#Automatic Liquid Filling Machine

Explore tagged Tumblr posts

Text

#Automatic Liquid Filling Machine#Liquid Filling Machine#Automatic Liquid Filling Machine Manufacturer in India#Liquid Filling Machine Manufacturer in India#Liquid Filling Machine Manufacturer#Automatic Liquid Filling Machine Supplier in India

0 notes

Text

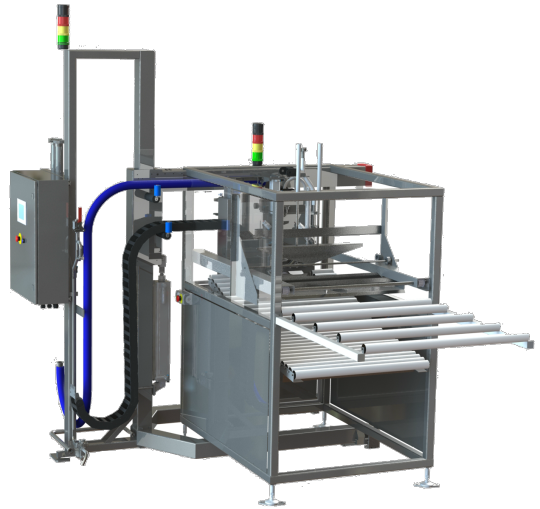

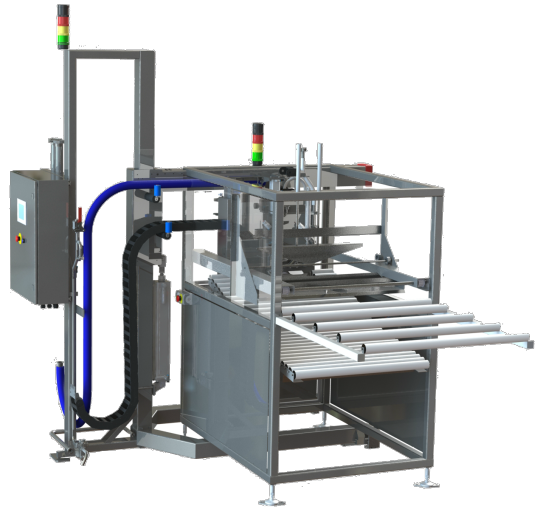

Engi-O Australia: Introducing the Autofeed for Enhanced Flexibility in Convertible Combination Fillers (Automatic Liquid Filling Machine)

Here at Engi-O Australia, we're dedicated to providing innovative solutions for the liquid filling industry. We understand the importance of efficiency and flexibility in production lines, and we're thrilled to announce the addition of the autofeed system to our popular convertible combination filler. This exciting development empowers users with greater control and adaptability in their liquid filling operations.

Beyond the Standard: Unveiling the Convertible Combination Filler

The convertible combination filler is a versatile workhorse in the world of automatic liquid filling machines. Its unique design allows it to seamlessly switch between filling from:

Bulk Tanks: For high-volume production runs.

Small Bags: Ideal for handling smaller batches or specialty liquids.

This adaptability makes the convertible combination filler a valuable asset for manufacturers dealing with diverse production needs. However, manually transferring bags into the filling head could introduce inefficiencies and potential for operator error.

Introducing the Autofeed: A Game Changer for Efficiency

The new autofeed system seamlessly integrates with the convertible combination filler, specifically when operating in the small bag configuration. Here's how it elevates your filling experience:

Automated Bag Feeding: The autofeed system automatically pulls bags from a designated magazine, eliminating the need for manual bag placement and significantly boosting productivity.

Reduced Operator Dependence: With the autofeed taking care of bag handling, operators can focus on other critical tasks within the production line, optimizing overall workflow.

Enhanced Consistency: Automatic bag feeding ensures consistent bag positioning and alignment, minimizing the risk of errors and potential product spills during the filling process.

Improved Safety: The autofeed system reduces the need for operators to be in close proximity to the filling head during operation, enhancing safety within the production environment.

Engi-O Australia: Your Partner in Streamlined Liquid Filling

As a leading provider of automatic liquid filling machines in Australia, Engi-O Australia is committed to offering solutions that cater to your specific needs:

Expert Support: Our team of knowledgeable specialists is here to answer your questions, guide you through the autofeed system, and ensure its seamless integration into your existing convertible combination filler.

Unwavering Commitment to Quality: The autofeed system is built with high-quality components and adheres to stringent safety standards, ensuring reliable operation and longevity.

A Range of Filling Solutions: Beyond the convertible combination filler, Engi-O Australia offers a comprehensive range of automatic liquid filling machines to suit diverse production requirements.

Imagine a Filling Process Tailored to Your Needs

The autofeed system for the convertible combination filler empowers you to achieve a new level of efficiency and flexibility in your production line. Imagine automated bag handling freeing up valuable operator time, ensuring consistent filling processes, and ultimately, boosting your overall productivity.

Beyond the Autofeed: A World of Filling Solutions

Engi-O Australia understands that one size doesn't fit all. We offer a variety of automatic liquid filling machines to suit your specific needs, including:

Piston Fillers: Ideal for precise filling of viscous or foamy liquids.

Gravity Fillers: A cost-effective solution for free-flowing liquids.

Net Weigh Fillers: Ensures accurate filling by weight, particularly for powders and granular products.

Contact Engi-O Australia Today!

Ready to take your liquid filling operation to the next level? Contact Engi-O Australia today! Explore the benefits of the autofeed system for your convertible combination filler, or discuss other filling solutions that perfectly align with your production needs. Let Engi-O Australia be your partner in achieving optimized and efficient liquid filling processes.

Contact Web - https://engi-o.com/products/aseptic/autofeed Ph - +61 3 8820 0090 Address - Factory 20, 257 Colchester Road, Kilsyth VIC 3137 Australia

0 notes

Text

Packaging Resolution

Food packaging has in-depth applications that demand the provision of varied supplies for packing different objects. Optimizing package measurement utilizing automated packaging machines can help us create an extra sustainable future by decreasing the quantity of food we waste and minimizing our impression of the setting. Paper and paperboard are used as main and secondary packaging materials by meal manufacturers. Many curry packaging options are plain, opting for plastic containers or tin foil, leaving limited room for personalization or presentation - automatic liquid filling machine.

Our staff of filling specialists outlines some top suggestions for selecting the best packaging. That says it can be the best step as a model proprietor to make your model sustainable while still selling its top quality by adopting measures like switching to renewable power and practicing recycling. We feel a better understanding all our packaging just isn't solely sturdy and strong but 100 percent recyclable by any waste firm. We work with giant businesses trying to cut back their storage and transport prices - automatic packaging machine.

Some merchandise merely wants it, as there's nothing else that offers the extent of protection plastic presents and that the product needs. We work with purchasers to develop probably the most sustainable and eco-friendly packaging in your requirements. We delight ourselves on creating packaging formats that offer mutually beneficial value for our shoppers and their end customers. Using colors and logos, cardboard can quickly be reworked from boring packaging into vibrant and exciting safety that makes your brand straightforward to determine.

With many years of expertise in manufacturing sturdy and reliable packaging solutions. We are all the time at the forefront of innovation; constantly pushing the boundaries and traditional pondering around packaging. We manufacture bulk packaging for businesses throughout many sectors, together with produce and prescription drugs. For more information, please visit our site https://packagingmachinesusa.com/

0 notes

Text

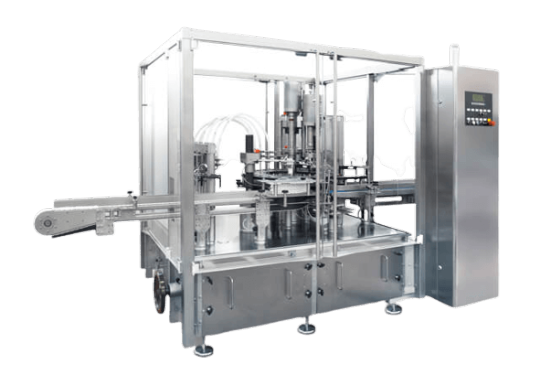

Leading manufacturer and exporter of Automatic Liquid Filling Machine in Kolkata, India

In the vibrant industrial city of Kolkata, India, Spectrum Packaging has risen as a distinguished leader in the field of manufacturing and exporting Automatic Liquid Filling Machines. These machines are the unsung heroes that underpin various industries by ensuring the precise filling of liquid products. In this blog, we will explore the significance of Automatic Liquid Filling Machines, Spectrum Packaging's pioneering role, and how they are reshaping the standards of liquid packaging.

The Role of Automatic Liquid Filling Machines:

Automatic Liquid Filling Machines are the backbone of modern production and packaging, ensuring that each container is filled accurately and consistently. From beverages to pharmaceuticals, these machines preserve product quality and quantity while streamlining the packaging process. Spectrum Packaging's innovations have made them indispensable across a range of industries.

Spectrum Packaging's Commitment to Excellence:

At the core of Spectrum Packaging's success is an unwavering commitment to innovation and precision. Their Automatic Liquid Filling Machines are a testament to this dedication. Meticulously designed and engineered, these machines incorporate state-of-the-art technology and expert craftsmanship to ensure accuracy and efficiency in liquid filling.

Versatility for Diverse Industries:

Spectrum Packaging's Automatic Liquid Filling Machines are designed to cater to a wide range of liquid products, accommodating various viscosities and consistencies. Their adaptability makes them a valuable asset for businesses in diverse industries, ensuring that every product leaving the production line is perfectly filled.

Precision Engineering for Consistency:

Precision is non-negotiable in liquid packaging. Spectrum Packaging's Automatic Liquid Filling Machines excel in delivering consistent measurements, minimizing the risk of overfilling or underfilling. This not only upholds product quality but also reduces waste, making these machines a cost-effective investment.

Customization for Optimal Performance:

One of Spectrum Packaging's unique strengths is its ability to offer customized solutions. They understand that each industry and production process is unique. By closely collaborating with clients, they tailor Automatic Liquid Filling Machines to seamlessly integrate into specific workflows, enhancing efficiency and productivity.

Conclusion:

In the fast-paced world of modern production, Spectrum Packaging's Automatic Liquid Filling Machines are a testament to their dedication to innovation and precision. With these machines, they have redefined how industries package liquid products, setting new standards of accuracy and efficiency. As businesses seek to optimize their processes and enhance product quality, Spectrum Packaging's Automatic Liquid Filling Machines emerge as the ultimate choice, raising the bar for precise and efficient liquid packaging in Kolkata and beyond.

0 notes

Text

Innovations in Dairy Product Packaging Machines: Enhancing Shelf Life and Hygiene for Africa’s Dairy Sector

The Dairy industry in Africa is milking every opportunity to expand, driven by the rising population, increasing health and wellness awareness, and growing urbanisation. This has been stemming from the increasing demand for safe, fresh, and longer-lasting dairy products, be it milk, yogurt, and margarine, to flavoured milk, cream or even dairy powders.

However, how can you ensure a higher-quality product from farm to fridge in a continent where climate, infrastructure, and logistics can pose significant challenges? The answer to this problem is “Smart Dairy Packaging” with Nichrome. With 40+ years of pioneering experience in dairy packaging machines, we at Nichrome are at the frontlines of delivering innovative, efficient, and hygienic dairy solutions that are at par with the unique needs of the African markets.

With our smart and high-performing milk packaging machines and yogurt packaging machines, we, as the leading milk pouch packing machine manufacturers, are empowering African dairy producers to overcome bottlenecks in every segment.

Ready to pour into the details? Let’s dive into the creamy layers of dairy packaging innovation.

Types of Dairy Products and Their Packaging Needs

From farm-fresh milk to creamy yogurts and margarine, and powdered dairy goodness, every dairy product comes with its packaging personality. The key to delivering high-quality dairy products lies in understanding the unique packaging required and then tailoring packaging machines to handle them with precision, care, and hygiene. Our specialised range of dairy packaging machines caters to the entire dairy spectrum.

Let’s unpack the packaging needs of different dairy products and how Nichrome has been rising to the challenge:

Milk: Pouches and bottles that preserve liquid purity

Milk needs airtight, leak-proof and contamination-free packaging as it is highly perishable. Whether it’s pouches for rural markets or bottles for the urban retail, our milk packaging machines offer unmatched speed, precision, and hygiene.

Sprint 250 Plus and Excel Plus milk pouch packing machines – Ideal for small to large-scale milk packing needs.

Automatic lines with milk bottle filling machines - milk bottling in glass or PET bottles

Pouches are formed, filled, and sealed with minimal human contact, with hygienic processing.

Flavoured Milk: Keeping it Tasty & Cool

The delicious flavoured milk is a growing category among African youth. The products require tamper-evident packaging that preserves flavour and nutrients.

Our viscous liquid filling machines ensure accurate filling of flavoured milk varieties.

Multi-purpose milk filling machines can accept pouches, PET bottles, and Tetra Pak substitutes.

Advanced packaging maintains shelf stability without requiring preservatives.

Yogurt & Curd: Thick, Creamy, and Contained

Viscous and semi-solid, curd, and yogurt need extra care. We provide yogurt packaging machines with soft filling technology that prevents air pockets or spoilage.

Servo-driven filling provides hygiene and consistency.

Suitable for cups, pouches, or sachets.

Tamper-proof sealing ensures freshness and trust.

Ghee, Margarine, & Cream: The Rich Delights

For more viscous milk products such as cream, margarine, and ghee, accuracy and hygiene are important. Our milk products packaging machines provide heat-sealed, aseptic packaging that provides maximum shelf life.

Thicker consistencies with specific nozzles.

Perfect for pouch, jar, and cup packaging.

High-temperature packaging films prolong freshness.

Dairy Powders: Light but Strong

Milk powder, whey, and baby formula need protective packaging that is oxygen and moisture-proof.

Dry powder filling machines provide vacuum sealing and nitrogen flushing for extended shelf life.

Case packaging and retail-ready SKUs available.

Assists dairy processors in meeting export requirements.

Whatever your product pours, scoops, flows, or sprinkles, Nichrome has a dairy and milk packaging machine that can do it fast, hygienically, and accurately. From optimizing shelf life to optimizing operational efficiency, Nichrome's flexible packaging machines have Africa's dairy treats ever ready to serve, fresh and fabulous.

Major Packaging Challenges for Dairy Products

With the growth of the dairy business in Africa comes the need to keep packaging at the level required to meet demand, sanitation, and sustainability requirements. Dairy packaging is not a matter of simply covering milk—it's about purity, preventing loss, and defending brand reputation. But for the vast majority of dairy farmers on the continent, the path from cow to consumer is not without its complications.

The following are the biggest challenges that African dairies face, and how we help solve those:

Hygiene Maintenance - Milk and milk products are nutrient-rich but prone to bacterial contamination. Our milk filling machines are equipped with Clean-In-Place (CIP) facilities and stainless-steel construction to provide utmost sanitation.

Spoilage Prevention - Temperature fluctuation during storage and transport is prevalent throughout Africa. Nichrome battles this with air-tight, leak-proof pouches and high-barrier packaging films.

Handling Different Consistencies - From thin milk to thick ghee, yogurt, or margarine, every single product has a special flow. Our milk packaging machines feature speciality nozzles and programmable filling logic to accommodate any viscosity.

Affordability & Flexibility - Small dairies require scalable solutions. We provide milk packing machines and semi-automatic lines that are affordable to tight budgets without sacrificing performance.

It's obvious, dairy packaging in Africa is not a mass market phenomenon. It takes flexibility, dependability, and creativity. We at Nichrome not only get these issues, but we also address them. With a range of dairy packaging machines that are ideally suited to African conditions, we provide producers with the equipment they need to succeed in a competitive, fast-moving market. Because at Nichrome, we don't merely package dairy—we empower it.

Advanced Features in Nichrome's Dairy Packaging Machines

When it comes to packaging milk in a tough and dynamic market such as Africa, efficiency is not sufficient; you require smart, flexible, and forward-looking machines. At Nichrome, innovation is infused in each nut and bolt. Our milk & dairy packaging machines raise the bar on automation to deliver smarter, more efficient solutions that meet real-world requirements.

Here’s the breakdown of the features that set Nichrome's milk packing machines apart:

Automatic Pouch Filling & Sealing

Automatically operated models are the Sprint 250 Plus, Filpack Servo 12K, and Filpack CMD.

Provide uniform pouch sealing with minimal operator interference.

Servo-based operations produce fault-free sealing at high speeds.

Bottle & Jar Filling Lines

From bottling milk to curd in jars, we champion all the varied formats.

Modular systems allow easy integration into existing plants.

General-purpose for flavoured milk, yogurt, and margarine.

Hygienic CIP Systems

Equipments have Clean-In-Place capability for sanitary processing.

Conserves time, water, and detergent compared to hand washing.

Proper Filling for Viscous & Liquid Products

The milk filling machines employ piston and servo-based technology.

Oversees everything from raw milk to cream, yogurt, and margarine.

Reduces overfill loss and is cost-effective.

Packaging Material Compatibility

It accommodates high-barrier laminates, mono-material films, and recyclable ones.

Ensures safety without compromising on sustainability.

Compatible with all standard widths and thicknesses of film rolls.

In brief, our dairy products packaging machines do not just process your product; they process your problems. Whether it is keeping things clean, making things more precise, or making things more efficient, our machines are designed to keep pace with today and expand for tomorrow.

From small regional African dairy farmers to large-scale cooperatives, we offer precision, flexibility, and innovation in an amalgamation that makes packaging not only a process, but a source of differentiation.

Advantages of Applying Contemporary Dairy Packaging Machines

With Africa's dairy industry going into high gear to respond to growing demand, traditional methods no longer cut it. Outdated packaging technology not only keeps your production on ice but also amplifies the chances of spoilage and contamination, delivering a blow to your bottom line and consumer trust.

That is where Nichrome's second-generation dairy packaging solutions step in. Designed to combine hygiene with high-speed functionality, our machines are made to serve African dairies of all sizes, whether packaging raw milk in pouches or flavoured yogurt and margarine in cups.

Here's why it's a cream-of-the-crop choice to upgrade to Nichrome:

Long Shelf Life - Whether milk pouch packaging, yogurt cups, or margarine packs, Nichrome provides packaging that holds spoilage at bay.

Consistent Quality - Each packet is sealed, filled, and trimmed with machine accuracy.

Speed & Efficiency – Our automatic packaging machines produce thousands of pouches an hour, achieving a high throughput rate.

Fewer Wastages - Precise filling results in less wastage and higher output from your material.

Multi-SKU management - Convert SKUs on the fly. One milk packaging machine will switch between SKUs with minimal downtime.

Compliance & Certifications – Our packaging solutions enable compliance with FSSAI, ISO, and international standards of hygiene.

Energy-Efficient Operations - New drives and smart control panels lower energy use and boost plant ROI.

These advantages extend far beyond the pack—they enable your dairy plant to become a wise, forward-looking facility. In a business where margins count and quality sells, Nichrome puts you ahead of the competition. You need to grow efficiently, safely, and intelligently. Whether you're supplying urban supermarkets or rural cooperatives, with Nichrome, your packaging line is a productivity powerhouse.

Conclusion: Channelling Innovation into Africa's Dairy Future

Africa's milk industry is poised for a packaging revolution. With growing urbanization, cold chains, and dairy consumption, the demand for milk product packaging that is innovative, efficient, and hygienic also increases.

With state-of-the-art dairy packaging machines, we at Nichrome haven’t just kept pace but forged ahead. Whether it's milk pouch solutions or milk filling machines, our machines empower African dairies to dispense quality, safe products with speed and panache.

So, are you also looking to upgrade your milk packaging line or introduce a new dairy brand? As a new entrant or legacy co-op, Nichrome Africa offers the best of Indian technology for African conditions.

Call us today to discover a full range of dairy products packaging machines and experience the intelligent packaging first-hand.

Let's change the way Africa consumes milk. Pouch by pouch.

#dairy packaging machines#milk packaging machines#yogurt packaging machines#milk pouch packing machine manufacturers#dairy packaging#dairy packaging machine#milk packaging machine#milk pouch packing machines#milk bottle filling machines#liquid filling machines#milk filling machines#yogurt packaging machine#milk products packaging machines#Dry powder filling machines#nichrome dairy packaging machines#automatic packaging machines#milk packaging line

0 notes

Text

Top Packaging Machines for All Industries | Munky Packaging Machine

Looking for a High-Quality Packaging Machine to Streamline Your Business? Munky Packaging Machine Offers Durable, Efficient, and Versatile Solutions for a Wide Range of Industries Including Food, Agriculture, Chemicals, and Fmcg. Our Machines Are Designed for Precision, Speed, and Hygiene, Ensuring Your Product Is Packed Perfectly Every Time. Whether You're Packaging Powders, Granules, or Liquids, We Have the Right Equipment to Meet Your Needs. with Advanced Technology and a Strong Support System, Munky Ensures Minimal Downtime and Maximum Productivity. Choose a Packaging Machine That Boosts Efficiency and Reduces Labor Costs. Visit Our Website or Call to Get Started Today.

Call Now:- 9599919442

#Packaging Machine#Packing Machinery#Automatic Packing Machine#Chips Packing Machine#Filling Machine#Best packaging machine for small businesses#Industrial packaging machine manufacturers in India#High-speed packing machinery for FMCG industry#Packing machinery for spices and powders#Automatic packing machine for granules and powders#Affordable automatic packing machine in India#Fully automatic chips packing machine in India#Chips packing machine for small scale industry#Auger filler filling machine for masala and flour#Liquid filling machine with automatic capping

0 notes

Text

#integrated packaging solutions#Automatic bottle filling machine#liquid filling machine#bottle filling machine manufacture india

0 notes

Text

How Can Cup Filler Machines from Ambika Packaging Solution Streamline Your Packaging Process?

In today’s competitive market, packaging plays a crucial role in ensuring the safety, quality, and presentation of products. Whether you're in the food, pharmaceutical, or industrial sector, choosing the right packaging machine is essential to maintain product integrity and streamline production processes. Ambika Packaging Solution is a leading name in the packaging industry, offering a diverse range of high-quality packaging solutions. As a renowned Packaging Machine Manufacturer, we specialize in providing top-of-the-line equipment to meet the unique demands of various industries.

Why Choose Ambika Packaging Solution?

At Ambika Packaging Solution, we focus on delivering reliable, efficient, and cost-effective packaging machines. With years of experience and expertise in the field, we offer a comprehensive range of packaging equipment that can help businesses enhance their production efficiency and product presentation. Our machines are engineered with precision and advanced technology to ensure that each product is packed with care and perfection.

Wide Range of Packaging Solutions

Features of Our Pouch Packaging Machines

Our Automatic Pouch Packaging Machine Manufacturer equipment boasts advanced features like automatic feeding, high-speed filling, and precise sealing capabilities. These features ensure that each pouch is securely packed with the right amount of product. With minimal downtime and maximum efficiency, our machines help you scale your production effortlessly.

In addition to our standard pouch packaging solutions, we also offer customizable options to suit your unique packaging requirements. Whether you need specialized pouch sizes, unique sealing types, or multi-lane packaging, we have the perfect solution for your business.

We understand that businesses require diverse packaging solutions to meet specific demands. That’s why Ambika Packaging Solution provides a variety of packaging machinery, including Form Fill Seal Machines Manufacturer solutions that are highly adaptable. Our Form Fill Seal Machines Manufacturer are designed to work with multiple packaging materials and formats, making them perfect for industries ranging from food and beverages to pharmaceuticals and household products.

These machines allow you to create a wide variety of pack styles, from stand-up pouches to flat bags. With our Packaging Equipment Manufacturer expertise, we ensure that each machine is easy to operate, maintain, and adjust for different production requirements.

As a Food Packaging Machine Manufacturer, we understand the importance of packaging in the food industry. Packaging not only protects food items from contamination but also extends their shelf life. Our food packaging machines are designed with food safety and hygiene standards in mind, ensuring that each product is sealed and preserved properly.

We provide Liquid Packaging Machines Manufacturer solutions that are capable of efficiently handling liquids like juices, sauces, and oils. Our machines are equipped with precise measuring systems, ensuring that every package contains the correct volume of product. From juice packaging to liquid soap filling, our solutions are engineered for high performance and durability.

For businesses dealing with powders and granular products, our Auger Filler Machines Manufacturer offers a perfect solution. These machines are ideal for packaging powders such as spices, coffee, flour, and more. Our Auger Filler Machines Manufacturer equipment ensures precise, accurate filling with minimal waste, helping businesses maintain consistency in their products.

Custom Packaging Equipment to Meet Your Needs

At Ambika Packaging Solution, we are committed to delivering tailored solutions to meet the specific needs of our clients. As a leading Packaging Equipment Manufacturer, we offer a wide array of machines that can be customized based on your production requirements, product type, and packaging goals.

Whether you need a simple pouch packaging machine or a complex automated system, we work closely with our clients to understand their unique needs. Our engineers and technicians design packaging systems that not only meet industry standards but also provide efficiency and cost savings.

Why Choose Us?

Quality Assurance: As a prominent Packaging Machine Manufacturer, we ensure that all our machines are built to the highest quality standards. Each machine undergoes rigorous testing to guarantee reliability and performance.

Customization: We understand that one size does not fit all. Our team works with clients to develop bespoke packaging machines that perfectly align with their needs.

Innovation: We are always at the forefront of technological advancements. As a leading Pouch Packaging Machine Manufacturer, we incorporate the latest technologies into our machines, helping businesses stay competitive.

Affordable Solutions: We believe in offering high-quality packaging solutions at competitive prices. Whether you're a small business or a large enterprise, we offer cost-effective solutions without compromising on quality.

After-Sales Support: Our commitment to client satisfaction doesn’t end with the sale. We provide exceptional after-sales support to ensure that your machines continue to operate at peak performance.

Packaging Machines for Every Industry

Our comprehensive range of packaging machines is designed to cater to a variety of industries. From food and beverages to pharmaceuticals, cosmetics, and chemicals, Ambika Packaging Solution provides specialized equipment that ensures efficiency, consistency, and quality in your packaging process.

Whether you're looking for a Food Packaging Machine Manufacturer, a Liquid Packaging Machines Manufacturer, or an Auger Filler Machines Manufacturer, we have you covered. Our machines are designed for high-speed production, minimal downtime, and maximum output.

Conclusion

Packaging is a vital part of every production process, and having the right machinery can make all the difference. At Ambika Packaging Solution, we are proud to be a trusted Packaging Machine Manufacturer offering innovative and reliable packaging solutions. From Pouch Packaging Machine Manufacturer equipment to Auger Filler Machines Manufacturer, our comprehensive product line ensures that businesses across industries have access to the best packaging technology available.

If you’re searching for Packaging Solutions Near Me, look no further than Ambika Packaging Solution. We are here to provide cutting-edge packaging equipment that enhances productivity and product quality. Reach out to us today to learn more about how we can help you achieve your packaging goals.

#Packaging Machine Manufacturer#Pouch Packaging Machine Manufacturer#Automatic Pouch Packaging Machine Manufacturer#Packaging Solutions Near Me#Form Fill Seal Machines Manufacturer#Food Packaging Machine Manufacturer#Liquid Packaging Machines Manufacturer#Auger Filler Machines Manufacturer#Packaging Equipment Manufacturer#Cup Filler Machines Manufacturer

0 notes

Text

Liquid filling machines are essential in both the food and pharmaceutical industries. They guarantee accurate dispensing of liquids into containers and are available in a range of models, including semi-automatic, fully automatic, and manual varieties. For further explanation check out the video.

0 notes

Text

Motion Liquid Filling Machine

The most popular type of filling machine for filling liquid in various container types is the bottle filler, often known as the automatic bottle filling machine. Aqueous solutions, foamy liquids, and semi-viscous solutions can all be filled with our selection of filling machines. PET, plastic, glass, aluminum, stainless steel, copper, and other containers can all be filled using bottle liquid filler. Adinath bottle filling machines can be used to fill bottles, jars, containers, and other solid packing types. The foundation structure, piston pump, filling needles, and a conveyor belt with stainless steel slats make up the basic unit.

0 notes

Text

#Automatic Packing Machine Manufacturers In Chennai#Auger Packing Machine Manufacturers In Chennai#Weighmetric Packing Machine Manufacturers In Chennai#Multihead Weigher Machine Manufacturers In Chennai#Volumetric Packing Machine Manufacturers In Chennai#Multipurpose Packing Machine Manufacturers In Chennai#Liquid Packing Machine Manufacturers In Chennai#Paste Packing Machine Manufacturers In Chennai#Pharma Packing Machine Manufacturers In Chennai#Oil Packing Machine Manufacturers In Chennai#Mini Doy Pack Machine Manufacturers In Chennai#Horizontal PFS (Pick-Fill-Seal) Machine Manufacturers In Chennai#Ffs - Volumetric Packing Machine Manufacturers In Chennai#FFS TRAY Model Machines Manufacturers In Chennai#Multitrack Packing Machine Manufacturers In Chennai#Flow Wrap Packing Machine Manufacturers In Chennai#Semi – Automatic Machine Manufacturers In Chennai#Semi Automatic Weighmetric Filling Machine Manufacturers In Chennai#Semi Automatic Paste Filling Machine Manufacturers In Chennai#Semi Automatic Volumetric Filling Machine Manufacturers In Chennai#Heavy-Duty Band Sealer Machine Manufacturers In Chennai#Semi Automatic Auger Filling Machine Manufacturers In Chennai#Conveyor Machine manufacturers in Chennai#Z-Conveyor Manufacturers In Chennai#Screw Conveyor Machine Manufacturers In Chennai#Bucket Elevator Machine Manufacturers In Chennai#Roller Conveyor Machine Manufacturers In Chennai#Flat Belt Conveyor Manufacturers In Chennai#Inclined Conveyor Manufacturers In Chennai#Packing machine manufacturers in Chennai

0 notes

Text

A sticker labeling machine is an affordable and efficient solution for small businesses looking to enhance product presentation and streamline packaging processes. These machines ensure precise label application, improving brand visibility and customer appeal while reducing manual effort and errors. As a trusted sticker labeling machine supplier in India, Authentic Designers provides affordable machines to the needs of small-scale industries for professional packaging. For more information visit:- https://www.authenticdesigners.net/

#manufacturer#liquid filling machine#sticker labeling machine#round bottle labeling machine#automatic labeling machine#shrink labeler#shrink labeling machine#labeling machine

0 notes

Text

Enhancing Efficiency with Engi-O's Automatic Filling Machine

Engi-O is proud to announce an exciting new addition to our lineup of filling machines - the Automatic Filling Machine with autofeed functionality. Designed to streamline your production process and maximize efficiency, this innovative unit attaches seamlessly to the head of our convertible combination filler, offering users unparalleled flexibility and convenience. Let's explore how this cutting-edge technology can revolutionize your operations.

Streamlined Production:

With the Automatic Filling Machine from Engi-O, filling containers has never been easier. The autofeed addition eliminates the need for manual intervention, allowing for a continuous and uninterrupted filling process. Whether you're working with small bags or larger containers, this versatile unit ensures consistent and precise filling every time, saving you valuable time and resources.

Flexibility and Versatility:

One of the key advantages of Engi-O's Automatic Filling Machine is its ability to adapt to different configurations and applications. Whether you're filling bags, bottles, or other types of containers, this unit offers unparalleled flexibility, allowing you to customize your setup to meet your specific needs. The autofeed functionality adds an extra layer of convenience, giving you greater control over your production process.

Enhanced Efficiency:

By automating the filling process, Engi-O's Automatic Filling Machine helps increase productivity and efficiency in your operation. With fewer manual tasks to manage, your team can focus on other critical aspects of production, such as quality control and packaging. This not only saves time but also reduces the risk of errors and inconsistencies, ensuring a smoother and more streamlined workflow.

Seamless Integration:

The Automatic Filling Machine is designed to seamlessly integrate with Engi-O's convertible combination filler, providing a hassle-free solution for upgrading your equipment. The unit attaches directly to the head of the filler, allowing for easy installation and minimal downtime. Whether you're a small-scale producer or a large manufacturing facility, this versatile unit can be tailored to fit your specific requirements.

Optimized Performance:

With its advanced features and intuitive design, Engi-O's Automatic Filling Machine delivers optimal performance and reliability in even the most demanding production environments. Built to withstand the rigors of continuous operation, this unit is engineered for durability and longevity, ensuring years of dependable service with minimal maintenance requirements.

Experience the Difference:

Ready to take your filling operations to the next level? Experience the difference with Engi-O's Automatic Filling Machine. With its innovative design, flexible functionality, and unparalleled performance, this cutting-edge unit is the perfect solution for streamlining your production process and maximizing efficiency. Contact us today to learn more and discover how Engi-O can help you achieve your goals.

Engi-O now offers an autofeed addition to the convertible combination filler. The unit is attached to the head in the small bag configuration and delivers more flexibility to the user.

Contact Web - https://engi-o.com/products/aseptic/autofeed Ph - +61 3 8820 0090 Address - Factory 20, 257 Colchester Road, Kilsyth VIC 3137 Australia

0 notes

Text

Enhancing Packaging Efficiency with Automatic Carton Erector Machines

In the fast-paced world of manufacturing and packaging, efficiency is key. An automatic carton erector machine plays a crucial role in automating the packaging process, especially for industries such as pharmaceuticals. These machines are designed to form, fold, and seal cartons quickly, reducing manual labor and increasing production rates.

For companies in the pharmaceutical sector, where precision and speed are essential, automatic cartoning machines offer significant benefits. These machines seamlessly integrate with Pharma Packaging machines, ensuring the safe and secure packaging of products. With increasing demand for faster production times and error-free packaging, automatic carton erector machines meet industry needs by streamlining the packaging process.

Incorporating an automatic carton erector machine into the production line also complements High-speed liquid filling machines, which are commonly used in the pharmaceutical and cosmetics industries. Together, these technologies ensure that liquid products are filled and packaged with precision, maintaining high throughput without compromising quality.

When used in conjunction with other advanced packaging systems, such as labeling and sealing machines, automatic carton erectors help businesses reduce packaging costs and minimize downtime. This results in a more reliable and consistent packaging process, which is essential for the highly regulated pharmaceutical sector.

At Pharma Machinery, our range of automatic cartoning machines and pharma packaging solutions provide top-tier performance, reliability, and safety for any production environment. Whether you’re looking to upgrade your packaging line or need a complete automated system, we offer customized solutions to meet your specific needs.

Embrace automation today and enhance your packaging efficiency with cutting-edge machinery that delivers superior performance.

#automatic cartoning machines#Pharma Packaging machines#High speed liquid filling machines#tray forming machine

0 notes

Text

Pour, Pack, Preserve: Nichrome’s Packaging Powerhouse Arrives at ProPak East Africa

Packaging is experiencing a significant shift in Africa. Manufacturers in the Africa region are seeking smart, scalable solutions due to rising consumer interest, growing agro and dairy industry. ProPak East Africa 2025, the region's most significant and influential processing and packaging exhibition, is at the heart of this evolution. And, Nichrome is once again at the forefront.

With a rich legacy of experience, Nichrome has transformed the way brands package milk, grains, pulses, powders and liquids in India. Our focus at ProPak East Africa is not solely on machines, but also on facilitating new possibilities. Our show floor will showcase a powerful combination of state-of-the-art technology, application-specific engineering, and deep understanding of African market dynamics.

We're offering end-to-end packaging solutions for your business at an advanced level, so take a look at what Nichrome is exhibiting at ProPak East Africa 2025.

Liquid Packaging Solutions: Edible Oils, Detergents & Beyond

Handling liquids and ensuring their seals are free of any contamination. Filpack Servo 6K, FilPack Servo 12K and Filpack CMS 5L are Nichrome's VFFS and High Fidelity Flavors (HFFS) liquid packaging machines that can process edible oil sack or detergent pod fillings.

Edible Oils

Edible Oil Packaging Machine solutions come in the form of multi-layer, nitrogen-flushed pouches that retain freshness.

With servo-driven accuracy, our Bottle Filling Capping Machine lines, including the Filpack Universal bottle filler, can safely fill up to 6,000 bottles/hr.

Detergents & Powders

Our detergent packaging machine integrates an auger filler for powders and a volumetric cup filler for granules, ideal for washing powder and detergent sachets.

Washing Powder Packaging Machine setups feature quick‑change feed screws to switch between coarse and fine powders in minutes.

Mini Dairy Plant & Milk Packaging:

Hygiene and consistency are essential aspects of any dairy production. Our mini dairy plant puts pasteurization, homogenization, and pouch‑packing under one roof—ideal for small to medium cooperatives and private dairies.

We pioneered India’s first milk pouch packing machine in 1977, and today our milk filling machine range includes:Filpack Universal, Excel 400 and Filling lines.

Why settle for generic when you can get application‑specific? Our automatic powder packaging machine and bottle filling capping machine keep your line flexible, moving from edible oil pouches to detergent sachets with ease. We guarantee our products will never break.

Powder & Granular Packaging: Speed, Accuracy & Versatility

From sugar to spices, our powder and granule systems are built to scale. At ProPak East Africa, we’ll demo:

Powder sachet packaging machine for milk powder, RTE mixes, and spices

Volumetric cup filler units for rice, pulses, maize, and wheat

Auger filler packing machine modules for fine powders like flour and detergent

Key machines on display:

Excel 400 with Servo Auger Filler: Packs up to 400 sachets/min with ±1 % precision.

Sprint 250: Compact, high‑speed VFFS for small‑batch runs of spices and coffee.

Flexible 450: Multi‑lane powder sachet packaging machine—perfect for RTE coffee mixes.

Our solutions are suitable for center, threeside, gusseted, and zipper pouches, which can be used with rice packaging machines, maize packaging machinery, or wheat packaging equipment. Changeovers are now simple, meaning you can easily switch from sugar to coffee packaging machine formats.

Agrochemical & Seed Packaging: Precision Under Pressure

Agribusinesses require machines that handle corrosive chemicals and bulk seeds with extreme care. Enter our seed packaging machine and Pulses Packaging machine lines:

Anti-corrosive contact parts and dust-tight enclosure design are hallmarks of our seed packaging machine units.

Various pulses packaging machines are equipped with nitrogen flushing to prevent rancidity.

Our automatic powder packaging machine can control the dosage of powdered pesticides and fertilizer, while our powder packaging machines with multitrack heads achieve rates up to 1,200 packs/min. The ability to customize powder sachet packaging machine configurations for 5 g–50 ml is essential for small dose agrochemicals.

Our agro line is built with safety in mind: emergency‑stop interlocks, ATEX‑rated motors, and full CE certification. When you need a seed packaging machine that won’t quit halfway through planting season, you know who to call.

Tea, Coffee & Snack Packaging: Freshness You Can Taste

The scent of freshly ground coffee or crunch of your favourite snack is omnipresent almost everywhere, making it imperative that your packaging machine maintains that aroma and taste.

Coffee & Tea

Our Coffee packaging machines are equipped with features such as nitrogen flushing, vacuum sealing, and tamper‑evident sachets for singleserve and bulk configurations. Our cup filling sealing machine can divide leaf tea into individual cups with the lid applied automatically for tea delivery.

Snacks & Yogurt

The cup filling lines deliver up to 240 cups/min for pudding, yogurt, and RTE noodles. Coupled with our cup filling sealing machine, you get leak‑proof seals—crucial for chilled snacks. And yes, our Yogurt Packaging Machine ensures creamy consistency every time.

Whether you’re in the chai business or snack aisle, Nichrome has you covered: from Sugar Packaging machine sachets for traditional tea to multi‑serve coffee canisters.

Why Nichrome is Africa‑Ready

To cope with the exceptional conditions in Africa, machines must be robust enough to handle humidity levels, voltage fluctuations, and dust. We've invested in:

Local service hubs in Kenya, Uganda, Tanzania, Rwanda, and Nigeria

Tech‑savvy field engineers who speak Swahili, English, and French

Customized voltage stabilizers & heat‑resistant components

Our ROI calculators show payback in 12–18 months for mid‑range lines—thanks to reduced labour, lower scrap rates, and 24/7 reliability. We calibrate each rice packaging machine, maize packaging machine, and milk filling machine for local SKUs, ensuring your line doesn’t hiccup when you switch from 500 ml milk pouches to 50 g coffee sachets.

We’re not just here to be at booth C5, we’re to be your long‑term partner. From training your team on the mini dairy plant to stocking spares for your Detergent Packaging machine, we stand behind every solution with genuine, end‑to‑end support.

Ready to Package Smarter? Join Us at ProPak East Africa 2025

At Nichrome, we don’t just sell machines—we build packaging ecosystems designed to grow with you. Every solution we showcased at ProPak East Africa 2025—from the versatile Filpack CMD Alpha and compact mini dairy plant, to our advanced powder sachet packaging machines and bottle filling capping lines—is engineered with purpose. Whether it’s a milk pouch or a detergent sachet, a spice pack or an agrochemical dose, we customize and deliver with precision, speed, and scalability. Join us at:

Date: May 20–22, 2025

Venue: Sarit Expo Centre, Nairobi

Stall No.: Booth C5

Swing by to see live demos of our Filpack CMD Alpha, Excel 400, Sprint 250, and integrated mini dairy plant in action. Chat one‑on‑one with our experts, get tailored proposals, and pick up show‑only deals. We can’t wait to help you scale up, streamline, and dominate your category.

FAQs

1. Can Nichrome customize packaging machines for my specific product or pouch format? Ans: Absolutely! Whether you need a powder sachet packaging machine, rice packaging machine, bottle filling capping machine, or a cup filling sealing machine, Nichrome offers modular configurations with flexible fillers (auger, cup, weighers) and pouch styles (3-side seal, gusseted, zipper). We even help with product trials and format changeover support for smooth commissioning.

2. How do Nichrome machines handle sensitive products like dairy, detergent, or seeds? Ans: Our machines are engineered with product-specific technologies—like nitrogen flushing for milk and seeds, anti-corrosive components for chemicals, and hygiene-first designs for dairy. For example, the Yogurt Packaging Machine ensures cold-chain integrity, and the Automatic Powder Packaging Machine features dust-free enclosures for fine detergents or agrochemicals.

3. Does Nichrome provide after-sales support in East Africa? Ans: Yes! Nichrome has established service hubs across Kenya, Uganda, Tanzania, Nigeria, and Rwanda, with multilingual engineers and ready access to critical spares. We offer training, remote diagnostics, AMC packages, and performance optimization to ensure that every sugar packaging machine, seed packaging machine, or pulses packaging machine runs at peak efficiency.

4. What’s the ROI on investing in Nichrome’s packaging automation? Ans: Our packaging systems deliver ROI within 12 to 18 months, thanks to higher OEE, reduced wastage, and lower labor dependency. For instance, our mini dairy plant can reduce manual operations by 30% while increasing output with consistent quality. We also provide ROI calculators tailored to your product and throughput goals.

5. Why should I visit Nichrome at Propak East Africa 2025?

Visiting Nichrome at Propak East Africa 2025 means experiencing packaging innovation firsthand. You'll get to know more about our innovations across sectors like dairy, edible oils, detergents, seeds, and coffee. It’s your chance to meet our experts, explore tailor-made packaging systems, and get business-specific consultations that can future-proof your packaging line.

#Edible Oil Packaging Machine#liquid packaging machines#Bottle Filling Capping Machine#detergent packaging machine#Washing Powder Packaging Machine#mini dairy plant#milk filling machine#automatic powder packaging machine#Powder sachet packaging machine#rice packaging machines#maize packaging machinery#wheat packaging equipment#seed packaging machine#Pulses Packaging machine#Coffee packaging machines#cup filling lines#Yogurt Packaging Machine#Sugar Packaging machine#bottle filling capping lines

0 notes

Text

Filling Machines | Intelweigh Multi Head Weigher | Nichrome Bangladesh

Nichrome offers filler weighers for packaging with various filling capacities for solid, liquid & viscous food products like snacks, milk, oil

#vertical form fill seal machine#filling and packaging machine#packaging machine supplier in bangladesh#powder packaging machine#liquid filling machine in bangladesh#potato chip packaging machine#chub packaging machine#soybean oil packing machine#automatic sachet packing machine#silica gel packing machine#pouch packing machine#pouch sealing machine#table top blister packaging machine#powder bottle filling machine#small packaging machine#packaging machine price#shampoo filling machine#spices packing machine#liquid pouch packing machine#viscous liquid filling machine#ointment tube filling machine#ointment filling machine#airtight food packaging machine

0 notes