Don't wanna be here? Send us removal request.

Text

How Khakhra Making Machines Are Used in Commercial Settings

Khakhra, a crispy and savory Indian snack, has become a favorite among food enthusiasts worldwide. The increasing demand for this traditional snack has led to the adoption of khakhra-making machines in various commercial settings. These machines offer numerous benefits, including efficiency, consistency, and scalability. Here are some key applications of khakhra-making machines in the food industry.

Large-Scale Production

Large amounts of khakhra are frequently needed by commercial food producers to satisfy consumer demand. These companies are able to create khakhra on a huge scale thanks to khakhra-making machines. Multiple batches can be processed concurrently by fully automatic khakhra-making machines, guaranteeing great output rates without sacrificing quality. Manufacturers can increase their market reach and fulfill large orders thanks to these capabilities.

Consistent Quality

The capacity to maintain constant quality is one of the main benefits of employing a khakhra-making machine. The thickness, texture, and flavor may vary depending on the manual production methods used. On the other hand, khakhra-making machines is made to guarantee consistency in each batch. Customer satisfaction is increased since each piece of khakhra is guaranteed to fulfill the required quality standards thanks to the exact control over temperature, pressure, and cooking time.

Time and Labor Efficiency

In commercial settings, time and labor efficiency are crucial factors. Khakhra-making machines significantly reduce the time required for production. The automation of the process minimizes the need for manual labor, allowing businesses to allocate their workforce to other essential tasks. This efficiency not only increases productivity but also reduces operational costs.

Customization and Innovation

The ability to experiment with various flavors, ingredients, and shapes is provided by khakhra-making machines. Companies can adapt their khakhra offers to suit a range of customer tastes. For example, they may provide flavored khakhra, gluten-free khakhra, and multigrain khakhra. This capacity for innovation aids companies in maintaining their competitiveness and drawing in a larger clientele.

Hygiene and Safety

In the food sector, adherence to safety and hygienic regulations is crucial. Stainless steel parts and other food-grade materials are used in the design of khakhra-making machines, guaranteeing that the production process satisfies stringent hygiene regulations. Furthermore, the process's automation lowers the possibility of contamination, improving the product's overall safety.

Packaging Integration

Packaging is an essential part of the production process in commercial contexts. The entire production line can be made more efficient by integrating packaging systems with khakhra-making machines. By automating the packaging process, this integration enables companies to guarantee that the khakhra is appropriately branded and sealed. Effective packaging increases the product's shelf life and preserves its freshness.

Catering and Events

The efficiency and consistency of khakhra-making machines make them an ideal solution for the catering industry. Catering companies and event organizers frequently need to provide their clients with large quantities of snacks. By producing khakhra in bulk, these businesses can ensure that they can meet the demands of large gatherings and events.

The advent of the khakhra-making machine has revolutionized the production process, allowing businesses to scale up their operations and maintain consistent quality. Here are some success stories of businesses that have effectively used khakhra-making machines to achieve remarkable growth and success.

Case Study 1: Khakhra King

Overview: Khakhra King, a leading snack brand, was struggling to meet the growing demand for their products. The manual production process was time-consuming and inconsistent in quality.

Solution: The company invested in fully automatic khakhra-making machines. These machines allowed them to produce large quantities of khakhra with uniform quality.

Results:

Increased Production: The khakhra-making machines increased production capacity by 200%.

Consistent Quality: The machines ensured uniform thickness and texture, maintaining the brand's quality standards.

Reduced Labor Costs: Automation reduced the need for manual labor, cutting costs significantly.

Khakhra King successfully expanded its market reach and established itself as a top player in the industry.

Case Study 2: Local Delights

Overview: The goal of the regional brand Local Delights was to increase its distribution network without sacrificing the quality of its khakhra.

Solution: To enable manual intervention in critical operations, the company opted to adopt semi-automatic khakhra-making equipment.

Findings:

Preserved Authenticity: By allowing manual control over specific processes, the khakhra-making machines preserved the original flavors.

Scalable Production: The equipment made it possible to increase output without sacrificing quality.

Expanded Distribution: Local Delights was able to extend its distribution network throughout the area thanks to its improved production capability. The adaptability offered by khakhra-making machines allowed Local Delights to successfully strike a balance between tradition and scalability. Khakhra King, Healthy Bites, Traditional Taste, Global Snacks, and Local Delights are just a few of the success stories that demonstrate how khakhra-making equipment can change lives. Businesses have been able to boost output, maintain constant quality, and reach a wider audience thanks to this equipment. For companies trying to grow while maintaining the genuine flavor of traditional khakhra, the khakhra-making machine has become an essential tool.

0 notes

Text

Benefits of Using an Automatic Roti Maker

For those who enjoy freshly produced rotis but find the traditional approach labor-intensive and time-consuming, the automatic roti maker machine is a game-changer. Here, we go over the many advantages of using an automatic roti maker machine over more conventional techniques.

The ease that the automatic roti maker machine provides is among its biggest benefits. Kneading the dough, rolling it into flat discs, and frying each roti separately on a tawa (griddle) are all phases in the traditional roti-making process. You just need to put the dough into an automatic roti maker machine, and it will take care of the rest. For busy people and families, this hands-off approach is perfect because it saves time and effort.

The automated roti maker machine is made to be efficient. In a fraction of the time required to prepare them by hand, it can produce several rotis. This is particularly useful for big parties or events where a lot of rotis must be consumed fast. Every roti is cooked uniformly and flawlessly because of the machine's reliable operation, which does away with the uncertainty and guesswork involved in using conventional techniques.

Using an automatic roti maker machine ensures that each roti is of consistent size, thickness, and texture. This uniformity is challenging to achieve with manual methods, where variations in dough rolling and cooking time can lead to inconsistent results. The machine's precise controls guarantee that every roti is cooked to perfection, providing a superior dining experience.

Even someone with no prior cooking knowledge can easily use the automatic roti maker machine. Usually, the equipment has easy-to-follow instructions and needs little setup. After you get the hang of it, preparing rotis is simple and stress-free. Because of its simplicity, more people are enjoying homemade rotis without the trouble of more conventional ways.

Making rotis the old-fashioned way may be untidy, with dough and flour sometimes spilling onto floors and countertops. By keeping the mess inside the machine, the automatic roti maker machine contributes to a cleaner kitchen. With detachable sections that can be cleaned independently, the machine is very simple to maintain a clean and hygienic cooking area.

You have control over the ingredients that go into your rotis when you use an automatic roti maker machine. Whole wheat flour, multigrain flour, or gluten-free substitutes are healthier options. Because store-bought rotis may contain preservatives and other additives, this level of control isn't always achievable. An automatic roti maker machine produces healthier, fresher, and chemical-free homemade rotis.

Long-term cost savings may result from purchasing an automatic roti maker machine even though the first purchase might seem like a big outlay, the money saved on store-bought rotis and the decreased need to eat out soon add up. Additionally, the machine saves time and effort when making rotis by hand, freeing you up to concentrate on other activities or duties.

Moreover, investing in automatic Roti Making Machines can be a significant decision for any household. Here, we evaluate the cost-effectiveness of investing in Roti Making Machines compared to other kitchen appliances, along with safety considerations.

Machines for making roti require little upkeep. To keep them in good operating order, regular cleaning, and sporadic servicing are usually enough. Reliability and durability are features of high-quality models. Automatic Roti Making Machines can be a more enduring investment than other kitchen appliances that might need to be repaired or replaced more frequently.

With the help of roti-making machines, consumers may regulate the ingredients used to make healthy rotis. To steer clear of the preservatives and additives frequently found in store-bought rotis, you can use whole wheat, multigrain, or gluten-free flour. You can enjoy healthier meals and better dietary management by preparing fresh rotis at home.

The brand, model, and characteristics of roti-making machines affect their original cost. Advanced models with greater features can cost more, while some simple variants are reasonably priced. The initial cost of a roti-making machine may appear more than that of other household appliances like mixers, grinders, or toasters. But the advantages they provide outweigh this expense.

Machines for making roti require little upkeep. To keep them in good operating order, regular cleaning, and sporadic servicing are usually enough. Reliability and durability are features of high-quality models. Roti Making Machines can be a more enduring investment than other kitchen appliances that might need to be repaired or replaced more frequently. Numerous benefits, like time savings, consistent quality, health benefits, energy efficiency, convenience of use, safety, and durability, are revealed when evaluating the cost-effectiveness of investing in roti-making machines. The long-term advantages of Roti Making Machines outweigh the initial cost, which may be more than those of some other kitchen gadgets. These devices can improve your culinary experience and support a healthier lifestyle by making the process of producing fresh rotis easier.

0 notes

Text

The Evolution of Khakhra Making Machines: From Traditional to Automated

Khakhra, a popular Indian snack made from whole wheat flour, is loved for its crispiness and flavor. Traditionally, khakhra making was a labor-intensive process, requiring a significant amount of manual effort. However, the introduction of the khakhra-making machine has revolutionized this process, making it more efficient and less time-consuming. This article explores the evolution of the khakhra-making machine, from traditional methods to fully automated solutions.

1. Customary Khakhra-making machine

Making khakhra the old-fashioned way required a number of physical procedures. Water, spices, and whole wheat flour were combined to make the dough. The dough was then manually rolled out into thin discs in small pieces. On a heated griddle, these discs were roasted, necessitating continual supervision and hand labor to guarantee uniform cooking and avoid burning. Producing a tiny batch of khakhra was a time-consuming and arduous procedure that frequently took hours.

2. Semi-Automatic Machines' Introduction

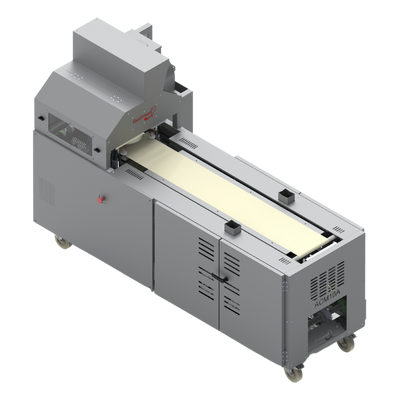

The introduction of the semi-automatic khakhra-making machine marked the first notable development in khakhra manufacture. While some steps of the process, including rolling and kneading the dough, were mechanized by these machines, roasting still required human interaction. Machines that khakhra making machines semi-automatically greatly decreased the amount of work required and enhanced output. They enabled small-scale firms to expand their operations and offered a more uniform product quality.

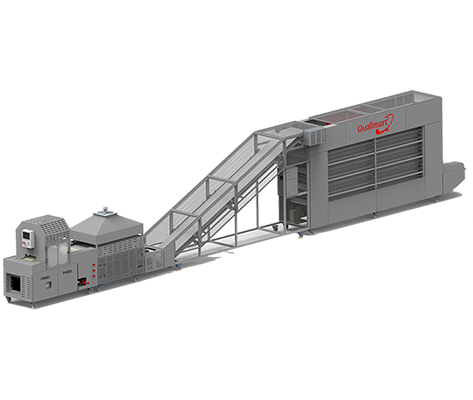

3. Fully Automated Khakhra-making machine

The creation of a completely automated khakhra-making machine marked the next advancement in khakhra production technology. Everything is automated by these machines, including the making of the dough, roasting, and packing. The following are essential components of a fully automated khakhra-making machine:

Dough Kneading: To guarantee consistent quality, the machine automatically kneads the dough to the ideal consistency.

Dough Rolling: The machine rolls out the dough into uniformly thin discs, removing the need for manual rolling.

Roasting: To guarantee uniform cooking and crispiness, the machine roasts the khakhra discs equally on both sides.

Packaging: To maintain freshness, some machines additionally include an automatic packaging function that seals the khakhra in airtight containers.

Benefits of Fully Automatic Khakhra Making Machines

The introduction of the fully automatic khakhra-making machine has brought numerous benefits to the industry:

Increased Efficiency: Fully automatic machines can produce large quantities of khakhra in a fraction of the time required by traditional methods. This allows manufacturers to meet higher demand and increase their market reach.

Consistent Quality: Automation ensures that each khakhra is rolled and roasted to the same standard, resulting in a uniform product that meets quality expectations.

Reduced Labor Costs: With the entire process automated, the need for manual labor is significantly reduced. This lowers production costs and increases profitability for manufacturers.

Hygiene and Safety: Fully automatic khakhra-making machines operate in a controlled environment, minimizing the risk of contamination and ensuring higher hygiene standards.

Scalability: These machines enable small and medium-sized enterprises to scale up their production without a proportional increase in labor costs, making it easier to grow their business.

Technological Innovations

The evolution of the khakhra-making machine continues with ongoing technological innovations. Modern machines are equipped with advanced features such as:

Touchscreen Controls: For easy operation and precise control over the production process.

Energy Efficiency: Machines are designed to consume less energy, reducing operational costs and environmental impact.

Customization: Machines can be customized to produce different types of khakhra, catering to diverse consumer preferences.

The snack industry is undergoing a notable change due to the introduction of fully automatic khakhra-making machines. These machines have transformed the production process, enhancing efficiency, consistency, and scalability to unprecedented heights.

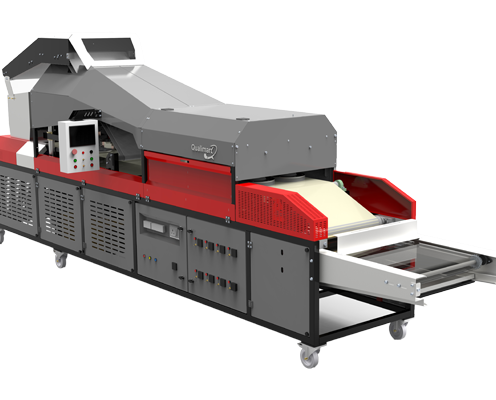

The foremost benefit of utilizing a fully automatic khakhra-making machine is the significant enhancement in production efficiency. These machines streamline the entire operation, encompassing dough preparation, roasting, and packaging. By automating these processes, the reliance on manual labor is diminished, leading to a reduction in production time and an increase in output. Consequently, manufacturers are now able to generate substantial quantities of khakhra in a considerably shorter timeframe compared to conventional methods.

The Khakhra-making machine fully automatic guarantees uniform product quality. By automating the production process, these machines ensure consistency in dough thickness, roasting duration, and overall texture. Such uniformity is essential for upholding a brand reputation and satisfying customer demands. Each batch of khakhra produced by a fully automatic machine adheres to the same elevated standards, providing a dependable product consistently.

The khakhra-making machine fully automatic is transforming the snack production sector by improving efficiency, uniformity, and scalability. These machines provide a variety of advantages, such as heightened production efficiency, consistent quality of products, lower labor expenses, improved hygiene standards, scalability, energy efficiency, and advancements in technology. With the increasing demand for premium khakhra, investing in a khakhra-making machine fully automatic enables manufacturers to maintain a competitive edge and address the changing requirements of their clientele.

0 notes

Text

How Automatic Roti Maker Machines Can Simplify Your Cooking?

Although cooking is a necessary daily task, it can frequently be labor-intensive and time-consuming. An automatic roti maker machine can be a lifesaver for people who love homemade, fresh rotis but find the preparation process tiresome. These cutting-edge gadgets are made to make preparing rotis easier and save you time and effort. This post will discuss the benefits of investing in an automatic roti maker machine and how it may improve your cooking experience.

1. Time-Saving Practicality

The time that an automatic roti maker machine saves is among its biggest benefits. The dough is kneaded, rolled out, and cooked separately for each roti in the traditional method. The entire procedure is expedited with an automatic roti maker machine. All you have to do is prepare the dough and feed it into the machine; it will do the rest. As the machine takes care of the labor, you may concentrate on other cooking duties or even unwind.

2. Reliable Quality

Every roti is cooked to perfection thanks to an automatic roti maker machine. Rotis are consistently cooked thanks to the constant heat and pressure maintained by these devices. With hand preparation, where variables like rolling technique and temperature control can change, this uniformity can be difficult to attain. You may have hassle-free, perfectly round, and evenly cooked rotis with an automatic roti maker machine.

3. Usability

It is really easy to use an automatic roti maker machine. Even inexperienced cooks can use the majority of models because they include easy-to-use controls and clear instructions. The automatic procedure lowers the learning curve, allowing you to begin creating mouthwatering rotis immediately. Whether you're a novice cook, a busy professional, or a home cook with little time, an automatic roti maker machine may make the procedure simple and fun.

4. Advantages for Health

You can ensure a healthier supper by controlling the ingredients used in your rotis with an autonomous roti maker machine. To make personalized rotis, you can use whole wheat flour, add herbs and spices, or add other wholesome components. Store-bought rotis frequently lack this level of control since they may contain hazardous ingredients or preservatives. Your family will have a healthier, more nourishing supper if you prepare your own rotis at home using an automatic roti maker machine.

5. Adaptability

Numerous automatic roti maker machines are multipurpose and may be used to manufacture a variety of flatbreads, including tortillas, parathas, and chapatis. Because of its adaptability, you may try out various recipes and cuisines without requiring a variety of appliances. Purchasing an automatic roti maker machine expands your culinary skills and gives your kitchen a multipurpose tool.

6. Efficiency of Energy

Compared to conventional stovetop cooking, modern automatic roti maker machines use less energy because of their energy-efficient design. This makes them an eco-friendly option in addition to lowering your energy costs. Choosing an automatic roti maker machine that uses less energy helps to promote more sustainable cooking methods.

7. Simple Upkeep

An automatic roti maker machine is easy to maintain. The majority of models have easily cleaned detachable pieces and non-stick surfaces. Frequent maintenance guarantees the machine's longevity, giving you dependable service for many years to come. The machine may usually be kept in good operating order with a simple wipe-down after usage.

Roti is a staple in many households, and with the advent of the roti-making machine, preparing this delicious flatbread has become easier and more convenient. Whether you are looking to make traditional plain rotis or want to get creative with different flavors, a roti-making machine can help you achieve perfect results every time. Here are some delicious roti recipes you can make using a roti-making machine.

Classic Whole Wheat Roti:

Ingredients:

2 cups whole wheat flour

1 cup water (adjust as needed)

A pinch of salt

Instructions:

In a mixing bowl, combine the whole wheat flour and salt.

Gradually add water and knead the dough until it is smooth and pliable.

Divide the dough into small balls.

Preheat the roti-making machine and place one dough ball on the machine.

Close the lid and let the roti cook until it is golden brown.

Serve warm with your favorite curry or chutney.

Using a roti-making machine ensures even cooking and a perfect round shape every time.

A roti-making machine can greatly simplify the process of making delicious and diverse roti recipes. From classic whole wheat rotis to creative stuffed variations, these machines ensure consistent results with minimal effort. By incorporating a roti-making machine into your kitchen, you can enjoy the convenience of freshly made rotis without the hassle of traditional preparation methods. Experiment with these recipes and discover the ease and versatility that a roti-making machine brings to your culinary adventures.

0 notes

Text

Case Studies: Successful Implementation of Chapati-Making Machines

The food industry continuously seeks innovations to streamline processes and improve efficiency. One such innovation is the chapati-making machine, which has revolutionized the preparation of this staple food in many commercial kitchens. Here, we explore a few case studies highlighting the successful implementation of chapati-making machines by leading chapati making machine manufacturers.

Case Study 1: Catering Services in Delhi

To satisfy the enormous demands of weddings and events, a well-known catering firm in Delhi looked to improve its chapati production. They added a completely automatic chapati-making machine to their operations by collaborating with chapati-making machine manufacturers. The outcome of this implementation was:

A 50% boost in output capability.

Chapatis of uniform size and quality.

Substantial decrease in the cost of manual labor.

The caterer stated that they were able to serve big groups of people with ease and maintain a high level of customer satisfaction because of the machine's dependability and effectiveness, which were supplied by the chapati-making machine manufacturers.

Case Study 2: Restaurant Chain in Mumbai

During peak hours, a well-known restaurant chain in Mumbai struggled to maintain the uniformity and speed of chapati preparation. They placed semi-automatic chapati-making machines throughout their locations after speaking with a reliable chapati-making machine manufacturer. The outcomes were striking:

40% less time was spent on preparation.

Chapatis that are all the same thickness and size.

Increased productivity in the kitchen.

The restaurant business admitted that the chapati-making machine's manufacturer knowledge and assistance were essential to attaining these advancements.

Case Study 3: Industrial Canteen in Bangalore

To meet the tremendous demand for chapatis, an industrial cafeteria in Bangalore that serves thousands of meals every day sought a solution. They adopted a high-capacity chapati-making machine in partnership with a forward-thinking chapati-making machine manufacturer. As a result of the implementation:

More than 2,000 chapatis are produced per hour.

Despite large volumes, quality remains constant.

Enhanced cleanliness and hygienic conditions throughout production.

The chapati-making machine manufacturers were commended by the canteen management for their innovative technology and smooth integration, which significantly increased their operating efficiency.

These case studies demonstrate the transformative impact of chapati-making machines in various commercial and institutional settings. The expertise and advanced technology provided by chapati-making machine manufacturers have enabled businesses to increase efficiency, maintain consistent quality, and reduce labor costs. Whether in catering services, restaurants, industrial canteens, school meal programs, or luxury hotels, the role of a reliable chapati-making machine manufacturer is crucial in achieving these successes. The continued innovation and support from these manufacturers ensure that chapati-making machines remain an integral part of modern food preparation.

The landscape of kitchen technology is ever-evolving, and chapati-making machines are no exception. With the growing demand for automation and efficiency in food preparation, chapati-making machine manufacturers are continuously innovating to meet these needs.

The combination of advanced automation and artificial intelligence (AI) is one of the most important trends. Chapati-making machine manufacturers are creating devices that can instantly modify settings in response to climatic conditions and the consistency of the dough. With little assistance from humans, AI-powered devices can ensure flawless chapatis by learning from previous experiences to increase productivity and consistency.

Chapati-making machine manufacturers will provide more personalization in their future designs. To meet particular needs, consumers will be able to modify characteristics like size, thickness, and cooking time using machines. Because of their adaptability, chapati machines can be used in a wide range of settings, from small homes to expansive commercial kitchens.

The rise of the smart kitchen means that chapati-making machine manufacturers are developing models that can connect with other smart appliances. These machines will be able to sync with kitchen management systems, providing real-time data and enhancing overall kitchen efficiency.

Sustainability is a growing concern in all industries, and chapati-making machine manufacturers are no exception. Future designs will incorporate eco-friendly materials and manufacturing processes, reducing the environmental impact of these machines.

As commercial kitchen space becomes more valuable, chapati-making machines, fully automatic designs will become more compact and space-efficient. These new models will be designed to fit seamlessly into various kitchen layouts without compromising on their output capacity or functionality.

When designing kitchen equipment, safety is still of utmost importance. Chapati-making machines fully automatic would have sophisticated safety features like temperature control, automatic shut-off, and integrated sensors to identify problems. In crowded kitchen settings, these characteristics will guarantee safe operation and lower the possibility of mishaps.

With so many improvements in the works, the future of completely chapati-making machines fully automatic is bright. Among the themes influencing this developing technology are increased automation, the integration of artificial intelligence, greater customization, enhanced energy efficiency, user-friendly interfaces, small designs, sophisticated safety measures, integration of smart kitchens, expanded manufacturing capabilities, and sustainability. Chapati-making machines fully automatic will be essential in revolutionizing the production of chapatis as they develop further, improving its consistency, efficiency, and usability in both home and commercial kitchens.

#Chapati making machine manufacturer#Chapati making machine#chapati maker#Chapati making machine fully automatic

0 notes

Text

Types of Khakhra Making Machines: Manual vs. Automatic

The popular Indian snack khakhra needs to be prepared accurately and consistently. Manual khakha-making machines are essential in small-scale production since they provide an economical and effective option.

Traditional Hand-Operated Khakhra-Making Machine:

The manual machine used to make khakhras by hand is a basic apparatus that mimics the rolling process by hand. It consists of a rolling pin mechanism and a flat surface. After putting the dough on the surface, the khakhra is pressed and shaped with a rolling pin. This kind of khakhra-making machine is perfect for household use and small-scale businesses. It keeps the genuine flavor and texture of homemade khakhra.

Hand-Powered Rotating Khakhra Manufacturing Device: An advancement over the conventional manual process is a hand-operated rotating khakhra-making machine. It has a rotating mechanism that makes uniform thickness and more constant pressure possible. A manual crank is used to rotate the plate with the dough on it.

Manual Khakhra Making Machine with a Lever Type: A lever mechanism is used in the manual khakhra-making machine of the lever type to exert pressure on the dough. Usually, it is made up of a lever arm with a pressing plate and a flat base. After the dough is positioned on the base, it is pressed into the required thickness and formed using the lever. This kind of khakhra-making machine provides more control over the pressure, enabling the production of consistently thin khakhras. For small-scale production, it is a well-liked option.

Multifunctional Handheld Khakhra Manufacturing Device: A manual khakhra-making machine with multiple uses is made to be adaptable. It can also be used to make various flatbreads like chapati and paratha, in addition to khakhra. Typically, this kind of khakhra-making apparatus

Small Handheld Manual Khakhra Making Machine: Small manual khakhra-making machines are made to be portable and simple to operate. These devices are perfect for mobile vendors and little kitchens because they are lightweight and convenient to store. Compact khakhra production machines are able to consistently produce high-quality khakhras despite their small size. They are ideal for anyone who wishes to create khakhra quickly and easily without requiring a lot of equipment.

Benefits of Manual Khakhra-Making machine

There are various benefits to using a manual khakhra making machine, particularly for home cooks and small-scale producers. First of all, they are more affordable than automated equipment, which enables a larger market to use them. Second, the thickness and texture of the khakhra may be more precisely controlled with manual khakhra machine making.

With the introduction of the fully automatic khakhra-making machine, the production method for the traditional Indian snack khakhra has undergone a change. This cutting-edge technology, which offers substantial benefits in terms of productivity, uniformity, and scalability, has completely changed the preparation of khakhra.

Cutting Edge Technology of khakhra making machine: Advanced features like temperature control, programmable settings, and automated dough feeding systems are among the advanced features found in a fully automatic khakhra-making machine. With the help of these elements, the production process may be precisely controlled, guaranteeing ideal cooking conditions for flawless khakhras. Because of the sophisticated technology employed, even those with limited technical knowledge may easily run a khakhra-making machine.

Efficiency in Energy Use of khakhra-making machine: Another significant benefit of a fully autonomous khakhra-making machine is its energy economy. Modern machinery is built to have a high manufacturing output with little energy consumption. This lowers operating costs and promotes sustainable production methods, which are in line with the increasing focus on environmental responsibility.

Cost-Effectiveness of Khakhra-making machine: Even though a fully mechanized khakhra-making machine may need a substantial initial investment, the long-term advantages greatly exceed the expenditures. Higher profitability is the result of lower labor expenses, more efficient production, and consistently high-quality products. Businesses can save money in the long run and get a competitive advantage in the market by making this investment.

Businesses' Ability to Scale: A completely autonomous khakhra-making machine is a priceless tool for companies aiming to expand. Businesses can increase their market share by efficiently producing huge volumes of khakhras. Business growth and expansion are supported by the scalability offered by a fully automatic khakhra-making machine, regardless of whether it is distributed to broader regions or serving local markets.

Safety and Hygiene: When producing food, hygiene is a major problem. A fully automatic khakhra-making machine successfully addresses this. The process is automated so that there is less chance of contamination because there is less human touch with the cooked khakhras and dough. The total hygiene standards are further improved by the safety elements included in this equipment, which guarantee safe operation and maintenance.

In summary, the fully automatic khakhra-making machine is revolutionizing the process of producing traditional khakhra. Its cutting-edge technology, efficiency, stability, and scalability make it a valuable tool for companies trying to increase their output. To address the increasing demand for this popular snack, businesses may ensure high-quality, hygienic, and cost-effective production by investing in fully automatic khakhra-making machines.

0 notes

Text

Using Khakhra Maker Step by Step

In today’s competitive market, efficiency and quality are key drivers of success, especially in the food industry. For businesses specializing in traditional Indian snacks, the ability to consistently produce high-quality snack is crucial. One such product is khakhra, a popular crispy flatbread that is a staple across India. Investing in a commercial khakhra making machine can be a game changer for businesses looking to enhance productivity, ensure consistency, and maintain the authentic taste that customers love.

Increased production capacity of khakhra making machine

A commercial khakhra making machine significantly boosts production capacity, allowing businesses to meet growing customer demand. Traditional methods of making khakhra are labor-intensive and time-consuming. Limiting the number of units that can be produced in a day. A khakhra making machine, on the other hand, can produce large quantities of khakhra with minimal manual intervention, making it an essentials investment for businesses aiming to scale up their operations.

Consistency in quality

Consistency is vital when it comes to food products. Customers expect the same taste and texture every time they purchase a product. A commercial khakhra-making machine ensures uniformity in thickness, size, and crispness of each khakhra, thereby maintaining the product’s quality. This level of consistency is difficult to achieve with manual methods, making a khakhra-making machine a valuable asset for business striving to build a loyal customer base.

Cost-effective production in Khakhra making machine

While the initial investment in a commercial khakhra-making machine might seem significant, the long-term benefits outweigh the costs. The automation provided by the machine reduces the need for a large force, thereby cutting down on labor costs. Additionally, the machine’s effect minimizes the wastage of raw materials, further reducing production costs. Over time, the savings generated by using a khakhra-making machine can lead to a substantial return on investments.

Time efficiency

Time is a crucial factor in business operations. The faster you can produce, the more you can sell. A commercial khakhra-making machine streamlines the production process, significantly reducing the time required to produce each batch. This not only increase the overall output but also allows businesses to respond quickly to market demands, ensuring that they never miss out on sales opportunities due to production delays.

Meeting health and safety standards of khakhra-making machine

Food safety is a top priority for any food-related business. Manual khakhra production can sometimes lead to inconsistencies in hygiene and cleanliness. A commercial khakhra-making machine is designed with food safety standards in mind, ensuring that the product is made in a clean and controlled environment. This reduces the risk of contamination and ensures that the khakhra produced meets all health and safety regulations.

Sustainability and energy efficiency

Modern khakhra-making machines are designed to be energy efficient, consuming less power while delivering high output. This not only reduces the operational costs but also aligns with sustainable business practices, which are increasingly important to consumers.

The food industry is constantly evolving, with automation playing a key role in streamlining production processes. For businesses specializing in traditional Indian snacks like Khakhra here’s a guide to using a khakhra-making machine fully automatic in industrial settings.

Preparation of ingredients: Before operating a khakhra-making machine fully automatic, it is essential to prepare the dough. The dough is typically made from whole wheat flour, oil, salt, and any other desired spices or flavorings. Ensuring that the dough is mixed thoroughly and has the right consistency is crucial for the machine to function optimally. The dough should be soft but not sticky, allowing it to pass smoothly through the machine.

Loading the dough: Once the dough is ready, it needs to be loaded into the dough feeder of the Khakhra-making machine fully automatic. The machine feeder is designed to take in the dough and automatically portion it into uniform balls. After the dough is loaded khakhra making machine fully automatic begins the process of flattening the dough balls into thin round sheets.

Roasting the khakhra: Once the dough is flattering, the next step in khakhra making machine fully automatic is roasting. The machine automatically transfers the dough sheets to the roasting section, where they are cooked at a controlled temperature.

Cooling and stacking: After roasting, the khakhras need to cool down before packaging. The khakhra-making machine fully automatic often includes a colling section where the freshly roasted khakhras are allowed to cool to room temperature

Packaging: The final step in the process involves packaging the khakhra distribution. While some Khakhra-making machines are fully automatic and come with built in packaging systems, other may require a separate packaging machine.

As the demand for traditional snacks continues to grow, investing in automated technology like a khakhra-making machine fully automatic can provide a competitive edge in the market, ensuring that your business remains at the forefront of the industry.

0 notes

Text

Convenience of Roti Maker in Modern Kitchen

In today’s fast world, convenience in the kitchen is more important than ever. One appliance that has gained significant popularity for its efficiency for its efficiency is the automatic roti maker machine. This innovative device simplifies the traditional process of making rotis, ensuring perfect results with minimal effort.

An automatic roti maker machine is a kitchen appliance designed to automate the process of making rotis, unlike manual methods, where rolling and cooking require significant effort. The automatic roti maker machine handles these tasks with ease. By pressing a button, you can achieve consistently round and evenly cooked rotis every time. Using an automatic roti maker machine is straightforward, you simply place the dough ball in the machine, and it rolls round in shape. The heated surface until it reaches the desired level of crispiness. This process ensures that each roti is cooked uniformity, without the need for constant monitoring.

Advantages of an automatic roti maker machine

Time-saving: One of the main benefits of an automatic roti maker machine is its ability to save time. Traditional roti-making can be time-consuming, but this machine has the ability to save time. Traditional roti making machine can be time consuming, but with this machine, you can prepare multiple rotis quickly and efficiently.

Consistency: An automatic roti maker machine ensures that each roti is of uniform size and thickness. This consistency in size and cooking leads to better results and a more enjoyable dining experience.

Ease of use: The user-friendly design of an automatic roti maker machine makes it accessible to everyone. Whether you’re busy professional or a homemaker, operating this machine requires minimal efforts.

Less mess: Using an automatic roti maker machine reduces the mess associated with rolling and cooking rotis on a traditional stovetop. The machine contains all the necessary components in one replacement, making cleanup easier.

Energy efficient: Many automatic roti maker machines are designed to be energy efficient, using less power than traditional cooking methods. This can contribute to lower energy bills and an eco-friendly kitchen.

When selecting an automatic roti maker machine, consider factors such as size, build quality, and additional features. Some machines come with adjustable settings for thickness and cooking time, allowing you to customize the roti-making process according to your preferences. An automatic roti maker machine is a valuable addition to any modern kitchen. Its convenience, consistency, and ease of use make out a popular choice for those looking to streamline their cooking process.

An automatic roti-maker machine is a specialized appliance designed to automate the preparation of rotis. It takes the hassle out of manual rolling and cooking by performing these tasks with precision and speed. By incorporating a roti maker into your kitchen, you can achieve constant results with minimal effort. By experimenting with various recipes, you can unlock a range of creative and delicious dishes using a roti maker. This machine is designed to simplify the roti preparation process, making it easier to achieve consistent results. This efficiency allowed you to experiment with different recipes, as the Machin handles the basic tasks of rolling and pressing. By using a roti maker, you can explore a variety of dishes without spending extra time in manual preparation.

Creative recipes using a roti-making machine

Stuffed parathas: A roti-making machine can be used to prepare delicious stuffed parathas. Simply roll out the dough with the machine, add your potatoes, paneers, or vegetables, and use the machine to seal the parathas. This method ensures uniform thickness and consistent cooking.

Mini pizzas: Create mini pizzas using your roti-maker by rolling out the dough to a thin, pizzas using roti-maker by rolling out the dough to a thin, even layer. Top with your favorite pizza sauce, cheese, and toppings. Bake or cook on a stovetop for a quick and tasty snack.

Roti wraps: The roti-making machine is perfect for preparing wraps. Roll out the dough into thin sheets, then fill with ingredients like grilled chicken, veggies, and sauces. Roll up and enjoy a quick, handheld meal.

Roti chips: For a crispy snack, use a roti-making maker to create a thin roti round. Cut them into crisp-sized pieces, brush with foil, and bake or fry until crisp. Season with your favorite spices for a flavorful treat.

Dessert rotis: Experiment with set treats by adding ingredients like cinnamon and sugar to the dough before rolling with your roti-maker. Cook and serve with a drizzle of honey or a sprinkle of powdered sugar for a delicious dessert.

Incorporating a roti making machine into your kitchen routine not only simplifies traditional roti preparations but also enhances your ability to experiment with new and exciting recipes. Embrace the versatility of the roti-maker and elevate your meal prep with innovative and delicious creations.

0 notes

Text

How khakhra maker can boost small-scale snack businesses?

Investing in a khakhra making machine can be a game changer for businesses looking to scale up production and improve the consistency of their products. With various models available in the market, it’s essential to know what features to prioritize when selecting the right khakhra-maker for your needs. Here are the top features to look for in a khakhra making machine.

One of the most critical aspects of a good khakhra making machine is automated temperature control, Khakhra requires precise cooking temperature control to ensure that each batch is cooked evenly, resulting in consistent quality. This feature is particularly important for maintaining the delicate balance between cooking the khakhra thoroughly while retaining its crunch. Different customers may prefer khakhras of varying thicknesses. A khakhra making machine that offers adjustable thickness settings allows you to cater to a broader audience. Whether you need thin, crispy khakhras or thicker, chewier ones, the ability to adjust the thickness is a valuable feature. This versatility ensures that your khakhra making machine can produce a variety of products, expanding your market reach.

For businesses looking to scale up, production capacity is a key consideration. A khakhra making machine with a high production capacity can significantly increase your output, allowing you to meet larger orders and grow your business. Look for a machine that can produce a substantial number of khakhras per hour, reducing the time and labor needed for manual production. This feature is particularly beneficial for small-scale businesses looking to boost their productivity.

Energy consumption is an important factor when choosing a khakhra making machine not only helps in reducing operational costs but also minimizes the environmental impact of your business. Look for machines with energy-saving features, such as automatic shut-off functions and efficient heating elements. This will ensure that your khakhra making machine operates cost-effectively while contributing to sustainable production practices. The durability of the khakhra making machine is crucial for long-term use. Machines made from high-quality, food-grade materials such as stainless steel are not only more durable but also safer for food production. A well-constructed khakhra making machine will withstand the rigors of daily use, reducing the need for frequent repairs or replacements, ensuring that the machine you choose is built to last, with components that can handle the demands of continuous production.

A khakhra making machine that is easy to maintain and clean is essential for ensuring hygiene and prolonging the machine’s lifespan. Look for machines with removable parts that can be easily disassembled and cleaned, this feature not only makes the khakhra making machine more user-friendly but also helps maintain the quality and safety of your products. Regular maintenance is key to preventing breakdowns and ensuring that your khakhra making machine operates smoothly over time. Simple, intuitive controls make it easier to adjust settings, monitor production, and troubleshoot issues as they arise. A khakhra making machine with an easy-to-use interface ensures that your production process is efficient and capable of delivering high-quality khakhra consistency.

On the contrary, the snack industry is booming, with an increasing demand for traditional and healthy snacks like khakhras, for small-scale snack businesses, meeting this demand can be challenging, especially when it comes to scaling up production while maintaining quality. This is where a khakhra making machine comes into play, offering a game-changer solution to enhance productivity, consistency, and profitability. One of the costs significant advantages of khakhra-makers is their ability to significantly increase production capacity,

Khakhra-making machines, fully automatic can produce a large number of khakhras in a short amount of time, surpassing the output of manual methods, for small-scale businesses, this means they can meet longer orders and expand their customer base without the need for a large workforce. The ability to produce more khakhras quickly allowed these businesses to take on more clients, including retailers and distributors to take on more clients, thereby boosting their market presence. The growing popularity of khakhra as a healthy snack option has led to increased demand in India and international markets.

Small-scale businesses equipped with khakhra making machines, fully automatic, are better positioned to capitalize on this trend. With the ability to consistently produce large quantities of high-quality khakhras, this engineer can explore export opportunities and tap into new markets. This expansion potential is crucial for small businesses looking to scale up and achieve long-term growth. Investing in a khakhra making machine fully automatic can be a transformative step for small-scale efficiency and meet the growing demand for khakhra.

In an increasingly competitive market, the ability to deliver high-quality products quickly and cost-effectively is key to success, for small-scale snack entrepreneurs, a khakhra maker is not just a piece of equipment- it’s a gateway to growth and profitability. This machine bridges the gap between the traditional and the modern kitchen, ensuring that khakhra making is accessible to everyone, from home cooks to large-scale producers.

0 notes

Text

The industry transformation with roti maker

The automatic roti maker machine is a boon for modern kitchens, offering a convenient and effective way to prepare perfect rotis. If you’re new to using one, here’s a c comprehensive guide to help you get started. Unboxing and initial setup; Unbox your automatic roti maker machine and ensure all parts are present.

Read the manufacturer’s manual for specific instructions related to your model. Place the roti maker on a flat, stable surface near a power outlet. Cleaning before use, wipe the surface of the roti maker with a damp cloth. Cleaning and maintenance, once the automatic roti maker machine is competently cool, wipe the cooking plates with a damp cloth. Avoid using abrasive cleaners or scouring pads. Regularly check the power cord and plug for any wear or damage. Store the automatic roti maker machine in a dry place when not in use. Ensure the dough is not too hard or too sticky. A soft, potable dough works best. Always preheat the roti maker before use to ensure even cooking. Apply even pressure when pressing the dough to avoid uneven thickness. Adjust the cooking time slightly based on your preferences for softer or crisper rotis. Using an automatic roti maker machine can simplify your cooking process and ensure consistent results every time. By following these steps and tips, you’ll be able to make perfect rotis with ease.

The food industry is constantly evolving, driven by demand for efficiency, consistency, and innovation. Among the many technological advancements, the introduction of automatic roti maker machines stands as a significant breakthrough, particularly in sectors where large-scale food production is essential. This machine is revolutionizing various industries, including restaurants, catering services, and large-scale food production units. Restaurants, especially those serving Indian cuisine, benefit immensely from automatic roti maker machines. These machines ensure that each roti is perfectly cooked and consistently sized, meeting the high standards expected by customers. By automating the roti-making process, restaurants can significantly reduce preparation time allowing chefs to focus on other aspects of meal preparation. Investing in automatic roti maker machines reduces labor costs associated with manual roti preparation. It minimizes waste by producing uniform rotis, thereby ensuring efficient use of ingredients. Catering services often handle large volumes of food, making manual roti preparation impractical. Automatic Roti maker machines can produce hundreds of rotis per hour, meeting the high demand without compromising on quality. They provide the flexibility to scale operations up or down based on the size of the event, ensuring optimal resource utilization.Automatic roti maker machines ensure that each roti meets the same quality standards, which is crucial for maintaining the reputation of the catering service. Consistent quality enhances customer satisfaction and can lead to repeat business and positive referrals. Large-scale food production units, such as those supplying rotis to schools, hospitals, and corporate cafeterias, benefit immensely from automatic roti-maker machines. These machines can produce rotis in bulk, ensuring timely delivery and meeting the high daily demands. Automation in roti-making aligns with the industry’s goal of maintaining high production volumes while ensuring food safety and hygiene. Modern automatic roti-maker machines offer customization options, allowing producers to adjust the thickness, size, and cooking time of rotis to cater to different preferences and dietary requirements. They can be programmed to produce various types of flatbreads, such as chapatis, parathas, and puris, adding versatility to the production line. Advanced automatic roti maker machines come equipped with smart features like programmable settings, touch screen interfaces, and automated dough handling, enhancing ease of use and operational efficiency. Integration with IOT (Internet of Things) allows for remote monitoring and maintenance, ensuring minimal downtime and efficient troubleshooting. Many automaticroti maker machines are designed to be energy-effective, reducing the carbon footprint of food production units; they also help in minimizing food waste by ensuring precise measurements and consistent output. The initial cost of purchasing and installing roti makers can be high, which might be a barrier for small businesses. However, the long-term benefits in terms of cost saving and efficiency often outweigh the initial expenditure. Operating an advanced roti-making machine requires a certain level of technical expertise. Training staff to use these machines effectively is crucial for maximizing their benefits. As technology continues to evolve, we can expect further advancements in roti maker, such as improved AI integration for Better precision and customization. The trend towards automation in the food industry is likely to grow with more businesses adopting these machines to stay competitive and meet increasing consumer demands. The advent of roti-making machines is transforming the food industry by enhancing efficiency, ensuring consistency, and reducing costs. From restaurants and catering services to large-scale food production units, roti-making machines are proving to be a valuable asset, driving innovation and setting new standards in food preparation.

0 notes

Text

Safety measures for fully automatic khakhra maker

Khakhra, a traditional Indian snack, is a popular healthy food item made from whole wheat flour. Traditionally, khakhra making is labor intensive proc, with advancements in technology, a process that involves rolling, roasting, and seasoning. However, advancements in a khakhra making machine can revolutionize the industry by increasing efficiency, consistency, and scalability. The development of a khakhra maker holds significant potential for the food industry. It can lead to increased production capacity, consistent product quality, and reduced labor costs. Future advancements could include. Integration with IoT, for remote monitoring and predictive maintenance.

Customization options allow adjustments for different khakhra types and flavors. Energy efficiency, further improvements in energy consumption to make the process more sustainable. The design and development of a khakhra maker is a complex but rewarding endeavor. By addressing the challenges and leveraging modern technology, such as machines can revolutionize the production process, making it more efficient and scalable while maintaining high quality and hygiene standards. As technology continues to advance, the future of automatic khakhra makers looks promising, with potential innovations that could further enhance their capabilities and efficiency.

The material selection for a khakhra maker is critical for ensuring durability, efficiency, hygiene, and safety. Let’s explore the key considerations and best practices in selecting materials for different components of the machine. Some of the key considerations of khakhra makers are food safety and hygiene. Materials must comply with food safety standards such as FDA, the Food and Drug Administration and EU regulations to ensure they are safe for contact with food. Materials should be non-reactive with food ingredients to prevent contamination and ensure the quality of the khakhra. Durability and wear resistance, components should be made from materials that can withstand the mechanical stress and high temperatures involved in the khakhra maker process.

Corrosion resistance is essential, especially for parts exposed to moisture and food acids. For ease of cleaning and maintenance, materials should have smooth surfaces to facilitate easy cleaning and prevent the buildup of food particles. Materials should be chosen to minimize maintenance needs and downtime. Cost-effectiveness, the material choice should balance performance with cost to ensure the machine is economically viable. Selecting the right materials for a khakhra maker is crucial for ensuring its performance, stainless steel, food-grade plastics, and heat-resistant alloys are among the best choices for different components due to their strength, hygiene, and ease of maintenance. Advanced coatings can further enhance the machine’s efficiency and safety.

Safety is of a paramount concern in the design and operation of a khakhra maker. Ensuring the safety of operators and maintaining high hygiene standards are essential to prevent accidents and contamination. Emergency stop buttons should be placed at strategic locations around the machine. Instantly halts all operations in case of an emergency, preventing further harm or damage. Install safety guards around moving parts such as rollers, belts, and cutting blades. Prevents accidental contact with dangerous components, reducing the risk of injury. Use interlock systems that prevent the machine from operating unless all safety guards are in place. Ensure that the machine cannot be used in an unsafe condition. integrate sensors to monitor key parameters alike temperature, pressure, and movement. Automatically shuts down the machine or triggers alarms if any parameters exceed safe limits. Equip motors and electrical components with overload protection devices. Prevent overheating and damage to components, reducing the risk of electrical fires. Insulated heating elements and roasting surfaces. Minimizes the risk of burns by reducing the surface temperatures accessible to operators. Use materials that are easy to lean on and design components with smooth surfaces and minimal services. Prevents the buildup of food practices and reduces the risk of contamination. Regular maintenance and inspection, develop a maintenance schedule, and perform regular inspections. Identifies and addresses potential safety issues before they lead to accidents.

Fail-safe mechanisms, design the machine with a fail-safe mechanism that ensures it enters a safe state in the event of a failure. Prevents accidents and damage by safety shutting down the machine or isolating faulty components. Automated diagnostic systems, integrate diagnostic systems that continuously monitor the machine’s performance. Identifies potential issues in real time, allowing for proactive maintenance and reducing the risk of accidents. Anti-microbial coating, apply antimicrobial coatings to surfaces in contact with food. Reduces the risk of microbial contamination, enhancing food safety. The implementation of comprehensive safety measures is crucial in the design and operation of a khakhra-making machine, fully automatic.

By integrating emergency stop mechanisms, safety guards, interlock systems, sensors, and overload protection, the machine can be made safe for operators and reliable in its performance. Advanced features like automated diagnostics, remote monitoring, fail mechanisms, and anti-microbial coating can enhance the overall safety, manufacturers can create machines that are not only productive but also protect the wellbeing of operators and ensure the highest standards of food safety.

0 notes

Text

The cultural impact of roti making machine

Roti, a staple in many South Asian households, is more than just a type of bread. It carries deep cultural significance representing tradition, family, and heritage. With the advent of technology, the introduction of automatic roti maker machines has sparked a blend of convenience and cultural evolution. Let’s explore the cultural impact of roti-making machines, examining how they have transformed the traditional art of roti-making while maintaining its essence. Historically, roti-making has been a cherished practice, passed down through generations. The process involves kneading dough, roiling it into flat discs, and cooking it on a hot griddle. This ritual not only provides nourishment but also serves as a bounding activity, often bringing families together in the kitchen.

Traditional roti-making is an art that requires skill and patience, making it a symbol of care and affection in many cultures. Technological advancements have introduced the roti maker, designed to automate the process and simplify the effort involved. Initially met with skepticism, these machines have gradually gained acceptance for their ability to produce consistent and high-quality rotis with minimal effort. The convenience they offer has become a significant factor in their growing popularity. One of the primary advantages of roti makers is the significant reduction in preparation time. In today’s fast-paced world, balancing work and home responsibilities is challenging. These machines provide a practical solution for busy households. They enable individuals to enjoy fresh, homemade rotis without the time-consuming manual processes seamlessly fitting into a modern lifestyle.

Roti makers ensure consistency which is hard to achieve with traditional methods. Each roti is uniformly cooked and maintains the desired texture and taste. This standardization benefits health and nutrition, as the machines can be programmed to produce rotis that meet specific dietary requirements. For those who value consistency, these machines offer a reliable alternative. The introduction of the roti maker has also influenced family dynamics. Traditionally, roti-making was often seen as a task for women, reinforcing certain gender roles within households. With machines taking over this task, there has been a shift, allowing for a more equitable distribution of household responsibilities.

However, this change also means adapting new family rituals, as the communal aspect of roti-making evolves. The market for roti making has seen significant growth, provided new business opportunities, and contributed to the economy. These machines are cost-effective for households in the long run, reducing the need for takeout or pre-packaged rotis. Additionally, the rise of this technology has spurred innovation and competition within the industries, fostering economic development.

Balancing cultural preservation with modernization is a complex challenge. While roti-making machines offer numerous benefits, there is a concern that traditional methods may be lost. Different generations have varying perspectives on the issue, with older individuals often valuing tradition, while younger ones lean towards innovation. Finding a balance is crucial to maintaining the cultural essence of roti-making. Freshly made rotis from a roti maker can be as healthy as those made by hand, provided quality ingredients are used.

These machines cater to various dietary preferences and needs, from whole wheat gluten-free options. The ease of making rotis at home encourages healthier eating habits and influences positive lifestyle change. Roti-making machines have transcended cultural boundaries, being adopted in various parts of the world. Their influence on global culinary practices is notable, as they introduce the art of roti-making to new audiences. This cross-cultural exchange enriches the global food landscape, promoting diversity and inclusivity from an environmental perspective. Roti maker offers energy efficiency compared to traditional cooking methods.

They reduce the need for multiple cooking utensils and the energy used in the manual preparation process. However, their long-term environmental impact depends on factors like durability and energy consumption patterns. The future of roti makers looks promising, with ongoing technological innovations enhancing their functionality and user experience. Future trends may include more advanced features, such as AI integration for personalized cooking preferences. As technology continues to evolve, these machines have the potential to become even more integrated into daily life, while preserving cultural traditions. Despite their advantages, roti makers face challenges and criticisms.

Some individuals resist the change, preferring the traditional methods they grow with. Quality concerns also arise, as some believe that machine-made ones. Addressing these critiques involves improving technology and fostering cultural acceptance. Numerous successes try to highlight the positive impact of the roti-making machine. Users report enhanced convenience, improved quality of life, and the ability to maintain their cultural practices with less effort. The cultural impact of roti-making machines is multifaceted, blending tradition with modern convenience. While they offer numerous benefits, it is essential to balance innovation with cultural preservation. As technology advances, roti makers will continue to shape the way we approach this timeless culinary practice, ensuring that the essence of roti maker endures for generations to come.

0 notes

Text

Future trends in khakhra maker

Khakhra, a traditional Indian snack, has seen a surge in demand due to its health benefits and versatility. To meet this growing demand, many manufacturers are turning to fully automatic khakhra making machines. With these machines promising increased efficiency and consistency, their implementation comes with its own set of challenges. Let’s explore these challenges and present solutions to ensure a smooth transition to automated production.

Challenges in implementing fully automatic khakhra maker:

High initial investment:

Challenge: the cost of acquiring a fully automatic khakhra maker is significantly higher than that of manual or semi-automatic machines. This high initial investment can be a major barrier for small to medium sized enterprises.

Solution: manufacturers can explore financing options such as loans, leasing or government subsidies designed to support technological advancements in the food industry. Additionally, conducting a thorough cost-benefits analysis can help justify the investment but highlighting long term savings and productivity gains.

Technical complexity

Challenges: fully automatic machines are complex, integrating advanced technologies such as AI, LOT and robotics. This complexity can lead to difficulties in installation, operation and maintenance, especially for operators with limited technical operators with limited technical knowledge.

Solution: providing comprehensive training for staff is crucial. Manufacturers should invest in training programs offered by machine suppliers or their party experts. Additionally, selecting machines with user friendly interfaces and robust customer support can mitigate technical support and can mitigate challenges.

Customization and flexibility

Challenge: Khakhra comes in various flavors and textures, requiring machines to be flexible enough to handle different recipes. Achieving the desired customization while maintaining efficiency can be challenging.

Solution: Manufacturers should opt for machines that offer programmable settings and easy adjustments. Collaboration with machine suppliers to tailor the equipment to specific production needs can also ensure that the machines meet diverse requirements.

Integration with existing systems

Challenges: Integrating new automated machines with existing production lines and system=s can be complex. Compatibility issues may arise, causing disruptions and inefficiencies.

Solution: Conducting a thorough assessment of existing systems and involving automation experts in the planning phase can facilitate smooth integration. Implementing modular machines that can easily connect with existing infrastructure can also help mitigate compatibility issues.

Quality control and consistency

Challenges: Maintaining consistent quality across batches is crucial in food production. Automated systems need to be finely tuned to ensure that each khakhra meets quality standards.

Solution: Incorporating advanced quality control mechanisms such as real time sensors and automated inspection systems can help maintain consistency. Regular calibration and maintenance of the machines are also essential to ensure consistent output.

Maintenance and downtime

Challenges: Fully automatic machines require regular maintenance to function optimally. Unplanned downtimes can disrupt production schedules and affect supply chain reliability.

Solution: Implementing a proactive maintenance schedule can help minimize unexpected downtimes. Manufacturers should also consider having a stock of critical spare parts and a reliable service agreement with the machine supplier to ensure quick resolution of any issues.

Transitioning to fully automatic khakhra makers, presents several challenges, from high initial costs to technical complexities and maintenance issues. However, with strategies planning, adequate trading and the right support systems in place, these challenges can be effectively addressed. Embracing automation not only enhances productivity and consistency but also positions manufacturers to meet the growing demand for khakhra efficiently and sustainility.by navigating the implementation challenges thoughtfully, manufacturers can reap the long-term benefits of automation in khakhra production.

The khakhra industry, traditionally dominated by small-scale artisans, has evolved into a more organized sector. This evolution is driven by increased consumer demand for healthy and convenient snack options. Key characteristics of the industry include:

Diverse product range: khakhra comes in v various flavors and types, catering to different taste preferences and dietary needs.

Health consciousness: as a low calorie, high fiber snack, khakhra appeals to healthy conscious consumers.

Export potential: the global Indian diaspora and growing international interest in Indian cuisine have expanded the export market for khakhra.

Case studies: successful implementation:

Large scale manufactures: A leading food processing company implemented fully automatic khakhra maker to expand its product line. The result was a significant increase in production capacity and market reach, enabling the company to meet both domestic and international demand.

Small and medium enterprise: A small scale khakhra manufacturer invested in a fully automatic machine to compete with larger brands. The move out only improved product consistency and durability but also allowed the business to scale up and cater to larger orders, leading to increased productivity. The integration of khakhra making machine, fully automatic, had transformed the khakhra industry, enabling manufacturers to meet increasing demand while maintaining high standards of quality and efficacy. As technology continues to advance, the industry is poised for further growth and innovation, making khakhra a staple snack both in India and around the world. Embracing automation not only enhances production capabilities but also ensures that manufactures remain competitive in a dynamic and evolving market.

0 notes

Text

Step by step guide to using an automatic roti maker

Using a roti maker can revolutionize your kitchen routine, making the process of preparing fresh, hot rotis quick and easy. Here's a comprehensive guide on how to use an automatic roti maker machine effectively.

Unboxing and setup: material needed:

Automatic roti maker

Measuring cups and spoons

Flour (whole wheat or preferred type)

Water

Salt(optional)

Instructions:

Unbox the machine, carefully unbox the roti maker and ensure all components are present. This typically includes the main unit, a kneading container and any additional accessories. Read the manual, go through the user manual to familiarize yourself with the parts and safety instructions. This will help you understand the machine’s features and functions.

Preparing the dough

Ingredients

2 cups of whole wheat flour

Water (as needed)

½ teaspoons salt(optional)

Instructions:

Mix the ingredients: in the kneading container, add the flour and salt. Gradually add water while the machine kneads the dough. Most automatic roti makers have a built-in kneading function, so you can simply add ingredients and let the machine do the work. The dough should be soft and pliable but not sticky. Adjust the flour as needed to achieve the right consistency.

Preheating the machine:

Instructions:

Plugin and plug on, connect the roti maker to a power source and turn it on. Most machines have a power indicator light. Preheat, allow the machine to preheat. This usually takes a few minutes. The machine will often signal (via alight or sound) when it’s ready to use.

Instruction:

Dough balls, divide the prepared dough into the small, even sized balls. The size can vary based on your preferences, but typically, they should be about the size of a golf ball. Placing the dough, open the lid of the preheat machine. Place a dough ball in the center of the cooking surface flattening the dough, close the lid and press down lightly. The machine will automatically flatten the dough into a thin, round shape. Cooking, the roti maker will then start cooking the roti. This usually involves heating elements that cook the dough from both sides. Some advanced models also rotate the roti for even cooking. Monitoring, watching the rotis as it cooks. It should puff up and develop golden-brown spots. Cooking time can vary, but it typically takes about 1-2 minutes per roti. Removing the roti, once the roti is cooked, use tongs to carefully remove it from the machine. Place it on a plate and cover with a clean cloth to keep it warm.

Cleaning and maintained

Instructions

Turnoff and unplug, after you’re finished making rotis, turn off and unplug the machine. Allow it to cool completely before cleaning. Wipe down the cooking surfaces and exterior. Avoid using abrasive cleaners or submerging the machine in water. Clean accessories: wash any removable parts, like the kneading container, with warm soapy water and dry thoroughly storage, store the roti maker in a cool, dry place when not in use.

Tips for perfect rotis

Dough consistency, ensure the dough is soft and pliable. Too stiff or too sticky dough can result in imperfect rotis. Always allow the machine to fully preheat to ensure even cooking. Make sure the dough balls are uniform in size for consistent roti thickness and cooking. Keep an eye on the cooking process, especially when using the machine for the first time, to prevent overcooking. Using an automatic roti maker simplifies the process of making fresh, homemade rotis, saving your time and effort. By following this step-by-step guide, you can ensure your rotis are perfectly cooked every time. Enjoy the convenience and delight of freshly made rotis with minimal hassles

Choosing the right roti maker can greatly simplify the process of making fresh, delicious rotis, especially for beginners. Here are some helpful features for a roti maker machine: Touch interface, it has a simple touch interface where you can select flour type, thickness and oil level. Quick preparations, make rotis in just a few minutes with consistent quality. Connectivity, WIFI enabled for software updates and troubleshooting.

On stick plates, equipped with non-stick plates that prevent dough sticking and ensure easy cleaning. Indicator lights, features power and red indicator lights for easy operation. Affordability, an economical option for those starting out. Cool touch handles, safe to use with a heat resistant, cool touch handle. User friendly, easy to operate with a simple on/off function and indicator lights. stainless-steel body, a perfect roti making machine is durable and robust construction with a stainless-steel body. Multi use, while designed for tortilla, it can also make excellent rotis, flatbread and more.

For beginners, choosing a user-friendly automatic roti maker can make the process of making rotis much easier and more enjoyable. Roti maker offers various features that cater to ease of use, affordability and consistent results. With a bit of practice with the right machine, you’ll be making perfect rotis in no time.

0 notes

Text

Uses of chapati making in different industries