Don't wanna be here? Send us removal request.

Text

The Glimepiride API Market: Trends, Growth, and Future Outlook

The Glimepiride API Market: Trends, Growth, and Future Outlook

The pharmaceutical industry is continuously evolving, with the development of active pharmaceutical ingredients (APIs) playing a crucial role in ensuring the effectiveness of medicines. One such API that has gained significant attention in recent years is Glimepiride, a widely used medication for managing Type 2 diabetes. In this blog post, we’ll explore the Glimepiride API market, including its growth drivers, key players, and future outlook.

What is Glimepiride?

Glimepiride is a second-generation sulfonylurea drug that is used primarily for managing Type 2 diabetes. It works by increasing insulin production from the pancreas and enhancing the body’s sensitivity to insulin, helping to regulate blood sugar levels. As part of a comprehensive diabetes management regimen, Glimepiride is often used in combination with other anti-diabetic medications when blood sugar levels cannot be controlled by diet and exercise alone.

The Growing Demand for Glimepiride API

The increasing global prevalence of Type 2 diabetes is one of the key factors driving the demand for Glimepiride API. According to the World Health Organization (WHO), the number of people suffering from diabetes worldwide is steadily rising, with an estimated 463 million adults affected by the condition in 2019. This trend is expected to continue, leading to greater demand for anti-diabetic medications, including Glimepiride.

The high prevalence of Type 2 diabetes, especially in emerging markets like Asia Pacific, Latin America, and the Middle East, has created substantial growth opportunities for the Glimepiride API market. In these regions, the growing awareness about diabetes management, coupled with improvements in healthcare infrastructure, is further fueling the demand for diabetes medications, including Glimepiride.

Market Drivers

Several factors are contributing to the growth of the Glimepiride API market:

Rising Prevalence of Type 2 Diabetes: As mentioned earlier, the increasing number of diabetes cases globally is the primary driver behind the growth of the Glimepiride API market. Both lifestyle factors (such as poor diet, lack of exercise, and obesity) and genetic factors contribute to the rising incidence of Type 2 diabetes.

Aging Population: The global population is aging, and older individuals are more likely to develop Type 2 diabetes. As the elderly population continues to grow, the demand for diabetes medications like Glimepiride will increase.

Cost-Effectiveness: Glimepiride is generally considered an affordable and effective treatment for Type 2 diabetes. With increasing healthcare costs worldwide, many healthcare systems are focusing on providing cost-effective alternatives to newer and more expensive diabetes medications, further boosting the demand for Glimepiride.

Advancements in Drug Formulations: The development of new formulations, such as combination therapies involving Glimepiride and other anti-diabetic agents, is another factor contributing to market growth. These combination drugs offer improved convenience for patients and better blood sugar control.

Generic Market Growth: As the patent for Glimepiride has expired, generic versions of the drug have flooded the market. This has not only made Glimepiride more affordable for patients but has also increased the availability of the API for pharmaceutical companies.

Key Players in the Glimepiride API Market

The Glimepiride API market is characterized by the presence of several established players that manufacture and supply the drug. Some of the leading companies in this market include:

Dr. Reddy’s Laboratories: Based in India, Dr. Reddy’s is one of the prominent players in the global generic pharmaceutical market. The company manufactures Glimepiride API and offers it to various pharmaceutical companies worldwide.

Aurobindo Pharma: Another major Indian pharmaceutical company, Aurobindo Pharma produces Glimepiride APIs and supplies them to both domestic and international markets.

Sun Pharmaceutical Industries: As one of the largest pharmaceutical companies in India, Sun Pharma manufactures a range of generic drugs, including Glimepiride.

Mylan Pharmaceuticals (now part of Viatris): Mylan, now part of Viatris, is a global leader in the production of generic medications, including Glimepiride.

Zydus Cadila: Zydus Cadila is a significant player in the global API market and produces Glimepiride as part of its portfolio of anti-diabetic medications.

In addition to these, numerous other manufacturers based in China, India, and Europe contribute to the global supply of Glimepiride API.

Challenges in the Glimepiride API Market

While the Glimepiride API market is growing, it is not without its challenges:

Regulatory Hurdles: The pharmaceutical industry is highly regulated, with stringent requirements for the production and sale of APIs. Companies need to adhere to Good Manufacturing Practices (GMP) and other international standards, which can be a costly and time-consuming process.

Price Pressure: The global shift towards generic drugs has led to significant price competition in the market. While this benefits patients by reducing medication costs, it puts pressure on API manufacturers to maintain profitability amidst price reductions.

Supply Chain Issues: Disruptions in the global supply chain, such as those caused by the COVID-19 pandemic, can affect the availability of raw materials and finished APIs. This poses a challenge for companies relying on consistent production and delivery schedules.

Market Fragmentation: With numerous players in the market, especially in emerging markets, the Glimepiride API market can be fragmented, making it difficult for companies to maintain significant market share.

0 notes

Text

Ezetimibe API Manufacturers in India: A Growing Market in the Pharmaceutical Industry

Ezetimibe API Manufacturers in India: A Growing Market in the Pharmaceutical Industry

Ezetimibe, a widely used medication that helps to lower cholesterol levels in the blood, is a key player in the fight against cardiovascular diseases. As a cholesterol absorption inhibitor, it works by reducing the amount of cholesterol absorbed by the small intestine. The active pharmaceutical ingredient (API) of Ezetimibe is produced by various manufacturers around the world, and India plays a significant role in the global supply chain for this essential drug.

In this blog post, we’ll take a closer look at the manufacturers of Ezetimibe API in India, their impact on the pharmaceutical market, and the country's role as a major supplier of generic medicines worldwide.

What is Ezetimibe?

Ezetimibe is used primarily to treat high cholesterol. It can be used alone or in combination with other cholesterol-lowering medications like statins. By inhibiting the absorption of cholesterol from the diet and bile, Ezetimibe helps reduce overall cholesterol levels, making it an essential part of managing cardiovascular risk. With millions of people worldwide suffering from high cholesterol, Ezetimibe has become a crucial medication in controlling lipid levels and preventing heart disease.

India’s Role in the Global Pharmaceutical Market

India is one of the world's leading producers of generic pharmaceuticals, supplying around 50% of global demand for various medicines, including APIs. The country's pharmaceutical industry is known for its robust manufacturing capabilities, cost-effective production processes, and ability to meet stringent regulatory standards. India’s strong presence in the API market has made it a go-to source for bulk drug supply, including Ezetimibe.

The manufacturing of APIs like Ezetimibe involves sophisticated technology, skilled labor, and adherence to regulatory requirements set by international authorities such as the US FDA, EMA (European Medicines Agency), and CDSCO (Central Drugs Standard Control Organization). Indian companies have been able to cater to both domestic and international demand, offering high-quality products at competitive prices.

Key Ezetimibe API Manufacturers in India

Several prominent Indian pharmaceutical companies are involved in the production of Ezetimibe API, offering it to both domestic and international markets. Here are some of the notable manufacturers in this space:

Aurobindo Pharma Aurobindo Pharma is a major player in the Indian pharmaceutical industry and one of the top manufacturers of generic drugs, including Ezetimibe. With a significant presence in over 150 countries, Aurobindo Pharma is known for its high-quality APIs and finished formulations. The company’s research and development (R&D) capabilities, along with its focus on cost efficiency, allow it to produce competitive Ezetimibe formulations.

Dr. Reddy’s Laboratories Dr. Reddy's Laboratories is another leading manufacturer of Ezetimibe API in India. The company is involved in the production of a wide range of generic medicines and has a strong global footprint. Dr. Reddy's is recognized for its high standards of manufacturing and quality assurance, which makes its Ezetimibe API a preferred choice for global customers.

Sun Pharmaceutical Industries Ltd. Sun Pharma is one of the largest pharmaceutical companies in India and a significant supplier of APIs worldwide. It has a wide range of API offerings, including Ezetimibe, and is known for its commitment to high manufacturing standards and innovative solutions. Sun Pharma's global reach and production capacity make it a top choice for the supply of Ezetimibe API.

Lupin Pharmaceuticals Lupin is a global pharmaceutical company that manufactures high-quality APIs, including Ezetimibe. With its strong R&D focus and robust manufacturing capabilities, Lupin is able to supply cost-effective and reliable products to the international market. The company’s experience in producing APIs for complex formulations positions it as a key player in the cholesterol management segment.

Cipla Limited Cipla, another prominent name in the Indian pharmaceutical industry, is a manufacturer of a wide range of generic drugs, including Ezetimibe. With its advanced production facilities and emphasis on quality control, Cipla is able to meet the global demand for cholesterol-lowering medicines. The company has a strong distribution network and exports to numerous countries, making it a leading supplier of generic APIs worldwide.

Zydus Cadila Zydus Cadila is a leading Indian pharmaceutical manufacturer with a broad portfolio of APIs, including Ezetimibe. The company operates state-of-the-art manufacturing facilities and adheres to international standards, which ensures that its products meet the highest quality requirements. Zydus Cadila has a significant presence in the global market, particularly in the US and Europe.

Why Choose Indian Manufacturers for Ezetimibe API?

India's pharmaceutical industry has garnered a reputation for producing high-quality medicines at competitive prices. This has made Indian manufacturers the preferred choice for sourcing APIs like Ezetimibe. Here are a few reasons why:

Cost-Effective Production Indian manufacturers benefit from lower labor costs, economies of scale, and a favorable regulatory environment, allowing them to produce high-quality products at competitive prices. This cost-effectiveness is particularly attractive to companies seeking to manufacture generic drugs in large volumes.

Quality and Compliance Many Indian pharmaceutical companies are compliant with international standards, including the US FDA, WHO-GMP (Good Manufacturing Practices), and European regulations. This ensures that the APIs produced meet the stringent quality standards required by global markets.

Innovation and R&D Indian companies have made significant investments in research and development, allowing them to produce advanced APIs, including complex formulations like Ezetimibe. Their strong R&D capabilities help them stay competitive and address the evolving needs of the global pharmaceutical industry.

Global Distribution Network India’s pharmaceutical companies have a well-established distribution network that allows them to supply APIs to numerous countries. The presence of Indian manufacturers in global markets ensures that Ezetimibe is readily available at affordable prices in various regions.

Conclusion

India has firmly established itself as a leader in the global API market, and its manufacturers of Ezetimibe API are playing an integral role in meeting the worldwide demand for cholesterol-lowering treatments. With a combination of cost-effective production, adherence to international quality standards, and extensive R&D capabilities, Indian pharmaceutical companies continue to be at the forefront of producing high-quality APIs like Ezetimibe. As the demand for cholesterol management solutions continues to grow, Indian manufacturers are well-positioned to remain key suppliers to global markets, ensuring that affordable and effective treatment options are accessible to patients worldwide.

0 notes

Text

Slab Tong Manufacturers

Slab tongs are specialized lifting devices used in steel plants, foundries, and manufacturing facilities to handle hot metal slabs during production processes, such as rolling, forging, and casting. These tongs are designed to grip and lift large, heavy slabs of metal safely and efficiently. Manufacturers of slab tongs typically specialize in industrial lifting and handling equipment for the steel industry.

Here are some well-known manufacturers and suppliers of slab tongs, as well as companies that provide related lifting and handling equipment:

1. Schneider (Lifting Equipment)

Overview: Schneider is a globally recognized manufacturer of lifting, material handling, and hoisting equipment. They offer a wide range of industrial tongs, including slab tongs for use in steel plants, foundries, and other heavy industries.

Products: They manufacture slab tongs with high-load capacities designed for heavy metal handling and high-temperature environments.

Website: www.schneider-industrie.com

2. Grab N Lifters PVT Ltd

Overview: Verlinde is a Hyderabad based company that designs and manufactures a wide variety of lifting equipment. They provide solutions for heavy-duty lifting applications, including slab tongs.

Products: They offer slab tongs with mechanical, hydraulic, and electric lifting mechanisms, designed to handle hot steel slabs in a safe and efficient manner.

Website: Grabnlifters.com

3. Bendini Engineering (Lifting Tongs)

Overview: Bendini Engineering is an Italian manufacturer of industrial lifting equipment, including slab tongs. They specialize in high-temperature handling solutions for the steel and metal industries.

Products: Their slab tongs are designed for handling hot slabs in steel mills, offering ergonomic designs, strength, and reliability.

Website: www.bendini.com

4. Jiangsu Huazhong Heavy Industry Co., Ltd.

Overview: Based in China, Huazhong Heavy Industry manufactures a variety of heavy-duty equipment, including slab tongs and other material handling tools for the steel industry.

Products: They offer customized solutions for slab lifting tongs, catering to various sizes, weight capacities, and industrial needs.

Website: www.huazhongsteel.com

5. Kito (Lifting Solutions)

Overview: Kito is a leading manufacturer of lifting and hoisting equipment globally. While they are more known for cranes, hoists, and other lifting mechanisms, they also supply slab tongs and related equipment.

Products: Kito slab tongs are designed to handle hot slabs in the steel manufacturing industry.

Website: www.kito.net

6. Manitowoc Crane Group

Overview: While primarily known for cranes and heavy lifting equipment, Manitowoc also manufactures lifting tools such as slab tongs for heavy-duty applications in steel mills.

Products: They offer a range of lifting attachments, including tongs for handling hot slabs and other large materials in the steel industry.

Website: www.manitowoccranes.com

7. Liebherr (Industrial Lifting)

Overview: Liebherr is a well-known manufacturer of construction and industrial equipment, including cranes and lifting tools. Their product range includes slab tongs, designed specifically for the steel and metal industries.

Products: Liebherr slab tongs are built for safe handling of heavy, hot slabs in steel production processes.

Website: www.liebherr.com

8. Stahl- und Maschinenbau (Steel and Machinery Construction)

Overview: A German manufacturer specializing in steel construction equipment, including lifting tongs and related material handling tools for heavy industries.

Products: They provide slab tongs designed to withstand extreme temperatures and heavy-duty lifting operations.

Website: www.smb-lifting.com

9. Inductotherm Group

Overview: Inductotherm is known for manufacturing a wide range of equipment for the metalworking industry, including induction furnaces and material handling tools. They also provide lifting equipment like slab tongs.

Products: Inductotherm’s slab tongs are specifically designed for lifting hot metal slabs in steel plants and other manufacturing processes.

Website: www.inductotherm.com

10. Elephant Lifting Equipment

Overview: Elephant Lifting is a UK-based manufacturer specializing in lifting equipment for industrial applications, including slab tongs. They offer solutions for a range of industries including steel and metalworking.

Products: They manufacture tongs specifically for slab lifting, designed for durability and efficiency in steel plants.

Website: www.elephantlifting.com

Considerations When Selecting a Slab Tong Manufacturer:

Customization: Some manufacturers offer custom-designed slab tongs based on the specific size, weight, and temperature conditions of the slabs being handled.

Load Capacity: Ensure the tongs are rated for the weight and dimensions of the slabs to be handled.

Material & Durability: Look for tongs made from materials that can withstand high temperatures and resist wear and tear from frequent use in industrial environments.

Safety Features: Quality slab tongs come with features like safety locks, adjustable gripping mechanisms, and ergonomic designs to ensure safe operation.

Industry Compliance: Choose manufacturers who comply with industry standards and certifications for safety and quality, such as ISO certifications or CE markings.

When selecting a manufacturer, it's essential to evaluate your specific needs, including the size of the slabs, the temperature they will be exposed to, and the required handling capacity. Many suppliers offer both standard and custom solutions, so working with an experienced supplier can ensure you get the best equipment for your operations.

0 notes

Text

The Process Involved in Making Quality TMT Bars :

The production of high-quality TMT (Thermo-Mechanically Treated) bars involves several key steps in a sophisticated manufacturing process. TMT bars are a type of reinforcement steel used in construction, known for their superior strength, durability, and corrosion resistance. The process of making TMT bars includes several stages, which ensure that the bars achieve the desired mechanical properties.

Here's an overview of the process:

1. Raw Material Selection

The process begins with the selection of high-quality raw materials, primarily iron ore, coal, and other alloying elements. These materials are fed into the blast furnace or electric arc furnace (EAF) to produce steel. The quality of raw materials significantly impacts the final product.

2. Melting and Refining

The selected raw materials are melted in a furnace. In modern steelmaking, this typically involves:

Blast Furnace: Used to produce pig iron, which is then converted into steel.

Electric Arc Furnace (EAF): Scrap steel is used as the primary raw material, melted by electric arcs.

After melting, the steel is refined by removing impurities such as sulfur, phosphorus, and carbon to obtain a cleaner, purer steel composition.

3. Casting

Once the steel has been refined, it is cast into billets or blooms using a continuous casting process. This process involves pouring molten steel into molds, where it solidifies into rough shapes. The size of the billets is crucial because it influences the final diameter of the TMT bars.

4. Rolling (Deformation)

The solidified billets are then reheated and passed through a series of rollers in the rolling mill. This process is called rolling and it progressively reduces the size of the billets while shaping them into long, cylindrical bars.

The temperature during rolling is crucial, as it determines the steel's properties. The temperature needs to be maintained within specific limits to ensure that the bars have the right mechanical properties (strength, flexibility, etc.).

5. Thermo-Mechanical Treatment (TMT) Process

This is the core step that differentiates TMT bars from conventional steel bars. TMT bars undergo a specialized heat treatment process that involves:

Reheating: After the bars are rolled to the desired diameter, they are reheated to a high temperature (around 1000–1100°C) in a controlled environment.

Quenching: The hot bars are rapidly cooled using water in a process called quenching. This sudden cooling hardens the outer surface of the bars, creating a strong, wear-resistant outer layer. The inner core of the bars, however, remains comparatively softer and more ductile. This unique combination of a hard outer layer and a soft core gives TMT bars their high strength and ductility.

Tempering: After quenching, the bars are passed through a process known as tempering, where they are slowly cooled in the air or through other controlled cooling techniques. This helps to reduce internal stresses, refine the microstructure, and enhance the toughness and flexibility of the bars.

6. Cooling

Once the bars have been quenched and tempered, they are allowed to cool to room temperature. The cooling process ensures that the outer layer becomes very hard (martensite) while the core remains relatively softer (pearlite), providing the bar with the perfect balance of strength and flexibility.

7. Cutting and Final Inspection

After cooling, the TMT bars are cut into the required lengths. These bars are then subjected to rigorous quality checks to ensure they meet industry standards. Tests may include:

Tensile strength tests

Bend tests

Surface quality checks

Chemical composition analysis

Any defects such as cracks, rust, or surface irregularities are identified and discarded.

8. Packaging and Dispatch

The final product is then packed according to specifications, which may include bundling the bars in coils or straight lengths. Packaging protects the bars from damage during transport and makes them easier to handle and store.

Key Features of TMT Bars

High Strength: Due to the rapid cooling process (quenching), the outer surface of TMT bars becomes hard, providing strength and high tensile properties.

Ductility: The core remains relatively soft, allowing the bar to bend without breaking under stress, making it ideal for construction in earthquake-prone areas.

Corrosion Resistance: The TMT bars have a tough outer layer, which offers excellent resistance to corrosion, making them more durable than other types of reinforcement bars.

Weldability: TMT bars can be easily welded, which is important for construction applications.

Conclusion

The process of making quality TMT bars involves careful control at every stage, from raw material selection to the final inspection of the bars. The key to producing high-quality TMT bars lies in the thermo-mechanical treatment process, which ensures that the bars possess superior strength, flexibility, and resistance to wear and corrosion.

0 notes

Text

Noscapine syrup : 101

Noscapine syrup is a medication that contains noscapine as its active ingredient. Noscapine is a non-opioid, antitussive (cough suppressant) that is used to relieve coughing. It is commonly used to treat dry, non-productive coughs (coughs that do not produce mucus).

How it works:

Noscapine works by suppressing the cough reflex in the brain, specifically by acting on the medulla (the part of the brain that controls coughing). Unlike opioids, noscapine does not have the same risk of dependence, sedation, or respiratory depression, making it a safer alternative for long-term use.

Common uses:

Cough suppression: Noscapine syrup is primarily prescribed for dry coughs, especially in cases where the cough is persistent and disruptive but not caused by an underlying infection.

Symptomatic relief: It can also be used for coughing caused by conditions like asthma, bronchitis, or other respiratory issues, though it is typically used for dry coughs rather than productive coughs.

Dosage:

The dosage of noscapine syrup depends on the specific formulation and the patient's age or condition. It is important to follow the instructions on the label or as prescribed by a doctor. Overuse of cough suppressants can be harmful, so it's important to use the medication only as directed.

Side effects:

While noscapine is generally well-tolerated, some potential side effects include:

Dizziness

Nausea or vomiting

Sleepiness

Constipation

Note: If you experience any unusual symptoms, or if the cough persists, it is important to consult with a healthcare provider. A cough can be a symptom of a more serious underlying condition that requires medical attention.

0 notes

Text

Noscapine syrup : 101

Noscapine syrup is a medication that contains noscapine as its active ingredient. Noscapine is a non-opioid, antitussive (cough suppressant) that is used to relieve coughing. It is commonly used to treat dry, non-productive coughs (coughs that do not produce mucus).

How it works:

Noscapine works by suppressing the cough reflex in the brain, specifically by acting on the medulla (the part of the brain that controls coughing). Unlike opioids, noscapine does not have the same risk of dependence, sedation, or respiratory depression, making it a safer alternative for long-term use.

Common uses:

Cough suppression: Noscapine syrup is primarily prescribed for dry coughs, especially in cases where the cough is persistent and disruptive but not caused by an underlying infection.

Symptomatic relief: It can also be used for coughing caused by conditions like asthma, bronchitis, or other respiratory issues, though it is typically used for dry coughs rather than productive coughs.

Dosage:

The dosage of noscapine syrup depends on the specific formulation and the patient's age or condition. It is important to follow the instructions on the label or as prescribed by a doctor. Overuse of cough suppressants can be harmful, so it's important to use the medication only as directed.

Side effects:

While noscapine is generally well-tolerated, some potential side effects include:

Dizziness

Nausea or vomiting

Sleepiness

Constipation

Note: If you experience any unusual symptoms, or if the cough persists, it is important to consult with a healthcare provider. A cough can be a symptom of a more serious underlying condition that requires medical attention.

0 notes

Text

Bilastine API Manufacturers in india

Bilastine is an antihistamine used to treat conditions like allergies and chronic urticaria (hives). Several pharmaceutical manufacturers in India produce Bilastine API (Active Pharmaceutical Ingredient). Some of the prominent manufacturers that supply Bilastine API in India include:

1. Hetero Drugs

Overview: Hetero is one of India's largest pharmaceutical companies and a significant player in the generic API sector.

Specialization: They manufacture a wide range of APIs, including Bilastine, for domestic and international markets.

Website: www.heterodrugs.com

2.Shobha Lifesciences

Overview: Shobha lifesciences is a global player with a strong portfolio of APIs, including those used for allergy treatments.

Specialization: Known for producing generic drugs and APIs, including antihistamines like Bilastine.

Website: www.Shobhalifesciences.com

3. Cipla Ltd.

Overview: Cipla is one of India's leading pharmaceutical companies and has a robust API manufacturing capability.

Specialization: Cipla manufactures a range of APIs, including for the treatment of allergic conditions.

Website: www.cipla.com

4. Granules India

Overview: Granules India is a key player in the Indian pharmaceutical industry, with a focus on API production.

Specialization: Known for producing high-quality generic APIs, including antihistamines.

Website: www.granulesindia.com

5. Mylan Laboratories (now Viatris)

Overview: Mylan, now known as Viatris, is a leading global pharmaceutical company with a strong presence in India.

Specialization: The company manufactures a wide array of APIs and generic medications.

Website: www.mylan.in

6. Zydus Cadila

Overview: Zydus Cadila is a major pharmaceutical company in India, involved in the manufacturing of both finished dosage forms and APIs.

Specialization: It offers a broad range of APIs, including antihistamines like Bilastine.

Website: www.zyduscadila.com

7. Sun Pharmaceutical Industries

Overview: Sun Pharma is one of the largest pharmaceutical companies globally, and they produce a wide range of APIs.

Specialization: The company manufactures high-quality APIs and is involved in research and development for generic drugs.

Website: www.sunpharma.com

8. Intas Pharmaceuticals

Overview: Intas Pharmaceuticals is a leading pharmaceutical manufacturer in India that specializes in APIs and generic medicines.

Specialization: Known for producing a variety of antihistamines and other APIs.

Website: www.intaspharma.com

9. Lupin Pharmaceuticals

Overview: Lupin is a global pharmaceutical company, and it is involved in the manufacture of APIs for a wide range of therapeutic areas.

Specialization: Known for its expertise in the production of generic APIs.

Website: www.lupin.com

10. AstraZeneca India

Overview: While AstraZeneca is a global pharmaceutical company, they have a significant presence in India and produce several APIs, including antihistamines.

Specialization: Primarily involved in innovative medicines but also engaged in API manufacturing for certain therapeutic areas.

Website: www.astrazeneca.com

11. Vee Excel Drugs & Pharmaceuticals

Overview: Vee Excel is an Indian manufacturer that specializes in APIs and contract manufacturing for several therapeutic areas, including allergy treatments.

Specialization: They produce a variety of APIs, including Bilastine.

Website: www.veeexcel.com

These manufacturers produce Bilastine API either in bulk or in cooperation with international pharmaceutical companies. If you’re looking for a specific supplier or details on pricing, regulatory compliance, or distribution, contacting the manufacturers directly through their business development or sales departments is recommended.

0 notes

Text

Ezetimibe Exporters India

hobhalifesciences is the leading Ezetimibe Manufacturers in India and exporters that also offers a wide range of superior products. Established in 2021, we are ISO and GMP certified.

Shobha Life Sciences is Pharameticual Manufactures In Hyderabad, as top-notch contract research organisation providing facilities for various pre-clinical experiments.

Do You Know About Ezetimibe Applications?:

Ezetimibe is a medication that is used to lower cholesterol levels in the blood. It works by decreasing the amount of cholesterol that is absorbed from food in the small intestine.

Ezetimibe is usually prescribed along with a low-fat diet and other cholesterol-lowering medications, such as statins.

Ezetimibe is typically used to treat patients with high cholesterol who are at an increased risk of heart disease, stroke, and other cardiovascular complications.

It is also used in some cases to treat people with a genetic condition called homozygous familial hypercholesterolemia, which causes extremely high cholesterol levels.

0 notes

Text

best quality tmt bars in india

When looking for the best quality TMT (Thermo-Mechanically Treated) bars in India, it's important to focus on established and reputable brands known for their superior manufacturing processes, consistent quality, and high-strength products. Some of the top brands for TMT bars in India are:

1. Tata Tiscon

Brand: Tata Steel

Overview: Tata Tiscon is one of the most trusted names in the Indian steel industry. Their TMT bars are known for excellent strength, durability, and flexibility. They offer high-quality bars that are widely used in construction across India.

Features: Corrosion resistance, earthquake-resistant, and superior weldability.

2. Keshree TMT

Brand: Keshree TMT

Overview: Keshree TMT bars are known for their advanced manufacturing technology and high-quality material. The brand ensures superior tensile strength and excellent bendability, making them ideal for construction in all weather conditions.

Features: Strong, durable, high-strength, earthquake-resistant.

3. Sail TMT Bars

Brand: Steel Authority of India Limited (SAIL)

Overview: SAIL is one of the largest steel manufacturers in India. Their TMT bars are widely recognized for their high tensile strength and ability to withstand seismic forces.

Features: High quality, earthquake-resistant, rust-resistant.

4. Kamdhenu TMT Bars

Brand: Kamdhenu Ispat Ltd.

Overview: Kamdhenu is known for its premium quality TMT bars, which are manufactured using the latest technology. The bars offer good strength and excellent bendability.

Features: Corrosion-resistant, high-strength, superior finish.

5. Rathi TMT Bars

Brand: Rathi Ispat Limited

Overview: Known for their consistency and high-quality standards, Rathi TMT bars are often used in large infrastructure projects and are trusted by builders and contractors across India.

Features: High strength, better ductility, corrosion resistance.

6. Shree TMT Bars

Brand: Shree Steel Group

Overview: Shree TMT Bars are known for their exceptional quality and excellent resistance to rust and corrosion. They are used in a wide variety of construction applications across India.

Features: Good strength, corrosion-resistant, earthquake-resistant.

7. Jindal Panther TMT Bars

Brand: Jindal Steel and Power Limited (JSPL)

Overview: Jindal Panther TMT Bars are produced using advanced technology and are known for their superior quality, high strength, and excellent durability.

Features: High tensile strength, corrosion resistance, and high ductility.

8. Bhushan TMT Bars

Brand: Bhushan Steel

Overview: Bhushan Steel produces TMT bars with advanced manufacturing processes and offers high-quality products used for construction in both residential and commercial projects.

Features: High strength, superior weldability, and corrosion resistance.

9. Vikram TMT Bars

Brand: Vikram Ispat Limited

Overview: Known for their exceptional strength and high-quality production, Vikram TMT bars are used in large-scale construction projects.

Features: Durability, high strength, and earthquake-resistant.

10. UltraTech TMT Bars

Brand: UltraTech Cement (Aditya Birla Group)

Overview: UltraTech produces TMT bars that are known for their strength, quality, and performance in harsh weather conditions. They have a wide distribution network and are widely used in the construction industry.

Features: Strong, durable, corrosion-resistant, and suitable for all construction needs.

Factors to Consider When Choosing TMT Bars:

Grade: TMT bars are typically available in grades like Fe 415, Fe 500, and Fe 550. Higher grades generally offer better strength.

Corrosion Resistance: Some brands offer TMT bars with special corrosion-resistant properties, which can be beneficial in coastal or humid environments.

Ductility: Good ductility helps in bending without cracking, making TMT bars suitable for earthquake-prone regions.

Manufacturing Process: Look for bars made using modern manufacturing techniques, such as the Thermo-Mechanical Treatment (TMT) process, which provides better strength and flexibility.

When selecting TMT bars, consider the specific needs of your construction project, such as strength requirements, environmental conditions, and budget.

0 notes

Text

Understanding Gliclazide API: A Comprehensive Guide to This Important Antidiabetic Drug

Title: Understanding Gliclazide API: A Comprehensive Guide to This Important Antidiabetic Drug

Introduction:

Gliclazide is a second-generation sulfonylurea medication widely used in the treatment of type 2 diabetes mellitus. As an Active Pharmaceutical Ingredient (API), it plays a crucial role in pharmaceutical manufacturing. Let's delve into its properties, manufacturing considerations, and significance in diabetes management.

Chemical Properties and Structure:

- Chemical Formula: C15H21N3O3S

- IUPAC Name: 1-(3-azabicyclo[3.3.0]oct-3-yl)-3-(p-tolylsulfonyl)urea

- Appearance: White to off-white crystalline powder

- Solubility: Practically insoluble in water, soluble in methylene chloride, slightly soluble in ethanol

Manufacturing and Quality Control:

1. Synthesis Route:

- The manufacturing process typically involves the reaction of p-toluenesulfonamide with azabicyclooctane derivatives

- Key steps include condensation, purification, and crystallization

- Strict temperature and pH control are essential during synthesis

2. Quality Parameters:

- Assay (97.0% - 102.0%)

- Related substances (≤0.5% individual impurities)

- Residual solvents

- Heavy metals content

- Particle size distribution

Mechanism of Action:

Gliclazide works by:

- Stimulating insulin secretion from pancreatic β-cells

- Binding to sulfonylurea receptors (SUR1)

- Closing ATP-sensitive potassium channels

- Increasing intracellular calcium, leading to insulin release

Storage and Stability:

- Store in tightly closed containers

- Protect from light and moisture

- Recommended storage temperature: 20-25°C

- Avoid exposure to extreme temperatures

Regulatory Compliance:

Manufacturers must ensure:

- GMP compliance

- Documentation of all manufacturing steps

- Validated analytical methods

- Stability studies according to ICH guidelines

- Drug Master File (DMF) preparation

Market Overview:

- Growing demand due to increasing diabetes prevalence

- Key manufacturing hubs in India, China, and Europe

- Competitive pricing and quality considerations

- Patent landscape and generic opportunities

Applications:

1. Immediate Release Formulations:

- Tablets (40mg, 80mg strengths)

- Quality control requirements

- Dissolution specifications

2. Modified Release Formulations:

- Extended-release technologies

- Bioequivalence considerations

- Manufacturing challenges

Safety Considerations:

- Handling precautions

- Environmental controls

- Personnel protection

- Waste management

- Cross-contamination prevention

Future Trends:

- Development of improved synthesis routes

- Green chemistry initiatives

- Enhanced purification techniques

- Cost optimization strategies

- Novel delivery systems

Quality Analysis:

Key testing parameters include:

- HPLC analysis

- Dissolution testing

- Content uniformity

- Related substances

- Microbial limits

Conclusion:

Gliclazide API remains a vital component in diabetes management. Understanding its properties, manufacturing requirements, and quality parameters is crucial for pharmaceutical manufacturers to ensure consistent product quality and regulatory compliance.

For API manufacturers and pharmaceutical companies, maintaining high-quality standards while optimizing production costs continues to be a key challenge. Staying updated with regulatory requirements and implementing robust quality management systems are essential for success in this competitive market.

Would you like me to expand on any particular aspect of the blog post or provide more specific information about certain sections?

0 notes

Text

Sitagliptin: Mechanism of Action and Clinical Pharmacology

Sitagliptin: Mechanism of Action and Clinical Pharmacology

Primary Mechanism

Sitagliptin is a dipeptidyl peptidase-4 (DPP-4) inhibitor that works through several interconnected mechanisms to improve glycemic control in type 2 diabetes:

1. DPP-4 Enzyme Inhibition

Selectively and competitively inhibits DPP-4 enzyme

Forms reversible bonds with the active site of DPP-4

Prevents the degradation of incretin hormones:

Glucagon-like peptide-1 (GLP-1)

Glucose-dependent insulinotropic polypeptide (GIP)

2. Incretin Effect Enhancement

The preserved incretin hormones lead to:

Increased insulin synthesis and release from pancreatic β-cells

Decreased glucagon secretion from pancreatic α-cells

Enhanced glucose-dependent insulin secretion

Improved β-cell function and survival

Physiological Effects

Glucose Homeostasis

Pancreatic Effects:

Increases glucose-stimulated insulin secretion

Reduces inappropriate glucagon secretion

Improves β-cell function

Enhances α-cell sensitivity to glucose

Extra-Pancreatic Effects:

Reduces hepatic glucose production

Improves peripheral glucose uptake

Decreases postprandial glucose excursions

Key Clinical Outcomes

Reduces fasting plasma glucose

Lowers postprandial glucose levels

Decreases HbA1c levels

Weight neutral effect

Low risk of hypoglycemia

Pharmacological Properties

Pharmacokinetics

Oral bioavailability: ~87%

Peak plasma concentration: 1-4 hours

Half-life: ~12 hours

Protein binding: 38%

Primary excretion: Renal (~80% unchanged)

Pharmacodynamics

DPP-4 inhibition: >80% over 24 hours

Duration of action: 24 hours

Dose-dependent increase in active GLP-1 levels

Sustained reduction in plasma glucose levels

Clinical Considerations

Advantages

Once-daily dosing

Low risk of hypoglycemia

Weight neutral

Good tolerability profile

Limited drug interactions

Special Populations

Dose adjustment needed in renal impairment

No dose adjustment needed in:

Mild to moderate hepatic impairment

Elderly patients

Based on race or ethnicity

Monitoring Parameters

Renal function

Pancreatic enzymes

Blood glucose levels

HbA1c

Signs of hypersensitivity reactions

0 notes

Text

rivaroxaban uses

Here are the main approved medical uses of Rivaroxaban:

Prevention and Treatment of Blood Clots:

Deep Vein Thrombosis (DVT)

Pulmonary Embolism (PE)

Prevention of DVT/PE recurrence

Cardiovascular Protection:

Prevention of stroke in patients with atrial fibrillation

Reducing risk of major cardiovascular events in patients with:

Coronary Artery Disease (CAD)

Peripheral Artery Disease (PAD)

Post-Surgery Prevention:

Prevention of DVT/PE after hip replacement surgery

Prevention of DVT/PE after knee replacement surgery

Dosing typically varies based on indication:

DVT/PE treatment: 15mg twice daily for 21 days, then 20mg once daily

Atrial fibrillation: 20mg once daily

Post-surgery prevention: 10mg once daily

Key considerations:

Regular monitoring required

Dose adjustments needed for kidney problems

Should be taken with food for 15mg and 20mg doses

Not recommended in certain conditions (severe kidney/liver disease, pregnancy)

Rivaroxaban Manufacturer In India. Shobhalifesciences is a leading supplier and also provides a wide range of other superior products. We established in 2021, we employ good manufacturing practices and thus are WHO-GMP, ISO, and ICE certified company.

0 notes

Text

Bilastine Intermediate Manufacturers

Bilastine is a second-generation antihistamine used to treat allergic rhinitis and urticaria (hives). The synthesis of bilastine involves several chemical intermediates, which are crucial for its production. Here are some common intermediates in the synthesis pathway of bilastine:

1. Pyridine Derivatives

Pyridine rings are core structures in bilastine. Some intermediates include pyridine derivatives that undergo further chemical modifications.

2. Benzimidazole Derivatives

Benzimidazole structures are essential in the synthesis of bilastine, and intermediate compounds with benzimidazole rings are involved at various stages of the production process.

3. Amino Alcohol Intermediates

Amino alcohol groups are incorporated into the bilastine structure through intermediates that contain these functional groups, often used in amine substitution reactions.

4. Carboxylic Acid Intermediates

Carboxylic acids or their esters play a role as intermediates in some stages, facilitating reactions like amide formation and cyclization.

5. Alkylating Agents

These agents are used to introduce alkyl groups into the molecular structure, modifying the properties of the intermediate and progressing toward the final bilastine molecule.

The exact intermediates can vary depending on the synthesis route chosen by the manufacturer. Are you looking for a specific synthetic route or particular intermediates?

0 notes

Text

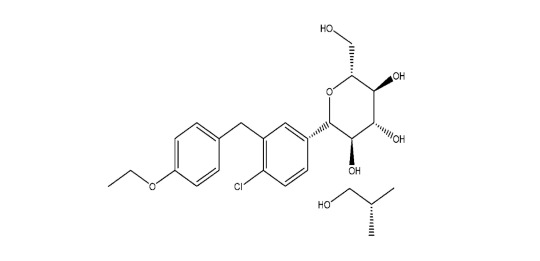

Empagliflozin

Empagliflozin is an oral medication used primarily in the treatment of type 2 diabetes. Here's a concise overview of key points about empagliflozin:

1. Drug class: It belongs to a class of drugs called sodium-glucose co-transporter 2 (SGLT2) inhibitors.

2. Mechanism of action: Empagliflozin works by helping the kidneys remove excess sugar from the body through urine.

3. Brand names: The most common brand name is Jardiance, manufactured by Boehringer Ingelheim and Eli Lilly.

4. Uses:

- Primary use: Treatment of type 2 diabetes

- Secondary uses: Reducing the risk of cardiovascular death in adults with type 2 diabetes and established cardiovascular disease

- Treatment of heart failure with reduced ejection fraction (HFrEF)

5. Administration: Taken orally, usually once daily.

6. Common side effects: Urinary tract infections, genital mycotic infections, and increased urination.

7. Benefits: Besides glucose control, it has shown cardiovascular and renal protective effects.

8. Contraindications: Not recommended for patients with type 1 diabetes or diabetic ketoacidosis.

Would you like more detailed information on any specific aspect of empagliflozin, such as its efficacy, dosing, or potential drug interactions?

0 notes

Text

Understanding Sitagliptin Tartrate

Understanding Sitagliptin Tartrate:

Sitagliptin tartrate Manufacturers is a medication belonging to the class of dipeptidyl peptidase-4 (DPP-4) inhibitors. It works by increasing the levels of incretin hormones in the body, which help to lower blood sugar levels in patients with type 2 diabetes. This drug has proven efficacy in improving glycemic control, often as a standalone therapy or in combination with other antidiabetic medications.

The Role of Manufacturers:

Sitagliptin tartrate manufacturers play a crucial role in ensuring the availability, quality, and affordability of this vital medication. Here are some key aspects of their contributions:

Research and Development (R&D): Manufacturers invest heavily in research and development to enhance the formulation, efficacy, and safety profile of sitagliptin tartrate. This includes conducting clinical trials, optimizing manufacturing processes, and exploring innovative drug delivery mechanisms.

Regulatory Compliance: Ensuring compliance with stringent regulatory standards is paramount in the pharmaceutical industry. Manufacturers adhere to guidelines set forth by regulatory authorities such as the FDA (Food and Drug Administration) in the United States and the EMA (European Medicines Agency) in Europe to guarantee the safety and efficacy of sitagliptin tartrate.

Scaling Production: With the increasing demand for sitagliptin tartrate worldwide, manufacturers must scale production to meet market needs. This involves investing in manufacturing infrastructure, optimizing production efficiency, and maintaining a robust supply chain to ensure uninterrupted availability of the medication.

Visit : Sitagliptin Tartrate Manufacturers

0 notes

Text

API (Active Pharmaceutical Ingredient) manufacturing company in india

In the dynamic realm of pharmaceuticals, the production of high-quality Active Pharmaceutical Ingredients (APIs) is the beating heart that drives innovation and healthcare advancements. In this blog post, we delve into the fascinating world of API manufacturing, exploring the crucial role it plays in the pharmaceutical industry and its impact on global health.

The Essence of API Manufacturing:

APIs are the foundation of pharmaceuticals, the bioactive compounds that make drugs effective. API manufacturing involves the synthesis or extraction of these key components, often from natural sources, followed by rigorous purification processes to meet stringent quality standards.

Key Aspects of API Manufacturing:

Research and Development (R&D):

The journey begins with extensive research and development to identify viable compounds with therapeutic potential. API manufacturers invest in cutting-edge technologies and scientific expertise to stay at the forefront of pharmaceutical innovation.

Synthesis and Production:

Once a promising compound is identified, the synthesis process commences. API manufacturing companies employ state-of-the-art facilities and adhere to Good Manufacturing Practices (GMP) to ensure the production of APIs with consistent quality and purity.

Quality Assurance:

Rigorous quality control measures are implemented throughout the manufacturing process. Advanced analytical techniques and quality assurance protocols guarantee that the APIs meet regulatory standards, ensuring safety and efficacy in the final drug product.

Regulatory Compliance:

API manufacturing is subject to stringent regulations imposed by health authorities worldwide. Compliance with regulatory requirements, such as those set by the FDA or EMA, is paramount to ensure the safety and efficacy of pharmaceutical products.

Environmental Responsibility:

Leading API manufacturing companies prioritize sustainable practices. From waste management to energy efficiency, environmental responsibility is woven into the fabric of API production, aligning with global efforts towards a greener and more sustainable future.

Innovation Driving Healthcare Solutions:

API manufacturing is a hub of innovation, driving advancements in drug therapies and treatment modalities. The ability to create complex molecules, coupled with a commitment to research, positions API manufacturers as key contributors to the development of groundbreaking pharmaceuticals.

Visit : Empagliflozin Manufacturers In India to knowmore !

0 notes

Text

What is the drug ezetimibe used for ?

What is the drug ezetimibe used for ?

What is Ezetimibe?

Ezetimibe is a prescription medication primarily used to lower cholesterol levels in the body. It belongs to a class of drugs known as cholesterol absorption inhibitors. Unlike statins, which work by inhibiting cholesterol production in the liver, ezetimibe works in the digestive system to reduce the absorption of cholesterol from the diet.

How Does Ezetimibe Work?

Ezetimibe acts by inhibiting the absorption of dietary cholesterol in the small intestine. It does this by targeting a protein called NPC1L1 (Niemann-Pick C1-Like 1) that is responsible for cholesterol uptake from the gut. By blocking this protein, ezetimibe reduces the amount of cholesterol that enters the bloodstream, resulting in lower total cholesterol and LDL (low-density lipoprotein) cholesterol levels.

Indications for Use:

Ezetimibe is primarily prescribed to treat high cholesterol, particularly elevated levels of LDL cholesterol. It is often used in conjunction with a healthy diet and exercise to manage cholesterol effectively. Additionally, ezetimibe may be prescribed to individuals who cannot tolerate statins or as an adjunct therapy for those who require further cholesterol reduction.

Benefits of Ezetimibe:

Cholesterol Reduction: The primary benefit of ezetimibe is its ability to effectively lower LDL cholesterol levels. By reducing cholesterol absorption from the diet, it contributes to an overall decrease in total cholesterol levels, which can help reduce the risk of cardiovascular diseases.

Combination Therapy: Ezetimibe can be used in combination with statins to provide additional cholesterol-lowering effects. This combination can be particularly useful for individuals who require more aggressive cholesterol management.

Tolerability: Ezetimibe is generally well-tolerated and has a lower risk of side effects compared to statins. It offers an alternative treatment option for individuals who experience adverse effects with statin therapy.

Complementary Lifestyle Changes: Ezetimibe works best when used in conjunction with lifestyle modifications such as a healthy diet, regular exercise, and smoking cessation. It can enhance the effectiveness of these lifestyle changes in managing cholesterol levels.

Possible Side Effects:

Although generally well-tolerated, like any medication, ezetimibe may cause side effects in some individuals. Common side effects may include diarrhea, stomach pain, fatigue, headache, and muscle pain. It is important to consult with a healthcare professional if any concerning side effects occur.

Conclusion:

Ezetimibe is a valuable medication for managing high cholesterol levels, particularly LDL cholesterol. By inhibiting cholesterol absorption in the small intestine, it helps lower overall cholesterol levels and reduces the risk of cardiovascular diseases. As with any medication, it is crucial to consult with a healthcare professional to determine the most appropriate treatment plan and to address any concerns or questions. Combining ezetimibe with a healthy lifestyle can greatly contribute to achieving optimal cholesterol levels and maintaining a healthy heart.

Disclaimer: This blog post is for informational purposes only and should not be considered medical advice. Please consult a healthcare professional for personalized guidance regarding your specific medical condition or treatment.

0 notes