Don't wanna be here? Send us removal request.

Text

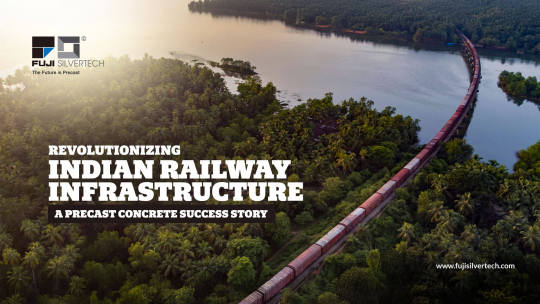

Revolutionizing Indian railway infrastructure: A Precast Concrete Success Story

India’s railway network is the lifeline of the nation, and as our economy and trade expand, so does the demand for robust and efficient infrastructure. The Dedicated Freight Corridor (DFC) project, a monumental undertaking by the Ministry of Railways, aims to significantly upgrade our freight transportation capabilities. But building infrastructure of this scale, especially alongside active railway lines, comes with unique challenges. That’s where precast concrete technology, pioneered by Fuji Silvertech Concrete Pvt. Ltd., truly shines. Their innovative solutions for the DFC project offer a glimpse into the future of Indian Railway construction.

The Challenge

The DFC isn’t just about more tracks; it’s about stronger, higher-capacity infrastructure. Designed to carry freight at nearly twice the height and with significantly increased axle loads compared to standard Indian Railways, the DFC demands an unparalleled level of structural integrity. This means dealing with heavier loads and increased vibrational forces from trains moving at speeds exceeding 65 kmph.

A significant component of the DFC Infrastructure is its minor bridges and drainage and ducting infrastructure which runs along the tracks and is as long as them. Efficient storm water drainage and ducting parallel to these tracks is very crucial to avoid situations of waterlogging that compromise track stability and affect safety and longevity. Additionally, minor bridges and cross drainage structures along and across the DFC need to handle some of the highest transportation loading in the country.

Fuji Silvertech Advantage

Fuji Silvertech provided precast concrete solutions for track-side and cross drainage, minor bridges, and earth retention structures for the DFC. The core idea was to deliver solutions specifically tailored for the DFC, allowing for undisturbed railway operations and expedited project completion.

The unique aspect? These precast components were designed for easy, fast, and light site operations. Imagine the complexity of building 9.15-meter-tall retaining walls on-site next to an active railway line. Traditional cast-in-situ methods would involve massive construction activities. Fuji Silvertech’s T-shaped segmental precast retaining walls offered a game-changing alternative, designed to withstand both earth and rail vibrational loads. This innovation was so significant it was verified, validated and patented for safe earth retention and railway vibration effects.

Innovations Beyond Construction

The benefits of precast technology extend far beyond just speed and ease of installation. The precast technology offers vast potential in terms of customization, design, innovation and scalability.

In offering this simplicity and scalability of construction, there is a vast effort beyond the construction site – in the design, in the production and the dispatch. The solution was custom designed, a first-in-India attempt and further to the functional and structural requirements, a stringent design approval process by the regulatory and statutory authorities for IRS & DFCC ensures the technical compliance aspects of the product. The individual segments being huge, the challenges of mass concreting were obvious – and every threat of high hydration temperatures and cracking were carefully combated with different actions in production. The logistics and dispatch of these components had to be very dynamic because the dispatch locations moved with the tracks for the same project and the segments to be transported were larger than anything FUJI had done before. It was surely another first time for FUJI Silvertech and a huge challenge.

The challenge was true, but the goal was worthy, and it turned to a progressive realization with the hard work and determination of the FUJI team and the genuine support and right direction from all the authorities.

The modular nature of these precast components accelerated the construction fivefold compared to traditional methods. Imagine the time savings when scaled to projects involving 100+ km of drains and numerous minor bridges. Standardized and factory-made, these solutions are now ready for dispatch across the entire pan-India railway network.

Fuji Silvertech’s work on the DFC is a testament to the power of new-age precast concrete solutions. It showcases novel design for earth retention and cross-drainage, demonstrates high-quality and durable approaches for national infrastructure, and exemplifies a commitment to sustainable construction. This project isn’t just about today; it’s paving the way for a faster, more modern, integrated, and sustainable rail infrastructure for India’s future.

0 notes

Text

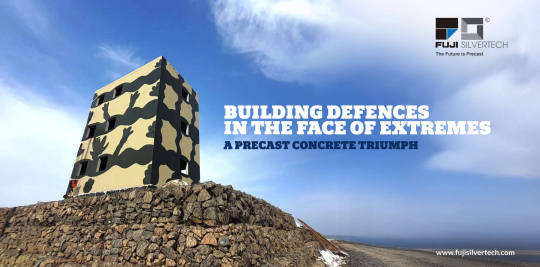

Building Defences in the Face of Extremes: A Precast Concrete Triumph

Imagine constructing a critical observation tower on a remote island, just 5 km wide, situated at the India-Pakistan border. Now, imagine that island is only accessible by a 25 km journey across the Arabian Sea. Add to those challenges like incredibly poor soil, high water tables, significant tide levels, a highly corrosive environment, and absolutely no existing infrastructure for power, housing, or sanitation. This was the reality for the Border Security Forces and CPWD, needing a robust solution for Observation Point (O.P.) Towers at Lakhpatwari, Narayan Sarovar, Kutch, Gujarat.

This site is not just remote; it’s classified as a high cyclone and high earthquake zone (Zone V). Traditional construction methods simply weren’t feasible.

Fuji Silvertech, in collaboration with CPWD, devised a complete precast concrete solution. The approach was ingenious: manufacture all components off-site in Bagodara facility, ensuring zero-millimeter tolerance for a perfect fit. These components included precast base slabs, raft footings, wall panels with couplers for the foundation, wall panels with door and window openings for observation, and precast slabs. The entire structure was then assembled on-site using bolted connections.

The result? A four-story O.P. Tower, built from 272 precast products of 29 variations, installed and finished in just 24 days. Each product weighed less than 1.5 tonnes, making transportation and handling manageable in such a challenging environment. The wall panels and floor slabs were 200 mm thick, designed to resist bullet penetration. Special attention was paid to protecting the foundation from the corrosive saline environment with bitumen paint.

The true test of these structures came shortly after installation. On June 15-17, 2023, cyclone Biparjoy, a very severe cyclone with sustained wind speeds of 125 kmph and gusts up to 140 kmph, along with a storm surge of 2 to 3 meters, hit the area directly. Not only did the towers withstand the combined force of the wind and tide, but they also encountered a minor earthquake during this period. Crucially, there was no damage.

This project stands as a powerful demonstration of the possibility and success of precast buildings in the most extreme and challenging conditions. The O.P. Towers were inaugurated by Shri Amit Shah, the Union Home Minister, and even received a Certificate of Merit as a “Best Completed Project” from the Director General, CPWD.

This case study is a testament to how innovative precast concrete solutions can overcome significant logistical and environmental hurdles, delivering resilient and crucial infrastructure for national defence.

0 notes

Text

World Environment Day – Bringing a Green Advantage for our Clients

As the construction industry shifts toward carbon-efficient and more transparent practices, clients are looking for ways to make their projects stand out. On World Environment Day, it’s worth highlighting how Environmental Product Declarations (EPDs) on Fuji Silvertech’s T25 Drains and selected sizes of Box Culverts can give your project a real advantage, especially when earning LEED or IGBC certification.

Statistics show that:

76%of construction product client want suppliers to be transparent about environmental impacts of their products.

72% of construction product clients want manufacturersto provide them with sustainable or green products.

With an EPD, a manufacturer is not just claiming a product is green but shows exactly how it performs across a range of environmental factors, all measured according to international standards. As a construction product manufacturer, having an EPD helps us be distinct from our competitors. EPDs use Life-Cycle Assessment (LCA) to quantify and communicate the lifetime environmental impact of a product. Since they are based on international standards and are verified by a third-party, they provide an objective, credible and neutral assessment.

Today, we want to spread awareness in our community and customers about our T25 drain and utility duct product and Box Culverts—with externally verified EPDs as per ISO 14025—which provides a competitive advantage to our clients who are interested in gaining green certifications like LEED or IGBC for their projects.

Our Environmentally declared products are as follows:

T25 drains: T25-300×300, T25-450×450, T25-600×600, T25-750×750, T25-900×900, T25-1200×1200

Box Culverts: BC-2000 x 2000 x 2000, BC-2600 x 2600 x 1500, BC-3000 x 3000 x 1000

0 notes

Text

Fuji Silvertech Leads the Way: Award of Excellence in Infrastructure Development

Fuji Silvertech Concrete Pvt. Ltd. has once again proven its industry leadership and commitment to excellence by securing multiple prestigious awards in 2024. The company’s recognitions at the 3rd Edition of The Corporate Titan Awards and FT Finance Summit initiated by Feather Touch underscore its firm dedication to innovation, quality and corporate leadership.

A Year of Recognition and Achievement

In a highly competitive landscape, Fuji Silvertech stood out among contemporaries, earning honours that highlight its innovative contributions to the business world. The Awards known for celebrating excellence in corporate leadership, recognized Fuji Silvertech for its outstanding performance, visionary strategies and impactful business practices. The list of awards won are as follows:

Outstanding Projects by a Manufacturing Company

Excellence In Infrastructure Development

Sustainable Manufacturing Award

Product Innovation and Design Excellence Award

Quality Manufacturing Award

Why Fuji Silvertech

Fuji Silvertech’s success is rooted in its relentless pursuit of innovation and its focus on delivering value to clients and stakeholders. The company’s leadership team has always encouraged a culture of continuous improvement, inspiring creative problem-solving and sustainable growth. These qualities have not only driven business success but have also set new benchmarks for excellence in the industry.

Impact and future vision

Receiving multiple awards in such a prominent forum is a testimony to Fuji Silvertech’s influence and reputation. These recognitions reinforce the company’s position as a role model for others aspiring to make a mark in the corporate world. As Fuji Silvertech continues to expand its footprint and embrace new opportunities, its assurance to ethical leadership, customer-centricity and social responsibility remains stronger than ever.

“Winning these awards is not just a recognition of our past achievements, but a motivation to continue pushing boundaries and setting new standards in the industry.”

Looking ahead

Fuji Silvertech’s honours are more than just trophies; they are milestones in a journey defined by passion, determination and purpose. As the company moves forward, it remains devoted to driving positive change, inspiring its team and delivering exceptional value to its customers and partners.

Congratulations to the entire Fuji Silvertech team for these well-deserved recognitions. Here’s to many more years of excellence and innovation!

0 notes

Text

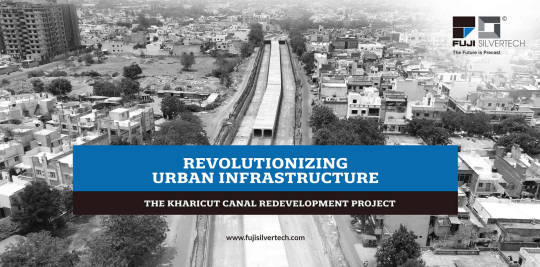

Revolutionizing Urban Infrastructure : The Kharicut Canal Redevelopment Project

The Kharicut Canal redevelopment initiative in Ahmedabad, Gujarat, epitomises a groundbreaking effort to modernise urban infrastructure. With a substantial budget exceeding 12000 Million INR, this ambitious project, backed by the Ahmedabad Municipal Corporation and state irrigation department, aims to revamp 22 km of the canal and replace 40 ageing bridges with continuous precast box culverts.

In a collaborative endeavour, Multimedia Consultants and FUJI Silvertech spearheaded the conceptualisation and structural design of this pivotal precast concrete canal. Stringent adherence to Indian Road Congress standards and meticulous scrutiny of over 150 load combinations underscored the project’s commitment to structural integrity.

Fuji Silvertech’s cutting-edge manufacturing facility was crucial for producing the precast box culverts. Utilising premium-grade materials such as self-compacting M50 grade concrete and high-strength Fe 550 D reinforcement steel, the factory maintained rigorous quality control standards accredited by ISO 17025:2017 and international benchmarks.

Navigating the complexities of urban construction, precast concrete box culverts emerged as the most practical solution. Precision engineering and innovative techniques, such as steam curing and monolithic construction joints, ensured seamless assembly and structural robustness.

The project’s emphasis on environmental sustainability is noteworthy. The redevelopment plan aligns with eco-conscious principles by integrating green spaces, fountain areas, and recreational zones into its blueprint. Moreover, the precast box culverts underwent rigorous life cycle assessments, earning third-party validation for their minimal carbon footprint and environmental adherence to ISO standards.

The Kharicut Canal redevelopment project is a testament to innovation, collaboration, and environmental stewardship. It sets a transformative precedent for urban infrastructure development in India.

0 notes

Text

0 notes

Text

From Individual Strengths to Collective Success : Lessons from Precast Construction

Behind every strong structure lies a team of skilled individuals—just like every precast element plays a crucial role in shaping the final masterpiece. At Fuji Silvertech, we believe innovation isn’t just about technology; it’s about people. When individual strengths come together with a shared vision, transformative infrastructure stands the test of time.

Like Puzzle Pieces, Every Role Matters

A bridge doesn’t stand on a single pillar, and a building isn’t held up by just one wall. Similarly, no project succeeds through individual effort alone. Every designer, engineer, project manager, and on-site worker contributes a vital piece of the puzzle. When these pieces fit together seamlessly—like precast components—the result is efficiency, durability, and excellence.

Precast Construction: A Model for Teamwork

Precast technology itself is a testament to the power of teamwork. Unlike traditional construction, where everything happens on-site, precast involves precision manufacturing in controlled environments. Designers ensure every measurement is perfect, engineers optimise strength and durability, and construction teams execute accurately. Like a relay race, each stage depends on the next, ensuring smooth execution and minimal delays.

Speed, Strength & Success Through Unity

One of the most significant advantages of precast construction is speed without compromising on strength. The same applies to teamwork. When individuals collaborate effectively, timelines are shortened, mistakes are minimised, and quality is elevated. True success is never a solo journey—it’s the outcome of people working together with trust and a shared purpose.

Building the Future, One Team at a Time

At Fuji Silvertech, we build infrastructure, partnerships, progress, and a culture where individual talent fuels collective success. When each person plays their role with passion and precision, we don’t just create buildings—we create lasting impact.

Because true strength isn’t in standing alone but in building together.

Let’s build better. Let’s build together. Let’s build better with precast.

0 notes

Text

Built Better Together : How Team Spirit Drives Long-Term Sustainability

Sustainability isn’t a sprint—it’s a marathon, and teamwork is the driving force that keeps us moving forward. At Fuji Silvertech, we believe creating infrastructure for a sustainable future requires collaboration at every level. Together, we are building solutions that meet today’s needs and stand the test of time.

Teamwork: The Foundation of Long-Term Impact

True sustainability goes beyond materials and processes—aligning every individual effort toward a shared vision. At Fuji Silvertech, our teams work seamlessly, combining design, engineering, and construction expertise to create infrastructure that lasts for generations. By focusing on durable, precast solutions, we’re reducing waste, conserving resources, and building a legacy of resilience.

Shared Innovation for Future-Ready Solutions

Collaboration sparks innovation, and innovation drives sustainability. When minds from diverse fields come together, the possibilities are limitless. Our precast solutions are a testament to this synergy—designed to lower environmental impact while delivering unmatched durability. This long-term approach ensures that every project contributes to a greener, more sustainable tomorrow.

Sustainability That Outlasts Trends

The infrastructure we build today will define the lives of future generations. That’s why we prioritise precast solutions that are efficient and sustainable for decades. By reducing on-site construction timelines, minimising resource consumption, and ensuring structural longevity, we’re creating infrastructure that serves communities well into the future.

Together, We Build for Tomorrow At Fuji Silvertech, we know that sustainability is a team sport. Every member of our organisation—from design to delivery—is committed to shaping infrastructure that empowers progress while protecting the planet.

We’re not just building for today; we’re building a better, greener future. With our team’s collective efforts and long-term perspective, we’re creating solutions that will stand strong for generations to come.

Let’s build better with precast—for a future that thrives together.

0 notes

Text

Building Resilient Water Management Systems with Precast Concrete

Effective water management is crucial for sustainable development and public health in today’s rapidly urbanising world. At Fuji Silvertech, we’re pioneering the use of advanced precast concrete solutions to revolutionise water and sewage systems. From stormwater drains to sewage treatment plants, our innovative precast components ensure cities and communities can handle water challenges with resilience, efficiency, and durability.

The Crucial Role of Water Management

Efficient water management systems are essential for preventing floods, ensuring a clean water supply, and maintaining public health by adequately handling sewage and wastewater. Traditional construction methods for these systems often lack durability and efficiency. Precast concrete solutions provide advanced solutions that offer unparalleled strength, quick installation, long-lasting performance and lower life cycle costs.

Stormwater Management: Fighting Floods with Precast Precision

Stormwater management is a cornerstone of urban infrastructure, particularly in regions prone to heavy rainfall. Fuji Silvertech’s precast concrete stormwater drains are engineered to handle large volumes of water efficiently. Manufactured in controlled environments, our precast components guarantee consistent quality and performance. Our precast concrete stormwater drains are designed for durability and can withstand heavy loads and extreme weather without deteriorating. They also offer rapid installation, minimising urban disruption and ensuring cities remain functional even during construction. With precise engineering, these drains facilitate optimal water flow, reducing the risk of blockages and flooding. The smooth surface of our drains reduces friction and lowers the slope required. Our storm water drains can take a load of traffic, thus increasing the right way and, more importantly, life cycle costs.

Advanced Solutions for Sewage Systems

Managing sewage effectively is critical for public health and environmental protection. Fuji Silvertech’s precast concrete solutions for sewage systems are built to the highest quality and durability standards, including precast pipes, manholes, and treatment plant components. Precast concrete’s resistance to corrosion and chemical damage ensures a longer lifespan for sewage systems, significantly reducing maintenance costs. Our watertight joints prevent leakage, safeguarding groundwater from contamination and ensuring efficient waste management.

At Fuji Silvertech, we’re not just building infrastructure; we’re building a sustainable future. Our advanced precast concrete solutions for water management—from stormwater drains and sewage systems to road drainage—are designed to enhance efficiency, durability, and sustainability. Fuji Silvertech’s precast concrete ensures robust, reliable, cost-efficient water management infrastructure that protects public health and the environment for future generations.

0 notes

Text

Enhance water management with Fuji Silvertech's precast concrete solutions for stormwater drains and sewage systems. Durable, efficient, and sustainable infrastructure.

0 notes

Text

Fuji Silvertech’s Leadership Vision: Empowering India’s Growth

India’s infrastructure story unfolds every day—new roads crisscross landscapes, modern rail networks connect communities, and sustainable solutions shape tomorrow’s cities. At Fuji Silvertech, we believe a visionary leader stands behind every transformative project. We’re not just building structures; we’re building a better India, and our leaders are the heartbeat of that mission.

Leading with Purpose and Imagination

True leadership isn’t just about guiding teams. It’s about daring to see what others can’t, turning challenges into opportunities, and never settling for “good enough.” Our leaders imagine a future where infrastructure isn’t just functional—it’s resilient, eco-friendly, and designed to uplift entire societies. Their purpose goes beyond construction; it’s about leaving a lasting positive impact on people’s lives.

Innovation That Shapes the Nation

At Fuji Silvertech, innovation is woven into everything we do. Leadership drives our innovations, from pioneering precast solutions that speed up projects to ensuring every component meets stringent quality and sustainability standards. These leaders ask, “How can we do this smarter, better, greener?” They challenge norms, inspire new ideas, and push the boundaries of what’s possible.

The Leaders We’re Looking For

We want leaders who embrace complexity and discover clarity. Leaders who see a blueprint not as a limit but as a canvas are ready for their vision to shine through. We seek:

Visionaries: People who look at today’s infrastructure and imagine a brighter, more connected tomorrow.

Innovators: Problem-solvers who harness creativity and technology to redefine what’s achievable.

Mentors: Those who lift others, value diverse perspectives, and build teams that work as one.

Adaptable Trailblazers: Individuals who grow and evolve as fast as our changing world demands.

Join Us in Shaping the Future

If you’re driven by purpose and guided by imagination, Fuji Silvertech is where you belong. Here, leadership means influencing real change—improving how people travel, work, and live. Each decision you make, and strategy you shape can leave a legacy that strengthens India’s foundation.

Ready to be part of something greater? Let’s create the future of infrastructure together.

Ready to lead the change? Join us, and let’s build better with precast.

Connect us on: [email protected] | +91 99100 23599

0 notes