ngi-O is a dynamic company committed to sophisticated, uncomplicated filling solutions for the Aseptic and ESL (Extended Shelf Life) Bag in Box industry. Contact UsWeb - https://www.engi-o.com/Address: Factory 20, 257 Colchester Road Kilsyth VIC 3137 Australia

Don't wanna be here? Send us removal request.

Text

Engi-O: Elevating Aseptic Bag-in-Box Solutions with FDA-Validated Equipment and Innovative Material Handling

Engi-O Australia, a leading innovator in bag-in-box (BIB) aseptic filling technology, is proud to announce two exciting advancements. Firstly, their flagship Engi-O Aseptic Filling Equipment has recently passed a rigorous Food and Drug Administration (FDA) validation in a new North American installation. This signifies international recognition of Engi-O's commitment to quality and adherence to the highest hygiene standards. Secondly, Engi-O is expanding its offerings to include materials handling solutions, aiming to further streamline and optimize the BIB aseptic filling process for its customers.

Beyond Convenience: Unveiling the Benefits of Aseptic Bag-in-Box Packaging

Bag In Box packaging Machine offers a unique and advantageous solution for aseptic applications, particularly within the food and beverage industry. Here's why Engi-O champions BIB technology:

Enhanced Product Shelf Life: Aseptic filling ensures the sterility of both the product and the packaging, significantly extending shelf life and reducing the need for preservatives.

Lightweight and Portable: BIB packaging is lighter and more compact than traditional rigid containers, minimizing transportation and storage costs.

Eco-Friendly Advantages: BIB packaging utilizes less material compared to glass or metal containers, offering a more sustainable packaging option.

Cost-Effective: Engi-O's BIB filling equipment offers a cost-effective solution compared to complex aseptic bottling lines.

Versatility: BIB packaging is suitable for a variety of liquid products, from beverages like juices and wine to dairy products and even pharmaceuticals.

Engi-O Australia: Pioneering Aseptic Innovation with FDA-Validated Equipment

The successful FDA validation of Engi-O's aseptic filling equipment signifies a significant milestone for the company. Here's what this achievement means for you:

Unmatched Quality and Hygiene: FDA validation confirms that Engi-O's equipment meets the strictest hygiene standards set by the FDA, ensuring the utmost product safety for your aseptic fillings.

Global Recognition: This validation opens doors for Engi-O's technology to be used in a wider range of markets, particularly in North America with its stringent regulations.

Peace of Mind for Producers: By choosing Engi-O's FDA-validated equipment, you gain peace of mind knowing your aseptic filling process adheres to the highest international standards.

Reliable and Consistent Performance: Engi-O's equipment is designed for reliable and consistent operation, minimizing the risk of contamination or production downtime.

Engi-O Unveils Innovative Material Handling Solutions

Building upon their success in aseptic filling equipment, Engi-O is taking things a step further by introducing material handling solutions. Here's how this expansion benefits you:

Streamlined Workflow: Engi-O's material handling solutions integrate seamlessly with their aseptic filling equipment, creating a more efficient and streamlined workflow.

Reduced Labor Costs: Automated material handling can minimize manual labor requirements, optimizing production efficiency and reducing overall costs.

Improved Ergonomics: Ergonomic material handling systems can reduce physical strain on your workforce, promoting a safer and healthier working environment.

Cost-Effective Integration: Engi-O's material handling solutions are designed to be cost-effective and easily integrated with existing BIB filling lines.

Scalability for Growth: As your production needs evolve, Engi-O's material handling solutions can be scaled to accommodate your growing business.

Engi-O Australia: Committed to Sustainable Practices

Sustainability is a core value at Engi-O. This commitment is reflected in their approach to both technology and business practices:

Reduced Waste: BIB packaging itself offers a more sustainable option with its reduced material usage compared to traditional containers.

Durable and Long-Lasting Equipment: Engi-O's equipment is built to last, minimizing resource consumption through frequent replacements.

Energy-Efficient Technology: Engi-O prioritizes energy-efficient design principles in their equipment and material handling solutions.

Responsible Manufacturing: The company strives to partner with suppliers committed to sustainable practices throughout the manufacturing process.

Engi-O: Your Partner for Aseptic BIB Packaging Solutions

Engi-O Australia is your one-stop shop for all your aseptic BIB packaging needs. From their FDA-validated aseptic filling equipment to their innovative material handling solutions, Engi-O provides a comprehensive suite of products to optimize your production process.

Contact Us Today

Visit Engi-O Australia's website or contact them today. Their expert team is eager to discuss your specific requirements and guide you towards the best aseptic BIB packaging

Contact Web - https://engi-o.com/products/non-aseptic/t140a Ph - +61 3 8820 0090 Address - Factory 20, 257 Colchester Road, Kilsyth VIC 3137 Australia

0 notes

Text

Filling the Future: Engi-O's Aseptic Equipment Revolutionizes Australian Production

The Australian landscape of food and beverage production is on the rise. Consumers are demanding high-quality, shelf-stable products that retain their freshness and flavor. To meet this growing need, Engi-O, a leading innovator in aseptic filling equipment, has expanded its reach across Australia, offering its cutting-edge solutions to manufacturers nationwide.

What is Aseptic Filling and Why Does it Matter?

Aseptic filling is a sterile packaging process that eliminates harmful microorganisms from both the product and the packaging environment. This ensures the product remains free from contamination and extends its shelf life without refrigeration. This translates to significant benefits for producers and consumers alike.

Benefits for Producers:

Extended shelf life: Aseptic filling allows products to remain fresh for longer periods, reducing waste and spoilage.

Increased production flexibility: Aseptic packaging enables manufacturers to cater to a wider market by eliminating the need for refrigerated transportation and storage.

Improved product quality: Aseptic filling preserves the taste, aroma, and nutritional value of products, ensuring a superior consumer experience.

Benefits for Consumers:

Convenience: Aseptic packaging offers a convenient option for busy lifestyles, eliminating the need for immediate consumption.

Reduced food waste: Longer shelf life translates to less food waste at home.

Wider product variety: Aseptic technology allows consumers to access a broader range of shelf-stable products.

Engi-O: Aseptic Filling Expertise for Australia

Engi-O has been a trusted name in aseptic filling equipment for decades. Their commitment to innovation and quality has resulted in a range of solutions perfectly suited for the Australian market. Here's what sets Engi-O apart:

Versatility: Their equipment caters to a wide range of products, from liquid foods like milk, juice, and soups to viscous products like sauces and condiments.

Scalability: Engi-O offers solutions for businesses of all sizes, from compact machines for small-scale production to high-capacity lines for large-scale manufacturers.

Efficiency: Their equipment is designed for optimal performance, minimizing downtime and maximizing production efficiency.

Reliability: Engi-O's aseptic filling equipment is renowned for its durability and reliability, ensuring consistent performance and minimal maintenance needs.

FDA Validation: Many Engi-O machines are FDA validated, meeting the strictest international standards for food safety and hygiene.

The Engi-O Advantage: Beyond the Equipment

Engi-O understands that aseptic filling is more than just equipment. They offer comprehensive support to their Australian customers, including:

Expert consultation: Engi-O's experienced team provides expert advice on choosing the right equipment for your specific needs and production goals.

Installation and training: Their technicians ensure a smooth installation process and provide comprehensive training to your staff on operating the equipment effectively.

Ongoing service and support: Engi-O offers reliable after-sales service and technical support, ensuring you have the resources needed to maintain optimal performance.

Engi-O: Partnering for a Brighter Australian Future

With Engi-O's aseptic filling equipment readily available across Australia, manufacturers now have the tools they need to meet the evolving demands of the market. This translates to a wider range of high-quality, shelf-stable products for consumers, reduced food waste, and a more efficient and sustainable Australian food and beverage industry. By partnering with Engi-O, Australian manufacturers can embrace the future of aseptic filling and ensure their products reach consumers with lasting freshness and flavor.

Ready to take your production to the next level? Contact Engi-O today and explore how their aseptic filling equipment can revolutionize your business.

Contact Web - https://engi-o.com/products/aseptic Ph - +61 3 8820 0090 Address - Factory 20, 257 Colchester Road, Kilsyth VIC 3137 Australia

0 notes

Text

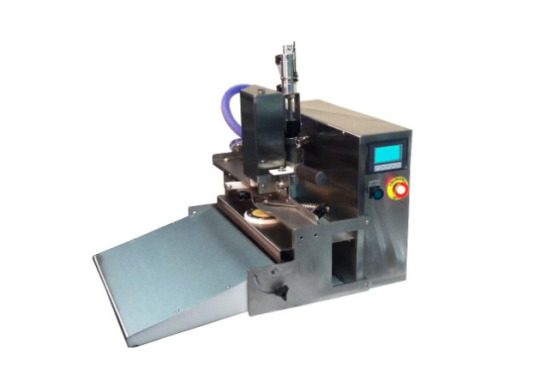

Beyond the Bucket Brigade: Unleash Efficiency with Engi-O's Manual Pouch Filling Machines

Imagine a world where filling pouches is no longer a messy, time-consuming chore. A world where you can say goodbye to overflowing buckets and repetitive scooping. At Engi-O, we understand the challenges of small-scale production, and that's why we offer a revolutionary solution: manual pouch filling machines that prioritize efficiency and precision.

Engi-O: Exceeding European Standards for Your Australian Needs

Our manual pouch filling machines, like the Semi-Manual BIB Filler Bag-in-Box 130M, are not just about convenience. They're built to comply with the strict CE standards of Europe, ensuring the highest quality and safety for your Australian production line. This translates to reliable performance, minimal maintenance, and peace of mind for you.

Manual Doesn't Mean Basic: The Advantages of Engi-O's Pouch Fillers

While manual pouch filling machines might seem basic compared to their automated counterparts, Engi-O's solutions offer a plethora of advantages for small-batch producers:

Simplified Operation: Our manual pouch filling machines are incredibly user-friendly. Even with minimal training, operators can quickly master the filling process, minimizing downtime and maximizing productivity.

Enhanced Accuracy: Say goodbye to inconsistent fills. Engi-O's manual pouch filling machines ensure consistent and precise filling with every pouch, eliminating product waste and ensuring consistent quality control.

Improved Hygiene: Manual filling can be a breeding ground for contamination. Our machines prioritize hygiene with features like pneumatic uncapping and recapping, minimizing operator contact with the product and pouch opening.

Cost-Effective Solution: For small-scale producers, investing in a fully automated filling line might not be feasible. Engi-O's manual pouch filling machines offer a cost-effective alternative, allowing you to scale up your production efficiently without breaking the bank.

Adaptability is Key: Our manual pouch filling machines are designed to handle a wide range of products, from viscous liquids like sauces and condiments to free-flowing powders and granules. This versatility allows you to fill a variety of pouches for different products within your range.

Compact Footprint: Space is often a premium in small production facilities. Engi-O's manual pouch filling machines boast a compact footprint, fitting seamlessly into your existing workspace without sacrificing functionality.

The Engi-O Difference: Solutions Tailored for Your Needs

We understand that every business has unique needs. That's why Engi-O offers a variety of manual pouch filling machines to cater to your specific requirements. Here's a glimpse into what sets us apart:

Customization Options: We offer various customization options, such as different filling head configurations and integration with existing filling tables. This allows you to tailor the machine to your specific production line and product characteristics.

Expert Support: Our team of experts is here to guide you every step of the way. From selecting the right machine for your needs to providing comprehensive training and ongoing support, we're here to ensure your success.

Commitment to Quality: At Engi-O, we prioritize quality in everything we do. Our machines are built with high-grade materials and meticulous engineering, ensuring long-lasting performance and minimal downtime.

Moving Beyond the Bucket: A Brighter Filling Future

Engi-O's manual pouch filling machines are the perfect solution for Australian businesses looking to transition from manual bucket filling to a more efficient and controlled process. Here's how our machines can benefit you:

Increased Production Capacity: With consistent and precise filling, you can increase your production output without compromising on quality.

Reduced Labor Costs: Manual pouch filling machines free up your workforce to focus on other tasks, improving overall production efficiency and reducing labor costs.

Enhanced Product Consistency: Consistent filling ensures consistent product quality, which translates to customer satisfaction and brand loyalty.

Improved Hygiene Standards: Minimized operator contact with the product during filling reduces the risk of contamination, ensuring a safe and hygienic production environment.

Invest in Your Future: Choose Engi-O's Manual Pouch Filling Machines Today

Are you ready to ditch the bucket brigade and embrace a more efficient and controlled filling process? Look no further than Engi-O's manual pouch filling machines. Contact us today to discuss your specific needs and explore how our solutions can revolutionize your Australian production line. With Engi-O, you can achieve exceptional results without breaking the bank. Let's embark on a journey towards a brighter, more efficient filling future together.

Contact Web - https://engi-o.com/products/non-aseptic/t130m Ph - +61 3 8820 0090 Address - Factory 20, 257 Colchester Road, Kilsyth VIC 3137 Australia

0 notes

Text

Ensuring Efficiency and Hygiene: Bulk Bag Filling Solutions with The Engi-O Aseptic Combination A5 Filler (Australia)

In today's fast-paced Australian manufacturing landscape, optimizing production processes is paramount. For businesses dealing with liquid or powder products in bulk quantities, efficient and hygienic filling solutions are essential. Here at Engi-O, we introduce the Aseptic Combination A5 Filler – a versatile bulk bag filler designed to cater to a diverse range of filling requirements.

Beyond the Sack: Unveiling the Significance of Bulk Bag Filling

Bulk bag filling offers numerous advantages for businesses handling large quantities of product:

Cost-Effectiveness: Bulk bags are generally more cost-effective than smaller packaging options, reducing overall packaging costs.

Efficiency: Bulk bag filling systems automate the filling process, significantly increasing production speed and throughput.

Reduced Labor: Automated filling minimizes manual labor requirements, allowing for a more efficient workflow.

Bulk Bag Filler: Aseptic Technology Meets Versatility

The Engi-O Aseptic Combination A5 Filler sets itself apart from traditional bulk bag fillers with its emphasis on aseptic technology:

Maintaining Product Integrity: The A5 Filler utilizes aseptic filling techniques to ensure product sterility and minimize the risk of contamination.

Configurable Filling Options: The A5 Filler offers a range of configurations to accommodate various product types, viscosities, and filling speeds.

Integrated Cleaning Systems: The filler boasts integrated cleaning systems, ensuring a high level of hygiene throughout the filling process.

Why Choose the Engi-O Aseptic Combination A5 Filler?

Here's what makes the Engi-O Aseptic Combination A5 Filler the ideal solution for your bulk bag filling needs in Australia:

Australian Expertise: Engi-O understands the specific requirements of the Australian market, ensuring the A5 Filler is designed to meet local regulations and standards.

Durability and Reliability: The A5 Filler is constructed with high-quality materials and components, guaranteeing long-lasting performance and minimal downtime.

Commitment to Innovation: Engi-O is dedicated to continuous improvement, ensuring the A5 Filler remains at the forefront of aseptic bulk bag filling technology.

Imagine Streamlined Production with Aseptic Efficiency

Imagine a bulk bag filling system that automates your process, minimizes product contamination risk, and adapts to your specific needs. Picture increased production speeds, reduced labor costs, and the peace of mind that comes with aseptic filling technology. That's the power of the Engi-O Aseptic Combination A5 Filler.

Beyond the A5 Filler: A Spectrum of Filling Solutions

While the Aseptic Combination A5 Filler excels in aseptic bulk bag filling, Engi-O offers a comprehensive range of filling solutions to cater to diverse needs:

Form-Fill-Seal Machines: Our FFS machines automate the entire process of forming pouches, filling them with product, and sealing them shut.

Liquid Filling Lines: We offer complete liquid filling lines, encompassing cleaning, filling, capping, and labeling equipment for optimal efficiency.

Powder Filling Systems: From auger fillers to dosing systems, Engi-O provides a variety of solutions for efficient and precise powder filling.

Contact Engi-O Today!

Ready to explore the potential of the Aseptic Combination A5 Filler and discover the perfect bulk bag filling solution for your Australian business? Contact Engi-O today! Discuss your specific filling requirements with our expert team, explore the capabilities of the A5 Filler, and find the ideal solution to optimize your production process and ensure aseptic product handling. Let Engi-O be your partner in achieving efficient and hygienic bulk bag filling.

Contact Web - https://engi-o.com/products/aseptic/combination-filler Ph - +61 3 8820 0090 Address - Factory 20, 257 Colchester Road, Kilsyth VIC 3137 Australia

0 notes

Text

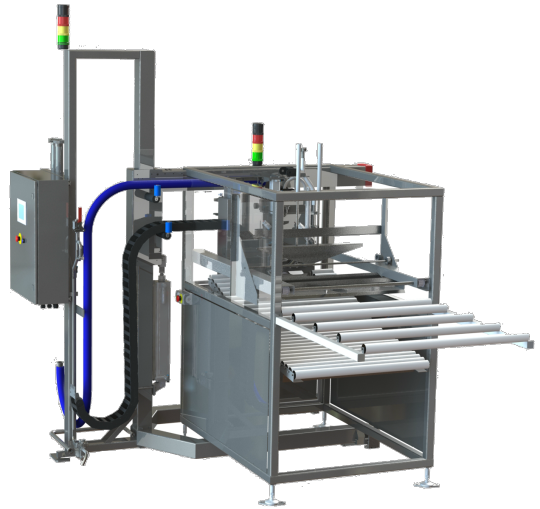

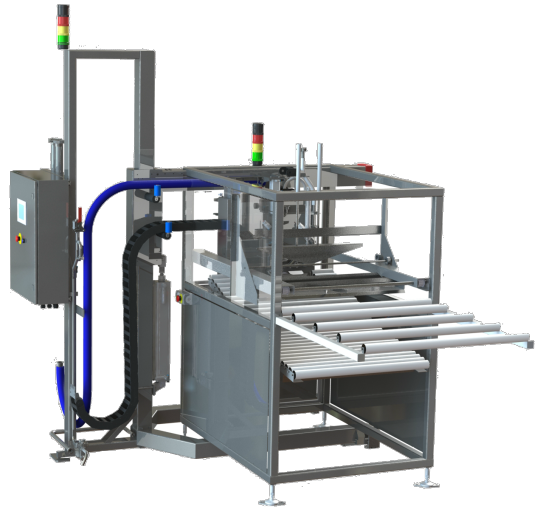

Engi-O Australia: Introducing the Autofeed for Enhanced Flexibility in Convertible Combination Fillers (Automatic Liquid Filling Machine)

Here at Engi-O Australia, we're dedicated to providing innovative solutions for the liquid filling industry. We understand the importance of efficiency and flexibility in production lines, and we're thrilled to announce the addition of the autofeed system to our popular convertible combination filler. This exciting development empowers users with greater control and adaptability in their liquid filling operations.

Beyond the Standard: Unveiling the Convertible Combination Filler

The convertible combination filler is a versatile workhorse in the world of automatic liquid filling machines. Its unique design allows it to seamlessly switch between filling from:

Bulk Tanks: For high-volume production runs.

Small Bags: Ideal for handling smaller batches or specialty liquids.

This adaptability makes the convertible combination filler a valuable asset for manufacturers dealing with diverse production needs. However, manually transferring bags into the filling head could introduce inefficiencies and potential for operator error.

Introducing the Autofeed: A Game Changer for Efficiency

The new autofeed system seamlessly integrates with the convertible combination filler, specifically when operating in the small bag configuration. Here's how it elevates your filling experience:

Automated Bag Feeding: The autofeed system automatically pulls bags from a designated magazine, eliminating the need for manual bag placement and significantly boosting productivity.

Reduced Operator Dependence: With the autofeed taking care of bag handling, operators can focus on other critical tasks within the production line, optimizing overall workflow.

Enhanced Consistency: Automatic bag feeding ensures consistent bag positioning and alignment, minimizing the risk of errors and potential product spills during the filling process.

Improved Safety: The autofeed system reduces the need for operators to be in close proximity to the filling head during operation, enhancing safety within the production environment.

Engi-O Australia: Your Partner in Streamlined Liquid Filling

As a leading provider of automatic liquid filling machines in Australia, Engi-O Australia is committed to offering solutions that cater to your specific needs:

Expert Support: Our team of knowledgeable specialists is here to answer your questions, guide you through the autofeed system, and ensure its seamless integration into your existing convertible combination filler.

Unwavering Commitment to Quality: The autofeed system is built with high-quality components and adheres to stringent safety standards, ensuring reliable operation and longevity.

A Range of Filling Solutions: Beyond the convertible combination filler, Engi-O Australia offers a comprehensive range of automatic liquid filling machines to suit diverse production requirements.

Imagine a Filling Process Tailored to Your Needs

The autofeed system for the convertible combination filler empowers you to achieve a new level of efficiency and flexibility in your production line. Imagine automated bag handling freeing up valuable operator time, ensuring consistent filling processes, and ultimately, boosting your overall productivity.

Beyond the Autofeed: A World of Filling Solutions

Engi-O Australia understands that one size doesn't fit all. We offer a variety of automatic liquid filling machines to suit your specific needs, including:

Piston Fillers: Ideal for precise filling of viscous or foamy liquids.

Gravity Fillers: A cost-effective solution for free-flowing liquids.

Net Weigh Fillers: Ensures accurate filling by weight, particularly for powders and granular products.

Contact Engi-O Australia Today!

Ready to take your liquid filling operation to the next level? Contact Engi-O Australia today! Explore the benefits of the autofeed system for your convertible combination filler, or discuss other filling solutions that perfectly align with your production needs. Let Engi-O Australia be your partner in achieving optimized and efficient liquid filling processes.

Contact Web - https://engi-o.com/products/aseptic/autofeed Ph - +61 3 8820 0090 Address - Factory 20, 257 Colchester Road, Kilsyth VIC 3137 Australia

0 notes

Text

Revolutionizing Small Bag Filling: Introducing the Aseptic Front-Entry Filler (A3) by Engi-O Australia

For Australian businesses seeking innovative solutions in small bag filling, the wait is over. Engi-O Australia is proud to introduce the A3 Model – the Aseptic Front-Entry Filler. This compact and versatile machine offers unparalleled efficiency and aseptic filling capabilities, making it the perfect solution for a variety of industries. Here, we'll delve into the world of small bag filling equipment and unveil how the A3 can transform your production process.

Beyond the Limits: Unveiling the Challenges of Traditional Small Bag Filling

Traditional small bag filling methods often come with limitations that hinder efficiency and safety:

Manual Processes: Manual filling can be time-consuming, labor-intensive, and prone to human error, impacting productivity and product consistency.

Inefficient Equipment: Outdated filling equipment may lack precision, leading to inconsistencies in fill volume and potential product waste.

Compromised Sterility: Maintaining sterility during the filling process can be challenging with traditional methods, increasing the risk of contamination.

The Aseptic Front-Entry Filler (A3): A Revolution in Small Bag Filling

The A3 Model by Engi-O Australia addresses these challenges head-on, offering a game-changing solution for small bag filling:

Aseptic Filling: The A3 boasts advanced aseptic technology, ensuring a sterile filling environment that minimizes the risk of contamination, safeguarding product quality.

Compact Design: The A3's compact footprint makes it ideal for businesses with limited space. It can be installed as a standalone unit or seamlessly integrated with existing bulk filling lines for increased production capacity.

Precise Filling: The A3 utilizes a highly accurate filling system, ensuring consistent and precise fill volumes across every bag, minimizing product waste and maximizing production efficiency.

Engi-O Australia: Your Trusted Partner for Aseptic Small Bag Filling Solutions

At Engi-O Australia, we're committed to providing Australian businesses with cutting-edge equipment and exceptional service. Here's why we're the ideal partner for your small bag filling needs:

Unparalleled Quality: We offer genuine A3 Fillers from a renowned manufacturer, guaranteeing superior performance, reliability, and long-lasting durability.

Expert Support: Our dedicated team of engineers possesses a deep understanding of the A3 and small bag filling processes. We offer comprehensive support, from installation and training to ongoing maintenance.

Diverse Applications: The A3 is suitable for a wide range of products, from food and beverages to pharmaceuticals and cosmetics, making it a versatile solution for various industries.

Beyond the Machine: Unveiling the A3's Impact on Your Business

The A3's capabilities extend far beyond just efficient and aseptic filling:

Increased Production: The A3 allows you to fill small bags quickly and precisely, significantly increasing production capacity compared to manual or outdated methods.

Reduced Waste: Precise filling minimizes product waste, ensuring you get the most out of your valuable resources and improve overall production efficiency.

Enhanced Safety and Product Quality: The Aseptic Front-Entry Filler prioritizes a sterile filling environment, safeguarding product quality and consumer health.

Embrace Efficiency and Aseptic Filling with Engi-O Australia

Investing in the Aseptic Front-Entry Filler (A3) from Engi-O Australia empowers your business to revolutionize small bag filling. Imagine achieving increased production, minimal waste, and aseptic filling practices for enhanced product quality – all within a compact and efficient system.

Contact Engi-O Australia today to discuss your small bag filling needs and explore the transformative potential of the A3 Model. Let our team guide you towards a more efficient and aseptic filling process, propelling your business forward.

Contact Web - https://www.engi-o.com/products/aseptic/front-entry-filler Ph - +61 3 8820 0090 Address - Factory 20, 257 Colchester Road, Kilsyth VIC 3137 Australia

0 notes

Text

Aseptic Drum Filling: A Streamlined Solution with the A4 Drum Filler by Engi-O Australia

In the fast-paced world of manufacturing, efficiency and versatility are the cornerstones of success. When it comes to aseptic drum filling, the A4 Drum Filler from Engi-O Australia stands out as a game-changer. This innovative machine offers a robust and adaptable solution, catering to a wide range of production needs while maintaining the highest standards of hygiene.

Contact Web - https://www.engi-o.com/products/aseptic/drum-bib-filler Ph - +61 3 8820 0090 Address - Factory 20, 257 Colchester Road, Kilsyth VIC 3137 Australia

0 notes

Text

Enhancing Packaging Reliability with Engi-O's Seal Integrity Tester in Australia

In today's competitive market, ensuring the quality and safety of packaged products is paramount. Engi-O, a leader in innovative packaging solutions, is proud to introduce its advanced Seal Integrity Tester to the Australian market. This cutting-edge device is designed to detect any potential leaks in heat seals, ensuring that products remain uncompromised after filling.

The Seal Integrity Tester operates by applying precise pressure to the sealed area, identifying even the smallest defects that could lead to product contamination. By incorporating this essential step into the production line, manufacturers can guarantee that their products reach consumers in perfect condition. This not only enhances brand reputation but also complies with stringent industry regulations.

Contact Web - https://engi-o.com/products/accessories/seal-tester Ph - +61 3 8820 0090 Address - Factory 20, 257 Colchester Road, Kilsyth VIC 3137 Australia

0 notes

Text

Revolutionize Your Packaging Process with Engio's Manual Pouch Filling Machine

In today's fast-paced manufacturing industry, efficiency and accuracy are paramount. That's why Engio's Manual Pouch Filling Machine is a game-changer for businesses looking to streamline their packaging process. Whether you're packaging liquids, powders, or granules, this innovative machine offers unparalleled precision and control, allowing you to meet the demands of your customers with ease.

Designed with user convenience in mind, Engio's Manual Pouch Filling Machine is easy to operate and requires minimal training. Its intuitive interface and customizable settings make it suitable for a wide range of products and packaging requirements. With its compact design and durable construction, this machine is ideal for small to medium-sized businesses looking to maximize their production capabilities without breaking the bank.

Contact Web - https://engi-o.com/products/non-aseptic/t130m Ph - +61 3 8820 0090 Address - Factory 20, 257 Colchester Road, Kilsyth VIC 3137 Australia

0 notes

Text

Enhancing Efficiency with Engi-O's Automatic Filling Machine

Engi-O is proud to announce an exciting new addition to our lineup of filling machines - the Automatic Filling Machine with autofeed functionality. Designed to streamline your production process and maximize efficiency, this innovative unit attaches seamlessly to the head of our convertible combination filler, offering users unparalleled flexibility and convenience. Let's explore how this cutting-edge technology can revolutionize your operations.

Streamlined Production:

With the Automatic Filling Machine from Engi-O, filling containers has never been easier. The autofeed addition eliminates the need for manual intervention, allowing for a continuous and uninterrupted filling process. Whether you're working with small bags or larger containers, this versatile unit ensures consistent and precise filling every time, saving you valuable time and resources.

Flexibility and Versatility:

One of the key advantages of Engi-O's Automatic Filling Machine is its ability to adapt to different configurations and applications. Whether you're filling bags, bottles, or other types of containers, this unit offers unparalleled flexibility, allowing you to customize your setup to meet your specific needs. The autofeed functionality adds an extra layer of convenience, giving you greater control over your production process.

Enhanced Efficiency:

By automating the filling process, Engi-O's Automatic Filling Machine helps increase productivity and efficiency in your operation. With fewer manual tasks to manage, your team can focus on other critical aspects of production, such as quality control and packaging. This not only saves time but also reduces the risk of errors and inconsistencies, ensuring a smoother and more streamlined workflow.

Seamless Integration:

The Automatic Filling Machine is designed to seamlessly integrate with Engi-O's convertible combination filler, providing a hassle-free solution for upgrading your equipment. The unit attaches directly to the head of the filler, allowing for easy installation and minimal downtime. Whether you're a small-scale producer or a large manufacturing facility, this versatile unit can be tailored to fit your specific requirements.

Optimized Performance:

With its advanced features and intuitive design, Engi-O's Automatic Filling Machine delivers optimal performance and reliability in even the most demanding production environments. Built to withstand the rigors of continuous operation, this unit is engineered for durability and longevity, ensuring years of dependable service with minimal maintenance requirements.

Experience the Difference:

Ready to take your filling operations to the next level? Experience the difference with Engi-O's Automatic Filling Machine. With its innovative design, flexible functionality, and unparalleled performance, this cutting-edge unit is the perfect solution for streamlining your production process and maximizing efficiency. Contact us today to learn more and discover how Engi-O can help you achieve your goals.

Engi-O now offers an autofeed addition to the convertible combination filler. The unit is attached to the head in the small bag configuration and delivers more flexibility to the user.

Contact Web - https://engi-o.com/products/aseptic/autofeed Ph - +61 3 8820 0090 Address - Factory 20, 257 Colchester Road, Kilsyth VIC 3137 Australia

0 notes

Text

Revolutionizing Filling Solutions with the Engi-O Aseptic Combination A5 Filler

In the dynamic world of manufacturing and packaging, efficiency, versatility, and precision are paramount. Enter the Engi-O Aseptic Combination A5 Filler, a cutting-edge solution designed to meet the diverse needs of modern production facilities. Whether you're in the food and beverage industry, pharmaceuticals, or any other sector requiring aseptic filling, this innovative machine offers a range of configurations to suit a variety of filling requirements, including the capability to function as a bulk bag filler.

The Power of Adaptability:

One of the standout features of the Engi-O Aseptic Combination A5 Filler is its adaptability. With multiple configurations available, it can seamlessly integrate into different production lines and accommodate various packaging formats. From bottles and cartons to pouches and bulk bags, this versatile filler can handle it all, ensuring maximum efficiency and flexibility for your operations.

Precision Engineering:

Precision is key when it comes to filling applications, especially in industries where product integrity and safety are paramount. The Engi-O Aseptic Combination A5 Filler is built with precision engineering at its core, utilizing advanced technology to deliver accurate fills with minimal waste. Whether you're filling liquid products, viscous substances, or powders, you can trust this machine to maintain consistency and reliability, ensuring superior product quality every time.

Aseptic Assurance:

Maintaining a sterile environment is crucial in industries such as pharmaceuticals and food processing, where contamination can have serious consequences. The Engi-O Aseptic Combination A5 Filler is designed with a focus on aseptic filling, incorporating features that minimize the risk of microbial contamination and preserve product freshness and shelf life. With its advanced sterilization systems and hygienic design, this filler provides peace of mind that your products meet the highest safety standards.

Streamlined Efficiency:

In today's fast-paced manufacturing environment, efficiency is non-negotiable. The Engi-O Aseptic Combination A5 Filler is engineered for maximum efficiency, with intuitive controls and automated processes that streamline production and minimize downtime. Whether you're filling small batches or running high-volume production lines, this machine helps optimize throughput and maximize output, ensuring you stay ahead of the competition.

The Future of Filling:

As industries continue to evolve and consumer demands change, the need for flexible, reliable filling solutions will only grow. The Engi-O Aseptic Combination A5 Filler represents the future of filling technology, offering unmatched versatility, precision, and efficiency to meet the demands of today and tomorrow. With its ability to function as a bulk bag filler and adapt to a wide range of packaging formats, this innovative machine is poised to revolutionize filling operations across industries.

Experience the Engi-O Advantage:

Ready to take your filling operations to the next level? Discover the power of the Engi-O Aseptic Combination A5 Filler and experience the difference it can make for your business. With its range of configurations, including the capability to serve as a bulk bag filler, this versatile machine offers unparalleled flexibility, precision, and efficiency, ensuring you can meet the diverse needs of your production environment with ease. Invest in the future of filling technology with Engi-O and stay ahead of the curve.

Contact Web - https://engi-o.com/products/aseptic/combination-filler Ph - +61 3 8820 0090 Address - Factory 20, 257 Colchester Road, Kilsyth VIC 3137 Australia

0 notes

Text

Elevate Your Packaging Game: Engi-O Aseptic Drum Filler A4 Takes Efficiency to New Heights

In the dynamic landscape of industrial packaging, finding solutions that seamlessly blend efficiency, precision, and versatility is paramount. Enter the Engi-O Aseptic Drum Filler A4—a technological marvel meticulously crafted to meet the diverse needs of modern manufacturers. Let's embark on a journey to explore why the Engi-O Aseptic Drum Filler A4 stands as the epitome of excellence in the realm of packaging solutions.

In industries where aseptic conditions are non-negotiable, precision becomes paramount. The Engi-O Aseptic Drum Filler A4 rises to the challenge with its advanced engineering and meticulous design. From sterile filling to hermetic sealing, every aspect of the filling process is executed with surgical precision, safeguarding product integrity and upholding the highest standards of hygiene and safety.

Aseptic bag-in-box Drum Filler A4 is ideal for filling drums of up to 240L. It can also be used to fill small 20L bags or sample bags.

Features:

2-200L bags 316 Stainless Steel components 1x1.5" Magnetic Flow Meter, +/-.5 accuracy Optional handheld screen for machine control flexibility Autofill and eject routine Gemu angle seat valves Two hand safety start Optional conveying accessory with remote commands Bioflex product hose (US 3A standards) Height adjustable

Contact Web - https://www.engi-o.com/products/aseptic/drum-bib-filler Ph - +61 3 8820 0090 Address - Factory 20, 257 Colchester Road, Kilsyth VIC 3137 Australia

0 notes

Text

Revolutionizing Small Bag Filling: Introducing the Engi-O Aseptic Front-Entry Filler (A3)

Step into the future of small bag filling with the Engi-O Aseptic Front-Entry Filler (A3), a cutting-edge solution engineered to redefine industry standards. Perfectly blending efficiency, precision, and hygiene, this compact filler is designed to accommodate the specific needs of industries demanding meticulous quality control, such as pharmaceuticals and food packaging. The A3 model boasts advanced aseptic technology, ensuring that each bag is filled under sterile conditions, safeguarding product integrity and consumer safety.

In our comprehensive review, explore how the Engi-O Aseptic Front-Entry Filler (A3) streamlines operations with its user-friendly interface and seamless functionality. Its compact design allows for easy integration into existing production lines, maximizing space utilization without compromising on performance. With the ability to handle small bag sizes effortlessly, this filler offers unparalleled versatility, catering to a wide range of applications. Experience enhanced productivity and peace of mind knowing that your small bag filling processes are optimized with the Engi-O Aseptic Front-Entry Filler (A3).

Aseptic Front-Entry Filler (A3) With the ability to fill small bags filling machine aseptically, this A3 Model filler is compact and can be installed as a standalone. It can also be installed with a bulk filler to increase production.

Contact Web - https://www.engi-o.com/products/aseptic/front-entry-filler Ph - +61 3 8820 0090 Address - Factory 20, 257 Colchester Road, Kilsyth VIC 3137 Australia

0 notes

Text

Revolutionizing Liquid Filling Solutions: Engi-O's Commitment to Aseptic and ESL Bag in Box Industry in Australia

In the ever-evolving landscape of liquid packaging, the demand for sophisticated yet uncomplicated filling solutions continues to rise. Among the frontrunners in this arena stands Engi-O, a dynamic company dedicated to providing cutting-edge filling solutions tailored specifically for the Aseptic and ESL (Extended Shelf Life) Bag in Box industry in Australia. With a keen focus on innovation and customer satisfaction, Engi-O is reshaping the liquid filling machine market with its advanced technologies and unwavering commitment to excellence.

Meeting Industry Demands

As the market for Aseptic and ESL Bag in Box packaging expands, the need for reliable and efficient filling solutions becomes increasingly paramount. Engi-O recognizes this demand and has positioned itself as a leader in providing state-of-the-art liquid filling machines designed to meet the specific requirements of the Australian market. Whether it's dairy products, beverages, or other liquid commodities, Engi-O's solutions offer unparalleled precision and reliability, ensuring product integrity and shelf life extension.

Cutting-Edge Technology

At the heart of Engi-O's success lies its dedication to innovation. The company continuously invests in research and development to stay ahead of industry trends and technological advancements. By leveraging the latest in automation, robotics, and precision engineering, Engi-O's liquid filling machines deliver superior performance and efficiency. From precise volumetric dosing to advanced sterilization techniques, each aspect of Engi-O's technology is meticulously crafted to optimize production processes and enhance product quality.

Uncomplicated Solutions

While Engi-O's liquid filling machines boast advanced features and capabilities, the company remains committed to simplicity and ease of use. Recognizing the diverse needs of its customers, Engi-O designs its solutions with user-friendliness in mind, ensuring that operators can efficiently operate and maintain the equipment with minimal training. This focus on simplicity not only enhances productivity but also reduces downtime and operational costs, making Engi-O's machines a preferred choice for businesses of all sizes.

Customer-Centric Approach

At Engi-O, customer satisfaction is paramount. The company takes a collaborative approach, working closely with clients to understand their unique challenges and requirements. From initial consultation to after-sales support, Engi-O's team of experts provides personalized assistance every step of the way. Whether it's customizing solutions to fit specific production lines or providing ongoing maintenance and technical support, Engi-O is dedicated to ensuring the success of its customers' operations.

Contact Us

Web - https://www.engi-o.com/ Address: Factory 20, 257 Colchester Road Kilsyth VIC 3137 Australia

1 note

·

View note