CONMACH has been established in Istanbul, Turkey to provide the intensive requests of the customers about the construction machineries. The company adopts itself to provide the best quality product and service with the reasonable price as a principle in stationary concrete batching plants, mobile concrete batching plants, compact concrete batching plants, portable concrete batching plants, concerete mixers, concrete block making machines, concrete block moulding machines, concrete interlock making machines, concrete pipe making machines,concrete manhole making machines.

Don't wanna be here? Send us removal request.

Text

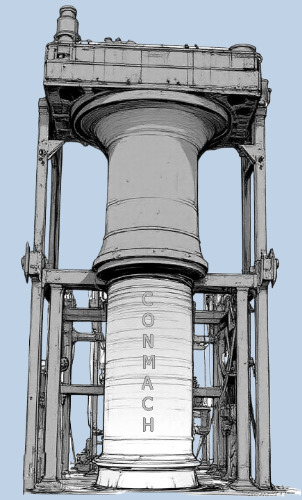

PIPEKING-1400 CONCRETE PIPE MAKING MACHINE

This machine produces between Ø130 mm and Ø1.400 mm in diameters and with a length of minimum 1.000 mm and maximum 2.000 mm concrete pipes. Each mould includes internal mould and external mould, plastering, pallet and fiber cap.

Features

Working Type : Semi Automatic Mortar Bunker : 2m3 Vibration Motor Power : 2 pieces x 22 kW Hydraulic Motor Power : 15 kW Mortar Delivery Car Motor Power: 5,5 kW Plastering Motor Power : 5,5 kW

Capacity

Ø300 mm Concrete Pipe –> 2 units/press –> 150 units/shift (8 hours)

Ø400 mm Concrete Pipe –> 2 units/press –> 120 units/shift (8 hours)

Ø500 mm Concrete Pipe –> 2 units/press –> 100 units/shift (8 hours)

Ø600 mm Concrete Pipe –> 2 units/press –> 80 units/shift (8 hours)

Ø800 mm Concrete Pipe –> 1 units/press –> 60 units/shift (8 hours)

Ø1.000 mm Concrete Pipe –> 1 units/press –> 50 units/shift (8 hours)

Ø1.200 mm Concrete Pipe –> 1 units/press –> 40 units/shift (8 hours)

Ø1.400 mm Concrete Pipe –> 1 units/press –> 30 units/shift (8 hours)

“…non-stop support 24/7 to the customers.”

CONMACH is able to supply special designs and productions according to customers’ demands. Besides, the assembly and start up operations of the machines are performed by CONMACH’ s experienced technicians. The quality and quickness of after-sale service is a must for CONMACH. For this purpose, a special departmant just for after-sale has been established and this department supplies non-stop support 7×24 to the customers.

#construction#concrete#machinery#concrete pipe machine#concrete pipe mould#export#product#exportbusiness#exporter

0 notes

Text

Agrega Bunkeri Nedir?

Agrega bunkeri, beton santrallerinde kullanılan, farklı türdeki agregaların (kum, çakıl, taş vb.) depolanması ve yönetilmesi için tasarlanmış yapısal bir elemandır. Bu bunkerlere, genellikle beton üretiminde kullanılan malzemelerin düzenli bir şekilde depolanması ve gerektiğinde kolayca alınabilmesi amacıyla ihtiyaç duyulur. Agrega Bunkeri Ne İşe Yarar? Agrega bunkeri, beton üretim sürecinde…

#4x4 m³ Agrega Bunkeri#Agrega Bunkeri#agrega bunkeri fiyatı#agrega bunkeri nedir#agrega bunkeri nerelerde kullanılır#agrega bunkeri yedek parçaları#üretim#bunker tasarımı#ihracat#satılık agrega bunkeri#tasarım

0 notes

Text

Beton Mikseri Nedir?

Beton mikseri, çimento, su, kum ve çakıl gibi malzemeleri karıştırarak beton üretmek için kullanılan büyük bir makinedir. Genellikle kamyon üzerine monte edilmiş dönen bir tambura sahiptir. Bu tambur, malzemeleri karıştırırken betonun işlenebilir halde kalmasını sağlar. Beton mikserleri, inşaat alanlarına taze beton taşıyıp dökmek için de kullanılır. Bu sayede büyük miktarda beton hızlı ve etkili…

#çift milli beton mikseri#çimento#beton mikseri#Beton Santrali#CONMACH#karıştırıcı#Mobil Beton Santrali#pan tipi beton mikseri#planet tipi beton mikseri#tek milli beton mikseri

0 notes

Text

CONMACH BETON SANTRALİ

Conmach Beton Santrali , beton üretim endüstrisinin çeşitli ve zorlu taleplerini karşılamak üzere tasarlanmıştır. Beton Santrali ekipmanlarını izlemek için yenilikçi teknolojiler kullanan Conmach Makine, çeşitli tiplerde Beton Santralleri üreten, taşıması kolay ve montajı kolay santraller tasarlayan , piyasadaki en dayanıklı ve güvenilir Beton Santrallerini üretmektedir.

#beton santrali#sabit beton santrali#export#construction#mobil beton santrali#satılık beton santrali#beton mixer

0 notes

Text

2025 yılı, inşaat sektörünün yeni yatırım ve projelerle ilerleyişini sürdüreceği bir yıl olarak karşımıza çıkıyor. Hem ülkemizde hem de dünya genelinde yaşanan ekonomik ve siyasi gelişmeler, inşaat sektörünü derinden etkilemiş ve birçok alanda farklı hizmet ağlarının ortaya çıkmasına neden olmuştur. Bu bağlamda, inşaat makineleri sektörü, dikkat çeken yatırımlar arasında ilk sırada yer almaktadır. Özellikle beton blok yapma makineleri, parke taşı makineleri ve beton boru makineleri, bu süreçte öne çıkan ürünlerdir.

CONMACH'ın 2025 Kampanyası

2025 yılı için çeşitli kampanya süreçleri başlatan CONMACH, yeni yılda müşterilerine sunacağı beton blok makinesi fiyatları ile dikkat çekiyor. Firma tarafından yapılan açıklamada, 2025 yılının ilk çeyreğine kadar beton blok makinesi ve ekipmanlarının ihracatında piyasa koşullarının altında hizmet verileceği belirtiliyor. Bu hizmet, beton blok makineleri ve ekipmanlarını kapsamaktadır.

Sunulan Ürünler

CONMACH'ın sunduğu ürün yelpazesi, sektördeki ihtiyaçları karşılamak üzere geni�� bir yelpazeye yayılmaktadır. Bu ürünler arasında:

Beton Blok Makineleri: Farklı kapasite ve özelliklere sahip beton blok makineleri, inşaat projelerinin temel taşlarını oluşturmak için kullanılmaktadır.

Beton Mikserleri: Beton karışımını sağlamak için gerekli olan mikserler, inşaat süreçlerinin hızlanmasına yardımcı olur.

Konveyör Bantlar: Malzemelerin taşınmasını kolaylaştıran konveyör bantlar, iş gücünü azaltarak verimliliği artırır.

Beton Blok Kalıpları: Farklı boyut ve şekillerde beton blok üretimi için kullanılan kalıplar, ürün çeşitliliğini artırır.

Tahta Paletler: Üretilen beton blokların taşınması ve depolanması için gerekli olan paletler, pratik bir çözüm sunar.

El Arabaları: Yaş ürünlerin toplanması için kullanılan el arabaları, inşaat alanında önemli bir yardımcıdır.

Ekonomik Fırsatlar

2025 yılında inşaat sektöründe yaşanacak olan büyüme, beton blok makinelerine olan talebi artıracaktır. CONMACH, bu fırsatları değerlendirerek müşterilerine uygun fiyatlarla kaliteli ürünler sunmayı hedeflemektedir. Özellikle yeni projelerin hayata geçirilmesiyle birlikte, beton blok makinelerine olan ihtiyaç artacak ve bu durum, firmaların büyümesine katkı sağlayacaktır.

2025 yılı, inşaat sektörü için heyecan verici bir yıl olacak. CONMACH'ın sunduğu kampanyalar ve uygun fiyatlar, sektördeki firmalar için büyük bir fırsat sunuyor. Beton blok makineleri ve ekipmanları, inşaat projelerinin temel unsurları arasında yer almakta ve bu ürünlerin kalitesi, projelerin başarısını doğrudan etkilemektedir. Müşteriler, CONMACH'ın sunduğu avantajlarla birlikte, kaliteli ve güvenilir makinelerle projelerini daha etkin bir şekilde hayata geçirebilirler.

#briket makinesi#2025 inşaat sektörü#Beton blok üretimi#Beton blok kalıpları#beton blok makinesi#Beton mikserleri#Beton yapım makineleri#CONMACH kampanyası#Ekonomik fırsatlar#El arabaları#Kaliteli makineler#Konveyör bantlar#Müşteri memnuniyeti#Piyasa koşulları#Tahta paletler#Yeni yatırımlar#İnşaat ekipmanları#İnşaat Makineleri#İnşaat projeleri

0 notes

Text

Müşterimizin Tercihi Memnuniyet

Visit our page! Get to know us! https://www.conmachconcretebatchingplants.com

View On WordPress

#beton üretimi#beton santrali#beton santrali açma maliyeti#beton santrali çizimi#beton santrali üreten firmalar#beton santrali beton üretimi#beton santrali ekipmanları#Beton santrali fiyatları#beton santrali istanbul#beton tesisi#conmach beton santrali#Hazır beton tesisi#kompakt beton santrali#mobil beton santrali#Satılık Beton Santrali#satılık beton santrali çorlu#satılık beton santrali conmach

0 notes

Text

Conmach Machinery Concrete Block Machine Catolog

#conmach#export#construction#africa#blockmould#concrete arabia#concrete batching plant#block#europa#exporter

0 notes

Text

https://www.conmachconcretebatchingplants.com/post/mob-30-sofia

Centrale à béton mobile MOB-30 ; Voyage à Sofia

La centrale à béton mobile CONMACH MOB-30 a été placée dans un conteneur spécialement conçu et envoyée à Sofia, la capitale de la Bulgarie, par transport routier. Le processus d'exportation de la centrale à béton mobile MOB-30 a été régulièrement vérifié par notre équipe technique pour éviter tout dommage lors de l'emballage, de l'étiquetage et du transport de la centrale à béton. Notre entreprise veille à ce que ses produits exportés soient transportés en toute sécurité et livrés à temps. Le voyage de la centrale à béton mobile vers Sofia comprenait des composants de machine tels qu'un malaxeur à cuve de 0,5 m3, une trémie à granulats de 4x4 m3, un silo à ciment, une vis à ciment et un jet de ciment, ainsi que des pièces de rechange demandées par le client. La centrale à béton mobile CONMACH MOB-30 est une machine aux fonctionnalités impressionnantes. Cette centrale est équipée d'un mélangeur à cuve de 0,5 m3. De cette manière, un mélange de béton homogène et de haute qualité est assuré. De plus, le bunker de granulats de 4x4 m3 offre une grande capacité de stockage et assure un processus de production de béton continu. Une autre caractéristique importante du MOB-30 est qu’il dispose d’un équipement de projection de ciment et d’une tarière. Ces équipements garantissent la bonne utilisation du ciment et augmentent l’efficacité de la production de béton.

#concrete#concreteplant#concretemixer#mobileconcreteplant#concretemobileplant#aggregatebunker#cementscrew#cementsilo#sandblastingcement#panmixer#sparaparts#product#products#concstruction#export#exportion#compactconcretebatchingplants#bulgariasofia#bulgaria#sofia#concreteplantexport#concreteplantforsale#concreteplantprice#mobileconcreteplants#compactconcreteplants#concreteplants

0 notes

Text

CONMACH BLOCKKING-42FSS, a state-of-the-art concrete block machine produced in our country, was exported to the Dominican Republic. This machine was shipped with a 3x15 m3 aggregate bunker, 100 tons cement silo and other equipment. In this blog post, I will discuss in detail the features of the CONMACH BLOCKKING-42FSS machine, the concrete block production market in the Dominican Republic, other equipment shipped and the importance of export.

CONMACH BLOCKKING-42FSS machine has many features that are extremely effective in concrete block production. This machine is equipped with high-performance hydraulic systems and automatic control mechanism. In this way, it can produce concrete blocks quickly and precisely. In addition, the machine is notable for its ability to produce blocks of different sizes and shapes. This provides flexibility for different projects in the construction industry and is ideal for meeting customer demands. Another important feature of the CONMACH BLOCKKING-42FSS machine is energy efficiency. This machine provides high efficiency while operating with low energy consumption. This supports environmental sustainability while reducing operating costs. Additionally, the machine is easy to use and has a user-friendly interface that will allow operators to learn quickly. CONMACH BLOCKKING-42FSS machine has been used in many successful projects and positive results have been achieved. For example, a construction company in the Dominican Republic quickly produced large quantities of concrete blocks using this machine, significantly shortening the project time.

Concrete Block Production Market in Dominican Republic

The Dominican Republic is a country where the construction industry is growing rapidly and therefore the demand for concrete blocks is also increasing. Concrete blocks are a durable and economical building material frequently used in construction projects. The country's rapidly developing infrastructure projects and housing sector contribute to the growth of the concrete block production market. The size and potential of the concrete block production market in the Dominican Republic is quite impressive. The country's increasing population and economic growth create a constant demand in the construction industry. Since concrete blocks are used as a basic building material in construction projects, this demand is constantly increasing. Local businesses and contractors benefit greatly from the use of high-tech block making machines. These machines offer faster and more efficient production. They also provide the precision required for the production of quality blocks. Many businesses in the Dominican Republic have gained a competitive advantage and offered high-quality products to their customers by using state-of-the-art block making machines such as CONMACH BLOCKKING-42FSS.

3x15 m3 Aggregate Bunker and 100 Ton Cement Silo

Among the equipment sent to the Dominican Republic along with the CONMACH BLOCKKING-42FSS machine, there is also a 3x15 m3 aggregate bunker and a 100 ton cement silo. Since the aggregate bunker has the capacity to store large amounts of aggregate, it ensures a continuous supply during the concrete production process. This minimizes disruptions in the production process and increases efficiency. Additionally, the 3x15 m3 dimensions of the bunker enable different types and sizes of aggregates to be stored, thus ensuring suitability for a variety of projects. 100 ton cement silo is also an important component in the concrete production process. Cement is the basic material that provides the strength and durability of concrete. Therefore, it is of great importance that the cement supply is uninterrupted and stored appropriately. The 100 ton cement silo has the capacity to store large amounts of cement, ensuring a constant supply. Additionally, the silo helps maintain quality by preventing the cement from being affected by moisture and other adverse weather conditions.

Other Shipped Equipment

Other equipment shipped with the CONMACH BLOCKKING-42FSS machine plays an important role in improving the overall efficiency and productivity of the concrete block production process. These equipment help provide other components required for concrete block production. For example, concrete mixing and transport equipment ensures the correct preparation of concrete and transportation of the material to be used for block production. Additionally, conveyor belts facilitate the transportation and storage of blocks. This equipment ensures that the concrete block production process is faster and more efficient. For example, automatic palletizing systems reduce labor costs by automatically stacking and palletizing blocks. At the same time, the molds used for concrete block production enable the production of concrete blocks in different sizes and shapes, allowing us to better respond to customer demands. When considered as a whole, these delivered equipment together with the CONMACH BLOCKKING-42FSS machine form the basis of a successful concrete block production operation.

Importance of Exporting CONMACH BLOCKKING-42FSS Machine

CONMACH BLOCKKING-42FSS machine export to Dominican Republic has great capability. Firstly, it will contribute to economic development by supporting growth in the construction sector in the country. The Dominican Republic has had a rapidly growing construction sector in recent years, and concrete blocks occupy an important place in this supply. The innovative innovations and efficiency of the CONMACH BLOCKKING-42FSS machine will enable local areas to produce concrete blocks with higher quality and faster. This initiates faster development of construction projects and economic growth.

The trade of the CONMACH BLOCKKING-42FSS machine is the contribution of the country's infrastructure infrastructure. Concrete blocks are an important material widely used in road construction, building construction and other infrastructure projects. CONMACH BLOCKKING-42FSS machine can produce higher quality and durable concrete blocks, these infrastructure projects will have a longer life.

#blockmachine#blockmould#concreteblockmachine#brickmakingmachine#pavingstonemould#curbmould#export#product#construction#conmach#africa#türkiye#blockmachineforsale#blockmachineprice#blockmouldforsale#RDCconcreteblocksmanufacturers#democraticcongo#concreteblockmachineexport#block#europa#exporter#concrete arabia

0 notes

Text

#export#construction#africa#europa#exporter#ghana#concreteplant#concretebatchingplant#concrete batching plant

0 notes

Text

MOB-30 Ready for Production in Benin

CONMACH MOB-30 Mobile Concrete Batching Plant, which was sent to Benin Cotonou port by sea transport in March 2023, continues at the construction site in Benin with its installation and assembly works. Careful planning and work at the construction site by a professional team proceed meticulously for the successful completion of the project. MOB-30 Mobile concrete batching plant plays an important role in the construction industry and is one of the most effective equipment used for concrete production. These plants facilitate the transport of concrete to the places where it is needed and save time.

Compatible with Flexible Construction Projects

In addition, the CONMACH MOB-30 is just one of two mobile concrete batching plants to be used at the construction site in Benin. These mobile concrete batching plants; With its 30 m3 concrete production capacity, it produces by using a planetary or pan mixer depending on the need, and by means of 2-3 or 4 mesh aggregate bunkers. Being a construction site type concrete batching plant has enabled them to be designed for use in construction projects where the need for concrete is low. In installation and assembly; Flexible equipment that can be easily disassembled and installed and compatible with project-based works is included.

Spare Parts Support

The mobile concrete plant has main parts consisting of mixer, aggregate bunker, weighing belt, transfer belt, weigher group, cement discharging unit, cement screw and automation system. With the completion of this project, which has a great importance in the construction sector, the needs of our customers will be met and the concrete production process in construction projects will become more efficient. As a company, we provide 24/7 support to our customers' concrete production process with the supply of all spare parts and other machinery equipment.

#export#construction#africa#concrete plant#concrete mixer#mobile concrete plant#benin#cotonou#cotonouport#concrete arabia#europa#products#production#exportbusiness#exporter#manufacturing

0 notes

Text

The BLOCKKING-09MS model concrete block machine is a unique model with its production and user-friendly design. 1 mixer, 2 transfer belts and wooden pallets used to collect wet products were delivered to the Ghanaian concrete block producer. 1 machine main chassis, 1 mixer, 2 conveyor belts, 4 product collection cars and 11 machine molds were sent to the capital of Mauritania, Nouakchott, in a 20 container, to the concrete block manufacturer located in Nouakchott, the capital of Mauritania.

#conmach#export#construction#block#blockmould#concrete block machine#blockmakingmachine#paving stone mould#ghana#accra ghana#accra#africa

0 notes

Text

MOB-30 on the roads of the capital Sofia

Concrete processings is one of the important processes required for construction projects. Without effective concrete processing, any construction project can become inefficient and time-consuming. At this point, we can consider MOB-30, the mobile concrete batching plant. A state-of-the-art concrete processing machinery can greatly improve the effectiveness and timing of construction projects. And the Conmach MOB-30 concrete batching plant model is one of the most effective solutions in this field.

Recently, the MOB-30 Mobile concrete batching plant from the Conmach factory building in Çorlu set off towards Sofia, the capital of Bulgaria. Having the best machines in its class, the MOB-30 is equipped with a 0.5 m3 pan mixer and a 2 x 10 m3 aggregate hopper. The ability of MOB-30 to complete large-scale construction projects quickly has made the importance of such innovative and efficient plants in the modern concrete production industry indisputable.

In parallel with the developing technology and changing needs, the concrete production sector is in a continuous renewal and development process. High-capacity and featured mobile concrete batching plants such as MOB-30 are of great importance due to their high production volume and capacity to meet the needs of projects spanning a wide area. MOB-30, a mobile concrete batching plant of Conmach brand, total capacity: 30 m3, mixer 750/500 l motor power: 37 kW, Weighing conveyor: Width: 700 mm, length: 12.500 mm, motor power 7.5 kW, Total engine power Standard 54 kw, Cement screw Diameter: 168 mm, length: 5.500 mm, motor power: 4 kW, Cement silo (ops.) Capacity: 50- 75 tons 1 Compressor, Capacity: 200 lt/min, working pressure: 4-6 bar, motor power 2.2 kW Water pump, Pump: 40 m3/hour motor power: 1.6 kW, Additive pump: Pump: 5 m3/hour, motor power: 0.37 kW.

#export#construction#conmach#africa#product#concreteplants#stationary concrete batching plants#concrete mobile plant#europa#concrete#bulgaria#bulgaristan#bulgaria construction

0 notes

Text

An Export Move

Conmach, which continues to make export moves, continues to grow in the international market and takes various steps to sell its products abroad. Company produces many construction equipment such as concrete batching plants, mobile concrete batching plants, stone crushing plants, cement silos, concrete block and brick machines. The company exports its products to many different countries. Conmach's export moves are designed to increase the quality of its products, increase their awareness around the world and enter different markets. While exporting, the company takes care to ensure that its products comply with international standards and service quality. The company is known worldwide for its production capacity and quality in many sectors such as construction equipment. Finally, the export of MOB-30 Mobile Concrete Batching Plant was carried out by the company to the African country Benin.

MOB-30 Technical Specifications

In March 2023, a mobile MOB-30 mobile concrete batching plant used for small-scale construction projects was shipped to the port of Cotonou, Benin. Today, we are experiencing the joy of exporting a second product with the same characteristics. The use of mobile power plants is quite common in developing countries such as Benin. Conmach brand and quality are among the preferred concrete plant companies in the country. A MOB-30 mobile concrete batching plant, which the company exports, has a capacity of 30 m3 /hour; It has technical features such as aggregate bunker, pan type mixer, transmixer conveyor, weighing conveyor, cement screw, cement silo, compressor, water pump, additive pump. Depending on the customer's request, pan and planetary mixer options and the number of aggregate bunkers can vary in product design.

MOB-30 Sent to Benin

A MOB-30 mobile concrete batching plant has been shipped to Cotonou Port for the second time, one month apart, for use on a construction project in Benin. The MOB -30 model is a plant that can produce 30 cubic meters of concrete per hour. Being mobile provides ease and flexibility of relocation in construction projects. Therefore, it is preferred for projects that require high volume concrete production. Moreover, the MOB -30 concrete batching plant is designed for the production of high quality concrete and can be customized according to customer requirements. The reason why the MOB -30 concrete batching plant is preferred for construction projects in Benin may be that it has a high concrete production capacity and provides high quality concrete production. In addition, being mobile facilitates the transportation of construction materials in the project area and reduces labor costs.

#concrete#concreteplants#concretebachkingplants#africa#europa#constructionmachinery#cementcilo#aggregatebunker#mixer#mobileconcretebatchingplant#contonou#benin#cotonouport#usa#export#england#france#product#readymixedconcrete#concretemanufacturers#conmach#concrete arabia#concrete mixers#construction

0 notes

Photo

BlockKing-42MS PRODUCT CAPASITE by CONMACH machinery Via Flickr: BlocKKıng-42MS Capacity 18.000 adet 20x20x40 cm briket (8 inch) 24.000 adet 15x20x40 cm briket (6 inch) 33.000 adet 10x20x40 cm briket (4 inch) 1.150 m2 paving stone

0 notes

Text

Jamaica Visit

CONMACH MACHINE

CONMACH Managing Director & CEO

13 yazı

26 Mart 2023

Jamaica Visit

Blockking-42MS, a concrete block machine model, was sent to Jamaica in the first days of July 2022 and started production. Concrete block machines are equipment used for the production of concrete blocks and are frequently used in the construction industry. The Blockking-42MS model is a concrete block machine that can work efficiently thanks to its high production capacity and automatic control system. In countries like Jamaica, the construction industry is growing with the increase of infrastructure development projects and there is an increasing demand for this type of equipment. We visited our machine that produces in its own construction site in Jamaica and exchanged ideas about our machine with our customer.

Blockking-42MS Features

Our customer reminded us about the Blockking-42MS model concrete block machine features. Capacity to produce 4,000 standard size concrete blocks per hour, high efficiency thanks to the automatic control system, easy switching between manual and automatic modes, Press system powered by hydraulic system, strip feeder system integrated with the concrete mixing unit, Precision thanks to the sensors on the concrete feeding belt The features such as size and weight measurement, ease of maintenance thanks to the automatic lubrication system and ease of use with multi-language options reveal the preference of the Conmach Block Machine.

Concrete Block Manufacturers' Choice

Blockking-42MS is a concrete block machine that is frequently used in the construction industry thanks to its high production capacity, automatic control system and integrated concrete mixing unit. Among the machinery equipment that continues production in Jamaica, there are 3 machine molds in total, including a 0.75 m3 Mixer, 2 mortar conveyors, 1 stacking robot, a block mold, a paving stone mold and a curb mold. The use of hydraulic system and sensors in our machine ensures the production of concrete blocks with high quality and precise measurements. On the other hand, the automatic lubrication system and multi-language options make the machine easier to use. Conmach Concrete Block Machine Blockking-42MS helps construction companies achieve high efficiency and quality in concrete block production.

#concreteblockmanufacturersinjamaica#hashtag#concreteblockmanufacturers#Kingstonconcreteblockmanufacturers#Kingstonreadymixedconcretemanufacturers#jamaicablockmachinery#export hashtag#product hashtag#concreteblockmakingmachine#blockmakingmachine#blockmachineforsale#concreteblockprices hashtag#readymixedconcreteplant#readymixedconcreteproduction#concreteblockmachinespareparts#concreteblockmold#blockmould#curbmould hashtag#cobblestonemould#pavingstonemould#Portmore#Spanish hashtag#Town#Mandeville#OchoRios#PortAntonio#Negril#MontegoBay#conmach

0 notes