#welding services

Text

youtube

#lasermachine#laser welding machine#welding services#laser welding#metal laser welding#welding#Youtube

2 notes

·

View notes

Text

How do potholes form?

Is there anything worse than driving down a road riddled with potholes? Not just these potholes are an annoyance but they can also be quite dangerous. These potholes are dreading and plaguing drivers ever since the construction of the first paved road.

While these potholes seem harmless at the first look, they can cause substantial damage to your vehicle. As these potholes pose potential hazards, we are sure you want to know the causes, the ways to minimize them and something about pothole repairs in Sydney.

How these potholes are formed?

Essentially, a pothole is a dip or deviation in a paved road’s smooth surface. They are formed when groundwater seeps underneath the pavement. As the water freezes underneath, it expands, the pavements swells, and starts cracking. As the ice melts, the gaps become present underneath the paved surface and as a result, the pavement weakens.

To make the matters worse, every time a car drives over this weakened surface, the pavement continues to break. After some time, the pieces of the roadway become dislodged and displaced completely. And so, you officially have a pothole now.

These potholes should be repaired on time. While we know all the civil work in Sydney is taken care of by the civil authorities, the civilians can also take voluntary roles in at least taking care of the roads. To get pothole repairs in Sydney at affordable costs, reach out to us. We will be glad to assist you.

6 notes

·

View notes

Text

Mobile Welding Services in New Jersey: High-Quality Welding On-Site with Ry’s Heavy Duty LLC

When your diesel vehicle breaks down, you need a reliable solution to get back on the road quickly. That's where Ry's Heavy Duty LLC's mobile welding services come in. With our team of experienced welders and state-of-the-art equipment, we bring high-quality welding directly to your location. You don't have to waste time and resources transporting your vehicle to a repair shop. Instead, our mobile welding services provide convenience, efficiency, and flexibility to address your unique welding needs.

Key Takeaways:

Convenience and Efficiency: Ry's Heavy Duty LLC's mobile welding services bring high-quality welding directly to your location, reducing downtime and allowing you to get back to work faster.

Comprehensive Services: The company offers a range of mobile welding services, including structural repairs, custom fabrication, and emergency repairs, to address various welding needs in different settings.

Expertise and Quality Guarantee: Ry's Heavy Duty LLC's experienced welders and high-quality equipment ensure that all repairs meet safety and performance standards, backed by success stories and customer testimonials.

The Benefits of Mobile Welding Services

To take advantage of the best possible welding experience, you need a service that can meet your unique needs and provide high-quality results. Mobile welding services offer a range of benefits that can revolutionize the way you approach welding projects.

Convenience and Time-Saving

Conveniently, mobile welding services bring the welding shop to your doorstep, saving you time and effort. You don't have to worry about transporting your vehicle or equipment to a welding shop, which means you can focus on other important tasks while our experts handle the welding.

Cost-Effective Solutions

To minimize downtime and reduce costs, mobile welding services provide on-site repairs that eliminate the need for expensive towing or transportation fees. By bringing the welding shop to you, we help you save money and get back to work faster.

A significant advantage of mobile welding services is the reduction in labor costs. With our experts coming to your location, you don't have to pay for additional labor costs associated with transporting your vehicle or equipment to a welding shop. This means you can allocate your resources more efficiently and focus on growing your business.

Ry's Heavy Duty LLC: Your Trusted Partner

The team at Ry's Heavy Duty LLC understands the importance of having a reliable partner for your mobile welding needs. With years of experience and a commitment to quality, we provide high-quality welding services that cater to your specific requirements.

Expertise in Brake Services and Field Service Repairs

For diesel vehicle owners, brake services and field service repairs are crucial to ensure optimal performance and safety. Our team of experts has the knowledge and skills to provide top-notch brake services and field service repairs, giving you peace of mind on the road.

Specialized Hydraulic Repair and Fuel System Services

Services like hydraulic repair and fuel system maintenance require specialized expertise. At Ry's Heavy Duty LLC, our team is trained to handle these complex tasks with precision and care, ensuring your vehicle operates at peak performance.

Hydraulic systems, in particular, require a deep understanding of their intricacies. Our technicians take the time to diagnose and repair hydraulic issues, ensuring that your vehicle's hydraulic system is functioning correctly. From hydraulic pump repairs to hose replacements, we've got you covered.

On-Site Welding Solutions

Many industries rely on heavy-duty equipment and vehicles to operate efficiently, but when welding issues arise, it can bring your entire operation to a halt. With Ry's Heavy Duty LLC's mobile welding services, you can get back to work quickly and confidently, knowing that our expert welders will provide high-quality repairs on-site.

Electrical System Repair and Maintenance

Fabricating repairs for electrical systems requires precision and attention to detail. Our skilled welders will assess your electrical system, identify the issue, and perform the necessary repairs to get your equipment up and running smoothly.

Customized Mobile Welding Services

Solutions tailored to your specific needs are what set us apart. Whether you require custom fabrication or unique repairs, our mobile welding services are designed to adapt to your situation, providing a personalized solution that meets your exact requirements.

Another advantage of our customized mobile welding services is that we can work with you to develop a preventative maintenance plan, reducing the likelihood of future breakdowns and saving you time and money in the long run. By understanding your specific needs and goals, we can provide a comprehensive welding solution that addresses your unique challenges.

The Importance of Quality and Safety

Unlike other mobile welding services, Ry's Heavy Duty LLC prioritizes quality and safety above all else. You can't afford to compromise on the integrity of your diesel vehicle's repairs, and we understand that. That's why we're committed to delivering top-notch welding services that meet the highest standards of quality and safety.

High-Quality Welding Equipment and Materials

Significance of using the right tools and materials cannot be overstated. At Ry's Heavy Duty LLC, we invest in the latest welding equipment and source premium materials to ensure that every repair meets your expectations and withstands the test of time.

Trained and Certified Technicians

Mastery of welding techniques is crucial to producing high-quality repairs. Our technicians are not only trained but also certified to handle complex welding projects, giving you peace of mind that your diesel vehicle is in good hands.

Plus, our technicians undergo rigorous training to stay updated on the latest welding techniques and industry standards. This means you can trust that your repairs will be done efficiently and effectively, minimizing downtime and getting you back on the road quickly.

Industries We Serve

Once again, Ry's Heavy Duty LLC proves its versatility by catering to a diverse range of industries that rely on heavy-duty equipment and vehicles. You can trust our mobile welding services to meet the unique needs of your business, ensuring minimal downtime and maximum productivity.

Construction and Heavy Equipment

Industrial sectors like construction and heavy equipment rely heavily on machinery that requires regular maintenance and repairs. Our mobile welding services ensure that your equipment is back in operation quickly, minimizing delays and losses.

Transportation and Fleet Management

The transportation industry, including fleet management companies, depends on the smooth operation of their vehicles. Our mobile welding services provide timely and efficient repairs, keeping your vehicles on the road and your business moving forward.

To ensure the longevity and performance of your vehicles, our mobile welding services focus on providing high-quality repairs that meet the highest safety and performance standards. Whether you need routine maintenance or emergency repairs, our team of experienced welders is equipped to handle any welding task, from simple fixes to complex custom fabrications.

Why Choose Ry's Heavy Duty LLC?

For reliable and efficient mobile welding services in New Jersey, you can trust Ry's Heavy Duty LLC to deliver high-quality results. Our team of experienced welders and state-of-the-art equipment ensure that your welding needs are met with precision and care.

Quick Response Times and Emergency Services

Duty calls, and we answer. At Ry's Heavy Duty LLC, we understand the urgency of emergency repairs. That's why we offer quick response times to get you back on the road or back to work as soon as possible.

Competitive Pricing and Flexible Scheduling

Flexible solutions for your unique needs. We pride ourselves on offering competitive pricing and flexible scheduling to accommodate your busy schedule. Whether you need a routine repair or an emergency fix, we'll work with you to find a solution that fits your budget and timeline.

For instance, our flexible scheduling allows us to work around your operating hours, minimizing downtime and ensuring that your business or personal activities are not disrupted. We also offer customized pricing packages to suit your specific needs, so you can rest assured that you're getting the best value for your money.

Summing up

The convenience, efficiency, and flexibility of mobile welding services can make all the difference for your diesel vehicle's repair needs. With Ry's Heavy Duty LLC, you get high-quality welding on-site, reducing downtime and getting you back to work faster. From structural repairs to custom fabrication and emergency fixes, our experienced welders and advanced techniques ensure top-notch results. Now, it's your turn to experience the benefits - contact us today for expert mobile welding solutions tailored to your specific needs.

FAQ

Q: What is the importance of having reliable mobile welding services for diesel vehicles?

A: Having reliable mobile welding services is crucial for diesel vehicles as it ensures that any welding repairs can be done quickly and efficiently, reducing downtime and getting you back on the road faster. This is especially important for commercial vehicles, construction equipment, and emergency response vehicles that require minimal interruption to their operations. With mobile welding services, you can avoid the hassle of transporting your vehicle to a welding shop, saving time and money.

Q: What types of mobile welding services does Ry's Heavy Duty LLC offer?

A: Ry's Heavy Duty LLC offers a range of mobile welding services, including structural repairs, custom fabrication, and emergency repairs. Our experienced welders can fix frames and structural components, tailor welding solutions to specific needs, and provide quick fixes to get you back on the road. Whether you need routine maintenance or urgent repairs, we've got you covered.

Q: What is the process of mobile welding with Ry's Heavy Duty LLC?

A: Our mobile welding process begins with an initial consultation where our expert welders assess the welding needs on-site. We then execute high-quality welds using advanced techniques and equipment. Finally, we perform a quality check to ensure the repair meets safety and performance standards. Our goal is to provide efficient and effective welding solutions that meet your specific needs.

Q: Why should I choose Ry's Heavy Duty LLC for mobile welding services?

A: You should choose Ry's Heavy Duty LLC for mobile welding services because of our experienced welders, high-quality equipment, and proven track record of success. We have a team of skilled professionals who can handle complex welding projects, and our state-of-the-art equipment ensures that every repair meets the highest standards. Don't just take our word for it – check out our customer testimonials and success stories!

Q: How do I get started with mobile welding services from Ry's Heavy Duty LLC?

A: Getting started with mobile welding services from Ry's Heavy Duty LLC is easy! Simply contact us to schedule an appointment, and we'll send our expert welders to your location. We'll work with you to assess your welding needs and provide a customized solution that meets your specific requirements. Don't wait – contact us today to experience the convenience, efficiency, and flexibility of our mobile welding services!

0 notes

Text

What is steel fabrication machines do?

Let's dive in! Steel fabrication machines are essential tools used to shape and assemble steel materials into various structures and products. From cutting and bending to welding and finishing, these machines streamline the fabrication process, making it efficient and precise. Whether you're crafting intricate designs or industrial components, steel fabrication machines are the backbone of the manufacturing industry. Explore the world of steel fabrication and unleash your creativity!

#steel fabrication#steel fabricators near me#custom sheet metal fabrication#welding machine#welding services

0 notes

Text

Best Welding Machine in India: Unveiling Excellence in Welding Technology

In the dynamic landscape of welding technology, finding the best welding machine in India is crucial for ensuring precision, efficiency, and durability in your welding projects. At Great Yuva, we take pride in offering state-of-the-art welding machines that redefine industry standards. Let's delve into the world of welding excellence and discover why our machines stand out.

Unmatched Performance

Cutting-Edge Features

Our welding machines boast cutting-edge features designed to elevate your welding experience. From advanced arc control to precise voltage regulation, our machines ensure optimal performance in various welding applications. The fusion of innovation and engineering excellence sets our products apart from the competition.

Superior Weld Quality

Achieving impeccable welds is a hallmark of our machines. With advanced technology and precision crafting, our welding machines deliver superior weld quality, meeting the demands of professionals and hobbyists alike. The robust build ensures stability, resulting in welds that stand the test of time.

User-Friendly Design

Intuitive Controls Navigating through welding parameters is made seamless with our user-friendly interfaces. Even for those new to welding, our machines provide an intuitive experience, minimizing the learning curve. This ensures that users can focus on their craft without being hindered by complicated controls.

Ergonomic Build

Comfort is paramount in long welding sessions. Our machines feature an ergonomic design, minimizing fatigue and promoting prolonged productivity. Whether you're a seasoned professional or an enthusiastic DIYer, our welding machines cater to your comfort needs.

Durability and Reliability

Robust Construction Investing in a welding machine is an investment in the longevity of your projects. Our machines are built with durability in mind, featuring robust construction that withstands the rigors of diverse welding environments. This durability ensures consistent performance over the years.

Reliable Power Source

Power fluctuations can disrupt welding processes and compromise results. Our machines come equipped with a reliable power source, offering stability in voltage supply. This ensures uninterrupted welding sessions, allowing you to focus on achieving flawless results.

Industry-Leading Technology

Innovation at its Core At Great Yuva, we embrace innovation as the driving force behind our products. Our welding machines incorporate industry-leading technology, staying ahead of the curve to meet evolving demands. From smart welding solutions to eco-friendly features, our commitment to technological advancement sets us apart.

The Great Yuva Advantage

Customer-Centric Approach Beyond providing the best welding machine in India, we take pride in our customer-centric approach. Our dedicated support team is ready to assist you at every step, ensuring a seamless experience from purchase to post-sale support. Your satisfaction is our priority.

In the realm of welding machines, Great Yuva stands as a beacon of excellence, offering the best in technology, performance, and customer satisfaction. Elevate your welding projects with our top-notch machines, setting new standards in precision and reliability.

1 note

·

View note

Text

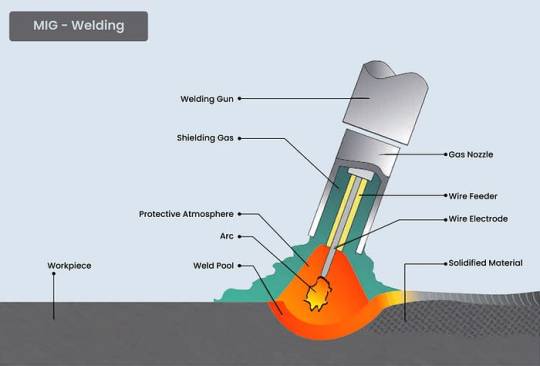

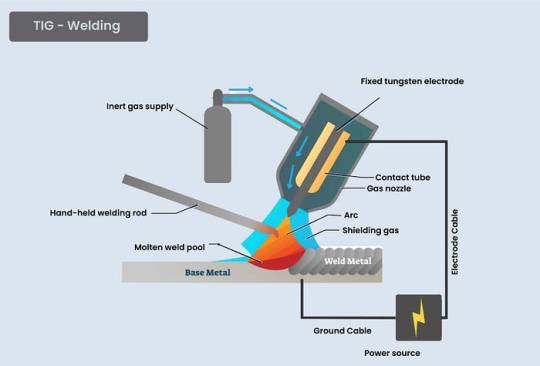

Choosing the Right Technique for Sheet Metal Welding: MIG vs. TIG Welding

Welding is a crucial process in metal fabrication, and when it comes to sheet metal cutting, two popular techniques stand out — MIG (Metal Inert Gas) welding and TIG (Tungsten Inert Gas) welding. Each technique has its strengths and weaknesses, making the choice between them essential for achieving optimal results in sheet metal applications. In this blog, we will delve into the key differences between MIG and TIG welding, explore their suitability for sheet metal cutting, discuss the pros and cons of each method, highlight factors influencing the choice between them, and provide real-life examples of successful sheet metal cutting using both techniques.

What is MIG welding?

MIG welding involves a continuous wire feed that is fed through a welding gun and melted into the joint. A shielding gas, typically a mixture of argon and carbon dioxide, protects the weld pool from atmospheric contaminants. MIG welding is known for its efficiency and speed, making it a popular choice for various applications

What is TIG welding?

TIG welding is done by using a non-consumable tungsten electrode. The welder manually feeds a filler rod into the weld pool, which is protected by an inert gas, usually argon. TIG welding is recognized for its precision, control, and ability to produce high-quality welds on thin materials.

Which Welding Technique Is More Suitable for Sheet Metal Welding?

The choice between MIG and TIG welding for sheet metal cutting depends on several factors, including the thickness of the metal, the required precision, and the desired finish.

– MIG Welding for Sheet Metal Welding:

MIG welding is well-suited for cutting thin sheet metals due to its high travel speed and efficiency. It is ideal for projects where speed is crucial, such as in mass-production environments. However, MIG welding may not provide the same level of precision as TIG welding, and the heat input can sometimes be a concern for thinner materials.

– TIG Welding for Sheet Metal Welding:

TIG welding is preferred for cutting thinner sheet metals when precision and a clean finish are essential. It offers excellent control over the heat input, reducing the risk of warping or distortion in the metal. TIG welding is commonly used for intricate designs and projects where aesthetics and precision are critical.

What are The Pros and cons of MIG and TIG welding in sheet metal applications?

Pros:

High welding speed, making it suitable for mass production.

Good for thicker sheet metals.

Minimal skill requirement compared to TIG welding.

Cons:

Limited precision, which may not be suitable for intricate designs.

More heat input increases the risk of warping with thin materials.

Pros:

Excellent precision and control, making it ideal for thin sheet metals.

Clean and aesthetically pleasing welds.

Low heat input, reducing the risk of distortion.

Cons:

Slower welding speed compared to MIG welding.

Requires a higher skill level.

What Factors Need to Be Consider When Selecting the Appropriate Welding Method?

Choosing the right welding method for sheet metal cutting involves considering various factors to ensure the desired outcome. Here are some key considerations:

– Material Thickness:

MIG welding is more suitable for thicker sheet metals, while TIG welding excels in precision work on thinner materials.

– Precision Requirements:

If the project demands high precision and intricate detailing, TIG welding is often the preferred choice.

– Speed and Efficiency:

MIG welding is faster and more efficient, making it suitable for projects with tight deadlines and large production volumes.

– Skill Level:

Consider the skill level of the welder, as TIG welding requires more expertise than MIG welding.

– Aesthetics:

If the appearance of the weld is crucial, such as in architectural or decorative applications, TIG welding is often preferred for its cleaner finish.

– Cost Considerations:

Evaluate the cost of equipment, consumables, and labour associated with each welding method to determine the most economical choice for the project.

Read More-https://www.lsw.co.in/choosing-the-right-technique-for-sheet-metal-welding-mig-vs-tig-welding/

#manufacturing#aviation#construction#sheet metal fabrication manufacturers#metalworking#welding services

0 notes

Text

Welding Services - Embracing Eco-Friendly Practices

Explore how welding services are evolving with sustainable practices to reduce environmental impact and embrace a greener future.

0 notes

Text

Are you looking for a reliable and efficient solution to protect yourself and your workers from welding fumes? If so, you should check out Translas’s welding fume extractor, Translas is a leading manufacturer of welding torches and welding equipment with integrated extraction. Translas offers welding fumes extractors that capture and remove welding fumes at the source, reducing the risk of health problems and improving the quality of your work. Translas products are famous for their ergonomics, durability, beautiful design, performance and high quality. Whether you need portable, stationary, central or custom engineered solutions, Translas has the right option for you.

1 note

·

View note

Text

The Right Way to Weld Aluminium

Aluminium welding can be exciting, especially for first-time hobbyists. However, safe aluminium welding is better for a number of reasons. Not only will abiding by best practices reduce the chances of accidents, but it can also improve the results you get.

Learning how to weld aluminium properly and safely can be done in a few ways. The first is through experience. The second is through getting the right information. The third is combining both.

Experienced welders understand best practices, safety precautions, and crucial information. Doing so allows them to finish any welding project in a timely manner without compromising the quality of the results.

To that end, here is what you need to know to weld aluminium the right way.

Background Details On Aluminium Welding

Welding aluminium is not all fun and games. It presents incredible potential from both a hobby and commercial standpoint. However, no one should go into it without having a basic level of understanding.

After all, you are dealing with a high-voltage machine that bonds materials together using high heat.

The first thing to note is the sheer ubiquity of aluminium welding. It’s done in every corner of the globe for a virtually endless number of reasons. From car manufacturers to aeronautic engineers, the practice is everywhere.

Aluminium welding also comes in many different forms in terms of machinery, techniques, and scope. Someone building a framework for their vehicle will likely be using similar methods as those welding buildings together.

From there, we come to the point of issues that can crop up when welding aluminium. Inexperience will certainly play a role in this. However, not having some relevant information can be even more damaging.

Aside from best practices that are worth sticking with, some of the worst mistakes that occur when welding stem from ignorance. This often leads to a lack of preparation, which can affect your safety and the quality of the results.

Best Practices and Key Information

There are some key details regarding aluminium welding that you simply must know. The same goes for certain practices that every expert welder adheres to. For the former, let’s take a look at the following:

Oxidation - Coats the surface of the aluminium immediately after it has been exposed to open air.

Porousness - Bubbles can form during the welding process and compromise the structural integrity of the project.

Thickness - Thicker or thinner aluminium objects vary in density, weight, and size.

Impurities - Grime, dirt, oil, grease, and others that can interfere with the welding process.

Thermal conductivity - Aluminium can disperse heat quite easily.

Hot cracking - Too much heat in one spot can lead to cracks.

Having all of those details in your head before you start welding can be the difference between failure and success. Too many who go into this practice for the first time don’t really think about such things.

They get a welding machine, and some metals, and start making sparks fly. Then they seem surprised that their dirty aluminium sheet didn’t bond properly with the rusty aluminium pole.

Preparations are always worth doing, especially with tasks as delicate as welding. It needs precision and control, along with knowledge and patience. While experience will eventually allow you to gain all of this as you keep welding, a good start would still be preferable.

Now that the key details have been covered, it’s time to move on to the best practices for aluminium welding:

Protective clothes like overalls, gloves, and boots are critical equipment for any welder. Wear them and keep wearing them until you’re done welding.

The smallest flaws can lead to catastrophic results when welding. Paying attention to the smallest details is needed.

No welding project can be rushed. You can only get faster with time. The actual process itself will still involve patience.

Exposing your materials and equipment to the elements via poor storage is highly ill-advised. Keep them clean and dry.

Conclusion

Those are everything you need to know about welding safely. For the most part, as long as you do your homework ahead of time, you should be fine. You just really need to prepare ahead of time by learning what to watch out for and what you should be doing for the best results.

Need high quality fully custom aluminium products and services? Contact us at Custom Aluminium.

0 notes

Text

Are you looking for quality custom welding services in Welland?

Precision Custom welding has an experienced team of welders, fabricators, and a machinist in-house. We assist our customers with design, material selection, and every day repairs. Call us at 905-687-7431.

0 notes

Text

Unveiling the Expertise of Khalsa Welding Toronto

Visit Us:- https://khalsaweldingtoronto.ca/

0 notes

Photo

Top Class Welding Services in London with 45 Years' Expertise!

Our team of friendly and knowledgeable experts are committed to providing you with the highest quality of welding or fabrication for your project. Explore our extensive catalogue of services to find out what best suits your needs. Our prices are affordable, our turnaround time is rapid, and we accept bookings and emergency walk-in requests. We are a family-run welding and fabrication services company that has operated in the London area for over 45 years.

#Welding Services#Metal Fabrications Company#welding workshop#fabrication workshop#welding repairs#custom fabrication#CNC laser cutting

1 note

·

View note

Link

#Metal Fabrication#welding services#maaching services#metal fabricators#metal fabrication services#steel fabrication#welding

0 notes

Text

Sheet metal fabrication

#design#autos#business#prototype#prototyping#rapid prototyping#prototype machining#sheet metal services tauranga#sheet metal manufacturing#sheet metal fabrication#sheet metal work contractor financing#sheet metal design#metal machining#sheet metal bending#sheet metal stamping#sheet metal welding#sheet metal

2 notes

·

View notes

Text

Welding Services and the Environment: Sustainable Practices in Welding

Welding, a critical process in various industries, often goes unnoticed in discussions about environmental sustainability. However, with the growing concern for our planet, it's imperative to examine how welding services can adapt and contribute to a greener future. This blog delves into the environmental impacts of welding and explores sustainable practices that can be integrated into welding services. You can visit us at JGW Machine for more information.

The Environmental Footprint of Welding Services

Welding services, essential in manufacturing, construction, and repair, have environmental implications mainly due to energy consumption, emissions, and waste generation. Traditional welding methods consume significant amounts of electricity or gas, contributing to greenhouse gas emissions. Moreover, the process often involves materials and solvents that can be harmful if not managed properly.

Advancing Towards Sustainability in Welding

The good news is that the welding industry is evolving, with new technologies and methods emerging to reduce its environmental impact. Let's explore some of these sustainable practices:

1. Energy-Efficient Welding Technologies

Innovations in welding technology focus on reducing energy consumption. For instance, advanced welding machines are designed to be more energy-efficient, minimizing electricity usage without compromising on performance. These advancements not only reduce carbon footprints but also lower operational costs for welding services.

2. Utilizing Renewable Energy Sources

Integrating renewable energy sources like solar or wind power in welding operations can significantly reduce reliance on non-renewable energy. This shift not only contributes to environmental sustainability but also makes welding services more self-reliant and less vulnerable to fluctuations in energy prices.

3. Eco-Friendly Welding Materials

The choice of materials used in welding services plays a crucial role in environmental impact. Opting for materials with a lower carbon footprint, such as recycled or sustainable metals, and using eco-friendly welding wires and gases can make a considerable difference.

4. Reducing Harmful Emissions

Welding can release harmful fumes and gases. Using advanced welding techniques that produce fewer emissions is crucial. For instance, processes like submerged arc welding (SAW) and gas metal arc welding (GMAW) are known for lower fume generation compared to traditional methods.

5. Waste Management and Recycling

Effective waste management is crucial in welding services. This includes recycling scrap metal, properly disposing of hazardous materials, and adopting practices that reduce waste generation. Welding services can also invest in equipment that captures and recycles metal filings and dust.

6. Sustainable Work Practices

Sustainable work practices involve training welders in eco-friendly techniques, optimizing welding processes to minimize waste, and implementing energy-saving measures in workshops. Simple actions like turning off equipment when not in use can have a significant impact over time.

7. Green Certifications and Standards

Adhering to green certifications and standards can guide welding services in adopting sustainable practices. Certifications like ISO 14001, which focuses on effective environmental management systems, can be a roadmap for welding services to become more eco-conscious.

8. Collaboration and Awareness

Creating a sustainable welding environment requires collaboration among various stakeholders, including welding equipment manufacturers, service providers, clients, and regulatory bodies. Raising awareness about the importance of sustainable practices in welding is equally important.

9. Continuous Innovation

The journey towards sustainability is ongoing. Welding services need to stay abreast of technological advancements and continuously innovate to find greener solutions.

The Benefits of Sustainable Welding Practices

Embracing sustainable practices in welding services is not just beneficial for the environment but also for the business. It can lead to cost savings, improved efficiency, and a better company image. Additionally, it prepares welding services for stricter environmental regulations in the future and opens up opportunities in markets that value sustainability.

Conclusion

The transition to sustainable practices in welding services is a critical step towards a greener and more responsible industry. By adopting energy-efficient technologies, utilizing eco-friendly materials, and implementing sustainable work practices, welding services can significantly reduce their environmental impact. This commitment to sustainability is not only a duty to our planet but also an opportunity for innovation and growth in the welding industry.

Through these efforts, welding services can demonstrate that industrial processes and environmental responsibility can go hand in hand, paving the way for a more sustainable future.

Read more:

JGW Machine: The Bright Revolution in LED

0 notes