#Automatic Filling Machine

Explore tagged Tumblr posts

Text

Liquid filling machines are essential in both the food and pharmaceutical industries. They guarantee accurate dispensing of liquids into containers and are available in a range of models, including semi-automatic, fully automatic, and manual varieties. For further explanation check out the video.

0 notes

Text

High-Quality Salt Packaging Machine for Precise Sealing.

Optimize your salt packaging process with our durable machine offering consistent performance and precise sealing to meet high production demands. Learn More:

#salt packaging machine#powder packaging machine#Automatic salt packaging machine#food packaging machines#sugar filling machine#milk packaging machine#powder filling machines#automatic filling machine#integrated packaging solutions

0 notes

Text

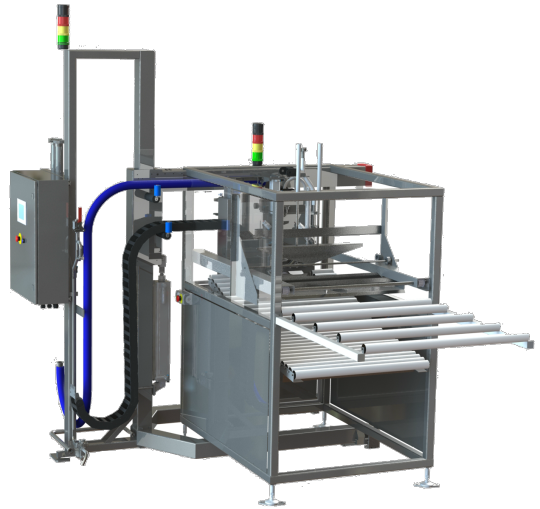

Engi-O Australia: Introducing the Autofeed for Enhanced Flexibility in Convertible Combination Fillers (Automatic Liquid Filling Machine)

Here at Engi-O Australia, we're dedicated to providing innovative solutions for the liquid filling industry. We understand the importance of efficiency and flexibility in production lines, and we're thrilled to announce the addition of the autofeed system to our popular convertible combination filler. This exciting development empowers users with greater control and adaptability in their liquid filling operations.

Beyond the Standard: Unveiling the Convertible Combination Filler

The convertible combination filler is a versatile workhorse in the world of automatic liquid filling machines. Its unique design allows it to seamlessly switch between filling from:

Bulk Tanks: For high-volume production runs.

Small Bags: Ideal for handling smaller batches or specialty liquids.

This adaptability makes the convertible combination filler a valuable asset for manufacturers dealing with diverse production needs. However, manually transferring bags into the filling head could introduce inefficiencies and potential for operator error.

Introducing the Autofeed: A Game Changer for Efficiency

The new autofeed system seamlessly integrates with the convertible combination filler, specifically when operating in the small bag configuration. Here's how it elevates your filling experience:

Automated Bag Feeding: The autofeed system automatically pulls bags from a designated magazine, eliminating the need for manual bag placement and significantly boosting productivity.

Reduced Operator Dependence: With the autofeed taking care of bag handling, operators can focus on other critical tasks within the production line, optimizing overall workflow.

Enhanced Consistency: Automatic bag feeding ensures consistent bag positioning and alignment, minimizing the risk of errors and potential product spills during the filling process.

Improved Safety: The autofeed system reduces the need for operators to be in close proximity to the filling head during operation, enhancing safety within the production environment.

Engi-O Australia: Your Partner in Streamlined Liquid Filling

As a leading provider of automatic liquid filling machines in Australia, Engi-O Australia is committed to offering solutions that cater to your specific needs:

Expert Support: Our team of knowledgeable specialists is here to answer your questions, guide you through the autofeed system, and ensure its seamless integration into your existing convertible combination filler.

Unwavering Commitment to Quality: The autofeed system is built with high-quality components and adheres to stringent safety standards, ensuring reliable operation and longevity.

A Range of Filling Solutions: Beyond the convertible combination filler, Engi-O Australia offers a comprehensive range of automatic liquid filling machines to suit diverse production requirements.

Imagine a Filling Process Tailored to Your Needs

The autofeed system for the convertible combination filler empowers you to achieve a new level of efficiency and flexibility in your production line. Imagine automated bag handling freeing up valuable operator time, ensuring consistent filling processes, and ultimately, boosting your overall productivity.

Beyond the Autofeed: A World of Filling Solutions

Engi-O Australia understands that one size doesn't fit all. We offer a variety of automatic liquid filling machines to suit your specific needs, including:

Piston Fillers: Ideal for precise filling of viscous or foamy liquids.

Gravity Fillers: A cost-effective solution for free-flowing liquids.

Net Weigh Fillers: Ensures accurate filling by weight, particularly for powders and granular products.

Contact Engi-O Australia Today!

Ready to take your liquid filling operation to the next level? Contact Engi-O Australia today! Explore the benefits of the autofeed system for your convertible combination filler, or discuss other filling solutions that perfectly align with your production needs. Let Engi-O Australia be your partner in achieving optimized and efficient liquid filling processes.

Contact Web - https://engi-o.com/products/aseptic/autofeed Ph - +61 3 8820 0090 Address - Factory 20, 257 Colchester Road, Kilsyth VIC 3137 Australia

0 notes

Text

#VFFS Machines#automatic filling machine#food packaging machine#milk packaging machine#liquid filling machines#innovative packaging solutions#integrated packaging solutions#Vertical Form Fill Seal Machines

0 notes

Text

Different applications of filling machines and its types

In manufacturing units especially involved in the manufacturing of food, beverage, pharmaceuticals, and other similar products, a filling machine, which is, in other words, a kind of packing machine that can dependably fill a large volume of suitable containers with particular ingredients to a desired level, is a mandatory undertaking. While discussing filling machines, numerous kinds of filling machines are available. Based on the necessities of the manufacturing unit, which is best suited to meet the needs. The right filling machine must be chosen that can significantly improve the production rate and passively contribute to meeting market demands, thereby boosting sales and enabling the business to grow towards progress. While filling machines are basically classified according to their applications, like powders, liquids, granules, and pastes, filling machines that are used to fill larger containers are usually referred to as drum filling machines. Liquid Filling Machines are normally used in the soft drink and fruit juice manufacturing industries to dispense the desired quantity of the relevant liquid product into suitable bottles, cans, and cups that are capped. These machines are hence used to fill liquids, such as water, various kinds of beverages, carbonated drinks, sauces, and much more. Liquid filling machines are further classified as manual, automatic, and semi-automatic liquid filling machine varieties; they are quite versatile in performance.

While in-line liquid filling equipment fill containers that are placed and supplied in a line through conveyor systems, rotary filling machines are supplied for filling in circular stations and are used to fill bottles, where each station is set to perform a specific function like filling and capping. Piston fillers are used in cases where accuracy is required in pouring liquids into specific containers in a specific quantity, and hence they are used to fill liquid soaps and semi-liquid food products like sauces. Another type of filling machine is the powder filling machine; these fillers are designed and developed in such a way that they are enabled with a complex mechanism that ensures accuracy in their operation. Appropriate for filling free-flowing powdered products, these machines are most suitable for filling talcum powder, certain types of medicines used for external application and dusting, powdered beverages, and more.

Feige Filling is one of the leading manufacturers of filling machines, known for its high speed performance and accuracy. The company is also well known for providing fillers required to fill large pails, drums, and similar containers. Apart from this, Feige Asia has a consistent reputation for dealing with, supplying, and servicing filling machines that include vibratory weigh filling machines, capsule filling machines, and positive displacement pump filling machines that are widely in need in different sectors like the food and pharmaceutical industries.

#automatic filling machine#semi-automatic liquid filling machine#semi-automatic liquid filling machine Singapore#automatic filling machine Singapore

0 notes

Text

Cup Filler Machines Manufacturer in Haryana

A Cup Filler Machines Manufacturer in Haryana specializes in producing automated machines for filling pre-formed cups with liquids, powders, or granules. These machines ensure precise filling, fast processing speeds, and minimal waste, making them ideal for the food, beverage, and pharmaceutical industries. With a focus on innovation and quality, the manufacturer provides tailored solutions to meet diverse packaging needs.

#Cup Filler Machines Manufacturer in Haryana#Form Fill Seal Machines Manufacturer in Haryana#Auger Filler Machines Manufacturer in Haryana#Automatic Pouch Packaging Machine Manufacturer in Faridabad#Packaging Equipment Manufacturer in Faridabad

2 notes

·

View notes

Text

fax machines are Good Actually but u should be able to preview it on a modern touch screen and reject the print job

#if thats already an option sorry folx but nobody has those fax machines#the ones that went out of production in 2003 are still working nobody has needed to replace them#like having to be like 'pls print this out uwu' no i can Force Print it and tell u to fill it out and send it back#and ideally have it automatically saved as a pdf on the receiving end#im a luddite and i think a digital signature doesnt mean SHIT thats basically just scouts honor tbh!!!!

19 notes

·

View notes

Text

Precision Filling Machines for Powders & Granules | Munky Packaging Machine

Munky’s Filling Machine Offers High-Accuracy Filling Solutions for Powders, Granules, Seeds, and Spices. Equipped with Advanced Controls and Sensor-Based Automation, These Machines Reduce Wastage, Maintain Hygiene, and Deliver Consistent Output. Whether You're in Food Production, Agriculture, or Industrial Manufacturing, Our Filling Machines Meet the Demands of Small and Large Batch Operations. the System Supports a Variety of Pouch Sizes and Integrates Seamlessly into Your Existing Packaging Line. Built with Stainless Steel for Durability and Easy Maintenance, Munky’s Machines Are Trusted Across India. Make Your Packaging Smart, Fast, and Precise with Our Industry-Leading Filling Technology. Request a Quote Now.

Call Now:- 9599919442

#Packaging Machine#Packing Machinery#Automatic Packing Machine#Chips Packing Machine#Filling Machine

0 notes

Text

Water Bottle Filling Machine: Enhance Your Bottling Process

Sufficiency, hygiene, and precision: the hallmarks of success in the ever-quickening bottled water industry. Whether a start-up or one of those water bottling establishments, the high quality of bottle filling machine is a must have for you. These specialized machines are designed to facilitate the entire filling process, keeping every bottle consistent, and making sure health standards in safe drinking water are met.

Discover "How to Select the Best Bottle Filling Machine: A Complete Buyer’s Guide" and make the right choice for your water bottling setup.

What is a Bottle Filling Machine?

Bottle filling machines are systems that automatically fill bottles with potable or mineral water and do so very quickly. They require no manual labor, less wastage of water, and ensure that each bottle contains an identical amount of water. Rinsing, filling, and capping are included in the system to establish a continuous operation in the production line.

These machines are common in water bottling facilities where speed and cleanliness are unnegotiable. Such kinds of machines are invented to reduce human contact through the bottling process in order to keep the water pure for the consumer.

Advantages of Automated Bottle Filling Machine

Using an Automated Bottle Filling Machine brings scaling up for the company without sacrificing quality or consistency. Some high points include:

High Speed Operation: Designed to deal with full loads, these machines can fill thousands of bottles per hour with true and minimum downtime.

Precision and accuracy: Advanced sensors and nozzles ensure that each bottle receives an accurate fill, reducing spillage and loss of product.

Hygiene Consistent: built-in washing and bio-cleansing keeps the residue out and life away from contamination, allowing you to meet hygiene regulations.

Lower Maintenance: State-of-the-art equipment; these machines can be cleaned easily and require less effort to maintain most of their time and pay costs.

Explore the Water Filling Machine and see how it enhances speed, hygiene, and precision in your bottling process.

Automation of this water bottling process reduces manual errors and increases productivity overall.

Characteristics of a Water Bottle Filling Machine

The dedicated Water Bottle Filling Machine is designed to specifically satisfy the individual application requirements of the bottling of water businesses. These machines come with various features like:

Integrated Rinsing Systems - Bottles are cleaned prior to filling to ensure cleanliness.

Automatic Capping Units - Once filled, bottles are sealed to secure water purity.

Touchscreen Controls - User-friendly interfaces allow for easy operation and parameter settings.

Adjustable Filling Volumes - From 200 ml to 2 liters, machines can fill different bottle capacities.

These features make water bottling more efficient and assist brands to keep a high level of quality assurance.

Explore the top 10 features to look for in a water bottle filling machine for efficient and consistent operation.

Why Choose a Mineral Water Filling Machine?

A Mineral Water Filling Machine would be the right choice for businesses dedicated to the bottling of mineral water. These machines are specifically designed to keep the water in its original mineral composition during the bottling process. The use of food-grade stainless steel and high-quality filtration systems ensures that what comes out at the end will be pure, safe, and maintain the taste and mineral profile intended.

They comply with industry regulations and are customizable according to the production capacity and packaging preferences.

Learn why water filling machines are vital for packaged drinking water quality and essential in achieving product safety.

Conclusion: Settle with Aim Technologies

Quality and performance are quite important when going for a trustworthy Bottle Filling Machine for water. Being automatic, it can either be called bottle filling machines or water bottle filling machines. But whatever it is, there's always a specially designed mineral water filling machine which can finalize your production line.

Aim Technologies brings you today the most technologically advanced filling solutions ever designed to assure fantastic speed and precision along with clean and hygienic results. By an unwavering commitment toward innovation in technology and customer satisfaction, Aim Technologies guarantees that your bottling operations will be economical, safe, and scalable. Choose Aim Technologies and take your water bottling operations to the next level.

#Bottle Filling Machine#automatic bottle filling machine#water bottle filling machine#mineral water filling machine

0 notes

Text

Oh nooo I hadn’t noticed that my cat’s automatic feeder was getting low on food so as usual she dashed off when she heard the machine start but I couldn’t hear the usual sound of her food falling into the bowl so I went to look and my poor cat was just. Sitting there. Staring at her empty food bowl. Then for a second she glanced up at me then right back to her bowl with the biggest, saddest, most bewildered eyes you could ever imagine on such a small creature. I filled her bowl and the machine right away ofc but I still feel a little guilty 😭

105K notes

·

View notes

Text

Safety First: Advanced Safety Features in Nichrome Packaging Machines

In today’s fast-paced manufacturing world, the emphasis on safety cannot be overstated. At Nichrome, we understand that the cornerstone of any efficient packaging operation is a commitment to safety, both for the equipment operators and the products being packaged. This blog delves into the advanced safety features integrated into our milk pouch packing machine, sugar filling machine, powder packaging machine, rice bag sealing machine, food bag sealing machine and auger filler packing machine showcasing how we prioritize safety without compromising on efficiency and performance.

In this blog, let us know the the basic safety features that come along with Nichorme’s packaging machines that enhances your packaging operations:

1. User-Friendly Interface and Controls

A critical aspect of operational safety is the ease with which operators can interact with the machinery. Our packaging machines in Kenya are designed with intuitive, user-friendly interfaces that simplify the control and monitoring processes. These interfaces often include touch screens with clear, graphical displays that reduce the risk of operator error and enhance overall safety.

2. Emergency Stop Mechanisms

Our VFFS packaging machine machines are equipped with strategically placed emergency stop buttons, allowing operators to quickly halt operations in case of an emergency. These buttons are designed to be easily accessible, ensuring that anyone in the vicinity can stop the machine immediately in case of unwanted accidents and injuries.

3. Safety Guards and Barriers

Physical safety guards and barriers are integral components of commercial food packaging machines. These protective features prevent accidental contact with moving parts, safeguarding operators from potential injuries. The guards are designed to be robust yet easily removable for maintenance purposes, ensuring a perfect balance between safety and operational efficiency.

4. Interlock Systems

To enhance safety during maintenance and operation, our packing machine for food products incorporates advanced interlock systems. These systems ensure that the packaging machine cannot be operated while the safety guards are removed or when certain parts of the machine are not correctly positioned. This prevents accidental startups and ensures that the machine operates only when it is safe to do so.

5. Regular Safety Audits and Training

At Nichrome, safety is an ongoing commitment. We conduct regular safety audits and provide comprehensive training for operators to ensure they are well-versed in safe operational practices. This continuous focus on safety education helps create a culture of safety awareness and vigilance among the workforce.

6. Advanced Sensor Technology

Modern Vertical Fill Form Seal machines are integrated with advanced sensor technologies that enhance safety and operational efficiency. These sensors can detect various parameters such as product presence, alignment, and package integrity, ensuring that the machine operates under optimal conditions and preventing mishaps caused by misaligned or faulty packaging.

8. Compliance with Safety Standards

All our packaging machines in Kenya are designed and manufactured in compliance with global safety standards. This adherence to safety regulations ensures that our machines not only meet but often exceed the stringent safety requirements set by regulatory bodies, providing our customers with peace of mind.

Conclusion

At Nichrome, the safety of our customers and their employees is our top priority. By incorporating advanced safety features into our packaging machines, we strive to create a safe and efficient working environment. Our commitment to safety, innovation, and quality ensures that Nichrome packaging machines remain at the forefront of the industry, delivering not only superior performance but also unmatched safety standards.

Choose Nichrome for your packaging needs and experience the peace of mind that comes with knowing you are investing in machines that put safety first.

#VFFS Machines#automatic filling machine#food packaging machine#milk packaging machine#liquid filling machines#innovative packaging solutions#integrated packaging solutions#Vertical Form Fill Seal Machines

0 notes

Text

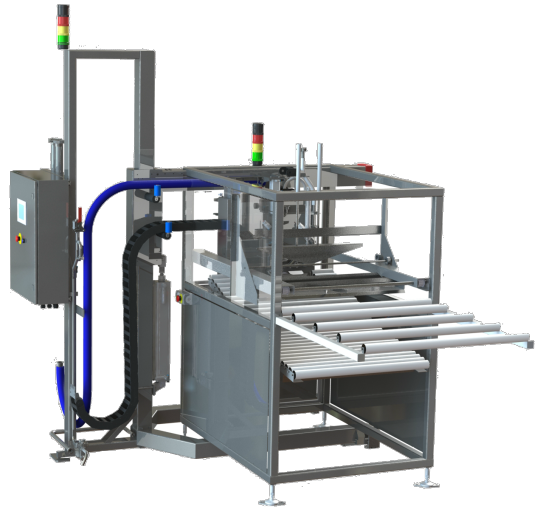

Enhancing Efficiency with Engi-O's Automatic Filling Machine

Engi-O is proud to announce an exciting new addition to our lineup of filling machines - the Automatic Filling Machine with autofeed functionality. Designed to streamline your production process and maximize efficiency, this innovative unit attaches seamlessly to the head of our convertible combination filler, offering users unparalleled flexibility and convenience. Let's explore how this cutting-edge technology can revolutionize your operations.

Streamlined Production:

With the Automatic Filling Machine from Engi-O, filling containers has never been easier. The autofeed addition eliminates the need for manual intervention, allowing for a continuous and uninterrupted filling process. Whether you're working with small bags or larger containers, this versatile unit ensures consistent and precise filling every time, saving you valuable time and resources.

Flexibility and Versatility:

One of the key advantages of Engi-O's Automatic Filling Machine is its ability to adapt to different configurations and applications. Whether you're filling bags, bottles, or other types of containers, this unit offers unparalleled flexibility, allowing you to customize your setup to meet your specific needs. The autofeed functionality adds an extra layer of convenience, giving you greater control over your production process.

Enhanced Efficiency:

By automating the filling process, Engi-O's Automatic Filling Machine helps increase productivity and efficiency in your operation. With fewer manual tasks to manage, your team can focus on other critical aspects of production, such as quality control and packaging. This not only saves time but also reduces the risk of errors and inconsistencies, ensuring a smoother and more streamlined workflow.

Seamless Integration:

The Automatic Filling Machine is designed to seamlessly integrate with Engi-O's convertible combination filler, providing a hassle-free solution for upgrading your equipment. The unit attaches directly to the head of the filler, allowing for easy installation and minimal downtime. Whether you're a small-scale producer or a large manufacturing facility, this versatile unit can be tailored to fit your specific requirements.

Optimized Performance:

With its advanced features and intuitive design, Engi-O's Automatic Filling Machine delivers optimal performance and reliability in even the most demanding production environments. Built to withstand the rigors of continuous operation, this unit is engineered for durability and longevity, ensuring years of dependable service with minimal maintenance requirements.

Experience the Difference:

Ready to take your filling operations to the next level? Experience the difference with Engi-O's Automatic Filling Machine. With its innovative design, flexible functionality, and unparalleled performance, this cutting-edge unit is the perfect solution for streamlining your production process and maximizing efficiency. Contact us today to learn more and discover how Engi-O can help you achieve your goals.

Engi-O now offers an autofeed addition to the convertible combination filler. The unit is attached to the head in the small bag configuration and delivers more flexibility to the user.

Contact Web - https://engi-o.com/products/aseptic/autofeed Ph - +61 3 8820 0090 Address - Factory 20, 257 Colchester Road, Kilsyth VIC 3137 Australia

0 notes

Text

#spice packaging machine#food packaging#pouch packing machine#automatic packaging machine#integrated packaging solutions#innovative packaging solutions#automatic filling machine

0 notes

Text

Injectable Liquid Filling Machine

Injectable Liquid Filling Machine (injectable vial filler) including Automatic vial filling machine is is suitable to fill injectable glass vials. The basic unit consists of turntable, Stainless Steel Stat conveyor belt, unique eccentric pre-gassing, filling and post-gassing. Highly efficient and precision built Stainless Steel 316L Syringes, non- toxic synthetic rubber tubing and easy reach compact panel.

The minimal distance between filling and stoppering units reduces the risk of contamination. The machines are designed for operation in a sterile area and for use under laminar flow protection. The un-scrambler itself has been redesigned to eliminate dead ends and difficult-to-clean spots.

Injectable Liquid Filling Machine suitable to fill 2ml to 250ml vials and provide production output ranging from 20 VPM to 300 VPM.

0 notes

Text

Automatic Capsule Filling Machine Manufacturer | IRM Enterprise Pvt. Ltd

Looking for a reliable Automatic Capsule Filling Machine Manufacturer? IRM Enterprise Pvt. Ltd. is a trusted name in the pharmaceutical machinery industry, offering high-performance automatic capsule filling machines designed for precision, speed, and efficiency. Our machines are ideal for pharmaceutical, nutraceutical, and herbal product manufacturers, providing consistent filling of powder, granules, or pellets into capsules of various sizes. With robust construction, user-friendly operation, and low maintenance requirements, IRM’s capsule fillers meet global quality standards and help streamline production processes. Choose IRM Enterprise Pvt. Ltd. for dependable, innovative, and cost-effective capsule filling solutions. Perfect for businesses aiming to scale up with automation and accuracy.

Visit: https://www.karnavatiengineering.com/cf-125.aspx?pid=118

#Automatic Capsule Filling Machine Manufacturer#Capsule Filling Machine Manufacturer#Automatic Capsule Filler#Capsule Filling Machine#Capsule Filler Machine#Pharmaceutical Capsule Filling Machine#Capsule Filling Equipment#High-Speed Capsule Filling Machine#Capsule Filling Machine India#Automatic Capsule Filling Machine Supplier

0 notes

Text

High-Speed Chips Packing Machine with Nitrogen Flushing | Munky Packaging Machine

Ensure Freshness and Crunch in Every Pack with Munky's Chips Packing Machine, Built for Speed, Hygiene, and Shelf-Life Enhancement. Our Machines Come with Nitrogen Flushing Technology to Preserve the Texture and Taste of Chips and Snacks. Whether You're Packaging Wafers, Namkeen, or Extruded Snacks, Our Chips Packing Machine Delivers Accurate Filling and Strong Sealing with Minimal Wastage. Ideal for Medium to Large-Scale Snack Manufacturers, the System Is Fully Automatic, Easy to Operate, and Low on Maintenance. Take Your Chip Brand to the Next Level with Munky’s Advanced Packaging Technology. Contact Us for Demos and Pricing Tailored to Your Requirements.

Call Now:- 9599919442

#Packaging Machine#Packing Machinery#Automatic Packing Machine#Chips Packing Machine#Filling Machine

0 notes