HT Fine Chemicals Company is a large scale textile auxiliaries chemicals manufacturer with years of experience in producing and exporting textile pretreatment, dyeing, printing and finishing agents.

Don't wanna be here? Send us removal request.

Text

Wetting Agent T-60

https://www.htfine-chem.com/product/wetting-agent-t-60.html

[Brief information]

1. An anionic surfactant with excellent wetting and dispersibility and biodegradation that has slight irritation to human skin.

2. Widely use in home chemicals, pigments, printing & dyeing, asbestos, pesticides, paper making, leather, etc.

3. Use for emulsifier, wetting agents, dispersing agent, etc.

[Main composition]

Di-iso-octyl sodium succinate.

[General properties]

Appearance: colourless to pale yellow viscous liquid

Solid content: above 60%

pH: 6 – 8

[Product features]

1. Excellent wetting and stripping to dirt as a scouring agent, while stable with bleaching agents.

2. Excellent thickening without use of alkanolamide and good compatibility to compound various washing chemicals.

3. Excellent wetting in concentrated washing powder and washing & bleaching to colour dirt, which sharply improves machine washing efficiency.

4. Uses for cotton, linen, viscous and their blends, while bleaching and dyeing can be done after treatment. And it confers soft and bulky hand feels to fabrics.

5. Compounds various wetting agents and scouring agents.

0 notes

Text

Auxiliaries for Cotton and Its Blends

https://www.htfine-chem.com/product/pretreatment-auxiliaries/auxiliaries-for-cotton-and-its-blends/

The cotton and its blends, also known as cotton, is a kind of woven fabric made of cotton yarn, which is one of the most commonly textile fabrics in clothing industry.

Cotton fabric manufacturing including spinning, weaving, knitting, dyeing, printing and finishing. The Spinning and weaving process is putting the textile fiber processed into yarn and fabric dyeing by machine, and finishing to reprocessing cotton fabric products by chemical and physical method of mechanical part. It can improve the performance of fibers and its products and improve its appearance by finishing processing. Therefore, textile agent and auxiliary chemicals is an indispensable part in textile industry. During finishing process, there is a pretreatment of textile fabric. You have to use good cotton chemistry and achieve good performances.

HT fine chemical products can meet your requirements, chemicals used in cotton production such as wax removing agent, sequestering powder CT, water softener, peroxide stabilizer, scouring agent, bio-polishing enzyme, acid releasing agent for textile chemical, scouring enzyme, peroxide killer etc. All of these cotton chemistry products are safe and environmental protection. We are the manufacturer of auxiliaries for cotton and its blends, we can supply best chemical auxiliary agent.

0 notes

Text

Pretreatment Auxiliaries

https://www.htfine-chem.com/product/pretreatment-auxiliaries/

Pretreatment auxiliary is mainly included auxiliary for cotton and its blends, auxiliary for polyester and other general auxiliaries.

The proper pretreatment is very important for textile dyeing and finishing, especially in recent years, customers and consumers strict in dyeing and printing products increasingly, such as color, color fastness, appearance, shrinkage, feeling, more highlights the importance of pretreatment. The main purpose is to make suitable for pretreatment of textile dyeing and printing, and has good uniformity and reproduction, and reduce the reparation dyes, additives and water, energy consumption, improve the rate of manufactured goods, reduce the manpower.

Used in order to eliminate the use of natural or man-made impurity on the fabric, and give full play of the excellent characteristics of fabric, such as white, soft and good permeability, to adapt to the needs of the subsequent process, the pretreatment auxiliaries mainly include wetting agent, penetrant agent, bleach, cleaning agent and so on.

Textile pretreatment chemicals as one part of textile auxiliary chemicals is the first step of textile treatment which is the purpose of removing slurry, oil, wax, and pectin etc impurity, improving absorbent and whiteness of the fabric, and to improve the hand feeling, so as to meet the requirement of subsequent dyeing and finishing process. Pretreatment auxiliaries chemicals can effectively solve the problems.

0 notes

Text

Dyeing Auxiliaries

https://www.htfine-chem.com/product/dyeing-auxiliaries/

Dyeing auxiliaries are fine chemical products in the textile printing and dyeing industry applications. Dyeing agent is an important type of textile printing and dyeing auxiliaries, generally according to the classification of dyes, to name different types of dyeing agents. Dyeing auxiliaries is mainly included auxiliary for cotton, auxiliaries for polyester, auxiliaries for wool and nylon, auxiliaries for acrylic etc.

To be specific, dyeing agents include leveling agent, fixing agent, dispersing agent, fluorescent whitening agent and softener. Textile dyeing auxiliaries are essential to enhance the value-added and upgrading of textiles, they can also make the textile more contemporary, functional, and high-grade. To some extend, dyeing auxiliaries quality affects directly the fabric quality.

HT Fine Chemical thinks that the color difference of reactive dyes of cotton knitted fabrics is mainly related to dyeing auxiliaries, such as leveling agent, dispersant, anti creasing agent or fiber protection agent and dyestuffs cosolvent.

Some example chemicals used in textile dyeing:

1. Leveling agent

Light-colored reactive dyes need to use a certain leveling agent to achieve uniform dyeing, and dark not necessarily to add leveling agent. In the actual production process, three kinds of dye coloring is often use a dye as the base (the amount of 80%~90%), the other two dyes for auxiliary colors (dosage accounted for 10%~20%).

2. Anti creasing agent or fiber protection agent

Because of the characteristics of the rope-like dyeing of knitted fabrics, it will inevitably form some wrinkles in the process of pretreatment and dyeing, and add such dyeing auxiliaries to improve the feel and appearance of the cloth.

3. Dyestuffs cosolvent

Turquoise and other active dyes with larger molecular weight, its dissolution and dyeing are more difficult, in the dyeing to add the appropriate amount of cosolvent, dye molecules can be better dissolved in the dye bath, on the other hand, can make the fiber swelling, in order to facilitate the dye molecules into the internal infiltration of fiber to achieve uniform dyeing purposes.

0 notes

Text

Bath Anticreasing Agent 1025

https://www.htfine-chem.com/product/bath-anticreasing-agent-1025.html

HT-1025 is a special bath anti creasing agent, which efficiently reduces the friction between fibres and fibres-dyeing tank that prevents creases or scratches, due to its smoothing and softening effects. The main ingredient of anti creasing agent is special polymer dispersion. It can prevent the rope from creasing in the pre-treatment (scouring, boil bleaching), dyeing and post-processing. After using anti creasing agent, it can make the material feel more thick, smooth, and the synthetic fiber fabric more durable hydrophilic, antistatic and easier to decontaminate. Anti creasing agent has the advantages of low foaming and excellent stability, suitable for all kinds of fabrics, especially knitted fabric pretreatment, dyeing, and post-processing. It is also applicable to the printing and dyeing processing. Anti creasing agent is environmental-friendly and non-dangerous, which can be shipped safely.

[Main composition]

Special polymer.

[General properties]

Appearance: colorless to pale viscous liquid

Ionicity: anionic

pH: 5-7

Solubility: easily soluble in water

Stability: stable to hard water, electrolytes, mild acid and alkali

[Product features]

1. Mainly for cotton, polyester and its blends.

2. Efficiently prevents creases of rope fabrics during pretreatment (scouring, boil bleaching), dyeing and finishing.

3. No influence on shade and fastness.

4. No foam and stable to high temperature that can be used in jet dyeing machine and dye bath at 130℃.

[Application]

General dosage: 1-5 g/L

To achieve best anti-creasing performance, please run the fabrics in softening bath for 5 to 10 minutes, and then run as normal operation.

0 notes

Text

Auxiliaries for Denim Sizing or Garment Washing

https://www.htfine-chem.com/product/auxiliaries-for-denim-sizing-or-garment-washing/

Garment washing process is a special process in the clothing process and treatment. The effect of water washing getting more and more popular, garment washing chemicals and sizing chemicals are widely used in all kinds of clothing & garments, especially the emergence of some new methods of washing, especially in daily life adds luster.

Garment Washing Chemical Application range:

1, Woven cotton denim or blended denim made jeans, denim jacket, this is our most common garment washing plant.

2, Pure cotton or cotton blended woven making casual trousers, casual jacket, which is now in our washing garment washing factory is more common, such as anti-wrinkle trousers, shirts and so on.

3, Knitted pure cotton or cotton blended fabric made of casual clothing, which should be based on customer requirements to determine whether or not to wash.

4, In short, the washing clothes are generally pure natural fabrics and blended natural fabric clothing.

0 notes

Text

Anti-pilling Agent 8168

https://www.htfine-chem.com/product/anti-pilling-agent-8168.html

This article is a kind of low temperature water environmental polyvinyl chloride ester copolymer emulsion, through the introduction of the monomer containing many double bond of the hinge component copolymerization, in polymerization process introduction of special fabric macromolecules, which is a main body of the surrender of the cross-linking density mesh structure, can effectively prevent the machining process of hook silk, holes and the generation of defects, played the twisting effect, thus greatly improve the fabric anti-pill fuzz performance

[Main composition]

Acrylate copolymer

[General properties]

Appearance: transparent liquid

Ionicity: nonionic

PH value: 5 ~ 7

Solubility: soluble in water

Stability: resistance to dilute acid and dilute alkali, the electrolyte, solid water stability

[Product features]

1. To all sorts of fiber material, all have strong fuzz ball to prevent the effect.

2. It won't cause fabric handle coarsening, can produce good backwash elastic and rich feel.

3. Does not contain harmful material such as formaldehyde, APEO.

[Application]

Recommended dosage and conditions

Pad method: dosage 5-15 g/l

The second dip two rolling: dry can

0 notes

Text

Leveling Agent

https://www.htfine-chem.com/popular-search-textile-chemicals/leveling-agent.html

Textile auxiliaries are essential to enhance the added value of textiles, not only make the textile functional, but also make its high-grade, more with the sense of the times. In order to have these advantages, the premise is the fabric dyeing to be evenly permeable, a very effective method that using leveling agent which features in slow dye or migration to achieve uniform dyeing effect.

In the dyeing process of fiber yarn, line or fabric , in order to promote uniform dyeing without color bars, spots and other added substances, leveling agents are here to use. Most of the leveling agents are water-soluble surfactants, which are divided into two types according to the effect of leveling agent on the diffusion and aggregation of dyes: one is fibrous leveling agent, which has little effect on the concentration of dyes. But the affinity of the fiber is greater than the affinity of the dye to the fiber, so in the process of dyeing, this kind of leveling agent will be combined with fiber first, reduce dyeing rate, but with the change of dyeing conditions, dyes will gradually replace the leveling agent, fixed on the fiber, this kind of leveling agent only has a slow dyeing effect; the second is the dye affinity leveling agent, which can significantly improve the dye aggregation degree, the affinity of the dye is greater than the affinity of the dye on the fiber. The leveling agent is combined with the dye to produce a stable aggregate, which reduces the dye diffusion rate and delays the dyeing time. As the condition changes, the dye gradually get rid of of the leveling agent, combined with the fiber, but at this time leveling agent on the dye still have a certain affinity, for unevenness of fabric can also be dyed from the fiber down, dye on the light of the place, so this kind of leveling agent not only has a slow dyeing effect, but also has the dye migration.

In addition, according to the type of fiber used, leveling agent can be divided into natural fiber leveling agent, nylon leveling agent, acrylic leveling agent, polyester leveling agent and blended fabric leveling agent.

0 notes

Text

Desizing Enzyme

https://www.htfine-chem.com/list-of-chemicals-used-in-textile-industry/desizing-enzyme.html

Definition of desizing enzyme

Desizing enzymes, is a compound using of microbial fermentation of starch enzymes and other effective substances. Applied in the textile industry, it helps to decompose the starch in the fabric size into short chain dextrin and oligosaccharide, and make it extremely easy to remove in the latter treatment process. Desizing enzymes can be used in cotton, silk, Vinylon, viscose fiber, blended fabric, yarn-dyed poplin and chemical fiber blended fabric.

Desizing process in textile

In the weaving process, the fibers need sizing to increase fastness. In the fabric dyeing, bleaching and printing processes, it’s required to remove the size. Desizing is good or bad, directly affect the quality of finished products, such as hand feeling, whiteness, smoothness, color content and strength. Now mostly using starch paste for sizing, and a lot of methods for desizing, such as caustic soda, sulfuric acid, hydrogen peroxide, etc., but these chemical products not only damage the fabric, trouble operation, but also pollute the environment. Thus using the desizing enzyme in certain conditions, starch pulp can quickly become dextrin, after liquefaction of soluble dextrin washed with washing, so as to achieve the purpose of desizing.

Advantages of desizing enzyme

Desizing enzyme has many advantages, which are adopted by more and more textile factories, especially some advanced fabrics having no other choice but desizing enzyme. In the whole textile market home and aboard, desizing enzyme process accounted for a large proportion. Its characteristics are: high efficiency and high speed, suitable for high temperature desizing, short time, desizing rate of up to 90%- 95%; fabric no damage, soft hand feeling after desizing, full and strong finish, bright color; desizing and color fixing can be treated with the same bath, thus to shorten process flow and improve labor productivity; used for whiteness, it, can improve the capillary effect, and improve the production conditions, save fuel, reduce cost, and can be used for continuous large production.

As a desizing enzyme supplier, we have exported our textile auxiliaries chemicals to overseas market for more than 10 years. With experienced exporting knowledge, quality chemicals, robust technical helps and services, we are able to deliver in 3-5 working days.

At HT, we can supply 2000 tons for a month. CAS No.: 38099100EINECS; No.: 230-993-8. Thanks for your reading. If you are interested to buy desizing enzyme, please feel free to contact us.

0 notes

Text

List of Chemicals Used in Textile Industry

https://www.htfine-chem.com/list-of-chemicals-used-in-textile-industry/

What is wetting agents in textile processing

what is textile sizing chemicals

Wax removing Agent

Textile Softeners - Surfactants Type

Softening Finishing Chemicals in Textiles

Soaping Agent

Soaping Agent for Acid Dyes

Silicone Softeners

At HT Fine Chemicals, we produce all types of textile auxiliaries for fabric printing, dyeing, finishing and washing industry. Here for the purpose of better understanding and communication, in this category, we accumulate all necessary knowledge and experience related and share with you. Before you buy these chemicals, it's good to have a read. Here is a list of chemicals used in textile industry, and the main talked chemicals about textile pretreatment, dyeing, printing, finishing and washing process.

0 notes

Text

HT FINE CHEM

https://www.htfine-chem.com/

TEXTILE AUXILIARIES

HT supplies a variety of fine chemical products including formaldehyde free fixing agent, acid fixing agent, multi-scouring enzyme, sequestering agent (CT powder), heat sublimation fastness improving agent, wet rubbing fastness improver, soaping agent, ice cool silicone softener, terpolymer silicone softener, brightening lubricant, softener, etc.

Pretreatment Auxiliaries

Pretreatment auxiliaries are crucial to the first step in textile processing involving bleaching, scouring,wetting and other pretreatment processes. HT offers a versatile range of pretreatment agents for various fabrics like cotton and polyester: scouring agent, anti-creasing agent, wax removing agent, sequestering powder, defoaming agent, oil removing agent, reduction clearing agent,peroxide stabilizers, anti releasing agent, etc.

Dyeing Auxiliaries

Dyeing auxiliaries are essential to textile dyeing and printing processing. HT produces dyeing agents for complete range of fibers including cotton, polyester, wool, nylon and acrylic. According to different functions, there are leveling and dispersing agent, fixing agent and powder,soaping agent and Enzyme, acid donor, stripping agent,expanding agent, retarding agent, oil removing agent and repairing agent.

Hand Feels Finishing Agent

The most significant function of finishing agents is to improve the fabric surface smoothness in the finishing process. At HT, there are softener, smoothing, silicone emulsion, and silicone oil series textile finishing chemicals for different fabrics chemical needs. With years of exporting experience and the assistance of dedicated fine chemical professionals, HT offers high quality finishing agents with competitive price.

Printing Auxiliaries

HT is specialized in production of all kinds of textile chemical auxiliaries with one-stop service and free samples delivery. Supplying, exporting, wholesaling and trading of printing auxiliaries mainly for Mid East, Southest Asia, Northern and Eastern Europe markets.

0 notes

Link

0 notes

Link

Tips for Using Color Fixing Agent

0 notes

Photo

ghrp 2 10mg

GHRP-2 HPLC Purity Test Report

0 notes

Link

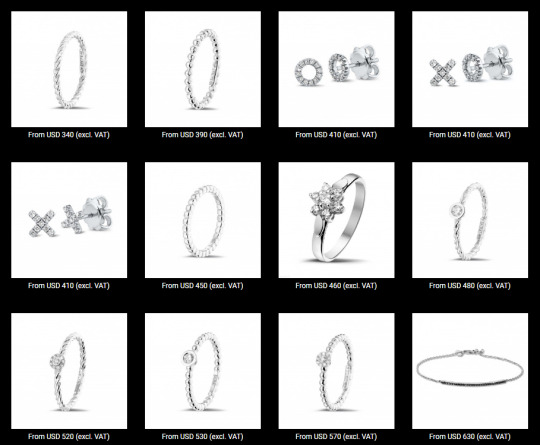

3 carat diamond ring

3 carat diamond ring? All women love it and there are certain classics every woman should have in her jewellery box. Our brand aims to satisfy its customers and that is why the BAUNAT Classics collection was born. It is a line of classic jewellery exclusively created and developed by our team of jewellery creators, also specialised in the creation of tailor-made jewellery.

0 notes

Link

diamond tennis bracelet

In our exclusive collection of high-end diamond bracelets, you will be spoiled for choice between our beautiful butterfly design bracelets, our diamond tennis bracelets, our satellite bracelets and our chain bracelets. All our bracelets are set with high quality diamonds, carefully selected from diamond traders renowned for their know-how. BAUNAT aims to offer diamond bracelets of remarkable quality that you can purchase at excellent prices.

1 note

·

View note

Link

black diamond ring

You wish to purchase a black diamond ring that will do more than simply please the love of your life? A diamond is a true symbol of love and a pledge of your affection, and it makes every woman dream. The ring could be set with a single solitaire or with two or three diamonds. You can also opt for a ring band completely enveloped in beautiful pavé diamonds. On BAUNAT, you can surely find the one ring that will enchant the woman of your heart.

1 note

·

View note