Text

Choosing the Right Technique for Sheet Metal Welding: MIG vs. TIG Welding

Welding is a crucial process in metal fabrication, and when it comes to sheet metal cutting, two popular techniques stand out — MIG (Metal Inert Gas) welding and TIG (Tungsten Inert Gas) welding. Each technique has its strengths and weaknesses, making the choice between them essential for achieving optimal results in sheet metal applications. In this blog, we will delve into the key differences between MIG and TIG welding, explore their suitability for sheet metal cutting, discuss the pros and cons of each method, highlight factors influencing the choice between them, and provide real-life examples of successful sheet metal cutting using both techniques.

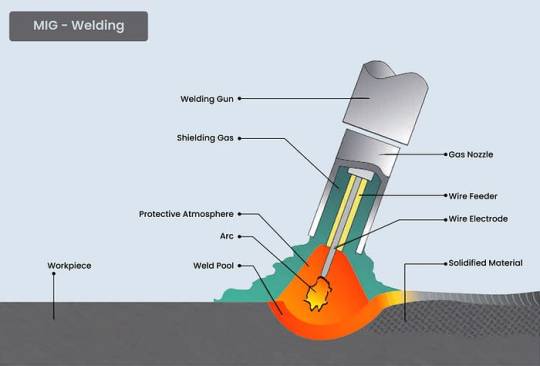

What is MIG welding?

MIG welding involves a continuous wire feed that is fed through a welding gun and melted into the joint. A shielding gas, typically a mixture of argon and carbon dioxide, protects the weld pool from atmospheric contaminants. MIG welding is known for its efficiency and speed, making it a popular choice for various applications

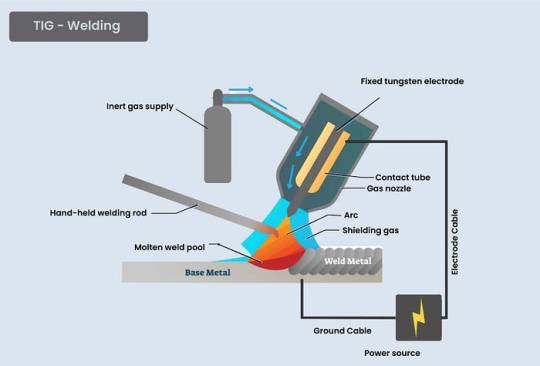

What is TIG welding?

TIG welding is done by using a non-consumable tungsten electrode. The welder manually feeds a filler rod into the weld pool, which is protected by an inert gas, usually argon. TIG welding is recognized for its precision, control, and ability to produce high-quality welds on thin materials.

Which Welding Technique Is More Suitable for Sheet Metal Welding?

The choice between MIG and TIG welding for sheet metal cutting depends on several factors, including the thickness of the metal, the required precision, and the desired finish.

– MIG Welding for Sheet Metal Welding:

MIG welding is well-suited for cutting thin sheet metals due to its high travel speed and efficiency. It is ideal for projects where speed is crucial, such as in mass-production environments. However, MIG welding may not provide the same level of precision as TIG welding, and the heat input can sometimes be a concern for thinner materials.

– TIG Welding for Sheet Metal Welding:

TIG welding is preferred for cutting thinner sheet metals when precision and a clean finish are essential. It offers excellent control over the heat input, reducing the risk of warping or distortion in the metal. TIG welding is commonly used for intricate designs and projects where aesthetics and precision are critical.

What are The Pros and cons of MIG and TIG welding in sheet metal applications?

Pros:

High welding speed, making it suitable for mass production.

Good for thicker sheet metals.

Minimal skill requirement compared to TIG welding.

Cons:

Limited precision, which may not be suitable for intricate designs.

More heat input increases the risk of warping with thin materials.

Pros:

Excellent precision and control, making it ideal for thin sheet metals.

Clean and aesthetically pleasing welds.

Low heat input, reducing the risk of distortion.

Cons:

Slower welding speed compared to MIG welding.

Requires a higher skill level.

What Factors Need to Be Consider When Selecting the Appropriate Welding Method?

Choosing the right welding method for sheet metal cutting involves considering various factors to ensure the desired outcome. Here are some key considerations:

– Material Thickness:

MIG welding is more suitable for thicker sheet metals, while TIG welding excels in precision work on thinner materials.

– Precision Requirements:

If the project demands high precision and intricate detailing, TIG welding is often the preferred choice.

– Speed and Efficiency:

MIG welding is faster and more efficient, making it suitable for projects with tight deadlines and large production volumes.

– Skill Level:

Consider the skill level of the welder, as TIG welding requires more expertise than MIG welding.

– Aesthetics:

If the appearance of the weld is crucial, such as in architectural or decorative applications, TIG welding is often preferred for its cleaner finish.

– Cost Considerations:

Evaluate the cost of equipment, consumables, and labour associated with each welding method to determine the most economical choice for the project.

Read More-https://www.lsw.co.in/choosing-the-right-technique-for-sheet-metal-welding-mig-vs-tig-welding/

#manufacturing#aviation#construction#sheet metal fabrication manufacturers#metalworking#welding services

0 notes

Text

Laser Cutting Innovation: A Close Look at the Future of Metal Sheet Cutting

Innovations in technology plays an important role in shaping the future of various industries. One such ground-breaking advancement that continues to revolutionize metalworking is laser cutting. The precision, speed, and versatility of laser cutting technology have transformed the landscape of metal sheet cutting, paving the way for unprecedented possibilities. In this blog, we will discuss the current state of laser cutting, its applications, and the exciting advancements that promise to shape the future of metal sheet cutting.

Current State of Laser Cutting:

Laser cutting, a process that uses a focused laser beam to cut through materials, has become an essential piece of equipment in the manufacturing industry. When it comes to metal sheet cutting, the precision offered by laser cutting machines is unparalleled. The technology utilizes high-powered lasers to melt, burn, or vaporize material, resulting in clean and precise cuts with minimal heat-affected zones.

Applications of Laser Cutting in Metal Sheet Cutting:

Automotive Industry: Laser cutting has become integral in the automotive sector for fabricating intricate components with high precision. Laser cutting assures precision and uniformity in production for anything from chassis elements to complex interior components.

Medical Equipment Manufacturing: Laser cutting is widely employed in the production of medical devices and equipment. Its ability to create complicated and small components with precision makes it ideal for manufacturing medical tools, implants, and components.

Architectural and Decorative Metalwork: Laser cutting has found its way into architectural design and decorative metalwork. From intricate metal panels to custom signage, the technology allows for the creation of detailed and aesthetically pleasing designs in metal sheets.

Advancements in Laser Cutting Technology:

Faster Cutting Speeds: The pursuit of enhanced productivity and efficiency has resulted in constant progress in laser cutting speeds. Innovations in laser source technology and machine design are facilitating faster cutting speeds without compromising precision.

Multi-Material Cutting: Future laser cutting systems are expected to handle a broader range of materials seamlessly. This includes a more efficient cutting of reflective materials like copper and brass, expanding the application of laser cutting across various industries.

Integration of Artificial Intelligence (AI): The integration of AI in laser cutting machines is on the horizon. AI algorithms can enhance the decision-making process during cutting operations, optimizing parameters for different materials and improving overall efficiency.

Adaptive Optics for Improved Precision: The use of adaptive optics in laser cutting is anticipated to improve precision by dynamically adjusting the laser beams characteristics based on real-time feedback. This technology ensures optimal focus and energy distribution, resulting in enhanced cut quality.

3D Laser Cutting: The future of metal sheet cutting is likely to witness a shift towards 3D laser cutting. This innovation allows for the fabrication of complex three-dimensional components, opening up new possibilities in design and manufacturing.

Read More-https://www.lsw.co.in/laser-cutting-innovation-a-close-look-at-the-future-of-metal-sheet-cutting/

0 notes

Text

Why Laser-Cutting is the Preferred Solution to Accelerate Your New Product Development?

n the dynamic world of product creation, where innovation is crucial to success, manufacturers are constantly looking for cutting edge solutions that will streamline their processes and accelerate the release of products. One such innovation that has changed the game recently is laser cutting. This advanced production technique has shown to be the most effective means of accelerating the development of new products across several industries. We will discuss the causes of laser cutting’s rising popularity as well as how it has revolutionized the field of product development in this blog.

What Sets Laser-Cutting Apart from Conventional Methods?

It’s important to understand how laser-cutting differs from conventional manufacturing techniques before exploring its benefits. A laser beam is used in the non-contact process of laser-cutting to accurately cut or imprint objects. When comparing this technology to traditional techniques like die-cutting or mechanical cutting, it delivers unmatched precision and versatility. Producers that wish to push the limits of product design will find laser-cutting to be an appealing option. It can create intricate shapes and complicated geometries with minimal material loss.

How Does Laser-Cutting Enhance Precision and Accuracy in Manufacturing?

In the process of developing new products, accuracy is crucial, and laser cutting excels at providing it in a way that traditional technologies find challenging. Manufacturers are able to make complicated parts with tight tolerances thanks to the focused laser beam’s ability to attain extremely tiny details. In fields where small, delicate parts are frequently used, like electronics, aircraft, and medical devices, this level of accuracy is very advantageous.

Additionally, laser cutting ensures constant quality throughout the production process by removing the possibility of tool wear associated with mechanical cutting methods. In order to satisfy the demanding standards of contemporary markets, where mediocre quality is not an option, this dependability is essential.

Read More-https://www.lsw.co.in/why-laser-cutting-is-the-preferred-solution-to-accelerate-your-new-product-development/

0 notes

Text

Choosing the Right CNC Machine For Sheet Metal Bending

Sheet metal bending is a crucial process in metal fabrication, playing a vital role in industries ranging from automotive to aerospace. To achieve precision and efficiency in sheet metal bending, manufacturers often turn to CNC (Computer Numerical Control) machines. Selecting the right CNC machine is paramount for ensuring high-quality output and minimizing production costs. In this blog post, we will delve into the key aspects of sheet metal bending and discuss the factors to consider when choosing the most suitable CNC machine for your needs.

Understanding Sheet Metal Bending:

It is necessary to have an in-depth understanding of sheet metal bending before diving into the complexities of CNC machines. This process involves deforming a metal sheet into a desired shape by applying force. The sheet metal is typically placed between a punch and a die, and the force is applied to achieve the desired bend angle.

Various factors influence the sheet metal bending process, including material thickness, bend radius, and the type of material being used. Achieving accurate and repeatable bends is critical, and this is where CNC machines come into play.

Key Factors to Consider For Selecting a CNC Machine:

1. Machine Type:

– Press Brakes: Press brakes are the most common CNC machines used for sheet metal bending. They can be used for a variety of purposes because they are available in different sizes and capacities.

– Turret Punch Presses: While primarily used for punching operations, turret punch presses can also perform bending tasks. They are suitable for high-speed production environments.

2. Material Compatibility:

-Different sheet metals have varying properties, including thickness, hardness, and elasticity. Ensure that the CNC machine you choose is compatible with the materials you frequently work with. Look for a machine that can handle a broad range of materials to enhance versatility in your fabrication projects.

3. Bending Capacity:

– Assess the bending capacity of the CNC machine, considering both the maximum length and thickness it can handle. It’s crucial to select a machine that aligns with the size of the sheets you commonly work with to avoid limitations in your fabrication capabilities.

4. Machine Type:

– There are two main types of CNC machines for sheet metal bending: press brakes and panel benders. Press brakes are versatile and suitable for various bending applications, while panel benders excel in complex, high-precision bending tasks. Choose the type that best aligns with your specific fabrication needs.

5. Accuracy and Precision:

– The primary advantage of CNC machines lies in their ability to deliver consistent and precise results. Look for a machine with advanced control systems and features like back gauge positioning to ensure accurate bends, especially when working on intricate designs or tight tolerances.

Read More-https://www.lsw.co.in/choosing-the-right-cnc-machine-for-sheet-metal-bending/

0 notes

Text

Revolutionizing Metal Fabrication: The Impact of CNC Laser Cutting Services

Adoption of cutting-edge technologies has become a cornerstone for industries striving to meet evolving demands. Among these innovations, Computer Numerical Control (CNC) laser cutting services have emerged as a transformative force, redefining precision, efficiency, and versatility in metalworking. This blog delves into the industry-level advances brought about by CNC laser cutting services, addressing the What, How, and Why aspects of its impact on metal fabrication across diverse sectors.

What Drives the Shift Towards CNC Laser Cutting Services Across Industries?

Demand for Precision Components:

The increasing demand for precision-engineered components spans various industries, from automotive to electronics. Modern product designs require complicated cuts and complex geometries, which are typically difficult to achieve using traditional cutting methods. CNC laser cutting, renowned for its high precision and accuracy, emerges as a pivotal solution, catering to the demand for precisely crafted components in diverse sectors.

Customization Imperatives:

Customisation is not just a necessary but also a preference in the fast-paced industry of today. Industries use specialised components and unique designs to set their products apart from the competition. CNC laser cutting’s unparalleled versatility allows manufacturers to meet these customization needs efficiently. Whether it’s crafting tailored components for automotive applications or specialized parts for industrial machinery, CNC laser cutting accommodates the diverse customization requirements of various sectors.

How Does CNC Laser Cutting Services Elevate Metal Fabrication Processes in Different Industries?

1. Seamless Digital Design Integration:

CNC laser cutting services commence with the integration of digital design into the manufacturing process. Designers input precise specifications into Computer-Aided Design (CAD) software, creating a virtual model of the intended metal component. This digital design seamlessly translates into a CNC program, acting as a precise roadmap for the laser cutting machine to follow.

2. Expertise in CNC Programming:

The heart of CNC laser cutting lies in the complex CNC programming that guides the entire process. Skilled programmers develop a set of instructions that direct the CNC system to operate the laser beam across the metal sheet with precision. This ensures that the actual cut aligns perfectly with the intended design, fostering consistency and maintaining high-quality standards throughout the production process.

3. Versatile Material Compatibility:

CNC laser cutting is not restricted to specific types of metals; it accommodates various materials with equal efficiency. This versatility broadens the spectrum of applications across different industries, reducing the need for specialized equipment for distinct materials. This adaptability streamlines the manufacturing process, making CNC laser cutting an attractive choice for industries dealing with a diverse range of materials.

4. Automation for Operational Efficiency:

The efficiency of CNC laser cutting services is closely tied to its automation capabilities. The process is highly automated, minimizing human intervention and reducing the risk of errors. Quick setup times, rapid cutting speeds, and minimal downtime contribute to a seamless and efficient production workflow. Automation not only accelerates production timelines but also enhances overall operational efficiency.

Read More-https://www.lsw.co.in/revolutionizing-metal-fabrication-the-impact-of-cnc-laser-cutting-services/

0 notes

Text

What are Sheet Metal Finishing Techniques?

Sheet metal finishing involves preparing the surface of the metal before applying a coating. The choice of finishing technique depends on the specific requirements of the application and the desired surface finish. Here are some common sheet metal finishing techniques:

1. Cleaning and Degreasing: Before any finishing can occur, it’s crucial to remove contaminants like dirt, grease, and rust from the surface of the sheet metal. This can be achieved through processes like solvent cleaning, alkaline cleaning, or abrasive cleaning.

2. Surface Preparation: To ensure proper adhesion of coatings, the sheet metal surface may need to be roughened or etched. Techniques like sandblasting, shot blasting, or chemical etching can be used to achieve the desired surface texture.

3. Deburring: Sheet metal often has sharp edges and burrs resulting from the cutting and forming processes. Deburring involves removing these imperfections to enhance safety and appearance.

4. Polishing and Grinding: For applications where a smooth and reflective surface is required, polishing and grinding are employed. This can be done using abrasive materials and specialized equipment.

5. Anodizing: Anodizing is a popular finishing technique for aluminum sheet metal. It involves creating an oxide layer on the surface of the metal, which not only provides corrosion resistance but also allows for color customization.

Read More-https://www.lsw.co.in/sheet-metal-finishing-and-coating-options-enhancing-durability/

0 notes

Text

Factors to Consider When Choosing Sheet Metal

Now that you have a basic understanding of the different sheet metal materials available, let’s explore the factors to consider when selecting the right one for your project:

Application

The first and most critical factor is the intended application of the sheet metal. Consider the environment it will be exposed to, whether it will be indoors or outdoors, and the specific demands of your project. For example, outdoor applications may require corrosion-resistant materials like stainless steel or galvanized steel, while indoor decorative projects might benefit from the aesthetic qualities of brass or copper.

Strength and Durability

Evaluate the strength and durability requirements of your project. Some materials, like steel and titanium, offer exceptional strength and toughness, making them suitable for structural components. Others, like aluminum and copper, may be more suitable for lightweight or decorative purposes.

Corrosion Resistance

If your project will be exposed to moisture or corrosive substances, choosing a material with good corrosion resistance is essential. Stainless steel, aluminum, and certain alloys like Inconel excel in such conditions.

Conductivity

For electrical or thermal conductivity applications, consider materials like copper or aluminum. Copper is an excellent conductor of electricity, while aluminum is often used for its heat-dissipating properties.

Aesthetics

If appearance matters for your project, select a material that complements your design. Brass and copper, with their attractive finishes, are popular choices for decorative elements.

Read More-https://www.lsw.co.in/choosing-the-right-type-of-sheet-metal-for-your-project-materials-overview/

1 note

·

View note

Text

What is the Importance of Sheet Metal Finishing and Coating?

Sheet metal components are often subjected to harsh environments, temperature fluctuations, chemicals, and physical wear and tear. Without proper finishing and coating, these factors can lead to several problems, including:

Corrosion: Sheet metal is particularly vulnerable to corrosion, especially in outdoor or humid environments. Corrosion can weaken the metal, compromise its structural integrity, and reduce its lifespan.

Aesthetic Degradation: In applications where appearance matters, such as automotive and architectural uses, surface imperfections, scratches, and discoloration can diminish the overall look and value of the product.

Wear and Tear: Moving parts or components that endure friction can suffer from premature wear and tear, affecting their functionality and efficiency.

Chemical Resistance: In industries where sheet metal comes into contact with chemicals, it’s essential to protect the metal from chemical reactions that could compromise its properties.

Sheet metal finishing and coating address these issues, providing a protective barrier that extends the life of the components and ensures they perform their intended functions reliably.

Read More-https://www.lsw.co.in/sheet-metal-finishing-and-coating-options-enhancing-durability/

0 notes

Text

Battery electric vs hydrogen — which is the future for electric vehicles?

The debate between battery electric vehicles (BEVs) and hydrogen fuel cell vehicles (FCVs) as the future of electric vehicles is complex and involves various factors. Both technologies have their advantages and challenges, and their potential roles in the future of transportation may vary depending on specific use cases and advancements in technology. Here's a brief overview of the key considerations:

Battery Electric Vehicles (BEVs):

Advantages:

Maturing Technology: BEVs have seen significant advancements in battery technology, leading to increased energy density, longer ranges, and faster charging times.

Infrastructure: Charging infrastructure for BEVs is more developed globally, with an extensive network of charging stations in many regions.

Market Adoption: BEVs have gained widespread consumer acceptance, and major automakers are heavily investing in electric vehicle (EV) development.

Challenges:

Range Anxiety: Despite improvements, some BEVs still face range limitations compared to traditional internal combustion vehicles, which can be a concern for consumers.

Charging Time: Although charging times have improved, they are still longer than refueling times for conventional vehicles.

Resource Intensity: The production and disposal of large batteries involve environmental concerns, including mining for raw materials.

Hydrogen Fuel Cell Vehicles (FCVs):

Advantages:

Quick Refueling: Hydrogen fueling is faster than charging a battery, offering a more conventional refueling experience.

Extended Range: FCVs generally have longer ranges compared to many BEVs.

Zero Emissions: The only byproduct of hydrogen fuel cells is water vapor, making FCVs environmentally friendly.

Challenges:

Infrastructure: Hydrogen refueling infrastructure is less developed globally, limiting the widespread adoption of FCVs.

Energy Efficiency: Hydrogen production, especially through electrolysis, can be energy-intensive and may rely on fossil fuels.

Cost: FCVs and hydrogen production technologies are currently more expensive than many BEVs.

Future Outlook:

The future of electric vehicles may involve a combination of both technologies, as each has strengths that can be suitable for different applications. BEVs are likely to continue dominating the consumer market and urban environments, where charging infrastructure is more accessible. FCVs, on the other hand, might find niche applications in specific industries, such as heavy-duty transport or regions where hydrogen infrastructure becomes more prevalent.

Ultimately, ongoing advancements in technology, improvements in infrastructure, and changes in market demands will shape the trajectory of both battery electric and hydrogen fuel cell vehicles in the future of transportation.

READ MORE-https://www.lsw.co.in/battery-electric-vs-hydrogen-which-is-the-future-for-electric-vehicles/

0 notes

Text

Applications of Laser Cutting in Various Industries

Laser cutting technology has found widespread applications across various industries due to its precision, versatility, and efficiency. Here are some notable applications of laser cutting in different sectors:

Manufacturing and metal fabrication:

1.Sheet metal cutting:Laser cutting is extensively used for the precise and rapid cutting of sheet metal in the manufacturing of components for various industries.

Automotive Industry:

1.Automotive Parts Production: Laser cutting is employed to manufacture components like chassis parts, brackets, and intricate automotive body parts with high precision.

2.Trimming and Welding: Laser cutting is used for trimming formed parts and welding various automotive components.

Aerospace and Aviation:

1.Precision Components: Laser cutting is crucial for producing precision components in the aerospace industry, where lightweight materials and intricate designs are common.

2.Turbine Blade Manufacturing: Laser cutting is employed in the production of turbine blades, ensuring high accuracy and quality.

Electronics and Electrical Industry:

1.PCB Manufacturing: Laser cutting is utilized for precise cutting of printed circuit boards (PCBs), allowing for intricate designs and miniaturization.

2.Electrical Enclosures: Laser cutting is employed in the production of electrical enclosures and panels with precise openings for switches and connectors.

Medical Device Manufacturing:

1.Implant Manufacturing: Laser cutting is used to produce precise components for medical implants and devices.

2.Medical Instrument Production: Instruments with intricate shapes and patterns are manufactured using laser-cutting technology.

Architectural and construction:

1.Architectural Models: Laser cutting aids in the creation of detailed architectural models and prototypes.

2.Metal Artwork: Artists and architects use laser cutting for intricate metal artwork and decorative elements in construction.

Textile Industry:

1.Fabric Cutting: Laser cutting is employed in the textile industry for precision cutting of fabrics, leather, and other materials in garment production.

2.Embroidery and Appliqué: Laser cutting is used for creating intricate designs in embroidery and appliqué work.

Packaging Industry:

1.Custom Packaging: Laser cutting is applied in the production of custom-designed packaging with precise cuts and perforations.

2.Die Board Manufacturing: Laser cutting is utilized in the creation of die boards for efficient and precise die-cutting in packaging.

Educational and Research Institutions:

1.Prototyping: Laser cutting is a valuable tool in educational institutions for prototyping and experimentation in various fields, including engineering and design.

These applications showcase the versatility of laser cutting technology, making it an indispensable tool across a broad spectrum of industries and contributing to increased efficiency, accuracy, and innovation.

READ MORE-https://www.lsw.co.in/applications-of-laser-cutting-in-various-industries/

0 notes

Text

Precision Metal Forming Services for Sheet & Roll Forming- LSW

In the intricate world of metal fabrication, precision and efficiency are paramount. Lasercut Steelworks stands at the forefront of this industry, offering a comprehensive suite of metal forming services that caters to diverse needs. Specializing in sheet metal forming and metal roll forming services, Lasercut Steelworks has earned a reputation for excellence and innovation.

Sheet metal forming is a crucial process in metal fabrication, transforming flat sheets of metal into complex shapes and structures. This method is employed in various industries, from automotive to aerospace, where precision and durability are non-negotiable. Lasercut Steelworks leverages cutting-edge technology and a team of skilled professionals to provide top-notch sheet metal forming services.

One of the key advantages of sheet metal forming is its ability to create intricate designs and geometric shapes with a high degree of accuracy. Lasercut Steelworks utilizes advanced machinery and computer-aided design (CAD) software to ensure that every project meets the exact specifications of its clients. Whether it's prototyping a new product or mass-producing components, the sheet metal forming services at Lasercut Steelworks are tailored to deliver precision and consistency.

Metal roll forming is another expertise that sets Lasercut Steelworks apart. This process involves continuously bending and shaping a metal coil to create a desired cross-section. The result is a product with uniform dimensions and excellent structural integrity. Metal roll forming is widely used in the construction and manufacturing industries, and Lasercut Steelworks excels at providing custom solutions to meet the unique requirements of each project.

The efficiency of metal roll-forming services lies in their ability to produce large quantities of components with minimal material waste. Lasercut Steelworks optimizes this process to offer cost-effective solutions without compromising on quality. Whether it's producing roof panels, automotive components, or structural elements, the metal roll-forming services at Lasercut Steelworks contribute to the seamless realization of diverse projects.

The commitment to quality extends beyond the manufacturing floor at Lasercut Steelworks. Rigorous quality control measures are integrated into every step of the metal-forming process to ensure that the final products meet or exceed industry standards. This dedication to excellence has earned Lasercut Steelworks the trust of clients across various sectors.

In addition to its technological prowess, Lasercut Steelworks places a strong emphasis on customer collaboration. The team works closely with clients to understand their unique requirements, providing valuable insights and recommendations to enhance the efficiency and cost-effectiveness of each project. This collaborative approach, combined with the expertise in sheet metal forming and metal roll forming, positions Lasercut Steelworks as a reliable partner for businesses seeking top-tier metal fabrication solutions.

In conclusion, Lasercut Steelworks stands as a beacon of innovation in the realm of metal forming services. With a focus on sheet metal forming and metal roll forming, the company blends cutting-edge technology with a commitment to precision and quality. As industries continue to evolve, Lasercut Steelworks remains at the forefront, ready to shape the future of metal fabrication through its unparalleled expertise and customer-centric approach.

METAL SHEEET FORMING

0 notes

Text

Steel Sheet Metal Fabrication India | Customize Metal Specialties | LSW

In the realm of metal fabrication, precision is paramount, and Sheet Metal Specialties stand as pioneers in the field. Renowned for their expertise in Steel Sheet Metal Fabrication, this company has carved a niche for itself by delivering top-notch solutions to industries demanding uncompromised quality and customization.

Steel Sheet Metal Fabrication involves the process of transforming flat sheets of steel into intricate and functional components. One of the standout technologies in this domain is laser cutting, a method that Sheet Metal Specialties has mastered to perfection. Laser-cut steelworks offer unparalleled precision, enabling the creation of intricate designs and complex shapes with remarkable accuracy.

Customization lies at the heart of Sheet Metal Specialties' ethos. As Customize Metal Fabricators, they understand that each project is unique, demanding tailor-made solutions. Whether it's a bespoke design for architectural elements or precision components for industrial machinery, their team of skilled craftsmen ensures that every piece meets the exact specifications of the client.

Sheet Metal Specialties has emerged as a leading Steel Metal Manufacturer in India, setting industry standards with their commitment to quality and innovation. Their state-of-the-art facilities house advanced machinery, including cutting-edge laser cutting technology, which allows them to deliver precision and efficiency in every project.

Laser-cut steelworks provide a plethora of advantages. The process results in clean, burr-free edges, reducing the need for additional finishing processes. This not only enhances the aesthetics of the final product but also contributes to cost savings and quicker turnaround times. The accuracy of laser cutting minimizes material wastage, making it an environmentally friendly option.

One of the key advantages of partnering with Sheet Metal Specialties is their ability to handle diverse projects. From small-scale intricate components to large-scale structural elements, their expertise covers a wide spectrum. The company's prowess in Steel Sheet Metal Fabrication extends to various industries, including automotive, aerospace, construction, and more.

The Customize Metal Fabricators at Sheet Metal Specialties take pride in their collaborative approach. They work closely with clients from concept to completion, ensuring that the end result not only meets but exceeds expectations. This dedication to customer satisfaction has earned them a reputation as a trusted partner for businesses seeking reliable and customized metal fabrication solutions.

In conclusion, Sheet Metal Specialties has positioned itself as a frontrunner in the world of Steel Sheet Metal Fabrication, standing out as Customize Metal Fabricators who prioritize precision and customization. As a prominent Steel Metal Manufacturer in India, their laser-cut steelworks exemplify a perfect blend of artistry and technology, setting new benchmarks in the field of metal fabrication.

0 notes

Text

CNC Laser Cutting Service in India | Metal Sheet Production | LSW

In the realm of metal fabrication, precision is paramount, and Lasercut Steelworks stands as a beacon of excellence in the field. As a leading provider of CNC laser cutting services in India, this company has revolutionized metal sheet production, setting new standards for quality and efficiency.

CNC (Computer Numerical Control) laser cutting is a cutting-edge technology that has transformed the landscape of metal cutting services. Lasercut Steelworks has harnessed the power of this technology to offer unparalleled precision in metal sheet manufacturing. The process involves the use of a high-powered laser to cut through metal sheets with incredible accuracy, allowing for intricate designs and complex shapes that were once challenging to achieve.

One of the key advantages of Lasercut Steelworks is its commitment to delivering top-notch laser cutting services in India. The company employs state-of-the-art CNC machines equipped with advanced laser technology, ensuring that each cut is executed with meticulous detail. This commitment to quality has positioned Lasercut Steelworks as a preferred choice for industries demanding precision in metal fabrication.

Metal cutting services have seen a significant evolution, and Lasercut Steelworks has been at the forefront of this transformation. The use of CNC laser cutting not only enhances accuracy but also increases efficiency by reducing production time. This is particularly crucial for industries where deadlines are tight, and the demand for high-quality metal components is constant.

The versatility of Lasercut Steelworks is evident in its ability to handle a wide range of materials and thicknesses. Whether it's stainless steel, aluminum, or mild steel, the company's CNC laser cutting services cater to diverse needs. This adaptability makes them a reliable partner for industries spanning automotive, aerospace, architecture, and beyond.

As a metal sheet manufacturer, Lasercut Steelworks understands the importance of staying ahead in a competitive market. The company invests in continuous research and development to stay abreast of the latest advancements in CNC laser cutting technology. This dedication to innovation ensures that clients receive cutting-edge solutions that meet the evolving demands of their respective industries.

The precision offered by Lasercut Steelworks extends beyond the cutting process. The company also excels in providing customized solutions tailored to the unique requirements of each client. Whether it's a specific design, dimension, or material preference, Lasercut Steelworks collaborates closely with clients to deliver metal sheet production that align seamlessly with their vision.

In conclusion, Lasercut Steelworks has emerged as a trailblazer in the world of CNC laser cutting service in India. Their commitment to precision, efficiency, and innovation has elevated the standards of metal cutting services, making them a go-to choice for industries seeking excellence in metal sheet production. As the demand for high-quality, intricately designed metal components continues to rise, Lasercut Steelworks stands ready to meet and exceed the expectations of its clients, reaffirming its position as a leader in the field of lasercut steelworks.

0 notes

Text

Battery electric vs hydrogen — which is the future for electric vehicles?

Battery electric vehicles (BEVs) rely on rechargeable batteries for power, offering established infrastructure and growing range. Hydrogen fuel cell vehicles (FCVs) use hydrogen to produce electricity, with potential for quick refueling. The future balance depends on technological advancements, infrastructure development, cost-efficiency, and sustainability considerations. BEVs currently dominate the market, but FCVs may find a niche in specific applications, like heavy-duty transport. Future trends will be influenced by advancements in both technologies and sustainable energy solutions.

https://www.lsw.co.in/hello-world/

0 notes

Text

Laser Cutting: Precision at Your Fingertips – Everything You Need to Know

🔥 Laser Cutting: Precision Unleashed at Your Fingertips! ✨ Your Guide to Laser-Powered Excellence! 🚀

Step into the future of precision craftsmanship with Laser Cutting—a symphony of light and technology, meticulously crafted to redefine what's possible! 🎯

Discover the art and science behind this cutting-edge marvel as we unveil the secrets that make lasers dance with unparalleled accuracy and finesse. 🌟 From intricate designs to industrial might, we've got all the insights you crave!

Get ready to unlock a realm where every cut is a masterpiece, every shape a revelation! 💎 Dive into the world of laser precision and make your creations gleam with unmatched brilliance. 💡

Join us for a journey through the pulsating heart of Laser Cutting—where imagination meets innovation, and your projects transform into impeccable works of art. 🎨 Stay tuned for a laser-powered revolution—ready to dazzle, inspire, and elevate your craftsmanship to unparalleled heights! 🚀✂️

0 notes

Text

Applications of Laser Cutting in Various Industries

Laser cutting finds versatile applications across industries. In manufacturing, it's vital for precise cutting of metal components for automobiles, aerospace, and machinery. In the electronics industry, it's used for intricate circuit board manufacturing. Architectural firms use it for detailed model creation. Healthcare utilizes laser cutting for intricate medical device manufacturing. Textile industry employs it for precise fabric cutting. Art and signage industries use it for intricate designs. Moreover, laser cutting is crucial in crafting jewelry and customized products. Its precision, speed, and versatility make it a fundamental technology in modern production and design processes across a multitude of sectors.

#Lasercutting#sheet metal fabrication manufacturers#sheet metal manufacturing companies#electric vehicle charger manufacturers

0 notes

Text

Sheet Metal Finishing and Coating Options: Enhancing Durability

Elevate your metal projects to new heights with our expert Sheet Metal Finishing and Coating options, tailored to enhance durability and aesthetic appeal. Unveil a seamless fusion of craftsmanship and innovation as we meticulously apply cutting-edge finishing techniques to your sheet metal creations. Our skilled artisans meticulously craft each piece, ensuring precision and finesse in every detail.

Experience a world of possibilities as we offer a diverse array of coating options, each designed to fortify against corrosion, wear, and environmental factors. Choose from an enticing palette of finishes, from sleek metallic coatings to vibrant colors that resonate with your vision. Our coatings not only protect your metal components but also bring out their true luster, leaving a lasting impression.

Trust us to deliver excellence in both form and function, elevating the durability of your sheet metal projects to withstand the test of time. Immerse yourself in a realm of superior quality and aesthetics, where every finished piece tells a story of durability, beauty, and unmatched craftsmanship.

0 notes