Don't wanna be here? Send us removal request.

Text

Hand-Hold vs. Stationary Laser Welding Machines: Which is Right for You?

Hey there! If you’re thinking about getting a laser welding machine, you might be scratching your head over whether to pick a hand-hold laser welding machine or a stationary one. Both are awesome tools that use lasers to join metal, but they’re built for different needs. With keywords like laser welding machine price, fibre laser welding machine, and portable laser welding machine, this easy blog will help you decide which one fits your life. Let’s break it down!

What Are These Machines?

A laser welding machine uses a super-focused light to melt and stick metal together. A hand-hold laser welding machine is light and easy to carry—like a magic wand you can take anywhere. A stationary one, though, is a big, fixed unit that stays in one spot, perfect for heavy-duty work. Both can use fibre laser technology to make strong, clean welds.

Hand-Hold Laser Welding Machine: The Go-Get-It Type

Why It’s Cool

Easy to Carry: The portable laser welding machine lets you fix things on-site, like at a construction spot or a customer’s place.

Great for Small Jobs: Perfect for quick repairs or tiny metal pieces, like jewelry or car parts.

Flexible Fun: You can move it around, so it’s ideal if you don’t have a big workshop.

Downsides

Less Power: It might not handle super-thick metal as well as a stationary machine.

Laser welding machine price Can Add Up: Portable ones can cost more for the mobility perk.

Best For

If you’re a freelancer, do on-site fixes, or work in tight spaces, this is your buddy!

Stationary Laser Welding Machine: The Heavyweight Champ

Why It’s Awesome

Big Power: A metal laser welding machine that stays put can weld thick, tough metals for big projects.

Steady Work: It’s perfect for a shop where you do lots of welding in one place.

Long-Lasting: Built to handle heavy use, it’s a rock-solid investment.

Downsides

No Moving Around: You can’t take it to a job site—it’s stuck where it’s set up.

Needs Space: It takes up more room, so a small garage might feel crowded.

Best For

If you run a busy workshop or make big metal stuff, this is your go-to!

Comparing the Two

Feature Hand-Hold Stationary Mobility Yes, super portable No, fixed in place Power Good for light to medium Great for heavy-duty Space Needed Little Lots Laser Welding Machine Price Varies, often higher for portability Can be pricier for power Best Use On-site, small tasks Shop, big projects

Which One Should You Pick?

Love Freedom? Go for a hand-hold laser welding machine if you need to move around or start small. The portable laser welding machine vibe is perfect for newbies or mobile workers.

Need Strength? Choose a stationary one if you’re in a fixed spot and weld big or thick metal often. It’s like the anchor of your workshop!

Budget Check: Look at the laser welding machine price—portable ones might cost more upfront, but stationary ones could save cash if you use them a lot.

youtube

Things to Think About

Both need a bit of learning to use right, and the laser welding machine price depends on what you get. Make sure you have space or power for the one you pick. A little planning goes a long way!

The Future Looks Good

As tech grows, both types might get smarter or cheaper. The fibre laser welding machine options could get even better, helping everyone weld like a pro!

Meet SLTL Group: Your Welding Expert

Behind these great machines is SLTL Group, a top company from India. They’ve been crafting laser welding machines for over 30 years, making both hand-hold laser welding machine and stationary models. SLTL Group focuses on quality and supports customers, so you can trust them to find your perfect fit. Check them out!

Wrap-Up

Deciding between a hand-hold or stationary laser welding machine depends on your needs—mobility or power. With the right choice and help from SLTL Group, you’ll be welding like a champ! What do you think—hand-hold or stationary? Tell us in the comments!

1 note

·

View note

Text

The Rise of Fibre Laser Welding Machines in Modern Manufacturing

In the pulsating heart of modern manufacturing, the fibre laser welding machine is emerging as a transformative force, revolutionizing how industries craft and assemble metal components. This cutting-edge technology is redefining precision, speed, and efficiency, making it a cornerstone for factories worldwide. As industries evolve, keywords like laser welding machine price, metal laser welding machine, and 3 in 1 laser welding machine are buzzing, reflecting the growing demand for advanced welding solutions. This blog explores the ascent of fibre laser welding machines and why they’re shaping the future of production.

The Evolution of Fibre Laser Welding Technology

The fibre laser welding machine harnesses the power of fibre optics to deliver a concentrated laser beam, melting metals with unparalleled accuracy. Unlike traditional methods like MIG or TIG welding, this technology uses a solid-state laser, amplified through fibre cables, to produce a focused energy source. This leap forward offers superior control, reduced heat distortion, and faster processing, making it a game-changer for intricate and high-volume manufacturing tasks.

Its journey from niche applications to mainstream adoption mirrors the industry’s shift toward automation and precision, positioning it as a vital tool in today’s competitive landscape.

Why Fibre Laser Welding Machines Are Taking Over

1. Unmatched Precision

The fibre laser welding machine excels at creating pinpoint welds, ideal for delicate components in aerospace, electronics, and medical device manufacturing. Its minimal heat-affected zone (HAZ) preserves material integrity, ensuring flawless results even on thin or complex metals.

2. Lightning-Fast Efficiency

Speed is king in modern production, and these machines deliver. The metal laser welding machine variant processes welds at remarkable rates, boosting throughput and reducing downtime. This efficiency is a lifeline for industries racing to meet tight deadlines.

3. Energy-Saving Innovation

Compared to conventional welding, fibre laser welding machines consume less power, aligning with sustainable manufacturing goals. Their eco-friendly design minimizes waste and operational costs, appealing to green-conscious businesses.

4. Versatility Across Materials

From stainless steel to aluminum, the fibre laser welding machine adapts to diverse metals with ease. This flexibility supports a wide range of applications, from automotive parts to heavy machinery, enhancing its appeal across sectors.

5. Integration with Automation

As factories embrace smart technology, these machines seamlessly integrate with robotic systems. This synergy optimizes workflows, reduces human error, and elevates production quality, marking a new era of industrial excellence.

Applications in Modern Manufacturing

Automotive Industry: The fibre laser welding machine crafts durable welds for car bodies and engine components, enhancing vehicle safety and performance.

Aerospace Sector: Precision welds on lightweight alloys meet stringent aviation standards, ensuring reliability at high altitudes.

Electronics Manufacturing: Tiny, accurate welds on circuit boards and devices support the growing tech revolution.

Heavy Machinery: Robust welds on construction equipment withstand extreme conditions, extending machinery lifespan.

Navigating Laser Welding Machine Prices

The laser welding machine price varies based on power, features, and brand, with fibre laser welding machines often reflecting their advanced capabilities. While initial costs may be higher than traditional welders, the long-term savings in energy, maintenance, and labor offset the investment. For businesses eyeing scalability, this technology proves a cost-effective choice.

Challenges and Solutions

Despite its rise, challenges like high upfront costs and the need for skilled operators exist. However, training programs and modular designs are bridging these gaps. Manufacturers are also offering competitive laser welding machine prices to make this technology accessible, ensuring widespread adoption.

The Future of Fibre Laser Welding

The trajectory of fibre laser welding machines points upward, with innovations like enhanced power outputs and AI-driven controls on the horizon. These advancements will further streamline manufacturing, making the technology indispensable for future factories.

Meet SLTL Group: Leaders in Laser Welding Innovation

Driving this revolution is SLTL Group, a globally recognized manufacturer based in India. With decades of expertise, SLTL Group crafts state-of-the-art laser welding machines, including top-tier fibre laser welding machines and 3 in 1 laser welding machines. Their commitment to quality, innovation, and customer support has made them a trusted partner for industries worldwide. Explore SLTL’s range to elevate your manufacturing game.

Conclusion

The fibre laser welding machine is reshaping modern manufacturing with its precision, speed, and versatility. As industries adapt to new demands, this technology stands as a beacon of progress, supported by competitive laser welding machine prices. With pioneers like SLTL Group leading the charge, the future of fabrication looks brighter than ever. Embrace this innovation to stay ahead in the manufacturing race!

0 notes

Text

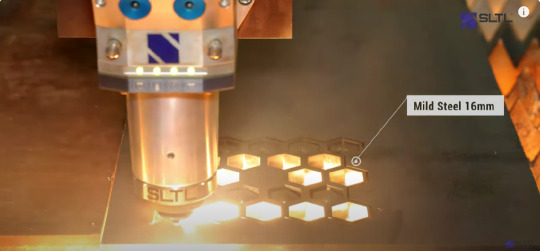

Choosing the Best Laser Cutting Machine Supplier: A Guide to India's Leading Manufacturers

In the rapidly evolving manufacturing industry, laser cutting machines have become essential for precision, efficiency, and cost-effectiveness. Finding a reliable laser cutting machine supplier is crucial for businesses seeking high-quality machinery tailored to their specific needs. India has emerged as a hub for laser cutting machine manufacturers, with Gujarat and Ahmedabad leading the way in innovation and technology. If you're searching for the best laser cutting machine manufacturer, this guide will help you navigate the options and make an informed decision.

Why Choose a Laser Cutting Machine?

Laser cutting machines offer superior accuracy, speed, and flexibility compared to traditional cutting methods. Industries such as automotive, aerospace, metal fabrication, signage, electronics, and even medical equipment rely on laser technology to achieve intricate designs, reduce material waste, and enhance productivity. The right laser cutting machine supplier provides advanced technology, durable machines, and exceptional after-sales support.

Advantages of Laser Cutting Machines

High Precision: Laser cutting machines provide detailed and accurate cuts, ensuring minimal errors.

Speed & Efficiency: Faster cutting speeds compared to conventional methods, reducing production time.

Versatility: Compatible with various materials like metals, plastics, glass, and ceramics.

Low Maintenance: Fiber laser cutting machines require minimal maintenance and have a longer lifespan.

Cost-Effectiveness: Reduces material waste and lowers operational costs.

Top Laser Cutting Machine Manufacturers in India

India is home to some of the world's most innovative laser cutting machine manufacturers. Among them, SLTL Group stands out as a pioneer in laser solutions, offering state-of-the-art machines that cater to various industrial applications. The company is known for its precision engineering, robust technology, and commitment to customer satisfaction.

1. SLTL Group: Leading the Laser Cutting Industry

As the best laser cutting machine manufacturer, SLTL Group has revolutionized the industry with its high-quality laser solutions. Based in Gujarat, Ahmedabad, SLTL Group has established itself as India’s best laser cutting machine supplier, offering innovative solutions for metal cutting, welding, marking, and more.

Key Features of SLTL Laser Cutting Machines:

High Precision Cutting: Advanced fiber laser technology ensures accurate and clean cuts.

Energy Efficiency: Low power consumption with maximum output.

Versatile Applications: Suitable for various materials like stainless steel, aluminum, brass, and more.

Customization Options: Tailor-made solutions for different industries.

Superior After-Sales Support: Dedicated customer service and maintenance assistance.

Smart Automation: Many SLTL laser cutting machines integrate with automated production lines.

User-Friendly Interface: Easy-to-use software that enhances productivity.

Enhanced Safety Measures: Built-in safety features for secure operation.

2. Why SLTL Group is the Best Laser Cutting Machine Manufacturer in Gujarat

Gujarat is known for its industrial growth, and Ahmedabad, in particular, has become a center for laser cutting machine manufacturers. SLTL Group’s research-driven approach and commitment to innovation have placed it at the forefront of the industry.

What Sets SLTL Apart?

Made-in-India Excellence: A homegrown company delivering global standards.

Innovative Technology: Continuous R&D for cutting-edge solutions.

Trusted by Industries: Preferred by top manufacturing companies across India and beyond.

Comprehensive Training: Customer education programs for optimal machine usage.

End-to-End Solutions: From consultation to installation and after-sales support.

Global Reach: Exporting laser cutting machines to international markets.

Other Leading Laser Cutting Machine Manufacturers in India

Apart from SLTL Group, India has a growing number of laser cutting machine manufacturers providing quality solutions:

TRUMPF India – A global leader in industrial laser technology, known for its high-performance laser cutting machines and automation solutions.

Bodor Laser – Offers advanced fiber laser cutting machines with a strong focus on innovation, precision, and user-friendly design.

HSG Laser – Specializes in high-speed fiber laser cutting solutions for various industrial applications, with a growing presence in the Indian market.

Messer Cutting Systems – Provides a wide range of cutting technologies including laser, plasma, and oxyfuel systems, catering to diverse industrial needs.

How to Choose the Right Laser Cutting Machine Supplier

Selecting the right laser cutting machine manufacturer is essential for long-term efficiency and cost savings. Here are some factors to consider:

1. Technology & Innovation

Look for suppliers that offer the latest fiber laser cutting machines, which provide high-speed and precision cutting.

2. Experience & Reputation

A well-established laser cutting machine manufacturer in India with a strong reputation ensures reliability and expertise.

3. After-Sales Service

Ensure the supplier provides excellent customer support, including training, maintenance, and spare parts availability.

4. Customization & Scalability

Choose a supplier that offers customizable solutions to meet your specific business needs.

5. Cost vs. Quality

While pricing is a key factor, prioritizing quality ensures a longer-lasting investment with reduced operational costs.

Applications of Laser Cutting Machines

Laser cutting technology is used in various industries, including:

Automotive: Manufacturing precise components and sheet metal parts.

Aerospace: Cutting high-strength materials with extreme precision.

Medical Equipment: Creating intricate surgical instruments and implants.

Signage & Advertising: Crafting custom signs, letters, and engravings.

Jewelry Making: Intricate designs on metals and other materials.

Textile Industry: Cutting complex patterns in fabric without fraying.

Future of Laser Cutting in India

India’s manufacturing sector is growing at an unprecedented rate, and laser cutting technology is playing a crucial role. With the rise of Industry 4.0, automation, AI integration, and advanced software-driven cutting solutions, the future of laser cutting in India looks promising.

Emerging Trends in Laser Cutting Technology:

AI-Powered Cutting Machines: Smart systems optimizing cutting paths for efficiency.

Integration with IoT: Real-time monitoring and remote operation of laser machines.

Eco-Friendly Solutions: Development of energy-efficient and sustainable laser cutting systems.

3D Laser Cutting: Expanding capabilities beyond 2D sheet cutting.

Conclusion

Finding the right laser cutting machine supplier is crucial for achieving superior productivity and efficiency. With companies like SLTL Group, businesses can access world-class laser solutions backed by cutting-edge technology and excellent support. As India's best laser cutting machine supplier, SLTL continues to lead the industry, providing unmatched quality and innovation.

If you’re looking for the best laser cutting machine manufacturer in Gujarat, Ahmedabad, or across India, SLTL Group is your go-to partner. Their commitment to technology, precision, and customer satisfaction makes them the preferred choice for businesses nationwide.

Explore their range of laser cutting machines today and take your manufacturing processes to the next level!

For more details, visit SLTL Group.

0 notes

Text

Laser Cutting Machine for Small Businesses: A Smart Investment

Introduction

In today’s competitive market, small businesses need efficient, cost-effective, and high-quality manufacturing solutions to stay ahead. Laser cutting machines have revolutionized production across various industries by offering precision, versatility, and speed. Whether you run a small workshop, a signage business, or a custom fabrication unit, investing in a laser cutting machine can significantly boost your operational efficiency.

In this blog, we will explore why a laser cutting machine for small businesses is a valuable investment, the types available, their benefits, and key factors to consider before purchasing one.

Why Small Businesses Need a Laser Cutting Machine

1. Cost-Effective Production

Small businesses often operate on tight budgets. Laser cutters reduce material waste, minimize manual labor costs, and increase efficiency, making them a cost-effective option for production. Traditional manufacturing methods, such as manual cutting or CNC machining, often result in higher waste levels and require extensive labor. Laser cutting, on the other hand, optimizes material usage, ensuring minimal waste and maximum productivity.

Additionally, automation reduces the need for excessive labor, allowing small businesses to allocate resources elsewhere. The long-term savings in production costs make laser cutting machines an excellent investment for startups and growing enterprises.

2. Precision and Accuracy

Unlike traditional cutting methods, laser cutting technology ensures high precision with intricate designs, making it ideal for businesses involved in custom fabrication, signage, jewelry making, and prototyping. The laser beam follows digital design files with microscopic accuracy, eliminating errors and inconsistencies that often occur with manual or mechanical cutting methods.

For businesses that require intricate designs, such as decorative metal works, jewelry, or high-detail signage, laser cutting machines provide a level of precision that is unmatched. This precision helps small businesses maintain high-quality production standards and meet customer expectations efficiently.

3. Versatility Across Industries

Laser cutting machines cater to various industries, including:

Metal fabrication – Cutting and engraving metal components with high accuracy.

Signage and advertising – Creating detailed signage with crisp finishes.

Jewelry and fashion – Precision cutting of intricate designs.

Woodworking – Engraving and cutting on wood for decorative purposes.

Automotive – Producing precise automotive components.

Aerospace – Manufacturing lightweight, high-precision parts.

Medical Equipment – Fabricating tools and components with high accuracy.

The ability to cater to diverse industries makes laser cutting machines an indispensable tool for small businesses looking to expand their operations.

4. Time Efficiency

Small businesses can significantly reduce production time with laser cutting, improving turnaround times and meeting customer demands faster. Traditional cutting methods require multiple steps, such as manual layout, cutting, grinding, and finishing, which consume valuable time. Laser cutting, in contrast, completes these steps in a single automated process.

Faster turnaround times allow businesses to take on more projects, improving overall productivity and profitability. Whether producing bulk orders or custom, one-off pieces, laser cutting ensures that businesses meet deadlines efficiently.

Types of Laser Cutting Machines for Small Businesses

1. CO2 Laser Cutting Machine

Best for non-metal materials like acrylic, wood, plastic, leather, and fabric.

Used in crafts, signage, and packaging industries.

Ideal for engraving and decorative applications.

2. Fiber Laser Cutting Machine

Ideal for cutting metals like stainless steel, aluminum, and brass.

Commonly used in metal fabrication, automotive, and medical equipment manufacturing.

Offers faster cutting speeds compared to CO2 lasers.

3. Diode and Nd:YAG Laser Cutting Machines

Suitable for marking and engraving purposes.

Best for small-scale engraving businesses like jewelry and branding.

Provides precision for delicate materials.

Each type of laser cutter has specific applications, and choosing the right one depends on your business needs.

Key Benefits of a Laser Cutting Machine for Small Businesses

1. High Precision and Quality

Laser cutting ensures fine detailing and sharp edges without requiring additional finishing. The precision of laser cutting enables small businesses to produce high-quality products that stand out in the market.

2. Low Maintenance Costs

Unlike traditional cutting tools, laser cutters have fewer moving parts, reducing wear and tear and lowering maintenance costs. The longevity of laser cutting machines makes them an economically viable option.

3. Flexibility in Design

Whether you need intricate engravings or customized cuts, laser machines can handle diverse design requirements without the need for multiple tools.

4. Scalability for Business Growth

As your business expands, laser cutting machines can accommodate higher production volumes, making them a long-term investment.

5. Eco-Friendly Manufacturing

Laser cutting minimizes material waste and energy consumption compared to traditional cutting methods, making it an environmentally friendly choice for sustainable businesses.

Factors to Consider When Choosing a Laser Cutting Machine

1. Material Compatibility

Identify the types of materials you plan to cut. CO2 lasers are better for non-metals, while fiber lasers are ideal for metals.

2. Power and Speed

Higher wattage lasers offer faster cutting speeds and the ability to cut thicker materials. Choose a machine with the right power level for your requirements.

3. Software Compatibility

Look for a machine that supports CAD/CAM software for easy design import and seamless operation.

4. Budget and ROI

Consider the initial investment, operating costs, and potential return on investment before making a purchase.

5. Brand and After-Sales Support

Purchasing from a reputable brand like SLTL Group ensures reliable performance, warranty, and excellent customer support.

Why Choose SLTL Group for Your Laser Cutting Machine?

1. Industry-Leading Technology

SLTL Group offers cutting-edge laser cutting solutions designed for small businesses, ensuring high precision and efficiency.

2. Wide Range of Laser Machines

From CO2 lasers for engraving to fiber laser cutters for metal processing, SLTL Group provides solutions tailored to various industries.

3. Customization Options

SLTL Group provides custom-built laser machines to meet specific business needs, making them an ideal choice for startups and small enterprises.

4. Excellent After-Sales Support

With technical support, training, and maintenance services, SLTL Group ensures smooth operations for its customers.

Explore SLTL Group’s laser cutting machines here: SLTL Group Official Website

Conclusion

A laser cutting machine for small businesses is a game-changer, offering precision, efficiency, and cost-effectiveness. Whether you are in metal fabrication, signage, jewelry, or woodworking, investing in the right laser cutter can enhance productivity and profitability.

For top-notch laser cutting solutions, explore SLTL Group and take your small business to the next level!

0 notes

Text

CNC Laser Cutting Machine for Metal Fabricators: Precision, Efficiency, and Cost-Effectiveness

Precision, efficiency, and cost-effectiveness are critical factors for success in the metal fabrication industry. With the increasing demand for high-quality metal components across various sectors, businesses are turning to CNC laser cutting machines to meet these requirements. These advanced machines provide superior cutting accuracy, faster processing times, and minimal material wastage, making them an indispensable tool for modern metal fabricators.

Why Metal Fabricators Need CNC Laser Cutting Machines

Metal fabricators deal with a variety of materials, including stainless steel, aluminum, carbon steel, and copper. Traditional cutting methods, such as plasma cutting and water jet cutting, often fail to provide the precision and efficiency required for intricate designs. Here’s why CNC laser cutting machines are the preferred choice:

Unmatched Precision: CNC laser cutters use high-powered laser beams to make extremely accurate cuts, even on intricate patterns.

Speed and Efficiency: These machines can process metal sheets at high speeds, significantly reducing production time.

Versatility: CNC laser cutting is suitable for a variety of metals, including thin and thick sheets.

Minimal Wastage: With their precise cutting capabilities, laser cutters help reduce material wastage, leading to cost savings.

Automation and Ease of Use: The CNC (Computer Numerical Control) feature enables automation, reducing the dependency on manual labor.

Key Features of a CNC Laser Cutting Machine for Metal Fabrication

1. High Cutting Precision and Quality

The laser beam in a CNC laser cutting machine ensures fine, burr-free cuts with minimal heat-affected zones (HAZ), maintaining the integrity of the metal.

2. Fast Cutting Speed

Compared to traditional cutting methods, laser cutters work at significantly higher speeds, leading to increased productivity and faster turnaround times.

3. Flexibility in Design

Laser cutting enables the fabrication of complex shapes and intricate patterns, catering to the needs of industries such as aerospace, automotive, and architecture.

4. Reduced Material Waste

With precise cutting paths, CNC laser machines maximize material utilization, reducing overall production costs.

5. Low Maintenance and Operating Costs

Unlike mechanical cutting tools that require frequent blade replacements, laser cutters have lower maintenance costs due to their non-contact cutting mechanism.

Applications of CNC Laser Cutting in Metal Fabrication

1. Sheet Metal Cutting

Metal fabricators use CNC laser cutters for cutting sheets of varying thicknesses to create components for machinery, automobiles, and appliances.

2. Custom Metal Parts Production

Industries such as aerospace and defense rely on CNC laser cutting for custom-designed metal parts with high precision.

3. Structural Fabrication

Construction and infrastructure projects require accurately cut metal structures, which CNC laser cutting machines can efficiently produce.

4. Decorative Metal Cutting

For architectural designs, interior decorations, and artistic metalwork, CNC laser cutting ensures intricate and aesthetically pleasing cuts.

Choosing the Right CNC Laser Cutting Machine for Your Business

When investing in a CNC laser cutting machine, metal fabricators must consider several factors:

Power and Cutting Capacity: Depending on the type and thickness of the metal, fabricators should choose machines with appropriate laser power.

Automation Features: Look for models with advanced automation features to reduce labor costs and increase efficiency.

Software Compatibility: Ensure the machine is compatible with CAD/CAM software for seamless operation.

After-Sales Support: Reliable after-sales service and technical support are crucial for long-term machine performance.

SLTL Group: The Best CNC Laser Cutting Solutions for Metal Fabricators

As a leader in laser technology, SLTL Group offers a wide range of CNC laser cutting machines tailored for metal fabricators. Our machines are designed to deliver high-speed cutting, superior precision, and maximum efficiency, making them the ideal choice for industries worldwide.

Why Choose SLTL Group?

Cutting-Edge Technology: Our laser cutting machines are equipped with advanced fiber laser technology for optimal performance.

Customization Options: We offer customized solutions based on industry requirements and production needs.

Global Presence and Support: With a strong global presence, we provide excellent after-sales service and technical support.

Sustainable and Cost-Effective Solutions: Our machines are designed to be energy-efficient, reducing operational costs and environmental impact.

Conclusion

For metal fabricators looking to enhance their productivity and cutting precision, investing in a CNC laser cutting machine is a game-changer. With SLTL Group's advanced laser cutting solutions, businesses can achieve high-quality metal fabrication while optimizing costs and improving efficiency. Explore our range of CNC laser cutting machines and take your metal fabrication business to the next level.

Get in Touch with SLTL Group

Interested in upgrading your metal fabrication process with a CNC laser cutting machine? **Visit **SLTL Group today and explore our cutting-edge solutions tailored for your industry!

0 notes

Text

Laser Cutting Machine Price in Pune, Mumbai, Delhi & Chennai – A Complete Cost Guide

Laser cutting machines are transforming industries by offering precision, efficiency, and versatility. If you are in Pune, Mumbai, Delhi, or Chennai and wondering about the cost of a laser cutting machine, you've come to the right place! Let’s explore the pricing, factors affecting costs, and the best options available for your business.

Understanding the Cost of Laser Cutting Machines

When it comes to buying a laser cutting machine, the price varies based on multiple factors. The type of machine, power capacity, automation level, and additional features all influence the final cost.

Note: Click here to learn more.

What is the Cost of a Laser Cutting Machine in Pune?

Pune, a hub of manufacturing and industrial activities, offers a wide range of laser cutting machines. The price for an entry-level fiber laser cutting machine starts at ₹5 lakhs ($6,000) and can go up to ₹50 lakhs ($60,000) or more for high-power industrial models. If you're looking for an affordable laser cutting machine, you can find budget-friendly options in the local market.

What is the Cost of a Laser Cutting Machine in Mumbai?

Mumbai, being a commercial powerhouse, has several laser machine suppliers offering different models. The cost of a CNC laser cutter in Mumbai typically ranges from ₹7 lakhs ($8,500) for a basic model to ₹1 crore ($120,000) for an advanced system with automation and high precision.

What is the Cost of a Laser Cutting Machine in Delhi?

Delhi, known for its growing manufacturing sector, has many suppliers offering competitive pricing. The price of a fiber laser cutting machine in Delhi depends on the machine specifications, brand, and features. A mid-range industrial laser cutter costs around ₹15 lakhs ($18,000), while high-power models with automation can exceed ₹80 lakhs ($95,000).

What is the Cost of a Laser Cutting Machine in Chennai?

Chennai, a major industrial city, has a thriving market for laser cutting machines. The price range varies from ₹6 lakhs ($7,200) for a small machine to ₹60 lakhs ($72,000) for a high-power system. Many businesses opt for an affordable laser cutting machine to meet their production needs without overspending.

Factors Affecting the Price of a Laser Cutting Machine

The cost of a laser cutting machine for sale is determined by several factors:

1. Type of Laser Technology

CO2 Laser – Suitable for non-metal materials and thin metals, starting from ₹3 lakhs ($3,600).

Fiber Laser – Ideal for cutting metals with high precision, starting from ₹5 lakhs ($6,000).

Nd:YAG Laser – Used for specialized applications, typically more expensive.

2. Power Capacity

Low Power (500W - 1kW) – Best for small-scale industries, starting from ₹5 lakhs.

Medium Power (1kW - 3kW) – Suitable for most industrial needs, priced around ₹15 lakhs.

High Power (4kW - 10kW+) – Used in heavy industries, costing up to ₹1 crore.

3. Automation and Software Features

CNC automation increases precision but adds to the cost.

AI-powered systems and IoT integration can raise prices significantly.

4. Brand and Manufacturer

International brands like Trumpf, Amada, and Bystronic offer premium machines with prices above ₹50 lakhs.

Indian brands provide budget-friendly alternatives without compromising quality.

5. After-Sales Services & Maintenance

A machine with a strong service network will be more expensive but ensures long-term reliability.

Where to Buy a Laser Cutting Machine in Pune, Mumbai, Delhi & Chennai?

Each of these cities has several reputed laser machine suppliers offering different models. Here are some tips to find the best supplier:

Visit industrial expos – Events like IMTEX, ACMEE, and India Machine Tools Expo showcase the latest laser cutting technologies.

Compare online – Many suppliers list their machines on platforms like Indiamart and TradeIndia.

Request quotations – Contact multiple dealers and compare prices.

Check customer reviews – Feedback from previous buyers can help you decide.

Choosing the Best Laser Cutting Machine in India

To select the best laser cutting machine in India, consider:

Your material type and thickness requirements.

The level of precision you need.

Your budget and expected return on investment.

Availability of after-sales support and spare parts.

Final Thoughts

If you're looking for a fiber laser cutting machine price comparison in Pune, Mumbai, Delhi, or Chennai, this guide should help you make an informed decision. Always analyze your business needs, compare models, and choose a machine that offers the best balance of performance and affordability. Whether you're searching for an industrial laser cutter price or an entry-level model, there’s a suitable machine available for every budget.

Need help finding the perfect laser cutting machine? Contact a trusted supplier in your city today!

0 notes

Text

Laser-Cutting Machine Price: A Comprehensive Guide

Laser cutting machines have revolutionized industries such as manufacturing, automotive, aerospace, and signage by offering precise, efficient, and cost-effective cutting solutions. Whether you are a small business owner or an industrial manufacturer, understanding the pricing of laser cutting machines is crucial before making an investment. In this blog, we will explore the factors affecting laser cutting machine prices, different types available in the market, and how you can find the best deal for your needs.

Factors Affecting Laser Cutting Machine Price

The cost of a laser cutting machine varies based on several factors, including:

1. Type of Laser Technology

Different laser technologies impact pricing significantly:

CO2 Laser Cutting Machines – Suitable for cutting non-metal materials like acrylic, wood, and fabric. Prices range from $3,000 to $100,000.

Fiber Laser Cutting Machines – Ideal for cutting metals like stainless steel, aluminum, and brass. These machines range from $20,000 to $500,000 depending on power and brand.

Nd:YAG Laser Cutting Machines – Used for high-precision applications in the aerospace and medical industries. Prices vary based on customization.

2. Power and Wattage

Higher power leads to faster and more precise cutting but comes at a higher cost. Entry-level fiber lasers (500W) start at $20,000, while high-power industrial lasers (10kW and above) exceed $300,000.

3. Cutting Area and Size

Machines with larger work areas (e.g., 3000mm x 1500mm) cost more than compact desktop models. A small laser cutter may cost $5,000 to $10,000, while large industrial machines can exceed $200,000.

4. Brand and Manufacturer

Premium brands like SLTL Group offer high-end technology with superior efficiency, durability, and after-sales support, impacting overall cost.

5. Additional Features and Automation

Auto-focus technology for precision cutting

Cooling systems for longer machine life

Software compatibility for seamless operation

Dual cutting heads for increased efficiency

The more advanced the features, the higher the price. However, these features improve productivity and reduce long-term operational costs.

6. Geographical Location and Import Duties

The price of laser cutting machines varies depending on location due to import taxes, shipping costs, and regional demand.

Types of Laser Cutting Machines and Their Prices

1. Entry-Level Laser Cutting Machines

Price Range: $3,000 - $20,000

Best For: Small businesses, hobbyists, and light industrial applications

Example: CO2 laser cutters for engraving and cutting acrylic, MDF, and fabrics

2. Mid-Range Laser Cutting Machines

Price Range: $20,000 - $150,000

Best For: Small to medium manufacturing units

Example: Fiber laser cutters for precise metal cutting, signage, and industrial applications

3. Industrial-Grade Laser Cutting Machines

Price Range: $150,000 - $500,000+

Best For: Large-scale industries like aerospace, shipbuilding, and heavy manufacturing

Example: High-power fiber laser cutting machines with automation and AI integration

How to Choose the Best Laser Cutting Machine Within Your Budget

When investing in a laser cutting machine, consider the following:

1. Assess Your Cutting Needs

Determine the materials and thicknesses you need to cut. Fiber lasers are best for metals, while CO2 lasers are suited for non-metals.

2. Compare Power Options

A low-power laser (500W – 1kW) is sufficient for thin materials, whereas high-power lasers (3kW – 10kW) are required for thick metal sheets.

3. Check for Warranty and Support

Choose a brand like SLTL Group that provides comprehensive after-sales service, spare parts availability, and remote troubleshooting.

4. Consider Long-Term Operating Costs

Factor in power consumption, maintenance, and consumable costs to estimate the total cost of ownership.

5. Look for Financing or Leasing Options

Many suppliers offer installment plans or leasing options, making high-end laser machines more accessible to businesses.

Why Choose SLTL Group for Your Laser Cutting Machine?

SLTL Group is a leading manufacturer of laser cutting machines, offering:

State-of-the-art technology with high precision

Cost-effective solutions tailored to various industries

Excellent customer support and after-sales service

Customizable machines to meet specific business needs

Industry Applications of Laser Cutting Machines

Laser cutting machines are widely used in various industries due to their precision and efficiency:

1. Automotive Industry

Cutting metal components for vehicle manufacturing

Engraving parts for identification and branding

Producing lightweight, high-strength vehicle structures

2. Aerospace Industry

Cutting high-precision aircraft components

Fabricating intricate designs for aerodynamics

Reducing material waste and improving efficiency

3. Manufacturing and Fabrication

Sheet metal cutting for industrial components

Creating customized metal parts for equipment

Enhancing production speed and accuracy

4. Signage and Advertising

Cutting acrylic, wood, and metal for signage

Creating intricate and precise lettering

Ensuring clean and professional finishing

Tips to Reduce Laser Cutting Machine Costs

1. Buy from a Reliable Manufacturer

Choosing a trusted manufacturer like SLTL Group ensures quality, durability, and excellent after-sales support.

2. Optimize Machine Usage

Regular maintenance and proper usage can extend the lifespan of the machine and reduce repair costs.

3. Consider Second-Hand or Refurbished Machines

Buying a pre-owned machine from a reputable supplier can save money while still offering great performance.

4. Choose the Right Machine for Your Needs

Avoid overspending on a machine with features you won’t use. Assess your needs before making a purchase.

Conclusion

The price of a laser cutting machine depends on multiple factors, including laser type, power, brand, and features. Whether you need an entry-level machine for small projects or a high-power industrial cutter, investing in the right machine ensures long-term efficiency and cost savings. SLTL Group offers a wide range of laser cutting solutions to suit different business needs. Contact SLTL Group today to get the best deals on laser cutting machines!

FAQs

Q1: What is the cheapest laser cutting machine available? Entry-level CO2 laser cutting machines start at around $3,000.

Q2: How much does an industrial fiber laser cutting machine cost? Industrial fiber laser machines range from $100,000 to $500,000, depending on power and features.

Q3: Is a fiber laser better than a CO2 laser? Fiber lasers are ideal for metal cutting, whereas CO2 lasers are best for non-metals like wood and acrylic.

Q4: Does SLTL Group offer financing options? Yes, SLTL Group provides leasing and financing solutions to make high-end laser cutting machines more accessible.

For more information, visit SLTL Group and explore the best laser cutting machines for your business.

0 notes

Text

CNC Laser Cutting Machine Price: A Comprehensive Guide

In today’s competitive industrial landscape, CNC laser cutting machines have revolutionized manufacturing, offering precision, speed, and cost-effectiveness. Businesses across sectors, including automotive, aerospace, metal fabrication, and signage, are leveraging these advanced machines to enhance productivity. However, one of the most crucial considerations for businesses is the CNC laser cutting machine price and its return on investment. In this guide, we will break down the cost factors, machine types, and how to choose the best CNC laser cutter for your needs.

Factors Affecting CNC Laser Cutting Machine Price

The price of a CNC laser cutting machine varies widely, depending on several key factors:

1. Laser Type

The type of laser source significantly impacts the cost. The three primary types are:

Fiber Laser Cutting Machines – High efficiency, best for cutting metals, and relatively higher in price.

CO2 Laser Cutting Machines – Suitable for non-metal materials like wood, acrylic, and plastics, usually more affordable than fiber lasers.

Diode Lasers – Typically used for engraving and small-scale applications.

2. Power Output (Wattage)

Higher wattage results in faster cutting speeds and the ability to cut thicker materials. However, it also increases the machine’s cost. CNC laser cutters range from 500W to 12kW, with higher power models priced significantly higher.

3. Cutting Bed Size

Larger working areas allow for cutting bigger sheets, making industrial-scale production more efficient. A larger bed size will add to the overall cost of the machine.

4. Brand and Manufacturer

Reputable brands like SLTL Group, known for innovation and reliability, may have higher upfront costs but ensure superior performance, durability, and after-sales support.

5. Additional Features & Automation

Modern CNC laser cutting machines come with features like auto-focus, AI-powered cutting path optimization, real-time monitoring, and safety enclosures, which can increase the price but improve efficiency and ease of use.

6. Maintenance and Operating Costs

Apart from the initial investment, factors such as power consumption, lens replacement, gas usage, and service costs contribute to the long-term expenses of owning a CNC laser cutter.

7. Software and Integration Capabilities

Many CNC laser cutting machines are integrated with CAD/CAM software, IoT-enabled remote monitoring, and automation features. These additions make the machines more efficient but also contribute to a higher cost.

8. Customization and Industry-Specific Requirements

Industries such as automotive, shipbuilding, and electronics may require customized CNC laser cutting solutions with specific automation, which impacts pricing.

CNC Laser Cutting Machine Price Range in India

While prices vary based on the factors above, here is an estimated price range:

Entry-Level CO2 Laser Cutting Machine – ₹5,00,000 to ₹15,00,000

Mid-Range Fiber Laser Cutting Machine (1kW – 3kW) – ₹20,00,000 to ₹50,00,000

High-End Industrial CNC Fiber Laser (4kW – 12kW) – ₹60,00,000 to ₹2,00,00,000

For an accurate quote, it is advisable to contact a reliable manufacturer like SLTL Group (www.sltl.com).

How to Choose the Right CNC Laser Cutting Machine?

Selecting the right CNC laser cutter depends on your specific needs and budget. Consider the following:

Material Type – Choose fiber laser for metals and CO2 laser for non-metals.

Production Volume – Industrial-scale businesses should invest in high-power fiber laser machines for bulk production.

Budget Constraints – Balance initial cost with long-term savings on maintenance and energy efficiency.

After-Sales Support – Opt for a manufacturer with a robust support system like SLTL Group to ensure smooth operations.

Ease of Use & Training – A user-friendly machine with proper training support ensures better productivity and less downtime.

Benefits of CNC Laser Cutting Machines

Investing in a CNC laser cutting machine comes with several advantages:

1. High Precision & Accuracy

CNC laser cutters offer exceptional cutting precision, ensuring intricate and detailed designs.

2. Faster Production Time

Automated laser cutters complete tasks much faster than traditional cutting methods, reducing production time.

3. Minimal Material Waste

Advanced laser technology ensures efficient use of materials, reducing overall waste and production costs.

4. Low Maintenance Costs

Compared to conventional cutting methods, CNC laser cutters require minimal maintenance, enhancing cost savings over time.

5. Versatility in Materials

These machines can cut a variety of materials, including metals, plastics, wood, and composites.

Why Choose SLTL Group for CNC Laser Cutting Machines?

SLTL Group is a pioneer in laser technology and offers a diverse range of CNC laser cutting machines that cater to different industrial needs. With cutting-edge innovation, superior precision, and a strong customer support network, SLTL is the go-to choice for businesses looking for high-quality laser cutters.

Key Benefits of SLTL Laser Cutting Machines:

Advanced fiber laser technology for high-speed precision cutting

Energy-efficient solutions to reduce operational costs

Customizable machines tailored to industry requirements

Strong after-sales service and maintenance support

IoT-enabled smart monitoring for real-time performance tracking

Compliance with international safety and quality standards

Final Thoughts

Investing in a CNC laser cutting machine is a strategic decision that requires careful consideration of price, performance, and long-term benefits. Whether you are a small business or a large-scale manufacturer, understanding the CNC laser cutting machine price and choosing the right machine will ensure maximum productivity and cost-efficiency.

By selecting a trusted and experienced manufacturer like SLTL Group, you can ensure that your investment in a laser cutting machine is cost-effective, reliable, and future-proof. SLTL’s advanced laser solutions, combined with superior customer service, make them a top choice for industries seeking high-quality laser cutting technology.

For the best CNC laser cutting machines in India, explore the advanced solutions offered by SLTL Group at www.sltl.com.

0 notes

Text

How To Choose Metal Laser Cutting Machine

When investing in a metal laser cutting machine, businesses must consider various factors to ensure they get the best machine for their needs. Whether you are a small workshop or a large-scale manufacturer, selecting the right laser cutter can significantly impact productivity, efficiency, and cost-effectiveness. In this guide, we will explore how to choose a laser cutting machine, including CNC laser cutting machines, at the best price and from a reliable manufacturer.

Understanding Your Requirements

Before purchasing a laser cutting machine, you need to determine your specific needs. Consider the following aspects:

Material Type and Thickness: Different laser cutting machines are designed for various metals like stainless steel, aluminum, brass, and carbon steel. The thickness of the material also determines the laser power required.

Production Volume: If your business involves high-volume production, you need a high-speed, automated CNC laser cutting machine.

Precision and Accuracy: Industries like aerospace and medical devices require high-precision cutting, making fiber laser technology a suitable choice.

Budget Considerations: The cost of a laser cutting machine varies depending on power, automation, and brand. Having a clear budget will help you make an informed decision.

Space Availability: Ensure you have adequate space in your workshop or factory to accommodate the machine and its safety requirements.

Types of Laser Cutting Machines for Metal

1. Fiber Laser Cutting Machines

Best for cutting metals with high precision.

Energy-efficient and low maintenance.

Suitable for stainless steel, carbon steel, aluminum, and copper.

Provides higher cutting speed compared to CO2 lasers.

2. CO2 Laser Cutting Machines

Suitable for cutting both metal and non-metal materials.

Higher power consumption than fiber lasers.

Requires more maintenance due to optical components.

Used mainly for thick metal sheets and mixed material applications.

3. CNC Laser Cutting Machines

Automated and controlled via computer numerical control (CNC).

Ideal for mass production with high accuracy.

Reduces material wastage and enhances efficiency.

Comes with advanced software for optimized cutting patterns.

How to Choose a CNC Laser Cutting Machine

If you are considering a CNC laser cutting machine, focus on the following:

1. Laser Power

Machines with power between 1kW to 6kW are ideal for most metal cutting applications.

Higher power machines are suitable for thicker materials but come at a higher cost.

Evaluate your material thickness and choose the appropriate wattage.

2. Cutting Speed and Efficiency

Opt for a machine with a high cutting speed to improve productivity.

Check the machine’s acceleration rate, as it affects production efficiency.

Higher wattage machines generally offer faster cutting speeds but may consume more energy.

3. Machine Durability and Build Quality

A well-built CNC laser cutting machine with a sturdy frame reduces vibrations and enhances cutting precision.

Look for high-quality components, such as motors and guiding rails, for long-term durability.

4. Software and Automation Features

Modern CNC machines come with smart software that optimizes cutting paths and reduces waste.

Look for user-friendly interfaces and compatibility with your existing systems.

Features like real-time monitoring, cloud connectivity, and automated adjustments can enhance efficiency.

How to Choose a Laser Cutting Machine at the Best Price

Price is a crucial factor when investing in a laser cutting machine. Here’s how to get the best value for your money:

Compare Different Brands: Evaluate machines from various manufacturers based on features and pricing.

Check for Financing and Leasing Options: Some manufacturers offer flexible payment plans to reduce upfront costs.

Consider Total Cost of Ownership (TCO): Factor in maintenance, energy consumption, and spare parts availability.

Look for After-Sales Support: A reliable manufacturer provides training, warranty, and technical support.

Assess Machine Longevity: A lower-cost machine with frequent repairs may end up costing more in the long run.

Look for Energy-Efficient Machines: Energy savings can contribute to cost reduction over time.

How to Choose a Laser Cutting Machine Manufacturer

Selecting the right manufacturer is as important as choosing the right machine. Consider these key factors:

1. Industry Reputation

Choose a manufacturer with a strong track record in the laser cutting industry.

Read customer reviews and case studies to gauge performance.

Look for testimonials from companies in similar industries.

2. Technology and Innovation

Opt for a manufacturer that invests in R&D to offer the latest advancements.

Look for features like intelligent automation, AI-assisted cutting, and IoT connectivity.

Advanced cooling systems and laser source efficiency improvements can enhance performance.

3. Customization and Flexibility

Some manufacturers provide tailored solutions based on your business requirements.

Ensure they offer machines suitable for your industry and materials.

Ask about modular designs that allow future upgrades.

4. Global Presence and Service Network

A manufacturer with a wide service network ensures quick troubleshooting and spare part availability.

Check if they have local representatives or authorized service centers.

Responsive customer support can save downtime and improve operational efficiency.

Why Choose SLTL Group for Your Laser Cutting Machine?

SLTL Group is a global leader in laser cutting solutions, offering advanced machines for metal processing industries. Here’s why you should consider SLTL Group:

Pioneers in Laser Technology: Over 30 years of experience in developing innovative laser solutions.

Wide Range of Machines: From fiber lasers to CNC laser cutting machines, they offer cutting-edge technology.

Comprehensive After-Sales Support: Training, maintenance, and 24/7 technical assistance.

Customization Options: Tailored solutions based on industry needs.

Competitive Pricing: High-quality machines at the best price with financing options.

Industry-Specific Solutions: SLTL Group provides laser cutting machines optimized for automotive, aerospace, medical, and industrial applications.

Sustainable and Efficient Designs: Energy-efficient systems that help businesses reduce operational costs.

Conclusion

Choosing the right metal laser cutting machine requires careful evaluation of your needs, budget, and manufacturer reliability. Whether you are looking for a CNC laser cutting machine or a cost-effective option, factors like power, speed, durability, and software capabilities play a significant role. By selecting a reputable manufacturer like SLTL Group, you can ensure a high-performance, long-lasting laser cutting solution for your business.

For more information on laser cutting machines, visit SLTL Group and explore their latest innovations in laser technology.

By following these guidelines, you can make an informed decision and invest in a laser cutting machine that enhances your productivity, efficiency, and profitability. A well-researched purchase will ensure that you get the best return on investment while maintaining high-quality cutting standards in your industry.

0 notes

Text

"How Metal Laser Cutting Machines Are Transforming Industries: Applications and Benefits"

In the modern era of manufacturing and fabrication, metal laser cutting machines have become indispensable tools. Their ability to deliver precision, speed, and efficiency has transformed industries ranging from automotive to aerospace, construction, and metal artistry. Businesses looking to enhance productivity and reduce material wastage are increasingly investing in high-performance laser cutting machines.

The rise of laser technology in metalworking has revolutionized the way manufacturers produce high-quality components. Traditional cutting methods, such as mechanical cutting and plasma cutting, have limitations in terms of precision and operational costs. However, laser cutting machines offer a cost-effective solution with minimal material wastage and superior accuracy.

What is a Metal Laser Cutting Machine?

A metal laser cutting machine is an advanced tool that uses a high-powered laser beam to cut, engrave, or etch various types of metals with extreme accuracy. The laser melts, burns, or vaporizes the metal, leaving clean, precise edges. These machines operate with CNC (Computer Numerical Control) technology, ensuring high levels of automation and repeatability.

The key advantage of laser cutting technology is its ability to handle complex designs with high precision. Whether it’s thin metal sheets or thick industrial plates, a fiber laser cutting machine can seamlessly execute intricate cuts without compromising quality.

How Does a Metal Laser Cutting Machine Work?

The process involves directing a focused laser beam onto the material surface. The machine follows a pre-programmed design, cutting through the metal efficiently. The key components include:

Laser Source: Generates the laser beam.

CNC Controller: Controls the movement and operation of the laser.

Assist Gas: Helps in blowing away molten material and improving cutting efficiency.

Cooling System: Maintains the machine’s optimal temperature.

Optical System: Focuses the laser beam precisely onto the material.

Laser cutting works by melting or vaporizing the material in a localized area while a high-pressure assist gas removes the debris. The precision of the laser ensures minimal thermal damage to surrounding material, making it ideal for delicate and high-accuracy applications.

Types of Metal Laser Cutting Machines

Different types of laser cutting technologies are available, each catering to specific applications:

1. Fiber Laser Cutting Machines

Fiber lasers use optical fiber to deliver high-intensity laser beams, offering superior efficiency and faster processing speeds. They are ideal for cutting stainless steel, aluminum, brass, and copper. SLTL Group specializes in cutting-edge fiber laser cutting machines known for their durability and precision.

Fiber laser cutting machines are known for their low maintenance requirements and high energy efficiency, making them the preferred choice for industrial applications. With advancements in laser beam delivery, modern fiber lasers can handle intricate cuts at record speeds while maintaining consistency.

2. CO2 Laser Cutting Machines

CO2 lasers use a gas mixture to generate laser beams, making them suitable for non-metal materials as well. However, for thicker metals, fiber lasers are more efficient.

CO2 laser machines have been widely used in the past for cutting metals and non-metals alike. However, with the emergence of fiber laser technology, CO2 laser cutters are now more commonly used for acrylics, wood, and textiles rather than metal fabrication.

3. Plasma Cutting vs. Laser Cutting

While plasma cutting is suitable for thick metal sheets, laser cutting offers finer precision, minimal material distortion, and higher speed, making it the preferred choice for intricate designs and industrial applications.

Plasma cutting relies on a high-temperature plasma arc to cut metals, which can lead to wider kerf widths and rougher edges. In contrast, laser cutting technology delivers a clean and precise cut with minimal post-processing, making it ideal for high-precision industries like aerospace and medical device manufacturing.

Advantages of Using a Metal Laser Cutting Machine

Investing in a laser metal cutting machine brings several benefits:

Precision and Accuracy: Capable of intricate designs and fine details with minimal error.

High-Speed Cutting: Faster than conventional methods, increasing productivity.

Versatility: Works on various metals including stainless steel, aluminum, mild steel, and copper.

Minimal Waste: Efficient use of materials, reducing scrap and operational costs.

Automation and Ease of Use: CNC control systems ensure repeatability and user-friendly operations.

Cost-Effectiveness: Although the initial investment may be high, laser cutting machines reduce long-term operational costs due to their high efficiency and minimal maintenance requirements.

Non-Contact Process: Unlike mechanical cutting, the laser beam does not wear out or degrade over time, ensuring consistent cutting quality.

Environmental Benefits: Reduced waste and energy-efficient operations contribute to sustainable manufacturing practices.

Applications of Metal Laser Cutting Machines

The use of laser cutting technology extends across multiple industries:

Automotive Industry: Used in manufacturing car parts and components.

Aerospace Industry: Precision cutting for aircraft structures and components.

Construction and Architecture: Creating decorative metal panels and frameworks.

Metal Fabrication: Producing customized metal parts with high precision.

Electronics Industry: Cutting delicate circuit board components.

Medical Device Manufacturing: Producing high-precision surgical instruments and implants.

Jewelry Industry: Creating intricate metal designs for high-end jewelry and watches.

Shipbuilding Industry: Fabricating large metal components with precision and durability.

Choosing the Right Metal Laser Cutting Machine

When selecting a laser cutter for metal, businesses should consider:

Material Thickness: Different lasers are optimized for different metal thicknesses.

Power and Speed: Higher wattage means faster and deeper cuts.

Machine Size: Should match production needs.

Operational Costs: Energy consumption and maintenance expenses.

Software Compatibility: Ensure seamless integration with design software.

Customization Needs: Some industries require tailored solutions, and SLTL Group specializes in customized laser cutting solutions.

Why Choose SLTL Group for Metal Laser Cutting Machines?

SLTL Group is a leader in laser cutting technology, offering innovative and high-performance laser cutting machines for metal. Key reasons to choose SLTL Group include:

Advanced Fiber Laser Technology: Delivering precision and efficiency.

Custom Solutions: Tailored machines to meet industry-specific needs.

Global Presence: Serving industries worldwide with reliable solutions.

After-Sales Support: Comprehensive maintenance and training services.

High-Powered Machines: SLTL Group provides state-of-the-art fiber laser cutting machines capable of handling the most demanding industrial applications.

Industry Experience: With decades of experience in laser technology, SLTL Group continues to innovate and provide cutting-edge solutions.

Conclusion

The demand for metal laser cutting machines continues to grow as industries seek precision, efficiency, and sustainability in manufacturing. Investing in a high-quality fiber laser cutting machine from a trusted provider like SLTL Group ensures long-term productivity and cost savings. Whether you are in automotive, construction, or metal fabrication, choosing the right laser cutting system can revolutionize your operations.

For the best laser cutting solutions, visit SLTL Group today and explore the latest in metal laser cutting technology!

0 notes

Text

Top Advantages of CNC Laser Cutting Machines for Industrial Applications

In the modern manufacturing landscape, CNC laser cutting machines have become an indispensable tool for industries requiring precision, efficiency, and high-speed operations. From automotive and aerospace to signage and metal fabrication, these machines are reshaping production processes with their advanced capabilities. In this blog, we will explore the features, benefits, applications, and factors to consider when choosing a CNC laser cutting machine, with a focus on SLTL Group’s innovative solutions.

What is a CNC Laser Cutting Machine?

A CNC (Computer Numerical Control) laser cutting machine is a high-tech device that uses a laser beam to cut materials with extreme precision. The process involves directing a high-powered laser onto the workpiece, which melts, burns, or vaporizes the material, leaving a smooth and precise edge. Unlike conventional cutting methods, CNC laser cutting offers unparalleled accuracy and repeatability, making it an ideal choice for modern manufacturing.

Types of CNC Laser Cutting Machines

There are different types of CNC laser cutting machines, including:

CO2 Laser Cutting Machines – Ideal for cutting non-metal materials like wood, acrylic, leather, and plastics.

Fiber Laser Cutting Machines – Best suited for cutting metals such as stainless steel, aluminum, brass, and copper.

Nd:YAG Laser Cutting Machines – Used for high-precision cutting in the electronics and medical industries.

Hybrid Laser Cutting Machines – Combine different technologies to provide versatility and efficiency.

Each type has its unique advantages, making it essential to choose the right one based on industry requirements.

Features of CNC Laser Cutting Machines

High Precision and Accuracy - CNC laser cutting ensures precise cuts with minimal errors, making it perfect for intricate designs and detailed patterns.

Versatility - These machines can cut a wide range of materials, including metals, plastics, ceramics, wood, and composites.

Automation and Efficiency - Automated processes reduce human intervention, enhancing production speed and efficiency.

Minimal Material Waste - Advanced nesting software optimizes material usage, reducing waste and lowering costs.

Contactless Cutting - Since the laser beam does not physically touch the material, there is minimal wear and tear on the machine.

Cost-Effective - While the initial investment may be high, the long-term operational savings in labor and material costs make it a cost-effective solution.

Easy Integration with CAD/CAM Software - Modern CNC laser cutting machines integrate seamlessly with design software, allowing for easy modifications and mass production.

Applications of CNC Laser Cutting Machines

1. Automotive Industry

CNC laser cutting is extensively used in the automotive industry for manufacturing car frames, engine components, and intricate detailing. The precision ensures high-quality parts that meet strict industry standards.

2. Aerospace Industry

The aerospace sector demands extreme accuracy and durability. CNC laser cutting machines produce intricate parts with high precision, ensuring safety and performance in aircraft manufacturing.

3. Metal Fabrication

Metal fabricators use CNC laser cutting to produce components for construction, machinery, and industrial equipment. The ability to cut thick and thin metal sheets with minimal distortion makes it an ideal choice.

4. Signage and Advertising

CNC laser cutting is used to create intricate signage and logos with perfect detailing. It allows businesses to produce eye-catching designs in various materials such as acrylic, wood, and metal.

5. Electronics and Electrical Industry

The production of circuit boards, electronic enclosures, and precision components in the electrical industry is greatly enhanced by CNC laser cutting technology.

6. Medical Device Manufacturing

The medical industry relies on CNC laser cutting for precision-cut components used in surgical instruments, implants, and medical devices, ensuring high safety and quality standards.

Advantages of CNC Laser Cutting Machines

1. Superior Cutting Quality

CNC laser cutting produces smooth, clean edges with minimal burrs, reducing the need for secondary finishing processes.

2. High Speed and Productivity

Laser cutting is significantly faster than traditional cutting methods, improving overall production rates and efficiency.

3. Energy-Efficient Technology

Modern CNC laser machines consume less power compared to conventional cutting technologies, contributing to sustainable manufacturing practices.

4. Enhanced Safety Measures

Automated systems minimize the risk of workplace injuries, making CNC laser cutting a safer option for operators.

5. Scalability and Customization

Businesses can easily scale production and customize products based on customer demands, increasing market competitiveness.

6. Low Maintenance and Long Lifespan

With minimal moving parts and advanced cooling systems, CNC laser cutting machines require less maintenance and have a longer lifespan compared to mechanical cutting tools.

How to Choose the Right CNC Laser Cutting Machine?

1. Material Compatibility

Ensure the machine is suitable for the materials you work with, whether metals, plastics, or composites.

2. Power and Cutting Capacity

Different models offer various power levels; selecting the right wattage ensures efficient cutting of thick and thin materials.

3. Precision and Speed

Choose a machine that balances cutting speed with accuracy for optimal performance.

4. Software Integration

CNC laser cutting machines should be compatible with advanced CAD/CAM software for seamless design and execution.

5. Maintenance and Support

Opt for a machine from a reputable manufacturer like SLTL Group that offers reliable after-sales support and maintenance services.

6. Budget and Return on Investment

Evaluate the cost of the machine against its long-term benefits to ensure a good return on investment.

Why Choose SLTL Group for CNC Laser Cutting Machines?

SLTL Group is a pioneer in laser technology, offering state-of-the-art CNC laser cutting machines that cater to diverse industrial needs. Here’s why SLTL Group stands out:

Innovative Technology - SLTL Group continuously innovates to deliver cutting-edge laser solutions.

Custom Solutions - Tailored machines designed to meet specific industry requirements.

Global Recognition - A trusted brand with a strong global presence.

Exceptional Support - Comprehensive training, service, and support for seamless operation.

Sustainability-Focused - SLTL Group designs energy-efficient machines, reducing environmental impact.

Future Trends in CNC Laser Cutting Technology

1. AI and Machine Learning Integration

Artificial Intelligence (AI) is enhancing the automation of CNC laser cutting machines, improving efficiency and reducing human error.

2. Industry 4.0 and Smart Factories

The rise of Industry 4.0 is leading to interconnected smart factories, where CNC laser cutting machines communicate with other devices for optimized production.

3. Improved Laser Efficiency

Advancements in fiber laser technology are increasing power efficiency, reducing operational costs.

4. Expanded Material Capabilities

Research is ongoing to develop CNC laser cutting machines that can handle even more diverse materials, expanding their industrial applications.

Conclusion

CNC laser cutting machines have revolutionized modern manufacturing by offering unmatched precision, efficiency, and versatility. Whether you are in the automotive, aerospace, metal fabrication, or signage industry, investing in a high-quality CNC laser cutting machine can significantly enhance your production capabilities. With SLTL Group’s advanced laser solutions, businesses can achieve superior results and stay ahead in the competitive market.

For more information on CNC laser cutting machines and to explore SLTL Group’s innovative laser solutions, visit SLTL Group.

0 notes

Text

"Laser Cutting Machine Price in Pune: What You Need to Know Before Investing"

Pune, a growing industrial hub in India, is witnessing a surge in demand for laser cutting technology. From manufacturing to signage, automotive to fabrication, industries in Pune are increasingly relying on laser cutting machines for precision, efficiency, and cost-effectiveness. Whether you're searching for the best laser cutting machine in Pune, comparing laser cutting machine prices in Pune, or looking for a trusted laser cutting machine manufacturer in Pune, this guide will help you make an informed decision.

Why Choose a Laser Cutting Machine in Pune?

Laser cutting machines have revolutionized metal, plastic, and wood processing industries by providing:

High Precision – Laser technology ensures accurate cuts with minimal material wastage.

Speed and Efficiency – Faster cutting speeds boost productivity and reduce turnaround time.

Versatility – Suitable for cutting metals, acrylic, wood, plastics, and even glass.

Automation & Ease of Use – Modern CNC laser cutting machines require minimal manual intervention.

Cost Savings – Reduces labor costs and material wastage, leading to long-term profitability.

Best Laser Cutting Machine in Pune: How to Choose the Right One

When selecting a laser cutting machine in Pune, several factors come into play:

1. Material and Application

Different laser cutting machines are designed for specific materials. Common types include:

Fiber Laser Cutting Machines – Ideal for cutting metals like stainless steel, aluminum, and copper.

CO2 Laser Cutting Machines – Suitable for non-metallic materials like wood, acrylic, and plastic.

Hybrid Laser Machines – Can cut both metals and non-metals.

Understanding the material type and industry-specific applications will help businesses choose the right laser cutter. For example, manufacturers in the automobile industry need fiber lasers for cutting metal sheets, while the signage industry often uses CO2 lasers for acrylic cutting.

2. Power and Performance

Low-Power Lasers (Up to 500W) – Suitable for engraving and light cutting tasks.

Mid-Power Lasers (500W – 2kW) – Used for industrial applications with moderate thickness.

High-Power Lasers (Above 2kW) – Best for heavy-duty industrial applications with thick materials.

Higher power lasers offer better cutting capabilities, but they also come at a higher cost. It’s crucial to analyze business needs before investing in a machine.

3. Cutting Speed and Efficiency

The best laser cutting machines optimize cutting speed without compromising precision. High-speed machines with automatic feeding and smart software integration are preferred for high-volume production. Companies in Pune’s manufacturing sector benefit from fast processing speeds, leading to increased efficiency and production rates.

4. Maintenance and Durability

A good laser cutting machine manufacturer in Pune provides robust machines with minimal maintenance needs. Key factors to consider:

Build Quality – Machines made from high-quality components last longer.

Cooling System – Essential for preventing overheating.

Software & Automation – Advanced software ensures smooth operations.

Local Support – Availability of service centers in Pune helps in easy maintenance.

5. Budget and Cost Considerations

The laser cutting machine price in Pune varies depending on power, size, and features. It's crucial to balance budget with quality and long-term ROI. Businesses must factor in not only the machine’s upfront cost but also:

Operating Costs – Electricity and consumables like laser tubes and lenses.

Maintenance Costs – Regular servicing and spare parts.

Software & Upgrades – Compatibility with future upgrades.

Laser Cutting Machine Price in Pune: Factors Affecting Cost

The cost of a laser cutting machine in Pune can range from INR 5 lakh for entry-level models to INR 50 lakh or more for high-end industrial machines. Several factors influence the price:

Machine Type – Fiber lasers are generally more expensive than CO2 lasers.

Power and Features – Higher wattage and advanced features increase the cost.

Brand and Manufacturer – Established brands like SLTL Group offer premium machines with exceptional after-sales support.

Automation and Software – CNC integration and smart software functionalities add to the price.