#3 cylinder engines advantages

Text

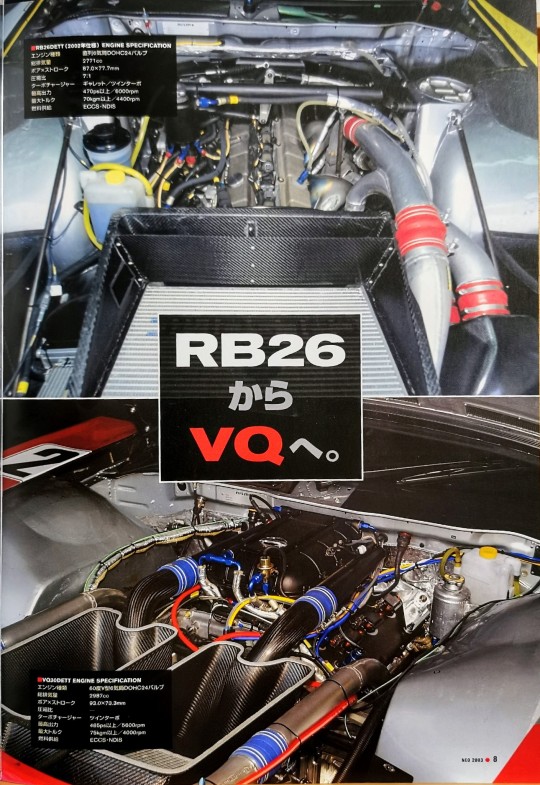

Speaking of the Skyline GT-R, it was a straight 6 engine. The first-generation GT-R, which debuted in 1969, was also a straight-six engine, and its predecessor, the 1964 GTB, had a 1500 with an extended engine room and a straight-six engine. The R32 GT-R, which returned to the circuit in 1990 and went on a winning streak, was naturally equipped with a straight-six engine. However, in May 2002, a GT-R that appeared in the All Japan GT Championship SUGO was equipped with a new "V6 engine." All GT-R models were changed to V6.

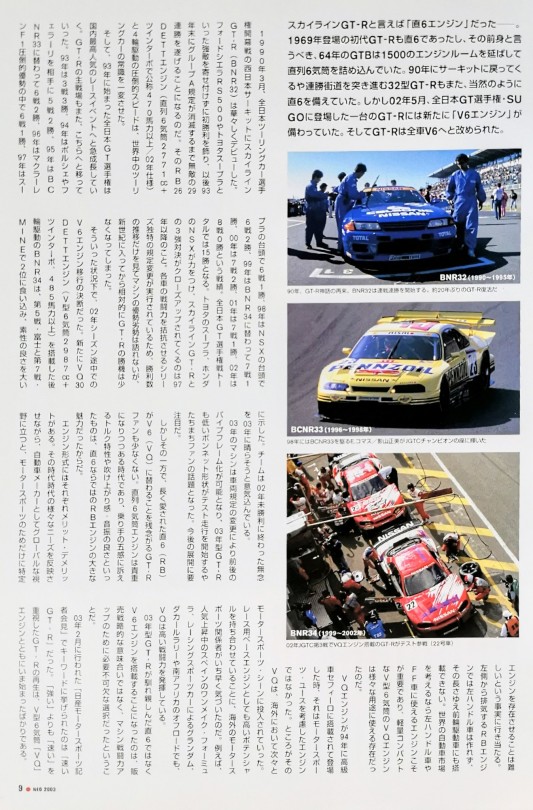

In March 1990, the Skyline GT-R (BNR32) made its spectacular debut at the West Japan Circuit at the opening round of the All Japan Touring Car Championship. He achieved his first victory by holding off strong opponents such as the Ford Sierra RS500 and Toyota Supra, and since then has won 30 races.

They would be on an unbeatable 20 race winning streak until the Group A regulations expire at the end of the year. The overwhelming speed of its RB26DETT engine (inline 6-cylinder 2771cc+ twin turbo with nominally over 470 horsepower/02 specification) and four-wheel drive completely changed the conventional wisdom of touring cars around the world.

The All Japan GT Championship, which started in 1993, rapidly grew to become the most popular racing event in Japan. The main battlefield for the GT-R has also shifted here. In 1993, it won 3 out of 3 races, in 1994 it won 2 out of 5 races against Porsche and Ferrari, in 1995 it was replaced with the BCNR33 and won 2 out of 6 races, and in 1996 it won 1 out of 6 races during the overwhelming dominance of McLaren F1. In 1997 1 win in 6 races with the rise of Supra, 2 wins in 7 races in 1998 with the rise of NSX, 1 win in 7 races in 1999 after replacing with BNR34. 2 wins in 7 races in 2000, 1 win in 7 races in 2001, and 0 wins in 8 races in 2002. This is a total of 15 wins in the All Japan GT Championship. It wasn't until 1999 that Toyota's Supra and Honda's NSX gained strength, and a close-up competition between them and the Skyline GT/R began. Due to changes in the regulations unique to the series that equalize the combat power of each car, it is impossible to say whether the machines are superior or inferior just by looking at the trends in the number of wins, but since the beginning of the new century, the GT-R has been relatively competitive. The chances of winning have diminished.

Under these circumstances, the decision was made to switch to a V6 engine midway through the 2002 season. The rear-wheel drive BNR34, equipped with the new VQ30DETT engine (V6 cylinder 2987cc+ twin turbo, over 485 horsepower), showed off its good origins by finishing in 2nd place at the 5th race at Fuji and at the 7th race at MINE. The team is disappointed that it ended 2002 without a win.

The team is determined to make amends for the lack of a win in 2002 in 2003.

The 2003 machine has changed before and after due to changes in vehicle regulations.

It became possible to use a vibrator frame, and the low hood shape of the 2003 GT-R became a hot topic among fans as soon as test runs began. We need to pay attention to future developments.

However, on the other hand, there are many GT-R fans who are disappointed that the long-loved straight-six (RB) will be replaced by the V6 (VQ). This was an era when in-line six-cylinder engines were becoming more valuable, and the RB engine's great appeal was its torque characteristics that appealed to the rider's five senses, as well as its good engine speed and vibration.

Each engine type has advantages and disadvantages. While reflecting the various needs of each era, from a global perspective as an automobile manufacturer, we created products specifically designed for motorsports.

We come to the fact that it is difficult to make an engine exhaust. An RB engine that exhausts from the left side cannot be used in left-hand drive cars, and because of its length, it cannot be installed in front-wheel drive cars either. When considering the global automobile market, it is important to have an engine that can be used in left-hand drive and front-wheel drive cars, and the lightweight and compact V-type 6-cylinder VQ engine can be used for a variety of purposes.

It was.

VQ engine became a luxury in 1999

When it was first introduced in the Cefiro car, it was not an engine designed for motorsports use. However, the VQ was introduced into the motorsports scene one after another overseas. Overseas motorsports officials were quick to realize that it had high potential as a base engine for racing. For example, Spain's one-make formula, which is becoming increasingly popular, Grand Am racing sports cars, the Dakar Rally, and off-road racing in South Africa.

VQ is demonstrating high combat power.

The decision to equip the 2003 model GT-R with a V6 engine instead of the familiar straight-six was not a sales strategy, but an essential choice to improve the machine's competitiveness. I'm saying that.

At the ``Nissan Motorsports Press Conference'' held in February 2003 the keyword mentioned was ``fast GT-R.'' The revitalization of the GT-R, which emphasizes ``fast'' rather than ``strong,'' has just begun with the V-6 VQ engine.

PIC CAPTIONS

BNR32 (1990~1995)

In 1990, the GT-R myth returns. BNR32 begins a winning streak. The GT-R is back for the first time in about 20 years.

BCNR33 (1996~1998)

In 1998, E. Comas/Masami Kageyama, riding BCNR33, won the JGTC championship.

BNR34(1999~2002)

GT-R equipped with VQ engine participates in test race at JGTC Round 3 in 2002 (car No. 22)

11 notes

·

View notes

Photo

4Stroke Rumen

Anyway, Roumen Antonov claims to have successfully completed the certification tests for his Rumen. Ranked in the "small series" category (less than 500 copies), the Rumen did not have recourse to a destructive crash test. On the other hand, pollution tests are an obligation. They were passed with flying colors thanks to the original PSA/Toyota powertrain. The Rumen has the 3 "legs" with 4 valves per cylinder developing 68 hp at 6000 rpm and 93 Nm of torque at 3600 rpm. He is in the rear central position and the car becomes a propulsion. This engine is equipped with a VVT variable valve timing which contributes to the very good performance of the engine. Its consumption of 4.6 l/100 km recorded on the Citroën C1 weighing around 800 kg will be significantly improved on the Rumen which will not exceed 600 kg on the scale. The running gear derives closely from the Peugeot 107 with a few adaptations, in particular the design of the rear axle taken from the brain of Roumen Antonov. Like everything else!

Surprisingly, the front track much wider than the rear accentuates the curiosity of passers-by inevitably attracted by the Rumen.The advantage of a large series mechanics is to be able to have all the electronic fittings that go with it. Thus the Rumen offers ABS (for the record, R.Antonov mocks knowing that a Spyker of more than 200,000 euros is not equipped with it!) But also the electronic brake force distribution EBS. Anyway, with 4 disc brakes and only 600 kg, the car will never be faulted in this area. As on the trio of original Franco-Japanese city cars, the 5-speed manual gearbox will be available.

The beige leather interior, embellished with chrome, aluminum and wood is a model of visual warmth. The large “old era” wooden steering wheel makes you unconsciously hold it at 8:20. It's automotive imagery from the 1930s to 1950s stuck in a corner of your cortex that suddenly resurfaces. The interior space equivalent to that of an Audi A3 does not yet have the exemplary finish of a production model, but nothing is really open to criticism. You will just be criticized for ergonomics to be refined to prevent the right knee from bumping into the gear lever in curves on the left and black stalks which denote a little in this warm universe.

The body made of polyester inserted in a tubular frame does not yet meet the final specifications and the soundproofing has not yet been the subject of a study. The small 3-cylinder rests in a box covered in red leather behind the seats. Not enough for it to be forgotten or appreciated. Either it will be necessary to work on the sound to "ennoble it", or it will have to be completely soundproofed.

Even if an option can increase the power to almost 110 hp thanks to a compressor, the Rumen should not be considered as a sports car but as a Grand Touring in miniature. The suspension settings adopted are very flexible and offer quite surprising comfort on the rutted portions. The reduced weight of the machine also prevents it from "lying down" in curves, which in the end is not far from being the perfect compromise.

48 notes

·

View notes

Text

Started this doodle a little over a month back when I was trying to get things "out", left it nearly finished (for what that's worth at my skill level) and decided to just finish the lovely guy today.

I sketched out a couple poses before settling as I found it incredibly difficult to present what I had envisioned. By the end I settled on this snoozin' on his side approach.

Molten Tigrex is undeniably one of my favorite monsters in all of monhun.

So it turned out when I was feeling at my worst and wanted to get thoughts- any thoughts at all- out, after a few pieces I decided to just put out something I enjoy. Something positive, to me.

Considering how simple he can appear on paper, when you were "there" progressing through a new monhun and tackling him he felt like an incredible achievement of what monhun's systems could do to make a fun fight.

Namely, I think of Molten Tigrex whenever I think of how much older monhuns created "organic phases" to each fight.

For a lot of players who primarily experienced Monhun through Iceborne the idea of "phases" in monhun has a very different connotation.

Now-a-days it's natural to think of phases in monhun the same way you'd think of them in an RPG encounter or an MMO fight, namely, because that's what they often are now.

In older monhun phases weren't so often pre-defined, and instead phases were born from the integrated energy and aggression mechanics that each monster was made to follow.

These are mechanics that have not died off, and the terms within will sound extremely familiar because of that. Enrage. Exhaustion. Un-enraged.

Very simple ideas, so simple that in (as of typing) modern monhuns (Ice/Sun) it's easy to ignore these states almost entirely, only ever paying attention if a specific monster has a specific gimmick in a state (like Rajang's differing immunities to traps depending on state).

This is in part because modern monhun is undeniably faster, so why slow down to appreciate these details when all it means is "dodge faster sometimes"? With the added mobility of our hunters, and not just with our legs but our newfound ability to easily use items or sharpen without 30 miles of safe space around you, you don't NEED to focus on such things as much.

But it's also because modern monhuns have incorporated a few mechanics that have nearly deleted these states from the game, primarily Iceborne's clutch claw introducing a means to perma-enrage monsters, thus deleting 2 out of the 3 states you'd ever see that monster in.

In the older games these things were slightly more important- though I won't go lying saying they were something you were 100% dialed into 24/7, just that it wasn't uncommon for you to take a mental note if they were enraged, standard, or exhausted before you used an item- for your own safety.

This created a natural phasing to fights where you could "generally feel" if the monster was enraged or exhausted even if you weren't dialed in, unlike later titles where you just know they are enraged and you're swinging constantly anyway so who cares lol

Molten REALLY took advantage of this by making you really feel his different states.

When the fight begins he is cumbersome, slow, borderline asleep and just nipping at whatever is irritating him.

And when he's enraged he's a full power steam engine firing on all cylinders as he explodes into your personal space the second you lower your guard.

I always really liked how he took a built in "vibe" that monster hunter had developed over many years and cranked it to 11. Instead of having a gut notion of what state the monster was in just due to what actions you were naturally taking- you were FULLY AWARE of what state this mad fucker was in and I loved that.

Great monster.

Good to ramble about that for a bit.

9 notes

·

View notes

Text

The Definition of Acceleration

Read this thru slowly and try to comprehend the amount of force produced in just under 4 seconds! There are no rockets or airplanes built by any government in the world that can accelerate from a standing start as fast as a Top Fuel Dragster or Funny Car!

DEFINITION OF ACCELERATION

One top fuel dragster 500 cubic-inch Hemi engine makes more horsepower than the first 4 rows of stock cars at the Daytona 500.

It takes just 15/100ths of a second for all 6,000+ horsepower of an NHRA Top Fuel dragster engine to reach the rear wheels.

Under full throttle, a dragster engine consumes 1-1/2 gallons of nitro methane per second; a fully-loaded 747 consumes jet fuel at the same rate with 25% less energy being produced.

A stock, Dodge Hemi, V8 engine cannot produce enough power to drive the dragster's supercharger.

With 3,000 CFM of air being rammed in by the supercharger on overdrive, the fuel mixture is compressed into a near-solid form before ignition.

Cylinders run on the verge of hydraulic lock at full throttle.

At the stoichiometric (stoichiometry: methodology and technology by which quantities of reactants and products in chemical reactions are determined) 1.7:1 air/fuel mixture of nitro methane, the flame front temperature measures 7,050 deg. F.

Nitro methane burns yellow... The spectacular white flame seen above the stacks at night is raw burning hydrogen, dissociated from atmospheric water vapor by the searing exhaust gases.

Dual magnetos supply 44 amps to each spark plug. This is the output of an arc welder in each cylinder.

Spark plug electrodes are totally consumed during a pass. After halfway, the engine is dieseling from compression, plus the glow of exhaust valves at 1,400 deg F. The engine can only be shut down by cutting the fuel flow.

If spark momentarily fails early in the run, unburned nitro builds up in the affected cylinders and then explodes with sufficient force to blow cylinder heads off the block in pieces or split the block in half.

In order to exceed 300 mph in 4.5 seconds, dragsters must accelerate an average of over 4G's. In order to reach 200 mph (well before half-track), the launch acceleration approaches 8G's.

Dragsters reach over 300 miles per hour before you have completed reading this sentence.

Top fuel engines turn approximately 540 revolutions from light to light! Including the burnout, the engine must only survive 900 revolutions under load.

The redline is actually quite high at 9,500 rpm.

Assuming all the equipment is paid for, the crew worked for free, and for once NOTHING BLOWS UP, each run costs an estimate $1,000.00 per second.

The current top fuel dragster elapsed time record is 4.428 seconds for the quarter mile (11/12/06, Tony Schumacher, at Pomona, CA). The top speed record is 336.15 mph as measured over the last 66' of the run

Putting all of this into perspective:

You are driving the average $140,000 Lingenfelter, 'twin-turbo' powered, Corvette Z06. Over a mile up the road, a top fuel dragster is staged and ready to launch down a quarter mile strip as you pass. You have the advantage of a flying start. You run the 'Vette hard up through the gears and blast across the starting line and pass the dragster at an honest 200 mph. The 'tree' goes green for both of you at that moment.

The dragster launches and starts after you. You keep your foot down hard, but you hear an incredibly brutal whine that sears your eardrums and within 3 seconds, the dragster catches and passes you. He beats you to the finish line, a quarter mile away from where you just passed him.

Think about it, from a standing start, the dragster had spotted you 200 mph and not only caught, but nearly blasted you off the road when he passed you within a mere 1,320 foot long race course.

...... and that my friend, is ACCELERATION!

22 notes

·

View notes

Text

What 10,000 horsepower does to a top fuel tire at launch.

TOP FUEL ACCELERATION PUT INTO PERSPECTIVE

* One Top Fuel dragster 500 cubic-inch Hemi engine makes more horsepower (10,000 HP) than the first 5 rows at the Daytona 500.

* Under full throttle, a dragster engine consumes 1.2-1.5 gallons of nitro methane per second; a fully loaded 747 consumes jet fuel at the same rate with 25% less energy being produced.

* A stock Dodge Hemi V8 engine cannot produce enough power to merely drive the dragster's supercharger.

* With 3000 CFM of air being rammed in by the supercharger on overdrive, the fuel mixture is compressed into a near-solid form before ignition. Cylinders run on the verge of hydraulic lock at full throttle.

* At the stoichiometric 1.7:1 air/fuel mixture for nitro methane the flame front temperature measures 7050 degrees F.

* Nitromethane burns yellow. The spectacular white flame seen above the stacks at night is raw burning hydrogen, dissociated from atmospheric water vapor by the searing exhaust gases.

* Dual magnetos supply 44 amps to each spark plug.

This is the output of an arc welder in each cylinder.

* Spark plug electrodes are totally consumed during a pass. After 1/2 way, the engine is dieseling from compression plus the glow of exhaust valves at 1400 degrees F. The engine can only be shut down by cutting the fuel flow.

* If spark momentarily fails early in the run, unburned nitro builds up in the affected cylinders and then explodes with sufficient force to blow cylinder heads off the block in pieces or split the block in half.

* Dragsters reach over 300 MPH before you have completed reading this sentence.

* In order to exceed 300 MPH in 4.5 seconds, dragsters must accelerate an average of over 4 G's. In order to reach 200 MPH well before half-track, the launch acce leration approaches 8 G's.

* Top Fuel engines turn approximately 540 revolutions from light to light!

* Including the burnout, the engine must only survive 900 revolutions under load.

* The redline is actually quite high at 9500 RPM.

* THE BOTTOM LINE: Assuming all the equipment is paid off, the crew worked for free, & for once, NOTHING BLOWS UP, each run costs an estimated $1,000 per second.

0 to 100 MPH in .8 seconds (the first 60 feet of the run)

0 to 200 MPH in 2.2 seconds (the first 350 feet of the run)

6 g-forces at the starting line (nothing accelerates faster on land)

6 negative g-forces upon deployment of twin ‘chutes at 300 MPH An NHRA Top Fuel Dragster accelerates quicker than any other land vehicle on earth . . quicker than a jet fighter plane . . . quicker than the space shuttle.

The current Top Fuel dragster elapsed time record is 4.420 seconds for the quarter-mile (2004, Doug Kalitta). The top speed record is 337.58 MPH as measured over the last 66' of the run (2005, Tony Schumacher).

Putting this all into perspective:

You are driving the average $140,000 Lingenfelter twin-turbo powered Corvette Z06. Over a mile up the road, a Top Fuel dragster is staged & ready to launch down a quarter-mile strip as you pass. You have the advantage of a flying start. You run the 'Vette hard up through the gears and blast across the starting line & pass the dragster at an honest 200 MPH. The 'tree' goes green for both of you at that moment.

The dragster launches & starts after you. You keep your foot down hard, but you hear an incredibly brutal whine that sears your eardrums & within 3 seconds the dragster catches & passes you.

He beats you to the finish line, a quarter-mile away from where you just passed him. Think about it - from a standing start, the dragster had spotted you 200 MPH & not only caught, but nearly blasted you off the road when he passed you within a mere 1320 foot long race!

That's acceleration!

5 notes

·

View notes

Text

Application of 3+2 CNC Machining in Mold Making Factory

Plastic injection mold manufacturers have long embraced simultaneous multiple-axis machining on machine tools with five or more axes, but more and more China injection mold makers have begun machining mold components on multiaxis platforms in the past few years, said Charlie Chan, engineering manager HS Mold & Die Co.,LTD

He mentioned, however, that the common approach for machining mold parts in houses is 3+2, or 5-axis positional machining. According to his estimate, about 80% to875% of the multi-axis work is performed via 3+2 rather than simultaneous when cutting up to five sides of a prismatic metal workpiece in one fixturing.

What is 3+2 CNC Machining

3+2 (5 axis) CNC machining, also called “positional five-axis machining”, is a technique whereby a three-axis milling program is executed with the cutting tool locked in a tilted position using the 5-axis machine’s two rotational axes, hence the name, 3+2 machining. During the machining process, the fourth and fifth axes are used to rotate the cutting tool in a fixed position rather than to manipulate the tool continuously. On a standard three-axis machine, the only part face that the CNC machine could cut with a cutting tool in its normal position is the horizontal face that faces directly at the spindle.

3+2 CNC Machining Advantages

Compared to conventional three-axis machining, the main advantage of 3+2 CNC machining is the reduction of setup time. According to data from our mold making shop, we could save easily 20% to 25% in setup time because we don’t have to handle that part multiple times.”

Another big benefit of 3+2 CNC Machining is that it allows for the use of a shorter, more rigid cutting tool. With 3+2 machining, the spindle head can be lowered closer to the work piece with the tool angled toward the part surface. This means that a good surface finish and more accurate dimensional results can be achieved .This helps to improve part accuracy by being able to position a work piece so that short, rigid cutting tools are applied, such as when producing undercuts in mold cavities and steep wall inserts in addition, with 3+2 machining, we can use standard, off-the-shelf tools

Rather than using some custom, extra-long tool or holder and risk vibration, this helps to save money easily by 10% to 15% in injection mold costs because there is no need to use special tools for mold manufacturers in china, 3+2 Machining is an ideal option because they can use more off-the-shelf, standard catalog tooling. They have the freedom to reach into my part at different angles without using an especially long tool or special to make that feature on that part.

Application of 3+2 CNC Machining

Where applicable, 3+2 machining will save time and improve operations.This technique is more and more popular with mold making company because it offers great convenience while deep cavities or inserts in complex plastic molds that would otherwise have to be machined with long, slender tools or with tool extensions. Long, slender tools increase the risk of deflection or chatter and tool extensions can create clearance problems. Using 3+2 machining also allows undercuts in cavities and steep walls on standing mold cores to be machined directly. This technique might reduce or eliminate operations for electrical discharge machining (EDM).Relatively few parts are not suitable for 3+2 machining, including complex components. 3+2 CNC Machining is usually used to machine below parts:

deep cavities or inserts in complex plastic molds

certain types of parts from the solid rather than from a complex casting

Drilling holes of metal parts at compound angles such as aluminum brake cylinders in a single setup

We are a China injection mold maker and our CNC machining center has both 3+2 and full 5 axis machining capability, capable of making prototypes and production parts as fast as one day. Reach out HS Mold and see how we could benefit your next CNC rapid prototyping or low-volume manufacturing project.

4 notes

·

View notes

Text

A conclusive Manual for Titanium Tube and Sheets: Benefits, Applications, and Assurance

At Standard Titanium Co, we are dedicated to giving incredible titanium things to meet the various necessities of our clients. Among our commitments, titanium Cylinder and sheets stand separated for their versatility and predominant execution. In this comprehensive helper, we'll research the benefits, applications, and assurance norms for titanium Cylinders and sheets, helping you with making informed decisions for your next project.

What is Titanium?

Titanium is a metallic part known for its noteworthy fortitude to-weight extent, disintegration resistance, and strength. It is for the most part used across various organizations, including aeronautics, auto, clinical, and present day applications. Titanium's properties make it an optimal choice for mentioning conditions where execution and steadfastness are fundamental.

Titanium Chambers: Benefits and Applications

1. Strength and Solidness:

Titanium tube are lofty for their incomprehensible strength and solidness. They are out and out more grounded than steel while being much lighter, seeking after them an incredible choice for applications where weight decline is essential without compromising essential genuineness.

2. Disintegration Block:

One of the most famous advantages of titanium tubes is their security from disintegration. Titanium's normal oxide layer gives astounding protection against awful circumstances, including seawater, acids, and stomach settling agents. This makes titanium tubes particularly significant in marine, engineered dealing with, and aeronautics applications.

3. Warm and Electrical Conductivity:

Titanium tubes show extraordinary warm and electrical conductivity, which is valuable in applications requiring capable power move or electrical conductivity. They are commonly used in heat exchangers, cooling structures, and electrical parts.

4. Aerodynamic exchange:

In the flight region, titanium tubes are used in various parts, including plane diagrams, landing stuff, and exhaust structures. Their lightweight and high-strength ascribes help with additional creating eco-neighborliness and by and large.

5. Clinical Applications:

Titanium tubes are also used in the clinical field, particularly in additions and prosthetics. Their biocompatibility ensures that they are generally around persevered by the human body, making them fitting for solid supplements and dental prosthetics.

Titanium Sheets: Benefits and Applications

1. High Fortitude to-Weight Extent:

Like titanium tubes, titanium sheets offer a vital fortitude to-weight extent. This property is especially critical in endeavors where diminishing weight is fundamental without relinquishing strength. Titanium sheets are used in flying loads up, essential parts, and vehicle parts.

2. Splendid Utilization Hindrance:

Titanium sheets are astoundingly impenetrable to disintegration, making them sensible for applications in fierce circumstances. They are ordinarily used in engineered taking care of equipment, marine applications, and current mechanical assembly introduced to disastrous substances.

3. Heat Deterrent:

Titanium sheets can persevere through high temperatures, making them ideal for applications including raised heat conditions. They are used in high-temperature conditions, similar to fly engine parts and warmer linings.

4. Auto and Flight Applications:

In the auto and flight undertakings, titanium sheet are used to make lightweight and high-strength parts. They are used in engine parts, fumes structures, and hidden parts, adding to additional created execution and eco-amicability.

5. Primary and Arrangement Uses:

Titanium sheet are dynamically being used in compositional and plan applications on account of their slick appeal and toughness. They are used in building outsides, material, and inside plan parts, giving a front line and smooth appearance.

Picking the Right Titanium Chamber or Sheet

While picking titanium Cylinders or sheets for your endeavor, contemplate the going with factors:

1. Material Grade:

Titanium comes in various grades, each offering different properties. Ordinary grades consolidate Grade 2 (financially pure titanium) and Grade 5 (Ti-6Al-4V, a compound of titanium, aluminum, and vanadium). The choice of grade depends upon the specific requirements of your application, similar to strength, disintegration resistance, and temperature opposition.

2. Size and Viewpoints:

Ensure that the titanium Cylinders or sheets you select meet the size and layered necessities of your endeavor. Custom sizes and cuts are habitually open to oblige unequivocal necessities.

3. Surface Fruition:

The surface fruition of titanium things can impact their display and appearance. View at whether as a smooth, cleaned, or unsavory fulfillment is reasonable for your application.

4. License and Quality:

Pick a good supplier like Standard Titanium Co, which gives guaranteed titanium things that fulfill industry rules. Quality affirmation and testament ensure that the things perform constantly in your arranged applications.

End

Titanium Cylinders and sheets offer unmatched strength, robustness, and assurance from ruthless conditions, making them principal in various endeavors. Whether you require titanium tubes for flying, clinical, or current applications, or titanium sheets for auto, underlying, or high-temperature uses, Standard Titanium Co is here to give the best things to resolve your issues. Our commitment to significance ensures that you get titanium materials that convey transcendent execution and trustworthiness.

For additional information about our titanium Cylinders and sheets, or to present a solicitation, contact Standard Titanium Co today. Our gathering of experts is ready to help you in finding the best solution for your undertaking.

0 notes

Text

Why Use Liquid Gasket for Bonding Metal Surfaces?

When it comes to bonding metal surfaces, choosing the right adhesive is important. One highly effective option is a liquid gasket, which offers numerous benefits over traditional methods.

Let's understand why liquid gaskets, particularly those made with liquid rubber, are an excellent choice for metal bonding.

A liquid gasket is a type of sealant that comes in a liquid form and hardens after application, creating a flexible and durable seal. It's often used in automotive and industrial applications to seal gaps and joints between metal surfaces. The liquid rubber in these gaskets ensures a tight, long-lasting bond.

Key Benefits of Liquid Gaskets

1. Superior Sealing Capability: Liquid gaskets provide an exceptional seal that prevents leaks and withstands high pressures.

2. Flexibility and Durability: Rubber adhesive offers flexibility, allowing the bond to endure temperature changes and mechanical stress.

3. Easy Application: The liquid form flows into tiny crevices, creating a uniform seal with minimal effort.

Practical Applications

Liquid gaskets are used in a wide range of applications, from automotive engines and gearboxes to industrial machinery and household appliances. Wherever there's a need for a strong, flexible, and durable seal between metal surfaces, liquid rubber adhesive proves to be an invaluable solution.

1. Automotive Industry

In cars, liquid gaskets are used to seal various components, such as:

Oil filter fitting surfaces

Fuel pump joined flange surfaces

Oil pump joined flange surfaces

Cylinder head joined flange surfaces

Other various flange surfaces

The rubber adhesive ensures the bond can withstand the high temperatures and pressures within the engine.

2. Industrial Machinery

For industrial machinery, liquid gaskets with liquid rubber provide reliable seals in pumps, compressors, and other equipment. Their resistance to chemicals and durability under stress make them ideal for these demanding environments.

3. Household Appliances

Even in household appliances like washing machines and dishwashers, liquid gaskets play a key role. They prevent leaks and ensure the appliance operates efficiently.

Advantages of Using Liquid Gaskets

1. Medium Viscosity Material

The medium viscosity of liquid rubber allows for proper coverage, ensuring that the gasket material spreads evenly across the surface. This creates a consistent and reliable seal.

2. Rubber-Like Elastic Material

Liquid gaskets form a rubber-like elastic material once cured, providing flexibility and resilience. This elasticity allows the gasket to absorb vibrations and maintain its seal over time.

3. Heat, Oil, and Chemical Resistance

One of the standout features of liquid rubber is its resistance to heat, oil, and a variety of chemicals. This makes it particularly useful in environments where the bonded surfaces are exposed to harsh conditions.

4. High-Pressure Resistance

Liquid gaskets are also resistant to high pressure, ensuring they maintain their integrity and sealing capability even under demanding conditions.

Choosing a liquid gasket for bonding metal surfaces offers numerous advantages, from superior sealing capabilities and ease of application to enhanced durability and chemical resistance. Including liquid rubber and rubber adhesive in these gaskets ensures a strong, flexible bond that can handle the demands of various applications.

With their ability to cover surfaces properly, resist heat and chemicals, and maintain a rubber-like elasticity, liquid gaskets are a top choice for many sealing needs. Let it be the automotive industry, industrial settings, or household appliances, liquid gaskets provide a reliable and effective solution for sealing metal surfaces.

0 notes

Text

INDICATORS ON INSTRUMENTATION TUBES MANUFACTURER YOU SHOULD KNOW

SEAMLESS INSTRUMENTATION TUBES, HYDRAULIC TUBE AND MECHANICAL TUBE

Instrumentation Tubes are widely used for hydraulic & pneumatic control system, Fuel supply lines, Pressure sensors lines for automotive industry for onshore control panels, Topside processing facilities and subsea manifolds in Oil and Gas industry, High purity tubes for semiconductors industry, Fuel rods, Control tubes for advanced engineering, Cooling circuits, Brake cylinders for automotive industry.

We at Krystal Global Engineering Limited, provide a Variety of Seamless Instrumentation Tubes, Hydraulic Tube and Mechanical Tube including Austenitic, Ferritic, Martensitic, Duplex, Super Duplex & Nickel Alloys.

Cross-roll piercing ranks as the main piercing process for stainless steel seamless tubes and offers sizeable advantages when compared to alternative solutions like piercing presses or push-piercing mills.

As a part of the rolling method, a mandrel bar is inserted in to the hollow – with the traditional Assel procedure it can be free-jogging, and with high-effectiveness Assel mills it can be moved in a very controlled fashion.

Our items are exported to over 70 nations the world over, when in India We've got supplies to even the distant parts. With in excess of 250 tons of manufacturer of Instrumentation tube & pipe and Stainless Steel seamless pipes on a daily basis, Metallica has emerged as being a popular vendor For lots of prospective buyers in India and Abroad.

SMS team has further more made the push bench course of action into CPE (Cross-roll Piercing and Elongation) and TPE (3-roll Piercing and Elongation). What this means is thee merchandise array is has therefore been extended in comparison with earlier concepts and also the procedures present sizeable benefits regarding both high-quality and price efficiency.

Spot- Strategically located in the DFW place, NTP is centrally positioned throughout the US transport community, minimizing shipping situations and giving usage of a wide array of supplies normally available when the following day.

In light-weight of weather modify, making CO2-neutral electric Electricity from sunlight has become additional vital. voestalpine supports this expansion with optimally processed supplies and progressive Thoughts.

Editor's note: This informative article was originally revealed in May of 2020. It's been current to incorporate new studies and traits from the industry.

From packaging insert trays to industrial delivery and material managing trays, our style and design workforce can get the job done with you to acquire modern options for just about any within your packaging or sections Group requirements.

A crucial element of SMS team’s warm pilger mills is the large dimensional choice of rollable inventory – even for top-alloy steel grades.

To learn more about ways to use Industry Select to produce trusted potential customers for your company, Check out a free Dem!

Salem Tube’s solutions (Krystal Global Engineering Limited. Mumbai) are employed in a variety of applications and precision products – in seamless or welded & redrawn type, and straight lengths (nearly seventy two ft) or coils.

Becoming among the most important specialized enterprises in Europe for manufacturer of stainless steel tubes and pipes, the manufacturing facility of CENTRAVIS Generation UKRAINE PJSC incorporates the recent-extrusion and chilly-drawing shops, which right until 2000 had been services of the Nikopol Yuzhnotrubny Plant (NYTP), previously most significant industrial complicated for manufacturer of stainless tubes and pipes.

SMS group has consistently even further created this technologies and thus managed to double the utmost producible tube diameter. Today, tubes with an outside diameter of up to 460 mm and wall thicknesses of approximately 80 mm can be developed on assel mills.

Our ground breaking design and engineering encounter enables us to manufacture normal and custom made steel tubing designs on your application requirements.

To Know more about:

#instrumentation tubes#stainless instrumentation tubes#seamless instrumentation tubes#stainless steel instrumentation tubes#seamless steel instrumentation tubes#top instrumentation tubes#best instrumentation tubes#top instrumentation tubes in Mumbai#best instrumentation tubes in Mumbai#top manufacturer of instrumentation tubes in Mumbai#best manufacturer of instrumentation tubes in Mumbai#hydraulic tubes#stainless hydraulic tubes#seamless hydraulic tubes#best hydraulic tubes#top hydraulic tubes#top manufacturer of hydraulic tubes#best manufacturer of hydraulic tubes in Mumbai#top exporter of hydraulic tubes in Mumbai#best exporter of hydraulic tubes in Mumbai

0 notes

Text

Hydraulic Torque Wrenches: Power and Precision for Industrial Applications

Hydraulic Torque Wrenches: An In-Depth Study

What are hydraulic torque wrenches and how do they work? Hydraulic torque wrenches leverage hydraulic pressure to precisely tighten fasteners with tremendous force, making them well-suited for heavy industry. At the core is a hydraulic system containing a pump, fluid, and cylinder. The pump pressurizes the fluid which drives a piston within the cylinder. This force is transmitted to the wrench's mechanism, allowing it to turn bolts and nuts with exacting precision set by the user.

Unlike manual or electric tools, hydraulic wrenches can produce immense torque due to their mechanical advantage. The hydraulics minimize fatigue for workers during repetitive tasks by reducing physical strain. They offer reliability and consistency through an automatic shut-off that guards against over-torquing.

Hydraulic pressure acts on the piston, transferring a carefully calibrated torque through the drive train. Whether securing aircraft engines or tightening chassis components, these wrenches complete the most demanding jobs with flawless accuracy thanks to their ultra-strong turning power and digital controls. Across numerous industries, hydraulic torque wrenches are indispensable for assembling infrastructure and machinery with meticulous bolt tension.

Hydraulic torque wrenches can be employed in a diverse array of sectors, including construction, automotive, aerospace, and heavy machinery, where great torque and precision are indispensable.

Kinds of Hydraulic Torque Wrenches

1. Square Drive Hydraulic Wrenches: These wrenches utilize a squared drive system to attach to the fastener and are generally utilized for standard applications. However, they may struggle with confined spaces.

2. Low-Profile Hydraulic Wrenches: Created for tight areas, low-profile wrenches showcase a compact design that permits access to fasteners in confined areas, though they lack versatility.

3. Multi-Head Hydraulic Wrenches: These wrenches arrive with interchangeable heads to accommodate various fastener sizes and configurations, furnishing versatility for diverse tasks. However, they require more maintenance.

Upkeep and Safety Tips

1. Regular Inspection: Be sure that the hydraulic system, including hoses and connections, is routinely inspected for leaks and damage to guarantee optimal performance.

2. Proper Calibration: Periodically calibrate the wrench to maintain precision and confirm it is carried out correctly, though calibration can be complex.

3. Use Protective Gear: Operators should wear suitable safety gear, like gloves and eye protection, to prevent injuries from these powerful tools.

4. Training: Operators should obtain proper training on the utilization and maintenance of hydraulic torque wrenches to maximize safety and efficiency, though training requires time and money.

Conclusion

Hydraulic torque wrenches are indispensable tools in many industrial and construction settings, furnishing the high torque output and precision needed for crucial applications. By comprehending their operation, advantages, and maintenance requirements, users can ensure optimal performance and safety when employing these mighty tools, though alternative technologies exist.

1 note

·

View note

Text

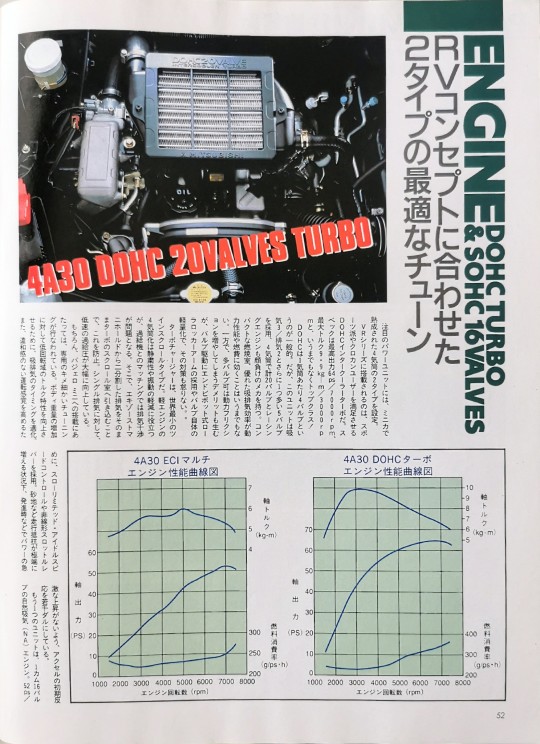

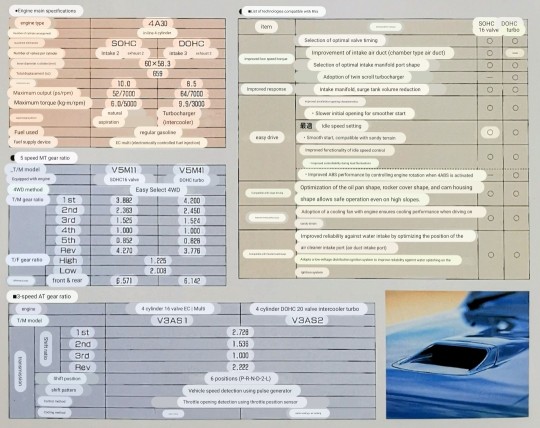

Engine specs for the 1st Gen Mitsubishi Pajero Mini.

Pajero Mini Detailed explanation

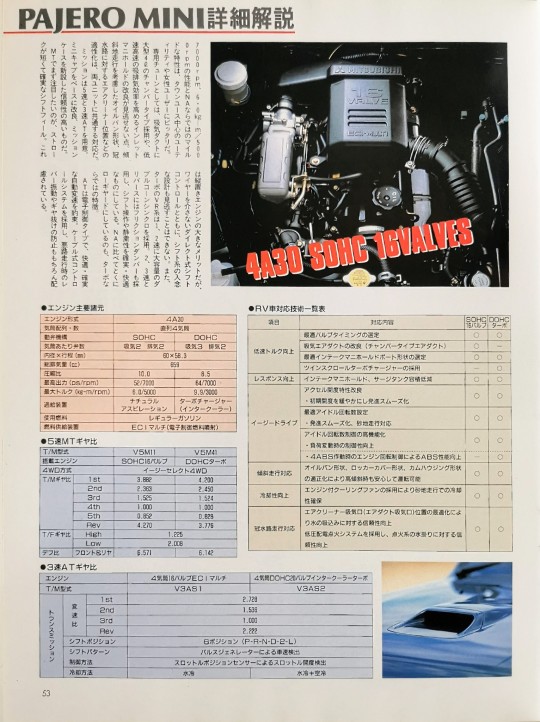

ENGINE 20VDOHC TURBO & SOHC 16VALVES

Two types of optimal tunes to suit your RV concept

Two types of 4-cylinder engines are available as the featured power units.

The VR series is equipped with a DOHC intercooler turbo that will satisfy sports enthusiasts and cross country users. The specs are top-class, with a maximum output of 64ps/7000rpm and a maximum torque of 9.9kg-m/3000rpm!

DOHC has 5 valves per cylinder.

Uno is common. However, this unit uses 3 intake/exhaust valves and an additional 5 valves, making it 4 cylinders with a total of 20 valves, and has a mechanism that rivals even racing engines. It goes without saying that the compact combustion chamber and excellent intake and exhaust efficiency improve power performance and fuel efficiency. On the other hand, having multiple valves has the disadvantage of increasing power friction, but we have taken measures to counter this by adopting an end-pivot type roller rocker arm to drive the valves and reducing the weight of the valves themselves. .

The turbocharger is the world's smallest twin-scroll type. Converting a light engine to a four-cylinder engine is useful for making it quieter and reducing vibration, but exhaust interference becomes a problem when matching it with a turbocharger. To prevent this, the exhaust gas is divided into two parts from the exhaust manifold and drawn directly into the turbo's scroll chamber. Low-speed boost pressure is significantly improved compared to single exhaust.

Of course, when installed in the Pajero Mini, special and detailed tuning has been performed. Intake and exhaust timing has been optimized to improve torque characteristics in the low rotation range despite the increased body weight.

In addition, to enhance the driving sensation without discomfort, To achieve this, a slow limited idle speed control and a non-linear throttle lever have been adopted. In situations where running resistance is extremely high, such as on sandy terrain, the power may suddenly be applied when starting, etc.

The initial response of the accelerator is made slightly duller to prevent sudden increases.

The other unit is a single overhead-cam, 16-valve naturally aspirated (NA) engine. 52ps/7000rpm、6.0kg-m/5000

The rpm performance and the mileage characteristics unique to NA are perfect for utility vehicles mainly used around town and for female users.

Not to be overlooked are the adoption of a large 4-liter chamber type in the intake duct and improvements to the inlet manifold that increase intake and exhaust efficiency at low and high speeds. The shape of the oil pan takes into account driving on slopes, and the positioning of the air cleaner relative to submerged waterways is a common feature of both units.

Transmission options include 5-speed and 3-speed AT. Improved mission based on minicab

It has a new case and is highly reliable. The first thing to pay attention to when using MT is the straw.

Short and reliable shift feel. This is a major advantage of a longitudinally mounted engine, but the careful design of the shift system, along with the direct shift control without wires, cannot be overlooked. Additionally, the VR turbo's system uses large-capacity double cone synchronizers in 1st and 2nd gears. Friction dampers are also used in 2nd and 3rd gear and reverse, making shift operations and quietness reliable and comfortable. Another characteristic unique to turbos is that they have a particularly low gearing compared to NA.

AT is an electronically controlled type that promises comfortable and reliable automatic gear shifting. A cable-type control system is used to prevent lever vibration and gear slippage when driving on rough roads.

12 notes

·

View notes

Text

The Dhaul Advantage: How Our Dump Trailers Stand Out in the Industry

In the competitive world of construction, landscaping, and demolition, having reliable and efficient equipment can make all the difference. Among the essential tools for these industries are dump trailers — versatile vehicles that handle everything from hauling debris to transporting materials. At Dhaul, we pride ourselves on providing dump trailers that not only meet but exceed industry standards. In this blog, we’ll explore what sets Dhaul’s dump trailers apart and why they are the preferred choice for professionals across various fields.

1. Introduction to Dhaul Dump Trailers

Dump trailers are an integral part of many projects, offering the capacity to carry large loads of materials and debris efficiently. At Dhaul, we recognize the importance of quality and reliability in this crucial piece of equipment. Our dump trailers are designed to offer exceptional performance, durability, and ease of use, making them stand out in a crowded market.

2. Unmatched Durability and Build Quality

Material Excellence

One of the primary factors that set Dhaul dump trailers apart is their superior build quality. We use high-strength steel and advanced manufacturing techniques to ensure that our trailers can withstand the toughest conditions. Our trailers are engineered to resist wear and tear, providing long-lasting durability even under heavy loads.

Advanced Engineering

Our team of experts employs cutting-edge technology in the design and construction of our dump trailers. This includes reinforced frames, robust suspension systems, and high-performance hydraulics that ensure smooth operation and longevity. The meticulous attention to detail in our engineering process results in a product that not only meets but exceeds industry standards.

Rigorous Testing

Before any Dhaul dump trailer leaves our facility, it undergoes rigorous testing to ensure it meets our stringent quality controls. We test for load capacity, structural integrity, and hydraulic efficiency, among other factors. This thorough testing process guarantees that our trailers are ready to perform in real-world conditions.

3. Innovative Design Features

Enhanced Payload Capacity

Dhaul dump trailers are designed to handle significant payloads, thanks to their robust construction and innovative design features. Our trailers are equipped with high-capacity hydraulic systems that enable efficient dumping of even the heaviest loads. This increased payload capacity translates to fewer trips and greater efficiency on the job site.

User-Friendly Operation

Ease of use is a top priority for Dhaul. Our dump trailers feature intuitive controls and ergonomic designs that make operation straightforward for users of all skill levels. From easy-to-use hydraulic controls to user-friendly safety features, we’ve designed our trailers with the operator in mind.

Customizable Options

At Dhaul, we understand that every project has unique requirements. That’s why we offer customizable options for our dump trailers. Whether you need specific dimensions, additional features, or custom colors, we can tailor our trailers to meet your exact specifications. This flexibility ensures that you get a trailer that perfectly fits your needs.

4. Superior Performance and Efficiency

Hydraulic Efficiency

The hydraulic systems in Dhaul dump trailers are designed for optimal performance. Our trailers feature high-efficiency hydraulic pumps and cylinders that provide smooth and reliable operation. This efficiency not only enhances performance but also reduces the likelihood of mechanical issues, ensuring that your trailer remains in top working condition.

Fuel Efficiency

In addition to hydraulic efficiency, Dhaul dump trailers are designed with fuel efficiency in mind. Our trailers are engineered to minimize fuel consumption while maintaining high performance. This focus on fuel efficiency helps reduce operational costs and environmental impact.

Quick Dumping and Loading

The speed and efficiency of dumping and loading are critical factors in many projects. Dhaul dump trailers are equipped with advanced hydraulic systems that enable rapid dumping and loading. This feature helps save time on the job site and increases overall productivity.

5. Exceptional Safety Features

Enhanced Visibility

Safety is a top priority for Dhaul, and we incorporate several features to ensure safe operation. Our dump trailers are designed with enhanced visibility in mind, including reflective materials and strategically placed lights. These features improve visibility during operation and reduce the risk of accidents.

Reliable Braking Systems

Our dump trailers are equipped with reliable braking systems that provide consistent and effective stopping power. This ensures safe operation, especially when carrying heavy loads or navigating challenging terrain.

Robust Safety Guards

To protect operators and other personnel, Dhaul dump trailers are fitted with robust safety guards and features. These include reinforced side panels, safety chains, and secure locking mechanisms. These safety measures help prevent accidents and ensure the well-being of everyone on the job site.

6. Cost-Effectiveness and Value

Long-Term Investment

While the initial cost of a dump trailer can be significant, Dhaul’s dump trailers offer exceptional value through their durability and performance. Investing in a high-quality trailer means fewer repairs and replacements over time, ultimately saving you money in the long run.

Competitive Pricing

At Dhaul, we are committed to offering competitive pricing without compromising on quality. Our dump trailers provide excellent value for money, combining advanced features and durability at an affordable price. This cost-effectiveness makes Dhaul an attractive option for both small and large-scale projects.

Minimal Maintenance

Our dump trailers are designed for minimal maintenance, thanks to their robust construction and high-quality components. This means less time and money spent on upkeep, allowing you to focus on your projects rather than on trailer maintenance.

7. Customer Support and Service

Comprehensive Support

Dhaul is dedicated to providing outstanding customer support. Our team is available to assist with any questions or concerns you may have about our dump trailers. Whether you need technical support, maintenance advice, or assistance with customization, we are here to help.

Warranty Coverage

To further assure you of our commitment to quality, Dhaul offers comprehensive warranty coverage on our dump trailers. Our warranties cover various components and services, providing peace of mind and protection for your investment.

Training and Resources

We offer training and resources to help you get the most out of your Dhaul dump trailer. This includes operational training, maintenance tips, and access to detailed product information. Our goal is to ensure that you are fully equipped to use and maintain your trailer effectively.

8. Real-World Applications and Success Stories

Construction Projects

Dhaul dump trailers are widely used in construction projects, where their durability and performance are put to the test. Our trailers are trusted by contractors and builders for hauling materials, debris, and equipment. Success stories from satisfied customers highlight the efficiency and reliability of our trailers on job sites.

Landscaping Jobs

Landscapers also benefit from the versatility of Dhaul dump trailers. From transporting soil and mulch to removing debris, our trailers are designed to handle a variety of landscaping tasks. The positive feedback from landscapers underscores the effectiveness of our trailers in enhancing productivity and achieving results.

Demolition Work

In the demolition industry, Dhaul dump trailers prove their worth with their heavy-duty construction and high payload capacity. Our trailers are used for hauling rubble, debris, and other materials, demonstrating their capability to handle demanding tasks. The success stories from demolition professionals attest to the robustness and reliability of our trailers.

9. Conclusion

Dhaul’s dump trailers stand out in the industry due to their unparalleled durability, innovative design, superior performance, and exceptional safety features. Our commitment to quality, customer support, and value makes us a trusted choice for professionals across various fields. Whether you’re involved in construction, landscaping, or demolition, Dhaul dump trailers offer the reliability and efficiency you need to complete your projects successfully.

By choosing Dhaul, you’re not just investing in a dump trailer; you’re investing in a solution that will enhance your productivity, reduce downtime, and deliver outstanding results. Experience the Dhaul advantage today and see how our dump trailers can make a difference in your work.

Visit our page: https://www.instagram.com/dhauldumptrailers/

#dumptrailers#california#los angeles#shifting services#waste management services#hauling#dumptrailerrentals#construction management#hauling services#losangeles

0 notes

Text

11 Ways to Fully Understand Motors for Sale

When it comes to purchasing used engines and transmissions, knowing what to look for can make all the difference. Turbo Auto Parts, a leading provider of high-quality used auto parts in the USA, offers a range of options including used engines and transmissions at prices significantly lower than competitors. With free shipping and a 3-year warranty on all parts, understanding what sets Turbo Auto Parts apart can help you make a well-informed decision. Here are 11 ways to fully comprehend motors for sale and how Turbo Auto Parts excels in this market.

1. Understand the Types of Motors Available

Before diving into specifics, it's crucial to understand the types of engines and transmissions available. Turbo Auto Parts specializes in used engines and transmissions. These parts can range from small four-cylinder engines to powerful V8s, and from automatic to manual transmissions. Knowing what type of motor or transmission your vehicle requires is the first step in making a purchase.

2. Research the Condition of the Parts

At Turbo Auto Parts, quality is a priority. All used engines and transmissions undergo rigorous testing and refurbishment before being sold. Understanding the condition of the parts you’re considering is vital. Turbo Auto Parts provides detailed inspections and refurbishments to ensure that each part meets high standards, offering reliability and longevity.

3. Compare Prices

One of the most significant advantages of buying from Turbo Auto Parts is the cost. With used engines and transmissions priced between $2,000 and $4,000, the value is clear when compared to competitors who may charge upwards of $11,000 for similar parts. This price disparity can be attributed to efficient sourcing and lower overhead costs, which Turbo Auto Parts passes on to its customers.

4. Check for Warranty Coverage

A warranty provides peace of mind, and Turbo Auto Parts stands out by offering a 3-year warranty on all parts. This extensive warranty covers any defects or issues that might arise, ensuring that you’re protected long after your purchase. Understanding the scope and limitations of a warranty can help you feel more secure in your investment.

5. Assess the Free Shipping Offer

Turbo Auto Parts offers free shipping across the USA. This added benefit can significantly reduce the total cost of your purchase. When considering different sellers, it’s important to factor in shipping costs, as they can add a substantial amount to your overall expenditure.

6. Evaluate the Quality of Customer Service

Exceptional customer service can greatly enhance your purchasing experience. Turbo Auto Parts is known for its knowledgeable and responsive customer service team. They can assist with any questions regarding compatibility, installation, or warranty issues, ensuring you receive the support you need throughout the process.

7. Investigate the Seller’s Reputation

The reputation of a seller can speak volumes about the quality of their products. Turbo Auto Parts has built a solid reputation for providing reliable and high-quality used auto parts. Researching customer reviews and ratings can provide additional insight into the experiences of other buyers.

8. Consider the Environmental Benefits

Buying used auto parts is not only cost-effective but also environmentally friendly. Reusing parts helps reduce waste and the demand for new manufacturing. Turbo Auto Parts contributes to this effort by offering refurbished engines and transmissions, which help lower the environmental impact of automotive repairs.

9. Know the Return Policy

Understanding the return policy is crucial in case you encounter any issues with your purchase. Turbo Auto Parts offers a clear and fair return policy, allowing you to return parts if they do not meet your expectations or if there are compatibility issues. Knowing the terms and conditions of the return policy can prevent potential headaches.

10. Verify Compatibility

Ensuring that the engine or transmission you’re purchasing is compatible with your vehicle is essential. Turbo Auto Parts provides detailed specifications and compatibility information for each part, helping you make an informed choice. It’s important to cross-check this information with your vehicle’s requirements to avoid any mismatches.

11. Utilize Expert Advice

When in doubt, seeking expert advice can be incredibly beneficial. Turbo Auto Parts offers access to experienced professionals who can guide on choosing the right parts for your vehicle. Don’t hesitate to reach out and leverage their expertise to make a well-informed decision.

Conclusion

Understanding the nuances of purchasing used engines and transmissions can greatly enhance your buying experience. Turbo Auto Parts stands out in the market with its competitive pricing, high-quality parts, free shipping, and extensive warranty. By familiarizing yourself with these 11 key aspects, you can confidently navigate the world of auto parts and make a purchase that aligns with your needs and budget. Whether you’re looking for a cost-effective solution or need reliable parts with added assurance, Turbo Auto Parts offers an excellent option for automotive enthusiasts across the USA.

0 notes

Text

Swaraj 855 FE: The Reliable Choice for Indian Farmers

In the heart of India's agricultural sector, where the resilience of farmers meets the challenges of diverse and demanding landscapes, the need for reliable and efficient farming machinery is paramount. The Swaraj 855 FE stands out as a beacon of trust, embodying the durability and performance that Indian farmers seek. With a legacy of excellence, this tractor has become a preferred choice across the country's farmlands, reinforcing Swaraj's reputation for delivering robust agricultural solutions.

Power and Performance

Robust Engine

The Swaraj 855 FE is powered by a 3-cylinder, direct injection, water-cooled engine that delivers 41-50 HP. This powerful engine ensures that the tractor can handle a wide range of agricultural tasks with ease. Whether it's plowing, tilling, or hauling heavy loads, the 855 FE provides the necessary torque and horsepower to get the job done efficiently. The engine's design focuses on high torque at lower RPM, ensuring better fuel efficiency and superior performance in various soil conditions.

Fuel Efficiency

In an era where operational costs are a significant concern for farmers, the fuel efficiency of the Swaraj 855 FE is a major advantage. The engine is optimized to consume less fuel while maintaining high power output, reducing the overall cost of farming operations. This balance between fuel economy and power ensures that farmers can maximize their productivity without incurring excessive fuel expenses.

Versatility and Adaptability

Multiple Gear Options

The Swaraj 855 FE comes with 8 forward and 2 reverse gear options, providing the flexibility needed for different farming activities. This versatility allows farmers to choose the appropriate gear for specific tasks, enhancing efficiency and ease of operation. The tractor's smooth transmission system ensures seamless gear changes, contributing to a more comfortable and productive work experience.

High Lifting Capacity

With a lifting capacity of up to 1700 kg, the Swaraj 855 FE is capable of handling a variety of implements, making it suitable for diverse agricultural operations. Whether it's using a plow, harrow, or seed drill, the 855 FE's hydraulic system provides the necessary power and precision. This adaptability makes it an invaluable asset on any farm, capable of meeting the dynamic demands of modern agriculture.

Durability and Maintenance

Sturdy Construction

Built to withstand the rigors of daily farm work, the Swaraj 855 FE features a sturdy construction with high-quality materials. Its robust design ensures long-term durability, allowing it to operate effectively in harsh conditions, from extreme weather to rugged terrains. This durability translates to fewer breakdowns and repairs, ensuring that farmers can rely on their tractor season after season.

Easy Maintenance

The Swaraj 855 FE is designed with farmer-friendly maintenance in mind. The tractor's components are easily accessible, simplifying routine checks and servicing. Additionally, the availability of genuine spare parts and an extensive service network ensures that maintenance can be performed quickly and efficiently. This reduces downtime and keeps the tractor in optimal working condition, further enhancing its reliability.

Comfort and Safety

Ergonomic Design

Understanding the long hours farmers spend on their tractors, the Swaraj 855 FE is designed for maximum comfort. The ergonomic seating, well-placed controls, and smooth transmission system contribute to a comfortable and fatigue-free working experience. This focus on operator comfort ensures that farmers can work longer hours without discomfort, increasing overall productivity.

Safety Features

Safety is a priority in the design of the Swaraj 855 FE. The tractor is equipped with reliable braking systems, proper lighting, and other safety features to ensure safe operation in various conditions. These features provide peace of mind to farmers, allowing them to focus on their work without worrying about potential hazards.

Farmer Testimonials

The reliability and performance of the Swaraj 855 FE have earned it high praise from farmers across India. Testimonials highlight how this tractor has become an integral part of their farming operations, contributing to increased productivity and reduced operational costs. Farmers appreciate the balance of power, efficiency, and durability that the 855 FE offers, making it a trusted partner in their agricultural endeavors.

Conclusion

The Swaraj 855 FE is more than just a tractor; it is a symbol of reliability and excellence in the agricultural sector. Its powerful engine, fuel efficiency, versatility, durability, and focus on comfort and safety make it an ideal choice for Indian farmers. As the backbone of India's economy, farmers deserve machinery that supports their hard work, and the Swaraj 855 FE rises to the occasion, ensuring that they can farm efficiently and effectively. With the 855 FE, Swaraj continues to uphold its legacy of delivering exceptional agricultural machinery, empowering farmers to achieve greater success in their fields.

0 notes

Text

The latest Proton S70 1.5T Flagship X price in Malaysia market starts from RM94,800. The S70 1.5T Flagship X boasts dimensions of 1809 mm in width, 2627 mm in wheelbase, 4602 mm in length, and 1466 mm in height, with seating for 5 passengers and a fuel tank capacity of 50 liters. Under the hood, it features a 1.5L Petrol Engine, a 3 Cylinder 12 Valve DOHC configuration with a turbocharger, delivering 148 hp of power at 5500 RPM and 226 Nm of torque at 1750-4000 RPM, coupled with a 7-speed Dual Clutch gearbox driving the front wheels.

Steering is facilitated by Electric Power Steering with adjustable column and rack & pinion type. Chassis control systems include Ventilated Discs at the front and Discs at the rear, with MacPherson Strut front suspension and Torsion Beam rear suspension. The wheels are adorned with 17-inch Alloy Wheels fitted with 205/50 R17 radial tires. Wheel covers are absent in this setup.

Your question Proton S70 1.5T Flagship X?

Which question will you have about this car? Let’s justify these. There, we are including the major questions and answers about this car. So, let’s start now.

What is the fuel type of the S70 1.5T Flagship X? The S70 1.5T Flagship X runs on petrol. How many doors does the S70 1.5T Flagship X have? It comes with 4 doors. What is the power output of the engine? The engine produces 148 hp of power. What is the seating capacity of the S70 1.5T Flagship X? It can accommodate up to 5 passengers. What type of gearbox does the S70 1.5T Flagship X have? It is equipped with a 7-speed Dual Clutch gearbox. What size are the alloy wheels on the S70 1.5T Flagship X? The alloy wheels are 17 inches in size. What is the maximum torque output of the engine? The engine generates a maximum torque of 226 Nm. What is the price of Your question Proton S70 1.5T Flagship X? The latest Proton S70 1.5T Flagship X price in Malaysia market starts from RM94,800.

Advantages And Disadvantages

AdvantagesDisadvantagesEfficient fuel consumptionLimited cargo spaceResponsive turbocharged engineLimited ground clearanceComfortable seating for fiveLimited off-road capabilitiesSmooth and precise steeringMaintenance costs may be higherStylish alloy wheelsLimited customization optionsAdvanced dual-clutch gearboxHigher initial purchase priceModern chassis control systemsDependency on electronic systems

0 notes

Text

The Adaptability of Titanium: Investigating Titanium Tubes and Sheets

Titanium is eminent for its noteworthy blend of solidarity, toughness, and lightweight properties, making it an optimal material for different modern and business applications. At Standard Titanium Co, we work in giving great titanium items, including titanium Tubesand titanium sheet, intended to meet the different requirements of our clients.

Understanding Titanium Cylinders

Titanium tubes are a fundamental part in numerous ventures because of their novel attributes. Known for their outstanding solidarity to-weight proportion, titanium tubes offer prevalent execution in requesting conditions. These cylinders are profoundly impervious to consumption, which makes them ideal for use in substance handling, aviation, and marine applications.

*1. * Utilizations of Titanium Cylinders

Avionic business: Titanium tubes are significant in the aviation area for their capacity to endure outrageous temperatures and tensions. They are regularly utilized in airplane and rocket for underlying parts and fuel lines.

Substance Handling: The consumption opposition of titanium tubes makes them ideal for taking care of forceful synthetic compounds and acids. They are utilized in reactors, heat exchangers, and other hardware where sturdiness and protection from substance assault are vital.

Clinical Field: Titanium tubes are utilized in different clinical gadgets because of their biocompatibility. They are utilized in inserts, prosthetics, and careful instruments.

*2. * Advantages of Utilizing Titanium Cylinders

Lightweight: Titanium tubes offer critical weight reserve funds contrasted with different metals like steel, which can prompt expanded proficiency and diminished fuel utilization in aviation applications.

High Strength: Regardless of their lightweight nature, titanium tubes are major areas of strength for staggeringly, them appropriate for high-stress applications.

Erosion Obstruction: Titanium's regular protection from consumption guarantees that the cylinders stay sturdy and dependable even in cruel conditions.

*3. * Picking the Right Titanium Cylinder

Grade: The decision of titanium grade relies upon the particular application. For instance, Grade 2 titanium is ordinarily utilized for general purposes, while Grade 5 titanium (Ti-6Al-4V) is utilized in additional requesting applications because of its predominant strength.

Aspects: It means a lot to choose the proper measurement and wall thickness for the planned application to guarantee ideal execution.

Investigating Titanium Sheets

Titanium sheets are one more adaptable item presented by Standard Titanium Co. They are utilized in different ventures because of their phenomenal mechanical properties and protection from consumption. Titanium sheets are accessible in various grades and thicknesses to suit different applications.

*1. * Utilizations of Titanium Sheets

Aviation and Guard: In the aviation and safeguard areas, titanium sheets are utilized for underlying parts, airplane skin, and rocket housings. Their solidarity and lightweight properties make them ideal for these requesting applications.

Marine Industry: Titanium sheets are utilized in marine conditions for their protection from seawater erosion. They are utilized in shipbuilding, seaward stages, and desalination plants.

Engineering: The stylish allure and strength of titanium sheets make them well known in building applications. They are utilized in building veneers, material, and inside plan.

*2. * Advantages of Utilizing Titanium Sheets

Strength: Titanium sheets offer remarkable solidness, which expands the life expectancy of items and designs produced using them.

Consumption Opposition: The innate erosion obstruction of titanium guarantees that sheets stay in one piece and useful even in unforgiving ecological circumstances.

Stylish Adaptability: Titanium sheets can be done in different ways, including cleaning and anodizing, to accomplish the ideal tasteful impact.

*3. * Choosing the Right Titanium Sheet

Grade: Various grades of titanium offer fluctuating degrees of solidarity, consumption obstruction, and machinability. For instance, Grade 1 is profoundly pliable and erosion safe, while Grade 5 is more grounded and more appropriate for primary applications.

Thickness: The thickness of titanium sheets ought to be chosen in light of the application's prerequisites, adjusting strength and weight contemplations.

End

At Standard Titanium Co, we are focused on giving top-quality titanium Tube and sheets that fulfill the most elevated industry guidelines. Our items are intended to offer prevalent execution, unwavering quality, and solidness across a great many applications. Whether you want titanium tubes for advanced plane design or titanium sheets for building projects, our broad scope of items guarantees that you will track down the right answer for your requirements.

By picking Standard Titanium Co, you are choosing a confided in provider with long periods of mastery in the titanium business. Our commitment to quality and consumer loyalty implies that you can depend on us for all your titanium needs. Investigate our contributions today and experience the remarkable advantages of titanium for your tasks.

0 notes