Don't wanna be here? Send us removal request.

Text

Strategies for Interview Success: Landing Your Dream Mechanical Engineering Job

So, you’ve done the hard part—sent resumes, applied on portals, maybe even followed up. And now, finally… you’ve landed the interview.

Pause. Breathe that in.

Feels good, doesn’t it?

Now, here's the next challenge: turning that “You’re shortlisted” into “You’re hired.”

And believe me, this is where most freshers (and even experienced pros) stumble—not because they don’t know enough, but because they go in unprepared for how interviews really work.

But you won’t make that mistake. Because you're about to get real-world, no-fluff strategies that mechanical engineers like you can use to walk into that interview room prepared—and walk out with an offer letter.

Let’s break it down step-by-step.

1. Know the Company Like It’s Your Final Year Project

Let me tell you a secret. The one question that silently screams “unprepared” is when the interviewer asks:

“So, what do you know about our company?” And the candidate says: “Umm… you’re an MNC, right?”

Game over.

Before you walk into that interview, act like you're joining their design team next week.

What does the company build or manufacture?

What design tools do they use?

Any recent launches or awards?

What kind of engineers do they typically hire?

Showing you’ve done your homework proves you're not just job hunting—you’re applying with intention.

Pro Tip: Mention a project or product they’ve worked on and say why it excites you.

2. Brush Up on Your Core Subjects — But Don’t Just “Mug” Them

We get it—you’ve studied thermodynamics and fluid mechanics more times than you’ve checked your Instagram.

But here’s the catch: In interviews, it’s not about remembering equations. It’s about applying them.

Can you explain why a material failed in your project? Or how you’d optimize a heat exchanger in a real-world plant? That’s what they want to hear.

Even if you're a fresher, show them your brain works like an engineer—not just a student.

Tip: Revisit your major projects and internships. Be ready to explain what you did, why you did it, and what you learned.

3. Be a Problem Solver, Not Just a Bookworm

Here’s something many engineers don’t realize: Companies don’t hire you just for your knowledge. They hire you for your ability to solve problems.

So when they ask you a technical question or a case scenario, don’t panic.

Instead, walk them through how you think.

“First, I’d identify the failure mode… then consider material properties… then analyze it using FEA…”

Even if your final answer isn’t perfect, your thinking process is what they’re judging.

Think out loud. Engineers respect logic more than luck.

4. Engineers Work in Teams — Show You Can Too

If you think engineering is all about sitting alone with a laptop or a machine, think again.

You’ll be working with:

Designers

Purchase teams

Production engineers

Sometimes even marketing and clients

That’s why communication matters.

Have stories ready from college or work where:

You worked in a group project

Solved a conflict

Explained technical stuff to someone non-technical

“I was working with the electrical guys, and they didn’t understand our CAD drawings—so I simplified it with 3D visuals.” Boom. That’s teamwork + communication + initiative—all in one example.

5. Master the Behavioral Questions (This Is Where Many Candidates Go Silent)

You’ll probably get questions like:

“Tell me about a time you failed.”

“How do you handle deadlines?”

“Describe a time you showed leadership.”

These aren’t trick questions. They’re chances to show who you are beyond the resume.

The best way to answer? Use the STAR method: Situation – Task – Action – Result

Example:

“In my final year, we were behind on our mini project due to material delays. As the team lead, I proposed splitting tasks and using 3D printing to build a quick prototype. We finished early and even won Best Design.”

Storytelling > Buzzwords.

6. Ask Your Questions Too — Interviews Go Both Ways

When they say, “Do you have any questions for us?” — don’t say “Nope, all good.”

This is your chance to flip the script.

Ask about:

The learning curve for new hires

Projects you might be involved in

Training or mentorship opportunities

Not only does it show interest, but it also makes you look like someone who’s planning to stay and grow.

7. Practice Like You’re Training for a Match

Would you walk into a cricket tournament without a single net session?

Nope. Then don’t walk into an interview without mock interviews.

Ask a friend to role-play interviewer

Record yourself answering questions

Time your responses

Watch how you sit, speak, smile

You'll fix so many small issues before the real day.

Confidence doesn’t just come from talent—it comes from practice.

Final Thoughts: It’s More Than Just a Job—It’s Your Launchpad

Let’s be real. An interview is scary. There’s pressure. There’s self-doubt. There’s that annoying voice that says, “What if I mess up?”

But here’s the truth: If you’ve made it this far, you already have something. Now it’s just about owning it—with preparation, presence, and purpose.

Walk in not just as a job-seeker. Walk in as a future engineer who’s ready to build, design, innovate, and solve real-world problems.

And hey—no matter what happens, every interview is progress. Every single one makes you sharper. You don’t have to be perfect. You just have to be prepared.

You got this. 🚀

If you want help with mock interviews, resume polishing, or technical guidance before your next big interview — just say the word. We’re here to make sure your dream job doesn’t stay a dream.

Shall we build your future together?

0 notes

Text

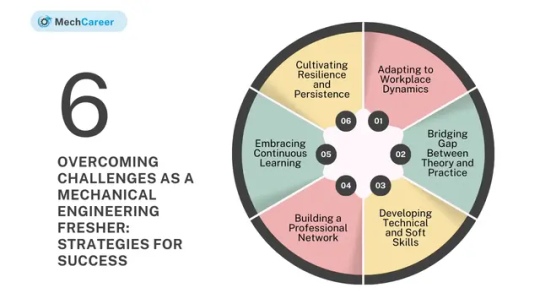

Overcoming Challenges as a Mechanical Engineering Fresher: How to Not Freak Out and Actually Win at Your First Job

So, you’re a mechanical engineering fresher. Congrats!

You’ve spent years grinding through lectures, endless problem sets, and maybe a few all-nighters just to get here. Now, you’re stepping into the “real world” — a place where textbooks don’t hand-hold you, and things aren’t always black and white.

If you’re feeling a bit like, “Wait… what now?” don’t worry. I’ve been there (okay, maybe not me, but like a million freshers before you). Let’s talk about the stuff no one tells you about when you graduate and how to survive — and even thrive — in your first engineering job.

1. The Workplace is NOT College 2.0

First up — the workplace vibe? It’s a whole different beast. No one’s handing you a syllabus, and everyone has their own way of doing things.

You’ll meet people who speak in acronyms faster than you can blink. Meetings that seem endless. And that one colleague who always talks in technical jargon like they’re from another planet.

Your job? Be the ninja observer. Watch how folks communicate, how meetings flow, and how deadlines really work. It’s like learning the secret handshake to the club.

Pro tip: Find a friendly mentor — someone who’s been around the block and won’t make you feel like an alien asking dumb questions.

2. Theory vs. Reality: Spoiler Alert — Reality Wins

Remember that time you solved perfect problems on paper? Yeah, real life is messier.

Things break, designs fail, and sometimes you’re asked to fix something you’ve never seen before — with zero instructions. Cue panic mode.

But here’s the secret sauce: It’s okay to not have all the answers. The best engineers are those who get their hands dirty, mess up, learn fast, and try again.

So get out there. Intern, shadow someone, build stuff — anything that moves you from textbook theory to actual, sweaty, hands-on engineering.

3. Soft Skills Are the Secret Weapon

If you think engineers only need to be math wizards, think again.

You’ve got to chat with clients who don’t speak “engineering,” work with teammates who drive you nuts, and explain your cool ideas without sounding like a robot.

Being able to talk clearly, listen well, and solve problems with others is what will make you stand out.

And yes, this stuff takes practice. So don’t roll your eyes next time someone says “communication skills.” They’re secretly your career MVP.

4. Networking: Not Just For Suits and Schmoozers

Networking isn’t about awkwardly collecting business cards at events. It’s about making real connections.

Talk to people who are where you want to be. LinkedIn is your friend. Join groups, comment on posts, ask questions.

One day, that random connection might tip you off about a job or give you advice that changes everything.

Remember: People like to help those who show genuine interest.

5. Never Stop Learning (Because Engineering Never Stops Changing)

Tech changes faster than your phone updates.

Today’s hottest software, tomorrow’s old news. So keep learning.

Find courses, watch tutorials, read blogs — whatever floats your boat.

Stay curious. Ask questions. Keep adding new tools to your engineering toolbox.

6. Mess Up, Get Up, Repeat

You’re going to mess up. It’s part of the deal.

Miss a deadline? Give a presentation that flops? Design that doesn’t work?

It stings. But instead of hiding or stressing, use it. Learn. Fix. Keep moving.

Remember: The engineers who succeed aren’t the ones who never fail — they’re the ones who never quit.

Wrapping It Up: You’ve Got This

Being a mechanical engineering fresher is tough. The learning curve is steep and sometimes scary.

But here’s the truth: No one expects you to be perfect. They want to see you try.

So take a deep breath, put on your engineering hat (bonus points if it’s a hard hat), and dive in.

Every challenge is just another chance to grow. And every small win is a step closer to your dream career.

0 notes

Text

Production & Manufacturing in Mechanical Engineering: Real Roles, Real Growth, and What to Expect

If you've ever looked at a car engine, a wind turbine, or even a simple household appliance and thought, “How is this actually made?”, you’re already asking the kind of questions that production and manufacturing engineers deal with every day. This field is all about turning designs into real-world products — efficiently, safely, and at scale.

Let’s break it down.

🏭 What Do Production/Manufacturing Engineers Actually Do?

At the heart of every mechanical product is a long journey that begins in design and ends on the shop floor. Production engineers are the people who make sure this journey runs smoothly. Here’s what a day in their life might involve:

Planning the Process: Before anything is made, there’s a blueprint — not just for the product, but for how it will be produced. Engineers map out the steps, estimate timelines, and decide what tools, machines, and materials will be used.

Running the Machines: It’s not all sitting behind a computer. These engineers often get their hands dirty, working with CNC machines, welding equipment, molding units, or robotic arms to make sure everything is working like clockwork.

Making it Better: Good engineers don’t just follow instructions — they improve them. They’re always looking for ways to reduce waste, save time, and cut costs without sacrificing quality. Methods like Lean and Six Sigma are more than buzzwords here — they’re everyday tools.

Quality is King: One faulty product can lead to a massive recall. So quality checks, inspections, and solving on-the-spot issues are a big part of the role.

Leading Teams: As engineers gain experience, they also manage teams — operators, technicians, and supervisors. Good communication becomes just as important as technical skills.

🚀 Career Scope: Where Can This Path Take You?

Production and manufacturing roles are never limited to just one industry. Whether it’s automotive, aerospace, defense, or home appliances, every sector needs skilled engineers to make their products a reality. Here’s what your journey might look like:

Start as a Trainee or Production Engineer, handling day-to-day operations and learning the ropes of the shop floor.

Grow into a Supervisor or Manager, leading larger teams, planning bigger projects, and optimizing workflows.

Move up to Plant Head or Operations Director, where you oversee entire facilities and take charge of output, efficiency, and performance.

Specialize as a Process Expert or Consultant, focusing on areas like CNC machining, additive manufacturing, or automation systems — advising multiple companies on how to improve their manufacturing game.

Thinking of Entering the Field? Here’s What You’ll Need:

A Solid Grip on Manufacturing Basics: Understand machining, welding, molding, and assembly processes inside-out.

Hands-On Mindset: Be curious. Visit factories, handle tools, and work with machines during internships. It’s not a desk job, and that’s the beauty of it.

Strong Problem-Solving Abilities: Every day brings new challenges — equipment breakdowns, raw material issues, or bottlenecks. You'll need to think fast and act smart.

Know Your Tools: Learn about automation tools, ERP systems, and quality control instruments. Being tech-savvy is a major plus.

Team Spirit & Leadership: You won’t be working alone. You'll coordinate with maintenance, design, and quality teams — and eventually, you'll lead them.

2. Design Engineering in Mechanical Engineering: Role, Responsibilities, and Career Scope

Ever wondered how a simple sketch turns into a product you use every day? From the car you drive to the appliances in your kitchen, there’s a design engineer behind it. In the world of mechanical engineering, design engineers are the creative minds who transform raw concepts into real-world solutions.

What Exactly Do Design Engineers Do?

Imagine being the architect of machines. That’s what design engineers do—turn ideas into working models. Their daily work blends creativity with logic.

Turning Concepts into Sketches: It often begins with brainstorming sessions, where they convert ideas into rough concepts. Think of it like doodling the first version of a future innovation.

Mastering CAD Tools: These professionals live inside design software like CATIA, SolidWorks, or AutoCAD. Using these tools, they sculpt detailed 3D models that manufacturers will later bring to life.

Prototyping & Testing: No design is perfect on paper alone. Engineers create prototypes—physical or virtual—and test them rigorously. It's here where ideas get fine-tuned to perfection.

Teamwork is Key: Design doesn’t happen in isolation. Engineers coordinate closely with manufacturing, R&D, and quality teams to make sure their designs are practical and production-ready.

Documentation & Detailing: Before the design heads to the shop floor, it needs proper documentation—specs, instructions, and blueprints that tell others exactly how to build it.

Why Choose a Career in Design Engineering?

Design engineering is more than a job—it’s a chance to leave your fingerprint on tomorrow’s innovations.

So Many Roles to Explore: You could be a Product Designer, CAD Engineer, or even lead a team as a Senior Design Engineer. Industries like automotive, aerospace, robotics, and consumer goods are always hiring creative minds.

A Growing Field: With new products launched every day, the demand for skilled design engineers is only going up. Mastering design tools gives you a serious edge.

Room for Specialization: Whether it's plastics, sheet metal, or interiors of luxury cars, you can choose your niche and grow deep in it.

Consulting & Freelance Gigs: As you gain experience, many engineers branch out as consultants, helping multiple companies with design expertise.

How Can You Prepare for a Career in Design Engineering?

Master the Tools: You must be fluent in at least one or two major CAD software platforms. That’s your bread and butter.

Be Creative—but Precise: Great designs are not just imaginative—they’re functional and meet real-world constraints. Attention to detail is your best friend.

Understand How Things Are Made: A good designer knows what goes on in the manufacturing unit. That knowledge ensures your designs are practical, not just pretty.

Enjoy Solving Problems: Every design challenge is a puzzle. If that excites you, you’re on the right path.

Be a Team Player: You’ll often work with cross-functional teams. Good communication and collaboration will take you far.

3. Production/Manufacturing in Mechanical Engineering: Role, Responsibilities, and Career Scope

If you’re someone who loves being where the action happens, the production and manufacturing side of mechanical engineering might be your playground. This department is all about turning designs and plans into actual products — making sure things get built right, on time, and up to quality standards.

What Does Production/Manufacturing Involve?

Think of it as the engine room of any manufacturing company:

Planning the Process: Before anything is made, someone needs to plan how and when it will happen. Production engineers create schedules and decide which machines will do what, making sure deadlines are realistic.

Running the Machines: From CNC machines that carve metal parts with precision, to injection molding machines shaping plastics, production engineers oversee operations and keep the machinery humming.

Making Things Better: The work isn’t just about keeping the line moving. It’s about making the process smoother, faster, and cheaper. Methods like Lean manufacturing or Six Sigma help cut down waste and boost efficiency.

Quality Checks: Nobody wants faulty products reaching customers. That’s why production engineers regularly check outputs to make sure everything meets the mark.

Leading the Team: Often, these engineers manage teams — keeping everyone coordinated, safe, and motivated on the shop floor.

Career Path: Where Can Production/Manufacturing Take You?

This field offers plenty of growth and variety:

Industry Choices Galore: Whether it’s cars, airplanes, heavy machinery, or consumer goods, almost every sector needs manufacturing experts.

Climbing the Ladder: Starting as a Production Engineer, you can move up to Production Manager or even Operations Director, taking on bigger responsibilities and leading larger teams.

Specialize and Stand Out: Becoming an expert in a specific manufacturing method like additive manufacturing or CNC machining can make you highly sought after.

Exciting Projects: Many roles revolve around launching new products or improving existing ones, so there’s always something fresh to work on.

Tips for Those Eyeing Production/Manufacturing Roles

Learn the Basics of Manufacturing: Know your processes well — this is the foundation of your job.

Get Hands-On: Practical skills with machinery and troubleshooting are invaluable.

Understand Lean and Six Sigma: These approaches can seriously boost your effectiveness.

Be a Good Leader: Strong communication and team management skills are essential.

Solve Problems on the Fly: From machine breakdowns to quality hiccups, being a quick thinker is a must.

4. Quality Department in Mechanical Engineering: Role, Responsibilities, and Career Scope

Quality isn’t just a buzzword—it’s the backbone of manufacturing and engineering success. The quality department makes sure that every product leaving the factory stands up to expectations and keeps customers happy.

What Does the Quality Department Do?

Quality engineers are like detectives — they track down issues and make sure products are built right from start to finish:

Setting Standards: They define quality benchmarks and make sure everyone in the company knows what “good” looks like.

Inspection and Testing: From raw materials to finished goods, quality engineers perform tests to catch defects early and often.

Analyzing Problems: When something goes wrong, they dig deep to find the root cause and fix it — preventing repeat issues.

Process Improvement: They constantly look for ways to improve manufacturing processes to boost quality and efficiency.

Documentation and Compliance: They keep detailed records and ensure the company meets all regulatory and industry standards.

Why Consider a Career in Quality?

If you have an eye for detail and love solving puzzles, quality engineering could be very rewarding:

Varied Roles: From Quality Inspector to Quality Manager, there are many levels to grow within.

High Demand: Companies across sectors need quality pros to maintain their reputation and avoid costly recalls.

Skills That Travel: Quality expertise is valuable worldwide and can open doors internationally.

Contribute to Excellence: Your work directly impacts customer satisfaction and company success.

Tips to Shine in the Quality Department

Be Detail-Oriented: Noticing small issues early can save a company big headaches.

Learn Statistical Tools: Knowledge of tools like SPC (Statistical Process Control) helps you track quality trends.

Communicate Clearly: You’ll often have to explain quality issues and train teams on best practices.

Keep Learning: Standards and technologies evolve, so staying updated is key.

Think Proactively: Quality isn’t just about fixing problems but preventing them.

0 notes

Text

You Wanna Be a Design Engineer? Here's What You're Really Signing Up For!

If you think design engineers just sit in AC offices clicking away on CAD software while sipping coffee… well, okay, sometimes that's true. But there's a lot more to it — and spoiler alert: it involves brainpower, patience, teamwork, and a love-hate relationship with deadlines.

Let’s break it down — human to human.

A) What Does a Design Engineer Actually Do (Besides Fighting with CAD)?

1. Comes Up with Cool Ideas

Design starts with the brain. A client says, “We need this widget to do this magic.” Your job? Make the magic happen — on paper first. Expect lots of sketches, wild ideas, and maybe a few “Wait, what if we just…?” moments.

2. Becomes Best Friends with CAD

If you're not vibing with CATIA, SolidWorks, or UG-NX, you’re in the wrong room. You’ll be modeling, dimensioning, zooming in 3000% just to fix a tiny fillet. Tip: Ctrl+Z will become your favorite move.

3. Builds & Breaks Things (Intentionally)

Next comes testing. You either build a prototype or run simulations to see if your “brilliant idea” survives real-world conditions. Sometimes it does. Sometimes it breaks. You learn. You cry. You design again.

4. Talks. A Lot.

Design engineers spend half the time discussing things with R&D, production, and quality teams. Because what works on screen doesn't always work on the shop floor — and trust us, the shop floor folks will let you know loud and clear.

5. Writes the Boring but Important Stuff

Drawings. BOMs. Assembly instructions. Documentation. Not exactly thrilling — but super important. Because without it, no one knows what you made, how to build it, or where to bolt that last screw.

B) Career Scope: Where Can This Crazy Ride Take You?

Job Titles You Might Hold

CAD Engineer, Design Engineer, Product Developer, or eventually, someone who says “Back in my day, we used a mouse to draw everything…”

Industries That Want You

Auto, aerospace, appliances, robotics, heavy machinery, medical devices — basically any industry that builds physical products.

Why It’s a Solid Career

Machines are evolving. Designs are changing. New products come out every week. That means more opportunities for people who can bring ideas to life (aka YOU).

Specialization = More Power

Want to be the go-to plastic parts guy? Or a BIW sheet metal champ? Specializing gets you deeper into niche roles and leadership positions — plus cooler job titles.

Bonus: Freelance & Consulting

Once you’ve got the experience, you can freelance or consult. Imagine being your own boss, working on multiple projects, and charging by the hour (yes, the dream is real).

C) Honest Tips If You're Serious About This

1. Master at Least One CAD Tool

You don’t need to learn them all — just pick one and go deep. Learn the shortcuts, the tricks, and the workarounds like your life depends on it (because your job might).

2. Pay Attention to the Tiny Details

That 0.2mm error? It’ll cost you hours later in redesign. Trust us. The devil really is in the dimensions.

3. Learn How Stuff Gets Made

Knowing how your design will be manufactured is game-changing. A good design looks cool. A great design works, is cheap, and can actually be built.

4. Be a Puzzle Solver

If fixing problems gives you a dopamine rush, welcome home. Whether it's interference errors or strength failures — you’ll have puzzles to solve every day.

5. Be a Team Player

This is not a lone-wolf role. You’ll work with every department and probably get blamed by all of them at some point. Stay calm, fix the issue, and grab some chai.

Final Thoughts (No Corporate Buzzwords, Promise)

Design engineering is where ideas become reality — but it’s not always pretty. Some days you’ll feel like a genius, others like a frustrated intern. But if you love solving problems, making things better, and leaving your mark on actual products, this job is for you.

Oh, and one more thing — Never underestimate the power of a Ctrl+S.

0 notes

Text

Curious About R&D in Mechanical Engineering?

If you’re a mechanical engineering student, fresher, or someone stuck in a "same design, different day" job… and you’ve ever wondered “What do people in R&D actually do?” – this post is for you.

Spoiler alert: it’s way cooler than you think.

A) What Does the R&D Department Actually Do?

Think of R&D (Research & Development) as the brain and heart of innovation in any company. These are the folks who don't just follow rules — they rewrite them.

Here’s what their day looks like (on a good day — not when the coffee machine’s broken):

1. Building New Stuff

From scratch. Be it a new engine part, a lighter chassis, or an improved cooling system – they design, prototype, and test like mad scientists with a mechanical degree.

2. Testing Wild Ideas

Ever wondered who comes up with that “new and improved” version of products? Yep – it’s R&D. They experiment with materials, processes, and technologies that don’t exist in textbooks yet.

3. Fixing What Ain’t Easy

R&D engineers solve the kind of technical puzzles that make you go, “How did they even think of that?”

4. Collaborating Like Pros

They don't work in isolation. They bounce ideas off design, production, and quality teams to turn theory into real, working machines.

5. Breaking & Rebuilding

Every idea, every design – tested, failed, fixed, and tested again. Safety and performance don’t happen by chance.

B) What’s the Career Scope in R&D?

Let’s be honest — you’re not just here to learn, you’re thinking, “Is this a solid career move?”

Short answer: Yes, and here’s why

Work in Cool Industries

Automotive, aerospace, renewable energy, robotics, consumer tech — take your pick. If it moves, heats, cools, rotates, or flies — R&D is behind it.

Career Growth? Oh, Yes.

You could start off testing materials and end up leading innovation for an entire company. Positions like R&D Lead, Technical Head, or Innovation Manager aren’t just titles — they’re real paths.

Become a Specialist

Love thermal systems? Materials science? Fluid mechanics? You can go deep and become that go-to expert every project depends on.

Go Global

Big MNCs and international collaborations? R&D opens doors to travel, learn, and work on futuristic stuff with teams around the world.

C) Thinking of Choosing R&D as a Career?

Here’s how to know if this is your thing:

You Love Core Engineering

You actually enjoyed subjects like mechanics, materials, or thermodynamics? You’re already ahead.

You’re a Curious Creature

If your brain is always asking “Why?” and “What if?”, welcome to the club.

You Like Solving Problems (Even the Tough Ones)

If debugging and testing doesn’t frustrate you but fires you up — you're R&D material.

You’re Okay with Failing (A Lot)

Let’s be real – not every experiment works. But the thrill of that one breakthrough? Totally worth it.

You’re a Team Player

You’ll be bouncing ideas off designers, manufacturers, analysts… R&D isn’t a solo sport.

Final Thoughts: Is R&D Right for You?

R&D isn’t just a department. It’s a mindset. If you want a career that challenges your thinking, values your ideas, and lets you build the future — then this is your calling.

You won’t just be designing parts.You’ll be asking, “What’s next?” — and then going out and building it.So, ready to step into the lab of ideas? Because real innovation needs real engineers — like you.

1 note

·

View note