#assemblies

Text

"life doesnt get better, you just get stronger" does NOT include ages 11-17. life does in fact just get better from there. those years are dogshit. like, you do get stronger but its mostly just a factor of not being 11-17 anymore. positive thinking helps but it doesnt fix whatevers going on at 15, you have to brute force through that one raw

#i originally posted this as just a 'hey remember how fuckin bad middle/highschool was? shit was wild' type post but now#there are a bunch of teens in the notes being like 'oh my god are you serious? it gets better? im not stuck in hell forever??'#and im reminded that the only people who told teenage ella 'it gets better' were speakers at mental health assemblies#aka the least relatable people alive who were seemingly born to lie to you#so. uh. yeah im a certified adult who isnt here to lie or sugarcoat the realities of being a teenager#the only thing more certain than the pain is the transcience

43K notes

·

View notes

Text

#free palestine#palestine#free gaza#freepalastine🇵🇸#current events#social justice#feminist#united nations#palestine will be free#breaking news#current news#politics#gaza news#gaza strip#gaza under siege#gaza genocide#general assembly#palestine is a country

41K notes

·

View notes

Text

- Left-wing deputies of the newly formed French parliament refusing to shake hand with the member of the far-right tasked with guarding the ballot

#LFI deputies you'll always be my guys I love you#the way it maybe isnt even top 10 best thing they did in this assembly#politics#france#french politics#video#oli schist!

19K notes

·

View notes

Text

#automotive & non automotive#automotive heavy vehicle & farm equipment parts#cold drawn seamless tubes#srb / honed hydraulic cylinder tubes & sub#assemblies#transformer - radiator butterfly valves#stainless steel welded tubes#submersible pump parts#textile machinery tubes & parts

0 notes

Text

The Worship Was Delayed And Nobody Cared!

Neal Pollard

I have never been a part of a service like last night. C.J. and Walter Moore met to study the Bible an hour before evening worship. At the end of the study, they knew they needed to obey the gospel. They did not want to wait. Their mom, Shannon Anthony, had also been studying and was ready to be baptized. This sweet family was ready, together, to be united with Christ. So, we asked…

View On WordPress

0 notes

Text

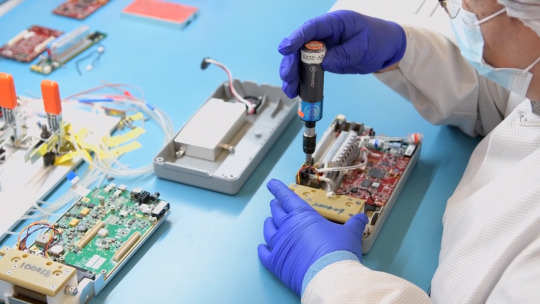

Designing Custom Sensor Assemblies: A Step-by-Step Guide

Designing sensor and assembling it is hard, such a one is custom reed sensors designing which can be a complex but rewarding process. Custom sensor assemblies are essential for applications requiring specific measurements or conditions that off-the-shelf sensors cannot meet. This guide will walk you through the step-by-step process of designing custom sensor assemblies, from initial concept to final implementation.

Sensor Designing Process

Step 1: Define the Requirements

Overview

The first step in designing a custom sensor assembly is to clearly define your requirements. This involves understanding the specific needs of your application, including the type of measurement, environmental conditions, and performance criteria.

Key Considerations

Measurement Type: Determine what physical property you need to measure (e.g., temperature, pressure, position).

Environmental Conditions: Consider factors such as temperature ranges, humidity, and exposure to chemicals or vibrations.

Performance Criteria: Define accuracy, response time, and sensitivity requirements.

Stats and Facts

Market Demand: The global sensor market, including custom assemblies, is expected to grow from $162 billion in 2020 to $345 billion by 2026, reflecting a CAGR of 13.3%.

Customization: Custom sensor assemblies account for approximately 15% of the total sensor market, driven by specific application needs.

Step 2: Select the Sensor Technology

Overview

Based on the requirements, choose the appropriate sensor technology. Common types include reed switches, Hall effect sensors, thermocouples, and strain gauges. Each technology has its advantages and is suited to different applications.

Sensor Technologies

Reed Switches: Ideal for applications where simple, reliable, and low-power sensing is required.

Hall Effect Sensors: Suitable for non-contact measurement of magnetic fields and rotation.

Thermocouples: Used for high-temperature measurements with wide range and durability.

Strain Gauges: Applied in measuring force, pressure, and strain.

Stats and Facts

Reed Switch Market: The reed switch market is projected to grow from $240 million in 2020 to $450 million by 2027.

Hall Effect Sensors: The global Hall effect sensor market was valued at $2.5 billion in 2020, with expectations to reach $4.2 billion by 2027.

Step 3: Design the Sensor Assembly

Overview

Once the sensor technology is selected, design the sensor assembly. This includes creating a detailed design that integrates the chosen sensors with the necessary electronic components and enclosures.

Design Components

Sensor Placement: Position sensors optimally to ensure accurate measurement.

Circuit Design: Develop the necessary circuitry to interface with the sensors and process the signals.

Enclosure Design: Create a protective enclosure that shields the sensors from environmental factors and physical damage.

Stats and Facts

Design Complexity: Custom sensor assemblies often involve advanced design tools and simulations, with approximately 20% of sensor design budgets allocated to prototyping and testing.

Simulation: Over 60% of sensor manufacturers use advanced simulation tools to validate designs before physical prototyping.

Step 4: Prototype and Test

Overview

Develop prototypes of the custom sensor assembly and conduct thorough testing. This phase is crucial for identifying any issues and ensuring the design meets the required specifications.

Testing Phases

Functional Testing: Verify that the sensor assembly performs its intended function accurately.

Environmental Testing: Test the assembly under various environmental conditions to ensure durability and reliability.

Performance Testing: Assess the assembly's performance against defined criteria such as accuracy and response time.

Stats and Facts

Prototyping Costs: Prototyping can account for up to 30% of the total development cost for custom sensor assemblies.

Testing Importance: 90% of sensor failures can be traced back to inadequate testing during the prototype phase.

Step 5: Manufacture and Deploy

Overview

Once testing is complete and the design is finalized, proceed with manufacturing and deployment. This involves scaling up production and integrating the sensor assemblies into the final application.

Manufacturing Considerations

Quality Control: Implement strict quality control measures to ensure consistency and reliability.

Scalability: Prepare for scaling up production to meet demand while maintaining high standards.

Integration: Ensure seamless integration of the sensor assemblies into the end application.

Stats and Facts

Manufacturing Scale: The manufacturing process for sensor assemblies can vary from small-batch to mass production, depending on application needs.

Integration Success: Successful integration is critical, with over 80% of sensor-related issues arising from poor integration practices.

Step 6: Monitor and Iterate

Overview

After deployment, continuously monitor the performance of the sensor assemblies and gather feedback. Use this information to make iterative improvements and ensure long-term success.

Monitoring Strategies

Performance Tracking: Regularly track the performance and reliability of the sensor assemblies.

Feedback Collection: Collect feedback from users and stakeholders to identify areas for improvement.

Continuous Improvement: Implement iterative improvements based on monitoring results and feedback.

Stats and Facts

Continuous Improvement: Companies that focus on continuous improvement see a 25% increase in sensor assembly performance and reliability.

Feedback Utilization: 70% of successful sensor designs incorporate user feedback to refine and enhance performance.

Conclusion

Designing custom sensor assemblies involves a comprehensive process of defining requirements, selecting sensor technology, designing the assembly, prototyping, manufacturing, and monitoring. By following these steps, you can create effective and reliable sensor solutions tailored to your specific needs.

Additional Stats and Facts:

Market Growth: The custom sensor assembly market is expanding rapidly, driven by advancements in technology and increasing demand for tailored solutions.

Innovation Impact: Innovations in sensor technology are expected to drive continued growth and improvements in custom sensor assemblies.

By carefully managing each step of the design process, you can ensure that your custom sensor assemblies meet performance expectations and provide valuable insights for your applications.

0 notes

Text

Improv in Action: Practical Tips for Teachers to Bring the Fun (and Learning) Back to School

In our last post, we explored the amazing benefits of improv training for teachers. Now, let’s dive into the practical side of things: how can you actually use improv in your classroom? And how does it relate to social-emotional learning (SEL) and the power of laughter?

Improv Games & Activities for the Classroom

Shows, workshops, residencies and professional development programming for K12…

View On WordPress

#assemblies#broadway#club#comedy#DOE VENDOR#Field Trips#improv#interactive#kids#new york#nyc#professional development#schools#sel#Social Emotional Learning#students#teachers#teens#times square

0 notes

Text

Distinguish a Top-Quality Surgical Implant Device Manufacturer

Surgical implant devices are a significant segment of the medical devices industry. These devices have a direct bearing on patients who undergo surgery. So, clinics should choose a competent surgical implant device manufacturer for the safety of their patients and efficiency in surgery.

A good idea for healthcare service providers is to learn about the fundamental attributes of a quality manufacturer. That way, they can choose a quality manufacturer, ensuring safe, reliable, and effective devices.

Advanced Technology

Technology is the primary aspect of consideration for a surgical implant device manufacturer. Usually, top-notch manufacturers use advanced technologies to create customized implants to suit different patient needs. Nowadays, factories deploy robots that help them to increase precision in implant production.

Implementation of advanced technologies can help in building improved products.

Quality Assurance

A reliable quality assurance system is essential for any manufacturer dealing in surgical implant devices. The company should ensure quality at every stage of production. In addition, the manufacturer should use quality raw materials.

Moreover, a high-quality testing process is essential to ensure the finished products meet quality standards. With high-quality devices, healthcare service providers can ensure reliability and patient safety.

Material Selection

Manufacturers should use high-quality materials in building their surgical implant products. The importance of good material quality arises from the fact that such devices remain inside the patient's body for a long time. As such, low-quality materials could hamper the patient.

Companies should use biocompatible materials to prevent adverse reactions, such as inflammation.

Ideally, the manufacturers should use Titanium and ceramic variants. These are biocompatible and durable. Their research & development professionals should be experts in material science. That can help them choose safe and high-quality materials to manufacture devices.

Moreover, the companies should use advanced techniques, such as electromechanical & fluidic assemblies.

Scalability

The manufacturer should scale up without compromising on the quality of the devices. The expertise becomes essential when the demand for their products increases.

In addition, scalability can help the company to adjust to changes in regulatory standards or shifts in market demands. It can also allow the company to stay agile and maintain competitiveness.

Research & Development Capabilities

Research & development capabilities are essential for a competitive surgical implant device manufacturer. The proficiency renders a manufacturer innovative. As such, such a company can improve its existing products and develop new products to cater to emerging needs.

Furthermore, research and development capabilities help the manufacturers to remain in sync with the latest industry trends. And they can cater to the evolving needs of the healthcare sector.

Proven Track Record

A proven track record of manufacturing quality products can help establish its credibility as a reliable manufacturer. Case studies, clinical trial data, and the history of the products should indicate reliability and safety. That also builds trust in patients.

Customer-Centricity

Such device manufacturers should have customer-centric policies. They should understand the evolving customer needs. Also, the companies should provide excellent customer service and technical support apart from quickly solving customer queries.

Such initiatives indicate that the companies care for their patients. Hence they offer good quality products.

Transparency

As the industry deals with sensitive implants, the companies should practice transparency. In addition, they should ensure ethical business practices and transparency to customers. As such, they should disclose their clinical trials and protect patient data.

Conclusion

The main attributes of a quality surgical implant device manufacturer are advanced technological expertise, customer-centricity, transparency, and conformity with regulations.

A top-notch manufacturer demonstrates adherence to quality, innovation, and commitment to providing patients with the best devices.

This article will help distinguish a quality manufacturer.

0 notes

Text

Making a weighted velvet baikal seal plushie :3

Head and tail end are stuffed w ultra plush fiber fill and the bulk of the body is packed full of weighted pellets that have a nice crunchy sound when you squeeze it. Not weighed yet, but it feels between 1.5 - 2lbs?

#Creepy chatter#Crochet#Waiting on some fishing line to make whiskers before attaching the mouth#Next I need to make the front flippers and then assemble everything :3

68K notes

·

View notes

Text

In every English town, especially London, where the 'season' (April-November) featured parties and even ticketed assemblies for elite youth, communities organised meeting places and events to introduce the wealthy young people to each other.

"Normal Women: 900 Years of Making History" - Philippa Gregory

#book quote#normal women#philippa gregory#nonfiction#england#english#london#towns#season#april#may#june#july#august#september#october#november#parties#assemblies#elite#youth#communities#meeting place#introductions#wealthy

0 notes

Text

presents user-friendly, extremely versatile, ultra-compatible Portable Wireless Amplifiers. This portable, rechargeable PA speaker amplifier with Bluetooth is widely used as personal DJ system.

Explore More : www.5core.com/portable-wireless-amplifiers

#PortableAmplifier#PersonalDJ#BirthdayParty#yoga#YogaClasses#Gym#SportsEvents#Auction#TeachingRoom#PublicMeeting#OutdoorFun#Confrence#Parades#wedding#HouseMusic#HouseParty#BeachClub#Assemblies#SalesPromotion#PASystem#FiveCore

0 notes

Text

The cult of...Danny Fenton?

So! Way back when Danny first moved into his new neighborhood in Gotham, he had some trouble controlling his Powers. The different Types and Levels of Ectoplasm in the air when compared to Amity had thrown off his control.

He was used to being in places where his Ectoplasm meshed well with the Atmosphere, like a Water Balloon in a Pool, but in Gotham that analogy would be closer to a Water Balloon in the sewers. It was too different from what he was used to to fully control his Powers.

So it's understandable that he messed up a few times and his neighbors found out about his Abilities.

They took it well at first, Danny wasn't going to go Rogues or anything, and he never used them maliciously, but eventually they got curious.

They asked what his limits were, how he got them in the first place, and what the hell the Ghost Zone was. The answers "None Really", "I died and was reborn", and "A Collective of every Afterlife at once" did spark some interesting reactions from them.

Most importantly, a few of them joked about him being an Eldritch God that they needed to worship. He was good enough friends with them that at that point they felt comfortable pranking eachother, so they did just that.

Danny woke up one day on his birthday, and saw all of his friends and neighbors surrounding the makeshift Throne they had made and put him on while he was asleep. The entire day they chanted stuff like "The Great One requires Ms. Smiths Apple Pie for his day of birth!" And "The Great One Wishes for us to sing the Ritual Song! Happy Birthday to You! Happy Birth-"

After his birthday, they kept up the joke.

It didn't help that his powers had evolved Again! And now he could bestow abilities onto his friends. The jokes they made about their God granting them Supernatural Powers to rule the world with were insufferable.

Then, one day while he was just resting at home, watching a movie on his TV, he felt a Pull at his Core. The same kind of Pull whenever he was being summoned. But why would they summon hi- Oh Shit! It's Mr Jenkins Party today! He was supposed to meet them at the Warehouse they used for special events an Hour Ago!

He quickly accepted the Summoning, but was met with a suprising sight. His Neighbors all tied up in a pile to his right, a spilled table of party food to his left, and right in front of him, Batman and his Family watching him with wary eyes.

Slowly, he opened his mouth. "...so, did you come for the party or..."

#Dpxdc#Dp x dc#Dcxdp#Dc x dp#Danny Phantom#Dc#Dcu#Danny is Worshipped by a Cult#It started out as a Joke from his friends#Then he started giving them powers and they decided to take it to the next level#They told their work friends that they were in a cult now#They showed off the minor powers Danny gave them#And slowly they inducted more people into the Danny Fenton Cult (most of them knew it was a joke on a friend)(some were serious)#They were planning on using the Party to introduce Danny to all his new “Followers” and get a laugh out of it#Unfortunately the Bats hears about a new Cult forming and went to go stop it#The Cult succeeded in Summoning their God#And he's just a Guy.#Not Phantom. He's in his Human Form and looked like the most average guys you've ever seen.#The Bats eventually leave with an order to them to never Form a Cult again#The Cult feels that Batman is oppressing their right to Free Religion and begin to make the Cult even BIGGER out of Spite#Danny might need to step in soon...#...but Batman did beat up his friends...and he did technically try to revoke their right to free assembly and religion...#...Maybe he should just let this play out...

4K notes

·

View notes

Text

Starter motor components for non-automotive applications OR automotive applications

Automotive & Non Automotive

#assemblies#automotive & non automotive#srb / honed hydraulic cylinder tubes & sub#stainless steel welded tubes#cold drawn seamless tubes#submersible pump parts#textile machinery tubes & parts#automotive heavy vehicle & farm equipment parts#transformer - radiator butterfly valves

0 notes

Text

Would like to concur with @gutof on Twitter and @Comegetyourjuice on Insta because the Facecard Team is delivering

#I'm assembling a team#kim ye-ji#flavia saraiva#rayssa leal#huang yuting#sunisa lee#jordan chiles#olympics#paris 2024

6K notes

·

View notes

Text

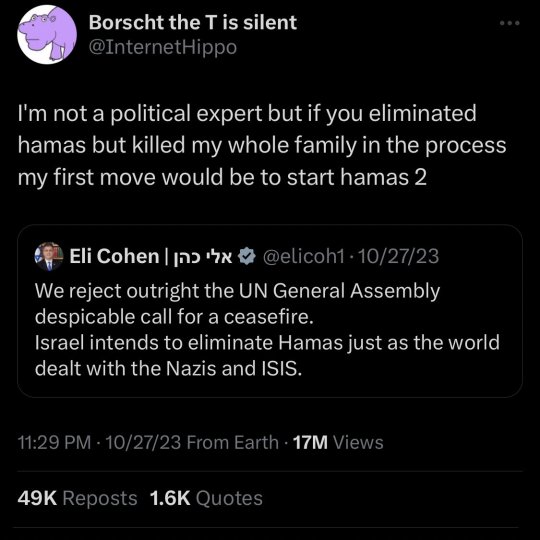

#eurovision#free palestine#twitter#democrats#republicans#united kingdom#united states#un general assembly#israel

7K notes

·

View notes

Text

Ready to assemble your very own kelp forest?

Just follow these easy steps:

✅ Assemble kelp parts in cold, nutrient-rich water

✅ Add fish and invertebrates

✅ Add sea otters! 🦦

✅ Watch your kelp forest thrive

⚠️Warning: Without sea otters, your kelp forest may end up with an urchin overload!

#monterey bay aquarium#sea otter awareness week#how to build a kelp forest#whalecome to the ikea of the sea#some assembly required#sadly no meatballs

2K notes

·

View notes