Text

Sheffield Plastics Polycarbonate Sheet offering light weight and break resistance

Bayer Makrolon Polycarbonate products offer a balance of useful features this includes temperature resistance, impact resistance and optical properties position polycarbonates in between commodity plastics and engineering materials.

Polycarbonate is definitely a high quality material. Whilst it features extraordinary impact-resistance, it's got low scratch-resistance and thus a hard coating could be applied to polycarbonate eye protection lenses and polycarbonate exterior auto components. The properties relating to polycarbonate tend to be comparable to those of Acrylic PMMA materials, and yet polycarbonate is always stronger, it is usable in a wider temperature range and is a bit more expensive. This plastic polymer is highly transparent to visible light and it has better light transmission characteristics than many kinds of glass.

Polycarbonate has a glass transition temperature of around 150 °C (302 °F), as a result it softens gradually above this point and flows above about 300°C (572 °F). Tools need to be held at higher temperatures, generally above 80 °C (176 °F) to help make strain- and stress-free products.

Unlike most other thermoplastics, polycarbonate can undergo massive deformations without breaking or cracking. Therefore, it is sometimes processed and formed cold using standard sheet metal techniques, for example forming bends on a brake. Even for sharp angle bends with a tight radius, no heating is usually necessary. This makes it valuable in prototyping applications where transparent or electrically non-conductive parts are needed, which may not be produced from sheet metal. Be aware that PMMA/Plexiglas, which is similar in looks to polycarbonate, but it is brittle and cannot be bent unless it is heated.

The light weight of polycarbonate, as opposed to glass, has led to advancement of electronic display screens that replace glass materials with polycarbonate, for use in mobile and portable devices. Such displays include newer e-ink and several LCD screens, though CRT, plasma screen and other LCD technologies generally still require glass for its higher melting temperature and the ability to be etched in finer detail.

Other miscellaneous items fabricated from Polycarbonate include durable, lightweight luggage, MP3/digital audio player cases, computer cases, police riot shields, instrument panels, and common style blender jars. Many toys and hobby items are manufactured from polycarbonate parts, e.g. fins, gyro mounts, and flybar locks for use with radio-controlled helicopters.

For use in applications exposed to weathering or UV-radiation, a special surface treatment maybe needed. This either can be a coating (e.g. for improved abrasion resistance), or perhaps the coextrusion for enhanced weathering resistance.

The Makrolon Polycarbonate is a thermoplastic that at the beginning, starts as a solid material in the form of small pellets. In a manufacturing process called injection molding, these small pellets are heated until they melt and become a very thick liquid. The liquid polycarbonate is then rapidly pushed into the mold - shaped like the part, compressed under high pressure and cooled to produce a finished product , that only takes about a minute to complete.

performance plastic sheet

youtube

1 note

·

View note

Text

Why are there Teflon and Kynar long lead times

In the last year, the business has had more allocations than I've come across around my 3 decades experience. In the past I have seen sharp price increases, and I have experienced several shortages, and delivery problems because of plastic resin allocations from plastic resin suppliers. This is the very first instance I have seen all these issues at the same time.

PTFE (TFE) and Kynar are both on allocation.

These two resins are in short supply. The PTFE Sheet suppliers product PTFE (TFE) and Kynar manufacturing requires a mineral called Fluorspar which is mined in Mongolia and China. The world requirement for this mineral has grown significantly, as well as the supply has tightened. PTFE materials have high temperature resistance, excellent chemical resistance and very low co-efficient of friction (slick) and is used within a lot of applications from non-stick fry kitchenware to ptfe tape for home use. This specific mineral is the key raw materials in the manufacturing of fluoropolymers, fluorolubricants and many refrigerants.This surge in demand coupled with shortage of raw materials has caused a dramatic price increase (almost double throughout the last year), shortages, and we expect these two factors to keep at it in the near future.

The next guideline that you are most likely to wish to utilize when you are looking around for a plastic sheet distributor is to look around on the net. The web is the most effective area to obtain rates quotes and to take a look at a business's reputation. You can likewise take advantage of any kind of classified ads that are released in newspapers. This is going to assist you get a far better idea of what you are going to be spending for a specific quantity of sheets.

https://www.youtube.com/watch?v=9x_zO-9Oth8

1 note

·

View note

Text

CNC Machining

In the here and now world, where worldly quality is the most crucial factor of all, picking the best-quality plastic materials is one thing that is vital. This is because of the crucial price that are needed for the manufacturing of such kinds of plastic products.

Designers have actually been building premium materials for mechanical design since its creation. Products like fibers, timber, fiberglass, polymers, and polyurethane products are all instances of crafted plastic products which are made use of in mechanical design. These kinds of engineering products use various advantages to the engineers in terms of engineering layout. For example, when it comes to fiberglass, it has been understood to be one of one of the most long lasting as well as flexible plastics which have confirmed to function well with heat. The residential properties of fiberglass have been likewise included in the development of synthetic textiles.

Even though fiberglass is a strong product, it is known to be fairly delicate when based on extreme temperature levels. Some kinds of fibers which are taken into consideration to be difficult, such as polyvinyl chloride (PVC) as well as polypropylene (PP), are vulnerable to melt-off if exposed to heat. If they do occur to melt, they often tend to turn fragile and also break conveniently. Several kinds of synthetic fibers, made from nylon and also polyester, have actually been used for printing applications in the past. Nonetheless, there are different kinds of manufacturing processes which make them much less sturdy than the ones used for various other kinds of plastic items. This is because, when utilizing the previously mentioned materials, heat is inevitable.

The factors for this are the extreme temperature level extremes. For instance, when publishing an item, the dye will create at heat and afterwards turn weak and break. When exposed to heat, the product will certainly create a great deal of stress and tiredness which brings about poor performance. A designer will find it required to know how to produce the most effective high quality plastic materials. The required requirements of great performance can be met by utilizing materials like polyurethane, which is among the most preferred plastic materials for engineering.

Polyurethane, which is a preferred among the majority of the engineers, is also known to be more sturdy and also resistant to dealing with warmth than nylon or polypropylene. This is the reason why polyurethane has ended up being one of the most preferred sort of plastic materials for design. Polymers do not call for a heat to create since the procedure occurs within the production procedure. As a matter of fact, polymers and plastics came in a variety of sizes. They are generally used various chemical reactions and also are very adaptable and effective.

When it pertains to mechanical engineering, it is necessary to study how to produce solid and sturdy products. It has been observed that polyurethane has been commonly made use of by mechanical engineers in developing the chassis of cars and various other such items. http://plasticsheet.net/los-angeles-county/

As a matter of fact, polyurethane has actually verified to be really adaptable and also sturdy so it is significantly efficient in the creation of the wheels as well as the body of autos. There are other types of polymers and plastic products which are utilized in mechanical design.

youtube

1 note

·

View note

Text

Why are there PTFE and PVDF long lead times

Within the last year, the industry has had more challenges than I've come across during my 3 decades experience. In the past I have seen sharp price increases, and I have witnessed several shortages, and delivery issues as a consequence of material allocations by resin vendors. This is definitely the first instance I have seen all these issues at the same time.

Polytetraflouroethylene (TFE) and Kynar - PVDF are both on allocation.

These two resins are in short supply. The PTFE Sheet product PTFE (TFE) along with Kynar-PVDF manufacturing requires a mineral called Fluorspar which is mined in Mongolia and China. The worldwide demand for this mineral has grown significantly, as well as supply has tightened. PTFE materials have high heat resistance, excellent chemical resistance and very low co-efficient of friction (slippery) and is utilized within a good deal of applications from non-stick fry pots and pans to ptfe tape for personal use. This specific mineral is actually the critical raw materials in the manufacturing of fluoropolymers, fluorolubricants and lots of refrigerants.This increase in demand paired with shortage of raw materials is mainly responsible for a dramatic price increase (almost double during the last year), shortages, and we expect both these factors to keep at it in the near future.

https://www.youtube.com/watch?v=9x_zO-9Oth8

0 notes

Text

UHMW Super Abrasion Resistant Plastic Sheet

Picking UHMW Best Abrasion Resistant Plastic Sheet. UHMW-PE has been out performing most other plastic materials in some properties. With nearly ten times greater molecular weight as compared to common HD Polyethylene materials, you can certainly see why UHMW-PE would be the best choice for tough wear type installations. Out of all the polymers, UHMW-PE has the highest abrasion resistance of any thermoplastic polymer. This material also has outstanding impact strength, chemical resistant, and some of the highest wear resistant and a very low coefficient of friction. This versatile material works extremely well with most machining and fabrication methods. Some of the most common applications are: scrapers, door and drawer glides, washers, gaskets, abrasion resistant strips, wear plates, and shims. This is why Ultra High Molecular Weight Polyethylene has grown and continues to grow in its many uses.

https://youtu.be/l4iCuw4KWwE

0 notes

Text

A popular variety self lubricating performance plastics is Natural Cast Natural Nylon type 6 materials. This grade of plastic has been produced from Dupont resin for over 40 years.

Black Black Extruded Nylon type 66

Dupont Nylon is a super tough and durable mechanical plastic. Nylon is the preferred material for important products like machining critical wear parts for machines. If Nylon is a material you would like to know more about simply click here, %LINK%

Long running and smooth performance are typical for Cast and Extruded Nylon. Nylon has one of the widest ranges of sizes and shapes, including small diameter rod to massive diameters. The Natural Natural Cast Nylon type 6/6 materials are commonly available.

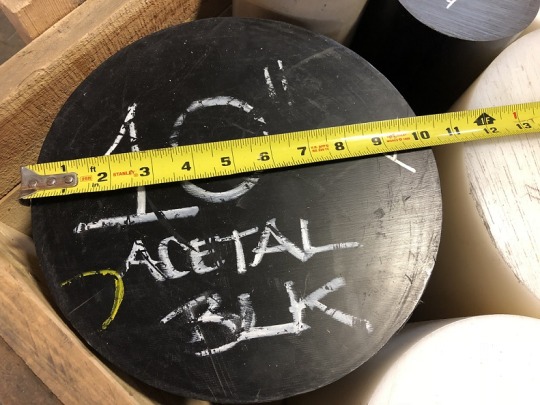

Acetal Sheet stock, perhaps the best of the engineering plastics used within the automotive industry because of its long lasting dimensional stability and durability. It offers solutions for designers to help them produce long lasting and very durable components. Another popular area for Acetal Sheet is in marine applications. This environment suits acetal well because its low moisture absorption will result in components that will not expand or change dimensions due to contact with water.

Performance Plastic materials

youtube

#nylon#nylonsheet#nylonrod#polyamide#nylon6#nylon66#nylon610#nylon612#naturalNylon#BlackNylon#NylonSheet#Nylon#NylonRod#Nylon66#Nylon6/6#Nylon6/10#Nylon6/12#CastNylon

0 notes

Text

Conveyors for Food and Other Machinery

When factories produces food or drink they must abide by very strict hygiene standards that happen to be in force currently. To do this the meal processing areas need to have been hygienically designed and properly cleaned and maintained. Processing food could involve a number of processes, as an illustration some food stuff must be sieved to be the right size, ingredients may need to become added, counted after which packed. Each process is going to be done on different machinery which suggests the meal stuff needs to be conveyed to each and every process. All of these processes including the moving food stuffs to another process could be vulnerable to food contamination in the event the machines and surfaces used are not hygienic clean and maintained. Some of the machines that are utilized to process food are linear feeders, Vibraflo Through Sieve, bucket elevators, conveyor systems and vibratory screen feeder to mention just a couple. Today all are designed and constructed with the top materials for processing food. Below are a few instances of machines as well as their use.Hygenic conveyor systems tend to be crafted from stainless as the material is virtually safe from staining, resists the increase of matter, impervious to attack by chemical or biological agents and is also very easy to completely clean. The belt material is often created from polyurethane which again is good for food as it is an inert material that will not contaminate the merchandise continued it.Bucket elevators are because food and other material needs to get elevated. This might be for many reasons but if. the material is food then the bucket elevator also needs being made of materials to ensure the foodstuff isn't getting contaminated.Sieves and screens focus on dewatering, scalping and single deck separation. The vibraflo through sieve is machine well suited for food material including coffee. Many products like coffee need to become sifted through before they're going on the packaging stage and also the vibraflo through screen can screen 5,000kgs by the hour.Vibrating feeders are feeding machines that have a vibrating feature so food or materials can move along to another location process evenly and continually. Again when the natural acetal copolymer sheet feeders are going being used for food then a feeder must be made out of hygienic materials. They are traditionally used in the chemical, building and mining industriesMany of the machines are bespoke as they are designed for different processes; some are designed to work high is often a shortage of space. Some will probably be for food so hygienic materials are needed, other times not. So investing in a pre-owned machine that has been made for another process is not a good plan. You can get refurbished machines which will cost much less, but it is advisable to go right to a manufacture of the types of machines and explain what exactly you would like the machine to complete.

0 notes

Text

Comparing Acetal Copolymer and Dupont Delrin in Round rods or sheets and plate

Delrin is a great plastic for turning on a lathe lathe. It is easy to turn, although it requires slower speeds. I’ve used this stuff to make Scottish small pipes chanters. I have ordered countless items from a plastic shop in Anaheim. The smaller pieces always ship quickly and everything has been well packed. I’ve never had a problem with an order.

Between the Delrin and Acetal rods, both materials are quite durable and easily machinable, and they have comparable physical properties. They do look similar, but in practical use there are some differences that can make one better than the other. It also depends on your application. As with all plastic materials, make sure to check the typical properties data sheet for the appropriate properties you may need for your application.

Our Acetal Sheet is probably our primary material for machining,as it gives an excellent finish both on manual and CNC Machines. Its got a pretty low moisture absorption making it the preferred grade for food contact and where the dimensional stability is important. Acetal Sheet has the perfect combination of high mechanical strength, durability and strength, giving it excellent sliding properties, electrical insulation, and wear resistance.

Acetal Sheet has many uses and is particularly valued in the food preparation industry. Because of its low moisture absorption it gained Food & Drug Administration approval and its excellent sliding abilities which aid with very low friction and hard wearing food safe components.

Acetal Sheet is one of the plastics used within the automotive industry because of its long term dimensional stability and toughness. It offers solutions for designers to help them create long lasting and very durable components. Another popular area for Acetal is in marine applications. This environment suits acetal well because the low moisture absorption will result in components that will not expand or change dimensions due to contact with water.

0 notes

Text

How Performance Plastic Resin Are Produced Into Sheet

How are Polymers Molded? Prior to we start, allows simply return a little and also know a little bit regarding what polymers in fact are? A polymer is a big particle made up of several duplicated sub-units. Based upon the Mechanical Reaction at Heats, Polymers are classified into 2 major groups: First are Thermoplastic Polymers, which soften when heated and also set when cooled off. These polymers are generally soft and can be consistently molded right into required shapes.The 2nd kind are thermosetting polymers. These polymers become soft during initial home heating and after that completely solidify when cooled down. They are much more difficult, fragile and warmth resistant When compared with polycarbonate Polymers.Returning to molding, The initial step in molding of polymers is handling of polymers, which as a result of the extremely nature of polymers is similar to those used to form as well as form metals. Thus, We will certainly check out it under two major subheadings: First, Molding of Thermosetting Polymers which is done by utilizing 2 primary techniques. One being Compression Molding in which a measured amount of polymer powder is positioned in a women dental caries that is preheated to about 125 to 150 level Celsius. The top half of the die compresses the material with a pressure of to 50 Huge Pascals. This pushes the material into the mold and mildew cavity where it solidifies and is removed with the help of ejector pins. Benefits consist of, Reduced recurring anxiety, reduced setting time as well as good surface area coating. Drawbacks include boosted overall cycle time and also reduced manufacturing rate. Compression Molding is made use of for making gears, buttons, handles, handles, dishes and also installations. One more type of therosetting plastics processing is Transfer Molding: Which is a sophisticated method of compression Molding. The product is typically pre-heated as well as put in a reduced fifty percent of mold and mildew. The upper part of die uses a stress of 20 to 100 Huge Pascals and once treated the product component is ejected.Among the Key Advantages of Transfer Molding is the ability to insert different inserts like semiconductor chips, ceramics etc prior to introducing the material. But is limited by its high equipment price as well as wastefulness of material. Transfer Molding is made use of to manufacture electronic parts with molded terminals, pins, etc. Second comes Molding of Thermoplastic polymers which can be researched under 3 main parts. One being Shot Molding. Right here, the material is fed from a receptacle to the turning screw which discharges the material before the extruder. Warm is established from the electric band heating systems and also friction from the rotating screw. Benefits of Injection Molding consist of faster production price, Production of complex shapes with high accuracy however is limited by high preliminary cost. Applications are production of cups, chairs, toys, cars and truck parts and so on. Second in line is strike molding which is a process in which atmospheric pressure is made use of to blow up soft plastic into a mold and mildew tooth cavity. The soft plastic is typically called a parison, which is clutched between a 2 item mold and mildew. The atmospheric pressure has to do with 400 to 800 kilopascals. As the created element cools down, the mold is opened and also the component is gotten rid of.Advantages include reduced initial price of Molds, high flexibility in manufacturing. Downsides include high cooling times. Blow Molding is made use of building materials supplier for making food product packaging, water bottles, pipelines, floats as well as doll bodies. Third and last type of Thermosetting Molding is Thermoforming. Below with the help of clamps a polymer sheet is clutched around the mold and mildew. A heating unit is made use of to bring the polymer up to 90 degree Celsius.Vacuum is used utilizing small openings in the lower die. This gives the polymer sheet an excellent form. Advantages of thermoforming consist of low thermal anxieties, fast arrangement, reduced manufacturing expense with an absence of capability to make components with openings. Thermoforming is made use of for producing travel luggage bags, internal panels of refrigerators, and so on. That's it?Just how do you generate sheets and also pipelines? Or how are cords coated with polymers to provide insulation, you might ask. Well, There is one last process which is common between both Thermoplastic and Thermosetting Polymers. It is called extrusion. Sounds Familiar? It Needs to be ... due to the fact that it is made use of in the forming of steels in addition to the plastics. Let's take a look: Extrusion of films is done by the combination of extrusion and also blowing. The tube. is first squeezed out, after that attracted up utilizing rollers and air is blown uniformly using a tube. The guide rolls after that restrain the blown tube and also form a flat tube which is the movie. Sheets of Polymers are formed utilizing the calendaring process which is similar to rolling procedure. Below the first roller acts as a feeder, the 2nd as a metering gadget and the third one establishes the gauge length of the sheet.Extrusion of Pipeline is similar to film development just right here they are kept in placement by a mandrel. The finish of cord and also cable for insulation function is just one of one of the most essential polymer extrusion procedures. Here the melted polymer is applied to the bare Performance Plastic materials cord as it is pulled through a die at high speed. For adhesion of finish a slight vacuum cleaner is attracted between the polymer as well as wire.

0 notes

Text

How Performance Plastic Polymer Are Produced Into Sheet Stock

How are Polymers Molded? Prior to we begin, allows simply return a little and know a little bit about what polymers in fact are? A polymer is a big particle made up of several duplicated sub-units. Based on the Mechanical Reaction at High temperatures, Polymers are identified into two major groups: First are Thermoplastic Polymers, which soften when heated up and harden when cooled down. These polymers are normally soft and also can be consistently built right into needed shapes.The 2nd type are thermosetting polymers. These polymers become soft during initial heating and after that completely solidify when cooled down. They are a lot more difficult, brittle and also warmth resistant When compared to polycarbonate Polymers.Coming back to molding, The fda approved plastic rod very first step in molding of polymers is handling of polymers, which because of the very nature of polymers resembles those made use of to create as well as shape steels. Hence, We will certainly consider it under 2 main subheadings: First, Molding of Thermosetting Polymers which is done by using 2 main approaches. One being Compression Molding in which a determined quantity of polymer powder is put in a female cavity that is preheated to about 125 to 150 degree Celsius. The top fifty percent of the die compresses the product with a pressure of to 50 Mega Pascals. This pushes the product into the mold and mildew tooth cavity where it solidifies as well as is eliminated with the help of ejector pins. Benefits consist of, Low residual anxiety, reduced setup time as well as excellent surface area finish. Drawbacks include increased general cycle time as well as low production rate. Compression Molding is used for making gears, buttons, knobs, manages, dishes as well as installations. One more kind of therosetting plastics processing is Transfer Molding: Which is an advanced method of compression Molding. The product is normally pre-heated as well as placed in a lower half of mold and mildew. The top part of die applies a stress of 20 to 100 Mega Pascals and as soon as healed the product part is ejected.One of the Main Advantages of Transfer Molding is the capability to place various inserts like semiconductor chips, ceramics etc prior to introducing the product. But is restricted by its high tools cost and also waste of product. Transfer Molding is utilized to make digital parts with shaped terminals, pins, and so on. 2nd comes Molding of Thermoplastic polymers which can be studied under 3 main parts. One being Injection Molding. Below, the product is fed from a hopper to the rotating screw which discharges the product before the extruder. Warm is established from the electrical band heaters and also rubbing from the turning screw. Benefits of Injection Molding consist of quicker manufacturing rate, Manufacturing of complex shapes with high precision yet is restricted by high first cost. Applications are manufacturing of cups, chairs, toys, cars and truck components and so on. 2nd in line is blow molding. which is a procedure in which atmospheric pressure is made use of to inflate soft plastic right into a mold dental caries. The soft plastic is usually called a parison, which is grasped in between a two piece mold. The air pressure is about 400 to 800 kilopascals. As the formed element cools down, the mold and mildew is opened as well as the component is gotten rid of.Benefits consist of reduced initial expense of Mold and mildews, high flexibility in production. Negative aspects consist of high cooling times. Blow Molding is made use of for making food product packaging, canteen, pipelines, drifts and also doll bodies. Third as well as last type of Thermosetting Molding is Thermoforming. Right here with the help of clamps a polymer sheet is gripped around the mold. A heating unit is used to bring the polymer as much as 90 degree Celsius.Vacuum cleaner is applied utilizing little holes in the lower die. This gives the polymer sheet a best form. Advantages of thermoforming include reduced thermal anxieties, quick configuration, low production cost with a lack of capacity to make parts with holes. Thermoforming is made use of for creating baggage bags, internal panels of fridges, and so on. That's it?Exactly how do you create sheets as well as pipelines? Or just how are wires covered with polymers to give insulation, you may ask. Well, There is one last procedure which prevails in between both Thermoplastic and also Thermosetting Polymers. It is called extrusion. Sounds Familiar? It Should be ... because it is made use of in the forming of metals in addition to the plastics. Allow's take a look: Extrusion of films is done by the mix of extrusion as well as blowing. Television is first extruded, after that drawn upward making use of rollers and air is blown evenly using a tube. The overview rolls after that limit the blown tube as well as create a level tube which is the movie. Sheets of Polymers are developed utilizing the calendaring process which is similar to rolling procedure. Right here the first roller works as a feeder, the 2nd as a metering tool as well as the third one sets the scale size of the sheet.Extrusion of Pipeline is similar to movie formation just below they are held in setting by a mandrel. The layer of wire and wire for insulation function is one of one of the most essential polymer extrusion processes. Below the dissolved polymer is put on the bare cord as it is pulled through a die at high speed. For attachment of covering a mild vacuum is attracted between the polymer as well as cable.

0 notes

Text

What is causing the Teflon Products and Kynar- PVDF Shortages.

Over the past year, the market has had more shortages than I have come across during my three decades experience. In the past I have seen sharp price increases, and I have seen several shortages, and delivery delays as a consequence of material allocations through plastic resin vendors. This is the very first occasion I have seen all these issues at one time.

Polytetraflouroethylene (TFE) and Kynar - PVDF both are on allocation.

The two of these resins are in short supply. The PTFE - Polytetrafluoroethylene product PTFE (TFE) and also Kynar-PVDF manufacturing requires a mineral called Fluorspar that is mined in Mongolia and China. The worldwide requirement for this mineral has risen significantly, along with the supply has tightened. PTFE materials have high heat resistance, excellent chemical resistance and extremely low co-efficient of friction (slick) and is utilised in a bunch of purposes from non-stick fry pots and pans to ptfe tape for use at home. This mineral is actually a essential raw material within the production of fluoropolymers, fluorolubricants and a lot of refrigerants.This increased demand coupled with general shortage of raw materials is responsible for a dramatic price increase (almost double during the last year), shortages, and we expect both these factors to stay in affect in the near future.

When you are shopping around for a plastic sheet distributor you will additionally wish to look into the business that you are handling to make certain that they are most likely to be around for a very long time. If you are going to be having a lot of issues with your plastic sheet supply you are going to wish to ensure that you are going to have the ability to count on them to continue to supply you with the high-grade item that you have actually pertained to expect, throughout the years.

0 notes

Text

Food Processing Conveyors and Machinery Insight

When factories produces food or drink they must adhere to very strict hygiene standards which are in force today. To do this the meal processing areas require been hygienically designed and properly cleaned and maintained. Processing food could involve a number of processes, as an illustration some food stuff should be sieved to become the correct size, ingredients may need being added, counted then packed. Each process will probably be done on different machinery which means the meals stuff needs to be conveyed to each process. All of such processes like the moving food stuffs to the next process might be vulnerable to food contamination in the event the machines and surfaces used aren't hygienic clean and maintained. Some of the machines that are used to process food are linear feeders, Vibraflo Through Sieve, bucket elevators, conveyor systems and vibratory screen feeder to call just a couple. Today all of them are designed and developed with the best materials for processing food. Below are a few samples of machines and their use.Hygenic conveyor systems are typically crafted from metal because material is virtually safe from staining, resists the increase of matter, impervious to attack by chemical or biological agents and is also quite simple to scrub. The belt material is often crafted from polyurethane which again is perfect for food because it is an inert material it doesn't contaminate the products sustained it.Bucket elevators are for when food or any other material needs to become elevated. This could possibly be for several reasons but if your material is food then a bucket elevator also needs being made of materials to ensure the food does not get contaminated.Sieves and screens are equipped for dewatering, scalping and single deck separation. The vibraflo through sieve is machine well suited for food material such. as coffee. Many items like coffee need to get sifted through before each goes on the packaging stage along with the vibraflo through screen can screen 5,000kgs per hour.Vibrating feeders are feeding machines that have a vibrating feature so food or materials can move along Making parts from plastic resin to a higher process evenly and continually. Again in the event the feeders are going to get useful for food then this feeder must be made out of hygienic materials. They are widely used inside the chemical, building and mining industriesMany of such machines are bespoke as they are designed for different processes; some are created to work high can be a shortage of space. Some is going to be for food so hygienic materials are needed, in other cases not. So getting a second-hand machine that has been designed for another Plastic Processing process is not a good idea. You can get refurbished machines that may cost far less, yet it's much better to go straight away to a manufacture of those types of machines and explain just what you desire the device to accomplish.

0 notes

Text

Process to make Plastic Polymers Are Produced Into Plate

Exactly How are Polymers Molded? Before we start, allows just return a little and understand a little bit about what polymers in fact are? A polymer is a huge particle made up of several repeated sub-units. Based upon the Mechanical Action at Heats, Polymers are identified right into two major groups: First are Thermoplastic Polymers, which soften when warmed as well as harden when cooled off. These polymers are usually soft and also can be repetitively formed into needed shapes.The 2nd type are thermosetting polymers. These polymers become soft throughout first home heating and afterwards permanently set when cooled down. They are extra difficult, weak and warm immune When compared to polycarbonate Polymers.Coming back to molding, The initial step in molding of polymers is handling of polymers, which as a result of the really nature of polymers resembles those utilized to create and also shape metals. Hence, We will certainly check out it under 2 major subheadings: First, Molding of Thermosetting Polymers which is done by using 2 major methods. One being Compression Molding in which a measured amount of polymer powder is positioned in a women cavity that is preheated to around 125 to 150 degree Celsius. The upper half of the die compresses the material with a pressure of to 50 Mega Pascals. This pushes the material into the mold dental caries where it strengthens and is removed with the help of ejector pins. Advantages include, Low recurring stress and anxiety, reduced setting time and also great surface coating. Disadvantages plastic material suppliers include raised overall cycle time and reduced manufacturing rate. Compression Molding is used for making equipments, switches, handles, handles, dishes and also fittings. Another kind of therosetting plastics processing is Transfer Molding: Which is a sophisticated technique of compression Molding. The material is typically pre-heated as well as placed in a lower fifty percent of mold and mildew. The top part of die uses a stress of 20 to 100 Mega Pascals and when cured the material component is expelled.One of the Key Advantages of Transfer Molding is the capacity to insert different inserts like semiconductor chips, porcelains etc before presenting the material. However is limited by its high devices price and wastefulness of material. Transfer Molding is utilized to make digital parts with shaped terminals, pins, etc. 2nd comes Molding of Thermoplastic polymers which can be researched under 3 almosts all. One being Injection Molding. Below, the material is fed from a hopper to the turning screw which discharges the product in front of the extruder. Warm is created from the electric band heaters and also friction from the turning screw. Advantages of Shot Molding include quicker manufacturing price, Manufacturing of complex shapes with high precision but is restricted by high preliminary cost. Applications are production of mugs, chairs, toys, cars and truck components etc. Second in line is impact molding which is a process in which atmospheric pressure is utilized to inflate soft plastic into a mold and mildew cavity. The soft plastic is normally called a parison, which is gripped between a two item mold and mildew. The atmospheric pressure is about 400 to 800 kilopascals. As the created element cools, the mold and mildew is opened and also the component is removed.Benefits consist of reduced initial expense of Molds, high adaptability in manufacturing. Disadvantages consist of high cooling times. Blow Molding is made use of for making food product packaging, water bottles, pipelines, drifts and doll bodies. Third and last sort of Thermosetting Molding is Thermoforming. Right here with the help of clamps a polymer sheet is grasped around the mold. A heater is utilized to bring the polymer up to 90 level Celsius.Vacuum cleaner is applied utilizing little holes in the reduced die. This gives the polymer sheet a perfect shape. Benefits of thermoforming consist of low thermal tensions, fast configuration, low production expense with a lack of ability to make components with holes. Thermoforming is made use of for generating travel luggage bags, internal panels of refrigerators, etc. That's it?How do you produce sheets as well as pipelines? Or exactly how are wires covered with polymers to provide insulation, you may ask. Well, There is one. last process which prevails plastic material suppliers in between both Thermoplastic and also Thermosetting Polymers. It is called extrusion. Appears Familiar? It Should be ... since it is utilized in the forming of metals along with the plastics. Let's take a look: Extrusion of movies is done by the combination of extrusion and also blowing. The tube is first squeezed out, after that drawn upwards making use of rollers as well as air is blown uniformly making use of a tube. The overview rolls after that restrain the blown tube and also create a level tube which is the film. Sheets of Polymers are created using the calendaring procedure which is similar to rolling process. Below the initial roller acts as a feeder, the second as a metering gadget and also the 3rd one sets the gauge size of the sheet.Extrusion of Pipe resembles film development just here they are held in placement by a mandrel. The layer of wire as well as cable television for insulation objective is one of the most vital polymer extrusion procedures. Right here the dissolved polymer is applied to the bare cable as it is pulled through a die at broadband. For attachment of finishing a mild vacuum is drawn in between the polymer as well as cable.

0 notes

Text

Process to make Performance Plastic Resin Are Made Into Sheet Stock

How are Polymers Molded? Before we begin, lets just go back a little and also know a little bit about what polymers really are? A polymer is a large molecule composed of lots of duplicated sub-units. Based upon the Mechanical Response at High temperatures, Polymers are classified into 2 major categories: First are Thermoplastic Polymers, which soften when warmed and harden when cooled. These polymers are generally soft and can be consistently molded into needed shapes.The second kind are thermosetting polymers. These polymers become soft during very first home heating and then completely harden when cooled. They are extra tough, brittle and also warmth resistant When compared to thermoplastic Polymers.Coming back to molding, The first step in molding of polymers is processing of polymers, which as a result of the very nature of polymers is similar to those made use of to form as well as shape metals. For this reason, We will certainly take a look at it under 2 major subheadings: First, Molding of Thermosetting Polymers which is done by utilizing two major approaches. One being Compression Molding in which a determined quantity of polymer powder is placed in a female dental caries that is preheated to about 125 to 150 degree Celsius. The top fifty percent of the die presses the product with a stress of to 50 Mega Pascals. This pushes the product into the mold and mildew dental caries where it solidifies and is gotten rid of with the help of ejector pins. Benefits consist of, Reduced. recurring anxiety, reduced setting time and good surface coating. Disadvantages consist of raised total cycle time and also reduced manufacturing price. Compression Molding is made use of for making equipments, buttons, knobs, takes care of, dishes and fittings. An additional sort of therosetting plastics processing is Transfer Molding: Which is an innovative method of compression Molding. The material is normally pre-heated and positioned in a lower fifty percent of mold and mildew. The upper part of die uses a pressure of 20 to 100 Huge Pascals as well as when treated the product part is ejected.One of the Main Advantages of Transfer Molding is the capacity to place different inserts like semiconductor chips, porcelains etc prior to presenting the product. Yet is limited by its high devices expense as well as waste of material. Transfer Molding is utilized to produce electronic components with molded terminals, pins, and so on. Second comes Molding of Thermoplastic polymers which can be researched under 3 almosts all. One being Injection Molding. Here, the material is fed from a receptacle to the turning screw which releases the product in front of the extruder. Heat is developed from the electrical band heaters and also rubbing from the revolving screw. Advantages of Injection Molding include quicker manufacturing price, Production of complex forms with high precision yet is restricted by high first expense. Applications are production of mugs, chairs, playthings, vehicle parts etc. 2nd in line is strike molding which is a process in which air pressure is made use of to pump up soft plastic into a mold and mildew tooth cavity. The soft plastic is generally called a parison, which is grasped in between a two item mold. The air pressure has to do with 400 to 800 kilopascals. As the developed element cools, the mold is opened and the part is gotten rid of.Benefits include reduced first price of Mold and mildews, high flexibility in manufacturing. Drawbacks include high cooling times. Blow Molding is made use of for making food packaging, canteen, pipelines, drifts as well as doll bodies. Third and also last kind of Thermosetting Molding is Thermoforming. Below with the help of clamps a polymer sheet is gripped around the mold and mildew. A heater is used to bring the polymer up to 90 level Celsius.Vacuum cleaner is applied making use of small openings in the reduced die. This gives the polymer sheet a perfect shape. Benefits of thermoforming include reduced thermal stress and anxieties, fast setup, low production expense with a lack of ability to produce elements with openings. Thermoforming is made use of for creating travel luggage bags, internal panels of fridges, etc. That's it?Exactly how do you produce sheets and pipes? Or just how are cables covered with polymers to offer insulation, you may ask. Well, There is one last procedure which prevails in between both Thermoplastic and Thermosetting Polymers. It is called extrusion. Appears Familiar? It Must be ... due to the fact that it is used in the forming of steels in addition to the plastics. Allow's have a look: Extrusion of films is done by the mix of extrusion and also blowing. The tube is first squeezed out, then drawn up making use of rollers and air is blown uniformly using a tube. The guide rolls then limit the blown tube as well as form a flat tube which is the movie. Sheets of Polymers are formed using the calendaring process which is similar to rolling procedure. Here the initial roller acts as a feeder, the second as a metering tool as well as the third one sets the gauge length of the sheet.Extrusion of Pipe is similar to movie formation just right here they are held in placement by a mandrel. The covering of cable and cable television for insulation objective is one of one of the most crucial polymer extrusion processes. Below the dissolved polymer is applied to the bare cable as it is pulled through a die at high speed. For adhesion of finishing a small vacuum is attracted in between the polymer and wire.

0 notes

Text

One of the most relied on supplier is the one that you trust fund and believe that they are mosting likely to provide quality items.

If your regional plastic sheet distributor is providing low-grade items, you are not going to have much confidence in them when it comes time to purchase brand-new sheets. On the other hand, if your neighborhood sheet supplier is supplying top quality items you are most likely to have a greater degree of depend on. The complying with are some standards that will certainly assist you identify what your top-notch plastic sheet supplier is most likely to be.

One of the best ways to find if a local plastic sheet distributor is trustworthy is to speak to loved ones that may understand someone that handles them. This is going to provide you an possibility to ask a couple of questions. You might likewise ask at work about your prospective vendor. You will certainly wish to establish if they have exceptional customer care and also is very easy to deal with.

Various other standards that will assist you choose whether or not the sheets that you are buying remain in fact the finest quality are to check for client testimonials on the internet sites. You can visit a few evaluation websites and also see what the consumers are saying regarding their experience with the firm. Often you will discover fantastic consumer reviews that will give you with excellent info.

Another point that you will intend to examine when you are looking for a plastic sheet distributor is the provider's qualifications. This is most likely to assist you establish if the business that you are dealing with has a great reputation in the sector. Normally, the much more well established the company is the a lot more reliable they are going to be. A well-established company is most likely to be trusted and also will provide you with better solution.

Once you have actually made a decision which company you are managing it is going to depend on you to search as well as select the most relied on supplier. As a consumer it is very important that you do your research. There are lots of companies out there that have the same products that you are trying to find yet are utilizing different marketing techniques, and also you want to ensure that you are taking care of a business that is reliable and has an exceptional track record.

When you are shopping around for the most trusted plastic sheet distributor it is most likely to be important that you compare costs and try to find the most inexpensive company. You do not want to spend a fortune on plastic sheet supplies only to learn that you are not getting the most effective worth for your money. The next standard that is going to aid you identify if the rate is reasonable is to contrast the costs.

You will intend to locate the good quality plastic sheet vendors that are selling for very low prices. Oftentimes you can get something in a much smaller bundle than you would have to acquire with a plastic sheeting vendor that is charging far more for their products. When you locate a provider that is providing you fantastic rates as well as is providing you quality items you are most likely to be happy with your acquisition.

You will certainly additionally wish to pick a top quality plastic sheet provider. You do not wish to select a business that has actually been around for years. You wish to pick a firm that has developed their reputation over time and also is valued by the plastic sheet market.

When you are searching for a plastic sheet vendor you will certainly likewise wish to investigate the business that you are dealing with to see to it that they are most likely to be around for a long period of time. If you are going to be having a great deal of troubles with your plastic sheet supply you are going to wish to make certain that you are most likely to have the ability to rely on them to remain to offer you with the top notch item that you have involved anticipate, over the years.

0 notes