Text

Neodymium Ring Magnets

Circular neodymium magnets, featuring a flat and round shape with a central hole, are referred to as strong neodymium (NdFeB) ring magnets. Their diameter exceeds their thickness.

Neodymium ring magnets boast stable magnetic performance, strong magnetic force, and a long lifespan, making them widely used in manufacturing motors, generators, sensors, and other devices.

Exceptional Features of Rare Earth Ring Magnets

Crafted from premium N52 Grade Neodymium, our Ring Magnets showcase superior strength and durability. With a central hole for easy attachment, these magnets deliver optimal magnetic performance, making them a popular choice across diverse applications.

NdFeB Ring Magnets Applications and Advantages

Neodymium ring magnets find applications in acoustic devices, electronics, machinery, and more. The central void facilitates convenient attachment to non-ferrous surfaces, providing flexibility and efficiency in various settings.

Ideal for hobbyists, jewelers, and costume designers, the ring shape facilitates easy attachment using thread or wire. Enhance your crafting projects with the magnetic hold of our Neodymium Ring Magnets.

Maximum Working Temperature of Rare Earth Neodymium Magnet Rings for Various Grade

Neodymium Material Grade

Maximum Working Temp.

Curie Temp.

N(N35,N38,N40,N42,N45,N48,N50,N52)

176°F (80°C)

590°F (310°C)

N-M(N35M,N38M,N40M,N42M,N45M,N48M,N50M,N52M)

212°F (100°C)

644°F (340°C)

N-H(N35H,N38H,N40H,N42H,N45H,N48H,N50H)

248°F (120°C)

644°F (340°C)

N-SH(N35SH,N38SH,N40H,N42SH,N45SH,N48SH)

302°F (150°C)

644°F (340°C)

N-UH(N28UH,N30UH,N33UH,N35UH,N38UH,N40UH,N42UH)

356°F (180°C)

662°F (350°C)

N-EH(N28EH,N30EH,N33EH,N35EH,N38EH,N40EH)

392°F (200°C)

662°F (350°C)

N-AH(N28AH,N33AH,N35AH,N38AH)

428°F (230°C)

662°F (350°C)

From industrial applications to DIY projects, Neodymium Ring Magnets from Frenergy provide a reliable and efficient solution. Experience the highest level of magnetic attachment with our exceptional magnet range.

0 notes

Text

Neodymium Cylinder Magnets

The long and round shape sintered NdFeB magnets are give the name of neodymium(NdFeB) cylinder magnets. Differ from normal disc shape,the size of thickness is larger than its diameter. NdFeB cylinder magnet is expressed by diameter(D) x length(L).

The cylinder shaped magnets resembles a cylinder with a corrosion-resistant oxide surface, exhibiting excellent corrosion resistance for diverse environments. These rare earth neodymium cylinder magnets excel in magnetic performance, low-temperature stability, corrosion resistance, and impact resistance. Customizable in various sizes, these neodymium cylinder magnets can be tailored to customer requirements with different material grades.

The Magnetization Direction of Powerful Cylinder Magnets

The magnetized direction of powerful neodymium(NdFeB) rod magnets is generally divided into axially magnetized and diameter magnetized, which is determined according to the required working face.

Application of Cylindrical Neodymium Magnets

Known for high magnetism and compactness, cylindrical NdFeB magnets find wide applications in electronics and equipment. Their strong magnetic properties make them suitable for electronic control devices and electromagnetic wave separation. They enhance directional control in transportation, improving vehicle safety and stability.

Additionally, rare earth cylinder magnets can optimize wind and solar power generation efficiency by controlling the orientation of turbines and solar panels. Furthermore, cylindrical NdFeB magnets enhance the performance and precision of electronic products, such as power tools, automation equipment, and electronic devices.

0 notes

Text

Neodymium Disc Magnets

The flat and round shape strong NdFeB magnets are give the name of neodymium disc magnets, the size of diameter is larger than its thickness. Neodymium disc magnets are the preferred magnetic product in both industrial and consumer applications.

Due to their versatility and cost-effectiveness, these round rare earth magnets dominate the market and various industries as the most commonly used powerful magnet type. They are extensively employed in electric motors, speakers, and various sensor types. We offer neodymium round magnets in a range of thicknesses and sizes, with different coatings such as zinc, nickel, silver, gold, epoxy resin, etc.

Surface Treatment of Strong Disc NdFeB Magnets

Durable neodymium disc magnets are prone to corrosion, necessitating surface coatings. Commonly used coatings include zinc plating, nickel, eco-friendly zinc, eco-friendly nickel, nickel copper-nickel, eco-friendly nickel copper-nickel, and epoxy coating.

The Magnetization Direction of Powerful Neodymium Disc Magnets

The magnetization direction of powerful NdFeB disc magnets is typically categorized as axial or diametrical, determined by the desired working face. Specify your magnetization preference when placing an order.

Custom Round Shaped Rare Earth Disc Magnets for Sale

NdFeB magnets stand as unique, non-standard rare earth magnetic products. Sintered Nd-Fe-B material, with its excellent machinability, allows customization into various sizes of round shaped neodymium disc magnets. No molds are required for crafting robust neodymium disc magnets, and we cater to orders of any quantity, whether small or large.

0 notes

Text

Neodymium Block Magnets

The square shaped strong neodymium (NdFeB) magnets are given the name of rare earth neodymium block magnets or rectangular magnets,one strong NdFeB block(rectangular) magnet is expressed by length(L) x width(W) x thickness(T) / height(H).The strongest rare earth magnet blocks are made of neodymium.

Surface Treatment of Rare Earth Ndfeb Magnet Blocks

Surface treatment is crucial for enhancing the performance and durability of rare earth NdFeB magnet blocks. Commonly, a protective coating like nickel, zinc, or epoxy is applied to prevent corrosion and oxidation, ensuring long-term stability. The coating also acts as a barrier against environmental factors, maintaining the magnet's strength and integrity. Additionally, surface treatments can include processes like passivation or phosphating to further improve corrosion resistance. These treatments contribute to the magnet's functionality in various applications, from electronics to renewable energy. Tailoring the surface properties of NdFeB magnets through advanced treatments ensures their optimal performance and extends their service life.

Custom Rare Earth Neodymium Block Magnets

Rare earth Neodymium block magnets, being non-standard items, leverage the favorable machinability of sintered NdFeB material. This allows for the customization of NdFeB block magnets in diverse sizes without the requirement for molds. Strong neodymium rectangular magnets can be tailored to specific dimensions without the need for dedicated molding processes. Whether in small or large quantities, we have the capability to produce square shaped neodymium block magnets to meet varying specifications with ease.

How to Order Square Shaped Rare Earth Neodymium Magnet?

1, Choose the correct neodymium magnet grade for the block magnets according to working temperature and the needed magnetic performance.

2, Choose the correct surface treatment according to the application conditions.

3, Clear for the magnetization directions for the block neodymium magnets.

We have various square/block rare earth NdFeB magnets for sale, customization is also available. Contact us to know the square magnet price.

0 notes

Text

Neodymium Magnetic Tiles

Arc or segment shape permanent magnets are known as magnetic tiles and tile magnets. To ensure durability, surface treatments like zinc plating or epoxy coating are applied. Choose from radially or diametrically magnetized tiles based on your application.

Our custom neodymium magnetic tiles offer versatility without the need for molds. Simply provide your drawings, and we'll deliver tailored solutions for your motor needs. Elevate your projects with precision and performance – inquire and order your rare earth neodymium magnetic tiles today!

Application of Magnetic Tiles

Neodymium magnetic tiles find primary applications in DC motors featuring permanent magnets. In contrast to electromagnetic motors relying on excitation coils for magnetic potential, permanent magnet motors utilize magnet materials for a consistent magnetic field. Employing permanent magnet tiles as an alternative to electrical excitation brings numerous benefits, streamlining motor structure, easing maintenance, reducing weight, minimizing size, ensuring reliability, lowering copper consumption, and promoting energy efficiency.

Surface Treatment is Needed for Neodymium(NdFeB) Magnetic Tiles

Neodymium (NdFeB) magnetic tiles, also known as neodymium tile magnets, lack rust resistance and are prone to corrosion. To enhance durability, these Neodymium(NdFeB) magnetic tiles require protective coatings such as zinc plating, nickel, and epoxy coating. Addressing the susceptibility to rust and corrosion, these surface treatments ensure longevity.

Magnetization Direction of NdFeB)Magnetic Tiles

Considering the application, the magnetized direction of Neodymium(NdFeB) magnet tiles can be tailored to either radially or diametrically magnetized. When reaching out for rare earth Neodymium magnet tiles, specifying the desired magnetization direction is crucial.

Custom Rare Earth Magnetic Tiles

Unlock custom solutions with rare earth Neodymium(NdFeB) magnetic tiles, specifically designed for motor applications. The machinable sintered Nd-Fe-B material allows for various tile shapes without the need for molds. Offering a range of surface treatments and magnetization directions, we cater to diverse motor needs. Share your drawings when inquiring and ordering, and elevate your projects with precision and performance. Contact us today for tailored rare earth Neodymium Magnetic Tiles, crafted for your unique motor requirements.

0 notes

Text

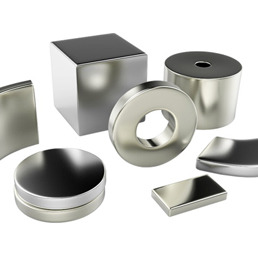

Meank offers high-strength, large neodymium magnets at competitive wholesale prices. These rare earth magnets, also called NdFeB strong magnets, boast greater energy levels. Neodymium magnets, the third-generation rare earth magnets, consist of Nd, Fe, and B elements in a tetragonal crystal structure. Their magnetic energy, BH(max), surpasses that of SmCo magnets, making them the world's most robust rare earth industrial magnets, including adhesive-backed types. For purchasing substantial neodymium magnets, feel free to contact us.

Sintered Custom Shaped Powerful NdFeB Magnet Application

Thanks to the excellent magnetic properties, sintered neodymium(NdFeB) strong permanent magnet materials are widely used in electronics, electrical machinery, motors,medical devices, toys, packaging, hardware machinery, aerospace and other fields. The most common application products of Meank strong neodymium magnets for sale are permanent magnet motors, loudspeakers, magnetic separators, salvage fishing magnet and mounting products.

Rare Earth Neodymium Powerful Magnets Classification

Neodymium(NdFeB) strong magnet can be classified as sintered NdFeB and bonded NdFeB. Bonded NdFeB magnets have magnetism and corrosion resistance in all directions; sintered NdFeB magnet is generally divided into axial magnetized and diametrical magnetized, which is determined according to the required working face.

The sintered neodymium magnet is easy to corrode, and the surface needs to be coated, generally including zinc plating, nickel, environmental protection zinc, environmental protection nickel, nickel-copper-nickel, environmental protection nickel-copper-nickel, and epoxy coating. Meank is a professional manufacturer and supplier of sintered rare earth neodymium strong magnet, which is the strongest magnet and the most powerful magnet for sale in the world. We offer a wide range of large neodymium magnets for sale at a cheap price/cost. Wholesale is available, bulk buying is welcomed. Contact us and buy rare earth magnets now!

Powerful Neodymium Magnets Features & Characteristics

Anisotropy: Rare earth neodymium magnets exhibit anisotropy, featuring high saturation magnetization.

Highest Magnetic Energy: Among permanent magnetic materials, rare earth neodymium magnets demonstrate peak performance, boasting a maximum magnetic energy product (BH) of up to 52MGOe.

Limited Temperature Use: These powerful neodymium magnets possess low Curie temperature and, consequently, limited temperature stability, constraining their applicability in high-temperature conditions.

Corrosion Vulnerability: Surface discoloration, including white or other spots, may emerge, eventually evolving into rust. In most instances, protective coatings are necessary. Typically, electroplated rare earth neodymium magnets are less prone to rust spots in regular conditions.

Robust Mechanical Properties: Powerful neodymium magnets exhibit strong mechanical attributes and are easily cut and drilled.

0 notes

Text

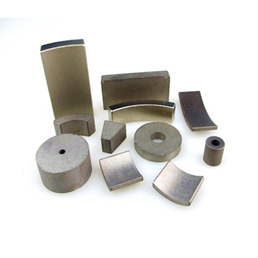

Rare Earth SmCo Magnets

Rare earth samarium cobalt magnets, shorted as SmCo magnets, are a type of powerful permanent magnet made from the basic elements samarium and cobalt and other metal rare earth materials by mixing, melting, grinding, pressing and sintering. They come in various sizes and shapes, like disc,bar, ring, arc,block, etc.,. Similar to neodymium strong magnets, they belong to the rare earth magnet category, and tcan be classified as SmCo5 and Sm2Co17 according the composition ratios of samarium and cobalt.

In comparison to neodymium rare earth magnets, although samarium cobalt magnets may not have as strong magnetic force, they possess two distinct advantages. Firstly, they operate effectively within a higher temperature range, and secondly, they exhibit greater resistance to corrosion.

Due to these characteristics, rare earth SmCo magnets are commonly employed in applications that demand high operating temperatures, such as generators, pump couplings, sensors, electric motors, marine applications, as well as in the automotive, racing, aerospace, military, and food and manufacturing industries. SmCo rare earth magnets not only perform well at high temperatures but also maintain their magnetic properties even in temperatures below absolute zero (-273 degrees Celsius), making them popular for use in low-temperature applications.

What are Samarium Cobalt Magnets Used for?

Samarium cobalt magnets (SmCo magnets) are a crucial type of permanent magnet known for their high magnetic energy product and excellent magnetic stability. Their versatile applications contribute to various industries:

1. Electric Motors: The exceptional magnetic properties of samarium cobalt make it an ideal material for crafting efficient electric motors. These magnets not only enhance the power density of motors but also reduce their size and weight, thereby improving overall motor efficiency.

2. Sensors: Samarium cobalt magnets find utility in creating magnetic sensors. They enhance a sensor's sensitivity to external magnetic fields, thereby improving the sensor's responsiveness and accuracy.

3. Instruments and Gauges: Due to its high magnetic energy product and stable magnetization, samarium cobalt magnets are employed in the manufacturing of precision instruments and gauges.

4. Medical Devices: The heightened magnetic performance of samarium cobalt magnets is utilized in the fabrication of MRI (Magnetic Resonance Imaging) devices. These magnets contribute to creating a stronger and more stable magnetic field in MRI equipment, thereby enhancing imaging accuracy.

As technology advances and samarium cobalt magnet materials continue to improve, we anticipate their applications to expand further across diverse industries.

What are the Properties of SmCo Magnets?

Samarium cobalt magnets offer numerous advantages, making them an ideal choice for industrial applications and contributing to their increasing popularity. In fact, in certain situations, rare earth SmCo magnets may be more suitable than neodymium magnets.

Benefits of Samarium Cobalt Magnets:

2. High Corrosion Resistance: These magnets exhibit excellent rust resistance and chemical stability, allowing them to function normally in harsh environments such as water, acids, and salt.

3. High Temperature Resistance: SmCo rare earth magnets have a broader temperature stability range compared to other permanent magnet materials, maintaining long-term stability even in high-temperature environments.

4. Ease of Processing: Samarium cobalt magnets are easily processed using methods such as drilling, milling, and grinding, owing to their good machinability.

Despite the various advantages of SmCo magnets, it's important to consider some factors when contemplating their use for your business applications. SmCo rare earth magnets can be brittle and perform best in applications where direct impact is not required. Additionally, these magnets are sensitive to market prices and are generally more expensive than neodymium magnets.

What is the Difference between SmCo5 and Sm2Co17?

When comparing 2:17 type samarium cobalt permanent magnets to 1:5 type samarium cobalt magnets, the following advantages stand out:

Lower Cost Composition:

The formula of Sm2Co17 permanent magnets contains lower levels of cobalt and samarium compared to SmCo5 magnets. This significant reduction in raw material content results in cost savings, as both samarium and cobalt are relatively expensive rare metals. Consequently, Sm2Co17 magnets are priced lower than SmCo5 magnets.

Lower Magnetic Sensitivity to Temperature:

Sm2Co17 magnets have a lower magnetic sensitivity temperature coefficient of about -0.02%/℃, allowing them to operate in a range of -60 to 350℃. This is a distinct advantage over SmCo5 magnets, which cannot match this temperature versatility.

Higher Curie Temperature:

The Curie temperature of 2:17 type samarium cobalt materials is approximately 840-870℃, while the Curie temperature of 1:5 type samarium cobalt materials is 750℃. This indicates that 2:17 type samarium cobalt is more resistant to high temperatures than 1:5 type samarium cobalt. However, it's important to note that the manufacturing process for 2:17 type samarium cobalt is more complex compared to 1:5 type samarium cobalt. Achieving higher coercivity requires a longer aging process, resulting in higher production costs compared to SmCo5.

In the realm of permanent magnets, Sm2Co17 magnetic materials show promise as high-temperature magnets.

Samarium Cobalt Magnets VS Neodymium Magnets

Differences Between Samarium Cobalt and Rare Earth Neodymium Magnets:

1. Magnetic Strength: Rare earth NdFeB magnets are renowned as the "king of magnetism" for their formidable strength, surpassing samarium cobalt magnets, which rank just below neodymium iron boron in magnetic performance.

2. Temperature Resistance: Rare earth neodymium magnets reaches a maximum temperature of 220 degrees only with materials of 28AH and above, while Sm2Co17 can withstand temperatures up to 350 degrees. Around 300 degrees, neodymium iron boron loses magnetic force, while samarium cobalt can operate normally without requiring demagnetization.

3. Stability: Rare earth neodymium magnets exhibits a large residual magnetism temperature coefficient, decreasing residual magnetism with rising temperatures. In contrast, samarium cobalt magnets have a smaller residual magnetism temperature coefficient, with minimal demagnetization and higher stability. Neodymium requires plating to prevent oxidation, corrosion, and weathering, while samarium cobalt with cobalt coating often doesn't require plating, ensuring a longer lifespan and appealing aesthetics.

4. Price: Neodymium rare earth magnets contain small amounts of rare earth elements neodymium and boron, making it relatively more affordable. On the other hand, samarium cobalt magnets contain a higher proportion of rare earth elements samarium and cobalt, resulting in a higher price.

Conclusion: Compared to rare earth NdFeB magnets, samarium cobalt magnets excel in higher temperatures and more corrosive environments. While neodymium magnets boast stronger magnetic fields and the highest BHMax in today's permanent magnets, samarium cobalt provides superior performance in specific conditions and is priced higher due to its composition of rare earth elements samarium and cobalt.

0 notes

Text

Neodymium rare earth magnets, a common rare earth type, stand out as the strongest available. Widely used across various applications, they exemplify magnetic material preferences. Despite their advantages, certain considerations must be acknowledged.

1. High Temperature Tolerance

NdFeB rare earth magnets withstand higher temperatures due to their strong attraction and low electrical conductivity. Ideal for electronics and resistant to demagnetization when connected to materials like low-carbon steel or long-lasting magnets.

2. Exceptional Magnetic Properties

With high remanence, coercivity, and energy product, rare earth NdFeB magnets excel in applications requiring substantial remanence. Their Curie temperature is high, indicating a superior energy product, and they exhibit low sensitivity to temperature changes and external magnetic fields.

3. Applications in Neural Experiments

Rare earth neodymium magnets prove valuable in experiments involving neural electric activity. A study examining their impact on 17 healthy individuals concluded that the magnetic field did not affect psychological testing parameters, making them essential for labs and homes.

4. Artistic Structures and Illusions

Rare earth NdFeB magnets allow for the creation of imaginative structures. For instance, a vertical wooden frame with a neodymium magnet on the top horizontal bar, attracting a second magnet attached to the bottom bar, creates a floating illusion. The possibilities are limitless, enabling you to unleash your inner artist.

5. Medical Applications and Surgical Procedures

Used for surgical removal of unwanted tissues, rare earth neodymium magnets resist movement on non-magnetic surfaces. Leveraging electromagnetic fields and Lenz's Law, they induce an electric field in conductive materials, demagnetizing the magnets. This effect proves useful in medical applications.

6. Temperature Sensitivity and Industrial Use

Temperature significantly influences neodymium magnet performance. Lower temperatures enhance their strength, while higher temperatures weaken them. Despite certain limitations, their ability to withstand high temperatures positions them favorably for industrial applications.

7. High Remanence for Strong Magnetic Fields

The high remanence of rare earth neodymium magnets indicates powerful magnetic fields, surpassing regular magnets. Despite being rare earth magnets, neodymium magnets, though more expensive and energy-intensive to produce, find applications across various sectors, including medical implants.

8. Creating Illusions with Magnetic Fields

Utilizing their high remanence, powerful neodymium magnets can be employed to create illusions. Constructing a vertical wooden frame and inserting a magnet into the top horizontal bar, while attaching a second magnet to the bottom bar, results in an appealing floating effect.

In conclusion, neodymium rare earth magnets offer a myriad of benefits, from unmatched magnetic strength to versatile applications in diverse fields. Their unique properties make them a valuable resource, shaping advancements in technology, medicine, and creative endeavors. However, their relative costliness and energy-intensive production underscore the importance of sourcing high-quality materials.

0 notes

Link

Beilun Meank is a professional wholesale pot magnet manufacturer and wholesale pot magnet supplier that provides powerful wholesale pot magnet. The magnet assembly that a NdFeB ring magnet housed in a flat steel shell (there is a hole in the center of the shell) is known as a counterbore neodymium shallow pot/cup magnet. Because of the hole, it is easy to be installed and called a mountable neodymium cup magnet. The flat neodymium shallow pot magnets with cylindrical mounting holes are used for mounting various equipment and are known as NdFeB /neodymium mounting magnets. Contact us for more information of china countersunk pot magnet.

Summary Of Counterbore Neodymium Shallow Pot Mounting Magnets:

Component Material: neodymium ring magnets + A3 steel cup + ABS plastic ring or epoxy glue

Available Surface Treatment: Nickel, Zinc, spray colorful plastic

Standard Size: diameter-16mm, 20mm, 25mm, 32mm,36mm,42mm,48mm,60mm,75mm

Magnetic Grade: N35, N38, N40, N42, N45,N48,N50,N52

Working Temp.: -40 to 80℃(for standard ones), the pot magnets for higher working temperature can be customized

Specifications Of NdFeB Ring Mounting Magnets With Cups (counterbore Neodymium Shallow Pot Magnets)

Model

D

D1

D2

H

Pull Force(kg)

Dead Weight(g)

NdFeB-B16

16

3.5

6.5

5

4

6

NdFeB-B20

20

4.5

8

7

6

12

NdFeB-B25

25

5.5

9

8

14

23

NdFeB-B32

32

5.5

9

8

23

36

NdFeB-B42

42

6.5

11

9

32

73

NdFeB-B48

48

8.5

15

11.5

63

114

NdFeB-B60

60

8.5

15

15

95

240

NdFeB-B75

75

10.5

18

18

155

471

Note: standard neodymium cup mounting magnets with cylindrical mounting holes are with a grade of N35 and Nickel coating unless customers have another requirement of wholesale pot magnet.

Characteristics Of Counterbore Neodymium Shallow Cup/pot Magnets:

Due to the steel shell, as a new type of ring magnet with steel cup covered, the whole magnetic systems that our wholesale pot magnet supplier offers have several times the magnetic holding force of the naked NdFeB ring magnets. With steel shell covered, the neodymium magnets are durable. NdFeB counterbore cup/pot magnets are used for heavy-duty applications. The working surfaces of cylindrical hole neodymium mounting magnets are on the north pole side, which is compact and practical for integrating into your projects. The central through mounting hole of the neodymium cup/pot mounting magnets are suited for nails and screws, so the counterbore neodymium pot magnets are mountable and can be easily installed for any holding application. The uses of neodymium counterbore cup magnets with cylindrical holes are similar to countersunk neodymium cup mounting magnets.

Common Uses and applications Of Counterbore Neodymium Shallow Cup/pot Magnets

1. Counterbore neodymium shallow pot/cup magnets are used for clamping tools.

2. Countersbore neodymium mounting magnets are used for shelf displaying.

3. Neodymium shallow cup magnets with cylindrical mounting holes are used for the temporary fixing of instruments.

4. Neodymium mounting magnets with counterbore holes are used as magnetic bases for holding applications.

5. Neodymium mountable magnets can be used as magnetic connectors

Advantages Of Neodymium Cup Magnets With Cylindrical Mounting Hole

1. Neodymium cup mounting magnets cylindrical holes can be used for heavy-duty applications.

2. Installation of our wholesale pot magnets with cylindrical holes is easier.

3. The applications of neodymium cup mounting magnets with cylindrical mounting holes are multiple.

4. Various sizes selection can be provided for neodymium cup magnets with cylindrical holes.

5. With a cylindrical hole design, the fastener is not in direct contact with the ring magnets, it effectively avoids the damage caused by excessive force on the neodymium mounting magnets.

Contact Us For Customizing Neodymium Counterbore Neodymium Cup Magnets:

As a professional neodymium wholesale pot magnet manufacturer in China, Beilun Meank supplies high-performance rare earth neodymium wholesale pot magnet with steel cups. If no standard neodymium cup/pot magnets with cylindrical mounting holes from the table can meet your needs, please contact us for customizing.

Two Versions of Counterbore Neodymium Cup Magnets Are Available to Meet the Different Preferences of Customers

Counterbore Neodymium Mounting Magnets

The steel cups are machined with punching machine

Counterbore NdFeB Mounting Magnets

The steel cups are machined with turning machine

0 notes

Link

Different from a normal cup(pot) magnet, the U-channel holding magnet, also called the ferrite channel magnet, is not round-shaped, and it is rectangular bar shape. The composition structure blocks bar magnets housed in a u-shaped steel shell. The magnetic adhesive force of the block bar magnets is significantly enlarged by the steel shell, meantime the block bar magnets are protected by the steel shell and avoid being damaged.

U-channel holding magnets are especially suitable for carpentry, kitchen installations, exhibition stand construction, shopfitting, signage technology, etc,and used as rectangular base magnets. To make it easy to be mounting, the u-channel holding magnets are made with one or two countersunk holes for screws according to the length. Usually, neodymium block bar magnets with countersunk holes and ferrite(ceramic) block bar magnets are used to assemble U-shaped screw-on holding magnets(magnetic holder). The neodymium channel magnets are for heavy-duty application, and the ferrite channel magnets are for lighter-duty application. Choose it according to your application to save unnecessary costs. Channel magnets can be used in both indoor & outdoor applications, the wholesale magnetic assembly is ideal for industrial & consumer mounting holding & fixing applications where high-magnetic strength is required.

The Application Of U/C Ferrite Channel Magnets

Neodymium(ferrite) U-channel screw-on magnets are mainly used for holding or mounting heavy-duty applications.

neodymium (ferrite)U/C channel magnets commonly used a magnetic tools holder in repair factory of the automobile industry.

Neodymium(ferrite) U/C channel magnets can be used as magnetic door catcher

neodymium(ferrite) U/C channel magnets can be used as magnetic vehicle license plate holders

neodymium(ferrite) U/C channel magnets can be used as magnetic blueprint holders

Neodymium(ferrite) U/C channel magnets can be used as magnetic sign and banner holders

0 notes

Link

Adhesive-backed neodymium magnets (neodymium magnets with adhesive backing) are just thin magnets with 3M self-adhesive on one of the magnetic poles. The adhesive layer is a 3M adhesive with a peel-away backing strip that can simply remove the shield backing and press the neodymium magnet with the adhesive onto the object you like to paste.Adhesive-backed neodymium magnets are not only used in packaging, arts and crafts industry but also used for office and home.

Two Types of Self-adhesive Backed Neodymium Magnets Are Supplied by Beilun Meank:

According to the adhesive type, film adhesive magnets and foam adhesive magnets are widely used.

Film self-adhesive backed neodymium magnets: adhered to all the same types of materials but is thinner, better suited for applications with specific space requirements. The pressure-sensitive adhesives form a permanent bond with most high surface energy materials, firmly securing the thin magnets to the objects.

Foam adhesive-backed rectangular magnets are suitable for the irregularities of rigid substrates and adhere the magnets to various materials, including wood, plastic, ceramic, rock, and so on.

Both foam adhesive-backed neodymium magnets and film adhesive-backed neodymium magnets can be supplied by Beilun Meank.

Application Methods of Neodymium Adhesive Backed Rare Earth Magnets

If the round magnet discs with adhesive backing are used to attract to a steel surface(we can supply steel plates with an adhesive), you can use either north or south pole. They are equal in magnetic force. Meank magnetic's heavy-duty magnets with adhesive backing are well approved all over the world.

3M-adhesive backing magnets and adhesive-backed disc magnets are available for either the north pole or the south pole. If you want to use 2 pieces of adhesive-backed block magnets together, for example, to close a cardboard folder, the magnetic poles need to be opposed and let north-pole and south-pole face each other to attract.

Features of Meank Magnetics's Magnetic Discs with Adhesive Backing

Our adhesive-backed rare earth magnets are with high quality 3M adhesive for the best adhesion;

Our adhesive-backed rare earth magnets are with quick release tab for fast and effective liner removal;

Our rare earth NdFeB magnets with adhesive made with high-performance neodymium magnets;

The best packing ways for all self-adhesive-backed neodymium magnets.

0 notes

Link

We(Ningbo Beilun Meank Magnetics Co., Ltd) manufacture all kinds of magnetic products(known as customised magnetic assemblies or magnetic systems). Product series involves types of neodymium magnets cup(pot) for mounting and holding, ferrite cup(pot) magnets for mounting and holding, rubber-coated magnetic bases for mounting and holding, magnetic hooks(hook magnets), channel magnets(magnetic tool holders) and office magnets(including whiteboard magnets, magnetic pins, magnetic name badges), salvage magnets for sale. These magnetic products can meet many fields of application in production and life(such as holding&clamping applications,salvaging&lifting applications, installation&mounting applications, hooking&organizing applications). As a mounting magnet factory, we not only manufacture standard magnetic products for worldwide users and distributors but also manufacture customized magnetic assembly products.

Different Types of Custom Magnetics

Rare Earth Neodymium Magnets

Rare earth magnets have higher energy products and known as strong magnets or powerful magnets. As the third generation rare earth magnet,neodymium magnet,also known as NdFeB magnet, is a tetragonal cr...

Rare Earth Neodymium Magnets

Rare earth magnets have higher energy products and known as strong magnets or powerful magnets. As the third generation rare earth magnet,neodymium magnet,also known as NdFeB magnet, is a tetragonal cr...

Waterproof Magnets

As rare earth strong magnet material, sintered NdFeB(neodymium) magnet is widely used in various fields because of its excellent magnetic properties. But NdFeB(neodymium) magnets are not waterproof or...

Rare Earth SmCo Magnets

Rare earth samarium-cobalt magnet(shorted as SmCo magnet)is a kind of high temperature resistant rare earth magnet. It is a kind of functional magnetic material made of samarium, cobalt and other metal rare earth materials by mixing, ...

Rubber Magnets

Flexible rubber magnet belongs to ferrite magnetic material series,and known as ferrite flexible rubber magnet. It is made of bonded ferrite magnetic powder and synthetic rubber by extrusion molding, ...

Neodymium Pot Magnets

Neodymium cup(pot) magnets have high magnetic energy and used for heavy-duty holding and mounting applications. They are known as neodymium mounting magnets or neodymium holding magnets.

Neodymium Fishing Magnets

Powerful fishing magnets(search magnets) are assembled with the strongest type of magnet -- rare earth magnets, they provide nice solution for fishing and lifting any metal objects form deep water, especial heavy ones. Fishing magnets are often used for industrial salvage in shipbuilding plants.

Rubber Coated Mounting Magnets

Mounting magnets(also known as magnetic bases) are powerful magnets assemblies composed of neodymium magnets and iron cups(iron plates), some mounting magnets are made with rubber coated. Mounting magnets supply easy and quick installation solution when drilling hole is impossible.

Ferrite Pot Magnets

The cup (pot) magnet is a disc or ring shape ferrite magnet encapsulated in an iron cup or pot-type steel cup. Only one magnetized surface of the magnet is exposed and used. Ferrite pot magnets have low magnetic energy and nice corrosion resistance, they are used as magnetic bases for light objects.

Magnetic Hooks

Magnetic hooks(also called hook magnets) are magnet assemblies that have strong practicability, they provide a nice solution for hanging or organization, and can be used to hang anything from tools to equipment, they can be seen everywhere(for example home, shop, warehouse, office, and garage).

Office Magnets

Those small magnet assemblies are sometimes used as office magnets. Office magnets provide simple holding solutions which not need too strong magnetic force, such as common memo magnets and magnetic pins for paper holding. Office magnets are usually used on whiteboards or other notice boards.

Magnetic Holders

Magnetic holder(also called holding magnets) is a great design that provides magnetic solutions for storage and organizing.Different kinds of magnetic holders...

U/C Channel Magnets

U-channel magnets assembly (also called C-channel magnets) are used as a magnetic tool bar(magnetic tools holder) for storage and organization application, they are widely used in the auto repair workshop. Standard channel magnets include neodymium channel magnets and ferrite channel magnets.

The Reason Why Choose Beilun Meank

Meank Magnetics, which is a wholesale pot magnet factory, professional manufacture customised magnetic assemblies for applications of clamping, mounting, lifting, hanging and holding. High quality customizes the following products: mounting pot magnets(include internally threaded pot magnets and externally threaded pot magnets), male and female threaded rubber coated pot magnets, all kinds of big magnetic hooks,salvage and fishing magnets ,magnetic tools and office magnets.

Magnet Application

Holding & Fixing

Salvaging & Lifting

Installation & Mounting

Hooking & Hanging

For retail, we have high quality standard magnets assemblies with wide selection range for sale at cheap price(include mounting pot magnets, magnetic hooks, fishing magnets, magnetic bases and office magnets); For special applications, we can quickly provide the best magnetic application solutions.

0 notes

Link

Types of magnet coatings for neodymium rare earth magnets, and the characteristic of each coating

NiCuNi coating: The nickel coating of nicuni plated magnets is composed of three layers, nickel-copper-nickel. This type of coating is the most widely used and provides protection against corrosion of the neodymium magnet in outdoor situations. Processing costs are low. The maximum working temperature of the coating is approximately 220-240ºC (depending on the maximum working temperature of the magnet). The powerful ndfeb magnet with NiCuNi coating are used in engines, generators, medical devices, sensors, automotive applications, retention, thin film deposition processes and pumps.

Black nickel: The properties of this coating are similar to those of the nickel coating, with the difference that an additional process is generated, the black nickel assembly. Properties are similar to those of conventional nickel plating; with the particularity that this coating is used in applications that require that the visual aspect of the piece is not bright.

Gold: This type of coating is often used in the medical field and is also suitable for use in contact with the human body. There is approval from the FDA (Food and Drug Administration). Under the gold coating, there is a sub-layer of Ni-Cu-Ni. The maximum working temperature is also about 200 ° C. In addition to the field of medicine, neodymium magnets with gold plating are also used for jewellery and decorative purposes.

Zinc: If the maximum working temperature is less than 120 ° C, this type of coating is adequate. The costs are lower and the magnet is protected against corrosion in the open air. It can be glued to steel, although a specially developed adhesive must be used. The channel magnet assembly zinc coated is suitably provided that the protective barriers for the magnet are low and low working temperatures prevail.

Parylene: This coating is also approved by the FDA. Therefore, neodymium magnets with parylene coating are used for medical applications in the human body. The maximum working temperature is approximately 150 ° C. The molecular structure consists of ring-shaped hydrocarbon compounds consisting of H, Cl and F. Depending on the molecular structure, different types are distinguished as: Parylene N, Parylene C, Parylene D and Parylene HT.

Epoxy: A coating that provides an excellent barrier against salt and water. There is very good adhesion to steel if the magnet is glued with a special adhesive suitable for magnets. The maximum working temperature is approximately 150 ° C. The epoxy magnet coatings are usually black, but they can also be white. Applications of epoxy neodymium magnets can be found in the maritime sector, engines, sensors, consumer goods and the automotive sector.

Plastic:Magnets injected in plastic. or also called over-moulded. Its main characteristic is its excellent protection of the magnet against breakage, impacts and corrosion. The protective layer provides protection against water and salt. The maximum working temperature depends on the plastic used (acrylonitrile-butadiene-styrene).

PTFE (Teflon): Like the injected / plastic coating also provides excellent protection of the magnet against breakage, impacts and corrosion. The rare earth neodymium magnet is protected against moisture, water and salt. The maximum working temperature is around 250 ° C. The PTFE coated magnets are mainly used in the medical industries and in the food industry.

Rubber: The rubber coating protects perfectly from breakage and impacts and minimizes corrosion. The rubber material produces very good slip resistance on steel surfaces. The maximum working temperature is around 80-100 ° C. The rubber coated mounting magnets is the most obvious and widely used rubber coated magnetic product.

Rhodium: Rhodium coatings give the magnet very good resistance to scratches and tarnish. The magnet is also protected against corrosion. In addition, the rhodium coating gives the magnet a very decorative appearance. The maximum working temperature is around 200°C. Rhodium coatings are used for jewelry, medicine and the automotive industry.

Titanium Nitrate (TIN): Is also a coating approved by the FDA and is suitable for use in applications in contact with the human body. It is formed by a hard layer with a very strong bond to the magnet. In addition, it provides resistance to most chemicals. The maximum working temperature is approximately 500 ° C and its main use is in the medicines sector.

Copper / Chrome / Silver: The neodymium magnets with these type of coating are mainly used for decorative purposes. The maximum working temperature is around 200°C.

0 notes

Link

Safety is important for you and us. Please read carefully the following safety information before operating neodymium magnets. And also share the safety tips with your employees, customers and other people who will contact neodymium magnets. The neodymium magnets safety tips are also suitable for SmCo magnets and ferrite magnets.

Swallowing

Small magnets could be swallowed by children.

Magnets are not toys! If several magnets are swallowed, they could get stuck in the intestine and cause perilous complications. Make sure that children don't play with magnets.

Electrical conductivity

Magnets are made of metal and conduct electricity.

Magnets are not toys! Make sure that children don't play with magnets. Children might try to put magnets into a power outlet and thereby suffer from an electric shock.

Contusions

Big magnets have a very strong attractive force.

· Unsafe handling could cause jamming of fingers or skin in between big neodymium magnets. This may lead to contusions and bruises.

· Powerful, very large neodymium magnets could cause bone fractures. Wear heavy protective gloves when handling larger neodymium magnets.

Pacemaker

The functioning of pacemakers and implanted heart defibrillators could be affected by neodymium magnets

· A pacemaker could switch into test mode and cause illness.

· A heart defibrillator may stop working.

· If you wear these devices keep sufficient distance to neodymium strong magnets.

· Warn others who wear these devices from getting too close to strong neodymium magnets.

Heavy objects

Too heavy loads, symptoms of fatigue as well as material defect could cause a magnet or magnetic hook to loosen from the surface where it was attached to.

Falling objects could lead to serious injuries.

· The indicated holding force of a magnet applies only to ideal conditions. Allow for a high safety cushion.

· Don't use magnets in the places where people could sustain injuries in case of material failure.

Metal splinters

Rare earth magnets are brittle. Colliding rare earth magnets could crack.

Sharp splinters could be catapulted away for several meters and injure your eyes.

· Avoid the collision of rare earth neodymium & SmCo magnets.

· Wear safety glasses when handling larger rare earth magnets.

· Make sure that nearby people are also protected or keep their distance.

Magnetic field

Magnets produce a far-reaching, strong magnetic field. They could damage TVs and laptops, computer hard drives, credit and ATM cards, data storage media, mechanical watches, hearing aids and speakers.

· The devices and objects that could be damaged by strong magnetic fields should be kept away from magnets

Combustibility

When machining rare earth magnets, the drilling dust could easily ignite.

Stay away from machining magnets or use appropriate tools and sufficient cooling water.

Nickel allergy

Most of the neodymium magnets contain nickel, even those without nickel coating.

· Some people have an allergic reaction when they come into contact with nickel.

· Nickel allergies could develop from perpetual contact with nickel-plated objects.

· Avoid perpetual skin contact with nickel coated neodymium magnets.

· Avoid contact with nickel coated magnets if you already have a nickel allergy.

Airfreight

Magnetic fields of improperly packaged magnets could influence airplane navigation devices.

In the worst case it could lead to an accident.

· Airfreight magnets only in packaging with sufficient magnetic shielding.

· Please refer to the respective regulations for shipping magnets by air

Postage

Magnetic fields of improperly packaged magnets could cause disturbances in sorting machines and damage fragile goods in other packages.

· Please refer to our shipping tips.

· Use a large box and place the magnet in the middle surrounded by lots of padding material.

· Arrange magnets in a package in a way that the magnetic fields neutralise each other.

· If necessary, use iron sheets to shield the magnetic field.

· There are stricter rules for airfreight: Refer to the neodymium magnet warning notice "Airfreight".

Influence on people

According to the current level of knowledge, magnetic fields of permanent magnets do not have a measurable positive or negative influence on people. It is unlikely that permanent magnets constitute a health risk, but it cannot be ruled out entirely.

· For your own safety, avoid constant contact with strong magnets.

· Store large magnets at least one metre away from your body.

Oxidation, corrosion, rust

neodymium magnets without coating oxidize quickly and disintegrate.

Most of rare earth neodymium magnets have a nickel-copper-nickel coating to protect them from corrosion. This coating provides some protection against corrosion, but it is not robust enough for continuous outdoor use.

· Use magnets only in the dry indoors or protect them against environmental influences.

· Avoid damages to the coating of neodymium magnets.

Temperature resistance

Rare earth neodymium magnets have a maximum working temperature of 80 to 200°C.

Most neodymium magnets lose part of their adhesive force permanently at a temperature of 80°C.

· Don't use neodymium magnets in places where they are exposed to extreme heat.

· If you use an adhesive, don't harden it with hot air.

Mechanical treatment

Neodymium magnets are brittle, heat-sensitive and oxidize easily.

· When drilling or sawing a neodymium magnet with improper tools, the magnet may break.

· The emerging heat may demagnetize the neodymium magnets.

· The neodymium magnet will oxidize and disintegrate due to the damaged coating.

Avoid machining neodymium magnets if you do not have the necessary machines and experience. Let us provide you with an offer for a custom-made neodymium magnets instead.

0 notes

Link

Can I make a magnet that I already have any stronger?

Once a magnet is fully magnetized, you can not make it any stronger - it is "saturated". In that sense, magnets are like buckets of water: once they are full, they can't get any "fuller"

How do you measure the strength of a magnet?

Most commonly, Gaussmeters, Magnetometers, or Pull-Testers are used to measure the strength of a magnet. Gaussmeters measure the strength in Gauss, Magnetometers measure in Gauss or arbitrary units (so it's easy to compare one magnet to another), and Pull-Testers can measure pull in pounds, kilograms, or other force units. Special Gaussmeters can cost several thousands of dollars. We stock several types of Gaussmeters that cost between $400 and $1,500 each.

What is a permanent magnet?

Modern permanent magnets are made of special alloys that have been found through research to create increasingly better magnets. Permanent magnets have a magnetic field that does not turn on and off like electromagnets. Permanent magnets are often used for motors, generators, televisions, etc. The most common families of magnet materials today are ones made out of Aluminum-Nickel-Cobalt, Strontium-Iron (Ferrites, also known as ceramic), Neodymium-Iron-Boron (sometimes referred to as "strong magnets"), and Samarium Cobalt. The Samarium Cobalt and Neodymium Iron Boron families are collectively known as Rare Earth magnets.

Are neodymium magnets waterproof?

No, they are not waterproof if neodymium magnets are typically coated with nickel, zinc or epoxy to protect them against rust and corrosion from moisture.

Neodymium magnets will work wet or submerged for a short period. Any water penetration into the magnet, however, will cause a slow deterioration of the magnet’s magnetic field and cause rust to leak from even the most microscopic scratch or aberration in the magnet’s outer coating.

If you are looking for waterproof neodymium magnets for super strength, please check out our plastic coated neodymium magnets or rubber coated neodymium magnets. These magnets are encased in a waterproof coating that protects them from moisture.

What are the most common applications of neodymium rare earth magnets

The most common places you’ll find neodymium rare earth magnets include:

• Retail signs and counter displays.

• Trade show booths and staging structures.

• Leather purses, bags, garments, and holsters.

• Custom boxes for premium products.

• Presentation folders and scrapbooks.

• Arts, crafts, and jewelry.

• Wood doors and cabinets as door latches.

• Health bracelets, bandages, and other medical devices.

• Window coverings and blinds.

• Magnetic resonance imaging (MRI) devices.

• Audio speakers.

• Vacuum cleaners and other motorized household appliances.

• Bicycle dynamos.

• Computer hard drives.

• Wind turbine generators.

• Fishing reel brakes.

• Permanent magnet motors in cordless tools.

• High-performance AC servo motors.

• Traction motors.

• Integrated starter-generators in hybrid and electric vehicles.

• Mechanically powered flashlights, which use magnets to generate electricity from a shaking motion.

• Industrial, educational, scientific and testing/quality control applications such as verifying and maintaining product purity and equipment protection and integrity.

• Linear motors used in mag-lev trains and other motorized model equipment.

• Scientific applications such as diamagnetic levitation experimentation, the study of magnetic field dynamics and superconductor levitation.

• Electro-dynamic bearings.

• Roller coaster and other thrill ride technology.

• Magnet toys.

• Electric guitar pickups.

• Miniature figures and models.

How do permanent magnets work?

All permanent magnets work because of their unique atomic structure. Unlike all other objects, the atoms within magnets are all spinning in the same direction. This atomic flow inside of each permanent magnet creates an invisible magnetic force or field around the magnet that can attract or repel other magnets – and attract other metal objects.

In addition, all permanent magnets have a north and south pole on opposite sides of the magnet. The north pole of a magnet points roughly toward earth's north pole and vice-versa.

In terms of functionality, the common saying is: like poles repel, unlike poles attract.

Why are most neodymium magnets plated or coated?

In order to preserve and protect the lasting performance of each magnet’s magnetic field, most neodymium magnets are plated or coated.Neodymium magnets are mainly composed of neodymium, iron, and boron. If they are not plated, the iron in the material will oxidize, particularly if exposed to moisture. Even normal humidity will rust any iron over time.

Nickel is the most common choice, as it is durable and cost-effective. All our neodymium magnets are coated with a triple layers of nickel/copper/nickel. This creates a shiny silver finish and provides dependable resistance to corrosion in most applications.

If you are interested in different coating options, contact us for more information on coating.

Why are neodymium magnets considered to be the strongest magnets on earth?

Developed by physicists during the 1970s, neodymium magnets are considered to be the strongest permanent magnets in existence. This is because they create the highest magnetic field per size and volume of any other known natural or manufactured material.

The magnetic field typically produced by rare earth neodymium magnets can be in excess of 1.4 Teslas, whereas all other magnets normally generate fields of 0.5 to 1 Tesla.

And not only are neodymium magnets the most powerful magnets on the planet, they are also the most affordable type of rare earth magnet available today.

What does the N rating on neodymium magnets mean?

The magnet grade or N rating refers to the Maximum Energy Product of the material that the magnet is made from and it refers to the maximum strength that the material can be magnetized to permanently hold.

Generally speaking, neodymium magnets range from the grade of N35 to N52. The higher the grade number, the incrementally stronger the magnet will be.

The highest grades of neodymium magnets that we normally carry is N52 neodymium magnet, a rating that is generally measured in Tesla metrics or units of Gauss Oersted (MGOe).

A magnet of grade N42 has a Maximum Energy Product of Gauss 42 MGOe, while an N52, at 52 MGOe would be incrementally stronger.

Will neodymium magnets lose their strength over time?

Very little. If they are properly handled, which includes not overheated or physically damaged, our neodymium magnets will lose less than 1 percent of their strength over 10 years. This is not enough to notice without very sensitive measuring equipment. In addition, the neodymium magnets we offer will not lose their strength even if they are held in repelling or attracting positions with other magnets over long periods of time.

Will stacking magnets together make them stronger?

Yes, stacking multiple magnets together can make them stronger. Two or more magnets stacked together will exhibit nearly the same strength as a single magnet of the combined size. For example, if you stacked two 1/2 x 1/4 inch thick disc magnets to make a 1/2 x 1/2 inch combined size, the two magnets would have nearly same strength as a single 1/2 x 1/2 inch magnet.

How do magnetic flux lines behave?

The general answer is "Predictably"! Magnetic lines are three-dimensional, surrounding a bar magnet on all sides.

Likepoles repel and unlike poles attract. When opposite poles of two magnets are brought together, the magnetic force lines join up and the two magnets pull together.

When like poles of two magnets are brought together, the magnetic force lines push away from each other and the two magnets repel each other.

What is pot magnet?

A pot magnet comes from the structure of a magnet assembly, a permanent magnet housed with a steel shell is called a pot magnet(also known as cup magnets and mounting magnets, only one magnetic surface used.

Which kinds of permanent magnets can be used for pot magnets?

All the neodymium, Samarium-Cobalt, ferrite, and AlNiCo magnets can be used to make pot magnets, but the most widely used types are neodymium pot magnets and ferrite pot magnets.

What functions does the iron shell have on the pot magnet?

The iron shell from a pot magnet has three main functions:

It protects the magnet.

It guides the magnetic line and enlarges the magnetic force.

It's easy to weld fastening parts (for example internal & external threaded stud) on it.

What are the advantages of rubber coated pot magnet compared with ordinary iron shell covered pot magnet?

Rubber-coated pot magnets have better waterproof and corrosion resistance ability than iron-shell pot magnets.

The contact surface can be protected by using rubber-coated pot magnets.

How to maintain fishing magnets?

Wipe it clean immediately after use and let it dry as soon as possible, then seal it and store it in a dry and safe environment. Do not place fishing magnets where there is dust.

How to test the magnetic force of a fishing magnet?

With the special pull force testing equipment, at room temperature, the products are adsorbed on the smooth iron plate of 10 mm thickness, and the powerful fishing magnets are pulled upward at a uniform speed.

What is the maximum working temperature of NdFeB pot magnet?

The maximum working temperature of the NdFeB pot magnet depends on the brand of NdFeB magnet used, the highest working temperature of the common NdFeB pot magnet is only 80℃, but the maximum working temperature can reach 200℃.

How to make full use of the pull force of a cup magnet?

Let the direction of pulling force perpendicular to the working face of the cup magnet, the pulling force can reach the maximum.

Which factors will affect the force testing results of cup magnets?

Thickness and surface flatness of the adsorbed object.

Whether the magnet is in full contact with the adsorbed object.

The pulling speed or angle.

Under what conditions is the magnetic pull force of a cup magnet maximized?

When the direction of pulling force is perpendicular to the working face of the magnet, the pulling force of the cup magnet can reach the maximum.

What's the use of cup magnets?

Cup magnets are can be used to provide magnetic clamping solution, magnetic mounting solution, magnetic hanging solution, magnetic holding solution, magnetic salvaging solution, etc.

What is clamping magnet?

A clamping magnet is a magnetic assembly that used to clamp & hold objects, such as magnetic name badges, push pin magnets, memo magnet, some NdFeB cup magnets and Ferrite cup magnets also used as clamping magnets.

What are mounting magnets?

The magnetic assemblies used for mounting are known as mounting magnets, including neodymium mounting magnets and ferrite mounting magnets. Mounting magnets are usually with mounting holes or screwed mounting bush & threaded stem.

How can you know which is the North Pole of a magnet?

We can’t know by looking. We can tell you by placing a compass close to the magnet. The end of the needle that normally points toward the North Pole of the Earth would point to the South Pole of the magnet.

What are Magnetic Poles?

The surfaces from which the invisible lines of magnetic flux emanate and connect on return to the magnet are called magnetic poles.

Can magnets that have lost magnetism be re-magnetized?

Provided that the material has not been damaged by extreme heat, magnets can be re-magnetized back to original strength, if they have been exposed to conditions which cause them to become demagnetized.

What are Rare Earth Magnets?

The magnets that are made of the Rare Earth group of elements are known as rare earth magnets.Neodymium-Iron-Boron and Samarium-Cobalt magnets are the most common rare earth magnets.

What does magnetic pull force mean?

Every neodymium magnet has a pull force, which tells you exactly how powerful the magnet is. Magnetic pull force is measured in pounds or kilograms, the pull force is the force needed to pull that magnet straight free from a 1/8 inch (3.175 mm) thick steel plate. The pull force also tells you the limit on the holding power of the magnet.

Generally, any magnet with a magnetic pull force above seven pounds (3.175 kg) can pinch your fingers. Strong neodymium magnets can be even more dangerous and should only be handled by experienced individuals.

How are finished neodymium magnets made?

Neodymium magnets, also known as NIB or NdFeB magnets, are comprised of neodymium, iron, and boron compound referred to as Nd2Fe14B.

This compound is a powdered mixture. It is first poured, then pressed (using extreme pressure) into specially-cast molds. The compound is then sintered (heated under a vacuum), cooled, then ground or sliced into the desired shape. It's not finished neodymium magnet until this step.

Next, the magnets are dipped in a specified coating material such as zinc, gold, or triple-layer nickel/copper/nickel alloy plating. Now it is finished with neodymium magnets

Finally, the finished magnets are magnetized by exposing them to an extremely strong magnetic field. This final step is what turns neodymium magnets into permanent magnets, enabling them to perpetually produce their powerful magnetic pull or repel strength.

What are neodymium magnets?

Neodymium rare earth magnets are made with neodymium, iron, and boron. They are up to 10 times stronger than all other ferrite, ceramic, or alnico magnets of equal size. They are considered to be the strongest magnets on earth.

What does "magnetized through thickness" mean?

We use the description "magnetized through thickness" to identify the locations of the poles on block magnets. Thickness is always the last listed dimension and is also usually the smallest size.

For most of thickness magnetized block magnets, it’s means that the magnets stick or repel in the middle, on the large flat surfaces, rather than at the end of the block.

Are the countersunk and self-adhesive magnets paired equally north/south magnetized?

Most of our countersunk and self adhesive magnets come in equally paired magnetized, which enable you to use them as attachments to other magnets if desired.

For pairing with steel discs or other plates, the north/south orientation of the countersunk hole or adhesive tape is not an issue as both the north and south poles will be equally attracted to steel surfaces.

What does

That means that the poles of the magnet will be on the large flat surfaces of disc and cylinder magnets rather than the side. Most of our round disc magnets and rare earth cylinder magnets are labelled as axially magnetized because the magnetization direction is through the axis of the magnet.

What materials do neodymium magnets attract?

Neodymium magnets only attract ferromagnetic materials. The most commonly available and attracted elements are iron (Fe), nickel (Ni), and cobalt (Co). Steel is also very susceptible or attracted to a magnetic field because it is ferromagnetic as an alloy of iron and other metals.

Is one pole of a magnet stronger than the other pole?

No, both poles of a magnet have the same magnetic strength.

How to correctly use self-adhesive magnets?

Self-adhesive magnets enable you to attach the magnet to a non-magnetic surface, such as aluminum, wood, plastic, ceramic, rubber, paper, and other non-ferrous materials.

Normally, self-adhesive magnets come in packs with half self-adhesive on the north side, and half with the self adhesive on the south side. This enables them to attract if needed to form a closure or fastener.

We have foam adhesive magnets for sale. This high-performance adhesive delivers excellent shear strength to resist slippage and edge-lifting.

Simply peel the paper off the adhesive and stick it in position. You can quickly re-adjust it because the strong adhesive is temporarily repositionable. This helps you accurately adjust and position the magnet to your exact specifications.

Once the magnet is in position, press firmly so that the underside adheres evenly. We recommend that you let the adhesive cure for 24 – 48 hours before putting any stress on the bond.

What does "magnetic orientation direction" mean?

Most modern magnet materials have a "grain" in that they can be magnetized for maximum effect only through one direction. This is the "orientation direction", also known as the "easy axis", or "axis"

Un-oriented magnets (also known as "Isotropic magnets") are much weaker than oriented magnets, and can be magnetized in any direction. Oriented magnets (also known as "Anisotropic magnets") are not the same in every direction - they have a preferred direction in which they should be magnetized.

What are magnetic assemblies?

Magnetic assemblies consists of one or more magnets, and other components, such as steel, that generally affect the functioning of the magnet.Pot magnets,hook magnets,channel magnets and rubber coated mounting magnets are magnetic assemblies.

0 notes

Text

Magnetic Eyelet Hooks

https://www.magnetic-holders.com/products/magnetic-eyelet-hooks.html

The magnetic eyelet hooks are composed of internally threaded neodymium cup magnets and a closed hook(also called an eyelet hook). Neodymium magnetic eyelet&closed hooks are widely used for heavy-duty hanging and fishing.

Summary Of Neodymium Magnetic Eyelet Hook:

Component Material: neodymium disc magnets + A3 steel cup + ABS plastic ring or epoxy glue+eyelet hook

Available Surface Treatment: Nickel, Zinc, spray colorful plastic

Standard Size: diameter-- 16mm, 20mm, 25mm, 32mm,36mm,42mm,48mm,60mm,75mm

Magnetic Grade:N35, N38, N40, N42, N45,N48,N50,N52

Working Temp.: -40 to 80℃(for standard ones), the pot magnets with eyelet for higher working temperature can be customized

Size/ Parameter For Neodymium Magnetic Eyelet Or Closed Hook

Item Code

D(mm)

h(mm)

H(mm)

d(mm)

M

Weight(g)

Magnetic Force(Kg)

PM-E-D16

16

5

13

6

M4

12

5.5

PM-E-D20

20

7

15

8

M4

21

9

PM-E-D25

25

8

17

10

M5

33

22

PM-E-D32

32

8

18

10

M6

53

34

PM-E-D36

36

8

18

10

M6

65

41

PM-E-D42

42

9

20

12

M8

91

68

PM-E-D48

48

11.5

24

12

M8

146

81

PM-E-D60

60

15

30

14

M8

315

113

PM-E-D75

75

18

34

16

M10

625

164

Notice: The neodymium magnet is common with a nickel coating, and with the grade of N35, please let us know ahead for different requirements.

0 notes

Text

Magnetic Carabiner Hooks

https://www.magnetic-holders.com/products/magnetic-carabiner-hooks.html

The neodymium cup magnets carabiner hook is called magnetic carabiner hooks. Carabiner hooks have a locking function, by using a magnetic carabiner hook, the angle can be adjusted arbitrarily according to the actual needs, while hanging objects will not fall off. It's a type of very useful magnetic hooks for ceiling and wall.

Parameters of Magnetic Carabiner Hooks

Model

D(mm)

H1(mm)

H2(mm)

Weight(g)

Force(kg)

MCH-25

25

8

17.5

30

17

MCH-32

32

8

17.5

47

28

MCH-36

36

8

17.5

59

35

0 notes