Don't wanna be here? Send us removal request.

Text

https://rsisxn95.tumblr.com/post/184522451632/industry-40

The core differences of "Industry 4.0" between Japan, Germany, the United States and China.

This article is from (Beijing Internet of Things Intelligent Technology Association) If there is infringement, please contact us and we will delete.

Summary: In the meantime, the German concept of “Industry 4.0” is often mentioned together with “Made in China 2025”.Are these two the same concept? What is the difference between these two under the great industrial foundation of China and Germany?

The relationship between big data and manufacturing

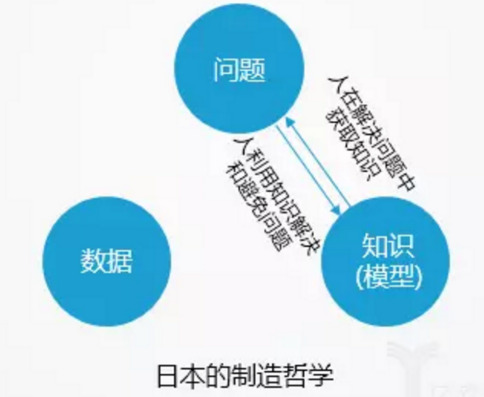

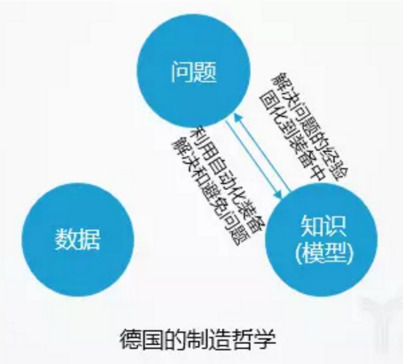

The relationship between big data and manufacturing can use the following figure, there are three important elements:

1, the problem: linear or hidden problems in manufacturing system , such as quality defects, lack of accuracy, equipment failure, processing failure, performance degradation, high cost, low efficiency and so on.

2, data, data from the five elements of the manufacturing system that reflect the course and the cause of the problem. Data access should be problem-oriented in order to understand, resolve and avoid problems.

3, knowledge: the core of manufacturing system, that is Know-how, including process, technology, design, process and diagnosis. Knowledge comes from the process of solving manufacturing system problems, and big data analysis can be understood as a means of quickly acquiring and accumulating knowledge.

The relationship between big data and intelligent manufacturing can be summed up as follows: A large amount of data will be generated in the process of the occurrence and solution of the problem in the manufacturing system. Through the analysis and excavation of the data, the process of the problem, the impact and the solution When these information is abstracted and modeled into knowledge, and then use knowledge to understand, solve and avoid problems. When this process can spontaneously and automatically cycle, which we call intelligent manufacturing.

Problems and knowledge are the ends, and data is the means. In the above elements,change the data to people, is the “craftsman spirit”, replaced by “automated production lines and equipment” ,is “Industry 4.0”, when replaced by the Internet it has become “Internet +.”

Differences in understanding, accumulation and inheritance of knowledge determine the different manufacturing cultures in different countries

Japan: Continuous Improvement through Organizational Culture and Human Training, Very Dependent on the Bearing and Inheritance of Knowledge

The most important feature of the Japanese manufacturing culture is ,Ihrough continuous optimization of the organization, cultural construction and human training to solve the problems in the production system.In the 1970s, Japan put forward the “production management system TPM” as the core of the production management system, the core ideas: full efficiency, system-wide and full participation, the improvement was mainly in three aspects: : improve work skills, improve the team Spirit and working environment. After the 1990s, Japan chose “lean manufacturing” as its transformation direction.

Japanese enterprises often solve problems in the following ways: Problems occur - personnel arrive at the scene, confirm the scene, explore the realities and solve the problems - analyze the causes of the problems, and avoid the problems through improvement. In the end, knowledge falls on people, and the ability to solve and avoid problems increases when people’s skills are improved.

For Japanese companies, employees are the most important value. They trust people more than their trust in equipment, data and systems. All automation and informatization are built around helping people to work. Therefore, Japanese companies Will never talk robots substitutions or unmanned factory. However, such a culture has encountered enormous challenges in recent years. Japan’s aging has led to a large shortage of manufacturing talent in the younger generation and no one can smriti knowledge. Japan is aware of its own lack of data and information. In Japan’s industrial value chain industry alliance architecture and goals, of the 19 projects, 7 are directly related to big data.

Japan’s transformation strategy is a helpless move to tackle its demographic structure and social contradictions. It faces many challenges in the process of transformation. The first is the lack of data accumulation, followed by the lack of software and IT professionals in the conservative culture of Japanese industrial enterprises.

Germany: Curing knowledge on equipment with continuous upgrading of equipment and production systems

Germany’s advanced equipment and automated production lines are world-famous.At the same time, German rigorous style and unique “apprenticeship” higher education model, making the German manufacturing style is very pragmatic. However, Germany faced the problem of labor shortage very early and Germany had to make up for the deficiencies by developing more advanced equipment and highly automated production lines.

The logic in Germany to solve problems is that problems occur - people solve problems - solidify problem-solving knowledge and processes into equipment and production lines - and automatically resolve or avoid similar problems. In addition to the automatic resolution of the pursuit of production lines, Germany also minimizes the human factors in business management. The best software vendors such as Enterprise Resource Planning (ERP), Production Execution System (EMS), Automated Scheduling System (APS) are from Germany. A great deal of information entry and planning are generated and tracked through software to minimize the uncertainty associated with human factors.

The same lack of data collection in Germany is due to the fact that German manufacturing systems have zero tolerance for faults and defects, and that problems are solved once and for all through equipment-side improvements. Due to the high degree of automation and integration of the production line, the overall equipment efficiency is very stable, and the space for data optimization is relatively small.

Germany get a huge economic return relies on exports of equipment, but most industrial products can only be sold once, When sell products to one customer,it means lose a customer. In the meantime, the equipment manufacturing and industrial capacity of developing countries have risen in recent two years. The German market is constantly being squeezed. There is almost no growth in Germany’s industrial exports in 2008-2012. Germany then proposed the Industry 4.0 program, Behind this is the system foundation that Germany has accumulated in manufacturing systems.at the same time, knowledge of German-made is also provided to customers in the form of software or kits as overweight service, enabling continuous profitability from customers. The core element of the German Industry 4.0 design framework is integration.

America: gaining new knowledge from data and immigration, and being good at subversives and redefining problems

In the process of solving the problem, the United States places the highest emphasis on the role of data. Customer demand analysis, customer relationship management, quality management, equipment health management, supply chain management, service management and other aspects of the data are heavily dependent on.The United States also proposed the concept of “product lifecycle management (PLM)” in the early 2000s. The core is to manage all product-related data throughout the life cycle, managing the data of the product, aiming at the value-added services of the whole life cycle and implementing the closed loop design (closed loop design).

In addition to using knowledge to solve problems, the United States is also good at using knowledge to subvert the innovation so as to redefine the problem. For example, in the field of aero-engine manufacturing, in order to reduce power consumption, most enterprises solve the problems in terms of design, materials, technology, control optimization and the like. When general Electric found that aircraft fuel consumption is closely related to pilots’ driving habits and engine maintenance. So it jump from the manufacturing side and turn to the maintenance side to solve the problem, the effect is obviously better than the manufacturing side.

China: lean system is chosen and data accumulation is lacking

China’s manufacturing industry mostly chose the lean system for quality and management reform after 2000. On the one hand, because of the similarities between China and Japan, the problem still exists due to the general lack of data accumulation and information basis.

The location of the value chain in manufacturing is a decisive factor in competitiveness, and the distribution of countries in the value chain is also different.

In production activities, the distribution of value elements from upstream to downstream ,it goes: ideas innovation and demand creation, raw materials and basic enabling technologies, key equipment and core components, production processes and production systems, products and services. Among the distribution of elements in the value chain, China has advantages in the production process and production system (mainly reflected in labor costs and production capacity), but it is at a disadvantage in all other aspects.Different countries have different distributions and layouts in the value chain.

The United States: firmly occupy the upper reaches of the factors of production, and try to extend to the downstream

In the distribution of elements of production activities, the United States has obvious advantages in creating ideas and creating demand, raw materials and enabling technologies, and product value-added services. The core competencies of US industrial systems come from the 6s ecosystem: space / aerospace, semiconductor, shale gas, smart ICT service, Silicon Valley spirit and sustainable talent pool.

In March 2012, the White House proposed the National Network Manufacturing Innovation Program (NNMI),establishing nine research and innovation centers in four major areas of manufacturing.With a firm grasp of the most valuable parts of the industrial value chain,even if Germany’s manufacturing facilities are advanced and China’s manufacturing systems are more efficient, they can ensure their core competitiveness from the source.

Germany: give full play to the technical advantages of key equipment and parts, technical advantages in production process and production system, enhance profitability and competitiveness through value-added services.

Germany has obvious technical advantages in both key equipment and key components, production processes and production systems. The invisible champion enterprises and apprenticeship dual education centered at small and medium-sized enterprises provide a solid foundation for German industry. High-skilled technical workers and engineering professionals have long been regarded as the economic pillars of Germany. However, the emerging economies represented by the BRICS have basically completed their industrialization, resulting in the stagnant demand for industrial equipment in Germany.

The core purpose of “Industry 4.0” put forward by Germany is mainly in two aspects. First, it increases the competitiveness made by Germany and opens up new markets for the export of German industrial equipment. The second is to transform the former selling equipment and the service income of the relatively small state,Focus on the product side to the server transfer, enhance the continued profitability of German industrial products.

Japan: Lost a large number of markets in the product chain, but industrial equipment competitiveness is moving upstream.

The core competitiveness that Japan made in the past mainly lies in the production process and production system, products and services. In the past two years, Japan’s most powerful traditional industries, such as automobiles and consumer electronics, are constantly occupied by Korea, the United States and China. Behind the scenes is actually a shift in Japan’s innovation direction, with more voice in the upstream raw materials and key equipment and key components. After losing the position of a leader in the field of consumer electronics, Sony made breakthroughs in the medical field and has occupied more than 80% of the global market share of endoscopes. In the “2015 Manufacturing White Paper,” Japan has taken the field of artificial intelligence and robotics as a key development direction and will also increase its investment in materials, medical , energy and key components and parts.

China: Deep Integration of Industrialization and Informatization as the Main Line to Achieve Breakthrough Development in 10 Key Areas

In 2015, China put forward “Made in China 2025”, which takes the deep integration of industrialization and informatization as the main line of development and strives to achieve breakthroughs in 10 key areas.

According to the previous analysis, the author made recommendations to the Chinese manufacturers that they should focus on filling the gaps in China’s industrial basic technologies, changing the status of over-reliance on imports of core components and advanced materials, making efforts to increase production efficiency and shifting from a crude production model to a lean model. Emphasis on technology and manufacturing process research and production process management,Constantly improve product quality; efforts to research and development of core production equipment and intelligent devices, and refine and information the management of the use of equipment.At the same time, we should pay attention to the innovation of the original ideas, enhance the product’s service capability and continuous profitability, create new market opportunities with the customer-end value gap and use value-added services to enhance the core competitiveness of China’s industrial products.

28 notes

·

View notes

Text

Industry 4.0

Industry 4.0 (https://www.indovisionglobal.com/industry4.0/) and the fast ascent of robotization is leading the consistently changing landscape of manufacturing intelligence (https://www.indovisionglobal.com/industry4-0/) processes of Sisteplant India (https://www.indovisionglobal.com/industry4-0/). Makers are given the test of redesigning and digitizing their frameworks as methods for introducing life span in their organizations. Inability to do as such dangers them falling behind their client’s developing requests. Digitisation, robotization and information gathering are the key standards of Industry 4.0 that makers must adjust themselves to. Thusly, makers can enhance efficiencies while streamlining costs and keeping up a quality client encounter. As a main provider and producer of basic part arrangements,smart factory (https://www.indovisionglobal.com/industry4-0/),Sisteplant,Sisteplant) India (https://www.indovisionglobal.com/industry4-0/) Essentra Components are one of the numerous makers simply beginning on their Industry 4.0 voyage.

www.indovisionglobal.com

1 note

·

View note