#ASHRAE 90.1

Explore tagged Tumblr posts

Text

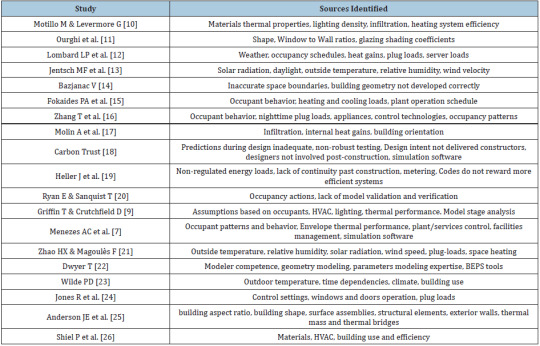

Accuracy of Code Compliant Design-Stage Building Energy Performance Simulation Models_Crimson Publishers

Abstract

Energy reduction standards have been adopted in legislation by many US states, such as ASHRAE 90.1. Aspects of 90.1 have also been adopted within many country’s national mandated building regulations. The development of Building Energy Performance Simulation (BEPS) models is one of the principal methods used to show compliance with these mandated building codes. In order to achieve the higher levels of certification of LEEDTM, a design stage model is virtually a requirement. Researchers and practitioners are indicating a growing concern with the perceived inaccuracies of BEPS models when compared to an occupied building’s energy usage. While the standard’s authors state that compliance models should not be used to compare to the actual building’s energy use, the developers funding the creation of such models, may not be aligned with this view.

This study has been undertaken in order to assess the accuracy of BEPS models developed to show code compliance and where these models fit on the spectrum of design stage models. A methodology has been developed to examine these model’s accuracy at different points through the building design process, from early stage conceptual design to finished construction, but pre-occupation. Four different building types have been examined to determine the relative complexity and accuracy of five typical pre-occupation model stages. The study assesses the accuracy of each of the five model types when compared to the actual energy usage figures for each building and discusses the industry expectations of a particular model type.

Read more about this article: https://crimsonpublishers.com/acet/fulltext/ACET.000581.php

For more articles in our journal:https://crimsonpublishers.com/acet/

#advancements in civil engineering & technology#open journal of civil engineering#peer reviewed journal of acet#open access journals#civilengineering#concrete#Building energy performance simulation#Building energy model#ASHRAE 90.1#Code compliance#Energy model sensitivity analysis#Performance Gap

0 notes

Text

Weather Design Conditions (ASHRAE)

ClimaticDesignInfo is a web app providing ASHRAE Climatic Design Information for over 8,118 global locations. It features an interactive map and allows downloading data in SI and IP units, supporting HVAC and energy-related applications across multiple sectors. ClimaticDesignInfo is a comprehensive web application designed to provide easy access to Climatic Design Information (CDI) from the…

#Ashrae#ashrae 2009 weather data#ashrae 2017 weather data#ashrae 90.1 weather data#ashrae california weather data#ashrae climatic design data#ashrae data#ashrae fundamentals#ashrae fundamentals 2017 weather data#ashrae fundamentals weather data#ashrae handbook weather data#ashrae international weather for energy calculations#ashrae iwec weather data#ashrae jeddah weather#ashrae online weather data#ashrae singapore weather data#ashrae toronto weather#ashrae weather#ashrae weather bin data#ashrae weather conditions#Ashrae Weather Data#ashrae weather data abu dhabi#ashrae weather data amsterdam#ashrae weather data bangkok#Ashrae Weather Data Download#ashrae weather data excel#ashrae weather data explanation#ashrae weather data files#ashrae weather data houston texas#ashrae weather data karachi

0 notes

Text

Tape Heaters Market: Industry Size, Share & Trends Forecast 2025–2032

MARKET INSIGHTS

The global Tape Heaters Market size was valued at US$ 467.2 million in 2024 and is projected to reach US$ 693.4 million by 2032, at a CAGR of 5.8% during the forecast period 2025-2032.

Tape heaters are flexible heating elements designed for precise temperature control across various applications. These devices utilize electrically conductive materials like silicone rubber or fiberglass insulation to generate and distribute heat efficiently. Common variants include silicone rubber tape heaters (dominating 62% market share) and fiber glass insulated variants, catering to industrial, commercial and residential needs.

Market expansion is driven by increasing adoption in chemical processing, food packaging, and medical equipment sectors where controlled heating is critical. The U.S. currently holds 28% of global demand, while China’s market grows at 7.1% CAGR through 2032 – fueled by manufacturing sector expansion. Recent innovations include Omega Engineering’s 2024 launch of ultra-thin (0.5mm) silicone heaters with improved energy efficiency, addressing sustainability concerns in industrial applications.

MARKET DYNAMICS

MARKET DRIVERS

Growing Industrial Automation to Fuel Tape Heater Demand

The global industrial automation sector is experiencing unprecedented growth, with automation investments projected to increase by over 8% annually through 2030. This surge directly correlates with rising demand for precise thermal management solutions like tape heaters across manufacturing facilities. These flexible heating elements are becoming indispensable for maintaining optimal viscosity in pipes, preventing freezing in instrumentation, and ensuring consistent temperatures in process equipment. The semiconductor industry alone accounts for nearly 22% of current industrial tape heater applications, where they maintain critical wafer fabrication temperatures within ±0.5°C tolerances.

Energy Efficiency Regulations Accelerating Adoption

Stringent global energy efficiency standards are compelling industries to replace conventional heating methods with advanced tape heater solutions. Modern silicon rubber tape heaters demonstrate 30-40% greater energy efficiency compared to traditional band heaters, while fiber glass variants reduce standby heat losses by up to 60%. Recent regulatory frameworks mandate minimum insulation standards for industrial heating applications, creating a US$120 million annual replacement market in Europe and North America. For instance, updated ASHRAE 90.1 standards now classify properly installed tape heaters as energy conservation measures eligible for green building certifications.

➤ Leading manufacturers report 18-24% shorter payback periods for tape heater retrofits compared to complete system overhauls, making them preferred solutions for compliance upgrades.

Furthermore, the aerospace sector’s shift toward electric aircraft thermal management systems presents new growth avenues, with next-generation tape heater specifications being developed for battery warming and de-icing applications.

MARKET RESTRAINTS

Material Cost Volatility Impacting Profit Margins

The tape heater market faces significant pressure from fluctuating raw material costs, particularly for silicone rubber and specialty nickel-chromium alloys. Since 2022, silicone rubber prices have varied by ±28% quarterly, directly affecting production costs for approximately 65% of tape heater products. This volatility stems from constrained silicone supplies amid growing demand from multiple industries, forcing manufacturers to either absorb costs or risk losing price-sensitive customers. Smaller manufacturers with limited inventory buffers are particularly vulnerable, with some reporting margin contractions of 300-500 basis points.

Additional Constraints

Installation Skill Gaps Proper tape heater installation requires specific techniques for optimal heat transfer and longevity, yet industry surveys indicate only 43% of maintenance technicians receive formal training. Improper installations lead to premature failures, creating skepticism among potential buyers about product reliability and lifecycle costs.

Competition from Alternative Technologies Self-regulating cable systems and thin-film heaters are capturing niche applications traditionally served by tape heaters, particularly in OEM equipment designs where space constraints favor newer technologies.

MARKET OPPORTUNITIES

EV Battery Manufacturing Creating New Demand Frontiers

The explosive growth in electric vehicle production is generating unprecedented demand for specialized tape heaters in battery manufacturing processes. Lithium-ion cell production requires precise thermal control during electrolyte filling and formation cycling, where tape heaters maintain ±1°C uniformity across large battery trays. With global EV battery manufacturing capacity projected to exceed 3,700 GWh by 2030, this single application could represent a US$280-320 million annual market for high-performance tape heaters. Leading manufacturers are already developing UL-recognized versions meeting stringent automotive safety standards.

Moreover, the medical device industry’s shift toward single-use systems incorporates sterilizable tape heaters for fluid warming applications. Recent product launches feature biocompatible silicone constructions validated for 50+ autoclave cycles, addressing infection control requirements in surgical suites.

MARKET CHALLENGES

Standardization Gaps Impeding Market Expansion

The lack of universal performance standards for tape heaters creates confusion among end-users comparing products from different manufacturers. While UL and IEC standards exist for electrical safety, there are no widely adopted metrics for comparative energy efficiency, heat flux density, or real-world durability. This ambiguity allows substantial performance variability between ostensibly similar products, with third-party testing revealing 25-40% differences in thermal output stability under identical conditions. Such inconsistencies discourage some potential buyers from transitioning from conventional heating methods.

Technical Complexities in Customization While custom-configured tape heaters represent approximately 35% of the market, the engineering lead times and prototyping costs deter smaller-scale adopters. The industry average 6-8 week delivery for specialty configurations forces some operators toward less optimal but immediately available solutions.

Thermal Cycling Durability Concerns Repeated on/off cycling in process applications accelerates aging in some tape heater constructions, with field data showing 18-30% degradation in heat output after 15,000 cycles. Manufacturers investing in enhanced materials and construction techniques must overcome entrenched user perceptions about product longevity.

TAPE HEATERS MARKET TRENDS

Growing Industrial Automation to Drive Demand for Tape Heaters

The rising adoption of industrial automation across manufacturing sectors is significantly boosting the tape heaters market. With industries increasingly relying on precision heating solutions for process control, tape heaters have become essential components in applications like pipe tracing, freeze protection, and equipment temperature maintenance. The reliability of these heaters in extreme conditions, combined with their energy efficiency, makes them particularly valuable in oil & gas, chemical processing, and food production facilities. Recent data indicates that industrial applications account for over 60% of global tape heater demand, with the market projected to exceed $1.2 billion by 2027.

Other Trends

Commercial Sector Expansion

Commercial buildings are increasingly incorporating tape heating systems for applications ranging from window de-icing to roof snow melting systems. This growing adoption is driven by stringent safety regulations and the need for reliable, low-maintenance heating solutions. The commercial segment currently represents approximately 25% of the market share, with particularly strong growth in regions experiencing harsh winters. Multi-zone temperature control capabilities and integration with smart building systems are creating new opportunities for premium tape heater products in this segment.

Technological Advancements in Heating Materials

Material innovations are transforming the tape heater landscape, with manufacturers developing next-generation silicon rubber and fiber glass insulated variants that offer superior thermal conductivity and durability. The silicon rubber segment, currently holding over 40% market share, is witnessing particularly strong innovation with products that can withstand temperatures exceeding 400°F while maintaining flexibility. These advancements are opening doors to applications in aerospace and defense sectors, where extreme environment performance is critical. Additionally, the integration of IoT capabilities for real-time monitoring and predictive maintenance is gaining traction among industrial users seeking to optimize energy consumption.

COMPETITIVE LANDSCAPE

Key Industry Players

Strategic Expansion and Innovation Drive Competition in the Tape Heaters Market

The global tape heaters market features a mix of established leaders and emerging competitors vying for market share. While the sector remains semi-consolidated, HTS/Amptek Co and Omega Engineering currently dominate the landscape, collectively accounting for a significant portion of 2024 revenues. Their leadership stems from extensive product portfolios and strong distribution networks across North America and Europe.

BriskHeat has emerged as another key player, particularly in industrial applications, due to its focus on durable silicone rubber tape heaters for harsh environments. Meanwhile, Eltherm GmbH continues to strengthen its European foothold through specialized heating solutions for chemical processing industries.

The market has witnessed notable activity recently, with Chinese manufacturers like Shenzhen Goodway and Beijing Shangkejiuye expanding aggressively in Asia-Pacific markets. Their competitive pricing strategies and rapid production capabilities are reshaping regional dynamics. Additionally, several players are investing heavily in R&D to differentiate their offerings—particularly in energy-efficient and smart heating solutions—as environmental regulations tighten globally.

Partnership strategies vary significantly across the competitive landscape. While larger players focus on vertical integration, mid-sized companies are forming strategic alliances with material suppliers to secure better pricing and ensure supply chain resilience. The industry’s evolution suggests continued consolidation may occur as companies seek to expand their technical capabilities and geographic reach.

List of Key Tape Heater Companies Profiled

HTS/Amptek Co (U.S.)

Omega Engineering (U.S.)

BriskHeat (U.S.)

Eltherm GmbH (Germany)

C-T Products Company (U.S.)

Flexotherm (U.S.)

Hotway Thermal Technology (China)

Synba Corp. Ltd (China)

Shenzhen Goodway (China)

Beijing Shangkejiuye (China)

Jiangsu Huanya (China)

Anhui Huanrui (China)

Segment Analysis:

By Type

Silicon Rubber Tape Heaters Segment Leads Due to Superior Flexibility and Thermal Conductivity

The market is segmented based on type into:

Silicon Rubber Tape Heaters

Subtypes: High-temperature, low-temperature, and self-regulating variants

Fiber Glass Insulated Tape Heaters

Other

Includes polyimide, mica, and ceramic-based tape heaters

By Application

Industrial Segment Dominates Owing to Widespread Use in Process Heating Applications

The market is segmented based on application into:

Industrial

Subdivisions: Chemical processing, oil & gas, and manufacturing

Commercial

Residential

By Power Rating

Medium Power Segment (100W-500W) Shows Strong Growth Potential

The market is segmented based on power rating into:

Low Power (Below 100W)

Medium Power (100W-500W)

High Power (Above 500W)

By End-Use Industry

Chemical Processing Industry Emerges as Key Consumer

The market is segmented based on end-use industry into:

Chemical Processing

Food & Beverage

Healthcare

Aerospace

Others

Regional Analysis: Tape Heaters Market

North America The North American tape heaters market is characterized by strong demand from industrial and commercial sectors, particularly in the U.S. where manufacturing and processing industries dominate. The region benefits from strict safety regulations and energy efficiency standards, which drive innovation in high-performance silicone rubber and fiberglass insulated tape heaters. Key players like Omega Engineering and BriskHeat have a significant presence, catering to applications ranging from pipe freeze protection to aerospace. The market is expected to grow steadily, supported by infrastructure upgrades and focus on energy-efficient heating solutions, though material cost volatility remains a challenge.

Europe Europe’s tape heaters market is driven by stringent EU regulations on energy consumption and industrial safety. Countries like Germany and France lead in adopting precision heating solutions for chemical processing and automotive industries. Silicone rubber tape heaters are preferred due to their durability and compliance with RoHS directives. The market faces pressure from rising raw material costs, but innovation in low-watt-density designs and smart temperature control systems offers growth opportunities. Eastern Europe shows potential with increasing industrialization, though adoption lags behind Western counterparts.

Asia-Pacific Asia-Pacific holds the largest market share, fueled by China’s massive industrial base and India’s expanding manufacturing sector. Demand for cost-effective fiberglass insulated heaters remains high for applications like plastic molding and food processing. Local manufacturers like Shenzhen Goodway compete on price, while international brands focus on high-end niches. Japan and South Korea lead in technological advancements, particularly for electronics manufacturing. However, price sensitivity and inconsistent quality standards in emerging markets pose challenges. The region’s CAGR is projected to outpace global averages due to rapid urbanization.

South America South America’s tape heater market is nascent but growing, with Brazil and Argentina as primary demand centers. Industries such as oil & gas and mining drive need for explosion-proof heating solutions, though economic instability limits large-scale investments. Import dependency on advanced products persists due to limited local manufacturing capabilities. While adoption is slower compared to other regions, government initiatives to boost industrialization could unlock long-term potential, especially for weather-resistant outdoor heating applications.

Middle East & Africa The MEA market is emerging with growth concentrated in GCC countries and South Africa. Oil & gas applications account for over 40% of demand, favoring high-temperature silicone rubber heaters. Infrastructure projects in the UAE and Saudi Arabia present opportunities, but market maturity is hindered by reliance on imports and lack of technical expertise. African nations show sporadic demand, primarily for commercial freeze protection, though political and economic uncertainties slow market penetration. Manufacturers are exploring partnerships with local distributors to strengthen footholds in this fragmented landscape.

Report Scope

This market research report provides a comprehensive analysis of the global and regional Tape Heaters markets, covering the forecast period 2025–2032. It offers detailed insights into market dynamics, technological advancements, competitive landscape, and key trends shaping the industry.

Key focus areas of the report include:

Market Size & Forecast: Historical data and future projections for revenue, unit shipments, and market value across major regions and segments. The global Tape Heaters market was valued at USD million in 2024 and is projected to reach USD million by 2032, growing at a CAGR of % during the forecast period.

Segmentation Analysis: Detailed breakdown by product type (Silicon Rubber Tape Heaters, Fiber Glass Insulated Tape Heaters, Others), application (Industrial, Commercial, Residential), and end-user industry to identify high-growth segments and investment opportunities.

Regional Outlook: Insights into market performance across North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. The U.S. market size is estimated at USD million in 2024, while China is projected to reach USD million by 2032.

Competitive Landscape: Profiles of leading market participants including HTS/Amptek Co, Omega Engineering, BriskHeat, Eltherm GmbH, and C-T Products Company, covering their product offerings, market share, and recent developments.

Technology Trends & Innovation: Assessment of emerging heating technologies, material innovations, and integration with IoT-enabled temperature control systems.

Market Drivers & Restraints: Evaluation of factors driving market growth including industrial automation trends along with challenges like raw material price volatility.

Stakeholder Analysis: Insights for manufacturers, suppliers, distributors, and end-users regarding the evolving market ecosystem and strategic opportunities.

Related Reports:https://semiconductorblogs21.blogspot.com/2025/06/fieldbus-distributors-market-size-and.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/consumer-electronics-printed-circuit.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/metal-alloy-current-sensing-resistor.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/modular-hall-effect-sensors-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/integrated-optic-chip-for-gyroscope.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/industrial-pulsed-fiber-laser-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/unipolar-transistor-market-strategic.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/zener-barrier-market-industry-growth.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/led-shunt-surge-protection-device.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/type-tested-assembly-tta-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/traffic-automatic-identification.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/one-time-fuse-market-how-industry.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/pbga-substrate-market-size-share-and.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/nfc-tag-chip-market-growth-potential-of.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/silver-nanosheets-market-objectives-and.html

0 notes

Link

0 notes

Text

What are some common building codes and energy efficiency standards that require specific insulation materials?

There are several common building codes and energy efficiency standards that may require specific insulation materials or prescribe certain performance levels. Here are a few examples:

International Energy Conservation Code (IECC): The IECC is a model energy code that sets minimum requirements for energy-efficient design and construction of buildings. It is widely adopted in the United States and provides guidelines for insulation materials and thermal performance. The IECC specifies thermal resistance (R-value) requirements for different climate zones, which influence the choice of insulation materials.

Leadership in Energy and Environmental Design (LEED): LEED is a green building certification program developed by the U.S. Green Building Council (USGBC). It promotes sustainable building practices, including energy efficiency. LEED certification requires meeting specific criteria related to energy performance, which often includes insulation requirements. LEED projects may need to comply with certain insulation standards to achieve certification.

youtube

ASHRAE Standard 90.1: This standard, developed by the American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE), provides guidelines for energy-efficient building design and performance. It sets requirements for insulation materials and thermal performance in commercial and high-rise residential buildings. ASHRAE 90.1 is referenced in many building codes and is considered a benchmark for energy efficiency.

Passive House Standard: The Passive House Standard, originally developed in Germany, focuses on achieving high energy efficiency and comfort in buildings. It sets stringent requirements for insulation, airtightness, and thermal performance. Buildings designed to meet the Passive House Standard often require specific insulation materials and installation techniques to achieve the desired energy efficiency goals to get EPS shredder.

Energy Performance of Buildings Directive (EPBD): The EPBD is an EU directive that aims to improve the energy efficiency of buildings across member states. It sets requirements for insulation and energy performance in new and existing buildings. The directive includes guidelines for insulation materials and thermal transmittance (U-value) requirements for different building elements.

These are just a few examples of the building codes and energy efficiency standards that may impact insulation material requirements from EPS shredder. It's important to consult the specific codes and standards applicable to your region, as requirements can vary based on local regulations and climate conditions. Local building departments, energy agencies, or industry professionals can provide more detailed information on the specific standards and codes that apply to your project.

0 notes

Text

Ashrae 90.1 Appendix A Pdf

Ashrae 90.1 Appendix A Pdf manual#

Ashrae 90.1 Appendix A Pdf code#

The review checks to verify that the proposed design reported in the Compliance Form reflects design documents that the configuration of the baseline/budget model is established correctly, that the baseline/budget and proposed design is modeled as reported, that the simulation is error-free, and that the compliance outcome is established correctly.

Ashrae 90.1 Appendix A Pdf manual#

The Review Manual includes the following: The Manual is a companion to the DOE/PNNL 90.1 Section 11 and Appendix G Compliance Form and supports 20 editions of ANSI/ASHRAE Standard 90.1. Review Manual - The ASHRASE 90.1 Section 11 and Appendix G Submittal Review Manual (the Manual) is a comprehensive reference for reviewing modeling-based submittals.

Ashrae 90.1 Appendix A Pdf code#

It standardizes compliance documentations and simplifies submittal reviews by code officials and administrators of above code program implementers.įor questions about use or customization of the form please contact the Building Energy Codes Help Desk It helps the modeler establish simulation inputs for the baseline/budget and proposed design models and includes a submittal checklist to ensure that all necessary supporting documentation is included in the submittal. This spreadsheet-based compliance form meets the documentation requirements of Standards 90.1-20 Section 11 Energy Cost Budget Method and Appendix G Performance Rating Method. Instead, the proposed building energy performance needs to exceed that of the baseline by an amount commensurate with the code year being evaluated.Ĭompliance Form - Proper enforcement of performance-based compliance submittals is necessary to ensure consistency and confidence in modeling results, yet, enforcement is a notoriously difficult process. Appendix G uses a stable baseline approach with efficiency levels set at values that are not intended to be updated with each new addition of the code.For example, in Appendix G credit is available for strategies not credited in ECB such as optimized window area and orientation, selection of more efficient HVAC and service water heating equipment type, right sizing HVAC equipment, efficient use of thermal mass, etc. Appendix G uses a more independent baseline where many of the characteristics of the baseline design are based on standard practice, meaning credit is available not only for exceeding prescriptive requirements in the code, but also for exceeding standard practice that is not regulated by the code.This approach is referred to as a dependent baseline. A building is deemed in compliance with ECB when the annual energy cost of the proposed design is no greater than the annual energy cost of the baseline building design.The baseline is essentially a clone of the proposed design with most of the building components adjusted to “just meet” current prescriptive requirements.The main differences between the ECB and PRM approaches in Standard 90.1 are the characteristics of the baseline building design. This is demonstrated using computer simulation to compare a proposed building design to a reference building design commonly referred to as a baseline. These methods provide more flexibility by allowing a designer to "trade off" compliance by not meeting some prescriptive requirements if the impact can be offset by exceeding other prescriptive requirements. The two performance-based approaches in Standard 90.1 are the Energy Cost Budget (ECB) method found in Section 11 and the Performance Rating Method (PRM), commonly referred to by its location in the Standard, Appendix G.The prescriptive path establishes criteria for energy related characteristics of individual building components such as minimum R-values of insulation, maximum U-factors and solar heat gain coefficients of fenestration, maximum lighting power allowance, occupancy sensor requirements for lighting control, and economizer requirements for HVAC systems.Commercial building energy codes such as ASHRAE Standard 90.1 typically include two types of approaches for demonstrating compliance prescriptive and performance paths.

0 notes

Link

Excerpt from this story from Inside Climate News:

Energy consumed in buildings produced more than 30 percent of U.S. greenhouse gas emissions in 2019, making them a key part of the climate challenge. And the window to decarbonize them is narrowing: Analysts at organizations such as the International Energy Agency have said that new construction worldwide will need to start switching to all-electric around 2025, if nations are to limit global warming to below 1.5 degrees Celsius (2.7 degrees Fahrenheit) in this century.

The United States does not have a national building code. Instead, states follow model codes: the International Energy Conservation Code (IECC) for homes and Standard 90.1, a building energy standard of the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), for commercial buildings. Certain states amend those standards to make them weaker or more stringent, or allow local governments to adopt codes. Other states, like California, set codes outside of the IECC process.

This decentralized approach leads to wide variation in code adoption. Nine states rely on IECC codes more than a decade old, according to tracking from the Department of Energy. Twelve states use standards set in 2015.

For efficiency advocates, that creates diffuse policy battles.

“You could be involved every three years in 52 fights over the code, because you’ve got 50 states plus the District of Columbia and the national model codes,” said Cheslak, a former D.C. codes official.

This year, those conflicts floated to the highest levels of national code development. The IECC development process—which takes place every three years—was embroiled in controversy when a significant number of local government officials turned out to vote on code changes, enacting efficiency improvements that could trickle down to jurisdictions across the country. In response, and reportedly under pressure from industry, the code council’s board of directors voted to change the process to one where local officials have less sway.

Now a growing group of clean energy and efficiency advocates, including Cheslak, are focusing on instituting local code amendments that improve on the model code. The New Buildings Institute is also already preparing language to submit in the IECC’s next code cycle, which will set standards for 2024, just one year before experts say building electrification needs to take hold.

2 notes

·

View notes

Text

Top 5 Energy Building Modeling Software

If you landed on this blog, it is obvious that either you are willing to learn about energy modeling software from scratch or you are interested in gathering some more information on it.

Building Energy Modeling (BEM) is a physics-based computer simulation of a building that can be used to analyze and predict the energy consumption, HVAC component sizing and utility bills. Building Energy Modeling software is used in new building construction and retrofit designs to achieve compliance for the energy code standards (ASHRAE 90.1, Title 24, NECB), different green building certifications like LEED v4 & Green Globes. BEM may also be used to get qualified for tax credits and utility incentives.

Energy modeling software, are used to assist various stakeholders:

● Designing a new building or renovating those

● Compliance of code

● Real-time building operation and control

● Qualification for utility incentives and tax

● Certification of green building

It is also widely used in:

● Large-scale analysis for decision making

● Developing energy codes

● Stock modeling

● Making grid-interactive efficient building etc.

Now, many building energy modeling software packages are already available in the market to serve your purpose. If you find the list quite overwhelming, check out the filtered list prepared here: The Top 5 Nuilding energy modeling software:

EnergyPlus

Energy Plus is one of the most celebrated energy modeling software. Its production began in 1996, funded by the USA, Department of Energy. The Energy Plus is meant for designing and organizing tech resources in modules that can be operated in an amalgamation or separately.

ESP-r

The energy modeling software ESP-r is designed to give realistic and accurate support to the construction project in terms of energy and environmental performance. It is a mathematical program for a project manager for managing the data, CAD applications, simulation, various performance evaluation tools, display and report generators, etc.

Cove.Tool

The energy modeling software cove.tool offers streamlined analysis to help the architects, engineers and contractor achieve energy, glare, radiation, embodied carbon, water targets while reducing construction cost. Integrating with energy codes and various CAD and 3D modeling platforms Revit, Grasshopper, SketchUp, Rhino, ArchiCAD, this software can assist in making better architecture and sustainable design. Cove.tool runs a complete heat balance for energy modeling, and detailed sky domes for daylight and glare modeling.

IES VE

The energy modeling software platform IES offers a range of variables for the architecture professionals in building simulation analysis. The model works on the representative geometric representation of the building. The software tool enables contact with other software tools for energy simulation. The software simulation framework integrates a framework for dynamic thermal simulation of building heat transfer systems.

TRNSYS

TRNSYS is a transitory system simulation software tool with a modular structure specifically designed for the development of complex energy-related systems, structuring the problem in a number of smaller components.

Hope you have got everything you are looking for in this blog. Share your thoughts with us.

1 note

·

View note

Text

DOE determina que a norma 90.1-2016 proporcionará mais economias em custos e energia, quando comparada a sua versão anterior (2013)

DOE determina que a norma 90.1-2016 proporcionará mais economias em custos e energia, quando comparada a sua versão anterior (2013)

Fonte: ASHRAE O U.S. Department Of Energy (DOE) determinou que a norma ANSI/ASHRAE/IES 90.1-2016 (Energy Standard for Buildings Except Low-Rise Residential Buildings) proporcionará uma maior eficiência energética em edifícios comerciais, se comparada a sua versão anterior (2013). Esta análise realizada pelo Departamento Norte-Americano concluiu que as edificações que aderirem integralmente à nova��

View On WordPress

#ANSI/ASHRAE/IES 90.1-2016#ASHRAE#ASHRAE 90.1#ASHRAE 90.1-2013#ASHRAE 90.1-2016#DOE#Eficiência Energética#U.S. - Department Of Energy

0 notes

Text

Why Heat Reflective Paint is Important?

Paints for heat-reflective roofs can help you save money on energy bills and just make your roof look better. They can also help your roof last longer in three ways:

How does heat reflective paint works?

Energy spectra must first be discussed before we can gain a better understanding of how Heat Reflective Paint works. The sun is the source of a certain range of energy. Another is derived not only from the earth but also from building materials. Energy is emitted by all objects to varying degrees.

The spectrum of solar energy includes both visible and invisible (infrared) wavelengths. The items you'd find in your home fall somewhere between the middle and the extremes of the spectrum. The normal transference of this energy is disrupted when heat reflective paint is applied.

They work to reflect sunlight away from the surface, lowering the amount of heat that enters a building—whether it's a house, office, factory, or warehouse—by doing so.

They reduce roof membrane thermal contraction and expansion, which, in turn:

Aids in leak control and prevention.

Your home may face significant issues as a result of defective or leaky roofing. When performing any roof maintenance, ensure that you have the appropriate tools at your disposal.

Why paint that reflects light?

First, let us explain what it is. On roofs with darker colors, reflective paints cut down on solar heat gain. The dark color of roofing materials can absorb heat and cause problems in the future. You can save money on air conditioning in the summer by lowering roof temperatures on a property. This will help you conserve energy, which is always a plus!

On a dark roof, you should use a paint like Blackfriar Professional Solar Reflective Paint. This paint is extremely adaptable because it can be applied to stable felt, bitumen, metal, concrete, brick, and other roof surfaces. This paint will leave you with a white, water-based finish that will increase the solar reflectivity of your roof. If you want to improve a new roof's solar reflectivity, this is the ideal product to use.

The heat from the roof will be dispersed and the sunlight that hits the roof will be reflected by this special paint. You can also use it to prevent surface fungal growth, so you get two benefits in one! This is also a two-coat system that self-primes, which is great if you really like a two-in-one.

How about aging roofs?

You might just be looking to fix some old roofing if you are not installing new roofing. Protexion Heat Reflective Paint Roof Coating is our recommendation for this. We love this paint because it is a great product for both pitched and flat roofs. It is one hundred percent silicone, 150 percent elastic, and it promises protection and waterproofing for twenty years. This can be applied any time of year, and in just two hours, you'll have a roof that is completely waterproof! even if you have a problem with water accumulating indefinitely. Let's move on to the reflective part, though.

Your roof will reflect more than 85% of the sun's rays with Protexion Heat Reflective Paint Roof Coating in Solar Reflective White! This helps prevent bring down thermal shock, which can damage your property and make the roof last longer. Did we mention that it will also save you energy while doing this?

Don't think so? It satisfies both the Cool Roof Rating Council's and Energy Star's requirements for reflectance performance on roofs with low and high slopes. It also meets the requirements for thermal admittance and solar reflectance: the International Code for Energy Conservation (IECC) from 2012; the Energy Standard for Buildings Other Than Low-Rise Residential Buildings, ASHRAE 90.1; The Underwriters Laboratories have listed and.

You now understand why heat reflective paint is necessary. It's time to start working on that roof repair or new roof project! We are one of the leading manufacturer and supplier of Heat Reflective Paint and Coating in Nashik, India. You can visit our site: http://www.protexion.in/heat-reflective-coating.php

0 notes

Text

Do You Need An Web Marketing System?

Though there isn’t a means so as to add alt text to your images, Instagram has no character limits for the publish description space (called a caption on this platform). Moreover, you can too begin a private blog on a free blogging platform like Blogger or WordPress, and generate substantial funds too. It could actually take slightly little bit of time. Then current the official contract you’ve created detailing all the providers you will provide them together with rates and time frame every portion of the web marketing can be completed.

happy new year Marriage ceremony photographers whom in ones personal excellent provide stunning together with breathtaking pictures that doc marriage ceremony ceremony in a imaginative in addition to story, from time to time and lots of times in the lovely trend. Some folks want to have face-to-face interplay with friends and beloved ones. Have your family, mates and group comply with these tricks to safely enjoy social media. All mates, family, and relatives gather collectively and have a good time. They use multiple methods to plan effective social media marketing campaigns.

When figuring out a social media plan for a enterprise there are various components to contemplate. And will also be glad you have discovered the most effective toy in your toddler by wanting round there. Whereas traditional advertising methods are pricey and onerous to measure, small businesses have by no means had larger access to value-effective, trackable marketing tools. Verzus Minimal Google Slides Template provides you the tools to create skilled displays. This really is an unobtrusive way to extend the visibility your affiliates get to your purchasers and therefore your potential profits.

That is the purpose at which you can see that catchphrases are the net crawler snare a site uses to get sees by websites the world over. Search by application, article language and beneficial Leviton options to get inspiration for designing ASHRAE 90.1 compliant functions. Are you considering hiring an professional search engine marketing (SEM) guide? 61,000 in a single month just from affiliate marketing. Social Sharing by Danny is considered one of my favourite social media plugins for WordPress.

One tweet can attain hundreds of thousands of people. You may even choose colour variations. By collaborating with each other, happy new year 2019 images you can broaden your customer base because you’ll be reaching new individuals. A product can be either a tangible good or an intangible service that fulfills a need or need of consumers. Compose the tweet such as you usually would, and then click on the arrow beside the “tweet” button as a substitute of the button itself. Many designers put a border across the hamburger icon or put it in opposition to a contrasting background drawing attention to the icon and making it look extra like a button.

Present us few extra information to understand the difficulty better. The difference with Yotpo is it uses social proof to promote your merchandise and simplifies the buying experience. I'm saying that each stylistic addition must be weighed against the person experience. That is from the yearly earnings gotten by professionals solely within the USA. Try one thing like “Bridal Makeup” or “First Car Service” or “Baby Blues Cure”. Try these great apps that may have you ever tweeting like a pro from the comfort of your desktop.

Do you've gotten an app particularly for kids? Now I've got a process that's outside my core competency and could use a pointer to a recipe for getting a daily oracle database and sufficient of an Apps server to run OID on the identical Solar 490 host. Our choices are streamlined through automation of huge methods by means of using software program, apps, and methods making certain the top notch possible profession levels for our proprietors and their tenants in the entirety of what we do.

1 note

·

View note

Video

youtube

تاكد انك مشترك في القناة 💯 ومفعل الجرس عشان يوصلك كل جديد 🔔 وما تنساش تعمل لايك للفيديو 👍 نشرك للمقطع هو اكبر دعم ممكن تقدمه لي ... https://bit.ly/3ObyRHH أتمنى أن ينال الشرح أعجابكم ...................................................................... https://bit.ly/3ux7pwI شير مشاركة #BIMarabia اشترك في القناة لمتابعة الشروحات الجديدة videos https://www.youtube.com/channel/UCZYaOLTtPmOQX1fgtDFW52Q?sub_confirmation=1 بيم ارابيا https://bit.ly/1TSqEbr Places to find me! https://bit.ly/OcqQ6x https://bit.ly/2nqASDv Instagram: https://bit.ly/2JY3wZP Twitter: https://twitter.com/BIMarabia Whole Building Energy Simulation Load Calculations HVAC System Selection and Sizing Parametrics and Optimization Energy Conservation Measures Code Compliance Ratings and Certificates Utility Bill and Meter Data Analysis Weather Data and Climate Analysis 0 Reviews 0Add to compare HOT2000 Detailed energy analysis for homes and low-rise residential buildings. Free. User support is limited. Whole Building Energy Simulation Load Calculations Energy Conservation Measures Residential Last Software Update: 03 August 2011Last Entry Update:25 August 2018 Ratings 4 Reviews 1Add to compare FREE Building Modeling for Energy Conservation FREE bin-weather modeling software provide accurate energy savings and penalties within seconds through your browser. Energy Conservation Measures Utility Bill and Meter Data Analysis Weather Data and Climate Analysis Building Energy Auditing Ratings and Certificates Building Energy Auditing Residential Last Software Update: 27 October 2017Last Entry Update:26 August 2018 Ratings 0 Reviews 0Add to compare Occupancy Simulator Occupancy Simulator is a web-based App that simulates occupant presence and movement in a building using the Markov-chain model. Other Commercial Last Software Update: 28 December 2018Last Entry Update:28 December 2018 Ratings 0 Reviews 0Add to compare Energy Model Quality Check Tool Energy Model Quality Check tool takes the Energy simulation software input and output files as input and generates instant reports on energy model quality of the building as per ASHRAE 90.1 Appendix G standards. Whole Building Energy Simulation Building Energy Benchmarking Commercial, Residential, Multi Family Last Software Update: 26 April 2016Last Entry Update:24 September 2018 Ratings 0 Whole Building Energy Simulation Energy Conservation Measures Building Energy Auditing Residential Last Software Update: 10 February 2012Last Entry Update:25 August 2018 Ratings 0 Reviews 0Add to compare Elements Elements is a free, open-source, cross-platform software tool for creating and editing custom weather files for building energy modeling. Weather Data and Climate Analysis Last Software Update: 29 November 2016Last Entry Update:11 October 2018 Ratings 5 Reviews 0Add to compare COMFEN India Version COMFEN India is a simple single-zone facade analysis tool for commercial building based on EnergyPlus and Radiance simulation engine developed for Indian context. Parametrics and Optimization Code Compliance Subsystem Level, Commercial Last Software Update: 18 March 2016Last Entry Update:19 September 2018 Ratings 0 Reviews 0Add to compare Building Energy Descriptor Exchange Specification (BEDES) The Building Energy Data Exchange Specification (BEDES) is a living data dictionary for building energy data. It facilitates the exchange of information on building characteristics and energy use. Other Subsystem Level, Commercial, Residential, Multi Family, Portfolio Scale, District Scale, Urban Scale Last Software Update: 02 November 2018Last Entry Update:02 November 2018 Ratings 0 Reviews 0Add to compare HEED Home Energy Efficient Design See how much energy and money and carbon you can save by making various design or remodeling changes to your home with this free new easy-to-use program. You can draw in the floor plan of your own house, then click and drag your windows to their correct location. Whole Building Energy Simulation Energy Conservation Measures Solar and Photovoltaic Analysis Residential Last Software Update: 17 December 2015Last Entry Update:29 August 2018 Ratings 0 Reviews 0Add to compare RESFEN A program to help consumers and builders pick the most energy-efficient and cost-effective window for a given application. Whole Building Energy Simulation Parametrics and Optimization Weather Data and Climate Analysis Subsystem Level, Residential Last Software Update: 30 June 2010Last Entry Update:20 September 2018 Ratings 0 Reviews 0Add to compare Pages Home About Us Contact Us Privacy Policy Terms and Condition Disclaimer Top Rated Software Most Reviewed Software Latest Software Sign In Register Forgot Password? Copyright: Best Directory | All Rights Reserved Follow Us On by BIMarabia

0 notes

Link

0 notes

Text

York Latitude Chiller Manual

The Liquid Chiller will be completely assembled with all interconnecting refrigerant piping and internal wiring, ready for field installation. The unit can be covered with an optional coat of Caribbean Blue enamel overspray. The unit will be pressure-tested, evacuated, and charged with dry Nitrogen (N 2) for shipment, and York ‘L’ (POE).

York Latitude YCIV0830V User Manual (140 pages) Air Cooled Screw Liquid Chillers R134a 150 - 385 TONS (527 - 1354 kWi) 2 and 3 Compressor 50 and 60 Hz ASHRAE 90.1 Compliant.

Read Free York Millenium Recip Chiller Manualyork millenium recip chiller manual, but stop in the works in harmful downloads. Rather than enjoying a fine book behind a cup of coffee in the afternoon, on the other hand they juggled in the manner of some harmful virus inside their computer. York millenium recip chiller manual is reachable in our.

York Latitude Chiller Manual Instructions

York Latitude Chiller Manual User

York Chillers Troubleshooting

York Centrifugal Chiller Manual

York Latitude Chiller Manual Troubleshooting

LIQUID CHILLERS INSTALLATION, OPERATION, MAINTENANCE Supersedes 201.21-NM1 (315) Form 201.21-NM1 (616) Issue Date: June 30, 2016 035-20552-000. 2 JOHNSON CONTROLS. To the manual or product owner. Updated manuals, if applicable, can be obtained by contacting the nearest. York Air-Cooled Chiller Latitude Model R134a Brochure 2004.

Updated December 12, 2020

Headquartered in York, Pennsylvania, York International Corporation sells residential and light commercial furnaces, heat pumps, ventilating units, refrigeration units, and central air conditioners. The company markets furnaces under the brand names Coleman, Luxaire, and York and serves more than 150 countries, making them a multinational leader in the industry. Their products are found in diverse locations such as the British House of Parliament, Sydney Opera House, and Los Angeles International Airport. Johnson Controls, York’s parent company, recorded approximately $30 billion in sales in 2017. They employ 13,800 people around the globe.

HVAC Cost Calculator

Want to know how much a new hvac unit should cost? Try our cost calculator to get free local price estimates for the top brands.

How much will my HVAC system cost?

York Latitude Chiller Manual Instructions

Get a free online estimate for your HVAC system.

Your email has been sent

Thank you for letting HVAC.com connect you with a certified contractor. A local specialist will contact you shortly.

Your HVAC.com estimate is $5,000 – $6,000

This estimate is based on current data and is not a guaranteed price. For accurate pricing contact a local HVAC pro.

Here are a few brands we recommend:

Trane

Founded over 100 years ago, Trane is a well-known provider of HVAC products systems.

Explore Trane furnaces

Lennox

Lennox specializes in innovative technologies that maximize efficiency and minimize noise.

Explore Lennox furnaces

Goodman

Goodman HVAC systems are proudly “designed, engineered and assembled in the U.S.A.

Explore Goodman furnaces

System Type

–

Home Size

–

HVAC Features

–

*Estimate is based on current data and does not represent a guaranteed price. For accurate pricing contact a local HVAC dealer.

York products

York brand believes in extraordinary innovation and exceptional reliability. Their air conditioner line is divided into two series; the Affinity series and the popular LX series.

Affinity Series

YXV is York’s most efficient air conditioner with a SEER rating of 20. This model boasts an ENERGY STAR® rating and won the 2017 Dealer Design Awards Gold Award. The Quiet Drive sound reduction technology puts decibel levels as low as 53Db, which is about as loud as the average dishwasher. A 10-year limited parts warranty and a 1-year labor warranty are offered.

YXT is a 2-stage system for improved temperature and humidity control. It rates a 19 on the SEER efficiency scale and an ENERGY STAR® rating. It works with a standard thermostat or the Hx3 4.3 inch touch screen thermostat. It also has Quiet Drive technology and decibel levels as low as 67.

LX series

The LX series of York air conditioners are affordable and efficient. They are designed to save you money on your utility bills.

YFK is a high-efficiency, two-stage air conditioner. It has an ENERGY STAR® rating and a SEER rating of 17. Decibel levels are as low as 68, and the unit works with conventional thermostats. The unit includes 10-year parts/compressor and 1-year labor limited warranties.

YCG is a high-efficiency single-stage air conditioner. It has a SEER score of 14 and is perfect for those living in southwestern climates. Decibel levels are as low as 70, and the unit offers a 10-year warranty on the compressor and a 10-year parts/1-year labor limited warranty.

York gas furnaces

York gas furnaces are divided into three lines: the Affinity, the LX, and the Latitude.

Affinity Furnaces

YP9C is York’s most efficient and comfortable furnace. It has a 98% AFUE rating and won the Consumer’s Digest Best Buy Award in 2017. The unit boasts an ENERGY STAR® rating and comes with a lifetime warranty on the heat exchanger and a 10-year parts/1-year labor warranty.

LX Series

TM9V is a two-stage furnace with variable speed. Boasting an ENERGY STAR® rating and an efficiency rating of 96% AFUE, this unit has a lifetime heat exchanger/10-year parts/1-year labor warranty.

TL9E is a single-stage ultra low NOx with a high-efficiency blower motor. It is ENERGY STAR® rated with an efficiency rating of 95%. It’s compact size of 33 inches fits in most spaces. This unit offers a 20-year heat exchanger/10-year parts/1-year labor limited warranty with registration.

Latitude Series

The Latitude series of York furnaces features quality and dependability in a compact package.

TG8S is a single-stage furnace that features 80% AFUE. It has low air leakage — less than 2% at 1.0 of static pressure — and a lifetime heat exchanger/10-year parts/1-year labor warranty.

Currently, York does not make an oil furnace.

York heat pumps

Once again, York divides its products into two product lines: the Affinity, being the most efficient, and the LX series, which is a more economical line.

Affinity Series

YZV is a variable capacity split system featuring a SEER rating of 20 and ENERGY STAR® rating. This unit is compatible with the Hx3 4.3 touch screen thermostat, although it can also work with a standard thermostat. Decibel levels are as low as 66 for high-stage heating and 69 for cooling; levels are of 54 for low-stage heating or cooling, which is about as loud as the average dishwasher. The YZV offers a lifetime warranty on the compressor and a 10-year parts/1-year labor warranty.

YZT is a two-stage communicating heat pump. This heat pump has an ENERGY STAR® efficiency rating of 19 SEER and 10.0 HSPF to help lower energy bills. It also has a lifetime compressor, 10-year parts, and 1-year labor warranty. It has decibel levels as low as 66 for cooling and 67 for heating.

LX Series

YHG is a single-stage heat pump. It has a SEER rating of 17 and an HSPF rating of 10 heating efficiency. It has a 10-year parts and 10-year limited compressor warranty. Decibel levels are as low as 69 for cooling and 70 for heating.

York Packaged Systems

York residential packaged systems consolidate all the components of a traditional, split HVAC system into a single unit.

PCE6 is a two-stage cooling package unit with a SEER rating of 16. It’s Energy Star rated and also provides up to 25 Kw electric heating. Decibel levels are as low as 64 for cooling and 63 for heating. It offers a 10-year electric heat warranty as well as a 10-year compressor, 10-year parts and 1-year labor warranty.

PHE6 is a 16 SEER rated, two packaged heat pump unit. It also has 8.2 HSPF heating, plus 25 kw of supplemental electric heating. Decibel levels as low 73 for cooling and 72 for heating. The unit boasts 10-year compressor, 10-year parts, 10-year supplemental electric, and 1-year labor warranties.

PCG4 is a single-stage packaged unit with a SEER rating of 14 and 81% AFUE efficiency. Lifetime heat exchanger, ten year compressor, 10-year parts and 1-year labor limited warranties come with this unit. Decibel levels as low as 74.

York pricing

Many things affect the price of an HVAC system. Some of them are:

The size of your home

The climate you live in

The efficiency of your system — the SEER rating

The condition of your ductwork

The type of home

Some homes require more complicated installation. The best way to determine the cost of a new York HVAC system is to contact a local HVAC professional. He/she will be able to advise you on what size you need, evaluate your ductwork and estimate at how complicated the installation will be.

York reviews

For consumers’ unbiased opinions on the York brand, it’s important to read reviews. Customers can tell you about the reliability of the unit, how good customer service is, the energy efficiency of their unit, and how smoothly the installation process went. Look for patterns among the reviews. Just one or two negative or positive reviews might not mean anything. Consider the overall consensus.

York warranties

York offers standard and (optional) extended warranties. The unit offers 10-year parts and 10-year compressor warranties, although conditions apply. Register your York product online to take full advantage of the warranties.

For a full list of York product warranties, go here.

November 1, 2018

York furnaces offer high energy efficiency and reliable comfort for homes across the U.S. As one of the nation’s leading furnace manufacturers, York delivers the warmth your family needs throughout the cold season while conserving energy to keep your utility bills low. York furnaces come with a selection of manuals to help you better understand how your furnace operates, how to use it, and how to care for it.

York furnace manuals should always be kept after installation for future references. If your York furnace manuals have been misplaced or are otherwise inaccessible, don’t sweat! HVAC.com has you covered – access your York furnace manuals online, as well as manuals for HVAC equipment manufactured by other leading brands.

York Furnace User’s Manuals

User guide York furnace manuals give homeowners valuable information about installation, operation, maintenance, and service. Learn how to operate your new York furnace and how to care for it throughout its years of service.

York Latitude Chiller Manual User

(table id=8 /)

York Furnace Technical Manuals

Technical information in York furnace manuals explain the features of your new York furnace. York furnace warranty information is available in the technical manual as well as information regarding accessory equipment compatible with your York furnace.

(table id=9 /)

York Chillers Troubleshooting

Find a York Furnace Manual on HVAC.com

HVAC.com provides thorough resources to help you best understand and operate your York furnace and other heating, cooling, and indoor air quality equipment. Find the manuals associated with your HVAC equipment easily on HVAC – visit our collection of HVAC equipment manuals and quickly access the information you need to install, operate, troubleshoot, and care for your home’s heating, cooling, and indoor air quality equipment.

Related Posts

November 30, 2019

What Are The Different Types of Furnaces?

York Centrifugal Chiller Manual

November 25, 2019

York Latitude Chiller Manual Troubleshooting

How to Buy A Furnace

0 notes

Text

"If we act together now, we change the world"

Architects can prevent the worst effects of climate change by deciding to design and build to net-zero carbon standards, argues Edward Mazria, architect and founder of non-profit organisation Architecture 2030.

Architecture 2030 is calling on all architects, planners, engineers and those responsible for designing and constructing the built environment worldwide to design all new buildings, renovations, landscapes, cityscapes and infrastructure to be zero carbon beginning right now.

If we act together today, we prevent the worst effects of climate change. Our calling is, and has always been, to make the world a better place. Now we get the chance to do it on a global scale and help protect life on the planet. If we act together now, we change the world.

Almost 15 years ago, in 2007, I was sitting next to doctor James Hansen at the Architecture 2030 Global Emergency Teach-in and asked him: "When will we begin to see the actual effects of global warming?"

He leaned over and whispered: "At about one degree Celsius warming". Today, I checked NASA’s "Vital Signs of the Planet" website and sure enough, the planet is currently at 1.02 degrees Celsius warming above pre-industrial levels.

The time for half measures and outdated timelines is over

As I write this, the IPCC just released an alarming report on the state of the climate crisis, and brutal heat waves, droughts, deadly flooding and fires are shattering records all over the planet and currently ravaging Europe, North America, China and India – the regions currently responsible for 58 per cent of all global CO2 emissions.

These events have driven home two essential facts: we’re all in this together and must all act quickly and boldly. The time for half measures and outdated timelines is over if we are to prevent irreparable destruction of our cities, towns, and natural environments.

As architects and design professionals, we have a unique and critically important role to play. Buildings alone account for about 40 per cent of total annual global CO2 emissions and with building interiors, sitework, landscapes, cityscapes and infrastructure, that percentage is much, much greater.

Our community must provide the leadership necessary

If the world is to meet the 1.5 degrees Celsius carbon budget set out in the Paris Agreement, our community must provide the leadership necessary and reduce CO2 emissions in the entire built environment by 65 per cent by 2030 and to zero by 2040.

We directly shape and influence the built environment worldwide and are the one industry across all political and geographic boundaries with the design and planning freedom to affect global emissions immediately. In other words, we can decide to design and build to zero-carbon today.

How difficult is it to design to zero carbon? Not difficult at all.

Zero carbon in three steps:

1. Design to the latest code standards Design all new buildings, major renovations and developments to the most current energy code standards – ASHRAE 90.1 2019 and IECC 2021, their equivalent, or better. In other words, design energy-efficient buildings that use little energy to operate.

Local building energy codes only set minimum energy efficiency requirements and do not prevent architects, engineers and building sector professionals from designing to the most current code standards or producing energy-efficient buildings.

Designing to current standards has several advantages – they are evaluated to be cost-effective, reduce occupant energy burdens, and include ready-to-use energy modeling compliance tools, checklists and trade-off options such as COMcheck and REScheck. In the developing world, free EDGE software can be used to design energy-efficient commercial or residential buildings in over 160 countries. EDGE will pinpoint least-cost options, calculate utility savings, payback periods and a building’s carbon footprint.

2. Design all-electric and renewables Design all new buildings, major renovations and developments to use no on-site fossil fuels – no gas, oil or propane – and to be 100 per cent powered by on-site and/or new off-site renewable energy.

Burning fossil fuels directly in buildings accounts for about 5.4 per cent of total worldwide greenhouse gas emissions, and burning gas, oil and propane in buildings accounts for 35 per cent of all US building sector CO2 emissions. To meet the 1.5 degrees Celsius carbon budget, buildings must be designed all-electric, with the electricity supplied by on-site and/or new off-site renewable energy (see the Zero Code and 2021 IECC Zero Code Appendix).

The health, economic and environmental benefits of all-electric buildings are well documented. This will also further lay the groundwork for new renewables to decarbonize the power sector and, in turn, the existing building sector.

3. Zero out embodied carbon While steps number one and two will produce zero-carbon building operations, it is also critical that we confront the embodied carbon of construction and building materials if we hope to phase out CO2 emissions by the year 2040.

Architects, planners and designers can minimize the embodied carbon emissions from all new buildings, major renovations, infrastructure and construction by adopting the following:

a. Reuse Repurpose and upgrade urban areas and renovate existing buildings instead of constructing new buildings whenever possible; use local and recycled materials when available; design buildings so that they can be deconstructed and their materials reused at the end of life.

b. Reduce Infill and densify urban areas to utilize existing infrastructure; reduce material use by optimizing structural designs; specify low- to zero-carbon materials using comparative tools such as the Embodied Carbon in Construction Calculator (EC3), among many others.

c. Sequester Use mass timber and glue or cross-laminated wood from existing sustainably managed forests; use bamboo structural members and panels where available; specify materials that sequester CO2 in their manufacture or application; plan and design carbon-sequestering sites, parks and urban landscapes.

Twenty years ago, when I founded Architecture 2030 and issued the 2030 Challenge, achieving zero carbon buildings seemed a far-off aspiration. Today, thanks to many years of creativity and ingenuity on the part of the global design and building community, we have the knowledge, standards, tools and technologies readily available to achieve zero carbon buildings in all climates.

The global architecture, planning, engineering and building community has an extraordinary opportunity to lead efforts to solve the climate crisis. This is the ultimate design project; this is our legacy.

Edward Mazria is the founder and CEO of the nonprofit Architecture 2030 and is an internationally recognized architect, author, researcher and educator. Over the past four decades, his research into the sustainability, resilience, energy consumption and greenhouse gas emissions of the built environment has helped redefine the role of architecture, planning, design and building in reshaping our world. He was awarded the 2021 AIA Gold Medal for his "unwavering voice and leadership" in the fight against climate change.

The post "If we act together now, we change the world" appeared first on Dezeen.

0 notes

Text

Why Heat Reflective Paint is Important?

Paints for heat-reflective roofs can help you save money on energy bills and just make your roof look better. They can also help your roof last longer in three ways:

How does heat reflective paint works?

Energy spectra must first be discussed before we can gain a better understanding of how heat reflective paint works. The sun is the source of a certain range of energy. Another is derived not only from the earth but also from building materials. Energy is emitted by all objects to varying degrees.

The spectrum of solar energy includes both visible and invisible (infrared) wavelengths. The items you'd find in your home fall somewhere between the middle and the extremes of the spectrum. The normal transference of this energy is disrupted when heat reflective paint is applied.

They work to reflect sunlight away from the surface, lowering the amount of heat that enters a building—whether it's a house, office, factory, or warehouse—by doing so.

They reduce roof membrane thermal contraction and expansion, which, in turn:

Aids in leak control and prevention.

Your home may face significant issues as a result of defective or leaky roofing. When performing any roof maintenance, ensure that you have the appropriate tools at your disposal.

Why paint that reflects light?

First, let us explain what it is. On roofs with darker colors, reflective paints cut down on solar heat gain. The dark color of roofing materials can absorb heat and cause problems in the future. You can save money on air conditioning in the summer by lowering roof temperatures on a property. This will help you conserve energy, which is always a plus!

On a dark roof, you should use a paint like Blackfriar Professional Solar Reflective Paint. This paint is extremely adaptable because it can be applied to stable felt, bitumen, metal, concrete, brick, and other roof surfaces. This paint will leave you with a white, water-based finish that will increase the solar reflectivity of your roof. If you want to improve a new roof's solar reflectivity, this is the ideal product to use.

The heat from the roof will be dispersed and the sunlight that hits the roof will be reflected by this special paint. You can also use it to prevent surface fungal growth, so you get two benefits in one! This is also a two-coat system that self-primes, which is great if you really like a two-in-one.

How about aging roofs?

You might just be looking to fix some old roofing if you are not installing new roofing. Protexion Heat Reflective Paint Roof Coating is our recommendation for this. We love this paint because it is a great product for both pitched and flat roofs. It is one hundred percent silicone, 150 percent elastic, and it promises protection and waterproofing for twenty years. This can be applied any time of year, and in just two hours, you'll have a roof that is completely waterproof! even if you have a problem with water accumulating indefinitely. Let's move on to the reflective part, though.

Your roof will reflect more than 85% of the sun's rays with Protexion Heat Reflective Paint Roof Coating in Solar Reflective White! This helps prevent bring down thermal shock, which can damage your property and make the roof last longer. Did we mention that it will also save you energy while doing this?

Don't think so? It satisfies both the Cool Roof Rating Council's and Energy Star's requirements for reflectance performance on roofs with low and high slopes. It also meets the requirements for thermal admittance and solar reflectance: the International Code for Energy Conservation (IECC) from 2012; the Energy Standard for Buildings Other Than Low-Rise Residential Buildings, ASHRAE 90.1; The Underwriters Laboratories have listed and.

You now understand why heat reflective paint is necessary. It's time to start working on that roof repair or new roof project! We are one of the leading manufacturer and supplier of Heat Reflective Paint and Coating in Nashik, India. You can visit our site: http://www.protexion.in/heat-reflective-coating.php

Source : https://writeupcafe.com/why-heat-reflective-paint-is-important/

0 notes