EMP is a global, full-service manufacturer of precision aluminum die casting products. With more than 20 years’ experience in research & development, manufacturing, and precision machining for the aluminum die casting industry, we are proud to work with some of the world’s top automotive, engineering, electronics, and telecommunications companies. https://www.empcasting.com/

Don't wanna be here? Send us removal request.

Text

POST-PROCESSING

Post-processing mainly deals with the surface of the workpiece to achieve a certain degree of smoothness and brightness, eliminates surface stress and internal stress, so that the subsequent processes can be carried out smoothly.

https://www.empcasting.com/post-processing.html

0 notes

Text

PUMP & VALVE PARTS

Pump parts

A pump is a machine for conveying or pressurizing a fluid. It transfers the mechanical energy or other external energy of the prime mover to the liquid, so that the liquid energy increases. Pump parts china are mainly used to transport water, oil, acid and alkali liquid, emulsion, suspended emulsion and liquid metal and other liquids, also can transport liquid, gas mixture and liquid containing suspended solids.

From the performance range of the pump, the flow of the giant pump per hour can reach hundreds of thousands of cubic meters above, and the flow of the micro pump per hour is in the tens of milliliters below; The pressure of the pump can be up to 19.61Mpa(200kgf/cm2) from normal pressure. The temperature of the liquid to be transported can be as low as -200 ℃ or as high as 800 ℃. Pumps transport a wide range of liquid, such as water (clean water, sewage, etc.), oil, acid and alkali, suspension, and liquid metal.

Types of Valve Parts China

For liquids, environment types and operating systems are different, so there are a variety of valve types in China, each type can meet specific needs for different occasions. Some valves can be throttled, some valves are corrosion resistant and are specially designed for specific liquids, some valves are suitable for high pressure environments, and some can stop the flow of liquids. Buyers need to choose specific valves according to different needs and commercial uses, and each product has its own advantages and disadvantages.

It is important to understand these differences and how they affect the application or operation of the valve. The methods of controlling flow can be very different. Generally speaking, there are four: Move or rotate a disc, and slide a flat, cylindrical, or spherical surface, also can control the flow according moving a flexible material into the flow passage.controlling flow has a characteristic that makes it the best choice for a given application of function. ways to control flow through the valve.

Industries of Pump Parts

In agricultural production, pump is the main drainage and irrigation machinery. Pump parts in china are in great demand. Our country rural area original broad, every year rural area needs a large number of pumps, generally speaking, agricultural pumps accounted for more than half of the total output of the pump.

In the shipbuilding industry, there are generally more than 100 pumps used on each ocean liner, and the types are various.

Others such as urban water supply and drainage, steam locomotive water, lubrication and cooling machine tools, the textile industry in the transfer of bleaching and dye, pulp in the paper industry, as well as the food industry in the transfer of milk and sugar food, all need a large number of pumps.

Valve Parts

The device that controls the flow of water in the pipeline by changing the cross section of the pipeline is called valve. Valve parts in china has many kinds, such as bottom valve, gate valve, reverse valve and flap valve.

Valve Parts details

1)The bottom valve

Also calls as one-way valve, artificial water filling to prevent leakage and use, used to prevent leakage when filling water manually.

2)Gate valves

Installed on the outlet pipe, for closing valve (low pump) start, close valve stop, adjust the flow of accessories. Single valve should be selected according to the diameter of the water pipe, valve type, performance, specifications, working pressure and other correct choice.

3)Reverse valve

Installed on the water pipe, so as to prevent accidents when stop out of the water in the pool and outlet pipe back a one-way valve.

4) Flap valve

Installed in the outlet pipe outlet, in order to prevent the water in the pool to the outlet pipe backflow of a one-way valve, generally a complete set of water pump plant supply.

https://www.empcasting.com/pump-valve-parts/

0 notes

Text

OIL PUMP HOUSING

Overview of Oil Pump Housing

The influence of automobile oil pump is to suck the gasoline out of the tank, through the pipeline and the gasoline filter pressure to the carburetor float room, so that the vehicle motor has enough power to start,so as to start the vehicle. Because of the automobile oil pump housing, the tank can be placed at away from the back of the car, below the motor.

Application of Oil Pump Housing

Petrol vehicle oil pump housing

The Specification of Oil Pump Housing

Material

Aluminum alloy :A380 ,ADC12

Casting Process

HPDC

Die Casting Machine

280~400T

Weight

0.2~0.5 kg

Dimension

100*50*100~150*60*100mm

Annual Volume

200,000 per year

Porosity requirements

ASTM E505 Level 2

Leakage test requirement

0.3Mpa

Application

Hybrid Electric Vehicle

https://www.empcasting.com/oil-pump-housing.html

0 notes

Text

MARKET PATTERN OF ALUMINUM ALLOY DIE CASTING IN CHINA

The global die casting manufacturing center is transferred to the mainland of China. China's precision die casting enterprises are mainly distributed in Guangdong, Jiangsu, Zhejiang, and other places. Most of the large-scale and specialized enterprises are concentrated in the Pearl River Delta and the Yangtze River Delta. Due to the dominant position of Asia, especially China, in market demand, raw material supply, labor resources, industrial chain supporting, policy support, and the rapid development of China's automobile industry, since the 21st century, the global die casting production has shown a trend of transfer to Asia, especially to the mainland of China, which is still continuing. The expansion of market scale and the entry of international excellent enterprises have promoted the technical level and management level of domestic die casting manufacturers, and further promoted the development of the industry. China has formed the Yangtze River Delta, Pearl River Delta, northeast three provinces, southwest region and other pressure casting industrial clusters, of which the Yangtze River Delta and the Pearl River Delta are the most prominent. The two regions have an active economy, developed supporting industries and obvious regional advantages.

Advantages of Aluminium Parts in Automobile

Under the premise of ensuring vehicle strength and safety performance, vehicle lightweight can improve vehicle power, reduce fuel consumption and exhaust pollution by reducing vehicle quality. Reducing the mass of different parts such as body, interior, and exterior decoration, power system and so on will help to reduce the energy consumption in the process of driving. Aluminium parts in automobile is light, recyclable and easy to form, so it is widely used in the automobile body and parts. In theory, automotive aluminum parts can reduce the weight of steel cars by as much as30% - 40%, of which aluminum engine can reduce 30%, the aluminum radiator is 20% - 40% lighter than copper, the all-aluminum body is 40% lighter than steel, and aluminum hub of the automobile can reduce 30%. Therefore, aluminum alloy material is an ideal material for automobile lighting.

Reducing the vehicle weight can reduce the engine load, improve the driving performance of the vehicle, effectively reduce the braking distance, make the steering and bending process more flexible so that the vehicle is more stable, and the aluminum alloy structure can absorb and disperse more energy when impacted, so it is more comfortable and safe. As a result, in the next decade, the aluminum penetration rate of all major parts of the car will be significantly increased, and the penetration rate of the aluminum engine hood is expected to increase from48% in 2015 will increase to 85% in 2025, and the penetration rate of aluminum doors will increase from 6% in 2015 to 46% in 2025. Specifically reflected in the average aluminum consumption per vehicle in North America in 1975, the average aluminum consumption per vehicle in North America was 38kg, which increased to 180kg in 2015. In 40 years, the aluminum consumption per vehicle in North America continued to increase, with a compound growth rate of 4%. It is estimated that China will achieve 190kg / vehicle aluminum consumption in 2020, which is in line with North America, with a corresponding market space of about 152 billion yuan.

The concentration of the die-casting industry in China is relatively low. There are about there are more than 12000 enterprises, of which more than 70% are die-casting enterprises. The enterprises are mainly distributed in Guangdong, Jiangsu, Chongqing, and other places. Most of the large-scale and specialized enterprises are concentrated in the Pearl River Delta and the Yangtze River Delta, and the proportion of large-scale die-casting enterprises is only about 10%. There are two main types of domestic enterprises with large production scale of automobile die-casting, one is the supporting enterprise of automobile field, which is subordinate to the group company of downstream industry; the other is the independent automobile precision die casting production enterprise, which is specialized in the production of automotive casting components, and has established a relatively stable long-term cooperation relationship with downstream customers.

https://www.empcasting.com/market-pattern-of-aluminum-alloy-die-casting-in-china.html

0 notes

Text

MACHINERY PARTS

Mechanical parts are the basic components of machinery, which are the indivisible parts of machinery and machine. As a key part of the machinery, the quality of mechanical parts plays a very important role in the normal operation of machinery, so it is very important to choose high-quality mechanical parts. EMP Tech is a professional machinery parts manufacturer, offering high-quality machinery engine parts and attractive prices at the same time.

Machinery Engine Parts FAQs

Q How do I identify machinery engine parts?

A Part is the most basic unit, component is composed of parts, if it can move, it is a mechanism. Generally speaking, parts make up components, components make up mechanism, and mechanism makes up machine. Components can also be parts, such as large box parts, also known as components. Generally, weldments shall be treated as components.

Q What is engine and its types?

Q What is the most important part of an engine?

Q What machines are used in agriculture?

Q What are the advantages of mechanization in agriculture?

Q What are the basic machinery engine parts of an engine?

https://www.empcasting.com/machinery-parts/

0 notes

Text

HOW TO AVOID THE ALUMINUM DIE-CASTING GETS BLACKENED AFTER SHOT BLASTING?

The reasons for blackened aluminum die casting parts after shot blasting are:

1. The dust removal is not done in the equipment during shot blasting;

2. There are oil stains, mold release and moisture on the casting surface;

3. Stainless steel pellets are not pure enough.

To prevent the aluminum die casting parts from blackening after shot blasting, here is some suggestion:

1. The shot blasting equipment must have a relatively complete automatic dust removal effect;

2. The surface of the casting should not be contaminated with oil, mold release agent, moisture or other impurities. If necessary, the casting should be washed and dried before shot blasting;

3. Purchase pure steel shots, if necessary, add 10 ~ 30% aluminum shots to increase the whiteness after shot blasting. The specific amount depends on the requirement of the parts.

https://www.empcasting.com/how-to-avoid-the-aluminum-die-casting-gets-blackened-after-shot-blasting.html

0 notes

Text

HEAT SINK HOUSING

The heat sink enclosure uses aluminum with a high thermal conductivity as the main body of the heat sink, which has the advantages of light weight, corrosion resistance, strong thermal conductivity, non-magnetic and strong plasticity. Heat sink enclosure can be customized according to customer drawings.

Overview of aluminum heat sink enclosure

Aluminum is light in weight and easy to manufacture. Aluminum alloy is the most common radiator material. The cost of aluminum is lower than that of copper and has high performance-to-price ratio, so it is an ideal choice for most radiators. Its heat transfer capacity, or thermal conductivity, is about half that of copper. This limits the distance at which heat moves and conducts from the heat source in the radiator base. The radiator is designed to maximize the surface area in contact with the coolant.

https://www.empcasting.com/heat-sink-housing.html

0 notes

Text

FRICTION WELDING

Friction welding overview

Friction welding is a pressure welding method that uses the heat generated by the relative frictional movement of the weldment to achieve reliable connection of materials.

The welding process is under the effect of pressure, the friction between the materials to be welded increases the temperature of the interface and its vicinity and reaches in the thermoplastic state, with the action of upsetting force, the interface oxide film is broken, the material undergoes plastic deformation and flow, and the joint is formed by the interface element diffusion and recrystallization metallurgical reaction.

EMP Tech Co., Ltd, offering professional friction welding services, can finish many kinds of friction welding, including the continuous drive friction welding, rotational friction welding and orbital friction welding, etc..

Friction welding aluminum

The surface temperature of friction welding is the temperature of the heat source of friction welding, which will directly affect the heating temperature and temperature distribution of the joint and the deformation and diffusion of the joint metal. In the process of friction heating, the friction surface can also adjust the friction heating power through the influence of the friction coefficient, so that the heating power and the temperature of the heat source are in balance. Welding test and production practice show that when the diameter of the workpiece increases, the rotation number increases and the friction pressure increases, the temperature of the friction welding surface increases. Otherwise, the surface temperature of friction welding will be reduced.

Friction welding services overview

Heating deforms the material, and the rotating tool stirs the material at the weld. In this way, friction welding technology creates a uniform structure with excellent performance. The whole process is emission-free. When welding must be very tight, friction welding is the preferred method. It can connect the workpiece with repeatable pressure and medium seal. Friction welding can be optimized and integrated into industrial batch production. The result is top quality that is easy to copy.

As a machinery parts manufacturer, we provide various products and services in this area, and actually friction welding services and production, continuous drive friction welding, phase-controlled friction welding, inertial friction welding and friction stir welding are more common used.

Advantages of friction welding services

Durable, medium-sealed and pressure-sealed welds.

Height, repeatable seam quality.

Low warping joint.

No pores or hot cracks.

No exhaust emissions, no shielding gas, powder, welding wire and other auxiliary materials.

In actual friction welding services and production, continuous drive friction welding, phase-controlled friction welding, inertial friction welding and friction stir welding are more common.

Friction welding machine is mainly used for welding of medium-sized shaft parts. It can weld a wide range of metals, and has the characteristics of stable performance, high production efficiency and low energy consumption, which is important for friction welding companies.

Orbital friction welding

Rail friction welding is similar to rotary friction welding, but the two welding parts of rail friction welding rotate in the same direction and at the same speed,with axes offset up to 3 mm. At the end of the welding, the two parts return to the common shaft, the relative motion ends, and the welding relay remains intact or increases. Rail friction welding has the advantage of uniform surface velocity in the whole contact zone. You can connect non-circular components and multiple individual parts in a friction welding sequence. Although rail friction welding has been demonstrated in many materials and joint configurations, it is rarely used in industry.

https://www.empcasting.com/friction-welding.html

0 notes

Text

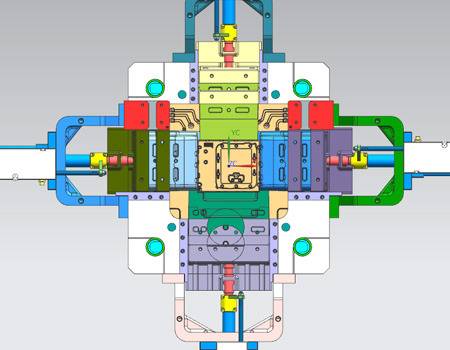

TOOLING DESIGN/MOLD DESIGN

2D / 3D PARTING DESIGN

MOULD RANK DESIGN

Confirm the size of the mold core and the mold base according to the product size, and reasonably distribute the ejection system, injection system and overflow system of the mold.

RUNNER DESIGN

The design of the runner system is based on the structure and special characteristics of the product.

OVERFLOW SYSTEM DESIGN

The design of the overflow material system is based on the structure and special characteristics of the product.

TOOLING DESIGN OVERVIEW

New technology is breaking through constantly, driven by innovative thinking. The die casting tool design team carries out new product development through professional 3D model design as well as mold flow analysis and validation to assure customers with satisfactory products.

Mold workshop is equipped with a group of professional mold design&manufacturing engineers who are proficient at computer software such as 2D/3D to assist mold design, manufacturing machines which includes CNC machining centers, EDM, WEDM, universal milling machines, friction welding equipment, etc.

DIE CASTING DESIGN FOR MANUFACTURING

Optimizing die casting process is an important step to improve efficiency and optimize die casting design. All types of die casting are used for production, so it is very important to consider the production process in the design process. Pursue the efficiency of manufacturing and reduce secondary operations, which is called "Design for manufacturing" to minimize costs before the project is put into operation, in order to prevent the reduction of efficiency.

TOOLING DESIGN PROCESS

EMP has advanced engineering and works cooperatively with customers with well-designs for cost-effective fabrication.

At the beginning, to meet customer’s requirements, we will communicate with the customers to discuss more details per drawings and gather their needs. Then we use tools such as FEA, mold flow simulation to clarify and identify critical open issues that could be resolved to make sure producing the part successfully.

In addition, some prototyping options also support our product development and casting part design process. As one of the top 10 aluminium die casting manufacturers in China, EMP, with die casting mold and tools factory, can provide rapid prototypes within 20 to 35days and HPDC components – all with engineering support to see results and recommend if necessary changes.

Advanced Product Quality Planning Process

Product Design in CAD/CAM, Pro/Engineer, CATIA, or Nx

Rapid Prototyping

Mold Flow Analysis

Die Design for Die Casting Tools

Die Casting Tooling Acquisition & Technical Review

https://www.empcasting.com/die-casting-tooling-mold-design/

0 notes

Photo

Die base is a tool for casting metal parts, a tool that completes the die-casting process on a dedicated die-casting die forging machine. Can be customized by drawings.

https://www.empcasting.com/die-base.html

0 notes

Photo

Overview of Cylinder Head Cover

There are three types of cylinder heads include flathead, overhead valve and overhead camshaft cylinder heads, each of which can be made of cast-iron or aluminum material, depending upon the specific system in which they are being used in. Our Cylinder Head Cover is made of aluminum alloy. In general, aluminum alloy is lighter and has stronger heat dissipation potential than any other material. Meanwhile, Why choose aluminum alloy to be the material of cylinder head cover? Not only aluminum cylinder head cover can reduce the weight of the car, but also improve the heat dissipation effect of the engine.Cylinder head covers serve to seal off the cylinder head space from the outside of the engine. As a result of operation of the internal combustion engine, blow-by gases from the combustion process and oil droplets from the lubricant system of the engine are present inside the cylinder head.

A cylinder head is usually located on the top of the engine block. It serves as a housing for components such as the intake and exhaust valves, springs and lifters and the combustion chamber.

https://www.empcasting.com/cylinder-head-cover.html

0 notes

Photo

Commonly used custom brackets are automobile generator brackets, engine brackets, and seat brackets.

https://www.empcasting.com/custom-bracket-adc12-aluminum-die.html

0 notes

Photo

CNC Machining is directly changing the size, shape, mutual position, surface roughness or properties of raw materials or semi-finished products to make them into finished products.

Including: casting, welding, electroplating, heat treatment, machining and assembly processes.

https://www.empcasting.com/cnc-machining.html

0 notes

Photo

Overview of auto starter parts

What is auto starter?Engine starting needs external support, the car starter is playing this role. Generally speaking, the starter use three parts to realize the whole starting process. The DC motor introduces the current from the battery and causes the driving gear of the starter to produce mechanical movement. The driving mechanism meshes the driving gear into the gear ring of the flying wheel and can automatically detach after the engine starts. The opening and closing of the starter circuit is controlled by an electromagnetic switch.Among them, the motor is the main internal part of the starter.

The starter is the core part of the starting system. The starter consists of three parts:DC series motor, transmission mechanism and control device in which there contain aluminum alloy parts of end cover, casing, and one-way clutch. Why there needs aluminum alloy part in a starter?Generally speacking, aluminum alloy is lighter and has stronger heat dissipation potential than any other material.

https://www.empcasting.com/auto-starter-parts.html

0 notes

Photo

ELECTRIC VEHICLE PARTS

Battery Electric Vehicles (BEVs) also known as New Energy Vehicles (NEVs) are made up of three main segments: the traction motor, the battery pack, and the electrical control units. EMP Die Casting specializes in not only the production of the larger BEV/NEV parts, but also the smaller sub-assemblies that make up each segment of the vehicle.

https://www.empcasting.com/automotive-parts/

0 notes

Photo

The mounting bracket is made of aluminum alloy, which can not only be integrated, but also stable and safe.

https://www.empcasting.com/aluminum-mouting-bracket.html

0 notes

Photo

Aluminum Die Casting Valve Parts Product Details:

1. Specification: Custom-made

2. Service: OEM/ODM Service

3. Material: Aluminum alloy

4. Application: Automobile,Truck,EV car,machinery

5. Die Casting Machine Type: Cold Chamber Die Casting Machine

6. Quality Control System: IATF16949, ISO9001:2015

7. Apllied Software: PRO/E, Auto CAD, Solid Works,IGS,UG, CAD/CAM/CAE

8. Surface Treatment: Sandblasting, Deburring, Sanding, CNC Machining, Powder Coating

https://www.empcasting.com/aluminum-die-casting-valve-parts.html

0 notes