Don't wanna be here? Send us removal request.

Text

Maximizing Machining Capacity with High-Performance End Mills

#proservtools#carbidetools#toolmaking#solidcarbideroundtools#proserv tools#cutting tools#end mill#end mill cutter#end miling

0 notes

Text

WORLD ENVIRONMENT DAY 2024

0 notes

Text

Maximizing Machining Capacity with High-Performance End Mills

Getting the most of machining capacity is essential in the highly competitive production environment in the manufacturing industry. High-performance end mills are critical to this project because they may save costs, increase precision, and boost production for your business. In this Article, Proserv Tools best cutting tools manufacturers in Pune will examine how these modern End Mill revolutionary tools can transform your machining processes and provide you with a competitive advantage.

Understanding End Mills and Their Importance

Used as cutting tools in contouring, slotting, and profiling; end mills are the most common tools to be incorporated in milling operations. It is designed to move in several directions inside the machine to help remove material. Nevertheless, end mills that are considered high-performance work with components and coatings, geometry, and precision production that are more accurate than ordinary end mills.

Key Features of High-Performance End Mills

Upgraded Materials: For instance, in manufacturing high-end end mills, carbide is often employed on account of its high level of hardness and wear resistance. Furthermore, to enhance heat resistance and increase the service time of tools, some are based on a layer of adjuvants such as titanium aluminum nitride (TiAlN).

Optimized Geometries: Many types of end mills are designed particularly for high-performance cutting geometries. Some of the characteristics that aid in increasing MRR, reducing chatter, and producing smooth surfaces include adaptable helix angles, irregularly placed flutes, and specific cutting edges.

Precision Manufacturing: Because high-performance end mills involve high levels of cutter reliability, these tools are created with high precision and excellent controlled tolerances. It also helps in consistency and reliability which are an important factor when dealing with quality control of the modules in large productions.

Benefits of Using High-Performance End Mills

Increased Material Removal Rates (MRR)

Typically, high-performance end mills hold a safe amount of chip thickness to remove material rapidly. HSS’s geometries are more complex and constructed from a better material to have a higher cutting speed and feeds than HSS. Giving rise to pleasant effects such as enhanced MRR and hence faster completion of jobs and improved productivity among manufacturers.

Enhanced Tool Life

An additional benefit of the items is increased tool life, which is also a result of durable high-performance end mills. Toto improves the tools' endurance and reduces the need for frequent tool replacements, sophisticated coatings on adhesion and other materials are also used. In addition to minimizing the amount of money spent on tools, it also helps to shorten the time that machines need to be repaired, which increases productivity.

Superior Surface Finish

For many machining applications, achieving a high-quality surface finish is essential. Because of their improved cutting edges and geometries, high-performance end mills create smoother surfaces and require fewer finishing steps. Time can be saved, and secondary process expenses can be decreased.

Reduced Chatter and Vibration

Noise and vibrations are some of the challenges that are well known for causing deterioration in milling tools as well as the quality of parts being produced. Problems such as advanced breakdown, heat build-up, and vibrations are minimized through such end mills as high-performance ones possess features such as variable helix angles and unequal flute spacing. These tools decrease the amount of chatter and vibration, which improves the stability and accuracy of the machining.

Selecting the Right High-Performance End Mill

To maximize its benefits, you must select the right high-performance end mill for your application. Here are some things to think about:

Material Compatibility

Various end mills are made for use with particular materials. Make sure the tool you use is appropriate for the material you are machining, be it titanium, steel, aluminum, or another material.

Coating Type

An end mill's performance can be greatly impacted by its coating. Coatings such as TiAlN are favored for applications that need high temperatures. Diamond-like carbon (DLC) coatings might be more appropriate for non-ferrous materials.

Tool Geometry

Consider the geometry of the end mill, including the number of flutes, helix angle, and cutting-edge design. These factors will influence the tool’s performance in terms of speed, feed rate, and surface finish.

Machine Capabilities

Ensure your machine can handle the cutting parameters recommended for high-performance end mills. This includes spindle speed, feed rate, and rigidity of the setup.

Implementing High-Performance End Mills in Your Operations

Training and Education

To get the most out of high-performance end mills, proper training and instruction are necessary. Make sure that the operators and engineers are knowledgeable about the special characteristics and ideal conditions for the operation of these tools.

Process Optimization

To get the most advantages from high-performance end mills, analyze and improve your machining procedures. This might involve modifying feeds and speeds, optimizing tool paths, and applying advanced machining techniques like trochoidal milling or high-speed machining.

Regular Maintenance

Regular maintenance will guarantee the best performance from your equipment. Frequent maintenance can assist in maintaining the high levels of productivity and quality attained with high-performance end mills by preventing problems that may come from tool wear or machine misalignment.

Conclusion

With the ability to greatly improve machining capacity, efficiency, and quality, high-performance end mills are revolutionizing the machining sector in the industry. The full potential of these sophisticated cutting tools can be realized by manufacturers through process optimization, tool selection, training, and maintenance. Purchasing high-performance Proserv Tools end mills is a big step toward maintaining a competitive edge in the manufacturing industry, not merely towards improved manufacturing because Proserv Tools is the best cutting tools manufacturer in Pune.

Click here for more details and info: www.proservtools.com

#proservtools#carbidetools#toolmaking#proserv tools#reliability#solidcarbideroundtools#endmill#end miling#end mill cutter#cutting tools manufacturers in pune#carbide cutting tools#cutting tools

0 notes

Text

5 Reasons Why Choose Us?

#proservtools#carbidetools#toolmaking#solidcarbideroundtools#spm machine#special purpose machine#spm manufacturers in pune#industries#proserv tools#cutting tools manufacturers in Pune#cutting tools#carbide cutting tools#best cutting tool#industry#manufacturers

0 notes

Text

https://proservtools.com/side-and-face-cutter/

0 notes

Text

https://proservtools.com/sharper-faster-smarter-mastering-precision-with-advanced-end-mill-techniques/

0 notes

Text

#carbidetools#proservtools#reliability#special purpose machine#toolmaking#cutting tools manufacturers in pune#carbide cutting tools manufacturers in pune#cutting tools#best cutting tools manufacturers in Pune

0 notes

Text

Proserv Tools " Extra Long End Mill "

" EXTENDING PRECISION MAXIMIZING RESULTS "

Want to achieve exceptional accuracy in your machining projects? Our Extra Long Endmill is the solution.

Our Extra Long End Mill delivers maximum precision !!!!!!!

Crafted with precision engineering, it guarantees great results every time.

Visit us at: www.proservtools.com

#proserv tools#proservtools#carbidetools#reliability#solidcarbideroundtools#toolmaking#extra long end mill

0 notes

Text

Discover accuracy with 'Proserv Tools' superior Form Tool. Craft your success with precision! Our Form Tools redefine shaping projects.

#proservtools#formtools#formtoolsforthewin#carbidetools#carbidecuttingtools#cuttingtoolsmanufacturers#cuttingtoolsindustry#qualitycuttingtools#cuttingtoolstechnology#precisioncutting#profilecutter#solidcarbideroundtools#solidcarbidetools#technology#industries#toolmaking#drilling#CutterTool#quality#reliability

0 notes

Text

https://proservtools.com/the-power-of-precision-spm-machine-and-their-impact-on-industries/

0 notes

Text

Carbide Cutting Tools: Your Ultimate Crafting Companions

Carbide-cutting tools are an essential instrument used by professionals and manufacturers in various industries for precise cutting. These remarkable tools, with their remarkable durability and precision, have completely changed the metalworking and machining sectors. In this article, Proserv Tools the best cutting tools manufacturers in Pune will examine the various forms, uses, and advantages of carbide-cutting tools as well as the important factors that should be taken into consideration when choosing into right cutting tool for your requirements.

What Are Carbide Cutting Tools?

Carbide-cutting tools are an essential part of the machining and metalworking industry. They are engineered to shape, cut, and form materials with extreme precision. The term 'carbide' refers to a composite material composed of tungsten and carbon, offering exceptional hardness and resistance to wear. This unique combination makes carbide-cutting tools highly desirable for a wide range of applications.

Types of Carbide Cutting Tools

Carbide End Mills: These versatile tools are a staple in machining. They come in various designs, including square end mills, ball end mills, and corner radius end mills, each designed for specific applications.

Carbide Drills: Ideal for creating holes in various materials, carbide drills maintain sharpness even under high-speed drilling conditions.

Carbide Inserts: These replaceable cutting tips can be used in a variety of cutting tools, extending the tool's lifespan and reducing overall costs.

Carbide Reamers: Used for precision whole finishing, carbide reamers ensure tight tolerances and a superior surface finish.

Carbide Burrs: These tools are perfect for deburring and shaping materials. They are available in a variety of shapes and sizes that suit a variety of applications.

The Advantages of Carbide-Cutting Tools

The widespread adoption of carbide-cutting tools can be attributed to their numerous advantages, which include:

1. Exceptional Hardness

Carbide-cutting tools are renowned for their exceptional hardness, making them capable of machining even the toughest materials. This durability ensures a longer lifespan and consistent performance.

2. Wear Resistance

The combination of tungsten and carbon in carbide tools results in outstanding wear resistance. They can withstand high temperatures and maintain their sharpness, reducing the need for frequent replacements.

3. High Precision

Precision is crucial in machining and metalworking. Carbide-cutting tools offer remarkable precision, allowing for accurate and intricate cuts, holes, and shapes.

4. Increased Productivity

The longevity and performance of carbide-cutting tools lead to increased productivity. Reduced downtime for tool changes and consistent results contribute to higher efficiency in manufacturing processes.

5. Versatility

Carbide-cutting tools are available in various types, each designed for specific applications. This versatility ensures that there is a suitable tool for every machining requirement.

Applications of Carbide Cutting Tools

Carbide-cutting tools find applications across a wide range of industries, including:

1. Aerospace

In the aerospace industry, precision is paramount. Carbide-cutting tools are used for machining components like aircraft frames, engine parts, and landing gear.

2. Automotive:

Carbide-cutting tools are essential for producing engine and transmission components, among other automobile parts.

3. Medical:

In the medical field, where accuracy is essential and can mean the difference between life and death, carbide-cutting tools are used to create surgical tools and implants.

4. Oil and Gas

Components for the oil and gas sector, including drilling and exploration equipment, are machined using carbide-cutting tools.

5. Mold and Die

Mold and die-making require intricate shapes and tight tolerances, making carbide-cutting tools an ideal choice for this industry.

Choosing the Right Carbide Cutting Tool

To get the desired effects, choosing the right carbide-cutting tool is crucial. Here are some important things to consider about:

1. Material Compatibility

Different materials require specific types of carbide-cutting tools. Make sure the tool you select is appropriate for the material you plan to work with.

2. Cutting Speed and Feed Rate

Optimal cutting speeds and feed rates vary depending on the material and tool. It's crucial to follow the manufacturer's recommendations for best results.

3. Coating

Some carbide-cutting tools come with specialized coatings to enhance performance. Consider the coating options available and choose the one that aligns with your requirements.

4. Tool Geometry

The cutting tool's engineering, which includes its angles and forms, has a big impact on the cut's quality. Make sure the tool geometry you choose is appropriate for the task at hand.

Maintaining Carbide Cutting Tools

To maximize the lifespan and efficiency of your carbide-cutting tools, regular maintenance is essential. Here are some tips for maintaining your tools:

1. Proper Cleaning

After use, clean the cutting tool to remove any built-up residue or chips. This prevents deterioration of the cutting edges.

2. Lubrication

Using the appropriate lubricants during machining reduces friction and heat generation, extending the tool's life.

3. Storage

Store carbide-cutting tools in a dry, cool environment to prevent corrosion and damage.

4. Inspection

Regularly inspect the cutting edges for signs of wear or damage. Replace or re-sharpen tools as needed to maintain precision.

Conclusion

In the world of machining and metalworking, carbide-cutting tools stand as a symbol of precision and efficiency. Their exceptional hardness, wear resistance, and versatility have made them indispensable in various industries. It is crucial to take into account aspects like material compatibility, cutting speed, and tool geometry when selecting a carbide cutting tool. Proserv Tools is the best cutting tools manufacturer in Pune. You can guarantee that your carbide-cutting tools continue to produce amazing results and increase the productivity and efficiency of your production processes by adhering to recommended maintenance procedures. So, whether you're in aerospace, automotive, medical, oil, and gas, or mold and die making, carbide cutting tools are your reliable partner in achieving precision and quality. Visit Proserv Tools Pvt Ltd company today and choose the best carbide-cutting tools as per your requirements and increase your productivity.

Visit us for more details: https://proservtools.com/

#proservtools#carbidetools#carbidecuttingtools#cuttingtoolsmanufacturers#cuttingtoolsindustry#qualitycuttingtools#cuttingtoolstechnology#precisioncutting#profilecutter#solidcarbideroundtools#solidcarbidetools#technology#industries#toolmaking#drilling#quality#reliability

0 notes

Text

https://proservtools.com/blaser-2/

0 notes

Text

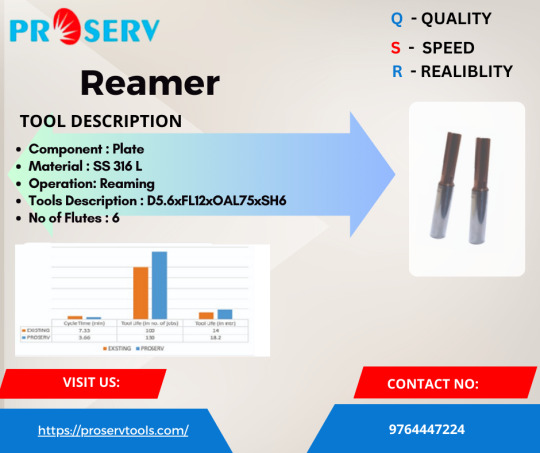

Proserv Tools follows : 'Quality' in Product. 'Speed' in Execution. 'Reliability' in performance.

Reamer: 1)High-performance Reamer 2)High productivity due to high cutting parameters 3)Consistent and productive saving Time and Cost 4)Uniform concentricity for long tool life and dimensional accuracy 5)Excellent surface finish on the component 6)Flute geometry with unequal flute spacing 7)Achievable hole tolerance H7

PARAMETERS: EXISTING PROSERV Cutting Speed Vc (m/min) 10 20 RPM 637 1274 Feed (mm/rev) 0.03 0.03 Table Feed Vf (mm/min) 19 38 No. of holes (per job) 20 20 Depth ap 7 7

Visit Our Site For More Details: https://proservtools.com/

#proservtools#Reamer#reamermaking#carbidetools#cuttingtoolsmanufacturer#qualitycuttingtools#cuttingtoolstechnology#precisioncutting#solidcarbideroundtools#solidcarbide#technologies#industry#tooling#toolmaking#qualitytools#reliability#toolsforlife#productivitytools

0 notes

Text

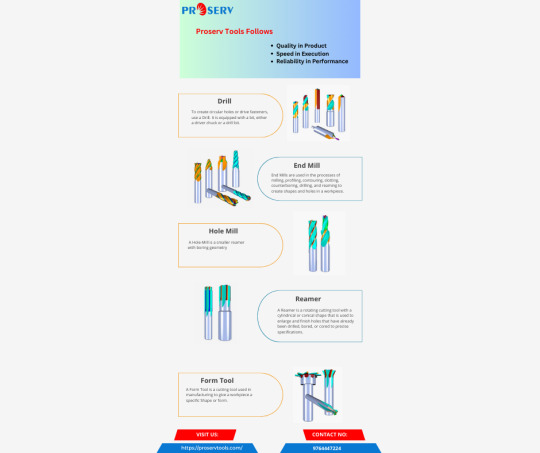

Proserv Tools follows :

'Quality' in Product.

'Speed' in Execution.

'Reliability' in performance.

#proservtools#carbidetools#carbidecuttingtools#cuttingtoolsmanufacturer#cuttingtoolsindustry#qualitycutting#cuttingtoolstechnology#precisioncutting#profilecutter#solidcarbideroundtools#solidcarbidetools#technology#industries#toolmaking#drilling#qualitytools#reliability#endmill#Reamer#holemill#formtool#tooling

0 notes

Text

https://proservtools.com/

0 notes

Text

https://proservtools.com/the-power-of-precision-spm-machine-and-their-impact-on-industries/

0 notes

Text

0 notes