#3d reverse engineering

Explore tagged Tumblr posts

Text

Unveiling the Power of Reverse Engineering Testing Services

In the dynamic landscape of software development, staying ahead of the curve is crucial. One key strategy gaining traction is the utilization of Reverse Engineering Testing Services. This innovative approach involves dissecting and understanding existing software systems to enhance their functionality, security, and overall performance.

Reverse engineering testing services are not just about breaking down code; they're a strategic tool to uncover the intricacies of complex applications. By deconstructing software, developers gain insights into its structure, enabling them to identify vulnerabilities, enhance functionality, and streamline performance.

One primary advantage of reverse engineering testing is its ability to unveil hidden features or diagnose issues that may not be apparent through conventional testing methods. This process helps developers create more robust and resilient software by understanding the underlying architecture.

Moreover, reverse engineering testing services play a pivotal role in ensuring compliance with industry standards and regulations. By dissecting software components, organizations can identify potential security loopholes and rectify them before they become exploitable vulnerabilities.

In a nutshell, the power of reverse engineering testing services lies in their ability to unravel the mysteries of existing software, paving the way for innovation, security, and improved performance. As the software development landscape evolves, embracing this approach becomes increasingly essential for organizations aiming to stay competitive and resilient in the digital realm.

#reverse engineering testing services#3d scanning reverse engineering services#3d reverse engineering services#3d scanning reverse engineering testing services#3d reverse engineering testing services#reverse engineering solutions#reverse engineering testing solutions#3d reverse engineering

1 note

·

View note

Text

3d Reverse Engineering

3d Reverse engineering is the technique of measuring or scanning an existing physical object to create a digital 3D representation of it. Creating a 3D model of an organic and complicated thing requires a lot of work and is sometimes inaccurate when measuring it using traditional methods. In contrast, scanning produces millions of precise data points from an organic and complicated object at a far faster rate.

After processing these data points, specialised reverse engineering tools can produce complex surfaces and primitives that can be used to create a new 3D CAD model of choice.Large, complicated as-built structures can be 3D laser scanned by V3D Technologies, which helps experts in the fields of architecture, engineering, and construction (AEC) expedite the process of documenting current conditions while enhancing accuracy and reducing expenses. We will create 3D point cloud data using an accurate 3D LiDAR scanner to assist you and your team in more thoroughly analysing, contrasting, and prioritising the financial and environmental effects of the suggested design in light of actual circumstances. Your time is the most valuable resource that our 3D solutions will help you preserve.Generating a precise 3D point cloud of an existing space or structure is the first and most important stage.

We precisely accomplish this by utilising state-of-the-art laser scanning tools, technology, and procedures. Your location or structure's visual and dimensional information is captured with millimetre accuracy by creating a colourized point cloud. After being integrated into a shared reference system, many overlapping scans collected from different perspectives inside the same space are combined into one comprehensive model. We refer to this procedure as alignment or registration.After registration, the complete point cloud model can be published as a ReCap file (RCS/RCP) or other industry-standard formats (E57, XYZ, LGS, PTS, LAS).

0 notes

Text

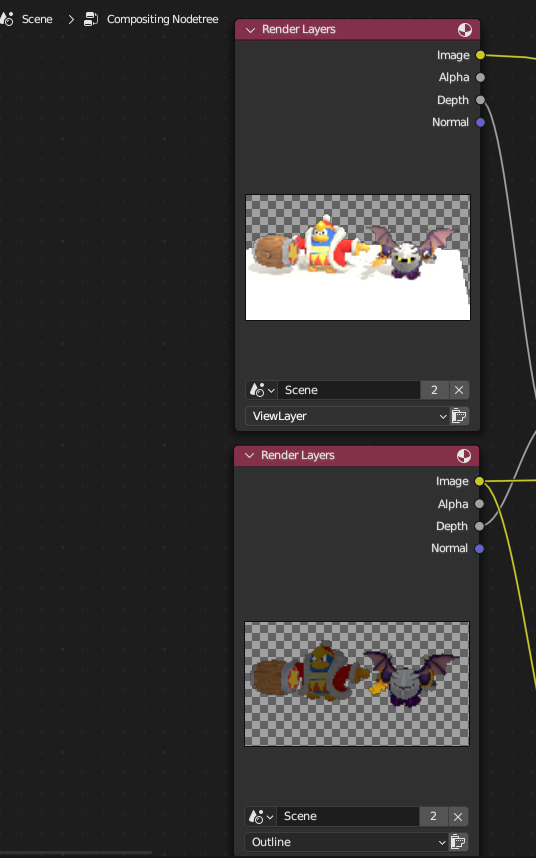

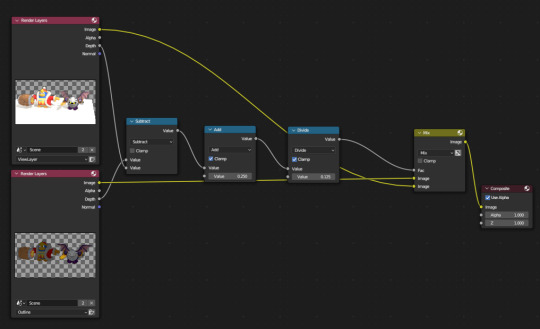

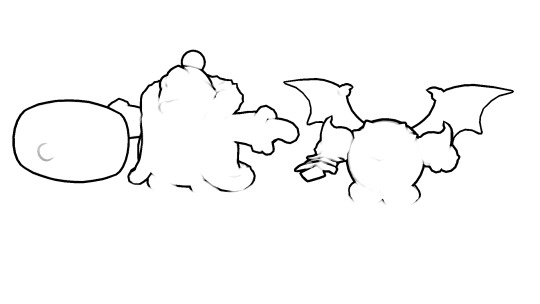

the outlines in kirby's return to dream land deluxe are very interesting, theyre definitely the cleanest 3d outlines i have ever seen anyone do

visually theyre just the model but darkened and expanded out a bit, and instead of clipping into any geometry they simply fade out and seem aware of the other outlines and models in the scene, merging together perfectly

im VERY surprised no one else has done this, because the way they pulled it off is actually EXTREMELY simple

(this will go into kinda technical graphics rendering talk)

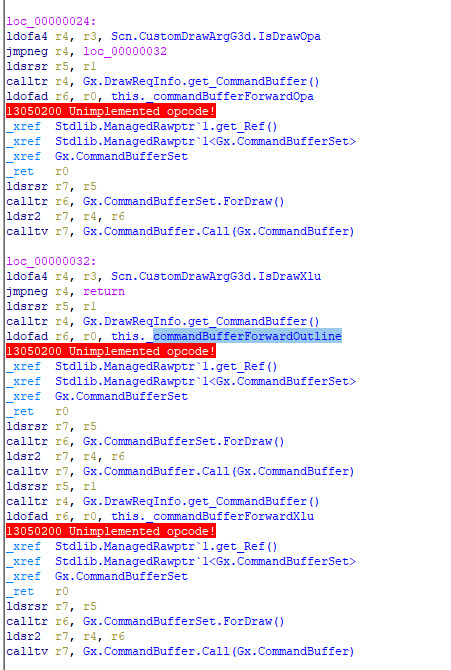

the first clue is that looking into the code used for rendering reveals that the game draws the outlines after the rest of the scene has been drawn

specifically, the order that objects are drawn from this function is:

opaque models (deferred rendering)

decals (deferred)

opaque models (forward rendering, essentially just fully rendering every single model)

outline models (forward)

transparent models (forward)

interestingly, outline models count as transparent, disabling transparency rendering will also disable outlines

the next hint about how it works comes directly from this enum listing all of the passes the game draws

the most important part of this is "OutlineDepth" and "Outline", which reveals that the outlines render their own depth buffer!! this contains essentially how far away each pixel is from the camera, in ingame/world space units

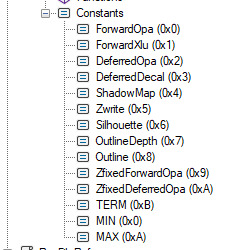

looking into the models themselves, all of the models for characters have duplicated meshes that use a material specifically for outlines

using this information alone, its very easy to recreate the outlines in blender!!

this is achieved in the same way, by rendering the raw scene and the outlines in two separate images using blender's render layers feature, with the outlines being significantly darkened, using only the diffuse texture, and the meshes themselves expanded slightly using geometry nodes

the rest of the models are rendered normally with PBR

determining where the outlines are drawn is just the result of some extremely simple math using the depth buffer of each layer

if you would like to see the result of this math, this is the "outline mask buffer":

as a bonus, if we gaussian blur the outline we can achieve a similar look to the game's promo art as well!! however, this doesnt look super good, improving on how this looks specifically most likely requires more tinkering in image editing software like photoshop

214 notes

·

View notes

Text

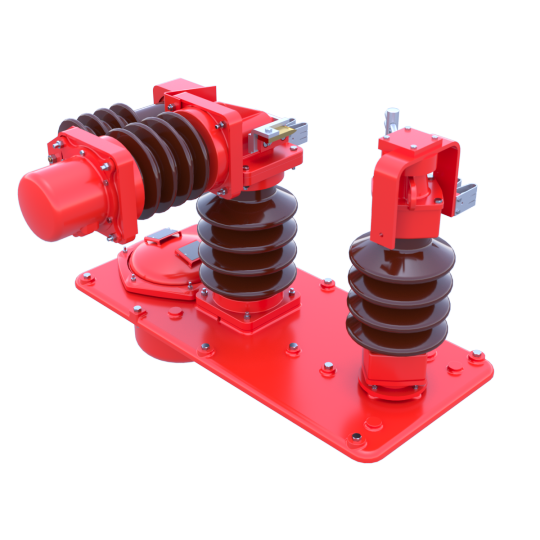

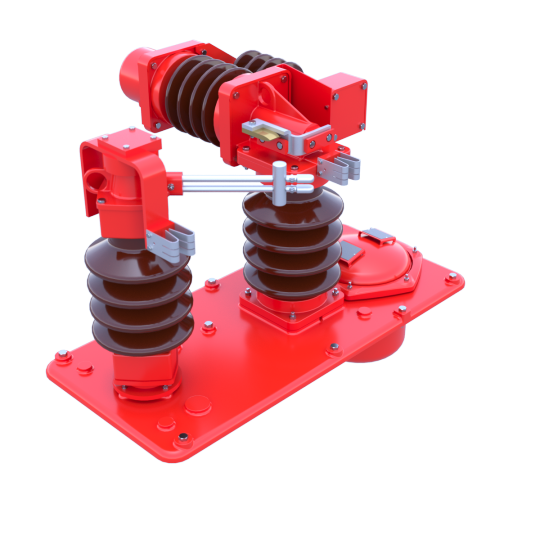

Electric locomotive compressed air quick switch Brown Boveri type DBTF 20i 200 25kV.

Complete assembly.

sketchfab

#kambalka#corona renderer#3d#solidworks#locomotive#dbtf#Brown Boveri#switch#trains#railroad#reverse-engineering

2 notes

·

View notes

Text

Exxjet Systems LLP

About Exxjet Systems:

Exxjet Systems is a premier provider of advanced additive manufacturing and 3D scanning solutions, renowned for transforming innovative ideas into reality. Specializing in industries such as automotive, aerospace, education, manufacturing, and healthcare, Exxjet combines cutting-edge technology with industry expertise to deliver superior products and services. By integrating high-precision 3D scanners, sophisticated CAD modeling, and advanced 3D printers technologies, Exxjet excels in reverse engineering and end-to-end production workflows, ensuring accurate digital modelling and the creation of exact physical replicas or improved designs.

Exxjet’s comprehensive approach ensures the successful deployment and onboarding of solutions at customer sites. They provide tailored support from initial consultation and design through production and installation, including training and ongoing support to integrate new capabilities into existing processes. This enhances productivity and innovation across various industries. With a focus

Offering Portfolio:

Zortrax M300 Dual: With dual-extrusion technology, this printer can handle complex designs with ease, especially those requiring water-soluble supports. It excels in printing intricate models, offering enhanced possibilities for multi-material prints.

Zortrax M200 Plus/ Zortrax M300 Plus: This printer offers high-speed printing capabilities, making it suitable for batch production and rapid prototyping. Its reliability and precision make it a popular choice for professionals looking to streamline their workflow.

Phrozen Sonic Mega 8K V2: Phrozen Sonic Mega 8K V2 boasts ultra-high-resolution printing capabilities, perfect for crafting intricate models and prototypes with exceptional detail. Its precision and clarity ensure faithful reproduction of even the most complex designs, making it a top choice for professionals seeking unparalleled printing quality.

EinScan HX: As a hybrid 3D scanner, the EinScan HX combines blue LED light and laser technology, resulting in enhanced compatibility with a wide range of materials and surfaces. Its high precision and resolution make it well-suited for industrial applications where accuracy is crucial.

EinScan H2: The EinScan H2 is an advanced handheld 3D scanner that incorporates hybrid technology for improved scanning versatility and efficiency. Its ability to adapt to various scanning scenarios makes it a valuable tool for professionals in industries ranging from manufacturing to healthcare.

Einscan Einstar: This handheld 3D scanner stands out for its high color accuracy, thanks to its RGB color camera. It captures true-to-life colors during the scanning process, making it ideal for applications where color fidelity is important, such as art restoration or product design.

3D Digitization Services

Under the banner of our 3D Digitization services, we offer both fused and individualized solutions tailored to meet specific industry requirements. Seamlessly blending cutting-edge 3D printing and scanning capabilities, we harness a comprehensive array of technologies including FDM, Resin, LCD, Polyjet, and DLP. Whether clients seek integrated solutions for streamlined processes or individual services to address particular needs, our expertise spans from prototyping and reverse engineering to post-processing and batch production. Explore the transformative potential of our 3D Digitization services across industries and applications, unlocking new possibilities in design, manufacturing, and beyond.

3D Printing Services

In the realm of manufacturing and prototyping services, with deep domain expertise we specialize in 3D printing services with comprehensive range of solutions utilizing cutting-edge technologies like FDM, Resin, LCD, Polyjet, and DLP. These technologies enable the production of high-quality parts using a variety of materials, from thermoplastics to photopolymers, catering to diverse application needs with precision and versatility.

FDM technology excels in producing robust, functional prototypes and end-use parts using thermoplastic filaments, making it ideal for engineering applications requiring strength and durability. On the other hand, Resin-based printing methods such as SLA and DLP provide exceptional surface finish and detail, perfect for creating intricate models, jewelry, and dental prosthetics. LCD and Polyjet technologies expand the possibilities further, allowing for the creation of multi-material, multi-color parts with high-resolution detail and smooth surface finishes. These capabilities are invaluable in industries such as consumer electronics, automotive, and medical devices where aesthetics and functional complexity are crucial.

Additionally, we offer a comprehensive range of post-processing options such as lacquering, painting, sanding, and surface finishing to further enhance the appearance and functionality of 3D printed parts. Moreover, for batch production requirements can engage in add-on services like vacuum casting, enabling the replication of high-quality parts in various materials with consistency and efficiency. This holistic approach ensures that clients receive end-to-end solutions tailored to their specific needs, from initial design to final production, all under one roof.

3D Scanning services

Our 3D scanning service offers comprehensive capabilities, accommodating objects ranging from micro to macro scale. From intricate small mechanical parts to imposing sculptures, vehicles, buildings, and boats, we cover a wide spectrum of items. Our scanning solutions serve various purposes, including reverse engineering objects into parametric 3D models, conducting deviation analyses, and providing a foundation for prototyping and 3D printing. These services find application across diverse fields such as industry, architecture, archaeology, art, and research.

Moreover, our expertise extends beyond mere data acquisition; we offer comprehensive post-processing services to refine and enhance scanned data, ensuring optimal compatibility with downstream applications such as CAD modelling and simulation. Explore the diverse range of customer stories showcasing the transformative impact of our 3D scanning solutions across various industries and applications.

Exxjet Expertise:

With 8 years of industry experience, our 3D printing services cater to a diverse range of sectors, offering advanced solutions for rapid prototyping, high-precision manufacturing, and custom medical device production. Leveraging cutting-edge technologies, we ensure detailed, realistic prototypes, durable end-use components, and streamlined workflows tailored to the specific needs of automotive, aerospace, education, manufacturing, and healthcare industries.

Automotive: Rapid prototyping and production of both full-color and functional custom parts, ensuring detailed and realistic prototypes as well as durable, end-use components.

Aerospace: High-precision components for complex assemblies, ensuring durability and performance through advanced 3D printing technologies.

Education: Advanced tools for teaching and research, including full-color models for enhanced learning experiences and visualization.

Manufacturing: Streamlined workflows for efficient production, utilizing high-resolution 3D printing to create detailed and functional parts.

Healthcare: Custom medical devices and anatomical models for pre-surgery analysis, improving patient outcomes with precise and accurate 3D-printed models.

#3d printers#types of 3d printers#best 3d printers#3d printers india#3d printers near me#3d printers in india#3d printers in bangalore#industrial 3d printers#different types of 3d printers#3d printers for sale#best 3d printers in india#what are 3d printers#3d printers cost#3d printers bangalore#3d scanners#types of 3d scanners#handheld 3d scanners#3d scanners for 3d printers#artec 3d scanners#top 3d scanners#3d scanners for reverse engineering#industrial 3d scanners#how do 3d scanners work#cheap 3d scanners#3d scanners for 3d printing#best 3d scanners#3d printers and scanners#3d scanners near me#3d scanners in india

1 note

·

View note

Text

Hades, A Korean Boomer Shooter Using The Original Voxel Engine.

#hades#boomer shooter#that game is using the original voxel engine instead of reverse engineered engine from mars 3d

1 note

·

View note

Text

What Is Reverse Engineering and When Should You Use It?

In today’s competitive and innovation-driven manufacturing landscape, companies are continually searching for methods to optimize designs, streamline production, and gain deeper insight into existing products. One of the most powerful yet often misunderstood tools that supports these objectives is reverse engineering.

Reverse engineering enables organizations to deconstruct a product or system to understand its components, functions, and design principles. This process is not only used to replicate products but also to analyze their structure, improve upon them, or integrate them into new applications.

This article offers a comprehensive explanation of reverse engineering—what it is, how it works, the technologies involved, its applications across industries, and the scenarios where it proves most valuable.

Defining Reverse Engineering

At its core, reverse engineering is the process of disassembling or analyzing an object to understand how it was designed and manufactured. It involves extracting design information from existing products, often in the absence of technical documentation or original design files.

Unlike traditional engineering, which moves from concept to product, reverse engineering starts with the finished item and works backwards to deduce the original specifications. The insights gained are often used to:

Create 3D models and CAD files

Improve product design

Develop compatible components

Diagnose failures or weaknesses

Reproduce obsolete or legacy parts

Reverse engineering does not necessarily imply copying or duplication. Rather, it is a legitimate and valuable practice in modern product development, maintenance, and innovation.

How Reverse Engineering Works

The reverse engineering process varies depending on the object, industry, and intended outcome, but it generally follows a consistent sequence:

1. Data Acquisition

The first step involves capturing detailed information about the object’s geometry, dimensions, and features. This is typically done using advanced 3D scanning technologies such as:

Laser Scanners: Emit laser beams to detect surface contours.

Structured Light Scanners: Project light patterns and measure distortions to determine surface geometry.

Computed Tomography (CT) Scanners: Capture both internal and external features using X-ray technology.

Coordinate Measuring Machines (CMMs): Use touch probes to precisely measure specific points.

These tools collect millions of data points, forming a comprehensive digital representation of the object known as a point cloud.

2. Data Processing and Mesh Generation

The raw point cloud data is cleaned, aligned, and processed to remove noise and inconsistencies. The next step is to convert the point cloud into a polygonal mesh—a 3D surface composed of interconnected triangles.

This mesh is then optimized to ensure it accurately reflects the physical object’s shape while maintaining a manageable file size for further use.

3. 3D Modeling and CAD Conversion

Once a high-quality mesh is obtained, it is used to reconstruct the object in a computer-aided design (CAD) environment. Engineers develop a fully parametric or feature-based CAD model that replicates the part’s geometry.

At this stage, material specifications, tolerances, and functional features may also be analyzed and documented. The final CAD model can be edited, shared, or integrated into larger assemblies.

4. Analysis and Application

The finished model is then used for various purposes, including design improvements, simulation, tooling development, or manufacturing reproduction. Engineers may also perform stress tests, fit checks, and other simulations using the digital model.

Key Technologies in Reverse Engineering

Advances in digital manufacturing and metrology have significantly expanded the capabilities of reverse engineering. The following technologies are essential:

3D Scanning

High-resolution 3D scanning tools rapidly capture the surface geometry of physical objects, forming the foundation for all subsequent steps. These scanners vary in accuracy, speed, and suitability depending on the object's size, complexity, and material.

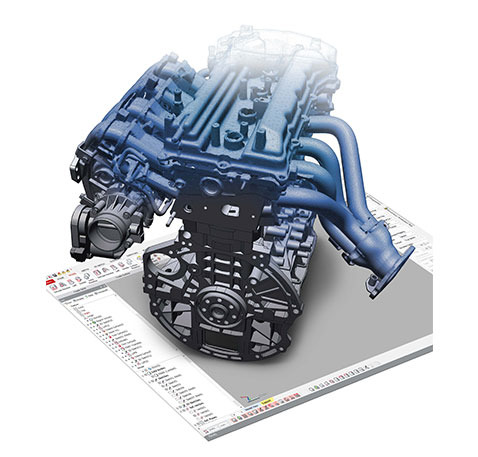

CAD Software

CAD platforms such as SolidWorks, Autodesk Inventor, Siemens NX, and others play a crucial role in interpreting scanned data and creating usable design files. These models are often parametric, allowing engineers to modify features and dimensions easily.

Simulation Tools

Finite Element Analysis (FEA) and other simulation tools are used in conjunction with CAD models to evaluate a product’s performance under various conditions. These insights support design optimization and failure analysis.

3D Printing and Prototyping

Rapid prototyping allows teams to test modifications derived from reverse engineering efforts. By printing physical models, engineers can assess fit, function, and ergonomics quickly and affordably.

When Should You Use Reverse Engineering?

Reverse engineering is applicable in a wide range of situations across multiple industries. It is especially useful when dealing with legacy components, product innovation, or systems integration. Below are the most common scenarios that justify the use of reverse engineering.

1. Recreating Obsolete or Legacy Parts

One of the primary uses of reverse engineering is to reproduce discontinued components for machines, vehicles, or systems that are no longer supported by the original manufacturer. With no access to original drawings or tooling, reverse engineering provides a reliable way to maintain critical assets and extend their lifecycle.

This is particularly valuable in aerospace, defense, rail, and heavy industries, where replacing entire systems is impractical or cost-prohibitive.

2. Product Improvement and Optimization

Reverse engineering enables manufacturers to analyze existing products and identify opportunities for improvement. Engineers can assess design weaknesses, material inefficiencies, or manufacturing complexities and apply innovative solutions to enhance performance, durability, or cost-effectiveness.

The process often leads to

Lighter and stronger designs

Reduced manufacturing steps

Better ergonomics or aesthetics

Improved energy efficiency

3. Competitive Analysis

Organisations often use reverse engineering to examine competitor products and gain insights into their features, performance, and manufacturing techniques. This helps in benchmarking, identifying intellectual property challenges, and driving innovation.

While care must be taken to respect legal and ethical boundaries, competitive reverse engineering is a legitimate practice used for market intelligence and strategic planning.

4. Integrating New Components with Existing Systems

In cases where new parts or systems need to work seamlessly with older components, reverse engineering ensures dimensional compatibility and functionality. By modeling the existing hardware accurately, engineers can design new components that align perfectly without trial and error.

This use is common in:

Automotive retrofits

Industrial equipment upgrades

Electronic system integration

5. Quality Control and Inspection

Reverse engineering is sometimes used as a validation tool in quality assurance. By scanning and modeling a manufactured part, teams can compare it to the original design and detect any deviations or defects.

This process enhances dimensional verification, especially for complex geometries that are difficult to measure with traditional tools.

6. Digital Archiving

Preserving the design data of critical components through reverse engineering creates a digital archive for future reference. This is important in museums, aerospace restoration, and asset management, ensuring that data is never lost even if physical components degrade or disappear.

Industries Benefiting from Reverse Engineering

The versatility of reverse engineering means it is widely applicable across a variety of sectors:

Aerospace

Airplane components, many of which have long service lifecycles, often require replacement or refurbishment after the original manufacturing data is lost. Reverse engineering ensures structural integrity and regulatory compliance.

Automotive

Classic cars, custom vehicles, and prototype parts benefit greatly from reverse engineering. It enables part reproduction, modification, and even digital recreation of entire vehicle systems.

Medical Devices

Medical implants, prosthetics, and surgical instruments are reverse-engineered to improve functionality, ensure anatomical fit, or replicate discontinued designs.

Consumer Electronics

Electronics companies often disassemble products to understand PCB layouts, circuitry, and design logic. This enables repair, customization, or the development of compatible accessories.

Industrial Manufacturing

Reverse engineering supports tooling design, process improvement, and machine maintenance. It is also used to digitize old parts or machinery for integration into modern workflows.

The Role of Reverse Engineering in Innovation

Beyond its practical applications, reverse engineering fosters innovation by bridging the gap between legacy knowledge and modern capabilities. It encourages experimentation, cross-functional learning, and iterative improvement.

By understanding the details of how a product works, engineers can:

Identify underutilized features

Explore alternative materials

Develop more efficient manufacturing methods

Combine legacy and modern technologies

This approach is particularly important for companies striving to remain competitive in rapidly evolving markets. It allows them to leapfrog development stages, reduce R&D costs, and bring products to market faster.

Ethical and Legal Considerations

While reverse engineering is a powerful tool, it must be practiced within ethical and legal boundaries. It is important to respect patents, copyrights, trade secrets, and intellectual property (IP) rights.

Organizations using reverse engineering must ensure their efforts do not infringe on protected designs. In many jurisdictions, reverse engineering for interoperability or repair purposes is legal, but copying patented elements without permission is not.

Working with professional providers of reverse engineering services in Australia ensures that all procedures are carried out in compliance with local laws and international IP standards.

Choosing the Right Reverse Engineering Partner

The effectiveness of reverse engineering relies heavily on the skill, experience, and tools used. Partnering with specialists who understand materials science, digital modeling, and manufacturing processes ensures accurate, high-quality results.

Providers offering reverse engineering services in Australia are equipped with advanced scanning systems, robust CAD platforms, and cross-industry expertise. They help clients navigate complex engineering challenges, from legacy part digitization to modern product development, while maintaining confidentiality and regulatory compliance.

Conclusion

Reverse engineering is a powerful, multi-purpose process that enables organizations to derive valuable design and manufacturing data from existing physical products. Whether used for reproduction, enhancement, integration, or analysis, it offers significant advantages across the product lifecycle.

By turning physical objects into digital intelligence, reverse engineering allows industries to move forward while learning from the past. It supports innovation, sustainability, and precision in a world where adaptability and speed are crucial to success.

As industries increasingly adopt digital technologies and advanced manufacturing techniques, reverse engineering will play an even more integral role—especially when executed by trusted professionals who offer comprehensive reverse engineering services in Australia and beyond.

#reverse engineering#product development#3D scanning#CAD modeling#engineering services#component analysis#design replication

1 note

·

View note

Text

3D Printing Service

Verso3D offers a wide range of 3D printing services for several industrial applications and sectors. Whether you need parts, prototypes, or custom products, 3D printing services can help throughout the product development and production phase.

Verso3D majorly deals with –

Automobile Plastics

Medical Products

Rubber Components

What Is 3D Printing Solutions?

3D printing is the process of producing a three-dimensional object from any digital file.

In short, if you have a prototype design with perfect measurement data, you can create any component you desire. In this process, the object is created by laying down very fine layers of materials as per the digital design provided.

The major benefit of using 3D printing over the traditional production method is that you save a lot of raw materials, especially when designing a complex component. We use the Figure 4 Standalone 3D Printer for ultra-fast and affordable prototyping

#3d printing service#3d printing automotive parts#3d printing plastic injection molding#3d printing rubber service#best 3d printing service in chennai#printing services#reverse engineering in 3d printing#best 3d printer for jewelry casting#3d printing shops in chennai

0 notes

Text

Unlocking the Power of Reverse Engineering Services in Canada with Digital Scan3D

In today’s fast-paced technological landscape, businesses are constantly seeking innovative solutions to stay ahead of the competition. One such solution that has gained significant traction is reverse engineering services. Whether you are looking to analyze, reconstruct, or optimize existing products, reverse engineering can offer invaluable insights and advantages. In Canada, Digital Scan3D stands out as a leader in providing top-notch reverse engineering services, helping businesses to unlock new opportunities and drive growth.

What is Reverse Engineering?

Reverse engineering is the process of deconstructing a product or system to understand its design, functionality, and components. This technique is often used to analyze the design, identify potential improvements, and replicate or enhance the product. In the context of reverse engineering services in Canada, companies like Digital Scan3D use advanced tools and technologies to capture detailed 3D models of physical objects, allowing for precise analysis and replication.

Applications of Reverse Engineering

Reverse engineering services have a wide range of applications across various industries. Here are a few examples:

Manufacturing: Companies can use reverse engineering to optimize existing products, improve manufacturing processes, and reduce costs.

Aerospace: Reverse engineering can help in the maintenance and repair of aircraft components by creating accurate digital models.

Automotive: Car manufacturers can analyze competitors’ products and integrate the best features into their own designs.

Healthcare: Medical device manufacturers can use reverse engineering to create custom prosthetics and implants that fit patients perfectly.

Why Choose Digital Scan3D?

When it comes to reverse engineering services in Canada, Digital Scan3D is a name you can trust. With years of experience and a team of highly skilled professionals, they offer comprehensive reverse engineering solutions tailored to meet your specific needs.

Advanced Technology

Digital Scan3D leverages the latest 3D scanning technologies to capture precise measurements and detailed 3D models. Their state-of-the-art equipment ensures accuracy and efficiency, making the reverse engineering process seamless and reliable.

Expertise and Experience

The team at Digital Scan3D consists of experts with extensive experience in various industries. Their deep knowledge and technical skills enable them to tackle complex reverse engineering projects with ease, ensuring high-quality results.

Custom Solutions

Every project is unique, and Digital Scan3D understands the importance of providing customized solutions. They work closely with clients to understand their requirements and deliver reverse engineering services that align with their goals and objectives.

Customer Satisfaction

Client satisfaction is a top priority for Digital Scan3D. They are committed to delivering exceptional service and support throughout the entire reverse engineering process. Their focus on quality and customer-centric approach has earned them a reputation as a trusted partner for reverse engineering services in Canada.

The Benefits of Reverse Engineering

Implementing reverse engineering services can bring numerous benefits to your business. Here are a few key advantages:

Cost Savings: Reverse engineering can help identify areas for cost reduction in production and maintenance.

Innovation: By analyzing existing products, companies can gain insights that lead to innovative designs and improvements.

Competitive Advantage: Understanding competitors’ products can provide a strategic edge in the market.

Quality Improvement: Reverse engineering can uncover design flaws and lead to enhancements that improve product quality.

Conclusion

In the ever-evolving business landscape, staying ahead of the curve is crucial. Reverse engineering services in Canada offered by Digital Scan3D provide a powerful tool for businesses to innovate, optimize, and thrive. With their advanced technology, expertise, and commitment to customer satisfaction, Digital Scan3D is the ideal partner for all your reverse engineering needs.

For more information about Digital Scan3D and their services, visit their website at https://digitalscan3d.com/.

#Reverse Engineering Services In Canada#Inspection And CMM Services In Canada#Faro 3D Scanner In Canada#Artec Leo Wireless 3D Scanner In Canada#Geomagic Design X Software In Canada

0 notes

Text

Artec Point

Introducing the Artec Point: Artec 3D's first target-based 3D laser scanner with ISO-certified, metrology-grade precision. Capture intricate surfaces with up to 0.02 mm accuracy, even on black or shiny finishes. Switch between grid, parallel, and single-laser modes for optimized results, while HD cameras tackle tight spaces. Built tough with a lightweight metal chassis for industrial use. Perfect for quality control and reverse engineering, delivering reliable data, fast!

Know More: https://altem.com/artec-point/

0 notes

Text

One of the biggest challenges in reverse engineering testing services is the lack of information or documentation about the product or system being analyzed. This can make it difficult to understand how the product works, what components it contains, and how those components are connected.

#reverse engineering testing services#3d scanning reverse engineering services#3d reverse engineering services#reverse engineering solutions#3d reverse engineering

0 notes

Text

3D reverse engineering cad software is a technique used to capture the geometry, dimensions, and features of a physical object and convert it into a digital format for analysis, modification, or replication purposes. The reverse engineering process may vary depending on the object being scanned, the quality of the acquired data, and the expertise of the professionals involved

0 notes

Text

>"we're a foss project, we welcome contributions from everyone in the community"

>look inside

>majority of development is coordinated in a private discord server

1 note

·

View note

Text

Unmatched Accuracy in Precision Engineering: The Power of CNC Machining

In today's engineering landscape, precision is the foundation of quality, particularly in aerospace, automotive, and medical devices, where even the smallest margin of error can determine success or failure. CNC (Computer Numerical Control) machining has transformed manufacturing by providing unmatched precision in producing highly accurate components.

The Impact of CAD/CAM Technology

A key factor in CNC machining’s precision is the seamless integration of CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) technologies. 3D modeling aids engineers in creating intricate 3D models of the desired part using CAD software. These digital blueprints capture every detail, ensuring that the design meets the exact specifications required for functionality.

Once the design is finalized, it is converted into CNC programs using CAM software. This process translates the digital blueprint into precise instructions for the CNC machine to follow, ensuring every dimension and specification is precisely met. By eliminating manual steps, CNC machining significantly reduces the chance of human error, ensuring consistency across both small and large production runs.

Automated Precision for Complex Geometries

CNC machines, once programmed, operate autonomously, reducing the need for continuous human oversight. This automation ensures each part is manufactured with the same high standard of accuracy, ensuring repeatability across batches. Moreover, CNC machines can work on multiple axes simultaneously, making it possible to create intricate, complex geometries that would be challenging to achieve through traditional machining methods.

Real-Time Monitoring for Maximum Accuracy

Modern CNC machines are equipped with advanced real-time monitoring systems that track the machining process. If any deviation from the programmed path occurs, the system immediately corrects it, ensuring precise output and minimizing waste. This results in a highly efficient, cost-effective process that guarantees optimal material usage and consistent accuracy.

At Engineering DNA, we harness the power of advanced CNC machining technology, combined with expert engineering knowledge, to produce precision-engineered parts for industries that demand the highest levels of accuracy. Whether you need a prototype or full-scale production, our CNC machining capabilities ensure consistent, unparalleled quality in every project.

#reverse engineering services#3d modeling for 3d printing#3d cad services#finite element analysis#3d modeling services#3d prototype in mumbai

0 notes

Text

Sheet Metal Forming: Enhancing Precision with 3D Scanning and Reverse Engineering

Reverse Engineering

Sheet metal forming is a vital manufacturing process used to create metal components for industries such as automotive, aerospace, and heavy machinery. This process involves shaping metal sheets into various forms using techniques like bending, stamping, and drawing. While traditional methods are still widely used, the integration of 3D scanning and reverse engineering technologies has revolutionized sheet metal forming, making it more efficient and precise than ever before.

How 3D Scanning is Transforming Sheet Metal Forming

One of the main challenges in sheet metal forming is ensuring that the final product meets exact design specifications. In traditional setups, this requires manual inspections and measuring, which can be time-consuming and prone to human error. 3D scanning has changed this landscape by enabling manufacturers to capture detailed and accurate 3D models of metal components. These models allow for precise analysis and ensure that parts are produced to exact measurements.

With high-precision 3D metrology, manufacturers can significantly reduce material wastage, minimize errors, and streamline the overall production process. This not only improves efficiency but also cuts down on costs related to rework and rejected parts.

Reverse Engineering in Sheet Metal Forming

Reverse engineering is another critical tool that complements 3D scanning in sheet metal forming. It allows manufacturers to recreate or modify existing parts when original designs or documentation are unavailable. Using reverse engineering, companies can scan a physical part, analyze its geometry, and generate digital models that can be used for redesign or reproduction.

This process is particularly useful when working with legacy equipment or when making design improvements to existing parts. Reverse engineering enables manufacturers to optimize designs for better performance, durability, and ease of production. Additionally, it plays a crucial role in quality control and inspection services, ensuring that every piece of metalwork aligns with the required standards.

Benefits of 3D Scanning and Reverse Engineering in Metal Forming

The integration of 3D scanning and reverse engineering into the sheet metal forming process offers numerous advantages:

Accuracy: Both technologies ensure high precision, reducing errors and improving product quality.

Cost Efficiency: Faster inspections and reduced material waste lower production costs.

Speed: Digital models from 3D scanners accelerate the prototyping and production process.

Quality Control: Inspection using 3D data allows for comprehensive analysis, ensuring that all parts conform to design specifications.

Future of Sheet Metal Forming

As manufacturing technologies continue to advance, 3D scanning, reverse engineering, and related digital tools will play an even more significant role in shaping the future of sheet metal forming. The ability to produce accurate, high-quality parts with minimal error will become an industry standard, ensuring that manufacturers stay competitive in an increasingly digital world.

By leveraging 3D scanning, reverse engineering, and other advanced technologies, businesses can improve the efficiency and accuracy of their sheet metal forming operations, leading to enhanced production processes and better end products.

0 notes

Text

3D Hero

(Yo, Is That SW's Wisps?)

0 notes