Cheeven New Material Technology Co., Ltd. It is located in Ningbo High-tech Zone, Zhejiang Province. Machining workshops and other main production workshops, the main products include new energy vehicle three-electric shell products (battery tray, electric control box shell, motor shell), water-cooled plates, semiconductor water-cooled parts, sealing cylinders, die-casting products, high-end new Materials (damping alloys, copper alloys and copper-nickel-indium powder materials) and friction stir welding equipment, etc. The company currently has more than 1,000 square meters of production and office workshops, with an annual output value of over 15 million yuan. It has ISO9001:2015 quality management system, ISO14001:2015 environmental management system and ISO45001:2015 occupational health and safety management system.The company has 4 associate senior researchers, 5 doctoral and master students, and has more than 15 years of rich aviation manufacturing experience. The company develops itself with the high-quality requirements of aviation manufacturing, and provides customers with advanced professional and intelligent friction stir welding equipment and products, and Relevant skills training and after-sales service. https://www.cheevenfsw.com/

Don't wanna be here? Send us removal request.

Text

Outdoor Heater

Cheeven has 5 heating elements to choose from: power switches, mechanical control, adjustable temperature control knob, an X-shaped heating element, overheating protection function and our modern outdoor heater is easy to install, environment friendly, and comfortable.

Cheeven has many types of outdoor heaters for sale, such as ceramic outdoor heaters, portable outdoor heaters, stand-up outdoor heaters, etc. If you want economical eco-friendly electric radiators, be free to contact us!

OUTDOOR HEATER SPECIFICATION

Model

NDW666

NDF666

Product Size

60.5*21*14

60.5*52*190

Product Size

53*22*56

62*13.5*22.5

Net weight

9

1.8

Gross weight

10.5

2.4

0 notes

Text

New Metal Alloy

As a leading manufacturer, Cheeven has rich experience in producing new metal alloys which are suitable for electronics, aviation, transportation, semiconductor integrated circuits, optical discs, flat panel displays, etc.

NEW METAL ALLOY TYPES

High Damping Copper Alloy

Damping material has high internal damping and a large elastic modulus. Attached to the vibrating body, different types of copper alloys can effectively suppress the vibration and reduce the noise radiation. As a leading company, Cheeven makes them by adding the right amount of plasticizer, fillers, and additives to well-performing adhesives.

High-strength and High-elasticity Copper-nickel-manganese Alloy

High strength and high elasticity copper alloy is a copper alloy with high strength and high elasticity, as one of copper nickel alloy suppliers, Cheeven provides many kinds of alloy made of copper manganese nickel.

High-strength and High-conductivity Copper-silver Alloy

High-conductivity and high-strength copper alloys have high strength and plasticity, good thermal conductivity, corrosion resistance, and no ferromagnetism.

Copper Nickel Indium Powder

Copper-nickel-indium powder is a superalloy powder with excellent powder properties, low oxygen content, high sphericity and good flow properties.

High Purity Titanium Target

The company can produce more than 99.99% high-purity titanium targets. It is used in semiconductor integrated circuits, optical discs, flat panel displays and other fields.

Products

FSW Products

Carbon Nanotubes Products

Electric Heating Radiator

Die Casting Products

New Metal Alloy

High Damping Copper Alloy

High-strength and High-elasticity Copper-nickel-manganese Alloy

High-strength and High-conductivity Copper-silver Alloy

Copper Nickel Indium Powder

High Purity Titanium Target

New Metal Alloy Introduction

NEW METAL ALLOY INTRODUCTION

There are many kinds of new metal alloys, such as copper alloy, copper nickel manganese alloy, and copper-silver alloy.

This kind of new metal alloy is a high-strength and high-conductivity Cu alloy material developed by the company. The material has high tensile strength, excellent electrical conductivity, and good stress relaxation resistance. New metal alloy will not produce sparks when it is impacted. You can easily find new metal alloys be widely used in mobile communication, aerospace, automotive industry and other fields: lead frame materials in various circuit boards, integrated circuits and other electronic systems; high-strength conductor materials; elastic components in electrical appliances, shrapnel, pins, elastic contacts, etc. At present, the company's main products are rods, rods, plates, strips and so on.

0 notes

Text

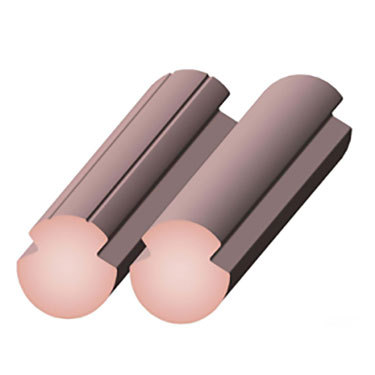

High-strength and High-elasticity Copper-nickel-manganese Alloy

High-strength and High-elasticity Copper-nickel-manganese Alloy is mainly used for the manufacture of various current-carrying elastic elements, elastic components of precision instrumentation, conductive springs for various relays, contact springs, various plug-ins, diaphragm pieces, film boxes, spring tubes, etc. As a kind of new metal alloy, copper nickel alloy is widely used in the automatic detection, instrument, electronic computer, and microelectronics fields of machinery, aviation, aerospace, and nuclear industry.

HIGH-STRENGTH AND HIGH-ELASTICITY COPPER-NICKEL-MANGANESE ALLOY DETAILS

product name

High strength and high elastic copper nickel-manganese alloy

material

Copper-nickel-manganese alloy / Cu-Ni-Mn alloy

Applicable industry

Machinery field, aerospace

Tensile strength (MPa)

700-1200

Stress relaxation characteristics

Quite QBe2.0

size

Bars: 10-100mm

Plate and belt: 0.1-20mm

Or custom

Minimum order

1Kg

0 notes

Text

High-strength and High-conductivity Copper-silver Alloy

High-strength and High-conductivity Copper-silver Alloy

High-conductivity and high-strength copper alloy are materials with excellent comprehensive mechanical properties and electrical conductivity. Copper and silver alloy is a new type of structural and functional material used in the fields of electric power and electrical technology, communication technology, transportation, aerospace, and major national defence equipment.

As one of the new metal alloys, Copper silver alloy not only has high strength and plasticity, but also has good electrical conductivity, thermal conductivity, corrosion resistance, no ferromagnetism, and beautiful color.

HIGH-STRENGTH AND HIGH-CONDUCTIVITY COPPER-SILVER ALLOY DETAILS

product name

High-strength and high-conductive copper-silver alloy

material

Copper-silver alloy / copper-silver alloy

Applicable industry

Electronics, aviation, transportation fields

Tensile strength (MPa)

850-1050

size

Bars: 10mm

Silk: 1mm

Plate and bar: 0.1-1mm

Or custom

conductivity

75-90%IACS

Minimum order

1Kg

1 note

·

View note

Text

High Purity Titanium Target

High Purity Titanium Target

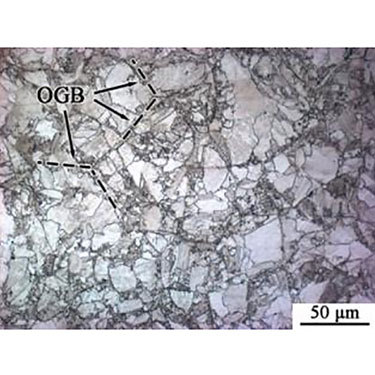

Based on high-purity titanium crystal raw materials, Cheeven can produce more than 99.99% high-purity titanium targets. The target titanium has a uniform structure and a small average grain size and is widely used in semiconductor integrated circuits, optical discs, and flat-panel displays.

HIGH PURITY TITANIUM TARGET DETAILS

product name

High purity titanium target

material

titanium (Ti)

Applicable industry

Semiconductor integrated circuit, optical disc, flat-panel display

medium grain size (μm)

≤50

fineness (%)

≥99.99

oxygen content

<250ppm

Minimum order

5

0 notes

Text

High Damping Copper Alloy

High Damping Copper Alloy

Depending on the types of adhesives, types of copper alloys can be divided into rubber series, plastic series and asphalt series. Asphalt series damping materials are easily accessible, cheap and versatile. The greater the force value of the loss factor, the better the damping performance. Damping also extends the service life of metallic structures under strong acoustic excitation. This kind of new metal alloy which is suitable for the circuit board of electronic instruments to further ensure the stability and reliability of the instrument. In addition to being widely used in noise control engineering, different types of copper alloys are also widely used in road transport, railway transport, ship transport, military tanks, aerospace and other fields.

HIGH DAMPING COPPER ALLOY DETAILS

product name

High damping copper alloy

material

Copper alloy/copper alloy

Applicable industry

Aviation, shipping

Tensile strength (MPa)

500-650

Specific damping performance

>S.D.C40%

prolongation (%)

30-40

Minimum order

1Kg

0 notes

Text

FSW Products

Cheeven is committed to the development, application and promotion of FSW friction stir welding technology. Pro in friction stir welding, Cheeven has rich experience in R & D and production of FSW products, especially in the design and manufacturing of battery tray, electric cabinets, motor products and aluminium alloy water cooling parts of new energy vehicles. After production FSW welding, the company will conduct professional ultrasonic nondestructive testing and provide FSW products testing reports.

As one of the leading friction stir welding companies, Cheeven has independently developed additive friction stir welding technology with upper and lower double heads and intelligent visual friction stir welding technology, which is at the leading level in the same industry.

TYPES OF FRICTION STIR WELDING PRODUCTS

Battery Tray

Battery tray, suitable for new energy vehicles, aluminum alloy materials, integral casting or aluminum profile welding, heat dissipation profiles, customized according to the picture.

Water Cooling Plate

New energy vehicle battery water cooling and heat dissipation, aluminum with strong thermal conductivity, fast water cooling and heat dissipation, aluminum alloy material, not easy to corrode, customized on demand.

Battery Cold Plate

Aluminum alloy, stainless steel and other materials, suitable for new energy vehicles, semiconductors, medical equipment, aerospace, with a variety of processing technologies, support for drawing customization.

Photovoltaic Cooling Panel

Aluminum alloy material water cooling, cold aluminum plate, water cooling plate, trial photovoltaic system industry, heat dissipation profile, friction stir welding process.

Medical Equipment Water Cooling Plate

High quality, aluminum alloy, water cooling radiator, medical equipment water cooling plate, heat dissipation profile, medical equipment, for medical equipment.

Copper Water Cooling Plate

Cold copper plate, suitable for medical equipment, semiconductor industry, excellent thermal conductivity, heat dissipation material.

Semiconductor Cooling Plate

Semiconductor water-cooling plate, suitable for semiconductor equipment, the main material is aluminum alloy, stainless steel, used in new energy vehicles, semiconductors, medical equipment, aerospace, various machining technologies

Water-cooled Motor Housing

Cheeven is pro in producing cooling/cold channel, water colored aluminum motor housing, aluminum alloy motor housing, main processes include aluminum extrusion, friction stir welding water channel, suitable for new energy vehicles, heat dissipation profiles.

Water Cooling Controller

Aluminum vehicle control unit shell, electric vehicle main drive controller, main processes include die casting, friction stir welding water channel, heat dissipation profiles, customized drawings, electric control box shell.

Aluminum Alloy Wheel Welding

Automobile friction stir welding FSW aluminum rim, automobile wheel hub with good noise function, the main materials are aluminum alloy, stainless steel, suitable for automobile field.

Products

FSW Products

Battery Tray

Water Cooling Plate

Battery Cold Plate

Photovoltaic Cooling Panel

Medical Equipment Water Cooling Plate

Copper Water Cooling Plate

Semiconductor Cooling Plate

Water-cooled Motor Housing

Water Cooling Controller

Aluminum Alloy Wheel Welding

Carbon Nanotubes Products

Electric Heating Radiator

Die Casting Products

New Metal Alloy

Friction Stir Welding Process

Friction Stir Welding ProcessFriction Stir Welding ProcessVIDEO

FRICTION STIR WELDING PROCESS

The working process of FSW friction stir welding can be summarized as follow.

1. First both the work plates are clamped together same as in the butt joint. Both plate's weldable surfaces are in contact with one another.

2. Now a rotating tool pin is inserted into workpieces at the interface surfaces until the tool shoulder touched the workpiece. This will deform the material plastically due to heating by friction force. This is a state of the joining process in which, inter-molecular diffusion will deform the material plastically due to heating by friction force.

3. Now the rotating tool is moving forward along the joint line. This will form a joint behind the tool.

4. The tool continuously moves unlit the whole weld is formed. After the joining process, the tool is separated from the workpiece. The hole created by the tool pin remains in the welding plates.

Its work can be clearly understood by the following video.

1 note

·

View note