Enclosure Shop is a leading UK supplier of high-quality GRP and Stainless Steel enclosures, providing durable, weather-resistant solutions for a wide range of industries. We offer an extensive selection of enclosures designed to protect electrical systems, telecom equipment, and other valuable assets. With a strong focus on quality, performance, and customer satisfaction, Enclosure Shop help businesses safeguard their infrastructure with confidence. Explore our products and find the ideal enclosure solution tailored to your needs.

Don't wanna be here? Send us removal request.

Text

The Importance of IP Ratings in Electrical Enclosures

In industrial, commercial, and even residential settings, electrical enclosures play a crucial role in protecting sensitive equipment from environmental hazards. Whether housing critical control systems or safeguarding simple wiring, the enclosure you choose must be capable of withstanding the specific environmental conditions it will face. One of the most important factors when selecting the right electrical enclosure is understanding IP ratings.

The IP rating (Ingress Protection rating) is a globally recognized standard that classifies the degree of protection an enclosure provides against solids and liquids. Simply put, IP ratings help you assess how well an enclosure will protect internal components from dust, dirt, moisture, and other environmental challenges.

In this blog, we will explore why IP ratings matter, how they impact safety and equipment longevity, and how they apply to solutions like Top Outdoor Walk-In Electrical Cabinets and Stainless Steel Electrical Enclosures.

What Are IP Ratings?

The IP rating system is defined by the international standard IEC 60529. IP ratings consist of the letters "IP" followed by two digits.

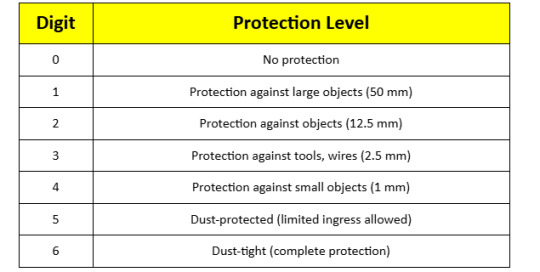

The first digit indicates the level of protection against solid objects (like dust and debris).

The second digit indicates the level of protection against liquids (like rain, splashes, or even immersion).

For example:

IP65: Complete protection against dust (6) and protection against low-pressure water jets from any direction (5).

IP68: Complete dust protection (6) and protection against long periods of immersion under pressure (8).

Understanding IP ratings helps ensure you select enclosures that meet the operational and environmental requirements of your equipment.

Why Are IP Ratings Important?

1. Protection Against Environmental Hazards

Electrical components are vulnerable to dust, water, and chemical exposure. A properly rated enclosure shields these components, ensuring reliable operation even in challenging environments. This is especially vital for Top Outdoor Walk-In Electrical Cabinets that are continuously exposed to harsh outdoor conditions.

2. Safety Compliance

Regulatory agencies often require specific IP ratings for electrical installations to minimize the risk of electrical shock, fire, and equipment failure. Choosing the correct IP-rated enclosure ensures compliance with local and international safety standards.

3. Equipment Longevity

Proper sealing prevents moisture and dust from damaging sensitive equipment, which can extend the life of your devices and reduce costly repairs or replacements.

4. Cost Efficiency

Preventing exposure to dust and water minimizes breakdowns, saving money on maintenance and reducing downtime.

5. Custom Application Suitability

Some environments, like food processing plants or outdoor substations, require specialized enclosures. For example, stainless steel electrical inclosures with high IP ratings are perfect for hygienic or corrosive conditions.

Understanding the IP Rating Breakdown

Let’s break down the IP rating digits more specifically:

First Digit: Protection Against Solids

Second Digit: Protection Against Liquids

Choosing the Right IP Rating for Your Application

The correct IP rating depends on where and how the electrical enclosure will be used.

For Outdoor Installations

Top Outdoor Walk-In Electrical Cabinets typically require a minimum of IP65 or higher to protect against dust, rain, and other environmental factors. These enclosures are often found in:

Electrical substations

Solar farms

Telecommunications infrastructure

Industrial process control stations

Walk-in cabinets provide ample space for complex electrical systems and personnel access while offering strong environmental protection. When properly rated, they prevent system failures due to weather exposure and ensure technician safety during maintenance.

For Hygienic or Corrosive Environments

Stainless Steel Electrical Enclosures with high IP ratings (often IP66 or IP67) are ideal for areas exposed to water, steam, and chemicals, such as:

Food and beverage processing plants

Pharmaceutical facilities

Chemical manufacturing sites

Marine and coastal applications

Stainless steel offers excellent corrosion resistance and is easy to clean, making it a preferred material where hygiene and longevity are critical.

IP Ratings in Top Outdoor Walk-In Electrical Cabinets

Walk-in electrical cabinets are essential for large-scale electrical and data infrastructure. These cabinets must often endure:

Heavy rainfall

Dust storms

UV exposure

Varying temperatures

To perform reliably in such demanding conditions, top outdoor walk-in electrical cabinets should typically have:

IP65 or higher to guard against dust ingress and water jets

Rugged stainless steel or powder-coated steel construction

Proper ventilation with protected filters

Optional climate control systems to manage internal temperature

Selecting walk-in cabinets with an appropriate IP rating ensures the internal equipment remains safe, even in extreme weather.

IP Ratings in Stainless Steel Electrical Enclosures

Stainless steel electrical inclosures offer a perfect combination of durability and high ingress protection. They are particularly suited for:

Outdoor control panels

Harsh industrial settings

Locations where hygiene is paramount

The most commonly used stainless steel grade is 316L, which provides superior resistance to corrosion, especially in salty or chemically aggressive environments.

For these enclosures, the ideal IP ratings often range from IP66 to IP68, providing protection against high-pressure cleaning, heavy splashes, and even submersion, if necessary.

Some benefits of stainless steel enclosures with high IP ratings include:

Easy cleaning: Perfect for sanitary environments.

Corrosion resistance: Long service life in aggressive conditions.

Impact resistance: Withstands accidental hits and vibrations.

Aesthetic appeal: Stainless steel maintains a clean, modern look.

Common Mistakes When Selecting IP Ratings

When choosing electrical enclosures, some common mistakes to avoid include:

Underestimating Environmental Factors: Assuming indoor locations don't need high IP ratings can lead to early equipment failure due to condensation, dust, or accidental spills.

Ignoring Long-Term Exposure: Outdoor cabinets must withstand years of rain, dust, and UV radiation. A low IP rating can result in corrosion and moisture damage over time.

Focusing Solely on IP Rating: While critical, the IP rating is only one aspect. Material choice, ventilation, and temperature control must also be considered.

Over-Specifying Unnecessarily: Selecting an IP68-rated enclosure for a dry, climate-controlled environment may lead to unnecessary expenses without added benefits.

Conclusion

Understanding IP ratings is essential when selecting electrical enclosures, whether you’re protecting small wiring systems or managing large outdoor control stations. The right IP rating ensures that your equipment remains safe, functional, and compliant with safety regulations.

For demanding applications like top outdoor walk-in electrical cabinets, high IP ratings are non-negotiable to guarantee protection against harsh weather and environmental stress. Similarly, stainless steel electrical enclosures with proper IP ratings provide unmatched durability, corrosion resistance, and hygiene benefits for industries like food processing and pharmaceuticals.

By selecting the correct IP-rated enclosure, you can significantly increase the longevity of your electrical equipment, improve safety, and ensure smooth operation in even the toughest conditions.

If you’re planning an installation or upgrade, always consult with enclosure experts to choose the right balance of material, IP rating, and additional protective features for your specific application.

#IP Ratings Explained#Electrical Enclosure Protection#IP65 vs IP66 Enclosures#Weatherproof Enclosures#Outdoor Electrical Cabinets#GRP Enclosures UK#Stainless Steel Enclosures#Industrial Enclosure Standards#IP Rating Guide UK#Enclosure Safety and Compliance#Best Electrical Enclosures for Outdoor Use#Electrical Housing Protection Levels#Ingress Protection Code#IP Rated Cabinets UK#Choosing the Right Enclosure

0 notes

Text

Understanding Feeder Pillars: Key Functions, Types, and How to Choose the Right One

Feeder pillars are essential components in modern electrical distribution systems. They play a critical role in ensuring the safe and efficient management of electricity, especially in outdoor environments such as streets, parks, industrial areas, and commercial complexes. Often referred to as power distribution cabinets or service pillars, these enclosures serve as the central point for controlling and distributing electrical power to multiple circuits from a single input source.

Feeder pillars not only enhance operational safety and flexibility but also provide easy access for maintenance and emergency isolation of electrical loads. In this comprehensive guide, we'll explore what feeder pillars are, their primary functions, the various types available on the market, how to select the most suitable option for your specific application, and practical maintenance tips to ensure long-term, reliable performance.

What is a Feeder Pillar?

A feeder pillar, also known as a power distribution box or control panel, is an outdoor electrical cabinet used to house electrical equipment like circuit breakers, switches, and fuses. These units act as centralized points where power is received from the main distribution line and distributed to various circuits or sub-panels.

Feeder pillars are usually made of durable materials such as galvanized steel, stainless steel, or weather-resistant plastics to protect against environmental hazards like rain, dust, and UV rays. They come in different sizes and configurations to cater to diverse voltage levels and current ratings.

Their modular design allows easy customization, making them adaptable to specific site and system requirements. Whether in compact residential areas or sprawling industrial zones, feeder pillars serve as a backbone of reliable power distribution.

Key Functions of Feeder Pillars

Feeder pillars serve several important functions in an electrical network:

Power Distribution: They receive electricity from the main supply and distribute it efficiently to multiple endpoints.

Circuit Protection: By housing protective devices like fuses and circuit breakers, they help prevent electrical faults such as short circuits and overloads.

Isolation and Switching: They allow safe isolation of electrical circuits for maintenance or emergencies.

Metering and Monitoring: Some advanced feeder pillars include metering devices to monitor electricity usage and performance.

Integration with Automation Systems: Feeder pillars can be equipped with smart controllers or communication interfaces for remote monitoring and automation.

Additionally, they ensure that power delivery is seamless, reducing downtime and improving overall system reliability.

Common Applications of Feeder Pillars

Feeder pillars are versatile and used across various sectors, including:

Street Lighting Systems

Parks and Public Spaces

Residential Complexes and Townships

Shopping Centers and Commercial Buildings

Industrial Plants and Factories

Construction Sites

Marinas and Ports

Their adaptability and robust design make them a go-to solution for reliable outdoor power distribution. They are also increasingly used in renewable energy applications, such as solar farms and wind turbine installations, for controlling and monitoring energy output.

Types of Feeder Pillars

Feeder pillars are classified based on several factors, including design, function, and protection level. Here are the most common types:

a. Based on Installation and Configuration

Floor-Mounted Feeder Pillars: Commonly installed at ground level; suitable for public spaces and industrial areas.

Wall-Mounted Feeder Pillars: Fixed to walls or panels; used in constrained spaces.

b. Based on Protection and Safety Features

Weatherproof Feeder Pillars: Designed for outdoor use, offering protection against rain, dust, and corrosion (typically rated IP55 or above).

Fire-Resistant Feeder Pillars: Built with fire-retardant materials for high-risk environments.

c. Based on Use and Control Options

Manual Feeder Pillars: Operated manually via switches and breakers.

Smart or Automated Feeder Pillars: Integrated with automation systems, sensors, and communication interfaces for remote control.

d. Based on Application

Street Lighting Feeder Pillars: Specifically designed to control and protect street lighting circuits.

Industrial Feeder Pillars: Heavy-duty units with high current capacities and enhanced safety mechanisms.

Temporary Feeder Pillars: Portable units used on construction sites and events for short-term power distribution.

Some specialized variants also offer hybrid functionalities, supporting both AC and DC systems for projects requiring flexible voltage handling.

Components Inside a Feeder Pillar

A typical feeder pillar contains various electrical components, such as:

Circuit breakers (MCBs, MCCBs)

Contactors

Relays

Terminal blocks

Surge protection devices

Energy meters

Control switches

Fuses

Busbars

Earth terminals

The configuration depends on the application and the level of control and protection required. In automated models, you'll also find PLCs (Programmable Logic Controllers) and IoT-based communication modules.

Materials and Construction

Durability is a crucial factor in feeder pillar design. Common construction materials include:

Mild Steel (Powder Coated): Affordable and moderately weather-resistant.

Stainless Steel: Excellent corrosion resistance; ideal for marine or industrial environments.

Glass Reinforced Polyester (GRP): Lightweight, rust-proof, and highly durable.

Feeder pillars are generally fabricated with double walls or ventilation features to dissipate heat and prevent internal overheating. Some also come with anti-condensation heaters and cable entry glands to ensure uninterrupted performance.

Standards and Compliance

To ensure safety and reliability, feeder pillars must comply with national and international standards such as:

IEC 61439 – Low-voltage switchgear and controlgear assemblies

BS EN 60529 – Degrees of protection (IP code)

IS 8623 – Indian standard for low-voltage switchgear

CE Marking – Indicates compliance with European safety standards

Always check for certification and conformity before purchase. Compliance also ensures insurance compatibility and simplifies regulatory approval processes.

How to Choose the Right Feeder Pillar

Selecting the appropriate feeder pillar involves assessing several key factors:

a. Load Requirements

Determine the total current and voltage your system will handle.

Choose a feeder pillar rated slightly higher than your expected load.

b. Environment and Location

Consider climate, exposure to elements, and risk factors like flooding or vandalism.

Opt for IP-rated, corrosion-resistant materials for outdoor installations.

c. Application Type

Select feeder pillars based on their specific application (e.g., lighting, industrial machinery, construction sites).

d. Control and Monitoring Needs

Do you need remote access or automation? Go for smart feeder pillars with integrated communication features.

e. Future Expansion

Choose a model with spare capacity and modular design to accommodate future load increases.

f. Budget and Warranty

Balance cost with quality and features. Look for warranties that ensure long-term reliability.

Also consider the ease of installation and availability of after-sales service when choosing a vendor or brand.

Installation Guidelines

Ensure a level and stable base, preferably a concrete slab.

Follow manufacturer instructions for cable routing and earthing.

Use proper sealing to prevent ingress of dust and water.

Ensure proper segregation of high and low-voltage components.

Professional installation is recommended for safety and compliance. Using certified electricians can prevent costly errors and ensure the system meets local codes.

Maintenance and Safety Tips

Regularly inspect for signs of wear, corrosion, or overheating.

Test circuit breakers and safety devices periodically.

Clean internal components to prevent dust accumulation.

Keep logs of maintenance and any repairs performed.

Also, ensure proper lock-out/tag-out procedures are in place before servicing. Using infrared scanning for hotspot detection can help in early fault identification.

Conclusion

Feeder pillars are indispensable in electrical distribution systems, offering a safe and organized way to manage power. Their wide-ranging types and features make them suitable for various applications—from street lighting to industrial power control. Understanding the key functions, types, and selection criteria ensures you invest in the right solution for your needs.

Whether for urban infrastructure, industrial operations, or temporary power setups, choosing the right feeder pillar enhances safety, reliability, and operational efficiency. For specialized applications, consider options like root-mounted feeder pillars, which provide robust and secure installation for demanding environments. Always consult with professionals and adhere to standards to make the most out of your investment in power distribution systems.

As technology continues to evolve, future-ready feeder pillars will likely incorporate more smart features, better sustainability, and increased customization. Investing wisely today ensures resilient, scalable, and safe energy management for tomorrow.

1 note

·

View note