#3d printing simulation software

Explore tagged Tumblr posts

Text

#quantumcomputing#3d printing#cfd#additive manufacturing#cfd simulation#hvac services#3d printing simulation software#simulation#technology#aerospace engineering#additive manufacturing software#3d sculpting#blender#ai generated#artificial intelligence

0 notes

Text

Simulation Assessment Model

Randomized Orb Value: G2Z4E11

Projection Test Type: C

History Proposal:

On the train, denizens take many forms. Dogs, rock people, paper cranes, giant pig babies, and more. Although all of them are artificial beings projected through orbs on a perpetual train, it is an unfortunate fact that denizens only live a "normal lifespan" for whatever they are created as. Corgis have an average lifespan of 14 years, and that is about as long as Atticus will live for example.

The Cat, however, is an outlier.

Well over a hundred and fifty years old - in human years, not cat years - her unusual longevity shows no signs of stopping anytime soon. While no official statements nor more episodes have been made to help shed light on the mystery, I would like to preface my theory with a bit of context:

One of the oldest traditions in software is what is known as a "Hello, World!" program. In total, this program instructs a computer to display a message similar to the titular "Hello, World!" Simple and succinct, it is one of if not the first program students of new programming languages learn how to code. And with its simplicity, "Hello, World!" can be used to ensure the code compilation software has been installed properly and that the operator is using it correctly.

Similarly famous and historic is the "Utah teapot." Coming from the world of 3D modeling and computer graphics, it possess features familiar to many simple teapots: a spout, a handle, and a curvy shape. Lacking a need for surface textures, capable of casting shadows on itself, and possessing a decently complex yet easy to make model, it has been regarded a "perfect self contained object to test the creation of three-dimensional images." Even with today's advanced technology, it is still regarded as an effective standard reference model for beginners and experimenters alike.

Moving into the burgeoning field of 3D printing, one can find "Benchy," as well as its upcoming replacement "Boaty." Respectively a boat and a bench, these two unofficial models have been growing in popularity over the years, often finding themselves among many people's first prints. Either on a newly set up 3D printer, or with a new 3D printing material one hasn't used before. Whether through measuring a Benchy/Boaty's dimensional accuracy, checking its surface quality, and observing other attributes like overhangs (or the lack thereof), they are shaping up to become the next "Hello, World!" and Utah teapot.

In other words, the latest in a line of near ubiquitous benchmark tests for assessing the performance of a system upon first use.

With that established, picture a staircase where each step is a level of technology. From mere software to virtual models to physical printed objects, a few more steps is all it takes to climb aboard the Train. Memory tapes that hold an immersive snapshot of a person's mindscape. Wormholes that can disintegrate and reassemble people across time and space. An unknown level of influence over an entire parallel reality of reflections with all its existentially terrifying implications.

Orb-generated pocket dimension environments and so many intelligent and thinking people as denizens.

Maybe the reason the Cat doesn't have a normal lifespan like other denizens is because she isn't a 'proper' denizen in the first place. After all, the aforementioned benchmark tests lack the extra bells and features the systems they evaluate are capable of making when pushed. The original Utah teapot model didn't even have a base. So it's not hard to imagine the train's denizen creation system might have forgone extraneous programming like an artificial 'normal lifespan' limitation while performing startup checks, way back when the train first came online.

Thus, my proposal is that the Cat had started out as a benchmark projection for non-lifespan-related test requirements. Maybe her template just lacks the "normal lifespan" programming, and/or the "normal lifespan" programming was tested with a different, unfortunate benchmark projection. Either way, she served her vital system evaluation purpose and then got set aside as a no-longer critical part of the train. From that rock bottom, she could only go up from there. With a life as long as hers and having seen as much of the train as she has, there's so many potential answers for how she eventually transformed into the French con artist kitty we know today.

Like, for example, her collecting of many 'things.' It may seem like that's simply the norm she’s settled into by the present, but Simon's comment about how "she's collecting again" suggests it is actually her slipping into a bad old habit. As though rampant collecting is a coping mechanism for something. While the guilt from leaving Simon behind would easily explain such regression in behavior, therein lies the question of where said behavior came from in the first place.

If you ask me, I cannot help but look at the train of thought that started this all: Samantha lacking the programmed lifespan denizens have due to being a test object. Aka an immortal amongst denizens who will one day die, passengers who either die on the train or eventually disembark, and even car environments that are affected by time in ways she isn't.

Certainly makes one think about her having once gotten close enough with Simon for her to tell him to call her "Samantha," but now emphasizes to everyone she meets to merely know her as "THE Cat"...

#infinity train#infinity train theory#infinity train headcanons#it#it theory#it headcanons#the cat#infinity train the cat#infinity train samantha#the orb value and test parts are just fun little flavor text I made up#though the fun part is contemplating a few backstory options:#if there are others like her that she knows/have history with#Samantha being the only one to ever be created#or if she's one of/the last of her kind after the others met a terrible fate

8 notes

·

View notes

Text

Top 8 Applications of 3D Printing in Medical Industry

3D printing technology, with its highly customizable, responsive and material-saving features, is triggering profound changes in the medical field. Especially in the application of medical models, 3D printing technology shows unparalleled advantages and potential.

Furthermore, 3D printing technology, as an emerging additive manufacturing technology, has made breakthroughs in its application in the medical field in recent years. The application of 3D printing technology in the medical field is becoming more and more widespread. Through the layer-by-layer stacking of digital models, a variety of medical devices, prosthetics, orthotics and other aids, and even human organs, can be accurately printed.

1.Surgical preview model

With 3D printing technology, doctors can create surgical preview models to help them simulate operations before surgery, improving accuracy and safety.

It is important for medical workers to conduct preoperative planning for risky and difficult procedures. In the previous surgical preview process, medical workers often need to obtain the patient's data through CT, magnetic resonance imaging (MRI) and other imaging equipment, and then the two-dimensional medical image using software to convert into realistic three-dimensional data. Today, medical workers can use devices such as 3D printers to print 3D models directly. In this way, it not only can assist the doctor to carry out accurate surgical planning, improve the success rate of surgery, but also to facilitate the communication and exchange between medical workers and patients on the surgical program plan.

2.Surgical guide

Surgical guides can help the surgeon to accurately position and operate during surgery, reducing surgical errors and improving surgical outcomes.

As an auxiliary surgical tool during surgery, surgical guides can help medical workers to accurately implement surgical programmes. Currently, the types of surgical guides have included joint guides, spinal guides, oral implant guides, etc. With the help of 3D printed surgical guides, firstly, the 3D scanning technology can produce three-dimensional data on the patient's affected area, which allows the doctor to obtain the most realistic information, so as to better plan the surgery. Secondly, while making up for the shortcomings of the traditional surgical guide manufacturing process, the size and shape of the guide can also be adjusted as needed.In this way, different patients can have a guide plate that meets their real needs.

3.Dental applications

3D printing technology is also widely used in the field of dentistry to print personalized trays, moulds, etc., to help patients have better dental treatment.

The application of 3D printing in the dental field mainly focuses on the design and production of metal teeth, invisible braces, etc. The emergence of cutting-edge technology of 3D printing creates more possibilities for those who need orthodontic treatment to achieve personalized and customized braces. At different stages of orthodontic treatment, orthodontists need different sets of braces. With the help of 3D printing to create multiple sets of braces needed for orthodontic treatment, it not only helps the healthy development of teeth, but also reduces the cost of braces production. The significance of these digital technologies is that they are gradually making it less necessary for doctors to make models, dentures, etc. by hand, and returning more of their efforts to the diagnosis of oral diseases and the performance of oral surgery itself.

4.Rehabilitation medical equipment

Through 3D printing technology, a variety of rehabilitation medical devices, such as prosthetics and orthotics, can be created to help patients regain function.

The real value of 3D printing for orthopaedic insoles, bionic hands, hearing aids and other rehabilitation devices is not only to achieve accurate customization, but also to allow accurate and efficient digital manufacturing technology to replace the traditional production methods, reducing the cost of individual customized rehabilitation medical devices and shortening the production cycle. 3D printing process is diversified, and there is a wide range of 3D printing materials. SLA light-curing 3D printing technology has the advantage of being able to provide the most efficient and cost-effective 3D printing technology. SLA light-curing 3D printing technology is widely used in rapid prototyping by the medical device industry due to its advantages of fast processing speed, high precision, good surface quality of photosensitive resin material moulding and moderate cost.

5.Medical Equipment Cases

3D printing technology can also be used to create a variety of medical devices, such as surgical instruments and medical equipment, to improve the personalization and accuracy of medical devices.

Take the example of 3D printing for mass customized production in the hearing aid shell industry. In the traditional way, injection moulds need to be made from a model of the patient's ear canal. The final shape of the hearing aid is obtained by drilling sound holes and manually processing the plastic product. If a mistake is made during the process, the mould needs to be recreated. The process of making a hearing aid using a 3D printer, on the other hand, begins with the design of a silicone mould or impression of the patient's ear canal, a step that is done using a 3D scanner. CAD software is then used to convert the scanned data into a design file that can be read by the 3D printer. The designer can then use the software to modify the 3D image and create the final product shape.

6.Precision replication and personalization

3D printing technology is able to accurately restore a patient's anatomy and produce full-size, high-fidelity medical models based on the patient's CT, MRI and other imaging data. These models not only have extremely high geometric accuracy and surface quality, but also reflect the unique physiological characteristics of the patient, providing doctors with real and reliable references.

7.Teaching and training

3D printed medical models also play an important role in medical education and training. By printing out models of various typical cases, medical students can perform practical operations in a simulated surgical environment to enhance their surgical skills and resilience. At the same time, these models can also be used as teaching tools to help students better understand human anatomy and disease principles.

8.Scientific research and experimentation

In the field of medical research, 3D printed medical models also have important applications. Researchers can use these models to conduct experimental studies such as drug screening and biomechanical testing to explore new treatment methods and technologies. In addition, by printing tissue or organ models with specific physiological functions, they can also provide strong support for research in cutting-edge fields such as organ transplantation and regenerative medicine.

In summary, 3D printing technology has a wide and far-reaching significance in the application of medical models. It not only improves the accuracy and efficiency of medical services, but also promotes the innovative development of medical education, research and clinical practice. With the continuous progress of technology and the expansion of application scope, we have reason to believe that 3D printing will play a more important role in the future medical field.

#3d printing#3d printing services#3d printed#additive manufacturing#3d print#medical device machining#medical 3d printing#3d printed parts#3d printing materials market#3d printing market share

4 notes

·

View notes

Text

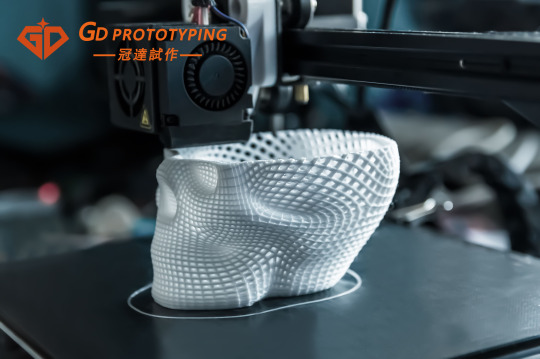

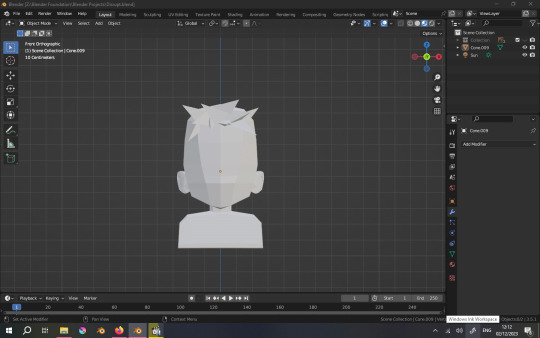

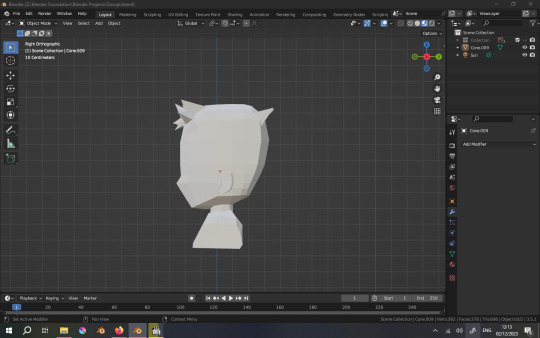

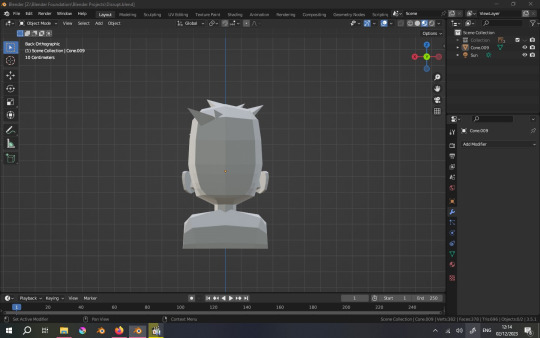

Disrupt Project Week 8 - 3D Printing Workshop with Jose Berna Moya

Above: The finished animation.

For week eight I ended up signing up for the 3D Printing Workshop, even though I didn't have much in the way of ideas on how to incorporate that into my disrupt project. Basically like always I kinda just signed up for whatever workshop was still available Sunday night.

Our tutor Jose ran us through the basics of 3D printing before helping us brainstorm on how we might leverage that process for our projects. This was a huge help to me and I really have to give Jose credit for going above and beyond to help us out.

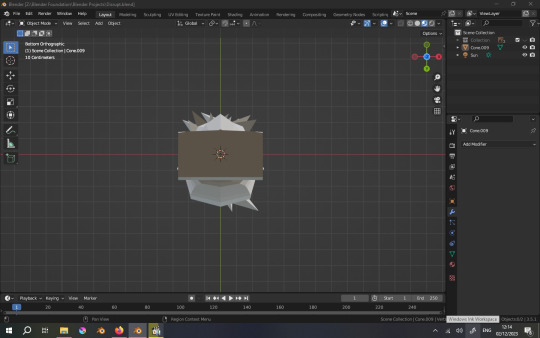

The plan he helped me formulate was to model a 3D version of my clay man in Blender, figure out how to run a destruction simulation on said model, and then 3D print a few select frames of the resulting animation. Walk in the park...

Above: The modelling process.

I engaged in a battle of attrition with Blender over the summer and came out the other side as someone who arguably knows how to use the software, arguably...

In translating the design I decided to use a character design by Katsuyoshi Nakatsuru as a base for the model. I thought the funny square heads he did for the Digimon anime would read well in a low poly style. I wanted this to be a younger version of my much older looking clay sculpture. I thought basing the model off a favourite childhood series of mine added real substance to this. As you can see in the final render I did still end up giving him a beard and moustache in the end.

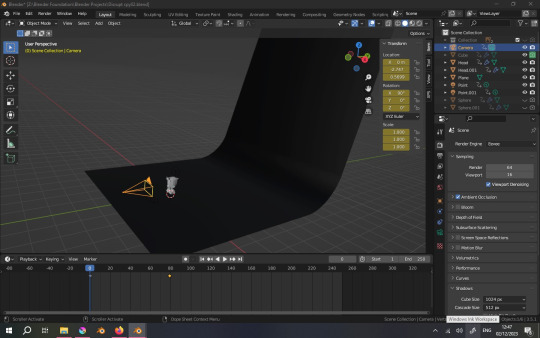

Above: The animating process.

With the model done, the next step was figuring out a good destruction simulation and the animating that. I was familiar with modelling in Blender but this part was all new to me. Luckily there's a great online community around this kind of stuff and finding helpful tutorials on Youtube was 90% of the work.

youtube

youtube

youtube

youtube

Above: The top two vids are what I watched for this project, and the bottom two are what I used to learn Blender over the summer.

All told this took a lot less time than I thought it might. This project isn't over yet though, as I still need to actually 3D print a couple of frames. I'll update my Tumblr again when I get to that, for now I just felt the need to explain what I've been up to over this week. A lot of my projects are nearing completion now, it's just that the timeframe of them doesn't always fit neatly into the weekly workshop format. The clay man for instance...

Above: Soon...

11 notes

·

View notes

Text

Mastering Realism: A Comprehensive Guide to Creating, Texturing, Animating, and Rendering in Autodesk Maya

Autodesk Maya stands as a premier 3D computer graphics software that has been an industry standard for years. Its versatile capabilities have allowed artists, animators, and designers to bring their imagination to life in breathtaking detail. In this blog post, we will delve into the world of Maya, exploring how to create realistic models, texture them, animate scenes, and achieve stunning renders that captivate audiences.

Creating Realistic Models

The foundation of any 3D project in Maya is the creation of lifelike models. With its robust set of modeling tools, Maya empowers creators to shape their ideas into three-dimensional objects that mimic real-world counterparts. Whether it's character models, architectural designs, or intricate props, Maya's toolkit offers both polygonal and NURBS-based modeling techniques to suit various project needs.

Polygonal Modeling: This method involves building models by connecting vertices, edges, and faces to form complex shapes. Maya's polygon modeling tools provide precision and control, enabling you to sculpt organic or mechanical structures with ease.

NURBS Modeling: Non-Uniform Rational B-Splines (NURBS) offer a mathematical approach to modeling, which is particularly suited for creating smooth and curvilinear surfaces. This technique is often used for vehicles, product design, and architectural elements.

Texturing for Realism

Texturing breathes life into models, giving them the appearance of materials and surfaces found in the real world. Maya offers an array of tools and workflows for applying textures to models, simulating materials like wood, metal, fabric, and skin.

UV Mapping: Properly unwrapping a model's UVs is essential for applying textures accurately. Maya provides tools for efficient UV unwrapping, allowing you to paint or apply textures in 2D editing software before bringing them back into Maya.

Shader Networks: Creating realistic materials involves combining various texture maps within shader networks. Maya's Hypershade editor makes it simple to connect textures to shaders and simulate intricate material properties like roughness, reflectivity, and translucency.

Animating with Depth

Maya's animation capabilities open the door to dynamic storytelling and captivating visual experiences. From character animations to complex motion graphics, the animation tools in Maya cater to a wide range of creative ambitions.

Keyframing: Keyframing is the foundation of animation, allowing you to set specific poses and positions for objects over time. Maya's Graph Editor provides granular control over keyframes, easing in and out of motions for a more organic feel.

Rigging: Rigging involves creating a skeleton or structure within a model, allowing it to be manipulated like a puppet. Maya's robust rigging tools facilitate the creation of intricate character rigs, enabling movements that closely resemble real-life actions.

Rendering Brilliance

The final step in the 3D creation process is rendering—transforming your 3D scene into a stunning 2D image or animation. Maya's rendering capabilities are powered by Arnold, a sophisticated rendering engine known for its realism and efficiency.

Arnold Renderer: Arnold provides a physically accurate rendering process, simulating lighting, shadows, reflections, and global illumination. Its integration with Maya makes achieving photorealistic results more accessible than ever.

Render Settings: Maya's Render Settings give you full control over image resolution, quality, and effects. You can adjust settings to match your project's requirements, whether you're rendering for print, web, or animation.

Conclusion

Autodesk Maya has long been an essential tool for artists and creators seeking to bring their visions to life with unparalleled realism. With its powerful modeling, texturing, animation, and rendering capabilities, Maya empowers users to create lifelike scenes and characters that resonate with audiences. By mastering these techniques, you can unlock a world of creative possibilities and take your projects to new heights of visual excellence. Whether you're a seasoned professional or just starting on your 3D journey, Maya remains a valuable companion in your pursuit of digital artistry.

3 notes

·

View notes

Text

Why Just Watch Animation When You Can Create It? Join Reliance Animation Academy for the #1 Animation Course in Ambernath!

Reliance Animation Academy introduces its flagship animation and graphic design training programs in Ambernath, crafted to meet the aspirations of students passionate about the visual arts. Our newly launched animation course in Ambernath is more than a conventional curriculum; it's a career launchpad. From VFX artistry to motion graphics, our courses bridge the gap between academic training and industry needs.

We believe that every creative student in Ambernath deserves world-class animation education without having to relocate to distant cities. With industry-standard infrastructure, experienced faculty, and mentorship-backed learning, students can now access future-ready creative careers from the comfort of their hometown.

Why Choose an Animation or Graphic Course in Ambernath?

Local Access to Global Education

Reliance Animation Academy in Ambernath has democratized access to top-tier design and animation education. Students in Ambernath no longer have to commute to Mumbai or Pune to gain professional creative training. With Reliance's well-curated curriculum, they receive the same quality of instruction and exposure as students from metropolitan areas.

Skill-Based Curriculum Over Theoretical Learning

Unlike traditional education models that focus heavily on theory, our animation and graphic courses are rooted in skill development. Every topic is taught with a hands-on approach that simulates real-world project requirements. This ensures students can build a solid portfolio that speaks to employers.

Career-Centric Training with Placement Assistance

All our programs are placement-oriented. That means we focus not just on teaching you software but preparing you for the real job market. We help you create an industry-ready portfolio, connect with hiring studios, and support you with internships and job interviews.

What You’ll Learn in Our Animation Course in Ambernath

The animation course at Reliance Animation Academy Ambernath covers the full spectrum of professional skills required to work in the animation and VFX industry. Here's a breakdown of what students will master:

Core Modules in Animation Training

Fundamentals of Animation

Understanding movement, timing, spacing, and squash & stretch principles form the backbone of quality animation. Students begin with hand-drawn frame-by-frame animation to understand classical techniques before transitioning into digital tools.

Storyboarding & Layout Design

Students learn how to translate stories into visual panels using storytelling logic, camera angles, scene transitions, and mood boards. This skill is vital for pre-production roles in studios.

2D Animation Techniques

Training includes digital 2D animation using tools like Adobe Animate. Character design, rigging, and lip-sync animation techniques are explored.

3D Animation with Autodesk Maya

One of the most critical parts of the course, students learn to animate characters and environments in 3D. This includes modeling, texturing, lighting, rigging, and rendering.

Visual Effects (VFX)

Learn the fundamentals of compositing, green screen effects, particle dynamics, and motion tracking using software like Adobe After Effects and Nuke.

Motion Graphics & Title Animation

Create animated logos, explainers, and dynamic titles for advertising and entertainment.

Editing & Rendering Techniques

Students are trained in non-linear editing systems like Adobe Premiere Pro, integrating audio, effects, and animated elements into a final cinematic presentation.

Software Taught in Animation Course

Adobe Animate

Adobe After Effects

Autodesk Maya

Blender

Adobe Premiere Pro

Photoshop (for texture and matte painting)

Graphic Course in Ambernath – Visual Communication for the Digital Era

Our graphic design course in Ambernath is curated to prepare students for careers in visual branding, print media, digital advertising, and UI/UX design. The program ensures that every student walks out with a portfolio capable of landing freelance gigs or full-time roles.

Core Modules in Graphic Design Training

Design Principles & Color Theory

Students begin by understanding the psychology of colors, layout symmetry, visual hierarchy, and design alignment to create balanced, engaging compositions.

Typography & Font Structuring

Learn to manipulate fonts for branding, readability, and creativity. Includes kerning, leading, and font pairing strategies.

Branding & Logo Design

Students will create complete brand identity systems, including logo design, brand color palettes, taglines, and mockups.

Layout Design for Print Media

This includes magazine layout, brochure design, pamphlet creation, and business cards. Learn industry measurements, bleed settings, and printing specs.

UI/UX Design Foundations

Introductory-level wireframing, user interface creation, and responsive web design mockups using Adobe XD and Figma.

Advertising Design

Students create ad campaigns, banners, social media graphics, product labels, and packaging designs.

Tools & Software Used in Graphic Course

Adobe Photoshop

Adobe Illustrator

CorelDRAW

Adobe InDesign

Figma

Canva (for beginners and social media marketers)

Reliance Animation Academy Ambernath – Key Features That Set Us Apart

National Brand Legacy

Backed by the larger Reliance Animation brand, our Ambernath center follows the same curriculum and quality protocols as our Mumbai flagship centers.

Learning by Doing

Our classes are designed as practical workshops. Assignments mimic real client briefs, teaching students how to meet deadlines, follow client feedback, and deliver professional-level work.

Flexible Class Schedules

We offer morning, afternoon, and weekend batches so students and working professionals can choose timings that suit them best.

Faculty with Industry Background

Our trainers have worked on animation films, ad campaigns, VFX pipelines, and real-world branding projects. They mentor students through every creative decision.

Career Opportunities After Animation Course in Ambernath

Students completing the animation course have access to the following career roles:

3D Animator

VFX Compositor

Character Designer

Storyboard Artist

Lighting & Rigging Artist

Motion Graphics Designer

Game Asset Developer

These roles are in demand in production studios, gaming companies, advertising firms, OTT platforms, and even e-learning firms.

Career Path After Graphic Course in Ambernath

Graphic design graduates have multiple career options:

Branding Specialist

Social Media Designer

UI/UX Intern

Packaging Designer

Freelance Illustrator

Digital Marketing Designer

Visual Storyteller for content creators

With the growing demand for visual content across startups, agencies, and influencers, graphic designers are no longer behind the scenes—they're leading campaigns.

Course Duration & Training Format

Animation Course

Duration: 12 Months

Mode: In-Campus

Includes: Project-based assessments, final portfolio showcase, studio simulation

Graphic Design Course

Duration: 6 to 9 Months (depending on specialization)

Mode: In-Campus

Includes: Real brand project work, client briefs, and mock campaigns

Tools, Labs & Infrastructure

Our center in Ambernath is equipped with high-end computers, licensed Adobe & Autodesk software, drawing tablets, green screens, and audio-visual equipment. Students work in an environment that replicates a production studio setting.

Internship & Placement Support

Reliance Animation Academy Ambernath offers dedicated placement assistance:

Resume-building workshops

Mock interviews

Direct interviews with partner studios

Freelance project guidance

Internship support with local and national agencies

Placement tie-ups include animation studios, advertising firms, print houses, and digital agencies.

Fee Structure & Financial Support

Flexible EMI payment plans

Group joining discounts

Scholarship options for early birds and top-performing students

Government-approved skill development loans (subject to availability)

Admission Open Now – Book Your Free Counseling Session

We offer a personalized career guidance session for every prospective student. Walk in to understand your best-fit course, explore demo classes, and interact with faculty members.

Contact Details – Reliance Animation Academy Ambernath

Address: Shop No.302, Sai Siddhi Apartment, Plot No.20, Opp. Shree Rath Hotel, Near Shivaji Chowk, Ambernath East, Kansai Section, Ambernath, Maharashtra 421501 Phone: 090671 68999 Website: https://relianceanimationambernath.com/

Conclusion: Your Creative Future Starts Here

Reliance Animation Academy in Ambernath is more than just an educational institution. It is a springboard for your creative journey into animation, visual effects, and graphic communication. With cutting-edge tools, dedicated mentors, real-world exposure, and placement support, you can build a future that merges passion with profession.

If you're looking for an animation course in Ambernath or a graphic course in Ambernath that delivers results, the journey starts with one step—a visit to Reliance Animation Academy. Enroll now and unlock the designer, animator, or visual storyteller within you.

0 notes

Text

B.Tech in Mechanical Engineering: A Timeless Branch with Limitless Possibilities

Mechanical Engineering is often referred to as the “evergreen branch” of engineering—and for good reason. It is one of the oldest and broadest disciplines, involving the design, development, manufacturing, and maintenance of mechanical systems. If you're someone who enjoys understanding how machines work and are passionate about innovation, then B.Tech in Mechanical Engineering could be the perfect course for you.

In the age of automation, robotics, and sustainable energy, mechanical engineers are playing a critical role in shaping the future. From automobiles and aerospace to energy systems and manufacturing, the scope is vast and continuously evolving.

What is B.Tech in Mechanical Engineering?

B.Tech in Mechanical Engineering is a four-year undergraduate program that provides students with a strong foundation in physics, mathematics, material science, thermodynamics, mechanics, and design principles. It blends theoretical knowledge with practical skills through laboratory work, industry projects, internships, and workshops.

Students learn to use advanced software like AutoCAD, SolidWorks, ANSYS, and MATLAB to design and analyze mechanical systems. In addition to core mechanical subjects, modern programs also include electives like robotics, artificial intelligence in manufacturing, and green energy technologies.

Why Choose Mechanical Engineering?

Mechanical engineering is ideal for students who are creative, analytical, and have a keen interest in building and improving machines or mechanical systems. Here are a few key reasons why this branch remains a top choice:

Versatile Career Options: Mechanical engineers can work in industries like automotive, aerospace, energy, HVAC, robotics, and even healthcare.

Global Demand: It is a globally recognized field with high employment potential both in India and abroad.

Gateway to Innovation: Mechanical engineers often lead innovation in product development, sustainable technologies, and automation.

Strong Earning Potential: With the right skills and experience, professionals can enjoy a lucrative career.

Career Opportunities After B.Tech in Mechanical Engineering

Graduates from B.Tech in Mechanical Engineering programs have a wide array of career paths available:

Design Engineer

Production Engineer

Quality Control Engineer

Maintenance Engineer

HVAC Engineer

CAD/CAE Analyst

Research & Development Engineer

Project Manager

Those interested in higher studies can pursue M.Tech, MBA, or specialized certifications in areas like mechatronics, 3D printing, or AI in manufacturing.

Choose the Right College: IILM College Greater Noida

For students seeking a high-quality engineering education, IILM College of Engineering and Technology, Greater Noida, stands out as a top choice. Recognized for its excellence in technical education, IILM offers a comprehensive B.Tech in Mechanical Engineering program that combines academic rigor with hands-on learning.

Here’s why IILM Greater Noida is considered a leading Mechanical Engineering College in Greater Noida:

Experienced Faculty: Learn from industry experts and PhD holders.

State-of-the-art Labs: Equipped with modern tools and simulation software.

Industry Exposure: Internships, live projects, and industrial visits.

Career Support: Strong placement cell with ties to top companies in manufacturing, automotive, and design sectors.

Skill Development: Emphasis on soft skills, leadership, and entrepreneurship.

1 note

·

View note

Text

medical devices manufacturing

Imagine a world where diagnosis, monitoring, and treatment of diseases were impossible without machines. That’s the world we would live in without medical devices manufacturing. This field is the backbone of modern healthcare, producing everything from surgical tools to smart implants.

With rising global demand, the industry has transformed significantly. One company making waves in this space is Foxxtechnologies, known for its cutting-edge manufacturing solutions tailored for the medical sector.

What is Medical Devices Manufacturing?

Simply put, it’s the process of designing, engineering, producing, and distributing devices that assist in medical treatment or diagnosis. These range from basic thermometers to complex robotic surgical systems.

Importance of the Medical Devices Industry

This industry ensures hospitals and clinics have the tools they need to save lives. It’s not just about machines — it’s about healthcare innovation, patient safety, and efficiency.

Understanding the Manufacturing Process

Research and Development (R&D)

Every great product starts with an idea. In medical devices manufacturing, R&D is where the magic begins.

Ideation and Concept Testing

Teams brainstorm, sketch, and simulate product ideas. Then, they test concepts through small trials and user feedback to determine viability.

Prototyping and Product Design

Before going to mass production, a prototype is created. This helps identify design flaws and gather early clinical feedback.

Role of CAD and 3D Modelling

Design engineers use advanced software to build detailed 3D models, helping predict performance and optimize the structure.

Materials Used in Medical Device Production

The choice of material can make or break a device.

Biocompatible Materials

Manufacturers use plastics, metals, and ceramics that are non-toxic and accepted by the human body. Titanium and medical-grade silicone are common choices.

Regulatory Standards and Certifications

You can’t just create a device and sell it — there are rules.

FDA, ISO, and CE Certifications

Medical devices must meet strict quality and safety regulations. These include FDA approvals in the U.S., CE marks in Europe, and ISO 13485 certification globally.

Key Technologies in Medical Devices Manufacturing

Automation and Robotics

Modern factories use robotics to improve precision, reduce errors, and accelerate production.

3D Printing in Medical Devices

3D printing is transforming the industry by allowing customized implants, faster prototyping, and reduced waste.

AI and IoT Integration

Smart medical devices connected through IoT can transmit real-time health data to doctors. AI helps in predictive maintenance and quality control.

Foxxtechnologies – Leading the Innovation

Overview of Foxxtechnologies

Foxxtechnologies is not your average manufacturer. They specialize in innovative, scalable, and high-quality medical device production services. With a solid reputation, they cater to both startups and large healthcare brands.

Unique Manufacturing Capabilities

Customization and Rapid Prototyping

Need a device tailored to your needs? Foxxtechnologies provides rapid prototyping, saving both time and cost in development.

Cleanroom Production Facilities

Sterility is crucial. Their ISO-class cleanrooms ensure that every product meets stringent hygiene standards.

Compliance and Quality Assurance

Foxxtechnologies doesn’t just build — they ensure every product is tested, validated, and certified according to international standards.

Trends Shaping the Future of Medical Device Manufacturing

Sustainability and Eco-Friendly Practices

As the world shifts towards greener practices, manufacturers like Foxxtechnologies are adopting recyclable materials and low-waste processes.

Smart Devices and Wearables

From fitness trackers to glucose monitors, wearable technology is booming and changing how we manage health.

Global Market Growth and Expansion

The global market for medical devices is expected to surpass $800 billion by 2030. Companies must scale fast — and smart.

Challenges in Medical Device Manufacturing

Navigating Regulations

Each country has its own rules. Global manufacturing means tackling multiple regulatory frameworks.

Ensuring Sterility and Biocompatibility

The challenge is to ensure every device is safe and performs flawlessly inside the human body.

High Costs of R&D and Manufacturing

Innovation isn’t cheap. It demands huge investments in technology, skilled labor, and compliance.

Why Choose Foxxtechnologies for Medical Device Manufacturing?

Industry Expertise and Experience

With years of hands-on experience, Foxxtechnologies knows what works and what doesn't in this highly sensitive sector.

Client-Centric Solutions

From idea to delivery, the team works closely with clients, offering end-to-end support.

Scalable and Efficient Processes

Whether it’s a batch of 100 or 10,000 units, Foxxtechnologies scales seamlessly without compromising quality.

Conclusion

Medical devices manufacturing is not just a process — it’s a commitment to healthcare, innovation, and patient safety. As technology evolves, companies like Foxxtechnologies are leading the charge by integrating cutting-edge tech, adhering to global standards, and providing client-focused solutions.

Whether you're a startup with a prototype idea or an established healthcare brand looking to expand production, Foxxtechnologies is your go-to partner in the realm of medical device manufacturing.

Email Us : [email protected]

0 notes

Text

Unlock Innovation: How Solid Edge CAD Software Can Revolutionize Your Business

In today’s competitive landscape, design and manufacturing companies are constantly seeking an edge. The ability to innovate faster, design with greater precision, and bring products to market quicker is paramount. This is where powerful CAD software becomes not just a tool, but a strategic advantage. At DDSPLM, we’re passionate about empowering businesses with the right technology. And when it comes to cutting-edge CAD solutions, Solid Edge stands out from the crowd.

What is Solid Edge CAD Software?

Solid Edge is a comprehensive and user-friendly 3D CAD (Computer-Aided Design) software that offers best-in-class capabilities for product design, simulation, manufacturing, and data management. Developed by Siemens Digital Industries Software, it’s renowned for its unique Synchronous Technology, which combines the speed and flexibility of direct modeling with the precision of parametric design.

Features:

Synchronous Technology

Generative Design

Additive Manufacturing (3D Printing) Capabilities

Cloud-Based Collaboration

Integrated Simulation Tools

Robust Assembly Design

2D Drafting & Annotation

Electromechanical Design

How Solid Edge CAD Software Can Transform Your Business:

Accelerated Product Development

Enhanced Innovation

Improved Product Quality

Reduced Costs

Seamless Collaboration

Increased Efficiency

Why Choose DDSPLM?

At DDSPLM, we’re more than just a software reseller; we’re your trusted partner in digital transformation.

Expertise

Comprehensive Support

Tailored Solutions

Commitment to Your Success

Conclusion:

In a world that demands continuous innovation, Solid Edge CAD software offers the power, flexibility, and intelligence to keep you ahead of the curve. By partnering with DDSPLM, you’re not just investing in software; you’re investing in a future of accelerated innovation, improved efficiency, and unparalleled success.

0 notes

Text

AM PravaH: 3D Printing Software By Paanduv Applications

About the case study

This document will help you run your first AM PravaH LPBF simulation for macroscale and microstructure modeling. The case study is done for a standard alloy of titanium i.e. Ti6Al4V widely used for aerospace and biomedical applications. The simulation is carried out for a multilayer, multi-track scan pattern. The process parameters for the laser are e.g. 300 W power and e.g. 1 m/s scan speed. D4 sigma or spot dia is 0.1 mm.

Exclusive features of AM PravaH include consideration of 4 phases, with no explicit formulation for recoil pressure because evaporation and recoil pressure effects are included in the vapor phase. AM PravaH takes the thermophysical properties of the 4 phases as inputs along with the process parameters such as laser power, laser scan speed, shielding gas flow angle and velocity, layer thickness, spot diameter, preheating temperature, chamber initial pressure, and substrate initial height, scan pattern, particle size distribution and number of layers. Macroscale modeling will generate the following outputs melt pool dimensions, porosity %, thermal gradients, cooling rates, and thermal cycling plots. The Microstructure module generates outputs such as grain size distribution, angular chord length distribution, misorientation angles, and Euler angles. AM PravaH leverages the amalgamation of computational modeling solvers performing multiphase macroscale modeling, microstructure modeling, and Artificial Intelligence (AI) at a unified platform.

Keywords: Additive Manufacturing, 3D printing, Meltpool dynamics, porosity, thermal gradients, cooling rate, microstructure analysis, grain size, angular chord length, 3D printing software

AM PravaH: 3D printing simulation software

Introduction

AM PravaH is a 3D printing simulation software that facilitates end-to-end solutions for Additive Manufacturing physics-based simulations. Additive Manufacturing is commonly known as 3D printing. This 3D printing software is the “World’s first all-inclusive 3D computational software for Additive Manufacturing”. This 3D printing software will be useful for new alloy development, process parameter optimization, and reducing defects. Not to confuse with other 3D printing software that only performs thermomechanical analysis and deformation, AM PravaH software offers much more.

The software capabilities in brief are as follows:

There are three modules in AM PravaH

(i) Macroscale modeling

(ii) Microstructure analysis

(iii) Integrated Deep Learning (AI) module

Relevance of the 3D printing software; AM PravaH

This 3D printing software is relevant for researchers, academicians, and industry professionals from large and small-sized companies working in the Additive Manufacturing field. Where the primary focus is to understand the in-depth physics, microstructures, and effect of process parameters on the melt pool dynamics and distribution and the root cause of the defects. If we have a much closer look at the fundamental processes of 3D printing; this is a transient, very quick, and very dynamic process, which can't be captured with the naked eye. Therefore, AM PravaH simulations can be extremely useful in understanding this part.

Based on that, one makes important decisions such as

Which alloy is better?

How do we get solidification, melting, and cooling rates information?

what are the best operating process conditions to get a defect-free and dense part

What do the microstructures look like?

What are the grain distribution and mean grain size?

What are the melt pool sizes?

How much will be the porosity %?

#3d printing simulation software#3d printing software#additive manufacturing software#additive manufacturing#3d printing#simulation software for additive manufacturing

1 note

·

View note

Text

Discover What an Architectural Visualization Company Can Do for Real Estate Marketing

An architectural visualization company plays a crucial role in the architecture, construction, and real estate industries by transforming ideas into visual realities. These companies use advanced 3D rendering technologies to create photorealistic images, animations, and walkthroughs that accurately represent future properties. Whether it’s for residential buildings, commercial complexes, or urban developments, architectural visualization helps stakeholders see the final outcome before the first brick is laid. It aids in refining designs, presenting to clients, and gaining approvals. As demand grows for high-impact visuals, hiring a professional architectural visualization company becomes essential for turning concepts into compelling digital experiences.

Bring Property Concepts to Life Before Construction Begins

One of the most valuable benefits of working with an architectural visualization company is the ability to bring property concepts to life before construction even starts. Through cutting-edge software and detailed 3D modeling, these companies turn blueprints and design ideas into lifelike representations that allow architects, developers, and clients to fully visualize the end product. This pre-construction clarity minimizes design errors, enhances collaboration, and speeds up decision-making processes. By investing in visualization services early, stakeholders can make informed adjustments, predict outcomes, and avoid costly revisions down the line. An architectural visualization company bridges imagination and execution with precision and artistry.

Help Buyers Visualize Homes with Photorealistic Renderings

An architectural visualization company empowers potential buyers to picture themselves in a space through high-quality, photorealistic renderings. These visuals go beyond floor plans and sketches by showcasing textures, lighting, materials, and furnishings that mirror real-life interiors and exteriors. For residential developments, these renderings provide emotional engagement, allowing buyers to emotionally connect with the property even before it's built. Whether used in brochures, online listings, or investor presentations, lifelike images created by a professional architectural visualization company can significantly increase interest and trust. Helping buyers visualize their future homes is a proven way to drive conversions in competitive property markets.

An Architectural Visualization Company Boosts Real Estate Sales

Hiring an architectural visualization company can dramatically boost real estate sales by transforming how properties are presented to clients and investors. In a crowded market, stunning visual content makes a listing stand out, generating more leads and faster sales. Visualization not only enhances online and print marketing materials but also helps clients envision the full potential of a space, especially for off-plan or under-construction projects. Real estate professionals leverage visualizations to tell compelling stories and simplify complex design concepts. As buying decisions increasingly rely on digital impressions, working with a top architectural visualization company can be a game-changer in sales strategy.

Enhance Listings with Immersive 3D Walkthroughs

Immersive 3D walkthroughs created by an architectural visualization company provide potential clients with a unique opportunity to explore properties virtually. These dynamic experiences simulate a realistic journey through each room, helping viewers understand scale, layout, and design intent without needing to physically visit the site. For real estate agents and developers, this technology allows global outreach and convenient viewing 24/7. Walkthroughs also cater to the modern consumer’s desire for interactive content. By enhancing listings with 3D walkthroughs, an architectural visualization company adds tremendous value, improves engagement, and increases the likelihood of buyer interest and faster decision-making.

Showcase Design Potential with Accurate Virtual Models

An architectural visualization company excels in showcasing a project’s full design potential through highly accurate virtual models. These models provide detailed insights into spatial relationships, materials, lighting dynamics, and landscaping—all of which contribute to a clear vision of the final structure. Clients, investors, and regulatory authorities can better understand complex projects through these virtual previews. They also enable architects to fine-tune concepts before physical construction begins. These models are not only functional but artistically crafted to inspire and persuade. With accuracy and aesthetics combined, architectural visualization companies help clients see what’s possible and push the boundaries of architectural innovation.

Attract Investors Through Compelling Visual Presentations

Securing investment in property developments often hinges on the strength of the presentation, and this is where an architectural visualization company adds immense value. Stunning 3D visuals, animations, and flythroughs can help convey the project’s scope, quality, and profitability in a way that spreadsheets and blueprints cannot. Investors are more likely to commit when they can clearly see the end product and its market potential. Visualization builds trust, supports financial projections, and gives investors a sense of confidence in the project’s direction. With compelling visual presentations, architectural visualization companies become essential allies in raising capital and gaining investor support.

An Architectural Visualization Company Improves Buyer Confidence

When potential buyers can see exactly what they’re purchasing through vivid and precise visuals, their confidence in the investment increases significantly. An architectural visualization company bridges the gap between imagination and reality, helping buyers understand the layout, finishes, and atmosphere of a space. Especially in pre-construction sales, high-quality visuals reduce uncertainty, answer questions, and eliminate guesswork. Buyers are more likely to proceed when they feel informed and emotionally connected to what they’re viewing. Whether it’s a custom home or a large development, architectural visualization builds trust, streamlines communication, and ensures a smoother transaction for everyone involved.

Conclusion

In today’s visually driven world, an architectural visualization company is more than a luxury—it’s a necessity for architects, developers, and real estate professionals aiming to succeed. From helping buyers envision future homes to attracting investors with stunning presentations, these companies bring immense value at every stage of a project. Through photorealistic renderings, 3D walkthroughs, and virtual models, they turn abstract ideas into immersive, impactful visuals. This not only accelerates sales but also improves collaboration, reduces costly errors, and enhances the overall client experience. Choosing the right architectural visualization company can ultimately define the success of any construction or development endeavor.

0 notes

Text

SHIMA SEIKI to exhibit at Future Fabrics Expo

Leading textile solutions provider SHIMA SEIKI MFG., LTD. of Wakayama, Japan will participate in the Future Fabrics Expo 2025 exhibition in London, England this month. Held during London Climate Action Week, Future Fabrics Expo showcases sustainably and responsibly produced materials to the textile industry, and is considered a platform for exchange of knowledge and sourcing of sustainable textiles, materials and leading innovations for fashion, home and interior brands.

SHIMA SEIKI is showcasing just such an innovation in the form of its APEXFiz subscription-based design software. APEXFiz supports the creative side of fashion from planning and design to colorway evaluation, realistic fabric simulation and 3D virtual sampling for various textiles including flat knitting, circular knitting, weaving, pile weave, socks, embroidery and print. Virtual samples are a digitized version of sample making that are accurate enough to be used effectively as prototypes, replacing physical sampling and consequently reducing time, cost and material that otherwise go to waste. Virtual samples can furthermore be used in e-commerce to gauge consumer demand before production begins, allowing production to be adjusted to optimize inventory and minimize leftover waste. Virtual sampling on APEXFiz thereby helps to realize sustainability and digitally transform the fashion supply chain.

SHIMA SEIKI will be displaying virtual sample swatches at both the Curated Textiles Area and the SHIMA SEIKI booth to demonstrate just how real and expressive digital simulations can be. Virtual sampling is not limited in use for product planning and design by visitors, but is perfect for consideration by fellow exhibitors as well, as it gives them the opportunity to consider a truly sustainable method of planning, designing and evaluating their sustainable fabrics made from sustainable materials.

Exhibition Details

NameFuture Fabrics Expo 2025DateTuesday, 24th – Wednesday, 25th June 2025Hours9:00 AM – 6:00 PMLocationMagazine London

11 Ordnance Cres, London SE10 0JH, United KingdomOrganizerThe Sustainable AngleBoothQ8D

Exhibited Technology

APEXFiz Design software subscription service

0 notes

Text

2D to 3D CAD Conversion Services: How to Choose the Right Provider

In today’s digital design and manufacturing landscape, the demand for 2D to 3D CAD conversion services is at an all-time high. Companies working with legacy blueprints, hand-drawn sketches, or outdated file formats often face difficulties modernizing their design processes. Converting 2D drawings into 3D CAD models opens the door to better visual representation, advanced simulations, seamless manufacturing, and smoother collaboration across engineering teams.

However, while the advantages are clear, choosing the right CAD conversion provider can be a complex decision. Not all providers offer the same level of accuracy, speed, or software compatibility. A small mistake in geometry or tolerancing during the conversion process could lead to expensive reworks, manufacturing defects, or failed prototypes. That’s why it’s critical to evaluate your options carefully before outsourcing this essential task.

Why 2D to 3D CAD Conversion is Critical in 2025

As digital workflows become the norm, industries are rapidly moving away from static 2D files. While 2D CAD drawings can provide basic structural details, they lack the dimensional depth needed for today’s technologies such as 3D printing, CNC machining, digital twin simulation, and AR/VR-based product demos.

With a 3D CAD model, designers and engineers can rotate, dissect, and inspect components from every angle. Assembly instructions can be derived automatically, and simulations can predict stress points or part failures before a prototype is ever built. This reduces both time-to-market and material waste, especially valuable in sectors like automotive, aerospace, consumer electronics, and industrial equipment.

Moreover, many modern design and manufacturing systems require 3D models as standard input. Whether you’re integrating with PLM (Product Lifecycle Management) platforms or handing off models to contract manufacturers, 3D CAD files are far more versatile and production-ready.

What Makes a CAD Conversion Provider Truly Reliable?

One of the first things to look for in a service provider is their technical proficiency with CAD software. Whether your team uses Revit, AutoCAD, SolidWorks, Fusion 360, or CATIA, the provider should be familiar with both your input and desired output file formats. It’s also important they understand not just the software commands, but design logic, how different components interact within an assembly, or how part tolerances affect final performance.

Equally important is the provider’s ability to handle design intent. A reliable CAD expert won’t simply redraw lines in 3D space. Instead, they will interpret the original 2D documentation to understand functional relationships, motion paths, or load-bearing structures, then build accurate 3D models that reflect these engineering realities.

A strong provider will also demonstrate a clear quality control process. This might include model verification, peer reviews, and adherence to dimensioning standards such as ASME Y14.5 or ISO 16792. These checks help ensure that the 3D output is more than just visually correct; it’s geometrically and functionally sound for downstream applications.

Questions to Ask Before Hiring

Vet your CAD provider with these essential questions:

Can you show examples of similar 2D to 3D CAD projects?

What CAD platforms and formats do you support?

How do you ensure model accuracy and compliance?

Do you provide native, editable files?

What’s your process for revisions or edits?

These questions help eliminate guesswork and establish clear expectations upfront.

Benefits of Working with the Right CAD Partner

When you choose a competent and experienced CAD conversion provider, the advantages extend far beyond a single project. You’ll gain a long-term partner who understands your standards, workflows, and engineering priorities. This results in smoother collaboration, reduced onboarding time for new projects, and improved scalability.

Additionally, professional services often offer revision support, integration with cloud collaboration tools, and even documentation for downstream users like machinists or fabricators. These add-ons may not be immediately obvious, but can provide huge value over time.

Final Thoughts: Invest in Precision, Not Just Service

2D to 3D CAD conversion is more than just digitizing old drawings; it's about preserving design intent and preparing files for future-ready manufacturing. The right service provider brings both technical expertise and industry insight, ensuring your project stays on track and within spec.

Take your time to research, ask smart questions, and never compromise on quality.

#2D to 3D CAD conversion#CAD Partner#CAD Conversion Services#Paper to CAD Conversion#PDF to CAD Drawings#CAD Conversion Provider

0 notes

Text

Digital Smile Design: The Future of Cosmetic Dentistry Is Here

What if you could see your dream smile before your dental treatment even begins? In 2025, that's not just possible—it's becoming the norm. Thanks to Digital Smile Design (DSD), cosmetic dentistry has entered a new era where aesthetics, precision, and personalization converge.

Whether you're considering clear braces, dental implants in Singapore, or just want a more confident smile, DSD offers a high-tech, patient-centered approach that eliminates the guesswork and delivers stunning results.

Here’s everything you need to know about Digital Smile Design and how it’s transforming the cosmetic dental experience.

What is Digital Smile Design (DSD)?

Digital Smile Design is a cutting-edge dental technology that allows both dentists and patients to digitally visualize the outcome of cosmetic treatments—before they even begin.

Using advanced software, photos, 3D scans, and videos of your face and mouth, your dentist can:

Map out your ideal smile in harmony with your facial features

Simulate different treatment options like veneers, clear aligners, implants, and whitening

Share a 3D preview of your future smile

Create precise treatment plans based on real data

This revolutionary planning tool is ideal for those who are serious about achieving a natural, aesthetic, and functional smile with minimal surprises.

Why DSD is a Game Changer in Cosmetic Dentistry

Unlike traditional cosmetic approaches, which rely heavily on 2D impressions or a dentist's eye, Digital Smile Design uses data-driven planning and visual communication to deliver better outcomes.

Benefits of Digital Smile Design include:

✅ Personalization: The design is tailored to your facial symmetry, lip shape, and smile line

✅ Visualization: You can see the “after” results in full detail—even before starting treatment

✅ Predictability: Reduces trial-and-error during procedures, improving precision and outcomes

✅ Confidence: Patients feel more in control and informed throughout their dental journey

Who Should Consider Digital Smile Design?

If you're exploring cosmetic dental treatments or full smile makeovers, DSD is for you. Common candidates include those with:

Misaligned, gapped, or overcrowded teeth

Missing teeth requiring dental implants in Singapore

Stains, chips, or uneven teeth

An uneven gum line

A desire for a more youthful or confident smile

It’s also perfect for patients deciding between clear braces vs. traditional options—or those weighing multiple procedures.

How Digital Smile Design Works: Step-by-Step

1. Digital Photography & 3D Scans

The dentist captures detailed facial photos, intraoral scans, and even short videos to study your facial expressions and symmetry.

2. Smile Simulation

Using DSD software, the dentist overlays your facial data with a simulated “ideal smile.” You can preview different outcomes with clear aligners, veneers, or implants.

3. Mock-Up & Trial Smile

In some clinics, a 3D-printed mock-up is created for a “test drive”—you can literally try your new smile before committing.

4. Treatment Planning

Once you’re happy with the design, your dentist uses this data to plan your procedures, whether it’s orthodontic adjustments or dental implants.

5. Execution & Refinement

Because everything is pre-planned and digitally mapped, treatments are faster, more efficient, and require fewer revisions.

How DSD Pairs with Popular Treatments

Let’s explore how Digital Smile Design enhances the most sought-after cosmetic dental treatments in 2025:

➤ Dental Implants with Perfect Harmony

Getting a tooth replaced? DSD helps ensure the size, shape, and angle of your dental implant blend naturally with surrounding teeth. This is especially important in aesthetic zones like the front of the mouth.

While cost remains a key consideration, knowing your dental implant Singapore cost upfront—and seeing the aesthetic value—makes the investment clearer and more justifiable.

➤ Clear Aligners for Subtle Perfection

Straightening your teeth with clear aligners is more precise with DSD. The software can simulate how your smile will evolve with each aligner stage, letting you preview your progress before you begin.

Patients often use DSD to compare clear braces and aligners visually, helping them choose the treatment that aligns best with both lifestyle and aesthetics.

➤ Wisdom Tooth Planning

While not typically a cosmetic concern, removing impacted wisdom teeth is often necessary before cosmetic work. Using 3D imaging, dentists can plan minimally invasive extractions. And yes, you can claim Medisave for wisdom tooth removal in Singapore, making it more affordable.

The DSD Experience: What to Expect During Your Visit

A Digital Smile Design consultation is unlike a typical dental check-up. Expect a multi-sensory, interactive experience that involves:

Seeing a preview of your new smile in motion

Participating in the design process

Having all your questions answered with visual aids

Receiving a comprehensive treatment plan with realistic timelines and costs

Many patients report feeling more confident and motivated after a DSD consultation, especially when paired with emotional visuals and smile mock-ups.

Common Misconceptions About DSD

Myth 1: It's only for celebrities. Fact: DSD is becoming more accessible and is used by general dentists and specialists alike.

Myth 2: It's expensive. Fact: The design phase is often included in comprehensive cosmetic packages, and it can reduce the need for costly revisions.

Myth 3: It's just for looks. Fact: While aesthetics are key, DSD also enhances functionality, improving bite, speech, and oral hygiene.

Final Thoughts: The Future of Your Smile Starts Today

Digital Smile Design is not just the future—it’s the present of cosmetic dentistry. By combining high-tech diagnostics, precision planning, and emotional visualization, it’s giving patients the power to co-create their perfect smiles.

Whether you're exploring clear aligners, evaluating dental implant costs in Singapore, or need Medisave for wisdom tooth removal before cosmetic treatment, Digital Smile Design ensures the process is smoother, smarter, and far more satisfying.

Ready to design your dream smile? Start your journey today with a trusted cosmetic dentist who offers the DSD experience.

#DigitalSmileDesign#CosmeticDentistry#DentalImplantsSingapore#ClearAligners#WisdomToothRemoval#SmileMakeover#DentalTechnology#MedisaveSingapore

0 notes

Text

Professional 3D CAD Modeling Services to Accelerate Your Product Development

In today’s fast-paced manufacturing and product design environment, 3D CAD modeling has become the backbone of innovation and precision. Whether you’re an industrial manufacturer, an architect, or a product designer, the ability to digitally visualize, test, and perfect your ideas before production is invaluable.

Shalin Designs, a trusted name in CAD outsourcing, offers top-tier 3D CAD modeling services to help you design faster, reduce costs, and ensure flawless execution from concept to creation.

🚀 What is 3D CAD Modeling?

3D CAD (Computer-Aided Design) modeling is the process of creating three-dimensional digital representations of physical objects using advanced CAD software such as SolidWorks, AutoCAD, Creo, and Fusion 360.

These models serve as accurate visual and structural blueprints, providing essential data for manufacturing, prototyping, simulations, and design evaluations. 3D CAD modeling helps in reducing material waste, detecting design errors early, and accelerating product delivery timelines.

💡 Why Choose 3D CAD Modeling Services from Shalin Designs?

At Shalin Designs, we believe design precision starts with clarity, creativity, and collaboration. Here’s what makes our 3D CAD modeling service a cut above the rest:

✅ Expertise Across Industries

Our skilled CAD designers have years of experience serving a range of industries including:

Furniture manufacturing

Industrial equipment design

Architectural structures

Consumer product design

Automotive components

Sheet metal and mechanical design

✅ High-Precision Modeling

We create detailed parametric and non-parametric models that are 100% production-ready. Our models align with real-world constraints, tolerances, and manufacturing standards.

✅ Software Flexibility

We work with all leading CAD software platforms and can adapt to your file requirements, design standards, and project workflows.

✅ Cost-Effective Outsourcing

Looking to save up to 50% in design costs without compromising on quality? Shalin Designs provides offshore 3D CAD modeling solutions that meet global standards at competitive prices.

✅ Fast Turnaround Time

Tight deadline? No problem. Our streamlined process and dedicated team allow us to deliver high-quality CAD models quickly — without sacrificing detail or accuracy.

🛠️ Our 3D CAD Modeling Capabilities

We offer end-to-end 3D CAD services for both simple and complex design requirements, including:

1. Concept to CAD Conversion

Have a sketch or an idea? We help you convert hand-drawn concepts, 2D drafts, or even ideas into detailed 3D models for validation and development.

2. Reverse Engineering

Need to recreate a legacy part or product? Our team uses digital measurements or 3D scans to generate accurate CAD files.

3. Mechanical 3D Modeling

Designing mechanical parts, assemblies, or machine components? We specialize in parametric modeling and detailed part analysis.

4. Furniture & Millwork Modeling

We provide detailed furniture and millwork models for custom manufacturing, visualization, and space planning.

5. Architectural & MEP Modeling

From BIM-ready models to architectural components, we create accurate and scalable 3D models for construction and infrastructure projects.

📈 Benefits of Partnering with Shalin Designs

Partnering with Shalin Designs means you gain a reliable design extension to your in-house team. Our clients enjoy:

Reduced product development time

Increased design accuracy

Easy integration with CAM and CNC workflows

Support for prototyping and 3D printing

Enhanced design collaboration via cloud-based file sharing

We ensure confidentiality and security for all your intellectual property. NDAs and service-level agreements are available for long-term partnerships.

🌍 Serving Clients Globally

From startups to large enterprises, Shalin Designs proudly serves clients across the USA, UK, Canada, Australia, and the Middle East. Whether you need a one-time CAD project or a long-term design partner, we deliver world-class service tailored to your goals.

📞 Ready to Digitally Transform Your Designs?

Don’t let your ideas stay on paper. Bring them to life with high-precision 3D CAD modeling from Shalin Designs.

👉 Contact us today to get a free quote or discuss your next design project.

#3DCAD#CADDesign#CADModeling#3DModeling#EngineeringDesign#MechanicalDesign#ProductDesign#SolidWorks#AutoCAD#3DCADServices

1 note

·

View note

Text

The Secrets Behind Accuracy Thermoforming Molds Created in China

Vacuum forming and thermoforming have come to be vital production methods throughout sectors, and much of their success exists in the precision of the molds used. In China, a hub for sophisticated manufacturing, thermoforming molds producers have actually created very efficient systems to make sure every mold satisfies limited resistances and exacting standards. From custom thermoforming molds to bespoken vacuum forming molds, precision is constructed right into every stage of the process to assure constant and trusted results for clients all over the world.

Advanced Engineering and also Mold Design

Precision begins with professional preparation. Every trustworthy thermoforming molds manufacturer in China counts on a seasoned engineering team to craft comprehensive CAD-based vacuum forming mold designs. These blueprints form the foundation for extremely precise production. Modern thermoforming tools makers also use simulation software application and 3d print vacuum form molds for prototyping, permitting improvements prior to final machining. This technique makes sure that each customized thermoforming mold aligns flawlessly with client specifications, making Chinese providers reputable companions in the international market.

Use Top Quality Products and Precision Machining

A reputable vacuum forming molds manufacturer understands that premium products are non-negotiable for lasting performance. Whether it's pure light weight aluminum, copper, or composite FRP, makers use only high-grade products for boosted mold toughness and precision. From there, CNC machining brings these products to life with micro-level accuracy. Leading vacuum forming tools producers in China integrate this with automated evaluation systems to guarantee that each mold is prepared for rigorous industrial usage, specifically in sectors requiring regular and reputable results.

Rigorous Examining and Quality Control

No mold leaves a trusted thermoforming molds supplier without comprehensive quality checks. Each tool is examined under practical forming conditions to verify warmth tolerance, vacuum stability, and dimensional precision. Licensed vacuum forming molds distributors follow worldwide requirements like ISO9001 and ISO13485, especially for clinical or digital applications. This level of analysis makes certain every item from a thermoforming tools manufacturer is resilient, reliable, and compliant - making them the best source for high-performance vacuum forming molds China throughout global markets.

Personalization and Customer Collaboration

What establishes a top-tier vacuum forming molds supplier apart is their technique to customization. These professionals don't just construct molds - they fix manufacturing issues. Whether you require a customized vacuum forming mold for food product packaging or a bespoken vacuum forming mold for auto components, Chinese vacuum forming tools manufacturers work closely with clients to adjust every information. A dependable thermoforming molds production will certainly lead you through material selection, surface coating, and part intricacy, making sure the last mold aligns with your business objectives.

Conclusion

Accuracy in vacuum forming molds China is not accomplished by chance. It's the result of careful vacuum forming mold design, cutting-edge machining, extensive screening, and solid customer relationships. As a trusted vacuum forming molds manufacturer, China has established the global standard for both quality and customization. Whether you require custom thermoforming molds, high-volume manufacturing molds, or experimental vacuum forming 3d published molds, Chinese suppliers offer trustworthy solutions. With a tested track record, companies like SME Plastic proceed to lead the means in supplying precision-engineered thermoforming solutions.

SME Thermoforming Molds

Address: No.10, 3rd st, Minying Industrial Zone,

Shawan Town,Panyu District, Guangzhou City, Guangdong, PRC

Mob: +86-13928889690

Location map: https://maps.app.goo.gl/2CfwLCx2WAPuEuCF8

0 notes