#Ingress Protection Code

Explore tagged Tumblr posts

Text

The Importance of IP Ratings in Electrical Enclosures

In industrial, commercial, and even residential settings, electrical enclosures play a crucial role in protecting sensitive equipment from environmental hazards. Whether housing critical control systems or safeguarding simple wiring, the enclosure you choose must be capable of withstanding the specific environmental conditions it will face. One of the most important factors when selecting the right electrical enclosure is understanding IP ratings.

The IP rating (Ingress Protection rating) is a globally recognized standard that classifies the degree of protection an enclosure provides against solids and liquids. Simply put, IP ratings help you assess how well an enclosure will protect internal components from dust, dirt, moisture, and other environmental challenges.

In this blog, we will explore why IP ratings matter, how they impact safety and equipment longevity, and how they apply to solutions like Top Outdoor Walk-In Electrical Cabinets and Stainless Steel Electrical Enclosures.

What Are IP Ratings?

The IP rating system is defined by the international standard IEC 60529. IP ratings consist of the letters "IP" followed by two digits.

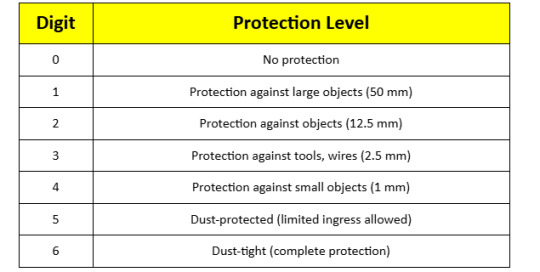

The first digit indicates the level of protection against solid objects (like dust and debris).

The second digit indicates the level of protection against liquids (like rain, splashes, or even immersion).

For example:

IP65: Complete protection against dust (6) and protection against low-pressure water jets from any direction (5).

IP68: Complete dust protection (6) and protection against long periods of immersion under pressure (8).

Understanding IP ratings helps ensure you select enclosures that meet the operational and environmental requirements of your equipment.

Why Are IP Ratings Important?

1. Protection Against Environmental Hazards

Electrical components are vulnerable to dust, water, and chemical exposure. A properly rated enclosure shields these components, ensuring reliable operation even in challenging environments. This is especially vital for Top Outdoor Walk-In Electrical Cabinets that are continuously exposed to harsh outdoor conditions.

2. Safety Compliance

Regulatory agencies often require specific IP ratings for electrical installations to minimize the risk of electrical shock, fire, and equipment failure. Choosing the correct IP-rated enclosure ensures compliance with local and international safety standards.

3. Equipment Longevity

Proper sealing prevents moisture and dust from damaging sensitive equipment, which can extend the life of your devices and reduce costly repairs or replacements.

4. Cost Efficiency

Preventing exposure to dust and water minimizes breakdowns, saving money on maintenance and reducing downtime.

5. Custom Application Suitability

Some environments, like food processing plants or outdoor substations, require specialized enclosures. For example, stainless steel electrical inclosures with high IP ratings are perfect for hygienic or corrosive conditions.

Understanding the IP Rating Breakdown

Let’s break down the IP rating digits more specifically:

First Digit: Protection Against Solids

Second Digit: Protection Against Liquids

Choosing the Right IP Rating for Your Application

The correct IP rating depends on where and how the electrical enclosure will be used.

For Outdoor Installations

Top Outdoor Walk-In Electrical Cabinets typically require a minimum of IP65 or higher to protect against dust, rain, and other environmental factors. These enclosures are often found in:

Electrical substations

Solar farms

Telecommunications infrastructure

Industrial process control stations

Walk-in cabinets provide ample space for complex electrical systems and personnel access while offering strong environmental protection. When properly rated, they prevent system failures due to weather exposure and ensure technician safety during maintenance.

For Hygienic or Corrosive Environments

Stainless Steel Electrical Enclosures with high IP ratings (often IP66 or IP67) are ideal for areas exposed to water, steam, and chemicals, such as:

Food and beverage processing plants

Pharmaceutical facilities

Chemical manufacturing sites

Marine and coastal applications

Stainless steel offers excellent corrosion resistance and is easy to clean, making it a preferred material where hygiene and longevity are critical.

IP Ratings in Top Outdoor Walk-In Electrical Cabinets

Walk-in electrical cabinets are essential for large-scale electrical and data infrastructure. These cabinets must often endure:

Heavy rainfall

Dust storms

UV exposure

Varying temperatures

To perform reliably in such demanding conditions, top outdoor walk-in electrical cabinets should typically have:

IP65 or higher to guard against dust ingress and water jets

Rugged stainless steel or powder-coated steel construction

Proper ventilation with protected filters

Optional climate control systems to manage internal temperature

Selecting walk-in cabinets with an appropriate IP rating ensures the internal equipment remains safe, even in extreme weather.

IP Ratings in Stainless Steel Electrical Enclosures

Stainless steel electrical inclosures offer a perfect combination of durability and high ingress protection. They are particularly suited for:

Outdoor control panels

Harsh industrial settings

Locations where hygiene is paramount

The most commonly used stainless steel grade is 316L, which provides superior resistance to corrosion, especially in salty or chemically aggressive environments.

For these enclosures, the ideal IP ratings often range from IP66 to IP68, providing protection against high-pressure cleaning, heavy splashes, and even submersion, if necessary.

Some benefits of stainless steel enclosures with high IP ratings include:

Easy cleaning: Perfect for sanitary environments.

Corrosion resistance: Long service life in aggressive conditions.

Impact resistance: Withstands accidental hits and vibrations.

Aesthetic appeal: Stainless steel maintains a clean, modern look.

Common Mistakes When Selecting IP Ratings

When choosing electrical enclosures, some common mistakes to avoid include:

Underestimating Environmental Factors: Assuming indoor locations don't need high IP ratings can lead to early equipment failure due to condensation, dust, or accidental spills.

Ignoring Long-Term Exposure: Outdoor cabinets must withstand years of rain, dust, and UV radiation. A low IP rating can result in corrosion and moisture damage over time.

Focusing Solely on IP Rating: While critical, the IP rating is only one aspect. Material choice, ventilation, and temperature control must also be considered.

Over-Specifying Unnecessarily: Selecting an IP68-rated enclosure for a dry, climate-controlled environment may lead to unnecessary expenses without added benefits.

Conclusion

Understanding IP ratings is essential when selecting electrical enclosures, whether you’re protecting small wiring systems or managing large outdoor control stations. The right IP rating ensures that your equipment remains safe, functional, and compliant with safety regulations.

For demanding applications like top outdoor walk-in electrical cabinets, high IP ratings are non-negotiable to guarantee protection against harsh weather and environmental stress. Similarly, stainless steel electrical enclosures with proper IP ratings provide unmatched durability, corrosion resistance, and hygiene benefits for industries like food processing and pharmaceuticals.

By selecting the correct IP-rated enclosure, you can significantly increase the longevity of your electrical equipment, improve safety, and ensure smooth operation in even the toughest conditions.

If you’re planning an installation or upgrade, always consult with enclosure experts to choose the right balance of material, IP rating, and additional protective features for your specific application.

#IP Ratings Explained#Electrical Enclosure Protection#IP65 vs IP66 Enclosures#Weatherproof Enclosures#Outdoor Electrical Cabinets#GRP Enclosures UK#Stainless Steel Enclosures#Industrial Enclosure Standards#IP Rating Guide UK#Enclosure Safety and Compliance#Best Electrical Enclosures for Outdoor Use#Electrical Housing Protection Levels#Ingress Protection Code#IP Rated Cabinets UK#Choosing the Right Enclosure

0 notes

Text

Astro Notes on Current Events:

The Fall of Sean 'Diddy' Combs

From my professional perspective: / cw for mentions of abuse:

Diddy's incarceration and undoing coincides w/ Pluto regressing back into Capricorn and conjoining his Mars and many factors but I had my eye on that transit for months. There's no getting out of this one. Our current and incoming south nodes are conjoining planets in his chart which can be associated with domestic power abuse, control issues, and legal disputes being magnified. The SN is associated w/ the 'karma' you inherit or reap from the past.

On Sep 18th, the partial lunar eclipse in Pisces directly opposes his Pluto. Moon-Pluto oppositions can deal with feminine-coded abuse. It's emotional negligence, gaslighting, and a complete conquering of an emotional reality which starts with caregivers. From a legal and symbolic standpoint, this translates to me as the private subjugation of women. Abuse of wives, live-in partners, domestic servants, and child abuse and trafficking.

Saturn isn't aspecting this but its co-presence adds tension to the landscape. The collective needs justice. Being ruled by Jupiter in Gemini for the time being, this has to do with what was said and what can be factually proven. Witness and survivor accounts are going to play a major role here. Saturn is also conjoined with his natal NN which is in retrograde at the moment. In December it'll be direct. From a prosecution standpoint, this is saying they'll have everything they need to charge him by this date or something even more damning may come to light at that time. Dec 10th.

But it goes deeper than you'd think. Many psychics and astrologers have forecasted potential ties to more powerful players coming to light through this. My guess is that they're going to try to pin it all on him..but as quickly as possible. With Mars transiting through all of Cancer between now and November, this happening in the US's 8H and squaring Diddy's Venus planets may be about uncovering that the trafficking and other criminal activity doesn't only incriminate him but anyone w/ power attached to him. It was never just about Diddy. There's more people involved and they're all at risk. I'd argue that astrologically, his Mars's exaltation was protecting him, especially if he has a night chart. But Pluto bouncing from that Mars to continuing its applying square to his Retrograde Saturn in Taurus spells out that any shadiness he thought he could get away with would inevitably come to light..with an ass beating attached. Pluto's official long term ingress in Aquarius starts on Nov 19th.

On March 14th '25, there'll be a total lunar eclipse conjoining his Pluto. There's potentially going to be more charges made and files/documentation being brought in. But on Sep 21st '25, there's a very interesting partial solar eclipse occurring right on the late Kim Porter's 29-degree Virgo Pluto. I'm just going to call it, but if the rumors are true that he played a part in her death, we're going to definitely find out then. Keep your eyes on Sep 21, 2025.

If it doesn't happen then, it'll be a couple eclipses down the line because the next Cancer/Cap eclipse cycle occurs right where Kim Porter's Moon and Diddy's Lilith fall and it's going to reveal how abusive (and fatal) that Moon-Lilith connection was. That's mother-coded and child-coded too. So, anything involving children, pregnancy, etc, may come to light as well. That'll be happening in 2028. Tbh, I'm calling it because there'll also be a partial eclipse on his Juno that's going to be conjoined with her Mercury as well. Kim Porter's life and the darkness she was forced to keep secret is going to fully (and finally) be told very shortly. That man is about to be destroyed. Tbh, it's giving a memoir she may have wanted to have published.

Her scorned (but vindicated) Lilith has a full lunar eclipse occurring on March 3 '26. This is why I'm thinking that it's not just going to be a single decisive punch of getting her spiritual lick back with one eclipse cycle. Kim Porter was an actual inner-planet Scorpio stellium. It's going to be a rolling and incapacitating series of punches. Or of slow and painful dismemberment, quite honestly. Between now and 2028 and beyond, everyone is going to know just how abysmally awful this man is.

But he won't be alone. Oh, no. With Pluto in Aqua occurring right at the start of everything, it'll be the beginning of the end for the entertainment world in its current state.

22 notes

·

View notes

Text

Low Voltage Switchgear for Commercial Buildings: Key Requirements, Standards, and Best Practices

In the construction and modernization of commercial buildings, low voltage switchgear plays a critical role in ensuring safe, reliable, and efficient power distribution. From office complexes and retail malls to hospitals and data centers, these buildings rely on robust electrical infrastructure — and low voltage switchgear is the backbone of that system.

Whether you’re an electrical panel manufacturer, a building contractor, or a facility manager, understanding the key requirements for selecting and integrating LV switchgear in commercial buildings is essential.

What Is Low Voltage Switchgear?

Low voltage switchgear is an assembly of electrical devices designed to control, protect, and isolate electrical circuits under 1,000V AC. It typically includes:

· Air Circuit Breakers (ACBs)

· Molded Case Circuit Breakers (MCCBs)

· Miniature Circuit Breakers (MCBs)

· Contactors and Relays

· Busbars

· Metering and Protection Devices

Why LV Switchgear Is Critical in Commercial Buildings

Commercial buildings demand:

· Continuous power availability

· High energy efficiency

· Electrical safety for occupants

· Scalability for future expansion

Low voltage switchgear delivers:

· Protection against overloads and short circuits

· Isolation for maintenance and fault conditions

· Load management for energy optimization

· Monitoring via smart metering and IoT integration

Key Requirements for LV Switchgear in Commercial Applications

Safety & Protection Standards

Must comply with IEC 61439 or UL 891 depending on the region

Must include overcurrent, short-circuit, and earth fault protection

Arc flash safety features (like arc fault containment) are crucial in populated buildings

2. Compact Footprint and Modular Design

Space is often limited in commercial utility rooms. LV switchgear should be:

Compact to fit tight electrical rooms

Modular for easy expansion as building loads increase

3. Smart Metering and Monitoring

Today’s commercial buildings demand energy-efficient and intelligent systems. Choose LV switchgear with:

Integrated smart meters

IoT-based energy monitoring

Remote control via BMS (Building Management Systems)

4. High Service Continuity (Form Segregation)

To ensure maintenance without full shutdowns, opt for:

Form 3b or Form 4b segregation

Withdrawable ACBs or MCCBs

Dual incomer and bus coupler arrangements for redundancy

5. Scalability and Flexibility

Commercial facilities evolve. Your switchgear must too:

Allow for load expansion

Be compatible with renewable sources (like solar panels)

Support future retrofits and upgrades

Standards to Follow

Ensure LV switchgear in commercial buildings is compliant with:

IEC 61439–1/2 — General and Power Switchgear Assemblies

UL 891 — US Standard for Dead-Front Switchboards

NEC (National Electrical Code) or local building codes

Also factor in:

Ingress Protection (IP Ratings) — IP54/IP65 for dusty or humid environments

Short Circuit Withstand Ratings — Ensure it matches building fault levels

Best Practices for Installation in Commercial Building

Centralize the switchgear for easy maintenance and reduced cable runs

Provide ample ventilation or forced cooling

Use color-coded wiring for clear identification

Ensure emergency shutdown mechanisms are accessible

Document the system with single-line diagrams and load calculations

Applications in Commercial Buildings

Office Buildings: Smart load shedding and energy metering

Hospitals: Redundant systems for life safety

Data Centers: N+1 configurations and continuous monitoring

Malls & Retail: Segmented load distribution for different zones

Hotels: Backup and emergency panel integration

Choosing the Right LV Switchgear Partner

Look for a supplier who provides

Customized switchgear assemblies

Fast lead times and local support

Engineering assistance for layout and specs

Pre-tested or type-tested assemblies

Future Trends in Commercial LV Switchgear

Digitization & predictive maintenance

Energy-efficient, low-loss designs

AI-assisted load forecasting

SF6-free eco-friendly designs

Need Help Choosing LV Switchgear for Your Next Commercial Project?

At Daleel Trading, we supply certified, compact, and smart low voltage switchgear solutions tailored for commercial buildings. Whether it’s a small retail site or a multi-floor office tower, we deliver performance, compliance, and reliability — on time.

👉 Contact us today for a quote, a technical consultation, or a custom panel solution.

8 notes

·

View notes

Text

Are Electric Bikes Waterproof? What You Need to Know Before Riding in the Rain

Understanding E-Bike Water Protection

Every electric bike owner worries about this. Rain clouds form overhead. Water starts to fall from the sky, and you wonder if your bike can handle it.

A recent survey showed that about 75% of e-bike users worry about water damage when riding on rainy days. So, let's answer the main question: are electric bikes waterproof? The simple answer is no.

Almost no electric bike is truly waterproof. However, most are highly water-resistant, which is good news for riders. This means they can handle rain and puddles but not being underwater or high-pressure cleaning.

In this guide, we'll explain what water resistance means, decode the ratings that define it, identify the most vulnerable parts of your bike, and give you practical advice for riding an electric bike in the rain safely.

Water-Resistant vs. Waterproof

Understanding these two terms helps protect your bike and gives you confidence when riding. They sound similar but mean very different things for e-bikes. The difference between them is critical for keeping your bike safe.

What Water-Resistant Means

Water resistance means a device can resist water to some degree, but not completely. For e-bikes, this means electrical parts are sealed to protect against splashes from wet roads and light to moderate rain. Think of a good rain jacket - it keeps you dry in a normal shower, but you wouldn't jump into a pool wearing it.

This is the level of protection most waterproof electric bikes offer. The seals and design work well for typical riding conditions. However, they have limits that riders need to understand.

What Waterproof Means

Waterproof means a complete barrier against water. A waterproof device can be fully underwater for a specific depth and time without any liquid getting inside. Examples include a diver's watch or submarine components.

Making an entire e-bike to this standard would cost too much and isn't needed for normal riding. Some individual parts might have high waterproof ratings, but the whole bike is not considered waterproof. This is why manufacturers focus on water resistance instead.

Decoding IP Ratings

Manufacturers use the Ingress Protection (IP) rating system to show protection levels. This code helps you understand exactly how well your e-bike handles water and other elements.

What is an IP Rating?

An IP rating is an international standard that shows protection against foreign objects and moisture. The rating has two numbers that tell you different things. The first digit (0-6) shows protection against solids, and the second digit (0-9) shows protection against liquids.

Common E-Bike IP Ratings

You'll typically see ratings from IPX4 to IPX6 on e-bikes and their parts. The "X" means the product wasn't tested for solid particle protection, which is common for bike components.

Here's what the water ratings mean in real-world use:IP RatingProtection LevelReal-World MeaningIPX4Protected from splashing water from any direction.This is a common baseline. It's safe for riding on wet roads and in light rain.IPX5Protected from low-pressure water jets from any direction.A solid rating. It can handle steady, moderate rain and careful cleaning with a low-pressure hose.IPX6Protected from high-pressure water jets from any direction.Very robust. This offers excellent protection against heavy rain and downpours.IPX7Protected from temporary immersion (up to 1m for 30 mins).Extremely rare for a full e-bike, but some premium batteries or displays may carry this rating.

2 notes

·

View notes

Text

Top 5 Factors to Consider When Choosing Switchgear in Qatar

The energy infrastructure in Qatar is evolving rapidly, driven by ambitious development plans, a booming construction sector, and growing demand for reliable and efficient power distribution systems. As such, selecting the right switchgear — an essential component in electrical distribution networks — is more important than ever. Whether for industrial, commercial, or residential projects, choosing the appropriate switchgear can significantly impact safety, operational reliability, and long-term costs.

In this article, we explore the top five factors to consider when choosing switchgear in Qatar, keeping in mind the country’s unique climatic, industrial, and regulatory environment.

1. Environmental and Climatic Conditions

Why It Matters:

Qatar’s climate is characterized by extreme heat, high humidity, and frequent dust storms, which can adversely affect the performance and longevity of electrical equipment.

What to Consider:

· Ingress Protection (IP) Ratings: Choose switchgear with high IP ratings (e.g., IP65 or above) to ensure resistance to dust and moisture.

· Temperature Tolerance: Equipment should be capable of operating in ambient temperatures above 45°C without derating.

· Corrosion Resistance: Opt for enclosures made from stainless steel or coated with anti-corrosive materials to withstand coastal and desert environments.

Tip:

Ask for switchgear that has been tested and certified for desert and tropical climates to ensure long-term reliability.

2. Compliance with Local Regulations and Standards

Why It Matters:

Qatar’s construction and energy sectors are tightly regulated. Non-compliance with local codes can lead to project delays, penalties, or unsafe installations.

What to Consider:

· Kahramaa Regulations: Ensure the switchgear complies with Qatar General Electricity & Water Corporation (Kahramaa) specifications.

· International Standards: Equipment should meet IEC (International Electrotechnical Commission) or ANSI standards for design and performance.

· Vendor Certifications: Choose manufacturers and suppliers who are approved by local authorities and have a track record of regulatory compliance.

Tip:

Request documentation and third-party certification to verify compliance before purchase.

3. System Voltage and Current Ratings

Why It Matters:

Mismatched ratings can lead to equipment failure, increased downtime, or even safety hazards.

What to Consider:

· Voltage Level: Identify whether your application requires low-voltage (LV), medium-voltage (MV), or high-voltage (HV) switchgear.

· Short-Circuit Withstand Capacity: The switchgear must handle the maximum fault current expected in the system.

· Load Type and Growth: Consider both current and future load expansions when sizing the switchgear.

Tip:

Conduct a detailed load analysis with a qualified electrical engineer to ensure proper equipment sizing.

4. Reliability and Safety Features

Why It Matters:

Switchgear is central to ensuring electrical safety and minimizing power outages, especially in critical infrastructure.

What to Consider:

· Arc Flash Protection: Look for internal arc classification (IAC) and arc-resistant features.

· Automation and Remote Monitoring: Smart switchgear with SCADA integration can improve uptime and facilitate preventive maintenance.

· Redundancy and Segmentation: Ensure the switchgear design allows for maintenance without shutting down the entire system.

Tip:

Consider intelligent switchgear with diagnostic features to enable predictive maintenance and minimize human error.

5. Availability of Local Support and Spare Parts

Why It Matters:

Even the best switchgear can require maintenance or part replacement. Having quick access to support minimizes downtime and operational losses.

What to Consider:

· Local Service Network: Choose brands with authorized service centers or partners in Qatar.

· Spare Parts Availability: Ensure that spare parts can be sourced locally with minimal lead time.

· Training and Technical Support: Ask about operator training, maintenance contracts, and emergency response services.

Tip:

Opt for suppliers with a strong presence in the GCC region and a proven track record in Qatar’s market.

Conclusion

Choosing the right switchgear in Qatar requires a thoughtful evaluation of environmental, regulatory, technical, and logistical factors. With the right equipment, businesses and developers can ensure electrical safety, regulatory compliance, and long-term operational efficiency in one of the world’s most challenging climates.

When evaluating options, always consider:

· Local conditions and regulatory landscape

· Equipment ratings and design

· Vendor support and technical reliability

By focusing on these core considerations, stakeholders can make informed, cost-effective, and future-ready decisions for their electrical infrastructure projects in Qatar.

#electrical equipment#qatar#switchgear#electrical#911 abc#arcane#artists on tumblr#batman#cats of tumblr#cookie run kingdom

2 notes

·

View notes

Text

i'm NOT putting this on my astro substack that i have irl people following. so it's going here. yeehaw

i've been reading more evolutionary astrology books lately and the timing is......................... interesting wrt experiencing black moon lilith transits -> uranus/asc transits. it was triggered in july (lilith's ingress into my libra 8th house: a queer healing gathering) then became fully operational following the august aquarius full moon (conjunct my natal uranus in 12th: seeing my abuser again).

black moon lilith in my chart is clearly a trauma signature. considering the mythological/cultural context of lilith being a figure outcasted, demonized for being sexually liberated (and other goddesses that demetra george associates bml with like persephone), the fact that she's in my 8th house, and that the last lilith eclipse activated her again—it becomes fairly obvious, to me anyway, what she is. lilith in my chart represents the shadow of shame. and other astrologers would likely be kinder about how she operates in my chart, but when i see where she's placed and how she's placed it's clear to me that sexuality = taboo = shame = secrets = trauma = death/rebirth. a libra 8th house ruled by venus in my 3rd, co-present with saturn. the foundations of these secrets inform the structure of my consciousness, my values, my relational dynamics. (how terribly profound. how terribly awful).

the other day when the sun was conjunct my natal lilith, i ended up spending the day with a friend and we had a huge debrief/vent session about the ways that scars from CSA—particularly incest CSA—completely warp, damage, eviscerate your fucking world sometimes. it takes a really, really fucking long time to come to terms with things. and just when you think you're over it—you've processed it—you'll uncover something new. you discover a new way that it affects you. and it feels like the wound opens up all over again.

never mind how your family may react. never mind the ways in which they may fail you, before and now.

there are not enough "helpers" in this world equipped to deal with our stories, because our experiences are apparently so god-awful that they have to dismiss us to protect themselves. the shame is not only within us for being victimized, but it's embedded within the systems that are supposed to help us: mental health services, inadequate. social services, inadequate. medical services, inadequate. and being forced to carry those systemic failures as a child?

even as an adult, who is that child—unfathomable. to imagine it happening to anyone else. i once went to counselling and she avoided discussing post-traumatic stress at all costs, despite the fact that i was suffering from dissociation at the time. there was a complete failure to engage with the totality of my life because it was "too much". anyone who should have seen what was happening, excluding my family—educators who are meant to detect these things, physicians who should be able to detect these things—not a single fuckin one could hold space or say a thing. that's insane.

as a helper confined within the parameters of these systems, trying to help other survivors—it gets triggering. it gets frustrating. to want to be able to use our experiences to help others process their own shit, but we can't even do that because we're bound by the colonial structures of systems we fuckin work within, too. by the time people get to us they've already experienced harm by these systems. by the time people get to us they don't want to re-engage with these systems because they're exhausted. disenchanted. profoundly hurt.

(it can be helpful to experience triggers in this sense, because it activates a kind of primal rage against institutional failures. and these are at the very least things that i can share with people who are trying to affect change, and it can be implemented within my own code of conduct as a helper. but still. holy fuck).

_______

the ingress of planets into libra this year, as well as lilith's ingress into libra, corresponds in terms of timing and the initiation of hypersexuality. the difference between this phase and other phases i've been in lies in the fact that it's

1. been an opportunity to explore reclamation of sexual desire, which is something i couldn't do previously out of shame/fear/repression/repulsion and

2. the shame/repulsion/compulsive part of the hypersexuality is less operational (meaning i haven't been quiet about what i'm experiencing: i'm not downplaying the ways in which my history have involvement with current exploration and processing, but i'm also accepting that i am allowed to express facets of my sexuality, given that it's a safe space for everyone involved).

there's still elements of this where i'm like... embarrassed, i think. i'm saying, feeling, portraying some really sexual things online. which is normalized, i think, especially in fandom spaces (and obviously encouraged in the current fandom space i'm occupying), but it isn't always something i've been comfortable to do.

i joke about the ways that i cope through a certain character—a persephone-like archetype himself—but when it really comes down to it, i suppose it isn't that funny how much i relate to him. it's too meaningful to be a joke. i love him, unfortunately, because i see myself in him, and it's easier to love a character than love myself. you already know what it is.

there's also the fact that i'm being open with my friends about the ways that this phase is affecting and changing me (because thank god, i have friends who are trauma-informed/can hold space for me even when i'm stuttering and struggling to convey some of the worse things). there's still a part of me suspended in disbelief that i am letting anyone see this unfold as it's happening, because it feels as though the worst parts of me are spilling out.

it's still a relief, though. to spill out. rejection sensitivity is a nightmare always, but to have the "worst" parts of myself seen and tolerated... that is a win, for me.

i think the spilling out is where uranus comes in. mark jones writes about the role that archetypal uranus plays in trauma—something i would have *never* clocked on my own, as so much of modern astrology is inundated with uranus as a revolutionary, a change-maker, a disruptor. he points out that uranus corresponds with subtle mental/memory body, and the deeper state of unconscious that can be "brought towards conscious awareness through the attention and focus of the individual as part of the process of individuation". uranus hit my natal jupiter/asc in july, which is when i was at a healing gathering where i unintentionally released a LOT of shame around things like Having a body. Being seen. (it's funny what being in safe spaces/community can like, do for you). Attraction to other people. The potential of being desired and feeling safe about being desired. he writes, "we are not alone, and although that idea may be quite hard to connect with under duress, we are all held by this larger field...this insight forms the basis of the recovery from trauma through a holding environment." and that's what that gathering facilitated, i think. a holding environment for some of my worst fears to be gently held.

and uranus is transiting my 3rd house of cognition, communication. close friends, extended relatives. my neighbourhood. social media. so these are the people and places and spaces where the holding environment to process the shame within the body (ASC) exists.

not all of the shame can be released obviously, because that would be miraculous. as part of the retrograde uranus will be transiting jupiter/asc between oct 27th -> nov 6th, and then once again next april (which, btw, so many meaningful transits, especially final hitting retrograde transits, are happening in my chart in april 2025. cannot fathom what this could possibly mean).

so clearly there are going to be other facets/dimensions to self that will be realized, especially when i experience the exact lilith return around late december.

anyway. i'm also thinking about how the plutonic symbolism in my chart references a need to talk, profess, in public spaces. like a sagittarian archetype. it's actually embarrassing how the true compulsive part of this process is the need to tell anyone. i suppose that's what happens when you spend a better part of your life holding onto pain.

#this a bizarrely intimate post#which. again. i do normally save for my substack. because there's a lot of astrology in here.#it's more or less the personal part of this that keeps me from posting it there.#mentions of csa sa incest hypersexuality etc etc

4 notes

·

View notes

Text

IP65 waterproof LED panel: the first choice for outdoor display

In outdoor advertising and information display, the performance of LED displays must not only consider brightness, clarity and color performance, but also have strong environmental adaptability. Especially under changing climate conditions, waterproofness has become a key factor in ensuring the stable operation of the display system. Among them, IP65 waterproof LED panels are currently widely used in the market and are highly favored by outdoor advertisers and system integrators.

What is IP65 protection level?

"IP" means "Ingress Protection". The protection level code consists of two numbers, indicating dust and waterproofing capabilities respectively. According to the International Electrotechnical Commission IEC 60529 standard:

The first number "6" means that it is completely prevented from entering dust, that is, it is completely protected from dust;

The second number "5" means that it can prevent damage caused by spraying water from any direction, that is, preventing water from being sprayed.

Therefore, IP65-level LED panels have complete dustproof and medium-pressure water jet capabilities, and are suitable for complex outdoor environments such as rainwater, dust, and humidity. Take you to learn about LED IP levels in 5 minutes.

Core advantages of IP65 LED panels

Strong protection, stable operation

We use sealed modules, silicone packaging, nanocoating and other technologies to ensure that water and dust cannot penetrate the interior and prevent circuit short circuits and aging.

It can also be displayed stably in heavy rain, without additional occlusion.

Adapt to multiple climates

Suitable for extreme environments such as tropical humidity, frequent sandstorms, coastal salt spray, etc., it is widely used in Africa, the Middle East, Southeast Asia and other places (data source: Allied Market Research, 2023 outdoor LED market analysis).

Extend service life

IP65 panels reduce the risk of circuit damage and corrosion, making the overall LED screen longer, and the common usage cycle can reach more than 5-8 years.

Low operation and maintenance cost

The structure is strong and has a high protection level, reducing the failure rate caused by water and ash inlets, and reducing maintenance frequency and cost. Are LED billboards expensive? How high is the operating cost?

Common application scenarios

Outdoor billboards: roads, viaducts, building facade advertisements.

Sports venue: external information screen, score screen, welcome screen.

Municipal construction: bus stops, subway entrances, square guide signs.

Tourist attractions: outdoor guide screen, interactive information screen.

Commercial complex: outdoor window advertising screen, shopping mall exterior wall large screen.

How to identify a true IP65 waterproof LED panel?

Check authoritative certification: Ensure that the product has passed CE, RoHS, FCC, IP protection level certification, etc.

Observe the structural design: whether integrated die-cast aluminum box, high-quality waterproof rubber ring, and drainage design are adopted. Give you a steel frame LED screen: key features, case studies and buying tips.

On-site water spray testing: Reliable manufacturers will provide IP waterproof on-site test or video information.

Check technical parameters: The product manual must clearly indicate "IP65" and indicate the protection scope.

Market Trends and Suggestions

According to Statista data, the global outdoor LED display market will reach nearly US$18 billion in 2025, of which products with high protection levels will become the mainstream. Choosing IP65 waterproof LED panels is not only a response to the needs of the natural environment, but also a wise move to improve brand exposure and ensure return on investment. Why do brands prefer LED display advertising?

If you are considering purchasing or integrating LED display projects, it is recommended to prioritize products with IP65 protection levels or above, and cooperate with LED manufacturers with practical engineering experience to ensure that installation and post-maintenance are in place.

Conclusion

IP65 waterproof LED panels have become an important cornerstone for outdoor display applications. With their advantages such as high protection, high stability, and long life, they have won the favor of many fields such as advertising media, municipal construction, and transportation information release. Faced with smarter and more extreme application scenarios in the future, IP65-level products are undoubtedly your trustworthy choice.

Thank you for watching. I hope we can solve your problems. Sostron is a professional LED display manufacturer. We provide all kinds of displays, display leasing and display solutions around the world. If you want to know: LED display: empowering scenes and reshaping experience. Please click read.

Follow me! Take you to know more about led display knowledge.

Contact us on WhatsApp:https://api.whatsapp.com/send?phone=+8613510652873&text=Hello

0 notes

Text

Introduction In the design of modern electronic products, Ingress Protection (IP) ratings are crucial standards for assessing a device’s ability to withstand environmental factors such as dust and water ingress. Among these, IPX7 waterproofing has garnered significant attention because it signifies that devices can endure immersion in 1 meter of water for up to 30 minutes without sustaining damage. This article will delve into the concept of IPX7 waterproofing, testing methodologies, their limitations, and introduce how Shanghai LISUN’s JL-X waterproof testing system effectively conducts waterproof rating tests. Understanding IPX7 Waterproof Rating The IP (Ingress Protection) code consists of two digits, representing protection against solid objects including dust and liquids. When an “X” appears, it indicates no information is available regarding that specific type of protection. Therefore, in IPX7, the “X” means there is no specified dust protection, while the “7” confirms compliance with internationally recognized waterproof standards, indicating the ability to withstand being submerged in 1 meter of water for 30 minutes without affecting functionality. Historical Background and Development The development of IP ratings began in the mid-20th century when the need arose for standardized measures to protect electrical equipment from environmental hazards. Over time, these standards have evolved to include increasingly stringent tests and criteria, reflecting advancements in technology and materials science. The introduction of IPX7 was a significant milestone, providing a reliable benchmark for consumer electronics manufacturers to ensure their products could withstand accidental water exposure. Initially developed by the International Electrotechnical Commission (IEC), the IP standard has since been adopted globally, influencing product design and manufacturing processes worldwide. Shanghai LISUN’s JL-X Waterproof Testing System waterproof test Equipment JL-X To ensure that electronic products meet stringent waterproof requirements, they must undergo precise testing procedures. Shanghai LISUN’s JL-X waterproof testing system is an advanced tool specifically designed for verifying the waterproof performance of electronic devices. Adhering to international standards like GB/T 4208, IEC 60529, and EN 60529, this system offers manufacturers a reliable method to determine if their products achieve IPX7 certification. Technical Specifications of JL-X The JL-X system is equipped with advanced sensors and control mechanisms that allow for highly accurate simulation of various water exposure scenarios. It supports customizable test parameters, enabling users to tailor the testing process according to specific product requirements. The system includes features such as temperature control, pressure regulation, and data logging to provide comprehensive insights into the performance of tested devices. One of the key features of JL-X is its ability to simulate different water conditions, including varying depths and temperatures, ensuring a thorough assessment of waterproofing capabilities. Advantages of JL-X System One of the key advantages of the JL-X system is its ability to simulate real-world conditions accurately. By controlling variables such as water depth, temperature, and duration of immersion, the system ensures that each test is conducted under consistent and repeatable conditions. This consistency is essential for obtaining reliable results and ensuring that products meet the required standards. Additionally, JL-X provides detailed reports and analytics, helping manufacturers identify potential weaknesses in their designs and make necessary improvements. Furthermore, the JL-X system supports remote monitoring and control, allowing engineers to oversee testing procedures from anywhere, enhancing efficiency and flexibility. Standards and Methods for IPX7 Waterproof Testing According to relevant international standards, when conducting IPX7 waterproof tests, samples need to be fully submerged under water following specific conditions: • For enclosures less than 850mm in height, the lowest point should be at least 1000mm below the water surface. • For enclosures equal to or greater than 850mm in height, the highest point should be at least 150mm below the water surface. • The test duration lasts 30 minutes. • The temperature difference between water and sample should not exceed 5K. These criteria ensure consistency and rigor across different batches of products tested under identical conditions. Moreover, employing Shanghai LISUN’s JL-X testing system enhances accuracy in controlling these parameters, thereby improving the reliability of test results. Detailed Test Procedures Each step of the IPX7 test is meticulously documented, ensuring transparency and reproducibility. After the initial setup, the device is submerged in water, and the test environment is monitored throughout the duration. Post-test inspections involve detailed examinations of the device’s internal components to check for any signs of moisture ingress. Any detected moisture is analyzed to determine its impact on the device’s functionality and safety. Detailed documentation helps manufacturers understand the exact conditions under which failures occur, aiding in future design improvements. For example, a recent case study involving a portable speaker manufacturer found that small gaps in the housing led to water ingress during IPX7 testing. Adjustments were made based on JL-X test results, resulting in a more robust waterproof design. Evaluation of Test Results for IPX7 Waterproofing After completing the aforementioned tests, it is essential to inspect whether moisture has penetrated inside the sample. If water ingress occurs, further analysis is required to assess potential impacts on device operation, such as damage to insulation components, entry into electrical parts, or accumulation near cables leading to potential safety hazards. Additionally, designs featuring drainage holes must prove effective in removing accumulated water without compromising device functionality. Case Studies Several case studies illustrate the effectiveness of the JL-X system in identifying weaknesses in product design. For example, one manufacturer found that their Bluetooth speaker, though meeting IPX7 standards, had issues with cable connections when exposed to prolonged submersion. Adjustments were made based on JL-X test results, leading to improved product reliability. Another case involved a smartwatch manufacturer who discovered that certain seals were not robust enough during the IPX7 test. By modifying the seal design and retesting with JL-X, the company was able to achieve a more durable product. These examples highlight the importance of rigorous testing and the role of advanced systems like JL-X in enhancing product quality. A third case involved an outdoor lighting fixture manufacturer who used JL-X to test their products for use in marine environments. The tests revealed areas where water could penetrate, prompting design changes that significantly improved the product’s durability. Practical Applications and Limitations of IPX7 Waterproofing Despite the robust waterproof performance demonstrated by IPX7-certified products, it is crucial to note that this does not imply immunity against all forms of water exposure. For instance, an IPX7-rated product may not necessarily withstand powerful water jets from various angles. Hence, when selecting outdoor Bluetooth speakers, users should consider the intended use scenario. Devices used around swimming pools might benefit more from IPX7 or even higher IPX8 ratings, whereas those used during hiking or picnicking would fare better with IPX4 to IPX6 ratings, offering protection against rain splashes and sprays. Comparative Analysis A comparative analysis between IPX7 and other waterproof ratings highlights the distinct advantages and limitations of each. While IPX7 excels in protecting against deep water immersion, ratings like IPX4 offer superior protection against spray and splashes, making them suitable for different applications. For example, a camera designed for outdoor photography may require an IPX4 rating to protect against unexpected rain showers, whereas a diving watch would benefit from an IPX7 or IPX8 rating to ensure functionality underwater. Understanding the differences between these ratings is essential for choosing the right product for specific use cases. An interesting comparison can be made with the automotive industry, where components must often withstand high-pressure washing, necessitating IPX9K ratings rather than IPX7. Conclusion With advancements in technology and increased consumer demand for high-quality products, understanding and mastering waterproofing standards like IPX7 along with corresponding testing methods have become increasingly vital. Utilizing advanced systems such as Shanghai LISUN’s JL-X not only aids manufacturers in enhancing product quality but also boosts consumer confidence. Looking ahead, we anticipate innovative techniques emerging in the assessment of waterproofing performance, propelling the industry towards new heights. Through meticulous research and technological improvements, we can ensure that electronic devices maintain optimal performance across diverse harsh environments. Future Trends in Waterproof Technology As technology evolves, so too do the methods for achieving and testing waterproofing. Emerging trends include the development of nano-coatings and advanced sealing technologies that promise even higher levels of protection. These innovations will likely push the boundaries of current IP standards, leading to the creation of new benchmarks for waterproof performance. Additionally, the integration of smart sensors within devices can provide real-time feedback on water exposure, helping to prevent damage before it occurs. For example, some smartphones now feature sensors that detect moisture and automatically shut down circuits to prevent short-circuiting. In the future, we may see more sophisticated self-healing materials that can repair minor damages caused by water exposure, further enhancing device longevity. Real-World Applications IPX7 waterproofing is widely applied in various industries, from consumer electronics to industrial equipment. Smartphones, tablets, and wearable devices often feature IPX7 ratings to ensure they can survive accidental drops into water. In the automotive industry, IPX7 ratings are used for connectors and sensors to protect critical components from water damage. Industrial machinery also benefits from IPX7-rated enclosures, ensuring reliability in harsh environments. For instance, agricultural drones equipped with IPX7 ratings can operate effectively in wet conditions, reducing downtime and increasing productivity. Another notable application is in the medical field, where devices used in sterilization processes must withstand repeated exposure to water and cleaning agents without compromising their integrity. Challenges and Solutions One of the challenges faced by manufacturers is balancing the need for waterproofing with other design considerations such as weight, size, and cost. Advanced materials and manufacturing techniques can help address these challenges. For example, the use of lightweight yet durable polymers can enhance waterproofing without significantly increasing the weight of the device. Similarly, precision engineering can minimize the size of seals and gaskets, reducing costs while maintaining performance. Manufacturers are also exploring new materials such as graphene and advanced composites to improve both durability and waterproofing properties. Innovations in 3D printing technology allow for the creation of complex geometries that optimize sealing and reduce material usage, thereby lowering costs. Consumer Education Educating consumers about the importance of IP ratings and what they mean is another challenge. Many consumers may not fully understand the implications of different IP ratings, leading to confusion when choosing products. Manufacturers and retailers play a crucial role in educating customers through clear labeling and informative content. Providing detailed explanations of IP ratings and their practical applications can help consumers make informed decisions and choose the right products for their needs. Online resources, tutorials, and customer support channels can further assist in bridging the knowledge gap between manufacturers and end-users. In conclusion, IPX7 waterproofing represents a significant advancement in protecting electronic devices from water damage. By adhering to rigorous testing standards and utilizing advanced systems like Shanghai LISUN’s JL-X, manufacturers can ensure their products meet the highest levels of waterproof performance. As technology continues to evolve, we can expect even more sophisticated solutions to emerge, driving innovation and enhancing the durability of electronic devices in challenging environments. The ongoing development of waterproofing technologies promises to revolutionize the way we interact with electronic devices, making them more reliable and versatile in a wide range of applications. With continued investment in research and development, the future of waterproofing looks promising, opening up new possibilities for innovation and product enhancement. Read the full article

0 notes

Text

Udhhyog’s Puddle Flanges for Underground RCC Applications

Reliable Waterproofing for Concrete Structures

In modern infrastructure projects, underground RCC (Reinforced Cement Concrete) constructions like basements, water tanks, manholes, sumps, STPs, and utility ducts demand airtight and watertight pipe entries. This is where Udhhyog’s puddle flanges provide a reliable, leak-proof solution.

Our precisely engineered puddle flanges are specially designed for underground RCC structures, ensuring long-lasting protection against water seepage and structural deterioration.

🔧 What Are Puddle Flanges in RCC Construction?

A puddle flange is a circular plate fixed or welded around a pipe, embedded into RCC during construction. Its primary purpose is to prevent water from traveling along the pipe surface, especially where pipes pass through slabs, walls, or base concrete.

When concrete cures around the flange, it forms a physical barrier, making it extremely difficult for water to seep through the joint—thus preserving the integrity of the entire structure.

✅ Why Udhhyog Puddle Flanges Are Ideal for Underground RCC Applications

Leak-Proof Performance: Creates a solid seal that prevents water or chemical ingress around pipes.

Built for Underground Pressure: Designed to withstand external hydrostatic pressure commonly found in subterranean tanks or foundations.

Available in All Grades & Sizes: Udhhyog offers puddle flanges in MS, GI, and SS with various thicknesses and diameters to fit standard and custom pipe sizes.

IS Standard Manufacturing: All puddle flanges are produced as per IS 1538 and other relevant civil engineering codes.

Corrosion Resistance: With galvanized or epoxy coatings, our flanges are rust-proof and long-lasting, even in moist soil environments.

🛠️ Where to Use Udhhyog Puddle Flanges in RCC Construction:

Underground water tanks

Basement drainage lines

Sewage Treatment Plants (STP)

Pump chambers and lift stations

Rainwater harvesting tanks

Utility conduits and ducting systems

Manholes and inspection pits

🧱 Installation Highlights:

Weld or seal the puddle flange onto the pipe before concreting.

Ensure the flange is fully embedded in the RCC slab or wall section.

Apply corrosion protection on mild steel versions before installation.

Follow proper alignment and vibration practices during concrete pouring.

❓ Frequently Asked Questions (FAQs)

Q1: Why are puddle flanges important for underground RCC tanks? A: They seal the entry point of pipes passing through concrete, stopping water ingress and protecting the tank’s structural integrity.

Q2: Can Udhhyog provide custom-size puddle flanges? A: Absolutely. We fabricate flanges to fit your required pipe diameter, wall thickness, and project-specific pressure requirements.

Q3: Which material is best for long-term underground use? A: GI or SS puddle flanges are preferred for their anti-corrosion properties in underground, moist environments.

Q4: Are your puddle flanges tested before dispatch? A: Yes, each batch undergoes dimensional checks, surface treatment tests, and material quality verification.

0 notes

Text

7 Tips for Choosing the Right Fiber Optic Splice Closure

Choosing the right fiber optic splice closure is crucial for ensuring the proper functioning and longevity of your fiber optic network. Here are some tips to help you make the right choice:

Compatibility

Choosing a fiber optic splice closurethat is compatible with your device is crucial for ensuring a reliable and efficient fiber optic network.

Begin by understanding the specifications of your fiber optic device, such as the type of cables it uses, the number of fibers, and any specific requirements it may have for splicing.

Ensure that the splice closure is compatible with the type of fiber optic cables your device uses. Different closures are designed for specific cable types, such as loose-tube or tight-buffered cables. Match the closure to the cable type to ensure proper fitting and functionality.

If your device uses connectors, ensure that the splice closure supports the specific connector types you are using. This includes considerations for connector sizes and compatibility with industry-standard connectors like LC, SC, or ST.

Consider the splicing method used in your device. Some closures are designed for fusion splicing, while others accommodate mechanical splicing. Choose a closure that aligns with the splicing method employed in your network.

Ensure that the size and form factor of the splice closure are suitable for your device and its installation environment. Consider factors such as available space, mounting options, and any restrictions that may impact the installation.

Sealing and Protection

Fiber optic cables are highly sensitive to moisture. Water ingress can lead to signal degradation, increased signal loss, and potential corrosion of the fibers. A well-sealed closure prevents moisture from penetrating and damaging the fibers, ensuring the long-term reliability of the network.

Fiber optic networks are often deployed in diverse environments, including outdoor installations. Sealing and protection help shield the enclosed fibers from environmental elements such as rain, snow, dust, and pollutants. This protection is essential to maintain optimal signal quality and prevent damage to the delicate fiber optics.

Sealing the closure provides a barrier against environmental factors that could contribute to the deterioration of the fibers and associated components. This helps extend the lifespan of the fiber optic network infrastructure, reducing the frequency of maintenance and replacement.

Here are steps you can take to identify whether the sealing of a fiber optic splice closure is effective:

Visual Inspection:

Start with a visual inspection of the fiber optic splice closure. Check for any visible cracks, gaps, or signs of physical damage on the box's housing. A well-sealed box should have a solid and intact exterior.

Rubber Gaskets and Seals:

Inspect the rubber gaskets and seals around entry points, such as cable entry ports and cover edges. Ensure that these seals are in good condition, without any visible wear or damage. Damaged seals can compromise the overall sealing effectiveness.

Tightness of Closure:

Verify that the closure or cover of the fiber optic splice closure is tightly secured. If the closure is designed with fasteners, such as screws or latches, ensure that they are properly tightened. An inadequately closed box can allow moisture or contaminants to enter.

Environmental Rating:

Check the environmental rating of the fiber optic splice closure, typically specified by an IP (Ingress Protection) code. The IP code indicates the level of protection against solids and liquids. Ensure that the environmental rating matches the conditions in which the box is installed.

Moisture Detection:

Use a moisture detector or indicator to check for any signs of moisture inside the fiber optic splice closure. Moisture can lead to signal degradation and damage to fiber optic components. If moisture is detected, it suggests a sealing issue that needs attention.

Capacity

Determine the number of fibers your device requires. Choose a splice closure with a capacity that meets or exceeds your current needs, allowing room for future expansions if necessary.

Installation Method

Evaluate the installation method of the closure. Some closures are designed for aerial installation, while others are suitable for underground or direct burial. Choose the one that aligns with your specific installation requirements.

Evaluating the installation method ensures that you choose a closure suitable for the environmental conditions in which it will be deployed, preventing issues related to exposure, moisture, and temperature variations.

The installation method determines the level of protection the closure provides against external factors such as weather, dust, and pests. Proper evaluation ensures that the closure is capable of withstanding these elements, preventing damage to the enclosed fibers and maintaining the reliability of the network.

Ease of Access for Maintenance:

Different installation methods impact the ease of access to the fibers for maintenance and repairs. Understanding the installation method helps ensure that the closure design allows for convenient access without compromising the integrity of the network. This is especially important for quick troubleshooting and efficient network management.

Durability

Assessing the quality of materials used in the construction of the closure. High-quality materials, such as UV-resistant plastics or corrosion-resistant metals, contribute to the overall durability of the closure. Check if the materials are suitable for the environmental conditions in which the closure will be deployed.

Examine the closure's environmental ratings, such as IP (Ingress Protection) ratings. These ratings provide information about the closure's resistance to elements like dust, moisture, and other environmental factors. Higher IP ratings generally indicate better durability in challenging conditions.

If the closure will be exposed to sunlight, consider its UV resistance. UV-resistant materials prevent degradation and discoloration caused by prolonged exposure to ultraviolet rays, ensuring the closure's durability in outdoor environments.

Accessibility

Consider how easily you can access the fibers for maintenance and repairs. Choose a closure with a user-friendly design that allows for quick and convenient access to the spliced fibers without compromising the integrity of the closure.

Accessibility is vital for maintenance tasks such as splicing, testing, and repairs. A closure with easy accessibility allows technicians to quickly access the fibers and components, facilitating efficient maintenance activities. This is especially important in minimizing downtime and ensuring the network's reliability.

In the event of a network issue or failure, rapid troubleshooting is essential. An easily accessible closure allows technicians to identify and address problems promptly. Quick access to spliced fibers and other components simplifies the troubleshooting process, reducing the time required to restore the network.

As network requirements evolve, there may be a need for modifications or expansions. An accessible closure allows for easier implementation of changes, additions, or upgrades without significant disruption to the existing infrastructure. This flexibility is important for future-proofing the network.

A closure with good accessibility often features a user-friendly design. This includes easy-to-open closures, well-designed trays, and organized cable management systems. User-friendly designs simplify the tasks performed within the closure, making it more intuitive for technicians.

Cable Management

Fiber optic splice closure for closures with efficient cable management features. Adequate space and organization for storing and managing excess fiber optic cable length will help maintain a neat and organized installation.

Proper cable management helps prevent signal degradation by ensuring that fibers are organized and do not experience excessive bending or stress. Maintaining the recommended bend radius and avoiding cable entanglement are critical for preserving signal integrity.

Well-organized cables simplify troubleshooting and maintenance tasks. Neat cable management reduces the risk of interference between fibers. Cross-talk or signal interference can occur if fibers are too close or improperly organized.

Efficient cable management allows for easier access to individual fibers, connectors, and splices. This facilitates future maintenance activities and network upgrades, making it simpler to add or modify connections without causing disruptions to the existing infrastructure.

0 notes

Text

Louvre Test for Ensuring Optimal Airflow and Ventilation Efficiency

Louvre Test plays a crucial role in evaluating the performance and reliability of ventilation systems in residential, commercial, and industrial structures. It measures the efficiency of air intake and exhaust systems to ensure that louvres—those angled slats designed to allow airflow while blocking unwanted elements like rain and debris—are performing as expected under real-world conditions.

Understanding the Louvre Test

A Louvre Test is designed to simulate various airflow and environmental conditions to determine how well a louvre manages air penetration, pressure drops, and resistance to water ingress. This assessment is vital in regions with fluctuating weather conditions or environments where precise climate control is essential.

The test not only measures how effectively a louvre ventilates but also its ability to keep moisture and contaminants from entering the internal environment. Properly functioning louvres are critical for maintaining air quality, operational efficiency, and long-term building integrity.

Key Parameters Measured

During a standard Louvre Test, technicians focus on several performance indicators:

Airflow Rate: Determines how much air passes through the louvre under specific pressure conditions.

Pressure Drop: Assesses the resistance the louvre creates, which affects overall ventilation efficiency.

Water Penetration Resistance: Tests how well the louvre blocks rainwater or spray under wind-driven conditions.

Free Area: Refers to the unobstructed area through which air can flow, indicating ventilation capacity.

All these parameters help in identifying whether the installed louvres meet the required building codes and safety standards.

Importance Across Industries

Louvre testing is applicable across various sectors including:

HVAC Systems: Ensuring maximum energy efficiency and proper airflow balance.

Data Centers: Maintaining strict cooling environments by preventing water intrusion and airflow disruptions.

Industrial Facilities: Enhancing ventilation while protecting sensitive equipment from moisture and dust.

Green Buildings: Supporting passive ventilation designs for sustainable architecture.

By conducting this test, businesses ensure that they meet both functional and regulatory requirements.

Enhancing System Efficiency

One of the core benefits of a Louvre Test is its ability to optimize overall HVAC and ventilation performance. A poorly functioning louvre can increase energy costs, reduce system lifespan, and compromise indoor air quality. With reliable testing, stakeholders can make informed decisions about repairs, replacements, or design adjustments.

It also helps in minimizing maintenance costs by preemptively identifying problem areas before they become major issues.

Compliance with International Standards

Many building codes and industry guidelines mandate Louvre Testing as part of their compliance requirements. By performing this test, facilities not only improve their operational safety and performance but also remain aligned with international ventilation and safety protocols.

This is especially crucial in sectors where air quality and moisture control are non-negotiable, such as healthcare, food processing, and high-tech manufacturing.

Future-Proofing with Accurate Testing

As climate conditions continue to evolve and buildings become more performance-driven, the importance of precision testing grows. Louvre Tests offer a proactive approach to ensuring ventilation systems can adapt to future challenges without compromising on efficiency or safety.

With smart building integrations becoming more common, automated monitoring and data analytics from such tests can also feed into larger building management systems (BMS), offering real-time insights and automation capabilities.

Final Thoughts

The Louvre Test is a critical assessment that supports energy efficiency, structural safety, and environmental control across a variety of building types. Whether for compliance, optimization, or sustainability, this test ensures that louvres perform at their best, ultimately supporting the health and functionality of the space they serve.

0 notes

Text

From Defects to Compliance: Building Surveys Cover It All

Understanding the Role of Building Surveys

Building surveys are a crucial component in the property and construction industry, especially in Australia, where compliance with stringent regulations and standards is non-negotiable. Whether for residential, commercial, or industrial properties, building surveys provide comprehensive evaluations that go beyond identifying defects. They ensure that structures adhere to local building codes, safety regulations, and environmental guidelines.

These surveys are typically conducted by qualified professionals with deep knowledge of construction practices, Australian standards, and statutory obligations. The objective is to deliver a clear and accurate picture of a building’s condition, performance, and compliance status.

Types of Building Surveys in Australia

There are several types of building surveys, each serving a unique purpose:

Condition Reports: These surveys focus on the current state of the property, identifying wear, tear, and defects.

Dilapidation Surveys: Often conducted before nearby construction work begins, these surveys document the existing condition of surrounding structures to prevent liability disputes.

Pre-Purchase Surveys: Essential for prospective buyers, these reports assess a property’s integrity before sale.

Compliance Surveys: These ensure the building meets all regulatory requirements, including fire safety, accessibility, and structural stability.

Strata Surveys: Specific to multi-unit developments, they evaluate shared areas and the overall structure.

Each type is designed to provide valuable insights tailored to the needs of property owners, investors, developers, and legal professionals.

The Importance of Identifying Defects

Defects in a building, if left unchecked, can lead to safety hazards, legal issues, and costly repairs. Building surveys play a vital role in early detection of problems such as:

Structural cracks and weaknesses

Roof leaks and water ingress

Pest infestations

Electrical and plumbing faults

Fire safety non-compliance

By identifying these issues early, property owners can undertake necessary remedial actions, preserve property value, and avoid legal ramifications.

Ensuring Regulatory Compliance

Australian building regulations are among the most comprehensive in the world. Ensuring a property complies with these standards is not optional—it is a legal obligation. Building surveys are the primary tool used to assess and document compliance with:

The National Construction Code (NCC)

Local council requirements

Environmental and sustainability standards

Health and safety legislation

Non-compliance can result in penalties, project delays, and even demolition orders in severe cases. Regular and detailed surveys help maintain a property’s legal standing and operational continuity.

Who Needs Building Surveys?

A wide range of stakeholders benefit from building surveys, including:

Homebuyers and Investors: To make informed purchase decisions and negotiate price adjustments.

Developers and Builders: To monitor construction progress and ensure regulatory compliance.

Property Managers: To plan maintenance schedules and protect asset value.

Legal Professionals: To support litigation or insurance claims involving construction disputes.

In the context of both new developments and existing properties, surveys are a risk management tool that supports decision-making at every stage of the property lifecycle.

Benefits of Regular Building Surveys

Undertaking building surveys on a routine basis brings multiple advantages:

Preventative maintenance becomes possible with early detection.

Property value is preserved through ongoing compliance and upkeep.

Insurance claims are supported with accurate documentation.

Legal risks are reduced through evidence-based reporting.

Stakeholder confidence is improved through transparency.

These benefits are particularly relevant in Australia’s diverse and often challenging climatic conditions, which can accelerate wear and tear on buildings.

The Process of Conducting a Building Survey

A typical building survey involves several steps:

Initial Consultation: Understanding the purpose and scope of the survey.

On-Site Inspection: A thorough evaluation of the property’s physical condition.

Documentation and Reporting: Detailed findings are compiled, often including photographs and diagrams.

Recommendations: Actionable advice is provided for rectifications or compliance upgrades.

Professional surveyors use advanced tools and technologies to enhance the accuracy of their assessments, ensuring no detail is overlooked.

Why Building Surveys Are Essential in Australia

With Australia’s complex regulatory landscape and environmental diversity, building surveys are not just a precaution—they are a necessity. From metropolitan developments in Sydney and Melbourne to coastal structures in Queensland and rural properties in Western Australia, every building must be assessed within the context of its specific risks and legal requirements.

A well-executed building survey empowers stakeholders to act decisively, avoid costly mistakes, and maintain the integrity of their investments.

Conclusion

Building surveys serve as a comprehensive solution for uncovering defects, ensuring legal compliance, and maintaining property integrity. Their importance in the Australian property market cannot be overstated. By offering a structured approach to building evaluation, these surveys protect both property and people, making them an indispensable service for anyone involved in real estate, construction, or property management.

0 notes

Text

Targeted Concrete and Waterproofing Solutions for Massachusetts Properties

Moisture intrusion and structural cracking are common issues for property owners across the region. Massachusetts basement waterproofing and concrete repair addresses both challenges by sealing water entry points and restoring concrete integrity in one streamlined process. This dual solution not only improves the stability of foundations but also mitigates risks associated with mould, water damage, and future deterioration. Proper basement waterproofing is especially important in older homes and flood-prone areas where long-term water pressure weakens concrete slabs and walls.

Why Elevator Pit Waterproofing Is a Priority in Massachusetts

Commercial and multi-storey buildings rely on safe, dry elevator systems. Over time, elevator pits become vulnerable to groundwater seepage, which can damage mechanical systems and create costly maintenance problems. Elevator pit waterproofing Massachusetts solutions are specifically designed to block water ingress, protect electrical components, and prevent corrosion of metal structures. A professionally waterproofed elevator pit ensures operational safety and compliance with inspection standards, particularly in high-moisture zones across the state.

Maintaining Indoor Air Quality with Crawl Space Dehumidifier Systems

Damp, enclosed crawl spaces are ideal environments for mould, mildew, and insect infestations. These conditions can affect air quality throughout the home and create musty odours that persist despite surface cleaning. Installing a crawl space dehumidifier Massachusetts helps regulate humidity, control condensation, and protect subfloor insulation and support beams from moisture damage. Dehumidifiers also improve energy efficiency by keeping indoor air dry and easier to heat or cool, making them a valuable long-term investment in both new and existing properties.