At Deep Kalsi Electric Works, we are passionate about delivering high-quality industrial machinery to meet the needs of professionals and experts alike.https://deepkalsielectricworks.com/

Don't wanna be here? Send us removal request.

Text

New Buyer’s Checklist: What to Look for in a Welding Machine

Before investing in a welding machine, consider key factors like welding processes, input voltage, output capacity, and duty cycle. Don’t overlook the machine’s weight, portability, and features. Whether you’re a beginner or expert, reliable support matters — especially from trusted providers of arc welding equipment repair in Haryana and arc welding machine repair services in Himachal. Choose only certified ARC welding Machines for efficiency, safety, and long-term performance in any industrial or commercial setting.

0 notes

Text

150 AMP ARC Welding Machine Specifications You Should Know

The 150 AMP choke ARC Welding Machine offers precision and reliability for various metal fabrication needs. Ideal for light to medium-duty tasks, this machine supports both AC and DC operations. It features a strong choke coil for stable arc flow and superior thermal protection. Known for its energy efficiency and compact design, it's a trusted choice among ARC welding Machines. Whether for workshops or industrial use, the 150 AMP choke ARC Welding Machine ensures optimal performance.

0 notes

Text

Inside the 350 AMP Choke ARC Welding Machine: Features, Parts & Functionality

The 350 AMP choke ARC Welding Machine is built for heavy-duty industrial tasks. With advanced components, it delivers consistent performance and deep weld penetration. This 350 amp welding machine includes a durable choke, transformer, and cooling system for long-lasting use. Widely used in fabrication and construction, ARC welding machines like this ensure stable arcs and efficient energy use. Its rugged design and reliable output make it a top choice for professional welders.

#350 amp welding machine#amp welding machine#commercial#economy#entrepreneur#finance#ecommerce#founder#business#branding#investing#accounting

0 notes

Text

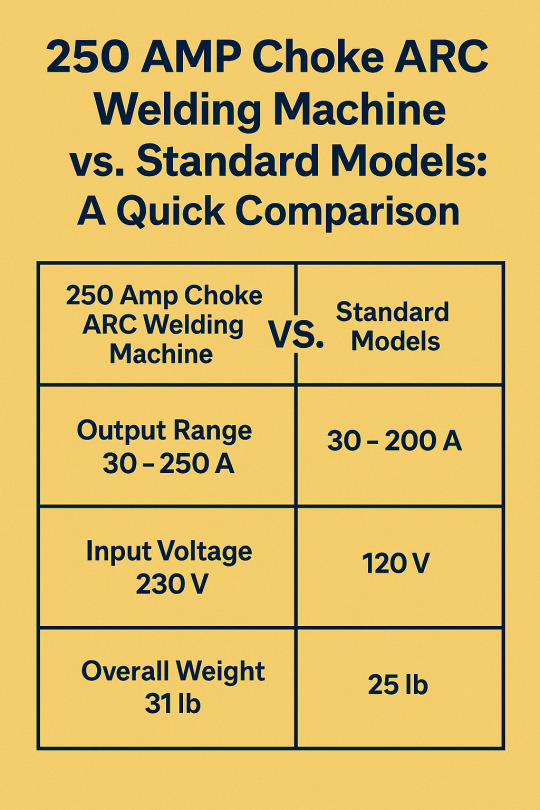

250 AMP Choke ARC Welding Machine vs. Standard Models: A Quick Comparison

Looking to upgrade your welding equipment? This quick infographic comparison highlights the key differences between the powerful 250 AMP choke ARC Welding Machine and standard models. Discover why professionals prefer the Single Holder 250 AMP ARC Welding Machine for enhanced output, better voltage compatibility, and higher durability. Ideal for industrial use, it stands out in performance and reliability. Trusted by top manufacturers of welding machines in Punjab, this machine is a game-changer for serious welders. Explore the advantages now

#250 AMP choke ARC Welding Machine#Single Holder 250 AMP ARC Welding Machine#manufacturers of welding machines in Punjab

0 notes

Text

Understanding New Welding Machines for Enhanced Productivity

The welding industry is undergoing a technological renaissance. Traditional methods are being redefined by new, advanced welding machines that boost productivity, ensure better safety, and improve overall operational efficiency. Whether you're a small workshop owner or a large industrial manufacturer, understanding the new wave of welding machines can be the key to staying competitive in a rapidly evolving market.

The Role of New Welding Machines

Modern welding machines are a far cry from the heavy, manual systems of the past. These new models, which include everything from compact mini welding machines to high-end robotic systems, are designed to cater to a wide range of industries and use cases.

Mini welding machines, for example, are revolutionizing how smaller tasks are approached. Lightweight, portable, and highly efficient, these machines are perfect for quick repairs, home use, or smaller fabrication projects. Their ease of use also makes them ideal for training new welders or handling on-site welding jobs where portability is key.

Meanwhile, automated and semi-automated machines are becoming indispensable in industrial settings. These systems not only speed up production but also deliver a level of consistency that is hard to match with manual welding. In sectors where precision and repeatability are essential—such as automotive, aerospace, and heavy machinery—automated welding technology is a game-changer.

Key Features of Modern Welding Machines

Today’s machines are equipped with features designed to meet the growing demands of the industry. These include:

Digital controls for precise adjustments

Multi-process capabilities, allowing MIG, TIG, and Stick welding with a single unit

Energy efficiency and low power consumption

User-friendly interfaces, making operation easier for both professionals and beginners

This level of innovation significantly reduces operator fatigue, lowers the chances of error, and leads to higher output in less time.

Boosting Productivity in Workshops and Industries

One of the primary advantages of investing in modern welding machines is enhanced productivity. These machines often include automated settings that adjust current, voltage, and wire feed rates in real-time. As a result, welders can achieve better weld quality with minimal effort. This not only improves the finish and strength of welds but also reduces material waste and the need for rework.

Mini welding machines play a vital role in boosting productivity on smaller scales. They are especially valuable in mobile repair services, DIY projects, and small fabrication units. The ability to perform high-quality welds on the go means fewer delays and faster project turnarounds.

Choosing the Right Supplier

As demand for advanced welding machines grows, so does the need for reliable suppliers. Finding the right partner is critical to ensuring long-term success and support.

If you are in India, two key regions stand out:

Welding machine supplier manufacturers in Rajasthan: Known for their quality craftsmanship and innovative approaches, manufacturers in Rajasthan have carved a niche for themselves in the welding equipment market. They offer everything from mini welding machines to large industrial models, backed by strong after-sales service and technical support.

Welding machine supplier manufacturers in JK (Jammu & Kashmir): Emerging as a new hub for manufacturing and engineering services, JK is home to suppliers that offer competitively priced, high-performance welding equipment. These manufacturers focus on durability, energy efficiency, and adaptability to harsh working environments, making them suitable for diverse applications.

The Future of Welding

The evolution of welding machines is set to continue, with further advancements in AI integration, real-time monitoring, and smart diagnostics. The integration of IoT in welding systems will provide remote control capabilities, data tracking, and predictive maintenance, making future machines even more reliable and productive.

For workshops and industries looking to scale operations or improve efficiency, embracing new welding technology is no longer optional—it’s essential. By investing in high-quality machines from reputable welding machine supplier manufacturers in Rajasthan or JK, and incorporating compact tools like the mini welding machine, businesses can stay ahead of the curve and meet the increasing demands of the modern manufacturing landscape.

1 note

·

View note