CCE's focus is in CAD interoperability software and engineering services. CCE has more than 25 years of CAD/CAM/CAE software development experience, as well as an extensive background in related services.

Don't wanna be here? Send us removal request.

Photo

Why don’t you take a look at “EnSuite-View” which is efficient and easy-to-use software that allows users to view all major CAD formats, as well as neutral formats http://bit.ly/2TfxtqF

February 4, 2017 I really enjoyed Computer 302 as we studied about CAD softwares, starting from STAAD. The lecture was about roof trusses and I already felt like a licensed engineer!! It was explained how could we know if the steel would pass or fail under different loads and load combinations and some troubleshooting!

#cad#engineering#engineeringdesign#engineeringservices#cadsoftware#ensuite#cadview#3d#3dcad#3d cad modeling

429 notes

·

View notes

Text

ENSUITE-VIEW

#FridayMotivation Save your files to all major #3D #CAD formats using free #Ensuite-View http://bit.ly/2TfxtqF

1 note

·

View note

Text

Check out CCE’s most downloaded free CAD software.

#CAD#cadview#cadsoftware#free software#cce#download#software#engineering#engineeringdesign#engineeringservices

1 note

·

View note

Text

Get your free tool which will help you in 3D CAD viewing.

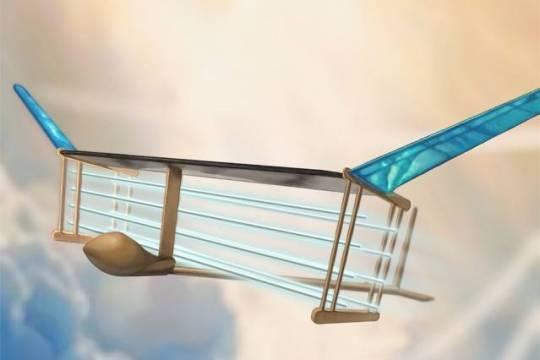

Engineers fly first-ever plane with no moving parts

Since the first airplane took flight over 100 years ago, virtually every aircraft in the sky has flown with the help of moving parts such as propellers, turbine blades, and fans, which are powered by the combustion of fossil fuels or by battery packs that produce a persistent, whining buzz.

Now MIT engineers have built and flown the first-ever plane with no moving parts. Instead of propellers or turbines, the light aircraft is powered by an “ionic wind” – a silent but mighty flow of ions that is produced aboard the plane, and that generates enough thrust to propel the plane over a sustained, steady flight.

Unlike turbine-powered planes, the aircraft does not depend on fossil fuels to fly. And unlike propeller-driven drones, the new design is completely silent.

“This is the first-ever sustained flight of a plane with no moving parts in the propulsion system,” says Steven Barrett, associate professor of aeronautics and astronautics at MIT. “This has potentially opened new and unexplored possibilities for aircraft which are quieter, mechanically simpler, and do not emit combustion emissions.”

He expects that in the near-term, such ion wind propulsion systems could be used to fly less noisy drones. Further out, he envisions ion propulsion paired with more conventional combustion systems to create more fuel-efficient, hybrid passenger planes and other large aircraft.

Barrett and his team at MIT have published their results in the journal Nature.

Keep reading

4K notes

·

View notes

Text

Software to view 3D CAD data

“Explore 3D has been a great tool to quickly see CATIA files.” -Jason Turek, Interplex, USA

0 notes

Text

The Newest TrEND is Here to Stay

Collaboration is an important factor that contributes to the success of any business. Perhaps no one understands this better than globally distributed companies who have been investing in collaborative product development for engineering and manufacturing for several years now. Professionals who have a wide variety of skills that can be shared and utilized all work towards the collective success of the product, and with it, the business.

CCE provides high-quality engineering product development services for global clients. Many of our experienced and knowledgeable engineers are located out of the country, which often invokes concerns about communication. However, CCE understands the importance of communication between collaborators. Distance is now a hindrance of the past.

CCE has leveraged technology to establish a stable communication system that fosters effective collaboration of design and engineering ideas. This way, ideas can be conveyed as if everyone is in the same room. We call this TrEND, or Trusted Engineer Next Door.

The premise of TrEND is simple, use advanced software to coordinate video, audio and screen sharing streams from both sides of the geographically dispersed conversation, to create a natural collaboration experience. Video cameras are positioned around the collaborators that include a projection of the room’s whiteboard, desk, and each collaborator’s face. Computer screens are shared so both parties can see each other's work when necessary. Additionally, a microphone is set up for clear and direct verbal communication.

With this infrastructure at both ends, sketching an initial concept during ideation or discussing feedback on a physical part is a cinch. With this level of interaction, everyone is on the same page during every project discussion. Location is no longer an issue, communication no longer a barrier. TrEND provides all of the accessibility you need when working with remote teams on collaborative projects and will certainly accelerate your new product development process.

0 notes

Text

CCE's New Product Development initiative accelerated by 3D Printing

3D printed functional prototypes created for new kitchen countertop appliance

FARMINGTON HILLS, Mich. (Jan 16, 2019) - CCE, a leading provider of mechanical & electro-mechanical design and related engineering services, has adopted 3D printing to create fully-functional prototypes of their new in-house designed product Quidli. After crossing several challenging milestones during the design phase of this new product development (NPD) initiative, the 3D printed prototypes were created to demonstrate functional viability of the product before investing in tooling for manufacturing at scale.

Quidli is a kitchen countertop appliance to automatically produce Idlis, a breakfast staple popular in South India. The product was conceptualized, designed and engineered by CCE and currently has successful 3D printed functional prototypes created to test for Form, Fit and Function

1. By testing for 'Form' the prototypes helped CCE’s product design engineers validate the shape, size, dimensions, and weight of each & every component of the product.

2. The product 'Fit' was validated by assembling the 3D printed components to make sure they all worked together as designed.

3. By testing for 'Function', the CCE team was able to ensure that idlis produced by Quidli were of high quality and edible.

“Adopting 3D printing for functional prototyping helped our product designers get feedback in the early stages of NPD. This made product development far more efficient. Consequently, our engineers had more time to do what they love, perfect the product and delight our customers.” says Vinay Wagle, CCE’s V.P. of Sales and Marketing.

For more information on CCE's new product development (NPD) initiatives and other engineering services, visit http://www.cadcam-e.com/engineering-design-services.aspx

About Quidli:

Quidli is a kitchen countertop appliance to automatically produce Idlis, a breakfast staple popular in South India. The appliance is 4 times faster, consumes a quarter of the energy and one-fifth of the water of the conventional cooking process.

About CCE:

CCE (www.cadcam-e.com) is a Michigan corporation in business since 1989. Our offices are located in Farmington Hills, Michigan and Fort Lee, New Jersey, as well as a state-of-the-art engineering development center in Chennai, India. CCE's focus is in engineering product development, CAD interoperability and related services. The CCE group currently employs over 225 software and design professionals worldwide.

Connect with CCE on Twitter and Facebook

0 notes

Video

tumblr

Engineers are working on CAM follower’s design to regulate Non-Return Valve (NRV) actuation.. http://bit.ly/2zQ27PU

0 notes

Photo

CCE manages its #newproductdevelopment or internal projects with all-in-one #projectmanagement software #PowerLink http://bit.ly/2zQ27PU

0 notes

Video

tumblr

CCE's product design and engineering services provide comprehensive solutions by taking product ideas from design to manufacturing http://bit.ly/2zQ27PU

#productdesig#cad#product development#newproduct#engineeringdesign#innovative#newproductdevelopment#technology

0 notes

Photo

Settle down. There’s no need to panic. We are not getting into a different line of business. Engineering is still our forte. But one can’t ignore the rapid rise of dating/matchmaking apps in the past decade or so. How do I know? You’d know too if you had a bunch of millennials in your office!

The premise of all such matchmaking apps is to use software algorithm to “match” you with someone who will likely be compatible. A lot of these apps use data like age, height/weight, education, interests, beliefs, and looks among other things.

So where am I going with this?

Consider for a moment that there was a matchmaking app for industrial companies looking for the perfect engineering "partner", and that you were actively exploring options. Check out our profile and let us know if you would consider swiping right at us (that's millennial lingo for "being interested in"). Here goes...

Age: Is just a number and ours is 29 (DOB: 1989)

Size: 225 people (so we're an "M" – don’t judge! At our size we're nimble and YOU command our full attention, the kind you will never see in "L" or "XL" companies)

Brief bio: Engineering product development is our passion. Our ability to keep up with the latest TrEND(s) has been the key to all our successful relationships. But we love our tech too!

Interests: Our interests are wide-ranging starting from semiconductor equipment, industrial machinery all the way to woodworking consumer appliances and everything in between. We excel in mechanical and electro-mechanical design, drive-control mechanisms, electronics with sensors, fluid flow, energy optimization etc.

Recent accomplishments, if any: Leveraging years of new product development experience, we recently developed a kitchen appliance from the ground up that automatically produces "idlis", a breakfast staple popular in India. We call it Quidli. Idlis are produced today by a conventional process that is time consuming, inefficient and wastes water and energy. Quidli is 4 times faster, consumes 1/4 of the energy and 1/5 of water of the conventional process!

Major Subsystems

1. Better Feed Arrangement2. Tray Carriage System3. Cooking Chamber4. Thermal and Electronics Control Systems5. Monocoque (Housing System)

So? You think we’re a match made in heaven?

To set up a date, just click here. Or call me maybe? 248-932-5295. We’re waiting.

1 note

·

View note