#hydraulic tubes

Text

Precision and Quality: DOM Tubes Manufacturers

Discover excellence with our DOM Tubes Manufacturers. As industry leaders, we produce top-grade Drawn Over Mandrel (DOM) tubes that guarantee precision and reliability. With cutting-edge manufacturing techniques, we deliver tubes that meet the most stringent requirements. Partner with us for unmatched quality.

#dom tube#hydraulic tubes#j525 tubes#astm-a519#seamless mechanical tubing (a519 tubing)#stainless steel pipe#Alloy Steel Pipe and Tube manufacturer and supplier#Carbon Steel Flanges Manufacturer#Carbon Steel Pipes#Duplex And Super Duplex pipes#stainless steel pipe suppliers#stainless steel pipe tubing#Stainless Steel Flanges Supplier#Low Temperature Carbon Steel Pipes#Duplex Steel Flanges#galvanized pipes#steel pipes manufacturer#galvanized pipe manufacturer#a519 tubing#astm a312 pipe#galvanized pipe suppliers#ppgl coil manufacturers#ppgl coil manufacturers in india#ppgi coil manufacturers in india#ppgi coil manufacturers.

0 notes

Text

Prominent Manufacturer of API 5CT Tubes: Grace Bao Steel Industry

Grace Bao Steel Industry is Prominent Manufacturer of steel pipes, Bars, coils and tubes. The API 5ct Pipe has different carbon and chromium contents in the different product specification levels. These are used in transportation of oil and gas, water and other fluids as necessary. API 5ct Pipe is a specification of pipes that are used for casing or tubing in industrial gas lines and in tube well.

#API 5CT Tubes#Alloy 4140 Steel bar#Dom Tubes#precision steel tubes#ASTM A519 Seamless Mechanical Tubing#hydraulic tubes#Stainless steel pipe#Stainless steel tube#Stainless-Steel Seamless Tubes#Steel Seamless Pipe#Carbon steel pipe and tubes#CS Seamless Pipes#Alloy Steel Pipes#duplex and super duplex steel#galvanized pipes and tubes#Stainless steel coils and sheet#Carbon steel coils and sheets#Stainless steel bar#carbon steel bar#alloy steel bar

0 notes

Text

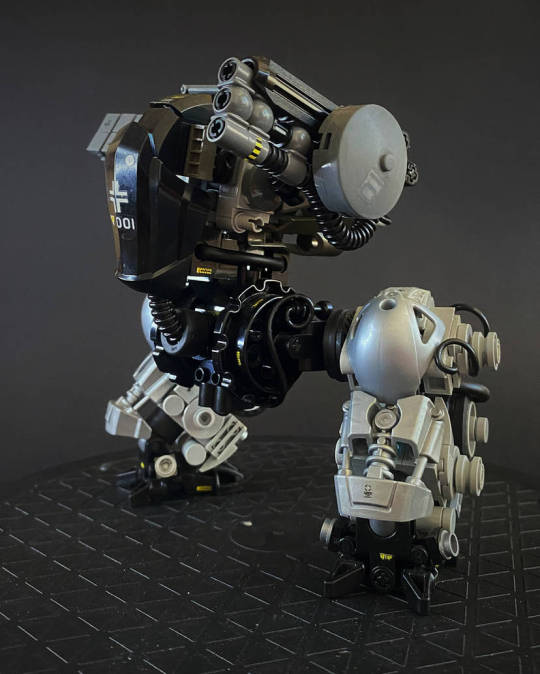

KZ.20 Mech [Advanced Design]

An even greater tool for the dispensing of sweet DEMOCRACY!!!!

Source

Creator: marcomarozzi

#lego#bionicle#armor#armor plates#mech#mechanical#machine#war#war machine#vehicle#walker#tubes#hydraulics#robot#robotic#robotic unit#guns#machine gun#cannon#bricks#faceless#armless#cannons#bipedal

36 notes

·

View notes

Text

None of you could handle me if I had the means to Justice post the way I Jack-O' post

Anyway good night

#textpost#I won't make wife jokes about Jack-O' because she deserves better but Justice.......#Justice can kill me with her giant lasers and her swordhands if she wants. If it would bring her enrichment#Kicking my feet and giggling as Justice charges up a giant laser. Frolicking and twirling my hair when we stab each other#I don't talk about my carnal lust for giant dangerous robots on here enough#Me when a girl has hydraulic tubes and jet boosters and pistons that go schhhhhhhhk schhhhhhhhk when she walks

30 notes

·

View notes

Text

something they don’t tell you abt working with big machines all the time is this

their fluids, grease etc may start out being kinda taboo and weird but no it becomes so normal and def cemented in your mind the reality that these are quite literally the same to them as our fluids are to us and just as normal

machines can sweat, machines can bleed, machines eat and drink, they get a little moist and messy and they smell like stuff, sometimes it’s good, sometimes it’s bad. If u think machines don’t get B.O. or have bad breath I assure you you’re wrong because they do and it’s very normal ok

#objectum#Machine things#they do these things ok#sometimes they’re so right for it#like yeah mate grease tubes do look yummy. Girl dinner#and it’s so fucking annoying when u get a cut and start bleeding hydraulic oil and fucking sand gets in it innit

18 notes

·

View notes

Text

Hydraulic Power Tongs | Sucker Rod, Tubing, Casing & Drill Pipe Power Tongs | Teda Style Power Tongs

Midland Oil Tools (MOT) offers high quality Hydraulic Power Tongs at affordable prices. Our Sucker rod, Tubing, Casing and Drill pipe power tongs are manufactured per API Specifications. Lightweight, simple, compact and portable. MOT offers cost-effective power tongs that will increase your productivity in the field.

#hydraulic power tongs#sucker rod power tongs#tubing power tongs#casing power tongs#drill pipe power tongs

2 notes

·

View notes

Photo

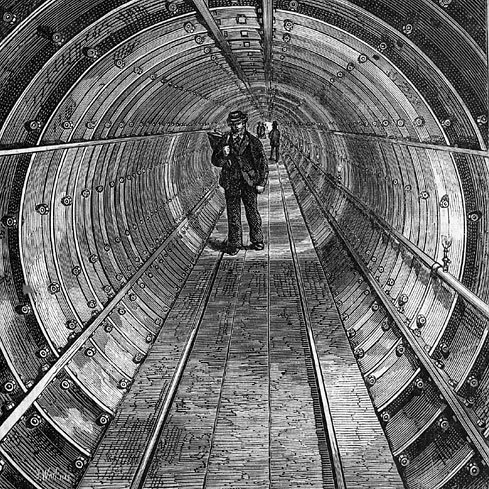

Tower Subway

The second tunnel under the Thames is now largely forgotten – which is quite remarkable, given that its method of construction paved the way for the first “proper” Tube line, the City and South London Railway (now part of the Northern Line). The subway was constructed by Peter Barlow using a circular tunnelling shield: workers would dig out the earth, which then enabled lime or cement to be used to line the tunnel as the shield was moved forward. Barlow’s pupil James Henry Greathead would later improve on the design, the principle of which is still used for digging Tube lines today.

The Tower Subway was only really a tube line (of sorts) for the first three months after it opened in 1870. There were narrow tracks and a single passenger car, pulled between the two entrance shafts by stationary steam engines. The enterprise was not very successful. The engines, car and tracks were removed, and gas lights installed, converting the tunnel into a pedestrian walkway, averaging 20,000 people a week, each paying a half-penny for the privilege. The subway was said, by contemporary writers, to be very dark and claustrophobic.

Its use a river crossing came to an end in 1898, four years after the opening of nearby Tower Bridge, which was free to use. The tunnel was sold to the London Hydraulic Power Company, who used it to take their hydraulic power and water mains under the river. These days, the tunnel still carries water mains, along with telecommunication cables. The original entrances are long gone, but a later one, built in 1926 the LHPC, still stands near to the Tower of London ticket offices – though confusingly it states the original 1868 date of construction!

#london#uk#england#tunnel#subway#tube#tower#thames#river#tunnelling shield#engineering#tracks#rails#steam engine#pedestrian#walkway#crossing#hydraulic#water#cables#mains#history#travel#lundene#londinium

31 notes

·

View notes

Text

1 note

·

View note

Text

Nickel Alloy Tubes

Nickel Alloy Tubes

KRYSTAL GLOBAL ENGINEERING LIMITED (Formally Known as Krystal Steel Manufacturing Private Limited) is a Stainless Steel company with the vision to be the Leader from INDIA in Stainless and Nickel Alloy Tubes with success based on Operational Excellence and Superlative Services.

We are dedicated to help our customers gain a competitive advantage by supplying a wide range of products such as Tubes, Pipes, U Tubes, Coil Formed Tubes.

KRYSTAL has well established “State of Art” facilitates with continuous enhancement of the product and services to serve the customers across the globe.

Tap here to know more about: https://krystalgeltd.com

#Bright Annealed tubes#Buy Seamless Tubes and Pipes#capillary tubes#Heat Exchanger Tubes Manufacturer#Inconel alloy#Instrumentation Tube#Seamless Tube Suppliers#Seamless Heat Exchanger Tube#Hydraulic Tubes Manufacturer#Manufacturer of Instrumentation Tubes#Manufacturer of Seamless tubes & Pipes#Manufacturer Heat Exchanger Tubes#Manufacturer of Stainless Steel Pipe#Manufacturer of Stainless Steel Tube and Pipe#Manufacturer of Stainless Steel Tubes#Monel alloy#Nickel Alloy Tubes#seamless pipe manufacturer#stainless steel bright annealed tubes manufacturers#stainless steel manufacturer in india#Stainless Steel Pipe manufacturers in India#Stainless Steel Pipe Manufacturing Company In Vadodara#Stainless Steel Seamless Pipes#stainless steel seamless tubes

0 notes

Text

What are tube fittings used for?

Tube fittings are an essential component in various industries, including manufacturing, construction, and plumbing. They are used to connect, control, and redirect the flow of liquids and gases in a safe and efficient manner. In this blog post, we will explore the importance of tube fittings, their applications, and the role of a tube fittings manufacturer in ensuring quality and reliability.

Chapter 1: The Basics of Tube Fittings

Tube fittings are mechanical components used to connect, terminate, control, or change the direction of tubing in a fluid system. They are commonly made from materials such as stainless steel, brass, or plastic, and come in various shapes and sizes to accommodate different tubing dimensions and pressure requirements. Some of the most common types of tube fittings include compression fittings, push-to-connect fittings, and flare fittings.

Chapter 2: Applications of Tube Fittings

Tube fittings are used in a wide range of industries and applications. In the manufacturing industry, they are used to connect hydraulic and pneumatic systems, while in the construction industry, they are used in plumbing and HVAC systems. Tube fittings are also commonly found in automotive, aerospace, and marine applications, where they play a crucial role in ensuring the safe and efficient transfer of fluids and gases.

In the oil and gas industry, tube fittings are used for connecting pipelines and for controlling the flow of fluids and gases. They are also used in the chemical industry for transporting corrosive and hazardous materials. In the food and beverage industry, tube fittings are used for connecting pipes and hoses in processing and packaging equipment.

Tube fittings come in various materials such as brass, stainless steel, and plastic, each with their own unique properties and benefits. For example, brass fittings are commonly used in low-pressure applications because of their affordability and corrosion resistance, while stainless steel fittings are preferred for high-pressure and high-temperature applications because of their strength and durability.

Tube fittings also come in different types, such as compression fittings, flare fittings, and push-to-connect fittings. Compression fittings are used for connecting pipes and tubes that have different diameters, while flare fittings are used for connecting pipes and tubes that have the same diameter but require a secure and leak-proof connection. Push-to-connect fittings, on the other hand, are designed for quick and easy installation without the need for tools or special skills.

Chapter 3: The Role of a Tube Fittings Manufacturer

A reputable tube fittings manufacturer plays a critical role in ensuring the quality and reliability of tube fittings. They are responsible for designing, testing, and producing tube fittings that meet industry standards and regulations. A reliable manufacturer will also provide technical support and customization options to meet the specific needs of their customers.

ConclusionIn conclusion, tube fittings are an essential component in various industries, and they play a crucial role in ensuring the safe and efficient transfer of fluids and gases. A reputable tube fittings manufacturer is essential in guaranteeing the quality and reliability of these components. Whether you are in the manufacturing, construction, or any other industry that relies on fluid systems, it is important to understand the importance of tube fittings and to work with a trusted manufacturer like Instrumxx Industries, to meet your specific needs

0 notes

Text

Leading Manufacturer of Stainless Steel Coils and Sheets: Grace Bao Steel Industry

Grace Bao Steel Industry is acknowledged as a manufacturer, exporter & supplier of Stainless-Steel Coils, Sheets, and Strips available in a variety of grades, materials, and finishes, in metric and inch sizes. Our high-quality Stainless-Steel Coil is well-known for its precision and long-lasting durability. Because of their thermodynamic properties, electromagnetic properties, and mechanical properties, Stainless Steel Coils are in high demand in the market.

https://gracebaosteel.com/stainless-steel-coils-sheets/

#Stainless Steel Coils Manufacturer in California#Stainless Steel Coils US#Stainless Steel Coils and Sheets#Alloy Steel bar#Dom Tubes#precision steel tubes#hydraulic tubes#Stainless steel pipe#Stainless steel tube#Stainless-Steel Seamless Tubes#Steel Seamless Pipe#Carbon steel pipe and tubes#CS Seamless Pipes#Alloy Steel Pipes#duplex and super duplex steel#galvanized pipes and tubes#Stainless steel coils and sheet#Carbon steel coils and sheets#Stainless steel bar#carbon steel bar#alloy steel bar

0 notes

Text

#Hydraulic Hoses#PTFE Hoses#PTFE Tubes#Convoluted PTFE Hose Manufacturers#Convoluted Hoses#High Pressure PTFE Hose#Threaded Pipe Connector#Threaded Connector#SS Wire Braided Convoluted Hoses#PTFE Hoses Aerospace#PTFE Plain Hoses#Two Axis Pipe Connector#Fixed Flange Connector#Copper Ended Connector#Dash 2 PTFE Hoses

1 note

·

View note

Text

What is a hydraulic pipe clamp?

In the world of hydraulic systems, where precision and reliability are paramount, the choice of components can make all the difference. One such crucial component is the hydraulic pipe clamp.

These unassuming devices play a pivotal role in ensuring the smooth and efficient functioning of hydraulic systems across various industries. In this extensive guide, we'll delve into the world of hydraulic pipe clamps, their types, applications, and why they are indispensable in the world of hydraulics.

What are Hydraulic Pipe Clamps?

Hydraulic pipe clamps, often referred to simply as pipe clamps, are mechanical devices used to secure and support hydraulic pipes and tubes within a hydraulic system. These clamps are designed to provide stability and protection to pipes, ensuring they remain in place even under extreme pressure and vibrations.

Types of Hydraulic Pipe Clamps

There are several types of hydraulic pipe clamps available in the market, each designed for specific purposes. Let's explore some of the most common types:

Standard Pipe Clamps: These are the most basic and widely used hydraulic pipe clamps. They are designed to secure pipes in a fixed position, preventing movement or vibration.

Heavy-Duty Pipe Clamps: As the name suggests, these clamps are built to withstand high levels of stress and pressure, making them ideal for rugged applications.

Twin Pipe Clamps: Twin pipe clamps are used to secure two parallel pipes, offering a convenient solution for installations where multiple pipes need to be supported.

Stacking Pipe Clamps: Stacking clamps allow for the mounting of multiple pipes on top of each other, conserving space and providing an organized setup.

Rail Pipe Clamps: These clamps are designed for mounting pipes on rails or beams, making them ideal for overhead or wall-mounted hydraulic systems.

Applications of Hydraulic Pipe Clamps

Hydraulic pipe clamps find application across a wide range of industries due to their versatility and reliability. Here are some of the key sectors where these clamps are essential:

Hydraulic Machinery: Hydraulic machinery relies on the precise positioning of pipes and tubes. Pipe clamps ensure that the hydraulic fluid is directed correctly, preventing leaks or failures.

Aerospace Industry: In the aerospace industry, where safety is paramount, hydraulic pipe clamps play a crucial role in securing vital hydraulic systems on aircraft.

Automotive Sector: From brake systems to power steering, hydraulic pipe clamps are used extensively in the automotive sector to keep hydraulic lines in place and prevent damage.

Construction and Infrastructure: In construction, hydraulic systems are frequently used in heavy machinery like cranes and excavators. Pipe clamps help maintain the integrity of these systems.

Marine Industry: In the challenging marine environment, hydraulic pipe clamps are essential for keeping hydraulic lines secure and resistant to corrosion.

The Advantages of Hydraulic Pipe Clamps

Hydraulic pipe clamps offer numerous advantages that make them an indispensable component in various applications. Some of the key benefits include:

Secure Mounting: These clamps provide a robust and secure means of mounting hydraulic pipes, preventing any unintended movement or vibration that could lead to system failure.

Reduced Wear and Tear: By minimizing movement and friction, pipe clamps help extend the lifespan of hydraulic pipes and tubes, reducing the need for frequent replacements.

Vibration Dampening: Hydraulic systems often generate substantial vibrations. Pipe clamps absorb these vibrations, protecting the system and the surrounding components.

Enhanced Safety: The secure positioning of hydraulic pipes with clamps ensures that there are no dangerous leaks or ruptures that could compromise the safety of the system and those working with it.

Selecting the Right Hydraulic Pipe Clamp

Choosing the right hydraulic pipe clamp for your specific application is crucial. Several factors need to be considered during the selection process:

Material: Hydraulic pipe clamps are available in various materials, including steel, stainless steel, and thermoplastic. The choice of material depends on factors like corrosion resistance and load capacity.

Size: The size of the pipe or tube to be clamped is a critical consideration. It's essential to choose a clamp that fits the diameter of the pipe snugly.

Operating Conditions: Consider the operating conditions of your hydraulic system, including temperature, pressure, and exposure to chemicals. Ensure the selected clamp can withstand these conditions.

Bu-LOK: Your Trusted Partner in Hydraulic Pipe Clamps

When it comes to hydraulic pipe clamps, one name stands out in the industry as a trusted manufacturer and supplier: Bu-LOK. Bu-LOK is renowned for its commitment to providing top-quality hydraulic components, including pipe clamps, pipe fittings, flanges, fasteners, plates, and round bars. Here's why Bu-LOK is your go-to source for hydraulic solutions:

Stainless Steel Expertise: Bu-LOK specializes in manufacturing stainless steel components, ensuring high corrosion resistance and durability, even in challenging environments.

Diverse Product Range: Whether you need pipe clamps, fittings, flanges, or fasteners, Bu-LOK offers a comprehensive product range, making it a one-stop shop for all your hydraulic system needs.

Quality Assurance: Bu-LOK is dedicated to delivering top-notch quality in all its products. Each component undergoes rigorous testing and quality control measures to ensure it meets industry standards.

Competitive Pricing: Bu-LOK's commitment to providing cost-effective solutions makes it an attractive choice for businesses of all sizes.

Conclusion

In the world of hydraulic systems, the significance of hydraulic pipe clamps cannot be overstated. These unassuming components play a pivotal role in ensuring the smooth and efficient operation of hydraulic systems in various industries. Whether you are in aerospace, automotive, construction, or any other sector that relies on hydraulics, choosing the right hydraulic pipe clamp is paramount.

When it comes to quality, reliability, and a diverse range of hydraulic components, Bu-LOK is the name to trust. As one of the leading and most prominent manufacturers and suppliers of stainless steel, high nickel steel, alloy steel, carbon steel components, Bu-LOK is dedicated to delivering top-quality products that meet the highest industry standards. From pipe clamps to fittings, flanges, fasteners, plates, and round bars, Bu-LOK has your hydraulic needs covered.

Contact Bu-LOK today for a quotation and further details to experience the benefits of their high-quality hydraulic pipe clamps and other hydraulic solutions. Your hydraulic systems deserve nothing but the best, and Bu-LOK delivers exactly that.

0 notes

Text

Mechanical Tests for Hydraulic Seamless Tubes and Pipes

#hydraulicpipe#hydraulic#hydraulic seamless tubes#annealedhydraulictube#highpressureline#highpressuretube#hydraulicpipeline#hydraulicseamlesspipe

0 notes

Text

Ensure Workplace Safety with Safety Clamp Type T

Precision is built into the Safety Clamp Type C. Its engineering enables accurate and secure fastening, improving operating safety. This clamp is perfect for workflows that need accuracy and reliability.

#hydraulic power tongs#sucker rod power tongs#tubing power tongs#casing power tongs#drill pipe power tongs

2 notes

·

View notes

Text

G8-R3

STAR WARS EPISODE I: The Phantom Menace 00:25:48

#Star Wars#Episode I#The Phantom Menace#Naboo Royal Starship#droid hold#G8-R3#R5 astromech droid#astromech recharge cradle#astromech droid#hydraulic arm shaft#photoreceptor#systems linkage and repair arm panels#acoustic signaller#system ventilation#power recharge coupling#interference pulse stabilizers#service lift tube

1 note

·

View note