Don't wanna be here? Send us removal request.

Text

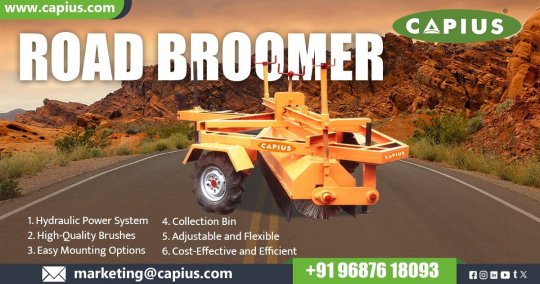

Road Broomer in Saudi Arabia

Capious Roadtech Pvt. Ltd. is a Manufacturer, Supplier and Exporter of Road Broomer in Saudi Arabia. We are an ISO 9001:2015 Certified Company in Ahmedabad, Gujarat, India. With over 25 years of experience, Capious has completed 400+ installations and exports to 35+ countries worldwide. Capious provides durable, reliable equipment for infrastructure needs, including their flagship product—the highly efficient Road Broomer machine. A Road Broomer is a versatile cleaning implement, built mechanically or hydraulically for heavy-duty road sweeping operations. It efficiently removes dust, debris, and particles from surfaces during maintenance, asphalt laying, and routine road cleaning tasks. Types of Road Broomer: Mechanical Broomer Hydraulic Broomer Features & Specifications: Sweeping Width: 2,100 mm (2.1 meters). Brush Diameter: 490 mm. Brush Material: Durable nylon bristles. Drive Mechanism: Helical bevel system driven via tyres. Towing Compatibility: Suitable for tractors or jeeps. Dust Discharge: Sweeps debris to the left side. Height Adjustment: Equipped with central and side screw adjusters. Wheels: Two heavy-duty wheels fitted with 6.00–12 tyres. Typical Applications: Wet Mix Macadam (WMM) surfaces Asphalt road cleaning Pothole debris removal FAQ: Q1: What brush materials are available? A: Nylon and polypropylene are standard; steel wire brushes are available for heavy-duty applications. Q2: How is dust managed? A: Through side sweep systems or hoppers; optional water sprays further suppress airborne dust. Q3: Hydraulic vs. mechanical—what’s best for me? A: Hydraulic models offer smoother drive and dust control; mechanical is simpler and cost effective. Your choice depends on surface type and cleaning needs. Capious Roadtech Pvt. Ltd. is a Manufacturer and Exporter of Road Broomer in Saudi Arabia including Riyadh, Jeddah, Mecca, Medina, Ad Dammām, Tabūk, Al Hufūf, Al Qaţīf, Al Ḩillah, Aţ Ţā’if, Al Jubayl, Buraydah, Ḩafr al Bāţin, Yanbu, Ḩā’il, Abhā, Sakākā, Al Qurayyāt, Jāzān, Najrān, Al Wajh, Arar, Al Bāḩah, Tathlīth. Feel free to contact us if you have any more information or questions. Read the full article

#Abhā#AdDammām#Ahmedabad#AlBāḩah#AlḨillah#AlHufūf#AlJubayl#AlQaţīf#AlQurayyāt#AlWajh#Arar#AţŢā’if#Buraydah#CapiousRoadtechPvt.Ltd.#Exporter#ExporterofRoadBroomer#Gujarat#Ḩā’il#ḨafralBāţin#India#Jāzān#Jeddah#ManufacturerofRoadBroomer#ManufacturerofRoadBroomerinAhmedabad#Mecca#Medina#Najrān#Riyadh#RoadBroomer#RoadBroomerinAhmedabad

0 notes

Text

Concrete Batching Plant in Cameroon

Capious Roadtech Pvt. Ltd. is a Manufacturer, Supplier and Exporter of Concrete Batching Plant in Cameroon. We are an ISO 9001:2015 Certified Company in Ahmedabad, Gujarat, India. A concrete batching plant combines cement, aggregates, water, and admixtures to produce concrete efficiently. These plants are essential in modern construction, ensuring a consistent and high-quality supply of concrete for projects ranging from residential buildings to large-scale infrastructure. Process Overview: Material Storage: Operators store raw materials like cement, aggregates, and water in separate bins or silos. Weighing: Technicians accurately weigh materials using electronic or mechanical weighers. Mixing: Workers transfer weighed materials to the mixer, combining them to form concrete. Discharge: The machine discharges the mixed concrete into transport vehicles for delivery to the construction site. Features: Key features of modern concrete batching plants include: Modular Design: Allows for easy expansion and customization based on project needs. Remote Monitoring: Enables operators to oversee plant operations from a distance, enhancing control and efficiency. Durability: Constructed with high-quality materials to withstand harsh working conditions. Safety Systems: Equipped with emergency stop buttons, safety guards, and alarms to ensure operator safety. Environmental Considerations: Incorporation of dust collection and water recycling systems to minimize environmental impact. Applications: Road and Highway Construction Building Construction Infrastructure Projects Residential and Commercial Complexes Airports and Runways Industrial Construction FAQs: Q1: How do I choose the right concrete batching plant for my project? A1: Consider factors such as project size, required concrete volume, site conditions, and mobility needs. Consulting with a supplier can help determine the most suitable plant type. Q2: What maintenance is required for a concrete batching plant? A2: Regular maintenance includes cleaning, lubrication, inspection of wear parts, and calibration of weighing systems to ensure optimal performance. Q3: Can a concrete batching plant be relocated? A3: Manufacturers design mobile and compact plants for easy relocation, making them ideal for projects at different locations. Capious Roadtech Pvt. Ltd. is a Concrete Batching Plant in Concrete Batching Plant in Cameroon Including Douala, Yaoundé, Bamenda, Bafoussam, Garoua, Maroua, Ngaoundéré, Nkongsamba, Bibémi, Buea, Kousséri, Bertoua, Bafut, Tiko, Ébolowa, Dschang, Mbouda, Baba I, Mokolo, Bamessing, Limbe, Bamessi, Bambalang, Bamumkumbit, Bamukumbit, Bafanji, Balikumbat, Bamali, Bandrefam. Feel free to contact us if you have any more information or questions. Read the full article

#Ahmedabad#Cameroon#CapiousRoadtechPvt.Ltd.#ConcreteBatchingPlant#ConcreteBatchingPlantinAhmedabad#ConcreteBatchingPlantinCameroon#ConcreteBatchingPlantinGujarat#ConcreteBatchingPlantinIndia#ExporterofConcreteBatchingPlant#Gujarat#India#ManufacturerofConcreteBatchingPlant#Supplier#SupplierofConcreteBatchingPlant

0 notes

Text

Bitumen Sprayer in Saudi Arabia

Capious Roadtech Pvt. Ltd. is a Manufacturer, Supplier and Exporter of Road Broomer in Saudi Arabia. We are an ISO 9001:2015 Certified Company in Ahmedabad, Gujarat, India. Capious Roadtech Pvt. Ltd., based in Ahmedabad, Gujarat, India, is a leading manufacturer of road construction machinery, including high-quality bitumen sprayers. These sprayers are integral to modern road construction, ensuring precise application of bitumen or bitumen emulsion for durable and smooth road surfaces. A bitumen sprayer is a specialized vehicle equipped with a heating system and a spray bar to apply a uniform layer of hot bitumen or emulsion onto road surfaces. This application is crucial for tasks like tack coating, surface dressing, and road maintenance, providing excellent adhesion and durability to the pavement. Types of Bitumen Sprayers: Truck-Mounted Models: Suitable for larger projects, offering higher capacity and mobility. Trolley-Mounted Models: Ideal for smaller projects or areas with limited access. Features: Fully Insulated Tank: Ensures efficient heat retention, maintaining bitumen at optimal temperatures. High-Efficiency Heating System: Equipped with a high-capacity imported burner for rapid heating. Positive Displacement Gear Pump: Delivers consistent bitumen flow at pressures up to 6 kg/sq.m. Adjustable Spray Bar: Standard width of 2.4 meters, extendable up to 4.2 meters, with pneumatically operated nozzles. Pressure Cleaning System: Facilitates easy cleaning post-operation, preventing blockages. Versatile Mounting Options: Available as truck-mounted or trolley-mounted units. Temperature Indicators: Analog and digital gauges monitor bitumen temperature. Applications: Road Resurfacing and Repair Road Surface Maintenance Airport Runways and Taxiways Road Construction FAQs: Q1: Can the sprayer be mounted on any truck chassis? Capious bitumen sprayers are designed to suit standard truck chassis, but customization options are available. Q2: Can these sprayers handle bitumen emulsion? Yes, Capious bitumen sprayers are suitable for both hot bitumen and bitumen emulsion applications. Q3: Are spare parts readily available? Yes, Capious ensures the availability of spare parts and provides quick after-sales service. Capious Roadtech Pvt. Ltd. is a Manufacturer and Exporter of Bitumen Sprayer in Saudi Arabia including Riyadh, Jeddah, Mecca, Medina, Ad Dammām, Tabūk, Al Hufūf, Al Qaţīf, Al Ḩillah, Aţ Ţā’if, Al Jubayl, Buraydah, Ḩafr al Bāţin, Yanbu, Ḩā’il, Abhā, Sakākā, Al Qurayyāt, Jāzān, Najrān, Al Wajh, Arar, Al Bāḩah, Tathlīth. Feel free to contact us if you have any more information or questions. Read the full article

#Abhā#AdDammām#Ahmedabad#AlBāḩah#AlḨillah#AlHufūf#AlJubayl#AlQaţīf#AlQurayyāt#AlWajh#Arar#AţŢā’if#BitumenSprayer#BitumenSprayerinAhmedabad#BitumenSprayerinGujarat#BitumenSprayerinIndia#BitumenSprayerinSaudiArabia#bitumensprayers#Buraydah#CapiousRoadtechPvt.Ltd.#Exporter#Gujarat#Ḩā’il#ḨafralBāţin#India#Jāzān#Jeddah#Mecca#Medina#Najrān

0 notes

Text

Planta de Mezcla Húmeda Macadam en Chile

Capious Roadtech Pvt. Ltd. es fabricante, proveedor y exportador Planta de Mezcla Húmeda Macadam en Chile. Capious Roadtech Pvt. Ltd., con sede en Ahmedabad, Gujarat, es un fabricante líder de maquinaria para construcción vial en India. Con más de 100 instalaciones en todo el mundo, Capious se especializa en ofrecer soluciones de alta calidad para proyectos de infraestructura vial. Su Planta de Mezcla Húmeda Macadam (WMM) está diseñada para producir una mezcla homogénea de áridos y aditivos, asegurando una base fuerte y duradera para la construcción de carreteras. Una Planta de Mezcla Húmeda Macadam es una instalación utilizada en la construcción de carreteras para producir una mezcla uniforme de áridos, agua y aditivos como cemento, cal o emulsión. Esta mezcla se utiliza luego como capa base o sub-base en la construcción de carreteras, proporcionando resistencia y durabilidad al pavimento. Tipos: 1. Planta de Mezcla Húmeda Macadam Móvil: Diseñada para proyectos que requieren reubicación frecuente. 2. Planta de Mezcla Húmeda Macadam Portátil: Ofrece flexibilidad con fácil transporte y montaje. 3. Planta de Mezcla Húmeda Macadam Estacionaria: Ideal para proyectos a gran escala con ubicaciones fijas. Características: Mezcla de Alta Calidad: Equipadas con puntas ajustables y reemplazables de Ni-hard para los brazos mezcladores, asegurando una mezcla uniforme. Construcción Duradera: Fabricadas con placas de acero de aleación especial resistentes a la corrosión y abrasión para mayor vida útil. Operación Eficiente: Bajo consumo de energía con estructuras robustas para transportadores. Dosificación Precisa: Mezcla exacta de áridos y aditivos para obtener materiales con gradación adecuada. Integración Flexible de Aditivos: Accesorios opcionales para dosificación precisa de aditivos como cemento, cal y emulsión. Aplicaciones: Construcción de Autopistas y Carreteras Express Desarrollo de Caminos Rurales Vías Industriales y Estacionamientos Pistas de Aeropuertos Obras Viales Urbanas Preguntas Frecuentes (FAQs): P1: ¿Cuál es el rango de capacidad de las Plantas de Mezcla Húmeda Macadam de Capious? R: Las plantas tienen capacidades que varían entre 100 TPH y 300 TPH. P2: ¿La planta puede manejar diferentes tipos de aditivos? R: Sí, la planta puede integrar aditivos como cemento, cal y emulsión mediante accesorios opcionales. P3: ¿De qué material está construida la planta? R: La planta está construida con acero especial de aleación resistente a la corrosión y abrasión para mayor durabilidad. P4: ¿La planta es adecuada para operaciones móviles? R: Sí, Capious ofrece modelos móviles, portátiles y estacionarios para adaptarse a diferentes necesidades de proyecto. P5: ¿Cómo garantiza Capious el control de calidad? R: Capious cumple con las especificaciones del M.O.R.T&H y realiza estrictos controles de calidad durante el diseño y desarrollo. Capious Roadtech Pvt. Ltd. tiene presencia con su Planta de Mezcla Húmeda Macadam en Chile, incluyendo ciudades como Santiago, Concepción, Puente Alto, Maipú, La Florida, Antofagasta, Viña del Mar, San Bernardo, Valparaíso, Temuco, Las Condes, Rancagua, Peñalolén, Talca, Coquimbo, Arica, La Serena, Iquique, Puerto Montt, Chillán, Osorno, Calama, Copiapó, Valdivia, Quilpué, Colina, Los Ángeles, Curicó, Punta Arenas, Melipilla, San Antonio, Ovalle, Linares, Quillota, San Felipe, Coyhaique, Los Andes, San Fernando, Talagante, Angol, Vallenar, Castro, La Unión, Tocopilla, Lebu, Puerto Natales, Illapel, La Ligua. Contáctenos hoy para más información o para realizar su pedido. Read the full article

#Ahmedabad#Angol#Antofagasta#Arica#Calama#Castro#Chile#Chillán#ciudadescomoSantiago#Colina#Concepción#Copiapó#Coquimbo#Coyhaique#Curicó#Exporter#ExporterofWetMixMacadamPlant#Gujarat#Illapel#India#Iquique#LaFlorida#LaLigua#LaSerena#LaUnión#LasCondes#Lebu#Linares#LosAndes#LosÁngeles

0 notes

Text

Road Broomer in Nigeria

Capious Roadtech Pvt. Ltd. is a Manufacturer, Supplier and Exporter of Road Broomer in Nigeria. Capious Roadtech Pvt. Ltd., based in Ahmedabad, Gujarat, manufactures reliable and high-quality road construction machinery for infrastructure projects. Their Road Broomer ensures efficient cleaning, providing a smooth, debris-free surface before applying asphalt or bitumen layers. A Road Broomer is a mechanical sweeping machine used to clean highways, streets, and other paved road surfaces. It features rotating brushes that remove dust, debris, and particles, preparing roads for construction or maintenance work. Types: Mechanical BroomerHydraulic Broomer Specifications: Mode of Towing: Tractor / JeepDrive for Brush: Helical bevel gear / HydraulicSweeping Width: 2,100 mmBrush Diameter: 490 mmTyre Size: 6.00 × 12Wheel: Heavy duty (2 nos.)Brush Material: Nylon bristlesAdjustment: Central & both-side via screwsApplication Surfaces: WMM, asphalt, pot-hole prepDust Collection: Left side; optional bin Features: Sweeping Mechanism: Nylon bristle brush, 490 mm diameter, driven via helical bevel gears or hydraulics.Sweeping Width: Up to 2,100 mm for mechanical models; hydraulic variants as wide as 2,250 mm.Adjustment System: Central and side pressure adjustments via hand screws for varying slopes.Wheels: Two heavy-duty wheels with 6.00‑12 tyre size.Drive Options: Available in mechanical (gear-driven by tyre rotation) and hydraulic variants, compatible with tractor, jeep, loader hydraulics.Dust Management: Manual debris collection to left side; optional hydraulic dust bins in some models. FAQs: Q1: What is the ideal ground speed during operation?Typically 5–15 km/h; slower speeds enhance fine dust removal; Capious models suit normal tractor speeds. Q2: How do I service or replace brushes?Replaceable nylon brush rings are easy to maintain; sleeves accessed via front cover and grease points provided. Capious Roadtech Pvt. Ltd. is a Road Broomer in Nigeria, Including Lagos, Abuja, Ibadan, Awka, Kano, Port Harcourt, Nneyi-Umuleri, Onitsha, Maiduguri, Aba, Benin City, Shagamu, Ikare, Ogbomoso, Mushin, Owerri, Ikeja, Agege, Somolu, Sokoto, Nnewi, Ilesa, Minna, Apapa, Bida, Ilobu, Ajegunle. Contact us today for more information or to place your order. Read the full article

#Ahmedabad#bitumensprayers#CapiousRoadtechPvt.Ltd.#Exporter#Gujarat#India#Nigeria#RoadBroomer#RoadBroomerinAhmedabad#RoadBroomerinGujarat#RoadBroomerinIndia#RoadBroomerinNigeria#Supplier

0 notes

Text

Planta de Mezcla Asfáltica por Lotes en Chile

Capious Roadtech Pvt. Ltd. es fabricante, proveedor y exportador de Plantas de Mezcla Asfáltica por Lotes en Chile. Una Planta de Mezcla Asfáltica por Lotes es un activo fundamental en la construcción moderna de carreteras, diseñada para producir mezclas asfálticas calientes (HMA) de alta calidad en lotes precisos. Capious Roadtech Pvt. Ltd., con sede en Ahmedabad, India, ofrece la serie CABP de plantas de mezcla asfáltica por lotes, reconocidas por su eficiencia, durabilidad y cumplimiento con estándares internacionales. Estas plantas atienden la creciente demanda de proyectos de infraestructura tanto a nivel nacional como global. Una planta de mezcla asfáltica por lotes es una instalación que combina agregados, betún y materiales de relleno en proporciones precisas para producir mezclas asfálticas. El proceso implica calentar y mezclar estos componentes en lotes para asegurar uniformidad y calidad. La serie CABP de Capious está diseñada para entregar resultados consistentes, siendo ideal para proyectos que requieren mezclas asfálticas variadas. ¿Por qué elegir Capious Roadtech Pvt. Ltd.? Experiencia: Más de 25 años en la fabricación de equipos para construcción vial.Aseguramiento de Calidad: Certificación ISO 9001:2015 con controles de calidad estrictos.Innovación: Investigación y desarrollo continuo para mejorar la oferta de productos.Alcance Global: Exportación a más de 35 países en todo el mundo.Soporte al Cliente: Servicio postventa integral y capacitación. Flujo del Proceso: Alimentación de Agregado Frío: Los materiales se alimentan en tolvas de frío.Secado y Calentamiento: Los agregados se calientan en un tambor rotatorio.Tamizado: Los materiales se tamizan para separar diferentes tamaños.Pesaje: Pesaje preciso de agregados, betún y relleno.Mezclado: Los componentes se mezclan en un molino pug para formar el asfalto.Almacenamiento: El asfalto terminado se almacena en tolvas calientes o silos.Descarga: El asfalto se descarga en camiones para su transporte. Aplicaciones: Construcción de Autopistas y Vías RápidasProyectos de Infraestructura UrbanaVías Industriales y EstacionamientosPistas de AeropuertosInfraestructura Pública y Proyectos GubernamentalesCalles de Rodaje de Aeropuertos Capious Roadtech Pvt. Ltd. ofrece Planta de mezcla asfáltica por lotes en Chile ofrece alta eficiencia, precisión y calidad en la producción vial., incluyendo ciudades como Santiago, Concepción, Puente Alto, Maipú, La Florida, Antofagasta, Viña del Mar, San Bernardo, Valparaíso, Temuco, Las Condes, Rancagua, Peñalolén, Talca, Coquimbo, Arica, La Serena, Iquique, Puerto Montt, Chillán, Osorno, Calama, Copiapó, Valdivia, Quilpué, Colina, Los Ángeles, Curicó, Punta Arenas, Melipilla, San Antonio, Ovalle, Linares, Quillota, San Felipe, Coyhaique, Los Andes, San Fernando, Talagante, Angol, Vallenar, Castro, La Unión, Tocopilla, Lebu, Puerto Natales, Illapel, La Ligua. Contáctenos hoy para más información o para realizar su pedido. Read the full article

#Ahmedabad#Angol#Antofagasta#Arica#AsphaltBatchMixPlant#AsphaltBatchMixPlantinAhmedabad#AsphaltBatchMixPlantinChile#AsphaltBatchMixPlantinGujarat#AsphaltBatchMixPlantinIndia#Calama#CapiousRoadtechPvt.Ltd.#Castro#Chile#Chillán#Colina#Concepción#Copiapó#Coquimbo#Coyhaique#Curicó#Exporter#ExporterofAsphaltBatchMixPlant#Gujarat#Illapel#incluyendociudadescomoSantiago#Iquique#LaFlorida#LaLigua#LaSerena#LaUnión

0 notes

Text

Concrete Batching Plant in Nigeria

Capious Roadtech Pvt. Ltd. is a Manufacturer, Supplier and Exporter of Concrete Batching Plant in Nigeria. Capious Roadtech Pvt. Ltd., established in 1996, is a leading manufacturer of road and civil construction equipment in India. With a commitment to quality and innovation, Capious offers a range of concrete batching plants designed to meet the diverse needs of the construction industry. Their plants are known for durability, efficiency, and user-friendly operation. Specifications: Stationary Models - CBP 20: 20 m³/hr output capacity - CBP 30: 30 m³/hr output capacity Mobile ModelsCMCP Series: - CMCP-20: 20 m³/hr - CMCP-30: 30 m³/hr - CMCP-45: 45 m³/hr Compact Models:CC-CP Series: - CC-CP 30: 30 m³/hr - CC-CP 45: 45 m³/hr - CC-CP 60: 60 m³/hr - CC-CP 75: 75 m³/hr All models feature digital load cell-based weighing systems, PLC-based control panels, and various mixer options including Twin Shaft, Pan, Turbo Pan, and Planetary mixers. They also offer modular construction for easy transportation and installation. Features: Fully Automatic Operation: Electronic operation with PLC control.Accurate Weighing: Independent weighing systems for cement, water, and additives.Hydraulic Discharge: Mixer discharge by hydraulic cylinder.Modular Construction: Bolted tower design for quick erection and dismantling.Low Maintenance: Negligible maintenance with replaceable liners and paddle tips.MIS Reporting: Generation of various combination reports. Applications: Capious concrete batching plants are suitable for:Infrastructure Projects: Roads, highways, bridges.Commercial Construction: Buildings, malls, complexes.Industrial Projects: Factories, warehouses.Residential Projects: Housing complexes, apartments. FAQs: Q1: Why choose Capious concrete batching plants?Capious offers high-quality, durable, and efficient concrete batching plants tailored to meet the specific needs of your project. Their plants are designed for easy operation and maintenance, ensuring maximum productivity. Q2: Where are Capious plants manufactured?Capious operates three well-equipped manufacturing plants in the Vatva Industrial area of Ahmedabad, India, covering over 45,000 sq. feet. Capious Roadtech Pvt. Ltd. is a Concrete Batching Plant in Nigeria, Including Lagos, Abuja, Ibadan, Awka, Kano, Port Harcourt, Nneyi-Umuleri, Onitsha, Maiduguri, Aba, Benin City, Shagamu, Ikare, Ogbomoso, Mushin, Owerri, Ikeja, Agege, Somolu, Sokoto, Nnewi, Ilesa, Minna, Apapa, Bida, Ilobu, Ajegunle. Contact us today for more information or to place your order. View Product: Click Here Read the full article

#Aba#Abuja#Agege#Ahmedabad#Apapa#Awka#BeninCity#Bida#CapiousRoadtechPvt.Ltd.#ConcreteBatchingPlantinNigeria#Exporter#ExporterofConcreteBatchingPlant#ExporterofConcreteBatchingPlantinNigeria#Gujarat#Ibadan#Ikare#Ikeja#Ilesa#Ilobu#India#Kano#Lagos#Maiduguri#ManufacturerofConcreteBatchingPlant#ManufacturerofConcreteBatchingPlantinAhmedabad#Minna#Mushin#Nigeria#Nnewi#Nneyi-Umuleri

0 notes

Text

Pulverizador de Betume em Moçambique

A Capious Roadtech Pvt. Ltd. é fabricante, fornecedora e exportadora de Pulverizador de Betume em Moçambique. A Capious Roadtech Pvt. Ltd., com sede em Ahmedabad, Gujarat, Índia, é uma fabricante líder de máquinas para construção de estradas. Seu Pulverizador de Betume aplica betume uniformemente e com precisão, ideal para superfícies rodoviárias e pavimentação eficiente. Os Pulverizadores de Betume da Capious oferecem eficiência, durabilidade e desempenho superior para projetos rigorosos de construção rodoviária. Um Pulverizador de Betume aplica betume quente ou emulsão consistentemente na superfície das estradas durante a construção. Esse processo é crucial para criar uma ligação forte entre as camadas, garantindo a longevidade e durabilidade do pavimento. Os Pulverizadores de Betume da Capious são equipados com recursos avançados para facilitar a pulverização precisa, aquecimento eficiente e operação fácil. Por que escolher a Capious Roadtech Pvt. Ltd.? Expertise comprovada: Com décadas de experiência na fabricação de equipamentos para construção rodoviária, a Capious é um nome confiável no setor.Garantia de qualidade: Todas as máquinas são fabricadas em conformidade com as especificações do M.O.R.T&H., garantindo altos padrões de qualidade e desempenho.Design inovador: A Capious integra as tecnologias mais recentes para aprimorar a funcionalidade, segurança e facilidade de operação.Suporte completo: Desde a personalização até o serviço pós-venda, a Capious oferece soluções completas para atender às necessidades dos clientes. Características: Tanque totalmente isolado: Mantém a temperatura ideal do betume, garantindo uma pulverização constante.Aquecimento eficiente: Queimador de alta capacidade aquece o betume rapidamente até a temperatura necessária.Operação amigável: Projetado para operação segura e fácil, com controles intuitivos.Barra de pulverização dobrável: Permite ajuste na largura de pulverização, atendendo a diferentes necessidades do projeto.Acessório de pulverização manual: Facilita a aplicação manual em áreas inacessíveis pela barra principal.Sistema de limpeza por pressão: Garante que o sistema fique limpo após o uso, prevenindo entupimentos e problemas de manutenção. Perguntas Frequentes: P1: Que tipos de pulverizadores de betume a Capious oferece?A Capious oferece Pulverizadores de Betume montados em caminhão e em carrinho, atendendo a diferentes tamanhos e necessidades de projeto. P2: A largura da barra de pulverização pode ser ajustada?Sim, a barra tem uma largura básica de 2,4 metros e pode ser estendida até 4,2 metros, permitindo flexibilidade conforme a necessidade do projeto. A Capious Roadtech Pvt. Ltd. oferece Pulverizador de Betume em Moçambique, incluindo Maputo, Matola, Nampula, Beira, António Enes, Chimoio, Cidade de Nacala, Malema, Quelimane, Tete, Vila Junqueiro, Lichinga, Pemba, Xai-Xai, Maxixe, Cuamba, Montepuez, Dondo, Mocuba, Inhambane, Chokwé, Manhiça, Pebane, Chibuto, Moatize, Songo, Macomia e Zumbo. Para mais informações ou para solicitar um orçamento, entre em contato com a Capious Roadtech Pvt. Ltd. hoje mesmo! View Product: Click Here Read the full article

#Ahmedabad#AntónioEnes#Beira#BitumenSprayer#BitumenSprayerinAhmedabad#BitumenSprayerinGujarat#BitumenSprayerinIndia#BitumenSprayerinMozambique#bitumensprayers#CapiousRoadtechPvt.Ltd.#Chibuto#Chimoio#Chokwé#CidadedeNacala#Cuamba#Dondo#Exporter#ExporterofBitumenSprayer#ExporterofBitumenSprayerinMozambique#Gujarat#incluindoMaputo#Inhambane#Lichinga#MacomiaeZumbo#Malema#Manhiça#ManufacturerofBitumenSprayerinAhmedabad#Matola#Maxixe#Moatize

0 notes

Text

Wet Mix Macadam Plant in Zimbabwe

Capious Roadtech Pvt. Ltd. is a Manufacturer, Supplier and Exporter of Wet Mix Macadam Plant in Zimbabwe. Capious Roadtech Pvt. Ltd., based in Ahmedabad, Gujarat, is a leading manufacturer of road construction machinery in India. Specializing in Wet Mix Macadam (WMM) Plants, Capious offers high-quality equipment designed to produce homogeneous base and sub-base materials for road construction projects. With over 100 installations worldwide, Capious combines innovation with reliability to meet the demands of modern infrastructure development. A Wet Mix Macadam Plant is specialized equipment used in road construction to produce a uniform mixture of aggregates, water, and additives like cement, lime, or emulsion. This mix serves as the base or sub-base layer in road construction, providing a stable foundation for the upper layers. The plant ensures precise control over the mixing process, resulting in high-quality and durable road surfaces. Why Choose Capious Wet Mix Macadam Plant? Proven Track Record: Over 100 installations globally, demonstrating reliability and performance. High Productivity: Offers capacities ranging from 100 to 300 TPH, catering to various project sizes. Advanced Technology: Incorporates wear-resistant alloy steel components and corrosion-resistant liners for durability. Customization: Available in mobile, portable, and stationary models to suit different project requirements. Global Standards: Designed and engineered to meet international quality standards. Features: Uniform Mixing: Ensures consistent quality of the mix, preventing segregation. Durable Components: Utilizes wear-resistant alloy steel and corrosion-resistant liners for longevity. Efficient Mixing: Equipped with high-capacity pug mills for thorough blending. Modular Design: Offers flexibility in installation and operation. Advanced Control System: Features a fully automated control panel for precise operation. Applications: Capious Wet Mix Macadam Plants are ideal for: Highways and Expressways: Providing a strong foundation for heavy traffic. Airport Runways: Ensuring stability and durability under aircraft loads. Industrial Roads: Supporting the weight and movement of heavy machinery. Urban and Rural Roads: Constructing reliable road networks in cities and villages. Frequently Asked Questions (FAQs): Q1: What is the capacity range of Capious Wet Mix Macadam Plants? A1: Capious offers Wet Mix Macadam Plants with capacities ranging from 100 to 300 TPH, catering to various project sizes. Q2: Can the plant handle additives like cement and lime? A2: Yes, the plant is equipped with optional accessories for precise metering of additives such as cement, lime, and emulsion. Q3: What types of models are available? A3: Capious provides mobile, portable, and stationary models to suit different project requirements. Capious Roadtech Pvt. Ltd. is a Wet Mix Macadam Plant in Zimbabwe, Including Harare, Masvingo, Bulawayo, Chitungwiza, Mutare, Gweru, Nkayi, Kwekwe, Norton, Kadoma, Chegutu, Chinhoyi, Marondera, Sakubva, Bindura, Hwange, Beitbridge, Chiredzi, Rusape, Zvishavane, Chipinge, Karoi, Victoria Falls, Redcliff, Mukumbura, Gwanda. For more information or to request a quote, feel free to contact Capious Roadtech Pvt. Ltd. today! Read the full article

#Ahmedabad#Beitbridge#Bindura#Bulawayo#CapiousRoadtechPvt.Ltd.#Chegutu#Chinhoyi#Chipinge#Chiredzi#Chitungwiza#Exporter#ExporterofWetMixMacadamPlantinZimbabwe#Gujarat#Gwanda#Gweru#Harare#Hwange#India#Kadoma#Karoi#Kwekwe#ManufacturerofWetMixMacadamPlant#Marondera#Masvingo#Mukumbura#Mutare#Nkayi#Norton#Redcliff#Rusape

0 notes

Text

Planta de Mezcla Asfáltica por Lotes en Perú

Capious Roadtech Pvt. Ltd. es un fabricante, proveedor y exportador de Plantas de mezcla asfáltica por lotes en Perú. Ubicada en Ahmedabad, Gujarat, Capious Roadtech Pvt. Ltd. fabrica y exporta maquinaria avanzada para la construcción de carreteras a mercados globales. Con dos décadas de experiencia, la empresa se especializa en plantas de mezcla asfáltica por lotes para diversos proyectos de desarrollo de infraestructura en todo el mundo. Su enfoque en la innovación, la calidad del producto y la satisfacción del cliente les ha ganado una reputación confiable en la fabricación de equipos para la construcción. Las plantas de mezcla asfáltica por lotes producen mezclas asfálticas combinando de forma precisa agregados, arena, relleno y betún en proporciones controladas. A diferencia de las plantas continuas, las plantas por lotes ofrecen mayor control y flexibilidad al producir asfalto en lotes medidos con precisión. Esto las hace ideales para proyectos que requieren diseños de mezcla variados y estándares de calidad exigentes. ¿Por qué elegir Capious Roadtech Pvt. Ltd.? Experiencia Comprobada: Con más de 20 años en la industria, Capious tiene un historial de entrega de plantas asfálticas confiables y eficientes. Presencia Global: Atienden a clientes en más de 35 países, demostrando sus estándares internacionales de calidad. Gama de Productos Completa: Ofrecen varios modelos para adaptarse a los diferentes requerimientos de proyectos. Garantía de Calidad: Certificación ISO 9001:2015 que asegura el cumplimiento de estándares globales de calidad. Enfoque al Cliente: Brindan un servicio postventa rápido y soporte para garantizar la satisfacción del cliente. Características: Tecnología Avanzada: Incorpora tecnología moderna de mezcla en tambor para una calidad superior de mezcla. Alta Capacidad de Producción: Diseñada para cumplir o superar las expectativas de producción. Diseño Fácil de Usar: Lubricación sencilla, fácil desmontaje y mantenimiento conveniente. Cumplimiento Ambiental: Equipadas con filtros de tela para asegurar bajas emisiones de polvo. Eficiencia Energética: Uso de motores AC con óptima eficiencia en consumo de combustible. Automatización: Control automático del quemador y sistemas de pesaje por celdas de carga de alta precisión. Diseño Modular: Facilita el montaje y la puesta en marcha. Aplicaciones: Construcción de Autopistas y Vías Rápidas Proyectos de Infraestructura Urbana Caminos Industriales y Estacionamientos Pistas de Aeropuertos Proyectos Públicos e Infraestructura Gubernamental Calles de Rodaje de Aeropuertos Preguntas Frecuentes: P1: ¿Cuál es el rango de capacidad de producción de las Plantas de Mezcla Asfáltica de Capious? R1: Capious ofrece plantas con diferentes capacidades para adaptarse a las necesidades de cada proyecto. P2: ¿La planta puede ser personalizada según los requisitos del proyecto? R2: Sí, Capious ofrece opciones de personalización para cumplir con las especificaciones particulares de cada cliente. Capious Roadtech Pvt. Ltd. ofrece Planta de Mezcla Asfáltica por Lotes en Perú, incluyendo las ciudades de: Lima, Arequipa, Trujillo, Chiclayo, Piura, Cusco, Callao, Huancayo, Iquitos, Pucallpa, Chimbote, Tacna, Ica, Juliaca, Tarapoto, Ayacucho, Cajamarca, Huacho, Huánuco, Sullana, Huaycán, Barranca, Puno, San Ignacio, Huaraz, Pisco, Tumbes, Chosica, Puerto Maldonado, Abancay, Moquegua, Víctor Larco Herrera, Cerro de Pasco, Moyobamba, Huancavelica, Camaná, Chancay, Chachapoyas, Ferreñafe, Moche, Jauja, Pacasmayo. Para más información, no dude en contactarnos. Read the full article

0 notes

Text

Road Broomer Machine in Kenya

Road Broomer Machine in Kenya Capious Roadtech Pvt. Ltd. is a Manufacturer, Supplier and Exporter of Road Broomer Machine in Kenya. We are an ISO 9001:2015 Certified Company in Ahmedabad, Gujarat, India. A Road Broomer, also known as a road sweeper, is an essential piece of equipment in the construction and maintenance of roads, highways, and industrial surfaces. Capious Roadtech Pvt. Ltd., a leading manufacturer in India, offers high-quality Road Broomers designed to meet the diverse needs of road cleaning operations. Engineers design these machines for efficiency, durability, and ease of use, making them ideal for road maintenance and construction. Manufacturers equip a Road Broomer with rotating brushes powered by a hydraulic or mechanical system. Operators use it to remove debris, dust, and other unwanted materials from road surfaces, ensuring cleanliness and safety. Capious Roadtech designs its Road Broomers to attach to tractors or loaders and utilize their hydraulic systems for operation. Features: Hydraulic Drive System: Utilizes the host vehicle's hydraulic system for efficient broom rotation and height adjustment. Adjustable Brush Angles: Allows for sweeping at various angles, enhancing cleaning efficiency. Durable Construction: Built with high-quality materials to withstand harsh working conditions. Easy Attachment/Detachment: Quick-connect systems enable fast setup and removal. Dust Control Systems: Optional water spray systems help in controlling dust during operation. Applications: Road Construction: Cleaning surfaces before and after laying asphalt or concrete. Municipal Maintenance: Regular cleaning of city streets and public areas. Industrial Sites: Maintaining cleanliness in factories and warehouses. Airport Runways: Ensuring debris-free surfaces for aircraft operations. Mining Operations: Clearing dust and debris from mining roads. FAQs: Q1: Why should I choose a Road Broomer from Capious Roadtech Pvt. Ltd.? A1: Capious Roadtech offers high-quality, durable, and efficient Road Broomers designed to meet the diverse needs of road cleaning operations. Their machines are engineered for optimal performance and ease of use. Q2: What maintenance is required for a Road Broomer? A2: Operators regularly check hydraulic fluid levels, inspect brushes for wear, and lubricate all moving parts. Capious Roadtech Pvt. Ltd. is a Road Broomer Machine in Kenya Including Naragoi, Bungoma, Dadaab, Eldoret, Killfi, Kisil, Lamu, Litein, Lodwar, Lokichoggio, Mombasa, Moyale, Ruiru, Mumias, Nairobi, Nanyuki, Narok, Wajir, Watamu, Watamu, Webuye, Wote, Wundanyi. For more information, please feel free to contact us. Read the full article

#Ahmedabad#Bungoma#CapiousRoadtechPvt.Ltd.#Dadaab#Eldoret#ExporterofRoadBroomerMachine#ExporterofRoadBroomerMachineinKenya#Gujarat#Kenya#Killfi#Kisil#Lamu#Litein#Lodwar#Lokichoggio#ManufacturerofRoadBroomerMachineinAhmedabad#ManufacturerofRoadBroomerMachineinKenya#Mombasa#Moyale#Mumias#Nairobi#Nanyuki#Naragoi#Narok#RoadBroomerMachineinAhmedabad#RoadBroomerMachineinGujarat#RoadBroomerMachineinIndia#RoadBroomerMachineinKenya#Ruiru#Supplier

0 notes

Text

Planta dosificadora de concreto en Perú

Capious Roadtech Pvt. Ltd. ofrece Planta dosificadora de concreto en Perú. Capious Roadtech Pvt. Ltd. es una empresa reconocida a nivel mundial en el campo de la maquinaria para la construcción de carreteras y el desarrollo de infraestructura. Con décadas de experiencia en ingeniería y un firme compromiso con la innovación de vanguardia, Capious se ha convertido en un socio preferido por clientes de todo el mundo. Nuestra maquinaria avanzada está diseñada para brindar durabilidad, alto rendimiento y sostenibilidad ambiental, cumpliendo con las más exigentes necesidades de construcción. Nuestras plantas dosificadoras de concreto destacan por su eficiencia y fiabilidad en producir mezclas de concreto de alta calidad. Ahora disponibles en Perú, nuestras soluciones de plantas de concreto están diseñadas para respaldar el crecimiento de la infraestructura y la construcción en el país. ¿Por qué elegir a Capious Roadtech Pvt. Ltd. en Perú? Fabricante internacional de confianza Compromiso con la innovación y la calidad Rendimiento comprobado en proyectos globales Soporte postventa integral ¿Por qué elegir nuestra planta de concreto en Perú? Diseñada para eficiencia y consistencia Ideal para proyectos de construcción grandes y pequeños Bajo mantenimiento y alto rendimiento Instalación rápida y lista para operar Construida para soportar climas severos y terrenos difíciles Características de la Planta de Concreto Capious Diseño confiable y fácil de usar Sistema de pesaje de alta precisión Producción constante con mínimo tiempo de inactividad Cilindro hidráulico para descarga del mezclador Construcción resistente y duradera Optimizada para eficiencia de combustible y energía Especificaciones Técnicas CBP 20 – 20 m³/hora CBP 30 – 30 m³/hora Beneficios de Nuestra Planta de Concreto Mayor velocidad en la construcción Mezclas de concreto uniformes y de alta calidad Reducción de costos operativos y de mano de obra Operación respetuosa con el medio ambiente Escalable según el tamaño del proyecto Usos de la Planta de Concreto en Perú Producción de concreto premezclado (RMC) Fabricación de componentes de concreto prefabricado Mezclas de concreto personalizadas para proyectos específicos Aplicaciones en Diversos Sectores Construcción de carreteras y autopistas Edificaciones residenciales y comerciales Desarrollo de infraestructura Construcción de aeropuertos y pistas de aterrizaje Instalaciones industriales y fábricas Proyectos de vivienda urbana y rural Preguntas Frecuentes P1. ¿Es adecuada la planta de concreto Capious para el clima y terreno del Perú? R: Sí. Nuestras plantas están diseñadas para funcionar de manera confiable incluso en terrenos accidentados y climas variables como los del Perú. P2. ¿Se puede personalizar la planta para proyectos específicos? R: Por supuesto. Ofrecemos opciones de personalización según el tamaño del proyecto, requerimientos de producción y otras condiciones del sitio. P3. ¿Con qué frecuencia requiere mantenimiento la planta? R: Planta de bajo mantenimiento, pero se recomiendan revisiones periódicas según el manual para rendimiento y vida útil óptimos. P4. ¿Cuánto tiempo toma instalar la planta en un sitio de construcción en Perú? R: Nuestras plantas son modulares y se instalan rápidamente con preparación mínima del terreno—generalmente operativas en pocos días. P5. ¿Ofrecen soporte postventa en Perú? R: Sí, contamos con una red local de servicio en Perú que ofrece soporte técnico y suministro de repuestos. Capious Roadtech Pvt. Ltd. ofrece Planta dosificadora de concreto en Perú incluyendo Lima, Cusco, Miraflores, Arequipa, Trujillo, Iquitos, Chiclayo, Huancayo, Ayacucho, Abancay, Huaraz, Talara, Tacna, Chimbote, Cajamarca, Puno, Ica, Cerro de Pasco, Huancavelica, Huánuco, Tumbes, Puerto Maldonado, Tingo María, Sullana, Barranca, Lambayeque, Huacho, Pucallpa, Chincha Alta, Tarapoto, Piura, Moquegua, Moyobamba, Ferreñafe, Pisco, Bagua Grande, Huaral, Juliaca, Chepén, Sicuani, San Vicente de Cañete, Sechura, Paita, Ilo, Yurimaguas, Andahuaylas, Chulucanas, Tarma, Chancay. Para más información, no dude en contactarnos. Read the full article

0 notes

Text

Bitumen Sprayer in Kenya

Capious Roadtech Pvt. Ltd. is a Manufacturer, Supplier and Exporter of Bitumen Sprayer in Kenya. We are an ISO 9001:2015 Certified Company in Ahmedabad, Gujarat, India. Capious Roadtech Pvt. Ltd. leads in manufacturing and exporting high-quality road construction equipment including advanced bitumen sprayers. With dedication to innovation, durability, and customer satisfaction, Capious offers bitumen sprayers for varied construction industry needs. A bitumen sprayer, or pressure distributor, is specialized equipment applying uniform hot bitumen or emulsion layers on surfaces. This important process creates durable, long-lasting roads by ensuring proper binding between different pavement layers during construction. Bitumen sprayers are widely used for tack coating, prime coating, surface dressing, and other road maintenance tasks. Types of Bitumen Sprayers: Truck-Mounted Bitumen Sprayers Trolley-Mounted Bitumen/Emulsion Sprayers Technical Specifications: Tank Capacity: Truck-Mounted Models: 3,000 to 12,000 liters Trolley-Mounted Models: 500 to 3,000 liters Spray Bar Width: 2.4 meters (standard), extendable up to 4.2 meters Spray Pressure: 0 to 6 kg/sq m Engine: Air-cooled diesel engine Pump: Positive displacement internal gear type Heating System: High-capacity imported burner with various fuel options Cladding Options: Galvanized, Aluminium, or Stainless steel sheets Features: Fully Insulated Tank: Ensures consistent temperature maintenance, reducing heat loss and improving efficiency. High-Efficiency Heating System: Equipped with imported burners to heat bitumen to the required temperature swiftly. Positive Displacement Gear Pump: Provides a steady and controlled flow of bitumen, ensuring uniform application. Unique Pressure Cleaning System: Standard feature that cleans the system after use, preventing blockages and ensuring longevity. Hand Spray System: Provides manual control for intricate areas, enhancing versatility. Speed Detection & Driver Control System: Integrates with vehicle speed to adjust spray output automatically, ensuring consistent application. FAQs: Why choose Capious Roadtech's bitumen sprayers? Capious Roadtech offers bitumen sprayers that combine quality, efficiency, and innovation. Their machines are designed to meet the specific needs of the road construction industry, ensuring durability, ease of operation, and compliance with industry standards. How is the cleaning process handled? The sprayers come with a unique pressure cleaning system that cleans the pipelines and nozzles after use, preventing blockages and ensuring longevity. Capious Roadtech Pvt. Ltd. is a Bitumen Sprayer in Kenya Including Naragoi, Bungoma, Dadaab, Eldoret, Killfi, Kisil, Lamu, Litein, Lodwar, Lokichoggio, Mombasa, Moyale, Ruiru, Mumias, Nairobi, Nanyuki, Narok, Wajir, Watamu, Watamu, Webuye, Wote, Wundanyi. For more information, please feel free to contact us. Read the full article

#Ahmedabad#BitumenSprayerinKenya#Bungoma#CapiousRoadtechPvt.Ltd.#Dadaab#Eldoret#Exporter#ExporterofBitumenSprayer#ExporterofBitumenSprayerinKenya#Gujarat#India#Kenya#Killfi#Kisil#Lamu#Litein#Lodwar#Lokichoggio#Mombasa#Moyale#Mumias#Nairobi#Nanyuki#Naragoi#Narok#Ruiru#Supplier#Wajir#Watamu#Webuye

0 notes

Text

Wet Mix Macadam Plant in Saudi Arabia

Capious Roadtech Pvt. Ltd. is a Manufacturer, Supplier and Exporter of Wet Mix Macadam Plant in Saudi Arabia. We are an ISO 9001:2015 Certified Company in Ahmedabad, Gujarat, India. A Wet Mix Macadam Plant is a specialized facility designed to produce a homogeneous mix of aggregates, water, and additives like cement, lime, or emulsions. This mixture forms the base and sub-base layers of roads, providing a stable foundation for the upper layers of pavement. The WMM process ensures uniform mixing, accurate proportioning, and efficient blending of materials, resulting in superior load-bearing capacity and durability of road structures. Capious Roadtech's Wet Mix Macadam Plants are designed to provide optimal solutions for blending aggregates, cement, water, and additives into a well-mixed base material. These plants are available in capacities ranging from 100 TPH to 300 TPH and come in mobile, portable, and stationary models to suit various project requirements. Specifications: Models Available: WMM 100, WMM 150, WMM 200, WMM 300. Output Capacities: 100 TPH, 150 TPH, 200 TPH, 300 TPH. Customization: Tailor-made models available upon specific demand. Additive Compatibility: Supports precise metering of additives like cement, lime, and emulsion. Construction: Rugged construction with components from world-renowned manufacturers. Mixing Efficiency: Uniform mixing and delivery of mixed materials without segregation. Automation: Equipped with accessories and controls for all types of additives. Proportioning Accuracy: Accurate proportioning and blending of aggregates and additives for properly graded materials. Wear Resistance: Wear-resistant alloy steel Ni-hard replaceable and adjustable tips for paddle arms. Durability: Replaceable corrosion and abrasion-resistant special alloy steel liner plates for longer life. Power Efficiency: Low power requirement. Conveyor Structure: All conveyor structures are fabricated from heavy-duty structure. Mix Discharge: Better mix and fluent discharge of mix material. Design: Finest industrial design built into the product aims at uniform mixing without segregation. Additive Metering: Easy add-on optional accessory equipment for precise metering of additives. Compliance: Designed and developed as per M.O.R.T&H. (formerly known as M.O.S.T.) specifications. Applications: Highway Construction: Laying base and sub-base layers for highways. Airport Runways: Providing stable foundations for runways. Urban Roads: Constructing durable urban road networks. Industrial Roads: Building roads within industrial complexes. Rural Roads: Developing road infrastructure in rural areas. FAQs: Why choose Capious Roadtech's Wet Mix Macadam Plant? Capious Roadtech engineers WMM plants for high productivity, durability, and international standard compliance. With over 100 installations worldwide, customers trust their plants for quality and performance. What capacities are available for WMM plants? Capious Roadtech provides WMM plants in capacities of 100 TPH, 150 TPH, 200 TPH, and 300 TPH. Manufacturers can also offer tailor-made models to meet specific demands. Capious Roadtech Pvt. Ltd. is a Manufacturer and Exporter of Wet Mix Macadam Plant in Saudi Arabia including Riyadh, Jeddah, Mecca, Medina, Ad Dammām, Tabūk, Al Hufūf, Al Qaţīf, Al Ḩillah, Aţ Ţā’if, Al Jubayl, Buraydah, Ḩafr al Bāţin, Yanbu, Ḩā’il, Abhā, Sakākā, Al Qurayyāt, Jāzān, Najrān, Al Wajh, Arar, Al Bāḩah, Tathlīth. Feel free to contact us if you have any more information or questions. Read the full article

#Abhā#AdDammām#Ahmedabad#AlBāḩah#AlḨillah#AlHufūf#AlJubayl#AlQaţīf#AlQurayyāt#AlWajh#Arar#asphaltbatchmixplants#asphaltdrummixplants#AţŢā’if#bitumensprayers#Buraydah#CapiousRoadtechPvt.Ltd.#concretebatchingplants#Exporter#ExporterofWetMixMacadamPlant#ExporterofWetMixMacadamPlantinSaudiArabia#Gujarat#Ḩā’il#ḨafralBāţin#India#Jāzān#Jeddah#ManufacturerofWetMixMacadamPlantinAhmedabad#Mecca#Medina

0 notes

Text

Planta de Mezcla por Lotes de Asfalto en Perú

Capious Roadtech Pvt. Ltd. es un fabricante, proveedor y exportador de Plantas de Mezcla por Lotes de Asfalto en Perú. Somos una empresa certificada por ISO 9001:2015, ubicada en Ahmedabad, Gujarat, India. Capious Roadtech Pvt. Ltd., con sede en Ahmedabad, Gujarat, fabrica maquinaria avanzada para la construcción de carreteras para proyectos de infraestructura globales. Sus Plantas de Mezcla por Lotes de Asfalto, especialmente la Serie CABP, cumplen con las necesidades modernas de construcción de carreteras, garantizando rendimiento y durabilidad. Estas plantas están diseñadas para ofrecer precisión, eficiencia y cumplir con los estándares ambientales, siendo adecuadas tanto para mercados nacionales como internacionales de infraestructura. Una Planta de Mezcla por Lotes de Asfalto mezcla agregados, betún y relleno en proporciones exactas para crear materiales de asfalto de alta calidad. El proceso de mezcla por lotes garantiza uniformidad, lo que la hace ideal para proyectos a gran escala que requieren una calidad de mezcla de asfalto constante y confiable. ¿Por qué elegir Capious Roadtech Pvt. Ltd.? Experiencia: Más de 25 años en la industria con más de 400 instalaciones en todo el mundo. Garantía de Calidad: Certificación ISO 9001:2015 con estrictas medidas de control de calidad. Innovación: Investigación y desarrollo continuos para incorporar las últimas tecnologías. Soporte al Cliente: Servicio postventa integral y programas de capacitación. Presencia Global: Exportado a más de 35 países a lo largo de los continentes. Características: Alta Tasa de Producción: Asegura una producción continua y eficiente de asfalto. Panel de Control Fácil de Usar: Sistema basado en PLC con HMI para una operación sencilla. Eficiencia Energética: Consumo de combustible optimizado para ahorro de costos. Cumplimiento Ambiental: Equipado con filtros de tela y colectores de polvo para minimizar las emisiones. Diseño Modular: Facilita el transporte, la instalación y el desmontaje. Sistema de Pesaje Avanzado: Arreglo de celdas de carga multipunto para una dosificación precisa. Mezclador de Alta Resistencia: Mezclador tipo Pug-mill diseñado para una mezcla homogénea. Aplicaciones: Construcción de Carreteras y Autopistas Proyectos de Infraestructura Urbana Carreteras Industriales y Áreas de Estacionamiento Pistas de Aeropuerto Infraestructura Pública y Proyectos Gubernamentales Vías de Rodaje de Aeropuertos Preguntas Frecuentes: ¿Cuál es la capacidad máxima de producción de las Plantas de Mezcla por Lotes de Asfalto Capious? La capacidad máxima de producción es de 240 TPH con el modelo CABP 3000. ¿Las plantas están equipadas para manejar RAP? Sí, Capious ofrece sistemas RAP como opción para sus plantas. ¿Cuál es la tasa de consumo de combustible de estas plantas? Las plantas consumen aproximadamente de 4 a 4.5 litros de combustible por tonelada de asfalto producido bajo condiciones ideales. Capious Roadtech Pvt. Ltd. tiene Plantas de Mezcla por Lotes de Asfalto en Perú, incluyendo Lima, Arequipa, Trujillo, Chiclayo, Piura, Cusco, Callao, Huancayo, Iquitos, Pucallpa, Chimbote, Tacna, Ica, Juliaca, Tarapoto, Ayacucho, Cajamarca, Huacho, Huánuco, Sullana, Huaycan, Barranca, Puno, San Ignacio, Huaraz, Pisco, Tumbes, Chosica, Puerto Maldonado, Abancay, Moquegua, Víctor Larco Herrera, Cerro de Pasco, Moyobamba, Huancavelica, Camaná, Chancay, Chachapoyas, Ferreñafe, Moche, Jauja, Pacasmayo. Para obtener más información o consultas, no dude en ponerse en contacto con nosotros. Read the full article

#Abancay#Ahmedabad#Arequipa#AsphaltBatchMixPlantinPeru#asphaltbatchmixplants#asphaltdrummixplants#Ayacucho#Barranca#bitumensprayers#Cajamarca#Callao#Camaná#CapiousRoadtechPvt.Ltd.#CerrodePasco#Chachapoyas#Chancay#Chiclayo#Chimbote#Chosica#concretebatchingplants#Cusco#Exporter#ExporterofAsphaltBatchMixPlant#Ferreñafe#Gujarat#Huacho#Huancavelica#Huancayo#Huánuco#Huaraz

0 notes

Text

Road Broomer in South Africa

Capious Roadtech Pvt. Ltd. is a Manufacturer, Supplier and Exporter of Road Broomer in South Africa. We are an ISO 9001:2015 Certified Company in Ahmedabad, Gujarat, India. Road broomers, also known as road sweeping machines, play a crucial role in maintaining clean and safe road surfaces across India. They are widely used in applications such as road construction, pavement cleaning, and urban maintenance. These machines are available in various configurations, including tractor-mounted and truck-mounted models, with options for both hydraulic and mechanical operation. Types of Road Broomer: Tractor-Mounted Road Broomer: These broomers attach to tractors, using hydraulic power for surface cleaning in road construction projects efficiently. Truck-Mounted Road Broomer: Mounted on trucks, these broomers clean large urban streets and are ideal for industrial cleaning tasks. Hydraulic Road Broomer: Hydraulic motors rotate brushes even while stationary, offering speed and pressure adjustments for diverse cleaning needs. Mechanical Road Broomer: Using gear-driven mechanisms, these broomers provide reliable, simple, and cost-effective performance in basic road cleaning applications. Features and Benefits: Hydraulic Drive System: Enables the broomer to function without vehicle movement, with adjustable speed and pressure for different cleaning needs. Dust Collection System: Some models are equipped with tanks to collect dust, minimizing air pollution and ensuring cleaner operation. Adjustable Brush Pressure: Facilitates effective cleaning across different surfaces and gradients. Replaceable Bristles: Easy maintenance with interchangeable brushes for extended equipment life and consistent performance. Applications: Road Construction: Essential for cleaning road surfaces before the application of bitumen or asphalt. Pavement Cleaning: Effectively removes dust, dirt, and debris from paved surfaces. Urban Maintenance: Used by municipalities and industries to keep city roads and factory premises clean and safe. Capious Roadtech Pvt. Ltd. is a Road Broomer in South Africa, Including Johannesburg, Cape Town, Soweto, Gqeberha, Pietermaritzburg, Durban, Pretoria, Rustenburg, Newcastle, East London, Katlehong, Khayelitsha, Randburg, Roodepoort, Mitchells Plain, Boksburg, Bloemfontein, Germiston, Centurion, Kimberley, Sandton, Klerksdorp, Bethelsdorp, Kempton Park, Nqutu, Kroonstad, Benoni, George, Potchefstroom, Pinetown, Krugersdorp, Mthatha, Polokwane, Springs, Alberton, Upington, Winterveld, Parow, Paarl, Empangeni, Witbank, Uitenhage, KwaDukuza, Worcester, Grahamstown, Oudtshoorn, Ermelo, Stellenbosch, Sasolburg. For detailed information or inquiries, please feel free to contact us. Read the full article

#Ahmedabad#Exporter#ExporterofRoadBroomer#Gujarat#ManufacturerofRoadBroomer#RoadBroomer#RoadBroomerinAhmedabad#RoadBroomerinGujarat#RoadBroomerinIndia#RoadBroomerinSouthAfrica#Supplier#SupplierofRoadBroomer

0 notes

Text

Usine de Centrale à Béton au Maroc

Capious Roadtech Pvt. Ltd. est un fabricant, fournisseur et exportateur d'usines de centrales à béton au Maroc. Nous sommes une entreprise certifiée ISO 9001:2015 située à Ahmedabad, Gujarat, Inde. Capious Roadtech Pvt. Ltd., basée à Ahmedabad, Gujarat, est un fabricant de premier plan d'équipements de construction routière et de bâtiments, y compris des centrales à béton haute performance. Leurs usines sont conçues pour répondre aux exigences rigoureuses des projets d'infrastructure, offrant fiabilité, efficacité et automatisation avancée. Une centrale à béton est une installation où divers ingrédients – tels que le ciment, les granulats, l'eau et les additifs – sont combinés pour produire du béton dans un environnement contrôlé et automatisé. Capious propose des centrales à béton fixes et mobiles, adaptées aux besoins divers des projets. Types : Centrale à Béton Stationnaire (Série CSCP) : Conçue pour les projets à grande échelle nécessitant un rendement élevé et une production constante. Centrale à Béton Mobile (Série CMCP) : Idéale pour les projets nécessitant de la mobilité et une installation rapide sans compromis sur la performance. Caractéristiques : Automatisation : Fonctionnement entièrement automatique avec contrôle PLC garantissant des performances constantes et une intervention manuelle minimale. Pesée Précise : Systèmes de pesée indépendants pour le ciment, l'eau et les additifs garantissant une répartition précise. Options de Mélangeurs : Choix entre un mélangeur à double arbre, un mélangeur PAN, un mélangeur Turbo et un mélangeur planétaire pour répondre à divers besoins de projet. Durabilité : Fabrication robuste de la structure et des bennes assurant longévité et fiabilité. Fondation Minimale : Nécessite une fondation minimale, facilitant une installation et un déménagement plus rapides. Entretien Facile : Les revêtements et les pales remplaçables du mélangeur réduisent les coûts de maintenance et les temps d'arrêt. Applications : Les centrales à béton Capious sont idéales pour : Projets Résidentiels et Commerciaux : Fourniture de béton de qualité constante pour les bâtiments et structures. Projets Industriels : Fourniture de béton pour les usines, entrepôts et autres installations industrielles. d'Infrastructure : Soutien à la construction de routes, ponts et viaducs. Développement Urbain : Facilitation du développement des zones urbaines avec une fourniture de béton fiable. FAQ : Q1 : Quelle est la capacité de production des centrales à béton Capious ? R1 : Capious propose une gamme de capacités : Modèles Stationnaires (Série CSCP) : 30 à 120 m³/h Modèles Mobiles (Série CMCP) : 20 à 45 m³/h Q2 : Quels types de mélangeurs sont disponibles ? R2 : Capious propose divers mélangeurs, tels que le double arbre, PAN, Turbo et planétaire, pour divers projets. Capious Roadtech Pvt. Ltd. fournit des centrales à béton au Maroc, notamment à Casablanca, Fès, Marrakech, Tanger, Salé, Rabat, Meknès, Oujda-Angad, Kénitra, Agadir, Tétouan, Taourirt, Témara, Safi, Khénifra, El Jadid, Laâyoune, Mohammedia, Kouribga, Béni Mellal, Ait Melloul, Nador, Taza, Settat, Barrechid, Al Khmissat, Inezgane, Ksar El Kebir, My Drarga, Larache, Guelmim, Berkane, Ad Dakhla, Bouskoura, Al Fqih Ben Çalah, Oued Zem, Sidi Slimane, Errachidia, Guercif, Oulad Teïma. Pour des informations détaillées ou des demandes, n'hésitez pas à nous contacter. Read the full article

0 notes