#Super Duplex S32760 Flanges Manufacturers

Text

Super Duplex S32760 Flanges Manufacturers in India

The manufacturer and supplier of Very Duplex Steel Flanges made their products in a variety of sizes and forms for the customer in response to interest. The manufacturer, stockist, and supplier of the entire stainless steel item, including this, is Sankalp Alloys Overseas. They provide everything and deliver the product while maintaining excellent quality and price as well.

Super Duplex Steel Flanges are regarded as the best in the series of steel Flanges based on their characteristics and strong points. The austenitic toughened steel is offered in Very Choice with a few components like copper, zinc, and chromium. The majority of businesses use a lot of Duplex steel products since they provide high strength when they come into touch.

There are many kinds of Flanges accessible, for example, Welding Neck Wall It is by and large utilized in low-temperature and high-pressure applications since they required the unhindered liquid stream conveyed by the line framework. Long welding Neck-They is equivalent to a weld neck just contrast in a lengthy welding neck the tightened center point (neck) is expanded and performs like an exhausting expansion. Slip-on Spine It is appended to the fittings or the line by two filet welds, one external the hole and the other one executed inside the rib. They are handily perceived by their minimal and thin shape.

Strung Rib This is attached by screwing the line into the spine rather than using a crease weld. They are typically used in small, low-temperature, low-stress applications like utility and water management. They are legally required in dangerous areas like petrol stations and industries. Since welding associations could be dangerous in this type of environment. Spine Attachment Weld To connect this type of rib to the lines, a single fillet weld is performed on the exterior of the rib. Joint-joint ribs This spine frequently uses an alloy with a stub end and a component with a level spacing. Dark Spine Due to the necessary catapulting forces and the structure pressure, these Flanges reduce outstanding mechanical forces.

A few other exceptional sorts of rib are Nipo rib, Weldo rib, Turn Rib, Elbo Rib, Lactro Rib, Growing spine, and Lessening Rib.

Specification of Super Duplex Stainless Steel S32750/S32760 Flanges

Super Duplex Stainless Steel Flanges Specification: ASTM A182 / ASME SA182

Dimension Standard : ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Standard: ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

Size: 1/2" (15 NB) to 48" (1200NB)

Class / Pressure : 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc.

Flange Face Type: Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

DIN Flanges : DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673.

JIS Flanges : JIS B2220 5K, JIS B2220 10K, JIS B2220 16K, JIS B2220 20K

BS Flanges: BS4504 PN 6, BS 4504 PN 10, BS4504 PN 16, BS4504 PN 25, BS4504 PN 40, BS 4504 PN 64, BS 4504 PN 100, BS 4504 PN 160, BS 4504 PN 250, BS 10, BS Table D, BS Table E, BS Table F, BS Table H.

11 notes

·

View notes

Text

#Super Duplex S32750/S32760 Flanges Manufacturers in India#Super Duplex S32750/S32760 Flanges Suppliers in India#Super Duplex S32750/S32760 Flanges Stockists in India#Super Duplex S32750/S32760 Flanges Exporters in India

0 notes

Text

Super Duplex S32760 Flanges Leading Supplier In Singapore | Bhagya Laxmi Industrial

In the area of industrial operations, the significance of top notch components can not be overstated. Every nut, bolt, and flange performs a pivotal role in ensuring the seamless functioning of equipment and infrastructure. Among those components, Super Duplex S32760 Flanges stand out as a testament to sturdiness, corrosion resistance, and overall performance. As a main supplier in Singapore, Bhagya Laxmi Industrial has emerged as a beacon of excellence in providing pinnacle-notch Super Duplex S32760 Flanges to satisfy various commercial needs.

Super Duplex S32760 Flanges Manufacturer: Crafting Excellence

When it involves the manufacturing of Super Duplex S32760 Flanges, precision and expertise are paramount. A producer's dedication to high-quality and adherence to enterprise requirements are important in turning in merchandise that stand the check of time. Bhagya Laxmi Industrial, as a prominent producer, exemplifies these qualities. With a focus on modern generation and a dedication to excellence, they have got mounted themselves as a dependable source for advanced Super Duplex S32760 Flanges.

Super Duplex S32760 Flanges Supplier in Singapore: Meeting Industry Demands

Singapore, acknowledged for its strong business landscape, needs products of the very best quality. As a supplier of Super Duplex S32760 Flanges in Singapore, they have consistently met and handed those demands. Their commitment to sourcing the finest substances and using stringent exceptional control measures ensures that their customers receive nothing but the high-quality. Whether it's for offshore oil rigs, chemical processing vegetation, or marine applications, their Super Duplex S32760 Flanges have verified to be a cornerstone of reliability.

Super Duplex S32760 Flanges Stockist: Ensuring Timely Availability

In the quick-paced international of enterprise, the supply of important components can make all the difference. They as a stockist of Super Duplex S32760 Flanges, understands this necessity. Their sizable stock and green logistics ensure that customers have get right of entry to to the required flanges precisely once they need them. This dedication to well timed availability has solidified their position as a trusted companion to severa industries across Singapore.

Super Duplex S32760 Flanges Supplier In Singapore: A Global Reach

The global marketplace provides its own set of challenges and possibilities. As an exporter of Super Duplex S32760 Flanges in Singapore, they have successfully navigated those waters. Their adherence to worldwide requirements, coupled with a focus on consumer pride, has enabled them to carve a spot inside the international arena. By exporting pinnacle-best Super Duplex S32760 Flanges, they've no longer handiest bolstered their personal popularity however have also contributed to the development of industries worldwide.

Super Duplex S32760 Flanges Dealer: A Commitment to Service

In the area of business additives, the role of a dealer extends beyond mere transactions. It features a commitment to carrier, reliability, and customer satisfaction. They as a trusted supplier of Super Duplex S32760 Flanges, embodies these principles. Their willpower to expertise client necessities and presenting tailored answers has earned them the agree with of severa organizations across Singapore. Through their unwavering dedication to provider, they have established enduring partnerships with their clients.

The Superiority of Super Duplex S32760 Flanges

Super Duplex S32760 Flanges, with their remarkable mechanical properties and resistance to corrosion, are quintessential in a big selection of industrial programs. Their capacity to withstand harsh environments and excessive-stress situations makes them a desired choice for crucial operations. Whether it is within the oil and fuel zone, chemical processing, or marine engineering, the reliability of Super Duplex S32760 Flanges is unheard of. As industries maintain to push the boundaries of performance and performance, the call for for such extraordinary additives is simplest set to upward thrust.

A Name You Can Trust

In end, the significance of Super Duplex S32760 Flanges can not be overstated in the context of business operations. As a main producer, dealer, stockist, provider, and exporter of those flanges in Singapore, they have continually upheld the very best standards of pleasant and service. Their unwavering commitment to excellence, coupled with their comprehensive range of commerci al components, makes them a move-to source for businesses in search of reliability and performance. To explore their widespread catalog of merchandise, including Super Duplex S32760 Flanges, and to experience their splendid carrier firsthand, reach out to Bhagya Laxmi Industrial today.

Contact them for all your commercial component needs, such as Super Duplex S32760 Flanges, and witness the difference that pleasant and reliability could make for your operations.

#Super Duplex S32760 Flanges Manufacturer#Super Duplex S32760 Flanges Supplier In Singapore#Super Duplex S32760 Flanges Stockist#Super Duplex S32760 Flanges Exporter In Singapore#Super Duplex S32760 Flanges Dealer

0 notes

Text

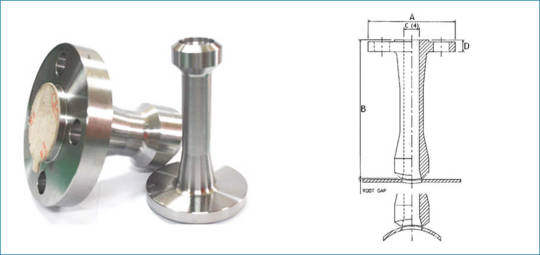

Nipo Flanges

Class 300 Nipo Flanges, Carb

on Steel Nipo Flange, Nickel Alloy Nipo Flanges, ASME B16.5 Raised Face Nipo Flange, ANSI B16.5 Nipo Flanges, Best Deals on Raised Face Nipo Flanges, ASME / ANSI B16.5 Nipo Flanges, Stainless Steel Nipo Flange dealer in India.

NIPO FLANGES MATERIAL & GRADES

Stainless Steel Nipo FlangesASTM A182 F 304, 304L, 304H, 309, 310, 310S, 316, 316L, 317, 317L, 321, 321H, 347, 347H, 446, 904LCarbon Steel Nipo FlangesASTM A105, ASTM A694 Gr. F42, 46, 52, 56, 60, 65, 70Alloy Steel Nipo FlangesASTM A182, F1, F5, F9, F11, F22, F91Duplex Steel Nipo FlangesASTM A182, F44, F45, F51, F53, F55, F60, F61Super Duplex Nipo FlangesASTM A182, F44, F45, F51, F53, F55, F60, F61Low Temperature Carbon Steel Nipo FlangesASTM A350, LF2, LF3

ASME B16.5 NIPO FLANGES SPECIFICATION

BS

BS4504 , BS4504, BS1560, BS10

FLANGE FACE TYPE

Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

2 notes

·

View notes

Text

Super Duplex Stainless Steel Grades With Astm Specification

Super Duplex Stainless Steel is a special type of stainless steel known for its strength and high resistance to corrosion. It’s used in industries like oil and gas, chemical processing, and marine applications where harsh conditions demand a tough material.

Super Duplex Stainless Steel is a metal that combines the benefits of two different types of stainless steel- austenitic and ferritic. It performs well in tough environments, like where there’s exposure to salty water or harsh chemicals. The word “super” refers to its superior performance when compared to regular stainless steel, especially in environments that cause other metals to corrode or fail.

ASTM Standards for Super Duplex Stainless Steel

The ASTM (American Society for Testing and Materials) sets important standards for materials like Super Duplex Stainless Steel. These standards ensure the metal meets certain requirements, like chemical composition, mechanical properties, and strength, so it can be used safely in different applications.

Here are some common ASTM standards for Super Duplex Stainless Steel:

ASTM A182: Covers fittings, flanges, and other parts made of Super Duplex Stainless Steel, used for high-temperature applications.

ASTM A240: Sets the standards for sheets and plates made from stainless steel, including Super Duplex grades.

ASTM A789: Covers tubing made from Super Duplex Stainless Steel, commonly used in heat exchangers and other applications that need strong, corrosion-resistant tubes.

Common Super Duplex Stainless Steel Grades

There are different types of Super Duplex Stainless Steel, each suited for particular jobs. Here are some common grades:

UNS S32750: This is a very popular grade, known for being strong and resistant to rust, especially in environments with saltwater or chemicals. It’s often used in the oil and gas industry, as well as in chemical processing.

UNS S32760: This grade offers higher corrosion resistance, particularly in chloride-rich environments making it perfect for subsea pipelines and offshore oil rigs where exposure to saline solutions and extreme conditions is common. For example, in desalination plants and shipbuilding due to its ability to withstand pitting and stress corrosion cracking.

UNS S32550: Another grade of Super Duplex, it offers good performance at a lower cost. It’s often chosen when top-level corrosion resistance isn’t needed, but strength is still important.

Why Super Duplex is So Special?

Super Duplex Stainless Steel is valued for two main reasons: its strength and its resistance to corrosion. Compared to regular stainless steel, Super Duplex is about twice as strong. This means thinner walls can be used in pipes and fittings, reducing costs without losing durability.

Its resistance to corrosion, especially in environments that contain chlorides, is much higher than regular steel. This makes it ideal for industries that work with chemicals, water, or high-pressure systems.

Where is Super Duplex Stainless Steel Used?

Super Duplex Stainless Steel is a favourite in industries that face tough conditions:

1. Oil and Gas: Offshore platforms and undersea pipelines use Super Duplex because it can handle the pressure and exposure to corrosive elements.

2. Chemical Processing: Super Duplex is used in tanks, reactors, and piping systems that must withstand harsh chemicals without corroding.

3. Marine Applications: Ships, desalination plants, and underwater equipment rely on Super Duplex to avoid rusting in salty environments.

We are the premium suppliers of Super Duplex Stainless Steel products and other top-quality forged pipe fittings in India. Our extensive range of products adheres to the highest Pipe Fittings Manufacturing Standards and Types, ensuring durability and performance across a wide variety of industrial applications.

Online Fittings offers raw materials for industrial fittings straight from the manufacturer at unbeatable factory prices. With fast global shipping and reliable post-sales support, you can trust us to deliver the best value with a seamless, secure buying experience.

0 notes

Text

What industries use fasteners?

Fasteners play a critical role in construction, manufacturing, and engineering. As a leading force in the industry, Bullion Pipes & Tubes LLP stands out as the premier fasteners manufacturer, supplier, stockist, and exporter worldwide. With an extensive range that includes Bolts, Nuts, Screws, Washers, Studs, Rivets, Self-Clinching Fasteners, and more, our commitment is to provide top-notch solutions that cater to diverse project requirements.

This blog post aims to shed light on the diverse industries that heavily rely on fasteners, emphasizing the broad spectrum of applications our products cater to.

Types of Fasteners We Offer

With us, we offer fasteners with a variety of Types and Features, including the following;

Bolts: These threaded fasteners require corresponding nuts for secure connections. Choose from an array of head styles, including hex head, socket head, and round head.

Nuts: Complementing bolts, nuts secure connections. Opt for hex nuts, lock nuts, or wing nuts based on specific application requirements.

Screws: Known for versatility, screws find use in diverse applications. Choose from different head styles like Phillips, flat, or hex, and opt for self-tapping or machine screws.

Washers: Flat and disk-shaped, washers play a pivotal role in distributing fastener loads and protecting surfaces. Types include flat, lock, and spring washers.

Studs: Characterized by threaded rods without heads on one end, studs are ideal for dual-threaded connections and situations where nuts are impractical.

Rivets: Permanent fasteners with a cylindrical shaft and deformed head create a secure connection.

Pins: Cylindrical fasteners for alignment, securing, or support, including types like dowel, cotter, and clevis pins.

Anchors: These fasteners affix objects to hard surfaces, such as concrete. Common types involve wedge, sleeve, and drop-in anchors.

Clips and Clamps: Secure items like hoses and cables using clips and clamps, such as hose clamps, spring clips, and wire rope clamps.

Threaded Rods: Lengthy straight rods with continuous threading, frequently used for hanging and providing support.

U-Bolts: Featuring a U-shaped design with threads on both ends, they secure round objects to surfaces.

Eye Bolts: Equipped with a loop or "eye," these bolts are designed for lifting and securing heavy loads.

Stud Bolts: Threaded at both ends with an unthreaded portion in the middle, commonly used in flange connections.

Self-Clinching Fasteners: Specifically designed for sheet metal and thin materials, including self-clinching nuts, studs, and standoffs.

Hinges and Latches: Serving as fasteners for attaching doors, gates, and panels, they include hinges, hasps, and latches.

Materials Wise Grade We Offer – Fasteners

At, Bullion Pipes & Tubes LLP, provides a wide variety of fasteners, including;

Copper – CDA 102, CDA 101, CDA 110

Titanium – Titanium Alloy Gr 2 & Titanium Alloy Gr 5

Monel – Monel K500 & Monel 400

Carbon Steel – ASTM A193/194 & ASME SA193/194 Carbon Steel

Brass – Alloy 260, Alloy C48200 – C48500, Alloy 385, Alloy 360, Alloy 353, Alloy 330, Alloy 272, Alloy 464

Tantalum – RO5200, RO5400, RO5252(Ta2.5W), RO5255(Ta10W)

Inconel – Inconel 718, Inconel 600, Inconel 601, Inconel 625

Aluminum – he 20 65032 6061, he 30 64430, ASTM 6061, 6063, 6351

Nickel – Nickel Alloy 200/201

SMO 254 – ASTM A 479 ASME SA 479

Duplex Steel – Duplex Steel UNS S32205, Duplex Steel UNS S31803

Hastelloy – Hastelloy C22 & Hastelloy B2, Hastelloy C276

Super Duplex Steel – Super Duplex Steel UNS S32750, Super Duplex Steel UNS S32760

Incoloy – Incoloy 800/800H/800HT, Incoloy 825

Alloy 20 – DIN 2.4460 Alloy Hexagonal Nut, Alloy 20 Bolts, UNS N08020 Alloy 20 Screws, Alloy 20 Washers

Industries Uses Fasteners

Here are some industries where fasteners are used extensively:

Construction: Fasteners such as bolts, nuts, screws, and anchors are widely used in the construction industry for connecting structural elements like beams, columns, and panels.

Automotive: The automotive industry relies heavily on fasteners for assembling vehicles. A variety of screws, bolts, nuts, and clips are used in the manufacturing of cars, trucks, motorcycles, and other vehicles.

Aerospace: Aerospace applications require precision and reliability. Fasteners play a critical role in assembling aircraft and spacecraft components, ensuring safety and structural integrity.

Manufacturing: In general manufacturing processes, fasteners are used to assemble a wide range of products across different industries, including appliances, electronics, and consumer goods.

Energy: Fasteners are used in the energy sector for assembling components in power plants, wind turbines, solar panels, and other energy infrastructure.

Shipbuilding: The shipbuilding industry relies on fasteners for assembling the various components of ships, including the hull, decks, and internal structures.

Railway: They are crucial in the railway industry for connecting rail tracks, assembling train components, and maintaining the structural integrity of railway infrastructure.

Oil and Gas: In the oil and gas industry, fasteners are used in the construction and maintenance of pipelines, platforms, and other infrastructure.

Electronics: Fasteners play a role in the assembly of electronic devices and equipment. They are used to secure components on circuit boards and in the housing of electronic products.

Medical Devices: Fasteners are used to ensure that components are held together in a precise manner in medical devices and equipment.

Furniture: In the furniture industry, fasteners such as screws, bolts, and nuts are used to assemble various types of furniture, from simple household items to complex office furniture.

Final Words!

As a global Fasteners Supplier, Manufacturer Stockist, and Exporter, Bullion Pipes & Tubes LLP takes pride in contributing to the success of diverse industries. Our fasteners, available in an array of sizes, specifications, standards, grades, materials, and types, offer versatility and reliability. Whether it's bolts, nuts, screws, washers, studs, rivets, or self-clinching fasteners, our commitment to quality ensures that our customers can confidently choose the perfect solution for their project requirements. Contact us today at [email protected] or [email protected] to explore how our fasteners can enhance the strength and durability of your applications.

0 notes

Text

Super Duplex S32760 flanges are high-performance components designed for extreme corrosion resistance and strength in demanding applications. Composed of a duplex stainless steel alloy, these flanges exhibit superior mechanical properties and exceptional resistance to harsh environments, making them ideal for offshore, chemical, and petrochemical industries. The S32760 grade offers enhanced pitting and crevice corrosion resistance, as well as excellent durability in high chloride and acidic conditions. These flanges are precision-engineered to meet international standards, ensuring reliability and longevity in critical operations. With a combination of high strength, corrosion resistance, and weldability, Super Duplex S32760 flanges provide a robust solution for connecting pipes and maintaining the integrity of fluid-handling systems in challenging settings. Whether used in oil and gas, chemical processing, or other demanding industries, these flanges demonstrate top-tier performance and durability.

For more Information

Visit website: https://www.deepsteelalloys.com/super-duplex-steel-uns-s32750-2507-seamless-welded-flanges-manufacturer-exporter.html

Email: [email protected]

Contact: 9930466755

0 notes

Text

Duplex Steel High Tensile Fasteners

CHHAJED STEEL & ALLOYS MANUFACTURES AND EXPORTS STAINLESS AND SUPER ALLOY BOLTING MATERIALS WHICH INCLUDES: HEX BOLT, HEX NUTS, STUD BOLTS, THREADED BARS, WASHERS, ETC. AS PER STANDARDS ASTM, ASME, DIN AND UNI, OUR MOST COMMON MATERIAL ARE IN STOCK AS WELL AS IN PRODUCTION ARE OF STAINLESS STEEL GRADE 304, 316, 321, 347, 310, 410, A453 660A/B/C, AISI 904L, ALLOY 20, DUPLEX UNS S32750 & UNS S32760, INCONEL 600, INCONEL 625, INCONEL 800, INCONEL 825, INCONEL 925, HATELLOY C-276, HASTELLOY C-22, TITANIUM GR 2 & GR 5 & ALUMINIUM BRONZE. BESIDE THIS WE ALSO SUPPLIES ALL KIND OF RAW MATERIAL IN STAINLESS STEEL, DUPLEX STEEL AND EXOTIC MATERIALS IN THE FORM OF PIPES, PLATES, ROUND BAR, WIRES, ELECTRODES, FLANGES AND PIPE FITTINGS.

#alloy 20 bolts exporters#astm a 479 duplex flat washer#alloy 20 fastners#alloy 20 bolts suppliers#alloy 20 bolts manufacturers#duplex steel bolts manufacturers#monel 400 bolts#duplex steel round washer#monel 400 fasteners

0 notes

Text

Super Duplex Globe Valve Manufacturer in India

Specialityvalve is a leading Super Duplex Globe Valve Manufacturer in India. We supply to France, Australia, Mexico and Turkey.

Description:

Available Materials: SS2328, SAF 2507(UNS S32750, F53), S32760( F55), UNS S32550, F61

Size: 1/8″- 24”

Class: 150 to 2500

Nominal Pressure: PN6 to PN300

Operations: Gear operated, Handwheel operated, lever operated, pneumatic actuated, electric actuated

Ends: Flanged, socket Welded, Buttweld, wafer, lug.

0 notes

Text

Super Duplex steel valve manufacturer in India

Specialityvalve is the top Super Duplex steel valve manufacturer in India. Super Duplex steel valve is a type of valve made from a high-performance alloy known as Super Duplex steel. This alloy is a combination of austenitic and ferritic stainless steels, which provides it with excellent corrosion resistance, high strength, and good toughness.

Super Duplex steel valves are commonly used in applications where high resistance to corrosion and erosion is required, such as in the oil and gas industry, chemical processing, and offshore and marine applications. These valves can withstand high pressures and temperatures and are suitable for use in harsh environments.

Specialityvalve is a well-known Super Duplex Valve Manufacturer in India which provides quality valves in different materials and design. All the products are tested according to requirements and standards.

Available Materials: Super Duplex (SS2328, SAF 2507(UNS S32750, F53), S32760( F55), UNS S32550

Size: 1/8″- 24”

Class: 150 to 2500

Nominal Pressure: PN6 to PN300

Operations: Gear operated, Handwheel operated, lever operated, pneumatic actuated, electric actuated

Ends: Flanged, socket Welded, Buttweld, wafer, lug

1 note

·

View note

Text

Super Duplex steel valve manufacturer in India

Specialityvalve is the top Super Duplex steel valve manufacturer in India. Super Duplex steel valve is a type of valve made from a high-performance alloy known as Super Duplex steel. This alloy is a combination of austenitic and ferritic stainless steels, which provides it with excellent corrosion resistance, high strength, and good toughness.

Super Duplex steel valves are commonly used in applications where high resistance to corrosion and erosion is required, such as in the oil and gas industry, chemical processing, and offshore and marine applications. These valves can withstand high pressures and temperatures and are suitable for use in harsh environments.

Specialityvalve is a leading Super Duplex Valve Manufacturer in India which provides quality valves in different materials and design. All the products are tested according to requirements and standards.

Types of super duplex steel valves:

Ball Valves

Gate Valves

Globe Valves

Check Valves

Butterfly Valves

Advantages of super duplex steel valve:

Toughness: Super Duplex steel valves have good toughness and can resist impact and fatigue, which helps to extend their service life.

Cost-effective: Super Duplex steel valves offer a cost-effective solution for applications where high-performance valves are required, as they have a long service life and require minimal maintenance.

Versatility: Super Duplex steel valves are available in various types and can be customized to meet specific requirements, making them suitable for a wide range of applications.

High Temperature Resistance: Super Duplex steel valves are capable of withstanding high temperatures, which makes them ideal for use in applications where high-temperature fluids or gases are present.

Improved Corrosion Resistance in Acidic Environments: Super Duplex steel valves are particularly useful in environments with high chloride concentrations or acidic conditions where conventional stainless steel valves would corrode.

Industry of super duplex steel valve:

Oil and Gas

Chemical Processing

Power Generation

Water Treatment

Marine

Aerospace

Available Materials: Super Duplex (SS2328, SAF 2507(UNS S32750, F53), S32760( F55), UNS S32550

Size: 1/8″- 24”

Class: 150 to 2500

Nominal Pressure: PN6 to PN300

Operations: Gear operated, Handwheel operated, lever operated, pneumatic actuated, electric actuated

Ends: Flanged, socket Welded, Buttweld, wafer, lug

https://www.specialityvalve.com/product-category/super-duplex-valves/

0 notes

Text

Buy Super Duplex S32760 Flanges | Bhagyalaxmi Industrial

In the area of metallurgy, in which precision, sturdiness, and reliability are paramount, the name "Super Duplex S32760" stands proudly as a testament to engineering brilliance. As industries continue to evolve, the demand for superior materials that could resist the most hard environments is on the rise. Enter Super Duplex S32760 flanges—the unsung heroes that ensure seamless connectivity and structural integrity in essential programs.

Understanding Super Duplex S32760 Flanges

The Manufacturing Marvel

Super Duplex S32760 flanges are made from a unique alloy that blends chromium, molybdenum, and nitrogen to create a material with high-quality corrosion resistance and mechanical energy. These flanges play a pivotal role in connecting pipes and facilitating the clean flow of fluids in industries ranging from oil and fuel to chemical processing.

Key Features of Super Duplex S32760 Flanges

Corrosion Resistance: The alloy composition of Super Duplex S32760 offers extraordinary resistance to corrosion, making it a perfect choice for harsh environments.

High Strength: These flanges boast superior mechanical energy, ensuring toughness and reliability in annoying programs.

Versatility: Super Duplex S32760 flanges locate programs in diverse industries, which include offshore oil rigs, chemical processing plants, and desalination facilities.

The Role of Bhagyalaxmi Industrial

Amidst the myriad of picks to be had in the market, Bhagyalaxmi Industrial emerges as an extraordinary participant as a Super Duplex S32760 Flanges Manufacturer, Super Duplex S32760 Flanges Supplier, Super Duplex S32760 Flanges Stockist, Super Duplex S32760 Flanges Exporter, Super Duplex S32760 Flanges Dealer. Specializing in an intensive variety of ferrous and non-ferrous metals, Bhagyalaxmi Industrial has carved a spot for itself as a reliable issuer of extremely good commercial additives.

Bhagyalaxmi Industrial Advantage

Diverse Product Range: Bhagyalaxmi Industrial offers a complete array of merchandise, together with pipes, tubes, pipe fittings, cast fittings, flanges, sheets, plates, coils, bars, rods, and fasteners, among others.

Material Expertise: The agency deals in diverse metals, such as stainless steel, duplex, and splendid duplex metallic alloy steel, carbon metallic, titanium, Inconel, Hastelloy, monel, nickel, cupro nickel, etc.

Quality Assurance: All products from Bhagyalaxmi Industrial are made from advanced high-quality uncooked substances, adhering to international requirements. Customization options ensure that clients obtain products tailored to their precise specs.

Competitive Pricing: Despite supplying top-notch first-class, Bhagyalaxmi Industrial keeps a commitment to affordable pricing, ensuring accessibility without compromising on excellence.

Super Duplex S32760 Flanges: Applications and Industries

The versatility of Super Duplex S32760 flanges extends throughout various industries, gambling a vital position in ensuring the efficient and dependable operation of critical strategies.

1. Offshore Oil and Gas

In the cruel conditions of offshore drilling rigs, Super Duplex S32760 flanges provide the durability and corrosion resistance required for seamless operations. These flanges contribute to the integrity of the pipeline community, ensuring the safe extraction and transportation of oil and gasoline.

2. Chemical Processing

Chemical processing flora calls for materials that can withstand corrosive chemicals and intense temperatures. Super Duplex S32760 flanges excel in such environments, ensuring the sturdiness and reliability of the difficult piping systems vital to chemical production approaches.

3. Desalination Facilities

As the worldwide call for freshwater increases, desalination facilities play a vital role in providing a sustainable answer. Super Duplex S32760 flanges, with their corrosion-resistant residences, contribute to the performance and longevity of desalination plants, wherein exposure to saltwater is a constant task.

Ensuring Quality and Satisfaction

The credibility of vendors is an important aspect of the industrial delivery chain, and Bhagyalaxmi Industrial places a robust emphasis on keeping the best standards. The continuous effort to stabilize and improve quality guarantees that clients acquire products that no longer best meet but exceed their expectations.

Customization for Client Satisfaction

Recognizing the various needs of customers, Bhagyalaxmi Industrial offers customization options for Super Duplex S32760 flanges. This guarantees that the products align with the unique necessities of each assignment, contributing to more desirable purchaser pride.

Conclusion: Connecting Excellence with Bhagyalaxmi Industrial

In the ever-evolving landscape of industrial additives, Super Duplex S32760 flanges have become a symbol of excellence. Bhagyalaxmi Industrial, with its commitment to quality, diversity, and customer delight, stands as a reliable accomplice for industries seeking top-notch merchandise.

As industries push the boundaries of what's viable, the selection of substances becomes increasingly vital. Super Duplex S32760 flanges from Bhagyalaxmi Industrial provide a robust answer, combining power, sturdiness, and corrosion resistance.

For those seeking to elevate their commercial approaches with the quality-in-magnificence Super Duplex S32760 flanges, Bhagyalaxmi Industrial is the name to trust. Contact them today and enjoy the difference that first-rate and commitment can make for your operations. Bhagyalaxmi Industrial – Connecting Excellence in Every Flange!

#Super Duplex S32760 Flanges Manufacturer#Super Duplex S32760 Flanges Supplier#Super Duplex S32760 Flanges Stockist#Super Duplex S32760 Flanges Exporter#Super Duplex S32760 Flanges Dealer

0 notes

Text

Nipo Flanges

Class 300 Nipo Flanges, Carb

on Steel Nipo Flange, Nickel Alloy Nipo Flanges, ASME B16.5 Raised Face Nipo Flange, ANSI B16.5 Nipo Flanges, Best Deals on Raised Face Nipo Flanges, ASME / ANSI B16.5 Nipo Flanges, Stainless Steel Nipo Flange dealer in India.

NIPO FLANGES MATERIAL & GRADES

Stainless Steel Nipo FlangesASTM A182 F 304, 304L, 304H, 309, 310, 310S, 316, 316L, 317, 317L, 321, 321H, 347, 347H, 446, 904LCarbon Steel Nipo FlangesASTM A105, ASTM A694 Gr. F42, 46, 52, 56, 60, 65, 70Alloy Steel Nipo FlangesASTM A182, F1, F5, F9, F11, F22, F91Duplex Steel Nipo FlangesASTM A182, F44, F45, F51, F53, F55, F60, F61Super Duplex Nipo FlangesASTM A182, F44, F45, F51, F53, F55, F60, F61Low Temperature Carbon Steel Nipo FlangesASTM A350, LF2, LF3

ASME B16.5 NIPO FLANGES SPECIFICATION

BS

BS4504 , BS4504, BS1560, BS10

FLANGE FACE TYPE

Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

2 notes

·

View notes

Text

Applications of High Pressure Forged Fittings - SPP Metal & Alloys

Forged steel fittings are used to connect several pieces of plumbing equipment. Their diameters range from 2 to 4 inches and they come in a variety of shapes. Forged steel fittings are used in many industries for a variety of high-pressure applications, particularly for threaded connections. It is commonly used to move high-pressure liquids and gases between locations at high temperatures.

With SPP Metals and Alloys you will find a wide range of forged pipe fittings such as 90 and 45-degree elbows, flow tees, Coupling, Union, end caps, nipples, reducers, etc. As SPP Metals and Alloys is one of the well-known - forged fittings manufacturers and suppliers in India.

These forged pipe fittings are available in various international standards such as B16.11, MSS SP43, and MSS SP75 to complete the client's requirements. Moreover, the products with SPP Metals & Alloys are made of high-strength forged metal and incredibly robust and resistant to environmental influences.

Forged pipe fittings.

High-pressure forged fittings are a type of piping component used in high-pressure and high-temperature applications. These fittings are typically made from materials such as carbon steel, stainless steel, and alloy steel, and are designed to withstand high pressure and temperature conditions.

Additionally, they are typically used to connect pipes and other components in a piping system and come in various shapes and sizes, such as elbows, tees, and reducers, to meet the specific needs of the application. High-pressure forged fittings are known for their strength and durability and are often used in conjunction with other high-pressure piping components, such as valves, flanges, and pipes, to create a complete piping system.

Types of Forged Fittings.

45 Deg Elbow

90 Deg Elbow

Tee

Couplings

Unions

Cap

Plug

Nipple

Benefits of High Pressure Forged Pipe Fittings.

High-pressure forged pipe fittings have several benefits that make them well-suited for high-pressure and high-temperature applications:

Corrosion Resistance

Cost-effective

Higher strength and durability

Customization

Easy to Install

Leak-tightness.

Grades in which forged fittings are available.

Super Duplex: S32750/S32760/F55/F53

Duplex: S31803/S32205/SMO 254

Nickel Alloys: Alloy 400, 625, 800, 825

Stainless Steels: 304, 316L, 310S, 321, 904L, etc

Carbon Steel: A105

LTCS: LF2

Alloy Steel: F9/F11/F12/F22/F91

Standards in which these forged pipe fittings grades are available.

B16.11

MSS SP43

MSS SP75

Applications of High Pressure-Forged fittings

High-pressure forged fittings can be used in a variety of applications and are produced from the finest raw materials. With its high level of consistency and dependability, forged fittings guarantee a long lifespan, high pressure, and no faults. High-pressure fittings are used in almost all industrial applications where a complex threaded connection is required. Additionally, it could be used to evaluate submerged structures.

In chemical fertilizer industries, instrumentation, nuclear thermal industries, heat exchanger, oil gas industries, pharmacy surgical industries, water gas-piping systems, and refineries petrochemicals seem to be just a few of the industries using these forged pipe fittings.

Forged pipe fittings can be used to change the direction of a piping system, and therefore the direction of a stream. The durability, leak-free operation, precise dimensioning, and smooth finish of such pipe fittings make them quite popular. In heavy-duty operations, where a line must be completely sealed, such long-lasting products are useful.

Final Thoughts.

If you are looking to purchase high-pressure forged fittings for an upcoming project which requires high strength, then you need to check out the best place which supplies the high-quality forged pipe fittings that will suit and fulfill your project requirements. In such case, you can visit, SPP Metals and Alloys the most well-known forged fittings manufacturers and suppliers in the Indian market. As supply a wide range of high-pressure forged fittings at the most competitive price all across India.

0 notes

Text

Super Duplex Steel S32760 F55 Flanges Chemical and Mechanical Composition

Citizen Metals is a distinguished Super Duplex S32760 F55 Flanges Supplier, which is supplied in the hot worked and solution annealed condition. Super Duplex S32760 F55 Slip on Flanges cannot be hardened by heat treatment but stronger surface strengths can be achieved by cold working. High impact strength at sub-zero temperatures, these Alloy UNS S32760 Blind Flanges displays excellent corrosion resistance.

Super Duplex Steel S32760 F55 Flanges Application Industries

Off-Shore Oil Drilling Companies

Power Generation

Petrochemicals

Gas Processing

Specialty Chemicals

Pharmaceuticals

Pharmaceutical Equipment

Chemical Equipment

Sea Water Equipment

Heat Exchangers

Condensers

Pulp and Paper Industry

#Super Duplex Steel S32760 F55 Flanges#Super Duplex Steel S32760 F55 Flanges Supplier#Super Duplex Steel S32760 F55 Flanges manufacturer#Super Duplex Steel S32760 F55 Flanges Exporter#Super Duplex Steel S32760 F55 Flanges Stockists

0 notes

Text

What are Flanges and their types?

Flanges are an essential component of any piping system, as they provide a secure and leak-free connection between two pipes or valves. As the leading Flanges manufacturers, suppliers, and exporters in India, Bullion Pipes & Tubes LLP understands the importance of choosing the right type of flange for your application.

In this blog post, we will cover everything you need to know about flanges, including their types, materials, and applications.

Before we dive into the details, let's start with the basics!

Introduction

Flanges are mechanical connectors used to join two pipes or valves. They are usually made of steel, and their main purpose is to provide a tight and leak-free seal between the two parts. Flanges come in various types and sizes, and choosing the right type of flange is essential for the safety and efficiency of your piping system.

Types of Flanges?

Flanges come in several types, including weld neck, slip-on, socket weld, lap joint, threaded, and blind flanges. Each type has its unique characteristics and applications, and selecting the right one will depend on several factors, such as pressure ratings, temperature ratings, size, material compatibility, and cost.

● Weld Neck Flanges

Weld neck flanges are the most common type of flange, known for their high durability and strength. They are welded to the pipe or valve, making them ideal for high-pressure and high-temperature applications.

● Slip-On Flanges

Slip-on flanges are easy to install and remove, making them ideal for applications that require frequent maintenance. They slide over the pipe or valve and are then welded or bolted in place.

● Socket Weld Flanges

Socket weld flanges are similar to slip-on flanges, but they are welded only on the outer side of the flange, leaving the inner side free of welding marks. They are ideal for smaller-sized pipes and low-pressure applications.

● Lap Joint Flanges

Lap joint flanges are used when a piping system requires dismantling frequently. They are also ideal for applications that require easy access to the pipe or valve.

● Threaded Flanges

Threaded flanges are designed to be screwed onto the pipe or valve, making them ideal for applications that require easy installation and removal. They are commonly used in low-pressure applications.

● Blind Flanges

Blind flanges are used to seal the end of a pipe or valve. They are commonly used for pressure testing and maintenance purposes.

Materials & Grades Available In Flanges with Bullion Pipes & Tubes LLP

Flanges can be made of various materials & Grades, such as,

●

Stainless Steel - 904L Flanges, 304/304L/304H, 316/316L/316Ti, 321/321H, 310/310S, 317/317L, 347/347H, 446 Flanges

● Hastelloy Flanges - C22, B2 Flanges, C276 Flanges

● Carbon Steel Flanges - ASTM A350 15LF1, LF2 CL1/CL2, LF3 CL1/CL2 Carbon Steel Flanges

● Nickel Alloy - 200/201

● Duplex Steel Flanges - Duplex UNS S32205/31803 Flanges

● Alloy Steel Flanges - P5, P9, P11, P12, P22, P91 Flanges

● Super Duplex Steel - UNS S32750/S32760 Flanges

● Titanium Alloys - Gr 2 Flanges, Gr 5 Flanges, Gr 7 Flanges

● Aluminium Flanges - 5052 Reducing Flanges, 5082 Flanges, 5082 Flanges, 6063 SORF Flanges, 6082 Blind Flanges, 2024 Aluminum Weld Neck Flanges, and 5052 Threaded Flanges.

● Tantalum Flanges - ASTM B521 Tantalum Flanges, Spectacle Blind Flanges, Orifice Flange, Ta-10W Flanges, Tantalum UNS R05200 Flanges, ASTM B365 Ta2.5W Flanges

● Monel Flanges - Monel K500 Flanges, Monel 400 Flanges

● Alloy 20 Flanges - Alloy 20 RTJ Flange, Alloy 20 WNRF Flanges, Alloy UNS N08020 Pipe Flanges, Alloy 20 Weld Neck Flange, Alloy 20 Nipo Flanges, ASTM B462 Alloy Threaded Flanges, Alloy 20 Spectacle Blind Flanges, Alloy 20 Industrial Flanges, and UNS N08020 Alloy 20 Forged Flanges

● SMO 254 Flanges

● Inconel Flanges - Inconel 718, 600, 601 and 625 Flanges

● Incoloy Flanges - 825, 800/800H/800HT Flanges

Choosing the right material for your flange will depend on several factors, such as the application's temperature, pressure, and corrosion resistance requirements.

Factors to Consider When Selecting Flanges

Selecting the right flange for your application can be challenging, as there are several factors to consider, such as pressure ratings, temperature ratings, size, material compatibility, and cost. At Bullion Pipes & Tubes LLP, we can help you choose the right flange for your application, ensuring safety and efficiency.

Flange Standard Ratings

Flanges come in various standard ratings, such as ANSI, API, DIN, and JIS. These ratings determine the flange's pressure-temperature rating and its compatibility with other components in the piping system.

Flange Installation

Proper flange installation is essential for the safety and efficiency of your piping system. It involves several steps, such as preparation of the piping system, installation of the flanges, flange tightening process, flange alignment, and testing and inspection.

Maintenance and Repair of Flanges

Maintaining and repairing flanges is critical for the longevity and safety of your piping system. Regular inspections, leak checks, and maintenance can help detect any potential issues before they become a more significant problem.

Applications of Flanges

Flanges have a wide range of applications in various industries, including:

● Oil and Gas Industry

● Petrochemical Industry

● Chemical Industry

● Power Generation Industry

● Water Treatment Industry

They are used in various applications, including HVAC systems, plumbing, and firefighting systems.

Why Choose Bullion Pipes & Tubes LLP for Flanges?

As the leading Flanges manufacturers, suppliers, and exporters in India, Bullion Pipes & Tubes LLP offers a wide range of flanges made from high-quality materials. We provide customized solutions to meet our customers' specific needs, and our flanges are available in various sizes, ratings, and materials.

We have been providing high-quality flanges to various countries, such as Ukraine, Australia, Syria, Iraq, Iran, Kazakhstan, Russia, Brazil, Armenia, Azerbaijan, Egypt, South Africa, Qatar, Turkey, Oman, Bahrain, and Germany, and our products are known for their durability, reliability, and safety.

Conclusion

Flanges are a critical component of any piping system, and selecting the right type of flange for your application is essential for safety and efficiency. Choosing a reliable and trustworthy supplier like Bullion Pipes & Tubes LLP can ensure that you get high-quality flanges that meet your specific requirements.

0 notes