Don't wanna be here? Send us removal request.

Text

Advantages of Using Rapid Prototype Casting for Product Development

Rapid prototype casting is a crucial technique in modern product development, offering numerous benefits that significantly enhance the design, testing, and manufacturing processes. Here’s an in-depth look at the advantages of using rapid prototype casting in Pune for product development:

Speed and Efficiency

One of the primary benefits of rapid prototype casting is the speed with which prototypes can be produced. Traditional casting methods can take weeks or even months to produce a single prototype, but rapid prototyping can significantly reduce this time. This accelerated process allows for quicker iterations and faster time-to-market for new products.

Cost-Effectiveness

Rapid prototype casting in Pune can be more cost-effective than traditional methods. By using less material and reducing the need for expensive tooling, companies can save money during the initial stages of product development. Additionally, the ability to identify and correct design flaws early in the process prevents costly modifications later.

Design Flexibility

Rapid prototype casting in Pune offers greater design flexibility, allowing for the creation of complex geometries and intricate designs that would be difficult or impossible to achieve with conventional casting methods. This flexibility enables designers to experiment with innovative ideas and refine their products to achieve optimal functionality and aesthetics.

Improved Testing and Validation

Prototypes created through rapid casting can be used for rigorous testing and validation. This process ensures that the final product meets all necessary standards and performs as expected under real-world conditions. By testing prototypes early and often, companies can identify potential issues and make necessary adjustments before full-scale production.

Material Versatility

Rapid prototype casting in Pune supports a wide range of materials, including metals, plastics, and composites. This versatility allows designers to select the best material for their specific application, ensuring that the prototype accurately represents the final product in terms of strength, durability, and other key characteristics.

Enhanced Collaboration

The speed and flexibility of rapid prototype casting facilitate better collaboration between design, engineering, and manufacturing teams. By quickly producing and sharing prototypes, teams can gather feedback, discuss improvements, and make informed decisions more efficiently. This collaborative approach leads to better-designed products and a smoother development process.

Risk Reduction

Creating prototypes early in the development process helps identify potential design flaws and production issues before they become significant problems. This proactive approach reduces the risk of costly mistakes and ensures that the final product is of the highest quality. By catching issues early, companies can avoid delays and additional expenses associated with late-stage modifications.

Customization and Personalization

Rapid prototype casting in Pune is ideal for creating customized and personalized products. Whether for medical devices tailored to individual patients or consumer products designed to meet specific customer preferences, this method allows for rapid production of unique items without the need for extensive retooling or setup.

Conclusion

Rapid prototype casting in Pune is transforming the manufacturing landscape, offering unprecedented speed, cost-efficiency, and precision. In Pune, Siddhalaxmi is leading the way with its state-of-the-art solutions and unwavering commitment to excellence. Whether you’re in the automotive, aerospace, medical, or consumer goods industry, our rapid prototype casting services can help you stay ahead of the competition and bring your innovative ideas to life.

Ready to take your product development to the next level? Contact Siddhalaxmi today and discover the future of manufacturing with rapid prototype casting in Pune.

To Know More: https://www.siddhalaxmi.com/advantages-of-using-rapid-prototype-casting-for-product-development/

0 notes

Text

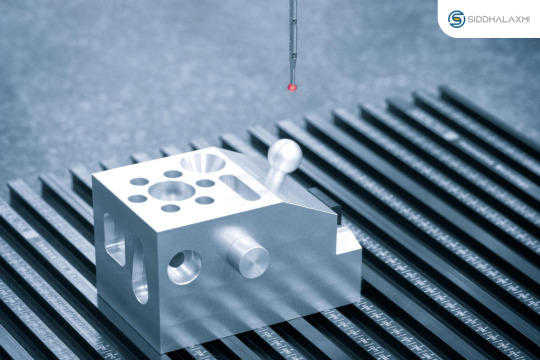

Innovation at Work: VMC and CNC Machining Solutions Transforming Pune’s Manufacturing Scene

In the heart of India’s industrial landscape, Pune has long stood as a beacon of manufacturing prowess. With a rich history of engineering excellence, the city continues to evolve, driven by technological advancements and innovative solutions. At the forefront of this transformation is Siddhalaxmi, a pioneering company harnessing the power of VMC and CNC Machining in Pune machining to redefine manufacturing processes.

The Evolution of Manufacturing in Pune

Pune’s journey as a manufacturing hub dates back to the early 20th century, characterized by traditional methods and manual labor. However, as global competition intensified and the demand for precision grew, the need for advanced machining solutions became evident. Enter VMC and CNC Machining in Pune technologies – game-changers that have revolutionized the way manufacturing is approached in Pune and beyond.

Understanding VMC and CNC Machining

Vertical Machining Centers (VMC) are cutting-edge machines that allow for high-precision milling operations. With a vertically oriented spindle, VMCs can perform a variety of tasks such as drilling, tapping, and contouring, making them indispensable in modern manufacturing.

Computer Numerical Control (CNC) machining, on the other hand, involves the use of computers to control machine tools. This automation enhances accuracy, consistency, and efficiency, allowing for the production of complex parts with minimal human intervention. Together, VMC and CNC technologies offer unparalleled precision and flexibility, crucial for meeting the rigorous demands of today’s market.

Siddhalaxmi: Leading the Charge in Technological Innovation

At Siddhalaxmi, we pride ourselves on being at the cutting edge of manufacturing technology. Our investment in state-of-the-art VMC and CNC Machining in Pune underscores our commitment to delivering superior products and services. Here’s how we’re making a difference:

Precision and Quality

The core advantage of VMC and CNC Machining in Pune lies in their ability to produce parts with exceptional precision. At Siddhalaxmi, we leverage these technologies to manufacture components that meet the most stringent quality standards. This precision translates to better product performance and increased reliability, fostering trust and satisfaction among our clients.

Efficiency and Productivity

Time is a critical factor in manufacturing. Our VMC and CNC Machining in Pune are designed for high-speed operations, significantly reducing production times. This efficiency allows us to meet tight deadlines and handle large-scale orders without compromising on quality, giving our clients a competitive edge in the market.

Versatility and Customization

The versatility of VMC and CNC Machining in Pune is another key advantage. These machines can handle a wide range of materials and complex geometries, enabling us to cater to diverse industry needs. Whether it’s aerospace, automotive, or medical equipment, Siddhalaxmi offers tailored solutions that precisely match our clients’ specifications.

Transforming Pune’s Manufacturing Scene

Siddhalaxmi’s adoption of VMC and CNC Machining in Pune is more than just a technological upgrade; it’s a paradigm shift that’s transforming Pune’s manufacturing landscape. Our commitment to innovation is fostering a culture of excellence and setting new benchmarks in the industry. Here are a few ways we are contributing to Pune’s manufacturing renaissance:

Skill Development: By investing in advanced technologies, we are also investing in our workforce. Our employees undergo rigorous training to master VMC and CNC operations, enhancing their skill set and boosting their career prospects.

Collaborative Ecosystem: We actively collaborate with other manufacturers, suppliers, and educational institutions to create a thriving ecosystem. This collaborative approach drives innovation and ensures the continuous improvement of manufacturing practices.

Sustainable Manufacturing: At Siddhalaxmi, we are dedicated to sustainable practices. Our advanced machinery optimizes resource usage, reduces waste, and minimizes our carbon footprint, contributing to a greener, more sustainable future for Pune.

Looking Ahead

The future of manufacturing in Pune is bright, with VMC and CNC Machining in Pune at its core. As we continue to push the boundaries of what’s possible, Siddhalaxmi remains committed to leading this transformation. By embracing innovation and excellence, we are not just meeting the needs of today’s market but also setting the stage for the manufacturing solutions of tomorrow.

In conclusion, the integration of VMC and CNC technologies is a testament to Siddhalaxmi’s dedication to innovation and quality. We are proud to be a part of Pune’s manufacturing evolution, and we look forward to continuing our journey of technological advancement and industrial excellence.

To Know More: https://www.siddhalaxmi.com/innovation-at-work-vmc-and-cnc-machining-solutions-transforming-punes-manufacturing-scene/

0 notes

Text

How IC is used in Stainless Steel Casting Alloys industry

In the world of metallurgy, stainless steel casting alloys are prized for their remarkable strength, resistance to corrosion, and versatility. At Siddhalaxmi, a leader in the stainless steel casting industry, we continuously strive to enhance our processes and products to meet the growing demands of various sectors. A critical component in achieving this excellence is the use of Best Investment Casting in Pune. This blog delves into how IC is revolutionizing the stainless steel casting industry and why it remains an indispensable technique at Siddhalaxmi.

What is Investment Casting?

Best Investment Casting in Pune, often referred to as precision casting or lost-wax casting, is a manufacturing process that has been used for thousands of years. It involves creating a wax model of the desired part, covering it with a ceramic shell, and then melting away the wax to leave a hollow mold. Molten stainless steel is then poured into this mold to create a precise and intricate component.

Advantages of Investment Casting in Stainless Steel Alloys

Precision and Accuracy: One of the most significant advantages of IC is its ability to produce components with exceptional precision and accuracy. This is particularly important for stainless steel casting alloys, which are often used in applications requiring high dimensional accuracy and tight tolerances.

Complex Geometries: IC allows for the creation of components with complex geometries and intricate designs. This capability is crucial in industries such as aerospace, automotive, and medical devices, where stainless steel parts often need to have detailed and precise shapes.

Material Efficiency: The IC process minimizes material wastage. At Siddhalaxmi, we understand the importance of resource efficiency, and IC helps us reduce scrap rates significantly, leading to cost savings and a more sustainable production process.

Surface Finish: Components produced through IC typically have a superior surface finish, reducing the need for additional machining and finishing processes. This results in faster production times and lower costs for our clients.

Versatility: IC is versatile and can be used to cast a wide range of stainless-steel alloys. This flexibility allows Siddhalaxmi to cater to diverse industry requirements, providing tailor-made solutions to our clients.

The IC Process at Siddhalaxmi

At Siddhalaxmi, we have perfected the IC process to ensure the highest quality stainless steel castings. Here’s a glimpse into our meticulous approach:

Pattern Creation

We start with creating a precise wax pattern of the component. Our skilled craftsmen and advanced technology ensure that the pattern is an exact replica of the final product.

Shell Building

The wax pattern is then coated with a ceramic slurry and stucco to build a robust ceramic shell. This shell is built layer by layer, allowing it to withstand the high temperatures of molten stainless steel.

Wax Removal

Once the ceramic shell is complete, it is heated to melt and remove the wax, leaving a hollow mold. This step requires precision to ensure that the mold remains intact and free from defects.

Casting

Molten stainless steel is poured into the ceramic mold. At Siddhalaxmi, we use advanced melting and pouring techniques to ensure the integrity and purity of the metal.

Finishing

After the metal has cooled and solidified, the ceramic shell is broken away to reveal the cast component. The component undergoes finishing processes such as grinding, machining, and polishing to meet the exact specifications and quality standards.

Inspection

Quality is paramount at Siddhalaxmi. Every component undergoes rigorous inspection and testing to ensure it meets the highest standards of accuracy, strength, and durability.

Conclusion

Best Investment Casting in Pune is a cornerstone of our production process at Siddhalaxmi, enabling us to deliver high-quality stainless-steel castings that meet the diverse needs of our clients. By leveraging the advantages of IC, we continue to push the boundaries of what’s possible in stainless steel casting alloys, ensuring that our customers receive components that are not only precise and reliable but also cost-effective.

Stay connected with Siddhalaxmi for more insights into our advanced manufacturing processes and industry innovations. Together, we are shaping the future of stainless-steel casting alloys.

To Know More: https://www.siddhalaxmi.com/how-ic-is-used-in-stainless-steel-casting-alloys-industry/

0 notes

Text

Investment Casting Innovations: Pune's Role in Elevating Exports to New Heights

In the dynamic world of manufacturing and precision engineering, investment casting plays a pivotal role in creating intricate and high-quality metal components. Pune, known for its industrial prowess, hosts several companies that excel in investment casting. Among these, Siddhalaxmi emerges as a standout performer, showcasing excellence in the field and earning a reputation as a reliable partner for Best Investment Casting Pune.

The Resurgence of Investment Casting:

Investment casting, also known as lost-wax casting, dates back thousands of years. It involves creating precise and complex metal components by pouring molten metal into molds created from wax patterns. While the method itself is age-old, recent innovations in materials, processes, and automation have revolutionized the Best Investment Casting Pune industry.

Pune's Technological Leap:

Pune, home to a plethora of engineering and manufacturing units, has played a pivotal role in pushing the boundaries of investment casting. Advanced techniques such as 3D printing for creating intricate wax patterns, computer simulations for optimized mold designs, and robotic automation for precision casting have become commonplace in Pune's foundries.

Leading the charge are several research and development centers, collaborating with industry giants to implement state-of-the-art technologies. These innovations not only enhance the efficiency of the investment casting process but also contribute to the production of high-quality components that meet global standards.

Export Boom:

The technological prowess of Best Investment Casting Pune sector has not gone unnoticed on the international stage. With a focus on producing components for aerospace, automotive, and energy sectors, Pune-based manufacturers are making significant inroads into global markets. The city's investment casting exports have witnessed an unprecedented surge, creating a ripple effect on the overall economy.

International clients are increasingly turning to Pune for their precision casting needs, drawn by the city's reputation for innovation, reliability, and cost-effectiveness. The growing demand for lightweight components in aerospace and automotive industries further fuels the export boom, with Pune-based foundries well-positioned to capitalize on these opportunities.

Collaboration and Knowledge Exchange:

Pune's success in elevating Best Investment Casting is not solely attributed to technological advancements. The city has also fostered a culture of collaboration and knowledge exchange among academia, research institutions, and industry players. Regular conferences, workshops, and training programs ensure that the workforce is up-to-date with the latest developments in the field, further enhancing the industry's competitive edge.

Sustainable Practices:

In addition to technological advancements, Best Investment Casting Pune sector is also embracing sustainable practices. Efforts are underway to reduce waste, optimize energy consumption, and explore eco-friendly materials. This commitment to sustainability not only aligns with global trends but also positions Pune as a responsible and forward-thinking player in the investment casting arena.

In the realm of investment casting in Pune, Siddhalaxmi stands tall as a beacon of excellence. With its state-of-the-art facilities, skilled workforce, commitment to quality, and global reach, Siddhalaxmi continues to set new standards in the industry. As the company paves the way for investment casting exports from Pune, it not only strengthens its own position but also contributes to the city's reputation as a hub for precision engineering and manufacturing.

To know more: https://www.siddhalaxmi.com/investment-casting-innovations-punes-role-in-elevating-exports-to-new-heights/

0 notes

Text

Sourcing Success: Tips for Evaluating and Selecting Investment Casting Suppliers in India

In the realm of manufacturing, the process of investment casting stands as a vital method for producing intricate parts with precision. From aerospace to automotive industries, investment casting finds extensive applications, demanding top-notch suppliers capable of delivering quality products consistently. For businesses eyeing India as a sourcing destination, navigating through the plethora of suppliers can be daunting. To ensure sourcing success, here are some indispensable tips for evaluating and selecting investment casting suppliers in India.

Understanding Your Requirements

Before delving into supplier selection, it’s crucial to have a comprehensive understanding of your requirements. Define the specifications of your components, including material type, dimensional tolerances, surface finish, and quantity. This clarity will serve as a guiding beacon throughout the supplier evaluation process.

Quality Assurance Standards

Quality is non-negotiable in investment casting. Look for suppliers who adhere to internationally recognized quality standards such as ISO 9001, AS9100, or IATF 16949, ensuring consistency and reliability in their processes. Additionally, inquire about their quality control measures, inspection protocols, and certifications relevant to your industry.

Technical Expertise and Capabilities

Evaluate the supplier’s technical expertise and capabilities in investment casting suppliers in India. Assess their experience in handling diverse materials, complexities of geometries, and ability to meet stringent specifications. A supplier equipped with advanced technology, such as 3D modeling, simulation software, and rapid prototyping, demonstrates a commitment to innovation and efficiency.

Production Capacity and Scalability

Scalability is a critical factor, especially for businesses with fluctuating demand. Assess the supplier’s production capacity, lead times, and flexibility to accommodate volume variations. A robust supply chain and production infrastructure ensure continuity of supply, mitigating the risks of delays or disruptions.

Cost Competitiveness and Transparency

While cost is a significant consideration, it should not overshadow quality and reliability. Evaluate the supplier’s pricing structure, considering factors like material costs, tooling expenses, and overheads. Seek transparency in pricing, with clear breakdowns of costs and any potential additional charges. Remember, value trumps price in the long run.

Supply Chain Resilience and Ethical Practices

Examine the supplier’s supply chain resilience, especially concerning raw material sourcing and dependencies. Ensure compliance with ethical and environmental standards, avoiding suppliers associated with labor exploitation or environmental degradation. Ethical sourcing not only aligns with corporate responsibility but also mitigates reputational risks.

Communication and Collaboration

Effective communication and collaboration are the cornerstones of successful partnerships. Evaluate the supplier’s responsiveness, willingness to address concerns, and ability to provide timely updates. Cultivate open channels of communication, fostering a collaborative environment based on trust and transparency.

References and Reputation

Finally, leverage references and assess the supplier’s reputation within the industry. Seek feedback from existing clients, industry associations, and online reviews. A supplier with a track record of reliability, integrity, and customer satisfaction is more likely to deliver consistent results.

In conclusion, In the realm of precision manufacturing, Siddhalaxmi shines as a beacon of excellence, redefining the standards of investment casting suppliers in India and beyond. With a relentless pursuit of quality, innovation, and customer satisfaction, they continue to leave an indelible mark on industries worldwide, one immaculate casting at a time. Trust Siddhalaxmi for your investment casting suppliers in India needs, and unlock the true potential of precision engineering.

To Know More: https://www.siddhalaxmi.com/sourcing-success-tips-for-evaluating-and-selecting-investment-casting-suppliers-in-india/

0 notes

Text

Sustainable Solutions: Examining Pune’s Efforts in Eco-Friendly Casting for Automobile Components

Welcome to the world of precision engineering and automotive innovation, where every part counts towards crafting the perfect driving experience. In the bustling city of Pune, amidst the thriving automotive industry, one name stands out for its commitment to quality, reliability, and excellence – Siddhalaxmi Castings.

In this blog, we delve into the realm of automobile components casting manufacturer in Pune, uncovering the story behind Siddhalaxmi and their journey towards becoming a premier manufacturer in Pune.

Casting a Greener Future

Casting is a fundamental process in automobile components casting manufacturer in Pune,, involving the pouring of molten metal into a mold to create components like engine blocks, transmission cases, and more. Traditionally, this process has been associated with significant environmental impacts, from high energy consumption to emissions of greenhouse gases and hazardous waste disposal. However, Pune’s automotive industry is challenging this narrative through innovative eco-friendly casting techniques.

Embracing Green Technologies

Pune’s automotive sector is embracing a variety of green technologies to minimize its ecological footprint. One notable approach is the utilization of recycled materials in casting processes. By incorporating recycled metals into their alloys, manufacturers reduce the need for raw materials extraction, thereby conserving natural resources and cutting down on energy-intensive mining operations.

Furthermore, advancements in casting technologies are enabling manufacturers to optimize their processes for efficiency and sustainability. Techniques such as precision casting and computer simulation allow for the production of components with minimal material waste, reducing both costs and environmental impact. Additionally, the integration of renewable energy sources, such as solar power, into foundry operations further decreases carbon emissions associated with casting.

Collaborative Initiatives for Change

The journey towards eco-friendly casting in Pune is not one that any single entity can undertake alone. Collaboration between industry stakeholders, research institutions, and governmental bodies is essential for driving meaningful change. Joint efforts focused on research and development are yielding innovative solutions for sustainable casting, while regulatory support is incentivizing the adoption of green practices through policies and incentives.

Environmental Benefits and Economic Viability

The shift towards eco-friendly casting in Pune’s automotive industry brings forth a multitude of benefits, both environmental and economic. By reducing energy consumption, minimizing waste generation, and curbing emissions, these sustainable practices contribute to a healthier environment and a cleaner future for generations to come. Moreover, investing in green technologies enhances the competitiveness of Pune’s automotive sector on the global stage, attracting environmentally conscious consumers and investors alike.

Experience Excellence with Siddhalaxmi

In conclusion, Pune’s efforts in eco-friendly automobile components casting manufacturer in Pune, serve as a shining example of sustainable innovation within the automotive industry. By embracing green technologies, fostering collaborative initiatives, and reaping the environmental and economic rewards, Pune is not just manufacturing automobiles – it’s driving towards a greener, more sustainable future.

In the dynamic world of automobile components casting manufacturer in Pune, Siddhalaxmi stands as a beacon of quality, precision, and innovation. With a rich legacy of craftsmanship and a steadfast commitment to customer satisfaction, Siddhalaxmi is more than a manufacturer – it’s a trusted partner in driving automotive excellence.

Post navigation

To Know More: https://www.siddhalaxmi.com/sustainable-solutions-examining-punes-efforts-in-eco-friendly-casting-for-automobile-components/

0 notes

Text

Environmental Sustainability in Investment Casting: Practices and Initiatives by Pune Companies

In the bustling industrial landscape of Pune, where innovation and entrepreneurship converge, lies a silent yet impactful revolution – the pursuit of environmental sustainability in Investment Casting manufacturers Pune. Investment casting, a process dating back millennia, has seen a modern resurgence, fueled not only by technological advancements but also by a growing consciousness towards environmental responsibility. Today, Pune-based companies are at the forefront of this movement, embracing practices and initiatives that not only enhance their bottom line but also contribute to a greener, more sustainable future.

Understanding Investment Casting:

Before delving into sustainability efforts, it’s crucial to grasp the essence of Investment Casting manufacturers Pune. This precision manufacturing process involves creating metal components through the use of wax patterns. These patterns are coated with ceramic to form molds, into which molten metal is poured, resulting in intricately detailed final products. Investment casting finds applications across industries, from aerospace and automotive to healthcare and consumer goods, owing to its ability to produce complex shapes with excellent surface finishes.

Challenges to Sustainability:

Despite its advantages, investment casting poses environmental challenges. Traditional methods often involve energy-intensive processes, chemical usage, and waste generation, contributing to carbon emissions and environmental degradation. Recognizing these challenges, Pune-based companies have embarked on a journey towards sustainability, driven by a dual commitment to innovation and environmental stewardship.

Initiatives Driving Change:

Adoption of Green Technologies: Pune companies are investing in advanced technologies to reduce energy consumption and emissions. This includes the implementation of energy-efficient furnaces, optimized production processes, and the adoption of renewable energy sources such as solar power.

Material Optimization: By optimizing material usage and recycling scrap metals, companies are minimizing waste generation while conserving resources. Additionally, research and development efforts are focused on the development of eco-friendly alloys with reduced environmental impact.

Water Conservation: Investment casting requires significant water usage for mold preparation and cooling processes. Pune companies are implementing water recycling systems and adopting water-efficient practices to minimize consumption and reduce their ecological footprint.

Lifecycle Assessment: Embracing the principles of lifecycle assessment, companies are evaluating the environmental impact of their products from raw material extraction to end-of-life disposal. This holistic approach enables them to identify areas for improvement and implement sustainable practices throughout the product lifecycle.

Collaborative Partnerships: Pune-based companies are actively collaborating with research institutions, industry associations, and government bodies to drive innovation and share best practices in Environmental sustainability. These partnerships foster knowledge exchange and accelerate the adoption of sustainable technologies and practices across the investment casting industry.

The Road Ahead:

While significant progress has been made, the journey towards environmental sustainability in Investment Casting manufacturers Pune is ongoing. Pune companies continue to explore new avenues for improvement, leveraging emerging technologies such as additive manufacturing and artificial intelligence to further enhance efficiency and reduce environmental impact. Moreover, they remain committed to fostering a culture of sustainability, integrating environmental considerations into their business strategies and operations.

Conclusion:

In the heart of Pune’s industrial landscape, a green revolution is underway. Through innovation, collaboration, and a steadfast commitment to environmental sustainability, Pune-based companies are transforming the Investment Casting manufacturers Pune industry, paving the way for a greener, more sustainable future. In a world where precision matters, Siddhalaxmi Investment Casting manufacturers Pune emerges as the trusted partner for all your casting needs. With a legacy built on craftsmanship, integrity, and innovation, Siddhalaxmi invites you to experience excellence like never before. Discover the difference precision casting can make and embark on a journey of quality, reliability, and unparalleled performance with Siddhalaxmi Investment Casting.

To know more: https://www.siddhalaxmi.com/environmental-sustainability-in-investment-casting-practices-and-initiatives-by-pune-companies/

0 notes

Text

Beyond Beauty: The Functional Applications of Lost Wax Casting in Pune

Welcome to the realm of Siddhalaxmi, where tradition meets innovation in the ancient art of Lost wax casting in Pune, a city steeped in cultural heritage and craftsmanship, Siddhalaxmi stands as a beacon of excellence in the realm of metal casting. Join us as we delve into the intricate process of Lost Wax Casting and discover the mastery behind Siddhalaxmi's creations.

Unveiling the Ancient Art

Lost wax casting in Pune, also known as investment casting, traces its roots back to ancient Mesopotamia and Egypt, where artisans used it to create intricate jewelry, religious artifacts, and sculptures. The process involves creating a wax model, encasing it in a mold, melting away the wax, and pouring molten metal into the cavity to create the final piece.

The Modern Renaissance

In Pune, this age-old technique has experienced a resurgence, blending traditional craftsmanship with contemporary innovation. Artisans and craftsmen have honed their skills to cater to a wide range of industries, from automotive and aerospace to medical and jewelry.

Functional Marvels

Automotive Industry

Lost wax casting in Pune plays a vital role in the automotive sector, where precision and durability are paramount. Pune's foundries produce intricate components like engine parts, gears, and transmission components using this method. The ability to create complex shapes with tight tolerances makes it indispensable in manufacturing critical automotive parts.

Aerospace Applications

In the aerospace industry, where lightweight yet robust components are essential, lost wax casting shines. Pune-based manufacturers supply aerospace giants with turbine blades, compressor components, and structural parts crafted with precision using this ancient method. The ability to produce near-net-shape parts reduces machining and material waste, making it a cost-effective solution for aerospace applications.

Medical Devices

Lost wax casting in Pune is also revolutionizing the medical device industry in Pune. From surgical instruments to implantable components, manufacturers rely on this technique to create intricate and biocompatible parts. The versatility of materials like stainless steel, titanium, and cobalt-chrome allows for the production of medical devices tailored to specific patient needs.

Jewelry and Art

Despite its industrial applications, Lost wax casting in Pune remains deeply rooted in the world of art and jewelry. Pune boasts a thriving community of artisans who craft exquisite jewelry pieces and sculptures using this ancient method. From traditional designs to contemporary creations, each piece tells a story of skill and craftsmanship passed down through generations.

The Future of Lost Wax Casting in Pune

As Pune continues to evolve as a hub of innovation and industry, the role of Lost wax casting in Pune is poised to expand further. With advancements in technology and materials, the possibilities are endless. From intricate prototypes to mass-produced components, this ancient technique continues to push the boundaries of what's possible, bridging the gap between tradition and modernity in the vibrant city of Pune.

Conclusion

In the bustling city of Pune, amidst the clamor of urban life, Siddhalaxmi stands as a testament to the timeless beauty of Lost wax casting in Pune. With a legacy steeped in tradition and a commitment to innovation, Siddhalaxmi continues to redefine the boundaries of craftsmanship, creating masterpieces that captivate the imagination and inspire awe. Join us on a journey of discovery as we celebrate the artistry, heritage, and excellence of Siddhalaxmi in the vibrant tapestry of Pune's cultural landscape.

To know more: https://www.siddhalaxmi.com/beyond-beauty-the-functional-applications-of-lost-wax-casting-in-pune/

0 notes

Text

Quality Assurance in Rapid Prototype Casting: Best Practices from Pune’s Manufacturers

Quality assurance (QA) in Rapid Prototype Casting in Pune is crucial to ensure precision and consistency in the manufactured parts. In Pune, known for its manufacturing prowess, several best practices are adopted by manufacturers to uphold quality standards:

Design Verification: Before casting begins, thorough verification of the design is essential. Utilizing computer-aided design (CAD) software helps in detecting potential flaws or inconsistencies in the design.

Material Selection: Choosing the right materials for rapid prototyping is vital. Pune’s manufacturers often test various materials to ensure they meet the required standards for strength, durability, and other specific properties.

Process Control: Implementing strict control measures during the casting process is key. This includes monitoring parameters such as temperature, pressure, and timing to guarantee the precise replication of each prototype.

Quality Checks at Each Stage: Inspections and quality checks are conducted at every stage of the casting process. This ensures that any defects or deviations from specifications are identified early and rectified promptly.

Training and Skill Development: Skilled labor is fundamental in maintaining quality standards. Manufacturers invest in training their workforce to handle casting equipment proficiently and to recognize and address potential issues.

Documentation and Traceability: Maintaining comprehensive documentation of the entire casting process and materials used allows for traceability. In case of any issues, this documentation helps in identifying the root cause and implementing corrective measures.

Post-Casting Inspection: After the casting process, thorough inspection and testing of the prototypes are conducted using various techniques such as visual inspection, dimensional analysis, and non-destructive testing methods.

Continuous Improvement: Establishing a culture of continuous improvement is crucial. Regular review of QA processes, gathering feedback, and implementing necessary changes ensures ongoing enhancement of quality standards.

Supplier Quality Management: For sourced materials or components, manufacturers in Pune emphasize supplier quality management. Ensuring that the raw materials meet predefined standards is integral to maintaining overall quality.

Compliance with Standards: Adhering to industry standards and regulations is non-negotiable. Pune’s manufacturers prioritize compliance with relevant standards to guarantee the quality and safety of the produced prototypes.

As Siddhalaxmi continues to forge ahead, their vision remains steadfast: to be at the forefront of technological advancement, to redefine manufacturing norms, and to continually deliver excellence.

In the landscape of Rapid Prototype Casting in Pune, Siddhalaxmi stands not just as a company but as a beacon of innovation and reliability. Their journey exemplifies the marriage of tradition with cutting-edge technology, setting a precedent for the industry to follow.

Siddhalaxmi’s commitment to excellence, precision, innovation, and environmental sustainability solidifies its position as a trailblazer in the world of rapid prototype casting, not just in Pune, but on a global scale. As they continue to evolve, one thing is certain where Siddhalaxmi treads, the future follows.

To know more: https://www.siddhalaxmi.com/quality-assurance-in-rapid-prototype-casting-best-practices-from-punes-manufacturers/

0 notes

Text

Cost-Effective Solutions: Understanding the Economic Benefits of Investment Casting in Pune

Investment casting, a centuries-old manufacturing process, has continually proven its worth by providing cost-effective solutions across various industries. In the bustling city of Pune, this technology has emerged as a key driver for businesses seeking efficient production methods. Let’s delve into the economic advantages that investment casting components pune offers, and how it has become a cornerstone for industries in Pune.

Understanding Investment Casting

Investment casting components pune, also known as lost-wax casting, involves the creation of intricate parts by pouring molten metal into a mold created through a wax pattern. This method facilitates the production of complex shapes with high precision, minimizing the need for extensive machining. Its versatility extends to various materials, including stainless steel, aluminum, and titanium.

Cost Efficiency at its Core

Precision Reducing Post-Processing

In Pune’s industrial landscape, precision and reduced post-processing are paramount. Investment casting ensures components are manufactured with exceptional accuracy, significantly decreasing the need for additional machining. This efficiency translates into substantial cost savings by minimizing material waste and labor hours.

Design Flexibility and Material Optimization

One of the hallmarks of investment casting lies in its ability to accommodate intricate designs and produce near-net-shape parts. This aspect enables engineers to create complex components without compromising on strength or functionality. By optimizing material usage and minimizing the requirement for secondary operations, businesses in Pune witness considerable savings in both material costs and production time.

Batch Production Benefits

The batch production capabilities of investment casting components pune further contribute to cost-effectiveness. Pune’s industries leverage this advantage by producing multiple parts simultaneously within a single casting, reducing per-unit costs and enhancing overall productivity.

Industries Benefiting from Investment Casting in Pune

Aerospace and Defense

Pune, known for its robust aerospace and defense sector, reaps significant benefits from investment casting. The production of intricate and high-strength components, such as turbine blades and structural elements, is streamlined through this process, enabling manufacturers to meet stringent industry standards while maintaining cost efficiency.

Automotive

The automotive industry in Pune thrives on innovation and efficiency. investment casting components pune facilitates the creation of lightweight, complex automotive parts that enhance performance while reducing fuel consumption. This aligns perfectly with the industry’s quest for cost-effective, eco-friendly solutions.

Medical and Engineering Applications

The medical and engineering sectors in Pune capitalize on investment casting’s ability to create intricate and biocompatible parts. From surgical tools to orthopedic implants, this technology offers precision and material variety, meeting the stringent requirements of these industries.

Conclusion

Siddhalaxmi’s investment casting components Pune exemplify the pinnacle of precision engineering. Their unwavering commitment to excellence, coupled with a relentless pursuit of innovation and sustainability, sets them apart in the competitive manufacturing landscape. As Pune continues to evolve as a center for technological advancements, Siddhalaxmi stands as a beacon of quality and reliability in the realm of investment casting.

To know more: https://www.siddhalaxmi.com/cost-effective-solutions-understanding-the-economic-benefits-of-investment-casting-in-pune/

0 notes

Text

In the heart of the oil & gas sector

In the heart of the oil & gas sector, our steel alloy castings thrive. Engineered for reliability, durability, and steadfast performance in the toughest conditions. Unearth enduring solutions with us.

To know more: https://www.siddhalaxmi.com/

0 notes

Text

Pune’s Role in Advancing Rapid Prototype Casting Technologies

Siddhalaxmi Rapid Prototype Casting Technologies (SRPCT) stands at the forefront of innovation, revolutionizing the casting industry with its cutting-edge technologies. One of the standout areas of expertise for Siddhalaxmi lies in Rapid Prototype Casting, where they have set new standards and pushed the boundaries of what’s possible in the manufacturing world.

The Rise of Rapid Prototype Casting Technologies:

Rapid Prototype Casting Pune has revolutionized the manufacturing industry by allowing for faster and more cost-effective production of complex components. These technologies enable engineers and designers to create prototypes and small-scale production runs with precision and efficiency, significantly reducing the time and resources traditionally required for casting processes.

Pune’s Role in the Advancement:

Industrial Hub:

Pune has established itself as an industrial hub, attracting a diverse range of manufacturing units, including automotive, aerospace, and engineering industries. By fostering a network of partnerships, SRPCT ensures that its Rapid Prototype Casting Technologies remain on the cutting edge, continuously evolving to meet the ever-changing demands of modern manufacturing.

Research and Development Centers:

The city is home to numerous research and development centers, collaborating with both academic institutions and industries to push the boundaries of innovation. These centers focus on developing advanced materials, refining casting processes, and integrating the latest technologies to enhance the overall efficiency of rapid prototype casting.

Educational Institutions:

Pune’s renowned educational institutions, such as the Pune Institute of Computer Technology and College of Engineering Pune, play a pivotal role in nurturing talent and fostering a culture of innovation. The synergy between academia and industry has led to the incubation of groundbreaking ideas and solutions in rapid prototype casting.

Collaborative Initiatives:

Collaborative initiatives between industry players, research institutions, and government bodies have further accelerated the progress of rapid prototype casting technologies in Pune. Siddhalaxmi recognizes the importance of material selection in the casting process. Their commitment to material innovation ensures that prototypes not only meet design specifications but also exhibit the desired mechanical properties.

Case Studies:

Bharat Forge:

Bharat Forge, headquartered in Pune, is a global leader in metal forming and forging technologies. The company has invested significantly in research and development to incorporate rapid prototype casting technologies into its manufacturing processes, leading to enhanced product development cycles and increased competitiveness in the global market.

Tata Technologies:

Tata Technologies, with a significant presence in Pune, has been at the forefront of adopting advanced casting technologies. The company’s commitment to innovation is reflected in its state-of-the-art facilities in Pune, where rapid prototype casting plays a crucial role in product development and validation.

Future Prospects:

As Pune continues to be a beacon of innovation in rapid prototype casting technologies, the future looks promising. With ongoing advancements in materials science, automation, and digital technologies, the city is poised to play a pivotal role in shaping the future of manufacturing on a global scale.

Looking to the Future:

As Siddhalaxmi continues to push the boundaries of innovation in Rapid Prototype Casting Pune, the future looks promising for businesses seeking efficient and cost-effective solutions for product development. The company’s commitment to excellence, coupled with its state-of-the-art facilities in Pune, positions Siddhalaxmi as a leader in the rapidly evolving landscape of manufacturing.

In conclusion, Siddhalaxmi’s contributions to the world of rapid prototype casting in Pune signify a paradigm shift in how prototypes are conceptualized and brought to life. By embracing cutting-edge technology and fostering a culture of innovation, Siddhalaxmi stands as a beacon of progress, showcasing the limitless possibilities that rapid prototype casting brings to the manufacturing industry.

To know more: https://www.siddhalaxmi.com/punes-role-in-advancing-rapid-prototype-casting-technologies/

0 notes

Text

Investment Casting Innovations: Pune's Role in Elevating Exports to New Heights

In the dynamic world of manufacturing and precision engineering, investment casting plays a pivotal role in creating intricate and high-quality metal components. Pune, known for its industrial prowess, hosts several companies that excel in investment casting. Among these, Siddhalaxmi emerges as a standout performer, showcasing excellence in the field and earning a reputation as a reliable partner for Best Investment Casting Pune.

The Resurgence of Investment Casting:

Investment casting, also known as lost-wax casting, dates back thousands of years. It involves creating precise and complex metal components by pouring molten metal into molds created from wax patterns. While the method itself is age-old, recent innovations in materials, processes, and automation have revolutionized the Best Investment Casting Pune industry.

Pune's Technological Leap:

Pune, home to a plethora of engineering and manufacturing units, has played a pivotal role in pushing the boundaries of investment casting. Advanced techniques such as 3D printing for creating intricate wax patterns, computer simulations for optimized mold designs, and robotic automation for precision casting have become commonplace in Pune's foundries.

Leading the charge are several research and development centers, collaborating with industry giants to implement state-of-the-art technologies. These innovations not only enhance the efficiency of the investment casting process but also contribute to the production of high-quality components that meet global standards.

Export Boom:

The technological prowess of Best Investment Casting Pune sector has not gone unnoticed on the international stage. With a focus on producing components for aerospace, automotive, and energy sectors, Pune-based manufacturers are making significant inroads into global markets. The city's investment casting exports have witnessed an unprecedented surge, creating a ripple effect on the overall economy.

International clients are increasingly turning to Pune for their precision casting needs, drawn by the city's reputation for innovation, reliability, and cost-effectiveness. The growing demand for lightweight components in aerospace and automotive industries further fuels the export boom, with Pune-based foundries well-positioned to capitalize on these opportunities.

Collaboration and Knowledge Exchange:

Pune's success in elevating Best Investment Casting is not solely attributed to technological advancements. The city has also fostered a culture of collaboration and knowledge exchange among academia, research institutions, and industry players. Regular conferences, workshops, and training programs ensure that the workforce is up-to-date with the latest developments in the field, further enhancing the industry's competitive edge.

Sustainable Practices:

In addition to technological advancements, Best Investment Casting Pune sector is also embracing sustainable practices. Efforts are underway to reduce waste, optimize energy consumption, and explore eco-friendly materials. This commitment to sustainability not only aligns with global trends but also positions Pune as a responsible and forward-thinking player in the investment casting arena.

In the realm of investment casting in Pune, Siddhalaxmi stands tall as a beacon of excellence. With its state-of-the-art facilities, skilled workforce, commitment to quality, and global reach, Siddhalaxmi continues to set new standards in the industry. As the company paves the way for investment casting exports from Pune, it not only strengthens its own position but also contributes to the city's reputation as a hub for precision engineering and manufacturing.

To know more: https://www.siddhalaxmi.com/investment-casting-innovations-punes-role-in-elevating-exports-to-new-heights/

0 notes

Text

Stainless Steel Casting Alloys - Siddhalaxmi

A ferrous alloy called stainless steel contains chromium, which acts as a barrier against rust and discoloration. In liquid conditions, it operates effectively, and at high temperatures, it offers heat resistance. There are several varieties of stainless steel, and each one has a unique chemical make-up. Mechanical properties are influenced by composition, which also determines whether heat treatment can be used to further strengthen the material.

High Quality Investment Castings Using Stainless Steel Alloys

For investment casting, we pour a variety of stainless steel alloys, such as the 300 series, 400 series, and precipitation hardening alloys. All AMS, MIL, Federal, and ASTM criteria will be met by the stainless steel grades we offer.

Close tolerances and complicated casting projects for the automotive, aerospace, defence, and other industries are our specialties. We carry out all of our investment casting manufacturing internally. Stainless steel, carbon steel, tool steels, aluminium alloys, and other air melt alloys can be poured using special lines at our foundry for both ferrous and non-ferrous materials.

We offer secondary and support services, such as heat treatment, CAD modelling, and non-destructive testing, in addition to stainless steel investment casting. To find out more about our precision investment casting services, get in touch with our staff.

300 Series Stainless Steel Casting Alloys

Chromium-nickel alloy 300 series stainless steel is nonmagnetic. Although heat treatment cannot increase the strength of these stainless steel casting alloys, they are renowned for their outstanding resistance to corrosion. Additionally resistant to corrosion brought on by welding and other high-temperature finishing procedures are the alloys 304-L and 316-L. 300 series alloys are often used to investment cast pipelines and housings for industries including medical, maritime, and food and dairy. We offer a variety of casting alloys for 300 series stainless steel, such as: 302, 303, 304, 304-L, 310, 312, 316, 316-L, 319, 330, 347, BS-3146.

400 Series Stainless Steel Casting Alloys

A chromium-magnesium alloy with good strength and machinability is martensitic 400 series stainless steel. This kind of stainless steel is magnetic and may be quenched and tempered to harden it and provide high strength. The 400 series is often used for investment casting valves and machine parts for the automotive and agricultural industries. These alloys are available from us:

410, 416, 418, 420C, 430, 436, 440A, 440C

Contact Us to Discuss Your Stainless Steel Investment Casting Project

We cast both ferrous and non-ferrous alloys and offer a range of house services to complete your investment casting project. To discuss your needs for precision investment casting or to obtain a stainless steel casting quote, get in touch with us right now.

To know more: https://www.siddhalaxmi.com/alloys-ss-casting-in-pune/

0 notes

Text

Pune's Stainless Steel Casting Industry: Paving the Way for Sustainable Manufacturing

Pune, the cultural and industrial hub of Maharashtra, has emerged as a key player in the stainless steel casting industry. This ancient city, with its rich history, has seamlessly blended tradition with modernity, making strides in various sectors, including manufacturing. In recent years, the SS Casting in Pune has garnered attention for its commitment to sustainable manufacturing practices, paving the way for a greener and more eco-friendly future.

A Glimpse into Pune's Manufacturing Heritage:

Pune has a longstanding tradition in manufacturing, dating back to its historical significance as a prominent center for trade and commerce. Today, it stands tall as a hub for various industries, with stainless steel casting playing a pivotal role in its economic landscape.

The Rise of Stainless Steel Casting in Pune:

Stainless steel casting involves the intricate process of creating complex and durable components using molten stainless steel. SS Casting in Pune industry has seen a significant uptick in demand due to the material's corrosion resistance, strength, and versatility. This surge in popularity has led to the establishment of numerous casting units across the city.

Sustainable Practices in Pune's Stainless Steel Casting:

One of the key highlights of SS Casting in Pune industry is its commitment to sustainable manufacturing practices. Manufacturers in Pune have embraced eco-friendly processes, reducing waste and energy consumption. From the use of recycled materials to the implementation of energy-efficient technologies, Pune's stainless steel casting units are making conscious efforts to minimize their environmental impact.

Technological Advancements Driving Sustainability:

The adoption of cutting-edge technologies has played a crucial role in making SS Casting in Pune more sustainable. Advanced manufacturing techniques, such as 3D printing and precision casting, not only enhance efficiency but also contribute to resource conservation. These innovations not only improve the quality of the final products but also align with global sustainability goals.

Paving the Way for a Green Future:

Pune's stainless steel casting industry is not just meeting the demands of the present; it is actively shaping a sustainable future. By embracing environmentally friendly practices and incorporating modern technologies, the industry is setting a precedent for other manufacturing sectors to follow suit. The focus on sustainability ensures that SS Casting in Pune remains a responsible contributor to the city's economic growth.

In the world of stainless steel casting, Siddhalaxmi SS Casting in Pune stands out as a beacon of quality, innovation, and reliability. With a legacy built on excellence, state-of-the-art facilities, and a commitment to sustainability, Siddhalaxmi continues to shape the future of the industry, one precision cast at a time. For those seeking top-tier stainless steel casting solutions, Siddhalaxmi is the name that signifies trust and performance.

To know more: https://www.siddhalaxmi.com/punes-stainless-steel-casting-industry-paving-the-way-for-sustainable-manufacturing/

0 notes

Text

Investment Casting and the Automotive Industry: Pune's Crucial Role in Advancements

Investment casting, a precision manufacturing process, plays a crucial role in creating intricate and high-quality metal components for various industries. Among the leading players in this domain, Best Investment Casting in Pune stands tall, offering unparalleled expertise and cutting-edge solutions in investment casting.

The Magic of Investment Casting in Automotive Applications

In the fast-paced world of automotive manufacturing, where components need to withstand extreme conditions and stringent quality standards, investment casting shines. This process allows engineers to create intricate designs, reducing the need for secondary machining and minimizing material waste. From turbocharger blades to engine components and even delicate parts within transmissions, investment casting has proven its mettle in crafting high-performance, reliable automotive parts.

Pune's Crucial Role in Advancing Investment Casting

Pune, often referred to as the "Detroit of India," has played a pivotal role in advancing investment casting in the automotive sector. The city's robust industrial ecosystem, skilled workforce, and collaborative spirit have fostered an environment conducive to technological advancements. Numerous foundries and manufacturing units in Pune have embraced cutting-edge investment casting technologies, pushing the boundaries of what's possible in terms of precision and efficiency.

Technological Innovations in Pune: A Glimpse into the Future

Pune's contribution to the evolution of Best Investment Casting Pune in the automotive industry extends beyond conventional methods. The city's research and development hubs are actively exploring additive manufacturing and 3D printing techniques to enhance the investment casting process. These innovations not only accelerate production timelines but also open doors to design possibilities previously considered unattainable.

Collaboration and Knowledge Exchange

One of Pune's greatest strengths lies in its collaborative culture. Industry leaders, research institutions, and educational establishments often join forces to share knowledge and expertise. This collaborative spirit has propelled the automotive sector in Pune to new heights, with investment casting standing out as a prime example of what can be achieved through shared insights and technological collaboration.

In conclusion, Siddhalaxmi's commitment to advanced facilities, engineering expertise, research and development, quality control, customized solutions, and global outreach makes them a pioneer in Best Investment Casting Pune technology. As industries continue to evolve, Siddhalaxmi remains at the forefront, driving innovation and setting new benchmarks in the world of investment casting.

To know more: https://www.siddhalaxmi.com/investment-casting-and-the-automotive-industry-punes-crucial-role-in-advancements/

0 notes

Text

Innovations and Advancements in Investment Casting Technology: Impact on Maharashtra’s Manufacturing Sector

In the heartland of India’s industrial prowess, Maharashtra stands as a beacon of innovation and manufacturing excellence. Among the numerous industries propelling its growth, Investment Casting Maharashtra technology has emerged as a transformative force, reshaping the state’s manufacturing landscape. Let’s delve into the advancements and the profound impact these innovations have had on Maharashtra’s industrial sector.

Evolution of Investment Casting

Investment casting in Maharashtra, also known as lost-wax casting, has been an integral part of manufacturing for centuries. This process involves creating intricate metal parts by pouring molten metal into a precision-designed mold, which is made by investing a wax pattern into a refractory material. Over time, this technique has undergone significant technological advancements, leading to enhanced precision, efficiency, and versatility.

Technological Breakthroughs

3D Printing Integration:

One of the most revolutionary advancements is the integration of 3D printing in investment casting. This merger has streamlined the creation of intricate molds, enabling manufacturers to produce highly complex components with unmatched precision. Maharashtra’s tech hubs have been at the forefront of adopting and refining these additive manufacturing techniques, reducing lead times and costs significantly.

Materials Innovation:

Innovation in materials used for investment casting has expanded the range of applications. High-performance alloys, superalloys, and exotic materials are now accessible, catering to diverse industry requirements in aerospace, automotive, healthcare, and beyond. This versatility has sparked a surge in demand from Maharashtra’s industrial sectors, enhancing their capabilities and competitiveness on a global scale.

Automation and AI:

Automation and AI-driven technologies have optimized the manufacturing process, increasing efficiency and minimizing errors. Robotics and AI-driven quality control systems have been implemented across various stages, from mold creation to post-casting inspection, ensuring higher precision and consistency in the final product.

Impact on Maharashtra’s Manufacturing

Economic Growth

The adoption of advanced investment casting technologies has propelled Maharashtra’s manufacturing sector, attracting investments and fostering economic growth. Small and medium-sized enterprises (SMEs) have leveraged these innovations to compete on a global level, contributing significantly to the state’s GDP.

Employment Opportunities

The technological evolution has not only improved productivity but also created new employment opportunities. Skilled workers proficient in handling advanced machinery and software are in high demand, thus bolstering Maharashtra’s workforce and fostering a culture of continuous learning and upskilling.

Sustainable Practices

Modern investment casting in Maharashtra techniques emphasize sustainability by minimizing material wastage and energy consumption. The shift towards eco-friendly practices aligns with Maharashtra’s commitment to environmental conservation, positioning the state as a hub for sustainable manufacturing practices.

Future Prospects

As technology continues to evolve, the future of investment casting in Maharashtra appears promising. Continued research and development efforts are expected to drive further innovations, pushing the boundaries of what’s achievable in terms of precision, material diversity, and production efficiency.

Conclusion

In conclusion, Siddhalaxmi Investment Casting Maharashtra epitomizes the union of artistry and precision, embodying the rich heritage of Maharashtra while embracing the future of industrial excellence. Through its commitment to quality, innovation, and community, Siddhalaxmi remains a beacon of inspiration in the realm of investment casting.

So, here’s to Siddhalaxmi’s unwavering dedication to craftsmanship, shaping a future where innovation meets tradition in Maharashtra’s vibrant industrial landscape.

To know more: https://www.siddhalaxmi.com/innovations-and-advancements-in-investment-casting-technology-impact-on-maharashtras-manufacturing-sector/

0 notes