Don't wanna be here? Send us removal request.

Text

A Grand visual inspection machine is an automated optical inspection system that uses AI-powered cameras to check product quality at high speeds. These vision inspection machines quickly analyze packaging and products, spotting defects like scratches, misprints, seal leaks, or foreign contaminants.

By integrating a GV visual inspection system into a Grand production line, manufacturers in food & beverage, pharmaceutical, and cosmetics industries can ensure every item meets strict quality standards. Vision inspection equipment prevents damaged or contaminated products from reaching consumers. For example, automated visual inspection can catch improperly applied labels or weak seals before items leave the line, improving safety and consistency.

0 notes

Text

Grand Since 2006

Grand is one of the earliest producers of pharmaceutical machinery in China.

Our mission is to achieve "Earn Limited Profits, High Quality Trust" .

With 18 years of professional manufacturing experience, Grand has earned customers' trust in over 120 countries.

0 notes

Text

Ampoule Filling Line can also be perfectly connected to the Grand cartoning machine series (case packing and palletizing can also be added) to achieve the entire process from filling to cartoning.

0 notes

Text

Ever wondered “how long does it take pills to dissolve” after you swallow a dietary supplement or prescription medication? The answer depends on several factors – from the pill form (capsule vs tablet) to coatings and stomach chemistry. In this blog post, we’ll explore the science behind pill digestion time and pill absorption, covering how pill composition, stomach acid, and coatings affect dissolution in the body.

0 notes

Text

Liquid Blister Packaging Machine-grand-pack

Grand liquid packaging machine and pharmaceutical capsule blister machine are similar in function. By using different pump heads and molds, the blister packaging machine can be transformed into a liquid packaging machine. Come to grandpack to explore more packaging machinery!

https://grandpackmachine.com/.../blister-packaging-machine

WhatsApp:+86 153 6128 5728

#LiquidBlisterPackaging#BlisterPackagingMachine

0 notes

Text

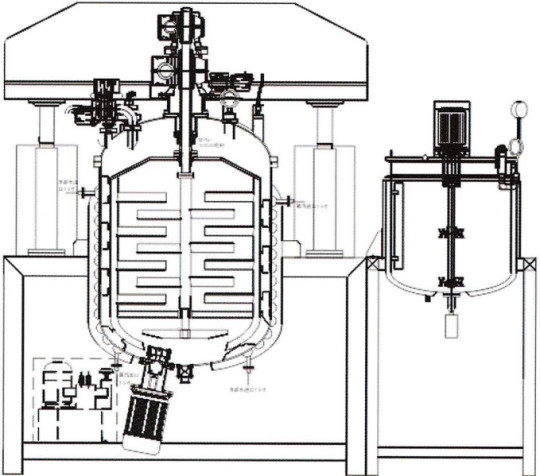

Emulsification tanks are suitable for the production of cosmetics, medicine, food, chemistry, dyeing, printing ink and other industrial products, especially for the preparation of emulsified materials with high matrix viscosity and high solid content.

The emulsified product material can also be further packaged with a tube tail sealing filling machine.

0 notes

Text

Automatic Checkweigher for Small Packages GCW100-A automatic checkweigher delivers ±0.02g precision at 120 PC/min. Ideal for food, pharma & more. https://grandpackmachine.com/packaging-automation-equipment/checkweigher-gcw-series/… #Checkweigher #SmallPackages #grandpackmachine

0 notes

Text

When it comes to pharmaceutical and healthcare packaging, blister type plays a critical role. The right blister pack not only ensures product protection and compliance but also affects production efficiency and packaging appeal. That’s where the Grand blister machine steps in—offering reliable solutions tailored to a wide variety of blister types.

1 note

·

View note

Text

Automatic Filling Machine for Cosmetics & Skincare – GF-600 Series

Key Features

Modular Design Flexible 8-module structure supports customized production needs.

Full Servo Control Precision and stability for high-speed and accurate filling.

Automatic Blowing & Suction Cleaning Ensures hygiene before filling, ideal for pharmaceutical and cosmetic standards.

Dual Compatibility Supports both inner plug pressing and pump head capping, no need for manual intervention.

High Speed Production Up to 50 bottles/min, ideal for medium and large-scale production.

Compact Footprint Total equipment length: 12.8 meters – efficient for modern production facilities.

Smart Upgrades Ready Supports inkjet printing, visual inspection, and future smart factory integrations.

0 notes

Text

The NYF-600 is equipped with a number of features and accessories that speed up and facilitate the process of filling capsules. First, it has the vacuum positioning mechanism, which rapidly loads the hopper with empty caps and sets it to the automatic loading point. Then, the optical sensor that separates the caps from the bodies of the capsules that have been automatically placed on the loading spot.

Filled capsules are transported by guide chutes in orderly way to the sealing machine. There are three basic process to seal the capsules, including creating a thin layer of glue on soap with rubber wheel, and heating up the container by a long conveyer system, to ensure the quality of the capsules sealed.

0 notes

Text

Colorful gummy candies spill out of a bottle, illustrating the booming demand that drives large-scale gummy candy production.

Scaling up the production of gummy candies from a kitchen recipe to an industrial level requires more than just a bigger pot. To make gummy candies at scale, confectionery manufacturers rely on specialized production lines that handle cooking, molding, and cooling in a continuous process.

0 notes

Text

Emulsification tanks are suitable for the production of cosmetics, medicine, food, chemistry, dyeing, printing ink and other industrial products, especially for the preparation of emulsified materials with high matrix viscosity and high solid content. (1) Cosmetic industrial products: face cream, lotion, lipstick, shampoo, etc. (2) Pharmaceutical industrial products: ointment, syrup, eye drops, antibiotics, etc. (3) Food industrial products: jam, cream, margarine, etc. (4) Chemical industrial products: chemical drugs, synthetic adhesives, etc.

0 notes

Text

In the world of industrial V mixing – the process of blending powders and granules in V-shaped vessels – a handful of manufacturers stand out for their quality, innovation, and global reach. Choosing the right V mixing machine is crucial for industries like pharmaceuticals, food, and chemicals where uniform blending is essential.

Below we compare the top 8 V mixing machine manufacturers in 2025

0 notes

Text

THE CRITICAL IMPORTANCE OF BLISTER PACKAGING IN PHARMACEUTICAL SAFETY

In the healthcare sector, ensuring the safety and efficacy of pharmaceutical products like tablets and capsules is paramount. Proper packaging plays a vital role in protecting these crucial medications from environmental factors such as moisture, light, and contamination, preserving their integrity until they reach the patient.

0 notes

Text

Importing equipment such as Capsule filling machines, Tablet presses, and related packaging systems into the United States requires a valid DEA License. Without authorization from the Drug Enforcement Administration (DEA), shipments of controlled machinery can’t clear U.S. Customs. To streamline your application, start at the DEA’s official portal (apps.deadiversion.usdoj.gov/tem/spri ng/login) and register for an account.

#DEALicense#Capsulefillingmachines#Tabletpresses

WhatsApp:+86 153 6128 5728

0 notes

Text

Launching a Gummy Bears with the SE-300 Gummy Production Line

Recent studies highlight exciting advances in gummy candy formulation and production.

#GummyBears#grandpack#SE-300

WhatsApp:+86 153 6128 5728

0 notes