Text

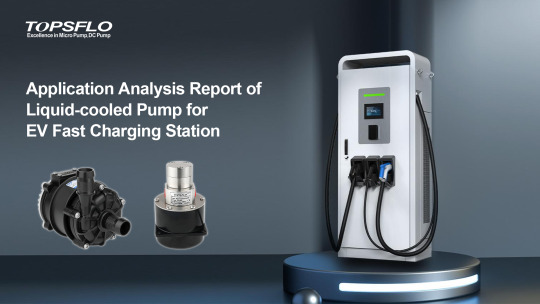

Application Analysis Report of Liquid-cooled Pump for EV Fast Charging Station

Introduction

In recent years, the rise of electric vehicles (EVs) and supportive national policies have propelled the EV charging station market into prominence as a burgeoning industry. Concurrently, the adoption of liquid cooling technology in charging stations has emerged as a significant trend. Liquid cooling not only enhances the efficiency of fast charging stations but also extends their service life. As the core component of a liquid-cooled charging station, the performance and stability of micro pumps are critical to the operation of charging stations. Therefore, an in-depth examination of the trends in liquid cooling for fast charging stations and the application characteristics of micro pumps is essential to advancing the charging station industry.

Current Status and Trends in the Charging Station Industry

In recent years, China's new energy vehicle market has developed rapidly, with significant growth in ownership and a marked increase in demand for electric vehicle charging.

According to data from Wisdom Research Consulting, as of December 2022, the total number of electric vehicle charging stations nationwide reached 5.21 million units, nearly doubling year-on-year. Of these, 1.797 million are public charging stations, accounting for 34.5%, while 3.413 million are private charging stations, making up 65.5%. The number of EV charging stations in China is expected to reach 10 million units by 2025.

In this fast-developing industry, various technologies and equipment are being widely adopted, with micro liquid cooling pumps being one notable example.

Principle and Application of Liquid Cooling Technology for Charging Stations

Liquid cooling technology is increasingly common in fast charging stations, offering efficient heat dissipation for key components like the battery pack, charging module, and controller. This technology utilizes a closed-loop system where coolant circulates through these components, removing heat and ensuring optimal performance.

In addition to the main components of the fast charging station, liquid cooling can also be applied to the charging cable itself. A high-power liquid-cooled charging connector employs an electronic water pump to drive coolant flow. This coolant passes through the cable, absorbing heat generated during high-current operation, and then returns to a storage tank. From there, it's circulated through a radiator to dissipate heat, maintaining low temperatures and high performance.

Liquid cooling offers several advantages over traditional air cooling methods. It provides better heat dissipation, prolongs component lifespan, and ensures a clean cooling process. As a result, it's becoming increasingly popular in fast charging technology.

Liquid cooling enables coolant recycling in a closed environment, ensuring efficient heat dissipation and cleanliness. Compared to traditional air cooling, it offers superior heat dissipation and longevity, making it a popular choice.

Application of Micro Pump Technology in Charging Station Liquid Cooling System

In a liquid cooling system for charging stations, micro water pumps circulate liquid to transfer heat to the radiator. These pumps are small, energy-efficient, and quiet. They typically run on DC power and can be paired with renewable energy sources like solar panels for even greater energy efficiency and environmental benefits.

Advantages and Disadvantages of Micro Pump

The application of micro pumps in charging station liquid cooling system has the following advantages:

Compact and Lightweight: Easy to install and move;

Energy-Efficient: Low energy consumption reduces operating costs;

Low Noise: Minimizes environmental and user disturbance;

Renewable Energy Compatible: Can be combined with solar panels and other renewable technologies for enhanced energy efficiency and environmental benefits.

Some water pumps on the market also have the following deficiencies when applied to EV charging station liquid cooling system:

Limited Flow Rate and Water Head: Restricts their scope of use;

Maintenance Challenges: Requires regular inspection and replacement;

Short Lifespan: Frequent replacements needed.

TOPSFLO Micro Pump Solution for Liquid-cooled System of EV Fast Charging Station

TOPSFLO specializes in producing micro brushless DC water pumps, diaphragm pumps, and gear pumps, widely used in EV charging stations, home appliances, medical equipment, data centers, and more. Our products are stable and certified by CE, RoHS, ISO9001, and recognized as a National High-tech Enterprise and Specialized New Enterprise in Hunan Province.

TOPSFLO was an early entrant into China's liquid cooling market for charging stations, holding a significant market share. Since 2015, we have supplied 500,000 liquid-cooled water pumps to leading electric vehicle and energy companies, offering a professional and mature fast charging station cooling solution.

Customized Service: We offer tailored solutions with our independent R&D team, customizing size, flow rate, water head, motor types, and electronic components to meet specific customer needs;

Small Size and Low Noise: Our pumps are compact with a patented silent design, ideal for installation in residential, business, and office areas without disturbing the environment;

High Reliability and Low Energy Consumption: Designed for stable, long-term operation with minimal energy use, our pumps feature high-efficiency motors and precision designs to enhance charging efficiency and reduce power consumption;

Long Service Life and Maintenance-Free: Engineered to endure harsh outdoor conditions, our pumps have a lifespan of up to 30,000 hours, ensuring long-term, maintenance-free operation.

TOPSFLO micro pumps address the shortcomings of ordinary water pumps, making them ideal for EV fast charging stations. At the same time, the delivery, pre-sale technical consultation and after-sale technical support of TOPSFLO pumps can be guaranteed. It is an ideal choice for liquid-cooled water pumps in EV fast charging station.

Wanna to get pump solution or apply free sample? Contact us now:

Email: [email protected]

Whatsapp/Wechat:+86-19376691419

Find more pumps: http://www.topsflo.com/

youtube

#dcwaterpump#waterpump#liquid cooling sytem#liquid cooling pump#water pumps#charging pile cooling circulating water pump#charging pile liquid cooled circulating water pump#ev charger#Youtube

0 notes

Text

How to Choose a Good Food Grade Water Pump for Your Application?

What is a Food Grade Water Pump

Food-grade water pump refers to a brushless DC pump driven by a DC motor with a voltage range of 4.5V to 24V. The materials used are food-grade and the pump meets food-grade certification standards.

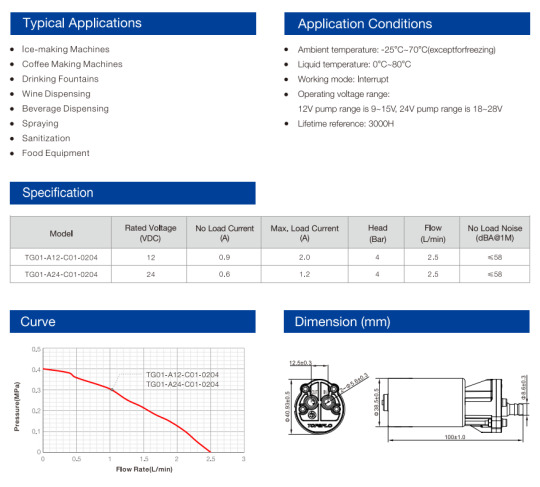

Application

Food-grade water pumps are suitable for various equipment used in transporting beverages, and drinking water. They have been widely applied in coffee machines, water boilers, carbonated beverage dispensers, juice machines, and under-sink water purifiers in Europe and America.

Advantages

Compared to traditional AC water pumps, food-grade water pumps using brushless motors offer several advantages:

Utilizes advanced DC frequency conversion technology for higher efficiency and lower noise levels;

Complete isolation between the motor and liquid, featuring a statically sealed design ensuring no leaks over prolonged usage;

Incorporates a built-in frequency conversion brushless DC motor, eliminating carbon brush wear issues, with low power consumption, minimal temperature rise, and a lifespan exceeding 20,000 hours.

Employs proprietary high-efficiency structural design, resulting in higher output efficiency and lower power consumption with a compact size.

Withstands temperatures up to 100℃, using FDA-compliant food-grade materials, making it suitable for the food and beverage industry's requirements for heat-resistant materials.

Offers various power supply options: food-safe water pumps can be powered by DC power sources, solar panels, and in some cases, even batteries, including dry batteries and rechargeable batteries.

How to Choose a Good Food Grade Water Pump for Your Application

There are many types of food-grade water pumps on the market. So, how to choose a high-performance water pump that meets your needs? As one of the global leaders in micro pumps field, we have nearly 20 years of experience and our professional engineers can recommend the most suitable pump for your equipment. Generally speaking, a good food-grade water pump must meet the following five points:

Food Grade Certified Materials: Food grade water pumps are used to transport beverage and drinking water. Therefore, all materials in direct contact with fluids must be food-grade certified materials, otherwise they will be harmful to human health. Such as WRAS and FDA food certification: FDA is recognized as one of the largest food and drug regulatory agencies in the world and has strict requirements; WRAS is the British drinking water safety certification.

Customizable Size and the Type of Water Inlet and Outlet: According to the actual situation of the equipment, determine the size of the pump or the size of the reserved space in your application equipment, and then consider the type of inlet and outlet : threaded or Barb? It is also necessary to determine the direction of inlet and outlet, pipe hole size, etc. Customizing matching water pumps according to actual needs can maximize the efficiency of the water pump and achieve the best quality of your equipment.

Save Costs: According to the application requirements, calculate the working voltage, current and other requirements of water pumps. Choose the same voltage as device power; choose lower power consumption while ensuring functionality. Save cost by choosing a pump whose performance is competitive for your application rather than choosing a bigger pump.

High Temperature Resistance: Small household appliances such as hot drink machines and coffee machines transport high-temperature liquid for a long time. Therefore, when selecting a water pump, the ambient temperature and working fluid must be taken into consideration. For application equipment with 100°C operating temperature, cannot choose a pump with only 50°C maximum operating temperature. Secondly, long-term operation also needs to be considered. Therefore, food-grade water pump that can withstand high temperatures for a long time is the first choice.

Customized Functions: Choose a water pump that can achieve customized functions, such as overvoltage protection, overcurrent protection, dry-running protection, PWM/5V intelligent speed regulation, speed feedback and other customized requirements.

Integrated many technical advantages, TOPSFLO food grade pumps have achieved the ultimate in noise quietness, high temperature safety, food safety, stable and reliable for batches. TOPSFLO made the pumps by heart, taking the highest standards and full comprehensive design into considerations, its performance are properly comparable with German and Japanese big brand pumps, besides, the cost is much competitive, so TOPSFLO food grade pumps have become the first choice for high-end applications by many internationally renowned customers. Sincerely hope that TOPSFLO food grade pumps can bring a safe and quiet experience to more families!

Wanna to get pump solution or apply free sample? Contact us now:

Email: [email protected]

Whatsapp/Wechat:+86-19376691419

Find more pumps: http://www.topsflo.com/

youtube

youtube

0 notes

Text

What Advantages Does a Customized Diaphragm Pump Offer?

Among many pump brands, Topsflo pumps are favored for their excellent performance and wide range of applications. The key behind this is the unique advantages brought by customized pumps. So what are the unique advantages of custom miniature diaphragm pumps?

Miniature diaphragm pumps have to deal with a series of stringent requirements when performing specific tasks. To meet these needs, Topsflo specializes in providing custom pump services, ensuring pump performance is precisely matched to the specific needs of each application. From material selection, design concept to setting of performance parameters, every aspect of the pump can be customized according to the specific needs of customers. This article analyzes in detail the unique advantages of deeply customized pumps compared to standard pump series, helping you gain a deeper understanding of the value and importance of customized diaphragm pumps.

1.Accurately match the working point:

Most application scenarios have specific requirements for flow, pressure or vacuum levels. Topsflo is committed to providing pump solutions that are highly tailored to customer needs by adjusting pump parameters such as speed, flow and pressure to more accurately meet customer needs. This not only helps to improve production efficiency, but also significantly reduces energy consumption, achieving a cost-effective and environmentally friendly win-win situation. In order to help customers find the most suitable custom diaphragm pump, Topsflo offers a variety of pump sizes and offers a variety of solutions to achieve the precise operating point, including the digital customization of the motor and the selection of carefully optimized eccentric, etc., to ensure that each pump can be precisely matched to the operating point, providing stable and reliable support for customers' production activities.

2. Excellent chemical compatibility:

In the face of challenging media unique to certain industries, such as corrosive, explosive, sensitive or environmentally hazardous substances, ensuring fluid integrity and safety is critical. To this end, Topsflo offers a range of highly screened, high-performance materials such as PP, PTFE, FKM, FFKM, EPDM and PPS for customising key components of miniature diaphragm pumps such as diaphragms, valves and pump heads. In harsh working environments, more corrosion-resistant and wear-resistant materials and structural designs can be used to reduce the failure rate and maintenance costs of the pump. Our goal is to provide you with custom diaphragm pump solutions with superior chemical compatibility to ensure the reliable operation of the entire system in a variety of complex environments.

3. Extend service life and optimize costs:

For some critical applications that rely on long-term continuous operation of the pump, Topsflo can provide high-quality brushless DC motors. Not only does this motor last long, but it also provides the custom pump with exceptional robustness and reliability, significantly extending the pump's service life. This means that, despite being a custom pump, it does not necessarily mean a higher cost. However, in some applications the pump may not need to be run for very long periods of time. For situations like these, we offer our customers the more economical and simpler option of brushed motors. Brushed motors have a relatively short service life due to brush wear, but they also offer excellent reliability.

Through this flexible customization strategy, Topsflo not only demonstrates the performance advantages of customized micro diaphragm pumps, but also highlights its great value in cost control. Through reasonable customization and selection, customers can optimize costs while meeting performance requirements and find the most cost-effective pump solution.

4. Lower maintenance costs:

Customized micro diaphragm pumps fully consider customer needs and usage scenarios during the design and manufacturing process, so their structure and material selection are more reasonable, which can reduce maintenance costs.

Imagine that many systems require adapters to connect when in use, which not only increases the complexity of installation and debugging, but may also cause leakage and resonance problems due to improper adaptation. However, custom micro diaphragm pumps are designed to fit perfectly into the customer's system without the need for additional adapters. This means the size, weight and installation are just right, avoiding potential performance issues and dramatically reducing the cost of repairs and replacement parts.

5. Enhance market competitiveness:

When customers choose Topsflo's customized pump services, they will receive the pumps that closely match their needs and enjoy strict confidentiality of specifications, which gives Topsflo customers a valuable advantage in the market competition. Competitors cannot easily imitate or understand the exact specifications of a custom pump, making it difficult to discover the core details of a customer's system. We are fully aware of the importance of business confidentiality and therefore solemnly promise not to disclose relevant details of customized pumps to any third party under any circumstances without the express written consent of the customer. Choosing Topsflo means choosing the most trustworthy partner.

Wanna to get custom pump service? Feel free to contact us now:

Email: [email protected]

Whatsapp/Wechat:+86-19376691419

Mini daiprahgm liquid pumps: https://www.topsflo.com/mini-diaphragm-pump/

Mini daiprahgm gas pumps: https://www.topsflo.com/mini-diaphragm-pump/

#diaphragmliquidpump#diaphragmairpump#microairpumps#micropump#microdiaphragmpump#minidiaphragmpump#dc air pump#12v air pump#12v vacuum pump#12v dc air pump#12v mini air pump#dc vacuum pump#mini air pump#micro air pump#mini vacuum pump#Micro diaphragm pump#Miniature Diaphragm Pump

0 notes

Text

What Changes does "Liquid Cooling" Technology Bring to Charging Stations and How to Choose a Reliable Liquid Cooling Water Pump?

Recently, Have you noticed that Huawei's "liquid-cooled 600kW supercharger station" caused tremendous repercussions on the internet? It is said that this charging station can achieve a "one kilometer per second" charging speed, providing car owners with a charging experience of "having a cup of coffee and setting off fully charged". This resolves many of the core pain points such as range anxiety and charging anxiety for electric vehicle owners, bringing a completely new charging experience.

Huawei Technologies plans to install 100,000 EV DC fast charging stations in more than 340 cities and major highways across the country in China by 2024, leading the way in achieving "high-quality charging wherever you're"

What is the Liquid Cooling Fast Charging Station?

Different from traditional air-cooled charger, liquid cooling technology utilizes liquids to dissipate heat and maintain equipment temperature. Liquid-cooled ultra fast charging stations use this technology to charge electric vehicles in a shorter period, effectively improving charging efficiency and speed.

First, let's understand the basic principles of liquid cooling fast charging technology. According to the formula "power = voltage x current" (P = UI), we can see that when either the voltage (U) or the current (I) increases, the power (P) will increase, accelerating the charging speed and reducing the time required to fully charge.

Therefore, achieving high power fast charging mainly involves two methods. Firstly, increasing the vehicle's charging voltage—the charging voltage for electric vehicles has transitioned from the previous 400V to 800V and 1000V. Secondly, increasing the charging current. The majority of third-party universal fast chargers in China have achieved the 250A current limit recommended by the 2015 national standard. However, vehicle manufacturers' self-built super-fast chargers can successfully surpass the 250A current limit, achieving a higher 600A current output.

Why Do Electric Vehicle Charging Stations Heat Up So Much?

When the current passes through the resistor, all the electrical energy consumed on the resistor is converted into heat energy. According to Joule's law (Q=I²RT), the heat generated by the current through the conductor is proportional to the second square of the current, proportional to the resistance and power-on time, that is to say, the greater the current, the more heat generated by the charging pile.

Under the premise of the same resistance and equal time, when charging at 250A, a single charging cable or two charging cables can generate 62,500 joules of heat. And when charging at 600A will generate 360,000 joules of heat. Thus, how charging stations can withstand such high levels of heat has become a technical challenge that charging station manufacturers need to overcome.

How to Achieve the "Black Technology" of Liquid Cooling EV Fast Charging?

In the liquid cooling EV fast charging technology, the role of the liquid-cooled water pump is crucial.This is because the all-liquid-cooled charging station uses a liquid-cooled charging module, with no air ducts on the front and back of the liquid-cooled module. The module relies on the internal circulation of the coolant in the liquid cooling plate to exchange heat with the outside. The heat dissipation liquid is circulated between the charging host and other components to stabilize the temperature and ensure that the charging process is efficient and stable.

Meanwhile, the fully liquid-cooled charging pile has a special liquid circulation channel between cable and charging gun. Liquid coolant for heat dissipation is added to the channel, and the coolant is circulated through a liquid-cooled water pump, thereby dissipating the heat generated during the charging process. The liquid cooling system extends from charging station to charging cable and connector, enabling low-temperature operation of the entire charging system. This enhances the heat dissipation performance, increases the device power density and output power, and is significantly improved compared to traditional air-cooled heat dissipation technology.

How to Choose a Good and Reliable Water Pump Manufacturer?

1. Check the qualifications of pump manufacturers:

TOPSFLO has focused on micro pumps for 19 years. The industries we mainly serve are automobiles, charging station liquid cooling systems, home appliances, medical and ect.. 80% of our pumps are exported to European and American high-end markets, with international trademarks from the United States and the European Union. We has a modern factory with 16,000 square meters. Also has a patch factory and an injection molding factory with all imported equipment, an ESD anti-static control digital dust-free workshop, and fully automated electronic lines, motor lines, and water pump assembly and testing line and etc..

2. Whether the water pump has passed strict certification?

TOPSFLO is the only enterprise in China certified by German Rheinland TÜV double quality system of ISO 9001 and IATF:16949 in the micro pump industry. Based on this standard, TOPSFLO strictly controls all aspects of water pump R&D and design, raw material procurement, and production processes. Pursue and achieve "zero defects" in quality.

3. Successful customer cases

TOPSFLO is one of the earliest domestic micro-pump companies to enter the field of liquid-cooling applications for charging piles, and occupies a large market share in the field of liquid-cooled water pumps for charging piles. Since 2015, the company has provided 300,000 liquid-cooled water pumps to world-renowned electric vehicle and energy companies, and has professional and mature liquid-cooling solutions for fast charging piles.

Wanna to get pump solution or apply free sample? Contact us now:

Email: [email protected]

Whatsapp/Wechat:+86-19376691419

Find more pumps: http://www.topsflo.com/

youtube

#ev charging station#liquid cooling sytem#liquid cooling#waterpump#water pump for ev charging#Youtube

0 notes

Text

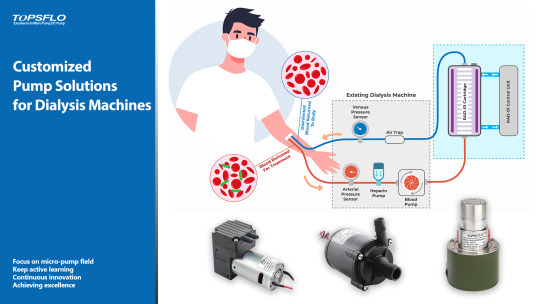

𝗠𝗶𝗰𝗿𝗼 𝗣𝘂𝗺𝗽 𝗮𝗻𝗱 𝗙𝗹𝘂𝗶𝗱𝗶𝗰 𝗦𝗼𝗹𝘂𝘁𝗶𝗼𝗻𝘀 𝗳𝗼𝗿 𝗠𝗲𝗱𝗶𝗰𝗮𝗹 𝗜𝗻𝗱𝘂𝘀𝘁𝗿𝘆 - 𝗛𝗲𝗺𝗼𝗱𝗶𝗮𝗹𝘆𝘀𝗶𝘀 𝗣𝘂𝗺𝗽

Overview

Hemodialysis serves as a vital renal replacement therapy for individuals battling chronic renal failure. Over the years, the prevalence of chronic renal failure has risen steadily, particularly due to factors like diabetic nephropathy, hypertensive nephropathy, and renal artery stenosis. This surge in patients necessitates hemodialysis treatment to sustain life.

Dialysis is a life-sustaining treatment for patients with end-stage kidney failure whose kidneys can no longer function. The dialysis machines removing water, solutes, and toxins from the blood. Dialysis works on the principles of diffusion across a semipermeable membrane. Blood flows by one side of a semipermeable membrane and a dialysate on the opposite side. The two main types of dialysis are hemodialysis and peritoneal dialysis.

In peritoneal dialysis, wastes and water are removed from the blood inside the body using the peritoneum as a natural semipermeable membrane.

However, in hemodialysis, the patient’s blood is pumped through a dialyzer. Blood flows through fibers, while dialysis solution flows around the outside of the fibers. The patient’s blood is cleaned in a dialyzer machine from waste products such as urea, creatinine, potassium, and extra fluid pass through the membrane, while the blood cells, protein, etc. remain in the blood.

Choosing the Right Dialysis Pumps

In hemodialysis machines, two circuits are crucial: the blood circuit for extracorporeal circulation lines and the hydraulic circuit for managing dialysis fluid. The hydraulic circuit involves various pumps, TOPSFLO offers a range of pumps engineered to meet OEM specifications for dialysis devices (Model recommendations are as follows):

1. Centrifugal Pumps

2. Diaphragm Gas Pump

3. Magnetic Drive Gear Pumps

External gear pumps are widely acclaimed for their pivotal role in powering dialysis machines, particularly in the medical sector. These pumps operate through the synchronization of two identical gears, commonly referred to as the "motor" and "driven" gears. The motor gear, propelled by a motor, in turn, drives the other gear, facilitating fluid transport by trapping small volumes between the gear teeth and the outer housing wall. This mechanism efficiently moves fluid from the inlet side to the outlet side, making external gear pumps a preferred choice for applications requiring precise fluid pressurization and minimal pressure fluctuations.

The distinctive advantages of external gear pumps contribute to their suitability for health technology applications, notably in hemodialysis machines. These advantages include exceptional priming capacity, ensuring swift initiation of fluid movement. Moreover, these pumps exhibit compatibility with wide temperature variations, a critical feature considering the temperature fluctuations experienced during post-treatment washing. Additionally, the compact size of external gear pumps further enhances their appeal for medical applications, offering an efficient and space-saving solution for fluid management in hemodialysis machines.

Pumps can operate at a temperature of 38°C throughout the dialysis cycle to prevent thermal shock to the patient. Their quiet operation is crucial for patient comfort. Stable performance, vacuum maintenance, and differential pressure are critical factors for the machine's operation, especially biocompatibility. The disinfectants in dialysis equipment pack strength, yet their corrosiveness poses challenges. Enter TOPSFLO pumps, crafted from materials demonstrated to endure numerous chemical heat clean cycles, ensuring unwavering performance. The outcome? A durable pump boasting biocompatibility, minimal noise, and significant reductions in long-term maintenance costs. Choose us for a pump solution where materials make the difference, offering reliability and longevity.

TOPSFLO pumps precisely and safely manage fluids within dialysis systems. As one of leaders in micro pump and fluidic solutions for the medical industry, TOPSFLO collaborates with customers to provide technical solutions, ensuring critical parameters for safety and performance are met.

Conclusion

TOPSFLO's commitment to innovation and collaboration makes it a reliable partner in the development of medical devices. For more information or to discuss a new project, welcome to have a consultation.

Wanna to get pump solution or apply free sample? Contact us now:

Email: [email protected]

Whatsapp/Wechat:+86-19376691419

Find more pumps: http://www.topsflo.com/

youtube

#hemodialysis#dialysis machine#hemodialysis machine#centrifugal pumps#gear pumps#diaphragmairpump#medical pump#Youtube

0 notes

Text

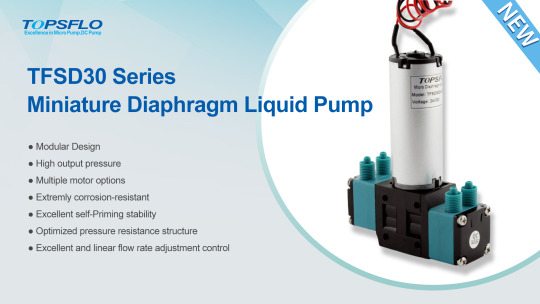

【New Product】| TFSD30 Series New-Generation High Performance Diaphragm Liquid Pump

Currently, in the fields of IVD and analytical instruments, high performance liquid pumps have long relied on imports. After the occurrence of global trade disputes and the COVID-19, issues such as the price and supply cycle of high-performance liquid pumps have significantly impacted the production of high-end medical and analytical instruments in China.

TOPSFLO has been deeply involved in the field of micro diaphragm pumps for more than ten years. In response to the above problems, the R&D center established a special project in 2020. After countless improvements and upgrades, it will finally launch a high-performance diaphragm liquid pump suitable for a variety of medical scenarios in the second half of 2022—TFSD30 Series. The launch of TFSD30 Series marks that domestically independently developed diaphragm liquid pumps have fully reached and surpassed German and Japanese products in performance, reliability and other fields.

High-performance diaphragm pumps face multiple challenges during operation, such as lifespan and reliability under high working pressure, tolerance to various corrosive chemical media, sealing performance under high pressure, the impact of noise and vibration on instruments, and issues related to valve plate adhesion and suction reliability when extracting viscous liquids.

To meet a wide range of customer needs and application scenarios, TOPSFLO focused on independent research and innovation in the development of TFSD30 Series pump. In the early stages of technical development, new technologies, structures, materials, and processes were employed. Multiple high-precision devices accumulated test data, and with collaboration from various sources, TFSD30 Series achieved another leap in product quality and performance.

1. Modular Design: TOPSFLO diaphragm pumps is designed with modularity, allowing flexible combinations of core components, materials, and processes. This enables rapid customization and production delivery with the shortest development cycle and minimal cost:

Miniature diaphragm pumps need to be integrated into fluid systems in various industries. Customers' working points, conditions, media, pipe types, power supply, and control systems vary significantly across different application industries. Even the same customer will have different requirements for fluid properties in different projects and systems. Our rapid customized services based on customer needs have always been well received and recognized by customers.

From the inception of the TFSD30 Series, TOPSFLO adopted a product mindset based on modular design, planning and designing the components, materials, and structure of the product. This approach allows us to provide customers with various high-quality and rapid customization services at the minimum cost. Customers can choose different pump heads, connectors, materials, and motors as needed, obtaining customized models with corrosion resistance, pressure, and flow characteristics. TOPSFLO sample line immediately customizes production based on customer choices, ensuring that customized products have fast delivery times and cost advantages comparable to standard products.

2. High output pressure for continuous operation in high-pressure conditions, providing a continuous power source for inkjet and cleaning applications:

TFSD30 Series is a liquid pump with a wide range of operating pressures. It can operate under -35kPa negative pressure, drawing liquid from a negative pressure container or from a location below the pump body installation position of 3.5m. It can also output liquid under +600kPa positive pressure, achieving a liquid lift of over 60 meters. Specially designed and pressure-resistant diaphragms and pump bodies, with optimized processes, not only enable the output of high-pressure liquid but also ensure continuous operational lifespan under rated high output pressure. When TFSD30 Series is connected to a micro atomizing nozzle, sufficient working pressure can produce ideal micro-sized mist droplets. When connected to a needle nozzle, it can output a strong high-pressure water column.

3. Adopt high-end corrosion-resistant materials to meet chemical compatibility requirements for various corrosive media applications:

Facing various corrosive media, TOPSFLO, in the selection of rubber and sealing materials, introduced not only conventional EPDM rubber but also fluororubber. Collaborating with leading suppliers of special rubber materials, TOPSFLO developed perfluoroether rubber (FFKM) valve plates and sealing systems with excellent corrosion resistance. Additionally, corrosion-resistant materials widely praised in the industry, such as polytetrafluoroethylene (PTFE), were also applied. The variety of corrosion-resistant material choices allows TFSD30 Series to be compatible with strong oxidizing agents, strong acids, strong bases, and organic solvents. It can be widely used in the transfer, washing, disinfection, cleaning, and inkjet applications involving highly corrosive liquids.

4. Optimized pressure resistance structure, elevating the pressure resistance capability of the micro diaphragm pump from 500kPa to 800kPa:

To meet the sealing and pressure resistance requirements for high-pressure applications, TOPSFLO R&D team comprehensively referred to the design features of various domestic and foreign high-pressure liquid pumps in the structural design, and made multiple improvements. Such as using glass fiber-reinforced polyphenylene sulfide (PPS) engineering plastic as the pressure-resistant pump body. This not only optimized the part structure but also reduced points of seal failure. The pressure-resistant pump body components' sealing and fastening pressure were optimized and strengthened, achieving a comprehensive pressure resistance performance of TFSD30 Series surpassing similar products at the 800kPa (0.8mPa) level. In addition to enhancing the pump body's pressure resistance, TFSD30 Series has undergone specific optimizations for pipe connection reliability and prevention of pipe detachment under high pressure. When used in high-pressure conditions, it can be equipped with a sleeve-type pipe sealing joint to enhance pipe pressure connection reliability.

5. Non-adhesive one-way valve structure for excellent self-Priming stability:

In order to minimize the industry-wide issue of self-priming failure caused by one-way valve adhesion when extracting viscous liquids, TOPSFLO significantly enhanced and improved the product structure during the development of TFSD30 Series. For example, the surface-sealing structure of the one-way valve plate was changed to a line-sealing structure to reduce medium retention and adhesive surface area. Fluid structure calculation simulations and 3D printing technology were introduced to minimize the working dead zone of the volumetric pump. This achieved higher suction negative pressure than similar imported foreign products, resulting in more stable and reliable self-priming performance.

6. Multiple motor options covering a wide range of lifespan and price ranges:

TFSD30 Series offers various motor options, including DC brushed motors, conventional brushless motors, and enhanced bearing custom brushless motors. These options cater to intermittent users, customers working under long-term continuous low loads, and those operating under long-term high-pressure and high-load conditions. This provides the most suitable configuration options, meeting the high reliability demands of challenging conditions and the cost-effective options for applications prioritizing cost. The diverse motor options also give users a broader range of choices in terms of power supply voltage, speed control mode, electromagnetic compatibility, and more.

7. Excellent and linear flow rate adjustment control characteristics:

To achieve stable liquid output flow rate control, TFSD30 Series can control motor speed through PWM signals. Optimizations were made for speed-flow characteristics. With the combined effect of the motor controller control program and optimized internal structure, the speed control curve of TFSD30 Series exhibits superior linearity compared to conventional diaphragm pumps. This enables customers to easily adjust and control the pump's output flow rate through programming and control signals in various applications.

The new generation high performance diaphragm pump TFSD30 Series has started prototype testing for initial users and will continue to iterate and improve based on customer feedback. TOPSFLO adheres to the core value of "creating value for customers" and is willing to work together with all customers to advance the continuous improvement of diaphragm pump technology and product quality. If you would like further information on TFSD30 Series high-performance diaphragm pump or apply for prototype testing, please contact our pre-sales engineers.

Wanna to get pump solution or apply free sample? Contact us now:

Email: [email protected]

Whatsapp/Wechat:+86-19376691419

Find more pumps: http://www.topsflo.com/

0 notes

Text

Elevating Coffee Experience: TOPSFLO Milk Gear Pump Solution for Fully Automatic Commercial Coffee Machines

Market Overview

Coffee, as a globally beloved beverage, has seen a growing popularity in consumption habits, with an increasing pursuit of the flavor and quality of coffee itself. In the fast-paced modern lifestyle, the emphasis is on convenience and efficiency. Driven by enormous market potential, freshly ground coffee is no longer limited to traditional coffee shops but has emerged in various new formats such as "convenience store coffee," "Luckin Coffee Ready-to-Go," "office coffee," "restaurant coffee," and more.

The advent of fully automatic commercial coffee machines meets these evolving demands, becoming an indispensable part of modern commercial settings. Whether in offices, hotels, restaurants, or coffee shops, fully automatic commercial coffee machines play a crucial role. They not only enhance the efficiency of employees but also allow customers to effortlessly enjoy the deliciousness of coffee. Furthermore, the introduction of smart technologies, such as human-machine interaction systems and preset coffee recipes, enables the adjustment of parameters like coffee strength and temperature based on individual tastes and preferences, providing a diverse range of coffee choices in a short time. From classic Americano to intricate latte art, these machines offer personalized coffee experiences to users. This innovation significantly accelerates the commercialization of freshly ground coffee, making the optimization of these machines' performance and customer experience crucial for enhancing the attractiveness of coffee shops and the efficiency of businesses. This article aims to assist coffee machine manufacturers in improving the efficiency, stability, and user convenience of their products.

The milk pump in coffee machines, as a critical component, plays a vital role in the performance of the coffee machine and the user's experience. Its primary function is to extract milk beverages, such as milk and coconut milk, from containers to create rich and delicate milk froth. Therefore, the coffee machine milk pump holds significant importance in enhancing the user experience of fully automatic coffee machines and diversifying coffee choices.

Market Pain Points and Solutions

1.Frothing Temperature Issue:

Issue: In the Chinese coffee market, optimizing the "milk coffee" experience is crucial for success. Major coffee machine brands focus on “frothing”, with the core being to ensure the temperature and density of the froth. Traditional venturi tubes cannot pump cold milk, limiting the ability of coffee shops and businesses to adjust based on different coffee types or individual customer preferences.

Solution: The diversity of froth temperatures and maintaining their stability is fundamental to creating an outstanding milk coffee experience. TOPSFLO Coffee Machine Pump TG01 can pump cold milk, producing iced lattes and iced cappuccinos, allowing users to customize their coffee experience to meet personal preferences. Providing users with the freedom of a personalized coffee experience satisfies diverse customer preferences, injecting more flexibility into coffee culture.

2. Inconsistent Milk Frothing Issue:

Issue: Different milk pumps have distinct performance characteristics, and the pump's performance can impact the density of milk froth.

Solution: To achieve optimal milk froth quality, it is necessary to adjust and coordinate the performance of the milk pump, frothing device, and other relevant components. Design parameters of the milk pump, such as pumping speed and pressure, directly affect the entry and injection of milk into the frothing device. Moderate speed and pressure contribute to the creation of fine milk froth. Milk pumps from different manufacturers may employ varying designs and technologies. TOPSFLO coffee machine milk pump TG01 features a more intelligent control system, allowing adjustment of the pumping speed according to the desired frothing quality, ensuring consistent froth quality.

Maintaining Hygiene Standards:

Issue: In commercial environments, especially in high-frequency usage settings, the residual milk or other dairy-based beverages in the pump may lead to bacterial growth, causing hygiene issues.

Solution: TOPSFLO coffee machine milk pump TG01 is made from materials that comply with NSF and FDA standards. Its simple internal structure is designed to minimize the risk of milk residue accumulation. Coupled with the coffee machine's unattended self-cleaning system, it is easy to clean and maintain.

4. Electromagnetic Compatibility Challenges

Issue: The electronic components and milk pump in automatic coffee machines may generate electromagnetic radiation, causing interference with other electronic devices. Ensuring the electromagnetic compatibility of the milk pump to prevent interference with surrounding electronic devices is a significant challenge. Additionally, ensuring the seamless integration of the milk pump's electronic control system with the overall control system of the coffee machine poses a technical challenge.

Solution: To address electromagnetic compatibility issues, the TOPSFLO direct drive DC micro gear pump TG-01 motor design takes into account European electrical electromagnetic compatibility standards. This ensures that the coffee machine is designed in compliance with EMC standards and regulatory requirements. Through compliance certification, the equipment will not cause interference with other electronic devices during use, ensuring stable operation and seamless integration.Furthermore, in the electronic design of the coffee machine, to further reduce the risk of electromagnetic interference, coffee machine manufacturers should attempt to keep the milk pump away from other sensitive devices, especially those sensitive to electromagnetic interference. By arranging the layout of the equipment reasonably, the spread of electromagnetic radiation can be minimized.

5. Operation noise issue:

Issue: Research on enhancing environmental experiences indicates that customers in coffee shops often express dissatisfaction with the noisy operation of machines, impacting their overall experience in the coffee shop. The noisy operation of water pumps is a key factor affecting the environment, disrupting the ambiance of coffee shops and businesses, diminishing the relaxed and enjoyable feelings when savoring coffee, and influencing the overall customer experience.

Solution: Opting for a coffee machine milk pump equipped with advanced noise reduction technology is a wise choice. The TOPSFLO coffee machine milk pump TG01 adopts optimized gear design and manufacturing processes to reduce vibration and noise during gear engagement. It ensures proper lubrication of the pump's mechanical components, minimizing noise caused by friction. Additionally, in the structural design of the coffee machine, resonance between the pump body and surrounding structures can be a source of noise. TG01 milk gear pump addresses this by strengthening the pump body structure, effectively preventing resonance and vibration propagation.

Conclusion

The milk gear pump for fully automatic commercial coffee machines aims to enhance the flexibility of coffee machine manufacturers' products. Looking ahead, focusing on efficiency, stability, and user convenience, these innovations will contribute to creating seamless and enjoyable coffee experiences for baristas and consumers. As the coffee industry continues to evolve, adopting these advancements will ensure that fully automatic commercial coffee machines stay at the forefront, providing outstanding quality and satisfaction for coffee enthusiasts worldwide.

TOPSFLO's milk gear pump offers comprehensive solutions to the challenges faced by manufacturers of fully automatic commercial coffee machines. Our coffee machine milk pump features high-precision structural design, precise flow control, quiet operation, durability, compactness, temperature resilience, and other characteristics. It meets the rigorous requirements of the coffee industry, providing a reliable and efficient solution. This not only enhances the quality of beverages but also strengthens the overall experience for customers.

Wanna to get pump solution or apply free sample? Contact us now:

Email: [email protected]

Whatsapp/Wechat:+86-19376691419

Find more pumps: http://www.topsflo.com/

0 notes

Text

TOPSFLO Magnetic Drive Gear Pump Solution for Raw Milk Vending Machine

Milk vending machine dispenses milk collected from cows, buffaloes, goats and sheep, it consists of an automatic dispenser which dispenses “raw milk” to a container/bottle after successful payment from the end-user. Some vending machines also provide container/bottle with the milk for easy buying. The raw milk is directly sold to customers at farm in countries such as France, Germany, Denmark, Italy, the Netherlands, Czech Republic, Austria, Slovakia, Lithuania, Ireland and the U.K. The major countries that have adopted raw milk vending machine include Italy, France, Romania,Germany, the U.K., Slovakia, Slovenia and Czech Republic. The key reason for adoption of raw milk vending machine was due to the revisions in regulations of respective countries regarding raw milk sale.Furthermore, majority of end-users in these countries prefer drinking raw milk and consuming raw milk related products due to their nutritional benefits.

Raw milk vending machine technological research is focused on solving problems related to the management of unpasteurized milk sales, especially for the safety, healthy and cleaning of the machine, simple operation, less daily maintain work, continuous supply reliable and quality guarantee. Our company have good cooperate relationship with some of most famous Europe raw milk machine supplier in recently years. TOPSFLO MG Magnetic Gear Pump is perfectly suit for this special market, details as follows:

● FDA certificated,all wetted material is food grade, which is very suit for the raw milk vending industry for health and safety requirement.

● SS316 precise build pump housing, PEEK gears & PTFE sealing material, which is robust joint & leak-less.

● Simple internal construction and its small dimension makes it space save and less or maintenance free.

● High flow-rate and high pressure continuous working, self-priming, and precise working performance. Besides,more control and protect function are available.

● Lower noise level of vibration makes the vending machine possibly to widely apply in the residential districts.

● Low power consumption, save more electricity costs.

● Suit for wide working circumstance, environment temperature range from -10~50℃,and fluid temperature range -10℃ ≤T≤100 ℃ ( unless freezing)

Wanna to get pump solution or apply free sample? Contact us now:

Email: [email protected]

Whatsapp/Wechat:+86-19376691419

Find more pumps: http://www.topsflo.com/

0 notes

Text

TOPSFLO Fully Automatic Commercial Coffee Machine Milk Gear Pump

With the continuous advancement of modern society, the application of automatic commercial coffee machines in the coffee industry is becoming increasingly widespread. Among them, the milk pump, as a crucial component, plays a pivotal role in the performance and user experience of coffee machines. We understand your systems, challenges and market situation. That's why TOPSFLO are the preferred choice for addressing common problems of your products. This article aims to explore solutions for automatic commercial coffee machine milk pumps, with a focus on helping coffee machine manufacturers enhance efficiency, stability, and user convenience.

How our milk pump solutions can improve the automatic commercial coffee machine experience for your customers:

Milk Frothing Temperature Issue: Coffee shops and businesses often require flexibility in milk foam texture and temperature that traditional venturis cannot provide. TOPSFLO automatic commercial coffee machine milk pump can froth both cold and hot milk, allowing users to customize the coffee experience to meet customer preferences.

Inconsistent Milk Frothing: Traditional pumps may struggle to achieve consistent milk frothing, leading to variations in beverage quality. TOPSFLO milk pumps ensure stable pressure and precise flow, guaranteeing uniform and high-quality milk froth for every cup of coffee.

Operational Noise: Noisy water pumps can disrupt the ambiance in coffee shops and businesses, impacting the overall customer experience. TOPSFLO milk pumps operate quietly, providing a peaceful environment for customers and maintaining the ideal atmosphere.

Maintaining Hygiene Standards: Residue and bacterial growth in pumps handling milk or other dairy-based beverages can pose hygiene concerns, especially in high-usage environments. TOPSFLO milk pumps are made with materials that meet hygiene standards, featuring a simple internal structure designed to minimize the risk of milk residue buildup, making them easy to clean and maintain.

Electronic Compatibility Challenge: TOPSFLO Micro Gear Pump TG-01 motor design fully takes into account the European electrical electromagnetic compatibility standards (EMC), which can reduce interference, ensure the stable operation of the equipment and seamless integration.

Advantages of TOPSFLO TG01 fully automatic commercial coffee machine milk gear pump

Compact Design for Space Efficiency: The ultra-compact design of the miniature gear pump ensures a small footprint and lightweight construction, effectively saving installation space.

FDA Compliance for Direct Food Contact Safety: Meeting FDA standards, TOPSFLO micro gear pump is certified for direct contact with food, ensuring the highest level of food safety.

Low Pulsation for Smooth Water Flow: With minimal pulsation, TOPSFLO gear pump ensures a smoother and more stable water flow, contributing to the consistency of beverage quality.

High Pressure with Low Losses: TOPSFLO gear pump delivers high pressure while minimizing energy losses, enhancing overall efficiency in the operation of the automatic commercial coffee machine.

Application Conditions for Automatic Commercial Coffee Machines Gear Pump

Operating Temperature Range: -25°C to 70°C (excluding freezing conditions)

Liquid Temperature Range: 0°C to 80°C

Voltage Range: For 12V pumps, 9-15V; for 24V pumps, 18-28V

These optimized features make milk gear pump an ideal choice for a wide range of conditions, ensuring reliable and efficient performance in automatic commercial coffee machines.

TOPSFLO Milk Gear Pumps offer a comprehensive solution to the challenges faced by customers in the context of fully automatic commercial coffee machines. With features such as precise flow control, quiet operation, durability, compact design, temperature resilience, our milk pumps provide a reliable and efficient solution for the demanding requirements of the coffee industry.

In conclusion, automatic commercial coffee machine milk gear pumps aim to empower coffee machine manufacturers in elevating their products. By focusing on efficiency, stability, and user convenience, these innovations contribute to the creation of a seamless and delightful coffee experience for both baristas and consumers alike. As the coffee industry continues to evolve, embracing these advancements ensures that automatic commercial coffee machines remain at the forefront of delivering exceptional quality and satisfaction to coffee enthusiasts worldwide.

Wanna to get pump solution or apply free sample? Contact us now:

Email: [email protected]

Whatsapp/Wechat:+86-19376691419

Find more pumps: http://www.topsflo.com/

0 notes

Text

TOPSFLO Water Pump Intelligent Customized FG Signal - Meet Diverse Needs and Enhance Pumping Experience

As an advanced fluid transfer device, brushless DC centrifugal pumps are playing an increasingly important role in various industries. This kind of dc water pump not only has the advantages of high efficiency, low energy consumption and smooth operation, but also has the advantages of easy installation and use, long life and is deeply loved by users, becoming the preferred device in many fields. The FG signal of the brushless DC centrifugal pump is very important for monitoring, controlling and optimizing the operation of the pump, which can improve the stability, safety and efficiency of the system.

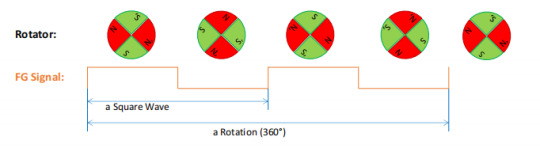

What is the FG Signal of a Brushless DC Centrifugal Pump?

The FG signal of a brushless DC centrifugal pump usually refers to the "Frequency Generator" signal line, which usually work through a square wave signal. The frequency of this square wave signal is proportional to the speed of dc water pump. When the motor speed increases, the frequency of the square wave signal will increase accordingly, and when the motor speed decreases, the frequency of the square wave signal will also decrease. Through the frequency change of this square wave signal, the control system can achieve precise control of the motor speed and control it as needed to ensure the stable operation of the water pump.

If the motor speed is lower than the set value, the control system can increase the output power of the motor by increasing the duty cycle of the speed regulation signal, thereby increasing the motor speed. On the contrary, if the motor speed is higher than the set value, the control system can reduce the output power of the motor by reducing the duty cycle of the speed regulation signal, thereby reducing the motor speed.

How is the square wave generated? The FG signal is actually the communication signal of the brushless DC motor. When a communication event occurs, the FG output will toggle. The rotor used in the TOPSFLO water pump has 4 poles, which means that 4 communication events will occur during one rotation of the rotator, and the FG will flip twice to produce a square wave.

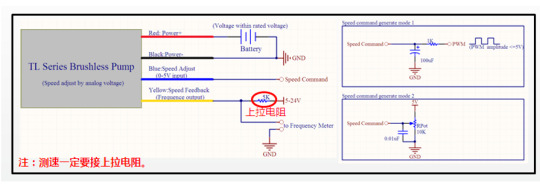

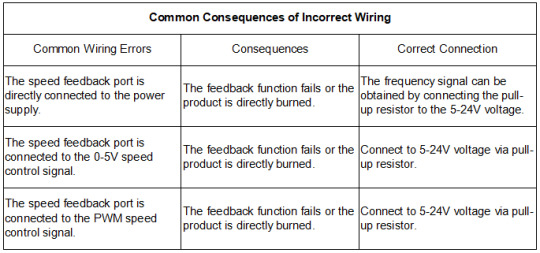

Wiring Method of the FG Signal Line

The wiring sequence of the customized 5V/PWM/FG signal line of TOPSFLO DC brushless water pump is generally: red line positive, black line negative, blue line 5V or PWM speed regulation, yellow line FG signal. When the red, black and yellow wires are connected, the water pump works normally; when the yellow wire is not connected, the water pump works, but there is no signal display; when the input current is >50mA, there is a risk of damage to the FG signal circuit of the pump. When measuring speed, a pull-up resistor must be connected. The pull-up resistor is recommended to be between 1K and 10K. It is adjusted according to the pull-up voltage. The greater the voltage, the greater the resistor selected.

FG Wiring Precautions

What kind of applications need to customize the FG signal lines?

The reasons for customizing FG signal for brushless DC centrifugal pumps involve many aspects such as control system requirements, accuracy, integration, and performance optimization. By customizing FG signal lines, customers' specific needs can be met to ensure that the water pump can achieve the best performance and functionality in its applications. The following are common applications that require customized FG signal lines:

Equipment control system requirements: The customer's control system requires specific types or specifications of signal inputs to ensure optimal performance. For control systems that require specific frequency ranges or signal types, customizing FG signal lines to meet these requirements is necessary.

Precision and accuracy requirements: Customer applications require higher measurement precision and accuracy, such as the medical industry, drinking industry, cooling industry, precision instruments, etc. By customizing the FG signal line, the speed of the water pump can be precisely controlled. For example, the speed regulation function needs to be implemented or the pump needs to run at a specific speed under specific conditions. At this time, the FG signal line can provide the operating status and speed information of the water pump to facilitate customers to accurately control and adjust the water pump.

Real-time monitoring requirements: The operating status of the water pump needs to be monitored in real time. For example, it is necessary to know the flow rate of the water pump or whether it has stopped due to failure. At this time, customized FG signal lines can collect and monitor these data, helping customers promptly detect abnormal pump operation and take corresponding measures.

Integration and compatibility requirements: Customized circuits or wiring schemes are required for customer system integration to meet the overall system design and requirements. In this case, customized FG signal lines can better meet the needs of system integration, providing a more flexible and reliable system solution.

Advantages of TOPSFLO's customized FG signal lines

TOPSFLO is one of the earliest manufacturers in China to focus on the R&D and manufacturing of micro pumps. It is a powerful enterprise that only produces high-end products and exports 90% of them to the European and American markets. It has long-term and stable cooperation with many world-renowned brands in Europe and the United States, and its business has been growing steadily every year. At present, the full series of TOPSFLO TL brushless DC centrifugal pumps can realize intelligent customization of FG signal lines. Our advantages are mainly reflected in the following:

R&D strength: TOPSFLO has independent electronic engineers, structural engineers and motor engineers to provide you with support and R&D. Each has their own practical R&D capabilities and can be flexibly customized according to customer requirements, ensuring that you can always receive a solution immediately. You can rest assured of our high-quality and professional service in the long run.

Successful cases: TOPSFLO cooperates with many leading international companies and provides OEM supporting services, such as Tesla, Whirlpool, Bosch, KTM, KOHLER, etc. Therefore, we have extensive experience in pump applications and OEM services in different industries, such as medical, solar pv, automotive, industrial cooling, home appliances, charging piles, hot beverage machines, etc.

Company strength: With nearly 18 years of experience, TOPSFLO is the leading comprehensive solution manufacturer in China specializing in the production of various micro dcwater pumps. We attach great importance to product quality and corporate integrity, which is why we have a strong R&D team to realize customers' customized needs throughout the process.

TOPSFLO can not only customize the speed regulation function of 5V, PWM and FG signal lines, but also realize the customization of pump size, structure, materials, etc. Any OEM project you can imagine and request for customization, TOPSFLO will try its best to meet your requirements. If you have any further questions, please feel free to let us know. We value your valuable suggestions and look forward to cooperating with you.

Wanna to get pump solution or apply free sample? Contact us now:

Email: [email protected]

Whatsapp/Wechat:+86-19376691419

Find more pumps: http://www.topsflo.com/

youtube

#dcwaterpump#waterpump#brushlessdcpump#12vdcwaterpump#12vwaterpump#24vdcwaterpump#dc water pump#bldcpump#topsflopump#Youtube

0 notes

Text

Precision Dispensing and Cross-Contamination Prevention: Applications of Micro Diaphragm Pumps in In Vitro Diagnostics

Introduction:

In the realm of in vitro diagnostics (IVD), precision and accuracy are paramount for reliable test results. The advent of mini diaphragm pumps has significantly contributed to enhancing these qualities by providing precise dispensing capabilities and preventing cross-contamination. This article explores the applications of mini diaphragm pumps in IVD, shedding light on their crucial role in ensuring the integrity of diagnostic processes.

Precision Dispensing in IVD:

Diaphragm pumps play a pivotal role in the precise dispensing of reagents and samples in IVD procedures. Their ability to control flow rates and deliver small, accurate volumes is particularly valuable in assays where minute quantities of substances can make a substantial difference. The precise dispensing facilitated by diaphragm pumps ensures that diagnostic tests achieve the required sensitivity and specificity, leading to more accurate and reliable results.

Cross-Contamination Prevention:

Cross-contamination is a persistent concern in diagnostic settings, as it can compromise the validity of test results and lead to erroneous conclusions. Miniature diaphragm pumps address this challenge by employing a barrier, the diaphragm, that isolates the pumped fluid from the pump mechanism. This design prevents the backflow of samples or reagents, minimizing the risk of contamination between different test samples. As a result, diaphragm pumps contribute significantly to the robustness of IVD processes and enhance the credibility of diagnostic outcomes.

Applications in Automated Systems:

The integration of mini diaphragm liquid and gas pumps into automated IVD systems has become increasingly prevalent. These pumps play a crucial role in automating complex assay protocols, where precise and programmable fluid dispensing is essential. Automated systems equipped with mini diaphragm pumps not only increase efficiency but also reduce the likelihood of human errors, further improving the overall reliability of diagnostic procedures.

Versatility in IVD Platforms:

Diaphragm pumps exhibit versatility in their application across various IVD platforms. Whether used in immunoassays, molecular diagnostics, or clinical chemistry, these pumps prove adaptable to the unique requirements of different diagnostic techniques. The compatibility of diaphragm pumps with a wide range of reagents and samples enhances their utility across diverse diagnostic applications, making them a valuable component in the IVD landscape.

Conclusion:

The application of mini diaphragm pumps in in vitro diagnostics represents a significant advancement in ensuring precision dispensing and preventing cross-contamination. Their role in enhancing the accuracy, reliability, and efficiency of diagnostic processes cannot be overstated. As technology continues to evolve, the integration of micro diaphragm pumps into IVD platforms is likely to grow, contributing to further improvements in diagnostic capabilities and ultimately benefiting patient care.

0 notes

Text

The Vital Role of Miniature Diaphragm Pumps in Medical Device Advancements

Introduction

In the ever-evolving landscape of medical technology, diaphragm pumps have emerged as indispensable components, contributing significantly to advancements in various medical devices. Among the key players in this field, TOPSFLO diaphragm gas and liquid pumps have proven to be pivotal in a wide array of medical applications. This article explores the critical role these pumps play in shaping the future of healthcare, focusing on in-vitro diagnostics, anesthesia monitoring, therapeutic and surgical equipment, and critical care devices.

In-Vitro Diagnostics: Diagnosis lies at the heart of effective medical treatment, and in-vitro diagnostics have become essential tools for clinicians. Miniature diaphragm pumps play a crucial role in supporting diagnostic processes by facilitating the movement of liquids and gases within diagnostic devices. Whether it's sample processing, reagent delivery, or fluid handling, the precision and reliability of these pumps contribute to the accuracy of diagnostic results, enabling early detection and intervention in various medical conditions.

Anesthesia Monitoring: Ensuring patient safety during surgical procedures is paramount, and anesthesia plays a pivotal role in this regard. Miniature diaphragm pumps are integral components in anesthesia machines, regulating the flow of gases and maintaining a precise balance to achieve optimal sedation levels. The reliability of these pumps is particularly critical during delicate surgical procedures, contributing to the overall success and safety of anesthesia administration.

Therapeutic and Surgical Equipment: From infusion pumps to surgical tools, therapeutic and surgical equipment rely on precise fluid control mechanisms. TOPSFLO micro diaphragm pumps provide the necessary precision and consistency required for drug delivery systems, ensuring accurate dosages and minimizing the risk of complications. In surgical settings, these pumps play a vital role in powering suction devices, controlling fluid flow, and contributing to the overall efficiency and safety of medical procedures.

Critical Care Devices: In critical care scenarios, where every moment is crucial, the reliability of medical devices becomes a matter of life and death. TOPSFLO mini diaphragm pumps are engineered to meet the stringent demands of critical care devices, such as ventilators and patient monitoring systems. These pumps contribute to the consistent delivery of gases and fluids, playing a pivotal role in sustaining patients' vital functions and improving overall outcomes in intensive care settings.

Conclusion

As medical technology continues to advance, the role of mini diaphragm liquid and gas pumps, becomes increasingly significant. The precision, reliability, and versatility of these pumps contribute to the efficacy of medical devices across various applications. From in-vitro diagnostics to critical care devices, TOPSFLO micro diaphragm pumps stand at the forefront of innovation, ensuring that healthcare professionals have the tools they need to provide optimal care and improve patient outcomes. As the medical field progresses, the vital role of these diaphragm pumps in shaping the future of healthcare is likely to expand, ushering in new possibilities for diagnosis, treatment, and patient care.

Wanna to get pump solution or apply free sample? Contact us now:

Email: [email protected]

Whatsapp/Wechat:+86-19376691419

Find more pumps: http://www.topsflo.com/

youtube

#medicalpump#IVDpump#medical devices#waterpump#dcwaterpump#24vdcwaterpump#12vwaterpump#12vdcwaterpump#brushlessdcpump#dc water pump#bldcpump#Youtube

0 notes

Text

Enhancing Energy Efficiency: Solar Water Heater Booster Pumps Pave the Way for Your Sustainable Lifestyle

Solar water heaters offer an efficient and economical alternative to traditional water heating systems, making them a popular appliance for homeowners looking to reduce their energy consumption and carbon emission. When it comes to enjoying a comfortable shower experience and worry-free hot water supply, a solar water heater booster pump becomes an indispensable home appliances. Because of the efficient pressurization of the water pump, users can not only use solar energy efficiently, but also easily enjoy a stable hot water supply.

The core function of TOPSFLO solar water heater booster pump is to increase the water pressure of the hot water supply, so that users no longer have to wait for the hot water to flow out, or endure the intermittent hot water supply, but can enjoy every drop of warm hot water. Ensure you get a new and comfortable hot water experience.

At present, TOPSFLO solar hot water circulation pump TS5 has been widely used in several hundred thousand of households around the world. Based on customer feedback, the following points are the main reasons why customers choose TOPSFLO DC solar hot water pumps:

PV power supply, no need to connect to the gridThe TOPSFLO DC solar pump can be directly connected to the photovoltaic (PV) panel and can directly use the solar DC power converted by the PV panel without the need for additional energy conversion equipment, which can maximize the use of solar resources and reduce energy conversion losses; It provides great convenience for rooftop installation,even remote areas or places lacking stable power supply. This is one of the important reasons why TS5 pumps are widely used around the world.

Highly efficient and energy-saving, suitable for small or single-family solar water heating systemsThe water pump can start working when the sunlight is weak. The TS5 pump is equipped with a 2W soft-start function and can also work continuously for 24 hours to meet daily hot water supply needs at any time. The low power of 15W can provide a strong flow rate of 12L/Min and a maximum pressure of 3M, reducing energy waste and ensuring efficient supply of hot water. The ultra-long life of 30,000 hours makes it an economical and reliable choice. Used with solar water heaters, it can help you minimize electricity or gas consumption and reduce users' energy expenses.

Add special protection functions for worry-free operationTS5 comes with a series of special protection functions, including polarity protection, idling protection, stall protection, etc. End users can clean and maintain the water pump themselves. When reinstalling, even if the positive and negative poles of the power supply are reversed, solar hot water pump circuit board will not be damaged. If the pipeline is short of water, the idling protection detection of TS5 will be triggered. The water pump will run at low speed when there is no water, and will automatically return to normal working status when there is water, without the risk of burning the PCBA. If impurities in the pipeline block the pump, the pump will be tested repeatedly until the blockage is cleared and normal operation resumes. These protection mechanisms greatly reduce the damage to the water pump caused by common operating errors by end customers.

Easy installation and maintenanceThe installation process of TOPSFLO solar water heater booster water pump is very simple and does not require complicated engineering and equipment, allowing you to quickly enjoy it at home. The TS5 water pump is small and lightweight, with a motor diameter of 46mm and can be directly fixed on the water pipe without a bracket. The high quality makes it almost free of maintenance costs. It only requires regular inspection and maintenance to remove possible impurities in the water pipes. TOPSFLO solar water heater booster pump TS5 will continue to provide long-term and reliable service for your solar water heater.

In practical applications, TOPSFLO Solar hot water Pump TS5 not only helps solar water heaters improve the hot water supply for end users, but also helps them save a lot of energy costs, and has won unanimous praise from the majority of end users. One of our end users wrote to TOPSFLO and said: "My TS5 water pump has been working perfectly for 4 years. Now I want to buy a new generation pump." Real user reviews and satisfaction guarantee are the best proof of our products.

If you have a specific working scenario or application needs and are looking for a pump solution, feel free to contact us. TOPSFLO will continue to provide you with more efficient and energy-saving solar water heater pumps.

Wanna to get pump expert recommendation or apply free sample? Contact us now:

Email: [email protected]

Whatsapp/Wechat:+86-19376691419

Offcial Web: http://www.topsflo.com/

youtube

youtube

#solarhotwaterpump#solar water heater#solar water heater booster pump#dcwaterpump#brushlessdcpump#12vdcwaterpump#bldcpump#24vdcwaterpump#12vwaterpump#dc water pump#waterpump#solar water pump#solar system#solar energy#Youtube

0 notes

Text

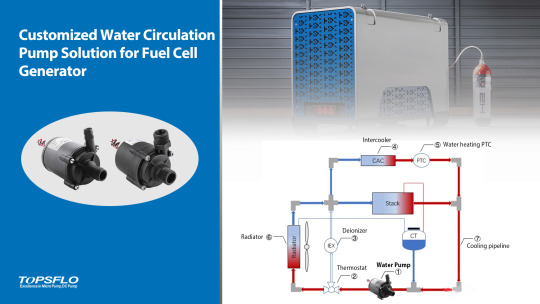

TOPSFLO Fuel Cell Generator Coolant Circulation Pump Solution

Market Overview

As power generation equipment and backup power supply, fuel cells can be widely used in transportation and industrial fields, greatly alleviating the energy pressure caused by the depletion of fossil fuels. Its zero-emission and renewable advantages make it one of the most potential energy supply solutions. The preferential policies currently implemented by various countries have promoted the rapid development of the global fuel cell market.

The system can be simply classified according to the internal electrolyte of the fuel cell: Alkaline Fuel Cell (AFC), Phosphoric Acid Fuel Cell (PAFC), Molten Carbonate Fuel Cell (MCFC), Solid Oxide Fuel Cell (SOFC), Proton Exchange Membrane Fuel Cell (PEMFC). Currently SOFC and PEMFC are the most popular research directions.

Market pain point

Research and improvement of fuel cells have always focused on improving efficiency and system operating stability, as follows:

Stable high-temperature operation: The precious metal catalyst of the fuel cell must be at an appropriate temperature to show good activity and stability. In order to ensure the most efficient electrochemical reaction, it usually needs to be stable between 80 and 95°C. If the temperature is too high or too low, the power generation efficiency will be reduced.

Precise control of water volume: In the actual operation of proton exchange membrane fuel cells (PEMFC), the dynamic water volume in the system is difficult to control. If excess water is not discharged in time, the membrane electrolyte will be flooded. If too little water is not replenished in time, it will reduce the overall performance of the battery and even have a negative impact on the life of the membrane.

Long-term stable operation: Fuel cell systems are usually designed for long-term operation. The core components of the system, such as the proton exchange membrane, need to have continuous operation performanceand a lifespan of several years to decades.All other accessories need to match its performance.

Leakage and cleanup: Core components are expensive, and system use requires regular maintenance and cleaning, and a special monitoring system. Once the pipeline liquid leaks, the electrochemical reaction will be interfered with, and even the key components of the battery stack will be corroded and damaged, polluting the environment, causing maintenance and economic losses.

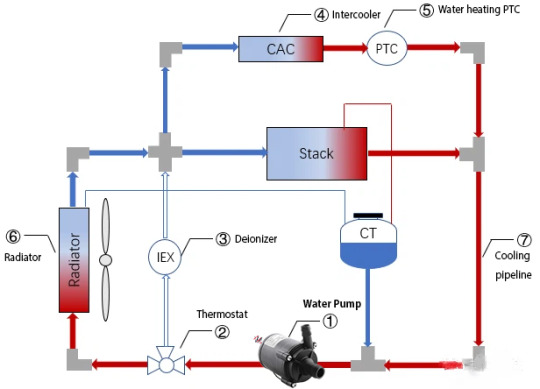

TOPSFLO Fuel Cell Water Pump Solution

Circulation water pumps play an important role in fuel cell systems, and TOPSFLO brushless centrifugal water pumps perfectly solve the needs of multiple uses:

TOPSFLO brushless dc water pump has been measured to operate continuously for 3,000 hours at a high liquid temperature of 95 degrees, and can easily cope with the high-temperature liquid circulation requirements of the battery system. TOPSFLO TL-C01 micro brushless dc water pump circuit board fully considers the temperature rise margin in the design and material selection, and has divided the strong and weak currents. It is matched with internationally renowned brand electronic components to help the system continue to maintain a stable working state.

In response to the different water management requirements of the fuel cell system under different loads and working conditions, TOPSFLO fuel cell generator cooling pump with PWM speed regulation function can be customized. That is, the battery system sensor dynamically controls the water supply of the pump based on the monitored battery load and environmental conditions such as flow, pressure, temperature, and liquid level to ensure efficient operation of the system.

The laboratory testing service life exceeds 20,000 hours, directly matching the long life requirements of the core components of the fuel cell. The moving components adopt wear-resistant design to greatly reduce operating wear. For example, without carbon brushes, self-produced ECM brushless motor, imported graphite bearings and ceramic shafts with good self-lubricating properties. Extends the life of cooling components and significantly reduces the risk of equipment repairs and downtime.

In order to ensure no leakage, TOPSFLO fuel cell generator coolant circulation pump are 100% air tight tested before leaving the factory, and the ultimate pressure can reach more than 18 Bar. As a rare moving part in the fuel cell system, high-quality water pumps can reduce the risk of pipeline leakage in the fuel cell system, ensure that core components work in a safe environment, and reduce system failure maintenance costs.

Wanna to get pump expert recommendation or apply free sample? Contact us now:

Email: [email protected]

Whatsapp/Wechat:+86-19376691419

Offcial Web: http://www.topsflo.com/

youtube

#fuel cell generator#fuelcellpump#fuel cell water pump#fuel cell pump#dcwaterpump#waterpump#brushlessdcpump#12vdcwaterpump#topsflopump#12vwaterpump#dc water pump#24vdcwaterpump#bldcpump#Youtube

0 notes

Text

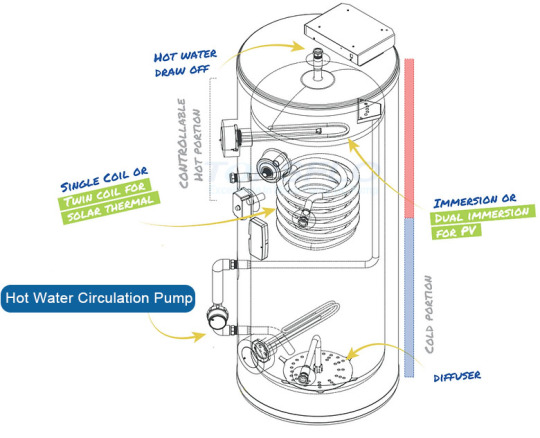

Heat Exchanger Tank Hot Water Circulation Pump Solution

Market Overview