-steel, such as 316 or 316L, is widely made use of due to its superb rust resistance, toughness, and sturdiness.

Brass: Brass fasteners are popular for their corrosion resistance as well as aesthetic charm, making them appropriate for sure marine applications.

Silicon Bronze: Silicon bronze fasteners are recognized for their remarkable rust resistance, making them perfect for marine hardware like cleats, hatches, and port lights.

Monel: Monel fasteners supply excellent resistance to saltwater corrosion and also are often used in marine applications where high stamina is called for.

Difficulties in Marine Fasteners

The aquatic setting provides special difficulties for fasteners, necessitating cautious style as well as option. Some of the major obstacles consist of:

Rust: The most significant obstacle faced by aquatic bolts is deterioration because of exposure to saltwater, causing galvanic corrosion, crevice deterioration, as well as matching. Picking the ideal corrosion-resistant material is important.

Tons and Vibration: Ships and boats experience constant lots and also resonances during operation, which can cause bolts to loosen in time. Appropriate tightening up techniques as well as lock nuts are used to neutralize these effects.

Temperature Extremes: Marine bolts should hold up against a wide range of temperature levels, from freezing conditions in polar areas to scorching heat in exotic areas.

UV Exposure: Fasteners on the outside parts of a vessel are exposed to harmful UV radiation, which can break down particular materials with time.

The choice of ideal materials and also designs is vital to fight deterioration and also mechanical anxieties, guaranteeing that marine fasteners continue to fulfill their necessary role in the seafaring market. As modern technology and material scientific research advance, marine bolts will definitely end up being even a lot more resistant, additional improving the safety as well as efficiency of vessels around the world.

0 notes

Text

Leading Pipe Fittings Manufacturer in India

Manilaxmi Overseas is one of the most prominent Pipe Fittings Manufacturer In India. In addition to stainless steel, titanium, hastelloy, inconel, monel, and nickel alloy, we also provide high-quality pipe fittings in a range of sizes, dimensions, and compositions. Along with some uncommon metals like Chromium Molybdenum Steel, Case Hardening Steel, and others, there are also several grades available, like SMO 254 Pipe Fittings, ASME B16.9 Pipe Fittings, ASTM A316 Pipe Fittings, and others.

A stainless steel pipe fitting is used to unite straight lengths of pipe, adapt to different sizes or forms, and perform additional functions such as regulating fluid flow. Elbow Pipe Fittings, SMO 254 Pipe Fittings, Tee Cross Pipe Fittings, Reducer Pipe Fittings, End Cap Pipe Fittings, Stub End Pipe Fittings, Stainless Steel Nipple Pipe Fittings, and so on. Making us a prominent Pipe Fittings Supplier in India.

We Manufacture and Supply a wide range of Pipe Fittings Manufacturer in India, Reducer Pipe Fittings Manufacturer In India

For More Detail

Website: manilaxmioverseas.com

Product: Pipe Fittings Supplier in India

Other Product: Reducer Pipe Fittings Manufacturer In India

0 notes

Text

Monel 400 Round Bars Exporters In India

Monel 400, a nickel-copper alloy renowned for its exceptional resistance to corrosion in a wide range of environments, is highly sought after for various industrial applications. Round bars made from Monel 400 are particularly valued for their combination of high strength, excellent mechanical properties, and resistance to acids, alkalis, and seawater. Indian exporters of Monel 400 round bars have earned a strong reputation in the global market for supplying high-quality products manufactured to stringent standards.

Manufacturers in India employ advanced production techniques and quality control measures to ensure that Monel 400 round bars meet or exceed international standards such as ASTM B164. These standards govern the chemical composition, mechanical properties, and dimensional tolerances of the round bars, ensuring consistency and reliability in performance across different applications. Monel 400 round bars are available in various diameters and lengths, catering to diverse industrial requirements.

Leading exporters like Ritinox Overseas, Jainex Steel & Metal, and Virwadia Metal & Alloys are known for their expertise in supplying Monel 400 round bars to customers worldwide. These exporters maintain comprehensive inventories and are capable of fulfilling both small-scale and bulk orders with efficiency and reliability. Additionally, they offer value-added services such as custom cutting, machining, and surface finishing to meet specific customer specifications and requirements.

Customer satisfaction is paramount for Indian exporters, and they prioritize timely delivery, competitive pricing, and responsive customer support. By adhering to the highest standards of quality and professionalism, these exporters have established long-term relationships with clients across various industries globally. When sourcing Monel 400 round bars from India, buyers can expect premium-quality products backed by technical expertise and excellent service throughout the procurement process.

For more information

Visit our website: https://www.navneetcorp.com/

Call us on: 8369128023

Email us: [email protected]

#Monel K500 Sheets & Plates Exporters In India#Monel 400 Round Bars Exporters In India#Monel K500 Round Bars Exporters In India

0 notes

Text

Unveiling the Potential of the Nickel Alloys Market: Key Insights and Future Prospects

The nickel alloys market refers to the global industry involved in the production, distribution, and consumption of various alloys that contain nickel as a primary element. Nickel alloys are metallic alloys that exhibit superior mechanical, chemical, and thermal properties due to the inclusion of nickel.

Nickel alloys market are extensively used in various industries, including aerospace, automotive, oil and gas, chemical processing, electronics, and power generation, among others. They are known for their exceptional corrosion resistance, high temperature strength, excellent mechanical properties, and good thermal stability.

Key Types of Nickel Alloys:

Pure Nickel Alloys: These alloys contain a high percentage of nickel (over 99%) and are primarily used in applications requiring excellent corrosion resistance.

Nickel-Copper Alloys: Also known as Monel alloys, they possess exceptional resistance to various corrosive environments, such as seawater and acidic solutions.

Nickel-Chromium Alloys: Widely known as Nichrome, these alloys exhibit high temperature strength and oxidation resistance, making them suitable for applications such as heating elements and furnace components.

Nickel-Iron Alloys: Also called Invar and Kovar, these alloys offer low thermal expansion properties, making them ideal for applications where dimensional stability is critical, such as precision instruments and electronic devices.

Nickel-Based Superalloys: These alloys are specifically designed for high-temperature applications, such as gas turbine engines in aerospace and power generation industries. They possess exceptional strength, creep resistance, and thermal stability.

Market Drivers:

Increasing Demand from Aerospace and Defense Industries: The growing need for lightweight and high-performance materials in the aerospace sector is driving the demand for nickel alloys.

Expansion of Oil and Gas Exploration: Nickel alloys are extensively used in oil and gas extraction and processing equipment due to their excellent corrosion resistance, contributing to market growth.

Rising Demand from Emerging Economies: Developing countries' rapid industrialization and infrastructure development are creating significant opportunities for the nickel alloys market.

Technological Advancements: Ongoing research and development activities aimed at enhancing the properties and performance of nickel alloys are propelling market growth.

Market Challenges:

Volatility in Raw Material Prices: Fluctuations in the prices of nickel and other alloying elements impact the overall cost of nickel alloys, which poses a challenge to market players.

Environmental Concerns: Nickel mining and refining processes have environmental implications, including habitat destruction and water pollution, leading to increased scrutiny and regulations.

Substitutes and Alternatives: The availability of alternative materials, such as composites and advanced ceramics, poses a threat to the nickel alloys market.

COVID-19 Impact: The global pandemic has disrupted supply chains, manufacturing activities, and demand, affecting the nickel alloys market.

Regional Outlook: The nickel alloys market is geographically diverse, with key regions including North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa. Asia Pacific dominates the market due to the presence of major industrial economies, such as China and India, which have a high demand for nickel alloys. North America and Europe are also significant contributors, driven by aerospace, automotive, and energy sectors.

Competitive Landscape: The global nickel alloys market is highly competitive and fragmented, with several key players competing for market share. Some prominent companies in the market include Precision Castparts Corporation, Haynes International Inc., Allegheny Technologies Incorporated, VDM Metals GmbH, Carpenter Technology Corporation, and Sandvik Materials Technology, among others. These companies focus on research and development, strategic collaborations, and product innovations to gain a competitive edge in the market.

Future Outlook: The nickel alloys market is expected to witness steady growth in the coming years. The increasing demand from end-use industries, advancements in alloy technologies, and the development of novel applications will continue to drive market expansion.

0 notes

Text

Using stainless steel pipes in different situations

Stainless steel, first developed over a century ago, has since risen to prominence as one of the world's most ubiquitous and versatile materials, serving as a need in a vast array of industries. Because of its many useful properties, stainless steel tubes may be used in a wide range of industries and consumer products.

Steel had been used for centuries, but it had limits due to corrosion and other factors, so researchers kept looking for new alloys that could be more effective in harsh conditions. ASTM A269 TP304 is the preferred choice.

IS IT TRUE THAT THERE ARE VARIOUS TYPES OF STAINLESS STEEL ALLOYS?

An iron alloy with 10.5% chromium or more is considered stainless steel. Different alloys on the market have their own unique chemical make-up. The strength, malleability, and other properties of stainless steel may be enhanced by adding alloying elements such as nickel, molybdenum, manganese, carbon, nitrogen, and copper. India is a world leader in producing ASTM A213 Tube.

In order to be labeled as stainless steel, an item must be resistant to corrosion in a certain setting. This durability is provided by a unique chromium oxide coating on the metal's surface. A passivation layer is a thin coating that forms on surfaces and prevents further corrosion via interactions with oxygen in the air. Moreover, the layer may fix itself if it becomes scratched or nicked. The producers of ASTM A268 Tubing are always there to assist you.

IN WHAT WAYS DOES STAINLESS STEEL BENEFIT ITS USERS ?

Stainless steel's primary benefit is its ability to withstand corrosion. Different alloys have different resistance levels. Monel 400 Tube suppliers in India are preferred by many people. The most used stainless steel alloy in the world, type 304, provides excellent corrosion resistance in most situations. In addition, 304 is inappropriate in a marine setting since it is very vulnerable to the chloride exposure inherent in seawater. High-quality Duplex Stainless Steel Tube manufacturers in India are always available.

However, an alloy like 316, which has an additional 2% molybdenum for improved performance, is the best option for any use in maritime environments. There are several places where you may find Super Duplex Tube manufacturers in India.

There are many more uses for stainless steel that are very useful. In comparison to regular steel, stainless steel alloys have increased cryogenic toughness, a quicker work hardening rate, greater strength and hardness, increased ductility, a more aesthetically pleasing appearance, and reduced maintenance costs. Considering all its advantages, it's not surprising that stainless steel has become a standard material in many industries, including the plumbing industry.Cold drawn seamless tube manufacturers in India has the finest results.

Since every alloy has its own unique properties, it's essential to be able to tell them apart. There are five distinct categories that characterize the various stainless steel compositions. Hastelloy C276 Tube suppliers in India has been fantastic. Austenitic, ferritic, martensitic, duplex, and precipitation hardening seem to represent the five groups. Get in touch with them if you're interested in learning more about the many kinds of stainless steel and which would work best for you. There are a variety of locations where you can find Inconel 625 Tube suppliers in India.

0 notes