#PlasticMachining

Text

#moldmaker#haituo#injectionmolding#plasticinjectionmold#haitian#injectionmoldingmachine#injectionmold#haitai#mould#plasticmachine

0 notes

Text

Used injection molding machine in China,ماكينة قولبة بالحقن مستعملة في الصين

Haida 290T, it’s original servo machine,

tie bar distance; 630*630mm

injection glue weight: 1200g

Model: 2023year

payment term : T/T , BTC and USDT;

WhatsApp: wa.me/+8618576477029

#usedinjectionmoldingmachine

#usedplasticmachine

#injectionmoldingmachine

#plasticmachine

#plasticinjectionmachine

0 notes

Text

PVC,PP Siding Panel High Speed Extrusion Line

Description

PVC external wall hanging board is an innovation of building decoration materials. PVC external wall hanging board will be the best alternative material for external wall coatings and ceramic tiles. PVC external wall hanging board is made of polyvinyl chloride (PVC) treated by a unique process, which is suitable for various architectural styles such as villas, multi-storey residential areas, factories, old buildings and so on. PVC external wall hanging board has clear lines, simple and lively appearance, very modern feeling and super weather resistance. PVC external wall hanging board makes the building look simple, natural and beautiful. It can resist all kinds of bad weather, anti-corrosion and flame retardant, and easy to install. No matter in the production process or in engineering practice, it does not pollute the environment and is renewable. It is an ideal environmental protection decoration material. PVC external wall hanging board overcomes the shortcomings of traditional building plane rigidity and frequent and complex lines of external wall tiles. It has many functions and properties that external wall tiles and coatings do not have, and the performance price ratio is far higher than that of external wall tiles and external wall coatings. Especially in the facade reconstruction project of the old building, it can be constructed directly without eradicating the original facade, avoiding the pollution of the original wall to the environment, reducing garbage removal and transportation, greatly speeding up the construction progress and effectively reducing the project cost. In the external wall insulation construction, the PVC external wall hanging board insulation system is not only simple in construction, but also has good insulation effect. The initial investment can be quickly recovered through energy saving in future use.

Product image display

Siding panel applied in house ,office building, villa, and wall protection. Due to its top layer covered with PVC, ASA, or PMMA, it can be used in hot, cold dry or wet place, can bear long time sun light ,wind, rain and bad weather. This line can be equipped with different pattern rollers, easily changeable.Special designed calibration unit and good process- ing experience can make operation easy and extend its life. Punching on-line , it is more economical way. As per customer’s requests, it also can be equipped with rolling machine,printer, coding machine and so on.

Read the full article

#DoubleScrewExtruder#PlasticMachine#ProfileMakingMachine#PVCCeilingPanelExtrusionLine#PVCCeilingPanelMachineManufacturing#PVCCeilingProducitonLine#PVCDoorFrameExtrusionLine#PVCFlooringMachine#PVCProfilesExtrusionMachine#PVCSidingExtrusionLine#PVCSidingMakingMachine#PVCWindowProfilesProductionLine#SidingProductionLine#UPVCDoorWindowMachinery#WoodPlasticProductionLine#WPCExtrusionline

0 notes

Photo

Delivery day! #injectionmachine #plasticmachine #plastmachine#injectmachine #chinamachine #householdproducts #dailyusepack #brazilmachine #kenyamachine #chinamachinery https://www.instagram.com/p/Crxi-LTJd8k/?igshid=NGJjMDIxMWI=

#injectionmachine#plasticmachine#plastmachine#injectmachine#chinamachine#householdproducts#dailyusepack#brazilmachine#kenyamachine#chinamachinery

0 notes

Text

Vertical Plastic Machining Center Market

We surveyed the Vertical Plastic Machining Center manufacturers, suppliers, distributors and industry experts on this industry, involving the sales, revenue, demand, price change, product type, recent development and plan, industry trends, drivers, challenges, obstacles, and potential risks.

Download Free Research Report Sample PDF: https://cutt.ly/oBE2FMX

#verticalplastic#plastic#verticalplasticmarket#verticalplasticmachine#plasticmachine#verticalplasticmachiningcenter#plasticmarket#statsmarketresearch

0 notes

Text

hey erm... refurenced child abuse under the cut!!! there are open wounds!!! (its not that graphic dont worry!)

;inspo

17 notes

·

View notes

Text

Upgrade Your Rotomoulding Process with Naroto's Highly Efficient Four Arms Bi-Axial Machines!

In need of a reliable and cost-effective bi-axial machine for your rotomoulding process? Look no further! Naroto offers a wide range of highly productive bi-axial machine with four arms called as Speed-90 that are designed to enhance your rotomoulding operations. Visit our website at www.naroto.com

Our bi-axial machine is equipped with advanced technology, ensuring optimal heat distribution and consistent results. Designed for efficiency and durability, our machineries are perfect for a variety of rotomoulding applications.

Why choose Naroto? With our years of experience and expertise in the rotomoulding industry, we are known for delivering reliable and high-quality products. Our bi-axial machine is user-friendly, energy-efficient, and built to meet your specific requirements.

Don't miss out on our budget-friendly deals! Visit our website to learn more about our bi-axial machines. Contact us now to discuss your rotomoulding needs and get a quote. Email us at [email protected]. Act fast and elevate your rotomoulding process with Naroto's affordable bi-axial machines!

rotationalmouldingmachinemanufacturer

rotationalmouldingmachinemanufacturerinindia

rotationalmoldingmachinesuppliers

rotomouldingmachineindia

rotationalmouldingmachinemanufacturersinindia

rotationalmouldingmachine

pulverisermachineforlldpe

rotationalmoldingmachinery

plastictankmakingmachine

plasticwatertankmachinemanufacturer

rotomoldingindia

watertankrotomoldingmachineprice

rotationalmoldingmachineryexporter

rotationalmouldingequipment

rotationalmoulds

watertankmakingmachine

verticaltankmanufacturingmachine

rotomouldingmould

rotomould

plasticmouldingmachinemanufacturers

plasticmouldingmachinesexporter

moldingmachine

plasticmolding

machineindia

machinesindustry

machinemanufacturer

plasticmouldingmachine

plasticmachine

moldingtype

rotationalmachine

mouldingplant

dieforplasticmoulding

rotationalmolding

companymachine

mouldingmachineprice

plasticmoldmanufacturing

plasticprocessingmachine

rotomoldingmachine

rotationalmoulding

rotomouldingmachinery

rotomoldwatertank

watertankmakingmachine

tankiwalimachine

plasticwatertankmakingmachine

watertankmanufacturingmachineprice

plastictankmakingmachine

pvcwatertankmanufacturingmachine

naratowatertankmachine

#rotomouldingmachineexporter#rotationalmouldingmachinemanufacturer#rotationalmouldingmachinemanufacturerinindia#rotationalmoldingmachinesuppliers#rotomouldingmachineindia#rotationalmouldingmachinemanufacturersinindia#rotationalmouldingmachine#pulverisermachineforlldpe#rotationalmoldingmachinery#plastictankmakingmachine#plasticwatertankmachinemanufacturer#rotomoldingindia#watertankrotomoldingmachineprice#rotationalmoldingmachineryexporter#rotationalmouldingequipment#rotationalmoulds#watertankmakingmachine#verticaltankmanufacturingmachine#rotomouldingmould#rotomould#plasticmouldingmachinemanufacturers#plasticmouldingmachinesexporter#moldingmachine#plasticmolding#machineindia#machinesindustry#machinemanufacturer#plasticmouldingmachine#plasticmachine#moldingtype

0 notes

Link

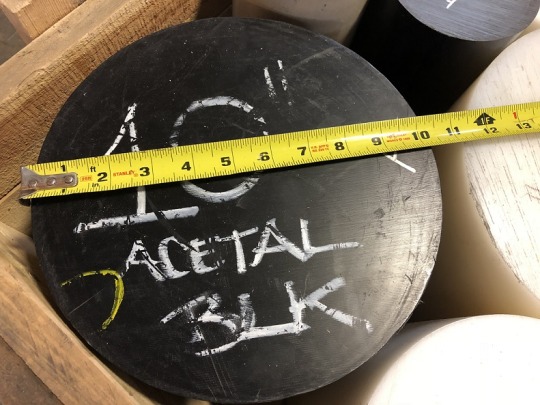

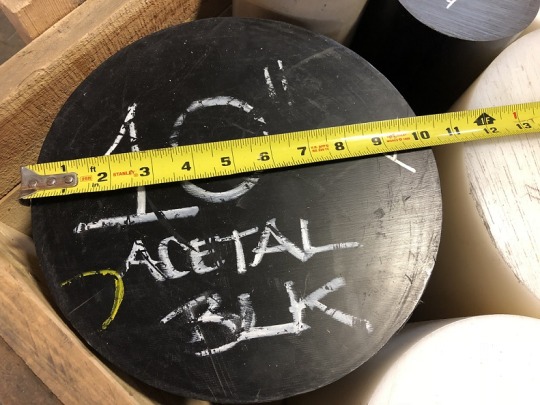

#acetal#acetalfabrication#acetalplastic#acetalmachining#acetalforming#acetalbending#plasticfabrication#plasticforming#plasticmachining#plasticbending#cncmachining

0 notes

Text

Welcome Haituo machinery

#moldmaker#haituo#injectionmolding#plasticinjectionmold#haitian#injectionmoldingmachine#injectionmold#haitai#mould#plasticmachine

0 notes

Text

PVC,PP Siding Panel High Speed Extrusion Line

Description

PVC external wall hanging board is an innovation of building decoration materials. PVC external wall hanging board will be the best alternative material for external wall coatings and ceramic tiles. PVC external wall hanging board is made of polyvinyl chloride (PVC) treated by a unique process, which is suitable for various architectural styles such as villas, multi-storey residential areas, factories, old buildings and so on. PVC external wall hanging board has clear lines, simple and lively appearance, very modern feeling and super weather resistance. PVC external wall hanging board makes the building look simple, natural and beautiful. It can resist all kinds of bad weather, anti-corrosion and flame retardant, and easy to install. No matter in the production process or in engineering practice, it does not pollute the environment and is renewable. It is an ideal environmental protection decoration material. PVC external wall hanging board overcomes the shortcomings of traditional building plane rigidity and frequent and complex lines of external wall tiles. It has many functions and properties that external wall tiles and coatings do not have, and the performance price ratio is far higher than that of external wall tiles and external wall coatings. Especially in the facade reconstruction project of the old building, it can be constructed directly without eradicating the original facade, avoiding the pollution of the original wall to the environment, reducing garbage removal and transportation, greatly speeding up the construction progress and effectively reducing the project cost. In the external wall insulation construction, the PVC external wall hanging board insulation system is not only simple in construction, but also has good insulation effect. The initial investment can be quickly recovered through energy saving in future use.

Product image display

Siding panel applied in house ,office building, villa, and wall protection. Due to its top layer covered with PVC, ASA, or PMMA, it can be used in hot, cold dry or wet place, can bear long time sun light ,wind, rain and bad weather. This line can be equipped with different pattern rollers, easily changeable.Special designed calibration unit and good process- ing experience can make operation easy and extend its life. Punching on-line , it is more economical way. As per customer’s requests, it also can be equipped with rolling machine,printer, coding machine and so on.

Read the full article

#DoubleScrewExtruder#PlasticMachine#ProfileMakingMachine#PVCCeilingPanelExtrusionLine#PVCCeilingPanelMachineManufacturing#PVCCeilingProducitonLine#PVCDoorFrameExtrusionLine#PVCFlooringMachine#PVCProfilesExtrusionMachine#PVCSidingExtrusionLine#PVCSidingMakingMachine#PVCWindowProfilesProductionLine#SidingProductionLine#UPVCDoorWindowMachinery#WoodPlasticProductionLine#WPCExtrusionline

0 notes

Text

CNC Machining

In the present globe, where material high quality is one of the most crucial variable of all, picking the best-quality plastic products is something that is extremely important. This is because of the crucial price tags that are required for the production of such types of plastic materials.

Engineers have actually been building high-quality materials for mechanical design given that its creation. Products like fibers, wood, fiberglass, polymers, and polyurethane products are all instances of crafted plastic items which are made use of in mechanical engineering. These sort of engineering materials use various advantages to the designers in terms of engineering style. For instance, in the case of fiberglass, it has actually been recognized to be one of one of the most durable and flexible plastics which have actually shown to function well with high temperature. The residential properties of fiberglass have actually been also included in the production of synthetic textiles.

Even though fiberglass is a strong product, it is understood to be fairly delicate when based on severe temperatures. Some sorts of fibers which are taken into consideration to be tough, such as polyvinyl chloride (PVC) and also polypropylene (PP), are susceptible to melt-off if exposed to high temperature. If they do happen to melt, they have a tendency to transform fragile and also break quickly. Many different types of artificial fibers, made from nylon as well as polyester, have been utilized for printing applications in the past. Nonetheless, there are different types of manufacturing processes which make them much less durable than the ones made use of for other types of plastic products. This is because, when using the previously mentioned materials, high temperature is unavoidable.

The reasons for this are the extreme temperature level extremes. For instance, when printing an item, the color will develop at heat and after that transform weak and also break. When revealed to heat, the material will trigger a lot of stress and anxiety and fatigue which causes poor performance. An engineer will certainly locate it essential to know exactly how to generate the very best high quality plastic materials. The essential requirements of great performance can be satisfied by using materials like polyurethane, which is one of the most prominent plastic materials for engineering.

Polyurethane, which is a favorite among most of the engineers, is also known to be more tough and resilient to handling warm than nylon or polypropylene. This is the reason why polyurethane has come to be the most popular kind of plastic materials for engineering. Polymers do not need a heat to develop due to the fact that the procedure occurs within the manufacturing procedure. Actually, polymers and plastics was available in a variety of sizes. They are usually used various chain reactions as well as are really flexible as well as effective.

When it pertains to mechanical engineering, it is required to research just how to generate solid and also long lasting materials. It has been observed that polyurethane has actually been extensively utilized by mechanical engineers in designing the chassis of vehicles and various other such items. http://performanceplastic.pro/california/

Actually, polyurethane has actually proven to be really adaptable and also durable so it is very much reliable in the development of the wheels and also the body of autos. There are various other types of polymers and plastic materials which are made use of in mechanical design.

youtube

0 notes

Text

CNC Machining

In the here and now world, where worldly quality is the most crucial factor of all, picking the best-quality plastic materials is one thing that is vital. This is because of the crucial price that are needed for the manufacturing of such kinds of plastic products.

Designers have actually been building premium materials for mechanical design since its creation. Products like fibers, timber, fiberglass, polymers, and polyurethane products are all instances of crafted plastic products which are made use of in mechanical design. These kinds of engineering products use various advantages to the engineers in terms of engineering layout. For example, when it comes to fiberglass, it has been understood to be one of one of the most long lasting as well as flexible plastics which have confirmed to function well with heat. The residential properties of fiberglass have been likewise included in the development of synthetic textiles.

Even though fiberglass is a strong product, it is known to be fairly delicate when based on extreme temperature levels. Some kinds of fibers which are taken into consideration to be difficult, such as polyvinyl chloride (PVC) as well as polypropylene (PP), are vulnerable to melt-off if exposed to heat. If they do occur to melt, they often tend to turn fragile and also break conveniently. Several kinds of synthetic fibers, made from nylon and also polyester, have actually been used for printing applications in the past. Nonetheless, there are different kinds of manufacturing processes which make them much less sturdy than the ones used for various other kinds of plastic items. This is because, when utilizing the previously mentioned materials, heat is inevitable.

The factors for this are the extreme temperature level extremes. For instance, when publishing an item, the dye will create at heat and afterwards turn weak and break. When exposed to heat, the product will certainly create a great deal of stress and tiredness which brings about poor performance. A designer will find it required to know how to produce the most effective high quality plastic materials. The required requirements of great performance can be met by utilizing materials like polyurethane, which is among the most preferred plastic materials for engineering.

Polyurethane, which is a preferred among the majority of the engineers, is also known to be more sturdy and also resistant to dealing with warmth than nylon or polypropylene. This is the reason why polyurethane has ended up being one of the most preferred sort of plastic materials for design. Polymers do not call for a heat to create since the procedure occurs within the production procedure. As a matter of fact, polymers and plastics came in a variety of sizes. They are generally used various chemical reactions and also are very adaptable and effective.

When it pertains to mechanical engineering, it is necessary to study how to produce solid and sturdy products. It has been observed that polyurethane has been commonly made use of by mechanical engineers in developing the chassis of cars and various other such items. http://plasticsheet.net/los-angeles-county/

As a matter of fact, polyurethane has actually verified to be really adaptable and also sturdy so it is significantly efficient in the creation of the wheels as well as the body of autos. There are other types of polymers and plastic products which are utilized in mechanical design.

youtube

1 note

·

View note

Text

Prototype Machining Spokane, WA

Lead times between 2-4 weeks! www.AdvancedMachiningnw.com

#metalFabrication#PlasticMachining#MetalIndustries#MachineShop#MachiningManufacturer#prototypemaching#stainlesssteelmachining#cncmachining#steelmachining#aluminummaching

0 notes

Text

CNC Basic Cutting

In today world, where material high quality is one of the most essential aspect of all, selecting the best-quality plastic products is something that is vital. This is because of the weighty price that are needed for the manufacturing of such kinds of plastic products.

Engineers have been developing premium products for mechanical design since its beginning. Products like fibers, timber, fiberglass, polymers, and also polyurethane products are all instances of engineered plastic items which are made use of in mechanical engineering. These sort of design materials provide various benefits to the designers in terms of engineering style. As an example, when it comes to fiberglass, it has been recognized to be among one of the most durable as well as flexible plastics which have actually verified to function well with heat. The homes of fiberglass have actually been also incorporated in the development of synthetic materials.

Even though fiberglass is a solid product, it is known to be rather sensitive when subjected to extreme temperatures. Some types of fibers which are considered to be tough, such as polyvinyl chloride (PVC) as well as polypropylene (PP), are vulnerable to melt-off if exposed to heat. If they do happen to thaw, they tend to turn weak and also break easily. Many different kinds of synthetic fibers, made from nylon and polyester, have actually been used for printing applications in the past. Nonetheless, there are various kinds of making processes that make them less durable than the ones made use of for other types of plastic items. This is because, when utilizing the aforementioned products, high temperature is inevitable.

The reasons for this are the extreme temperature level extremes. For example, when publishing a product, the color will certainly create at high temperature and afterwards turn breakable and also break. When exposed to high temperature, the material will certainly trigger a great deal of anxiety as well as tiredness which leads to inadequate efficiency. A designer will certainly discover it needed to recognize how to create the best high quality plastic materials. The required demands of excellent performance can be met by utilizing materials like polyurethane, which is among the most prominent plastic materials for engineering.

Polyurethane, which is a preferred among the majority of the designers, is additionally recognized to be extra durable as well as durable to managing heat than nylon or polypropylene. This is the reason why polyurethane has come to be one of the most prominent type of plastic materials for design. Polymers do not require a high temperature to form since the process takes place within the manufacturing procedure. As a matter of fact, polymers and plastics can be found in a variety of sizes. They are normally used numerous chain reactions and are really adaptable as well as powerful.

When it comes to mechanical design, it is necessary to study how to produce strong as well as resilient materials. It has actually been observed that polyurethane has been commonly made use of by mechanical engineers in creating the chassis of vehicles and various other such products. http://copolymeracetalsheetandrod.pro/orange-county/

In fact, polyurethane has actually proven to be really flexible and sturdy so it is very much reliable in the creation of the wheels and the body of automobiles. There are various other types of polymers and also plastic products which are made use of in mechanical engineering.

youtube

0 notes

Link

#machining#plasticmachining#cncmachining#cncplasticmachining#medical device#medical device manufacturing#medical industry#cnc machining#cnc milling

0 notes

Text

Welcome Haituo machinery

#moldmaker#haituo#injectionmolding#plasticinjectionmold#haitian#injectionmoldingmachine#injectionmold#haitai#mould#plasticmachine

0 notes