#Abrasives

Text

Laser Cutting Sandpaper with REDSHIFT CO2 Laser Cutter 160100 130W

𝐑𝐞𝐝𝐒𝐡𝐢𝐟𝐭 𝐋𝐚𝐬𝐞𝐫, 𝐲𝐨𝐮𝐫 𝐨𝐧𝐞-𝐬𝐭𝐨𝐩 𝐬𝐨𝐥𝐮𝐭𝐢𝐨𝐧 𝐩𝐫𝐨𝐯𝐢𝐝𝐞𝐫 𝐟𝐨𝐫 𝐥𝐚𝐬𝐞𝐫 𝐦𝐚𝐜𝐡𝐢𝐧𝐞𝐬 𝐚𝐧𝐝 𝐬𝐩𝐚𝐫𝐞 𝐩𝐚𝐫𝐭𝐬.

👉Visit our website to get more information: 🔹https://redshiftlaser.com

🔹Email [email protected]

🔹WhatsApp / WeChat +86 16727286207

#lasercutting#sandpaper#lasercutter#lasercuttingmachine#co2 laser#laser cutting#laser cutting machine#laser cutter#abrasives

2 notes

·

View notes

Text

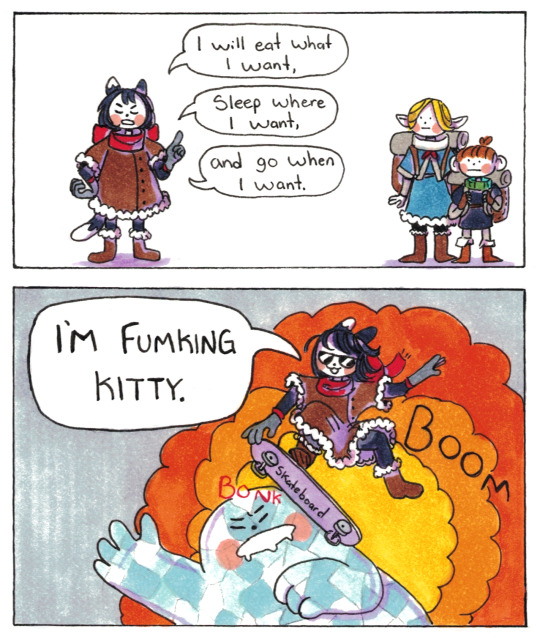

License to Kitty.

#dungeon meshi#izutsumi#marcille donato#chilchuk tims#I still stand by my tags on the Izutsumi character study piece I did in January - but I will repeat myself on a few lines here:#I *really* love this character. I love that all of the dungeon meshi crew are complicated and have difficult to love components.#But Izutsumi is a particular kind of hard to love. I foresee a lot of people being turned off by her abrasiveness and lack of teamwork.#She is very self-centered and openly goes against what the party agrees on.#She's a picky eater in a story that is 50% about eating good and healthy food!#It is in part about her growth but admittedly even *then* she remains rather true to her self-centeredness.#Even though she isn't as nice or funny or compassionate as the others...Izutsumi is still someone worth loving.#Even the more difficult people are someone worth loving.#And those people in turn are people who have something and someone they love.#She may be a girlcat but she is the most human of them all.#I hope that if you are an anime only watcher and are feeling put off by her at the moment; you'll give her a chance.#By the way: *yes* I worked very hard to draw that skateboard pose. It was worth it.#EDIT: HAPPY 500th POST OF POORLY-DRAW-MDZS!!! What a comic to commemorate the milestone with!

53K notes

·

View notes

Text

The Abrasives Market is projected to grow from USD 53,612.56 million in 2024 to USD 73,090.76 million by 2032, reflecting a compound annual growth rate (CAGR) of 3.95%.The abrasives market, integral to numerous industrial and manufacturing processes, is witnessing significant growth due to advancements in technology, increasing industrial activities, and evolving consumer preferences. This article delves into the current trends, challenges, and opportunities shaping the abrasives market.

Browse the full report at https://www.credenceresearch.com/report/abrasives-market

Market Overview

Abrasives are materials used to wear away the surface of other materials through friction. They are essential in various applications, including grinding, polishing, cutting, and drilling. The market for abrasives is diverse, encompassing different types such as bonded abrasives, coated abrasives, superabrasives, and non-woven abrasives. The global abrasives market is expected to grow steadily, driven by the expansion of the automotive, aerospace, construction, and electronics sectors.

Trends Driving Market Growth

1. Technological Advancements: The abrasives market is experiencing a surge in innovation. New technologies are enhancing the performance and efficiency of abrasives. For example, the development of advanced superabrasives like cubic boron nitride (CBN) and synthetic diamonds is improving precision and durability in high-precision applications.

2. Growth in End-User Industries: The automotive and aerospace industries are major consumers of abrasives due to their need for high-performance materials that can withstand rigorous conditions. The increasing production and demand for vehicles and aircraft contribute significantly to the abrasives market's growth. Additionally, the construction sector’s expansion, driven by urbanization and infrastructure development, fuels the demand for abrasives used in surface preparation and finishing.

3. Rising Automation and Industry 4.0: Automation and the implementation of Industry 4.0 technologies are transforming the abrasives market. Automated systems and smart manufacturing processes are enhancing precision and efficiency in abrasive applications. This trend is expected to increase the demand for high-quality and technologically advanced abrasives.

4. Sustainability and Eco-friendly Products: There is a growing emphasis on sustainable and eco-friendly abrasives. Manufacturers are focusing on developing abrasives that minimize environmental impact and are made from recyclable materials. This shift aligns with broader environmental goals and caters to the increasing consumer preference for green products.

Challenges Facing the Abrasives Market

1. Raw Material Prices and Supply Chain Disruptions: The abrasives market is affected by fluctuations in the prices of raw materials such as aluminum oxide, silicon carbide, and synthetic diamonds. Supply chain disruptions, often caused by geopolitical issues or natural disasters, can impact the availability and cost of these materials, posing challenges to manufacturers.

2. Regulatory and Environmental Compliance: The abrasives industry faces stringent regulations regarding the environmental impact of its products and manufacturing processes. Compliance with these regulations requires significant investment in research and development, as well as adaptation to new standards, which can be a challenge for companies operating on tight margins.

3. Competition and Market Saturation: The abrasives market is highly competitive, with numerous players offering a wide range of products. This competition, combined with market saturation in some segments, can lead to price wars and reduced profit margins for manufacturers.

Opportunities in the Abrasives Market

1. Emerging Markets: Developing regions, particularly in Asia-Pacific, Latin America, and the Middle East, present significant growth opportunities for the abrasives market. Rapid industrialization, infrastructure development, and increasing automotive production in these regions drive demand for abrasives.

2. Innovation in Product Development: Investing in research and development to create innovative abrasive products with enhanced performance and durability can provide a competitive edge. Developing specialized abrasives for niche applications, such as precision engineering or advanced materials processing, offers opportunities for differentiation and growth.

3. Strategic Partnerships and Mergers: Strategic alliances, mergers, and acquisitions can help companies expand their product portfolios, access new markets, and leverage complementary technologies. Collaborations with end-user industries and technology providers can also lead to the development of cutting-edge abrasive solutions.

Key Player Analysis

3M Company (US)

Fujimi Incorporated (Japan)

Tyrolit Group (Austria)

Kier Group PLC (UK)

Deerfos Co., Ltd (Korea)

Henkel AG & CO. KGAA (Germany)

Asahi Diamond Industrial Co., LTD (Japan)

Robert Bosch GMBH (Germany)

LafargeHolcim (France)

Carillon PLC (UK)

Carborundum Universal Limited (India)

Saint-Gobain Abrasives, Inc. (US)

Sak Industries (India)

Balfour Beatty PLC (UK)

Segments:

Based on Raw Material:

Natural

Synthetic

Based on Type:

Coated

Bonded

Super Abrasives

Based on End User:

Aerospace

Automotive

Machinery

Metal Fabrication

Electrical and Electronics Equipment

Others

Based on the Geography:

North America

US

Canada

Mexico

Europe

Germany

France

UK

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of Middle East and Africa

Browse the full report at https://www.credenceresearch.com/report/abrasives-market

About Us:

Credence Research is committed to employee well-being and productivity. Following the COVID-19 pandemic, we have implemented a permanent work-from-home policy for all employees.

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

Website: www.credenceresearch.com

0 notes

Text

Airboss Air Tools: Power and Precision for Industry Works

Airboss air tools have carved a niche for themselves as the go-to choice for professionals and DIY enthusiasts alike. Known for their efficiency, accuracy, and durability, these tools are designed to tackle a wide range of tasks, from automotive repairs to construction projects.

Why Choose Airboss?

Powered by compressed air, Airboss tools deliver exceptional power and performance. Their lightweight design and ergonomic grip make them easy to handle, reducing user fatigue. Whether you're an experienced tradesperson or a homeowner working on a weekend project, Airboss tools offer the precision and control you need to get the job done right.

Key Benefits of Airboss Air Tools:

Efficiency: Save time and effort with powerful tools designed for speed.

Accuracy: Achieve precise results with tools built for precision.

Durability: Built to last, these tools can withstand heavy use.

Versatility: A wide range of tools to suit various applications.

Sanjay Tools: Your Local Airboss Expert

When it comes to purchasing Airboss air tools in Pune, Sanjay Tools is your trusted partner. With a comprehensive selection of Airboss products and expert knowledge, they can help you find the perfect tools for your needs. Their commitment to customer satisfaction and competitive pricing makes them a top choice for both individuals and businesses.

Safety First

Always prioritize safety when using air tools. Wear protective eyewear and follow the manufacturer's guidelines. Proper maintenance and care will extend the life of your tools and ensure optimal performance.

Elevate Your Projects with Airboss

Upgrade your toolkit with Airboss air tools and experience the difference. Visit Sanjay Tools today to explore their range of products and discover how Airboss can enhance your productivity and results.

0 notes

Text

https://surfaceinternational.blogspot.com/2024/06/enhancing-surface-preparation-role-of.html

#AirlessShotBlasting#ShotBlastingMachine#SurfacePreparation#IndustrialCleaning#BlastCleaning#BlastingEquipment#RustRemoval#CoatingRemoval#SurfacePrep#AbrasiveBlasting#MetalPreparation#SteelCleaning#HighPressureBlasting#DustlessBlasting#SurfaceRestoration#Abrasives#CorrosionProtection#HeavyDutyCleaning#IndustrialMachinery#BlastingTechnology

0 notes

Text

Hardwood Flooring Abrasives Lexington, KY | Perspectives Inc.

Discover top-quality hardwood flooring abrasives in Lexington for impeccable sanding and refinishing results. At Perspectives Inc., we offer premium abrasives designed to enhance the durability and beauty of your hardwood floors. Elevate your flooring project with our professional-grade abrasives tailored to meet your needs. Experience superior performance and lasting quality with our hardwood flooring abrasives in Lexington.

#HardwoodFlooring#Abrasives#FlooringSupplies#LexingtonKY#WoodFloorRefinishing#SandingMaterials#FlooringTools#PerspectivesInc

0 notes

Text

Abrasives Market Outlook Report 2024-2030: Trends, Strategic Insights, and Growth Opportunities | GQ Research

The Abrasives Market is set to witness remarkable growth, as indicated by recent market analysis conducted by GQ Research. In 2023, the global Abrasives Market showcased a significant presence, boasting a valuation of US$ 53.41 billion. This underscores the substantial demand for Acetophenone technology and its widespread adoption across various industries.

Get Sample of this Report at: https://gqresearch.com/request-sample/global-abrasives-market/

Projected Growth: Projections suggest that the Abrasives Market will continue its upward trajectory, with a projected value of US$ 74.16 billion by 2030. This growth is expected to be driven by technological advancements, increasing consumer demand, and expanding application areas.

Compound Annual Growth Rate (CAGR): The forecast period anticipates a Compound Annual Growth Rate (CAGR) of 4.8%, reflecting a steady and robust growth rate for the Abrasives Market over the coming years.

Technology Adoption:

In the Abrasives market, technology adoption encompasses the development and utilization of advanced abrasive materials, manufacturing processes, and surface finishing techniques. Abrasives are used for grinding, polishing, cutting, and shaping materials such as metals, ceramics, composites, and stones. Various abrasive types include bonded abrasives (e.g., grinding wheels, honing stones), coated abrasives (e.g., sandpaper, abrasive belts), and superabrasives (e.g., diamond, cubic boron nitride). Advanced technologies such as precision grinding, electroplated coatings, and laser machining enhance abrasive performance, precision, and efficiency in diverse applications across industries.

Application Diversity:

The Abrasives market serves diverse applications across industries such as automotive, aerospace, metalworking, construction, electronics, and healthcare. In manufacturing, abrasives are used for surface preparation, deburring, and precision grinding of components in automotive and aerospace production. Additionally, abrasives find applications in metal fabrication for cutting, shaping, and finishing metal parts in construction, machinery, and consumer goods. Moreover, abrasives are utilized in electronics manufacturing for wafer dicing, circuit board fabrication, and precision polishing of semiconductor materials.

Consumer Preferences:

Consumer preferences in the Abrasives market are influenced by factors such as abrasive performance, durability, surface finish quality, and cost-effectiveness. End-users prioritize abrasives that offer high material removal rates, consistent surface finish, and long tool life for efficient machining and finishing operations. Additionally, consumers value abrasives with low clogging tendency, heat resistance, and compatibility with specific materials and machining processes. Moreover, cost considerations, including abrasive price, availability, and overall process economics, play a significant role in consumer purchasing decisions.

Technological Advancements:

Technological advancements in the Abrasives market focus on improving abrasive material properties, manufacturing processes, and tooling technologies to enhance performance, productivity, and sustainability. Research efforts aim to develop new abrasive formulations with enhanced hardness, toughness, and self-sharpening characteristics for improved cutting and grinding efficiency. Additionally, advancements in abrasive coating technologies, such as nanostructured coatings and engineered grain geometries, enhance abrasive adhesion, wear resistance, and tool life in coated abrasive products. Moreover, integration with digital manufacturing technologies, such as CNC machining and robotic automation, enables precise control and optimization of abrasive processes for increased productivity and quality consistency.

Market Competition:

The Abrasives market is characterized by robust competition among abrasive manufacturers, distributors, and end-users, driven by factors such as product performance, quality, pricing, and customer service. Major players leverage their manufacturing scale, R&D capabilities, and global distribution networks to maintain market leadership and gain competitive advantage. Meanwhile, smaller manufacturers and specialty abrasive suppliers differentiate themselves through niche product offerings, customized solutions, and technical expertise in specific applications or industries. Additionally, strategic partnerships, acquisitions, and product innovations are common strategies for companies to expand market presence and enhance competitiveness in the dynamic Abrasives market.

Environmental Considerations:

Environmental considerations are increasingly important in the Abrasives market, with stakeholders focusing on sustainable sourcing, manufacturing processes, and waste management practices. Manufacturers strive to minimize environmental impact by using recycled and eco-friendly abrasive materials, reducing energy consumption, and optimizing water usage in abrasive production processes. Additionally, efforts are made to develop environmentally friendly abrasive coatings and surface treatments that minimize emissions, VOCs (volatile organic compounds), and hazardous waste generation during abrasive machining operations. Moreover, initiatives such as product life cycle assessment (LCA), eco-labeling, and certification programs promote sustainable practices and responsible consumption in the Abrasives market.

Top of Form

Regional Dynamics: Different regions may exhibit varying growth rates and adoption patterns influenced by factors such as consumer preferences, technological infrastructure and regulatory frameworks.

Key players in the industry include:

3M Company

Saint-Gobain Abrasives

Robert Bosch GmbH (Bosch)

Norton Abrasives (A brand of Saint-Gobain Abrasives)

Klingspor AG

Tyrolit Group

Fujimi Incorporated

Deerfos Co., Ltd.

Asahi Diamond Industrial Co., Ltd.

Carborundum Universal Limited

Sia Abrasives Industries AG

Abrasiflex Pty Ltd

Hermes Schleifmittel GmbH

Abrasive Technology

Mirka Ltd.

The research report provides a comprehensive analysis of the Abrasives Market, offering insights into current trends, market dynamics and future prospects. It explores key factors driving growth, challenges faced by the industry, and potential opportunities for market players.

For more information and to access a complimentary sample report, visit Link to Sample Report: https://gqresearch.com/request-sample/global-abrasives-market/

About GQ Research:

GQ Research is a company that is creating cutting edge, futuristic and informative reports in many different areas. Some of the most common areas where we generate reports are industry reports, country reports, company reports and everything in between.

Contact:

Jessica Joyal

+1 (614) 602 2897 | +919284395731

Website - https://gqresearch.com/

0 notes

Text

Unlocking Efficiency and Precision: Industrial Cutting Discs Demystified

Unleashing the Power of Industrial Cutting Discs

In today’s industrial landscape, precision and efficiency reign supreme. Whether in the manufacturing sector, construction industry, or any other field requiring precise cutting, choosing cutting discs can make a monumental difference in your operations. Staarek Engineering Solutions brought an ideal abrasive product that can sustain for a longer time and provide you with an ideal outcome.

Why Industrial Cutting Discs Matter

Precision Cutting for Enhanced Efficiency

Industrial cutting discs are not just tools but the backbone of precise cutting operations. Designed with cutting-edge technology, they ensure accuracy and efficiency in every cut, saving time and resources.

Durability and Longevity

Investing in quality industrial cutting discs means investing in durability and longevity. These discs are engineered to withstand rigorous use and maintain their sharpness and effectiveness over prolonged periods.

Choosing the Right Industrial Cutting Disc

Material Matters: Selecting the Ideal Disc for Your Application

From stainless steel to concrete, different materials require different cutting discs. Understanding the material you’ll be working with is crucial in selecting the right disc for the job. Whether it’s abrasive materials or metals, there’s a cutting disc tailored to meet your specific needs. Our Cutting discs for Metals are much more sustainable on higher RPM with higher frictional rates.

Size and Thickness: Finding the Perfect Fit

The size and thickness of the cutting disc play a significant role in its performance. Opting for the correct dimensions ensures optimal cutting results and a lesser risk of accidents and damage to the workpiece.

Maximizing Efficiency with Industrial Cutting Discs

Precision Cuts for Enhanced Productivity

Industrial cutting discs offer unparalleled precision, making clean, accurate cuts with minimal material wastage. This precision translates to enhanced productivity, as each cut is executed accurately, eliminating the need for rework. Industrial Grade Cutting Dics know for prices result for sure.

Streamlined Operations and Cost Savings

Efficiency is the foundation for successful industrial operations. By harnessing the power of industrial cutting discs, businesses can streamline their operations, reducing downtime and optimizing resource utilization. This streamlined approach boosts productivity and leads to significant cost savings in the long run.If you find Cutting Discs price then you have many options but always look for a result that gives you a better return then investment

Safety First: Ensuring Safe Usage of Cutting Discs

Proper Handling and Maintenance

When using industrial cutting discs, safety should always come first. Proper handling and maintenance are essential to prevent accidents and prolong the discs’ lifespan. Regular wear and tear inspections, along with adherence to safety measures, can reduce unwanted injuries at work.

Training and Education

Equipping workers with the necessary training and education on the safe usage of cutting discs is paramount. Knowledge is essential for maintaining a safe and effective work environment, from basic handling procedures to recognising the limitations of various discs.There are the process of maturing and polishing surface of matel after cutting, You need Flexible Grainding Disc to smoothen cutting edges.

Conclusion

Industrial cutting discs are indispensable in various industries, offering unmatched precision, efficiency, and durability. By choosing the right cutting discs and adhering to safety protocols, businesses can enhance productivity, streamline operations, and achieve greater success. Invest in quality cutting discs today and unlock the full potential of your operations.

0 notes

Text

Abrasives: High-quality abrasives for industrial use. Durable, long-lasting, and effective for a wide range of applications. Get the perfect finish every time.

1 note

·

View note

Text

“I can fix him” I couldn’t fix him and I don’t want to. I think he grew prone to biting and scratching in order to get by in a harsh world, and to me his resilience is part of what makes him so beautifully himself. I could be kind to him, though. I could show him gentleness. I could, slowly but surely, in the same way one earns the trust of a skittish stray cat, convince him that my touch will never come accompanied by pain. That, around me, he can allow himself to be soft. To relax. I could be the one he associates with warmth and safety, the one he longs to be held by after a hard day. I could be his home.

#I’m very sad rn so I’m doing what I always do when I’m sad: thinking about being gentle towards my abrasive Blorbo#self shipping#Self-shipping#self ship#self ship imagine#f/o imagines#romantic f/o

4K notes

·

View notes

Text

Ace Commercial Equipment is a leading supplier of high-quality abrasives for industrial use. We offer a wide variety of abrasives to meet the needs of any industrial application, including:

0 notes

Text

LPSIS Industrial Cutting Wheels — Precision Cutting Solutions for Industry

LPSIS is your trusted source for industrial cutting wheels that deliver precision cutting solutions for a wide range of industrial applications. Our cutting wheels are engineered for superior performance, efficiency, and safety.

Key Features:

Comprehensive Cutting Solutions: Explore our diverse selection of industrial cutting wheels, including abrasive wheels, diamond blades, and more.

Premium Quality: Our cutting wheels are crafted from high-quality materials, ensuring precision cutting and lasting performance.

Industry Compliance: We prioritize meeting industry standards and regulations, guaranteeing the quality and safety of our cutting wheels.

Expert Consultation: Our experienced team is available to provide expert guidance and recommendations, helping you select the most suitable cutting wheel for your specific needs.

Customized Solutions: We offer tailored cutting-wheel solutions to meet the unique requirements of your industry or project.

Choose LPSIS Industrial Cutting Wheels for precision cutting that enhances your industrial processes. Contact us today to discuss your cutting wheel requirements, place an order, or inquire about bulk purchasing options. Your efficiency and safety are our top priorities.

Visit- https://lpsis.co.in/cutting-wheels

#Industrial Abrasives#Industrial Cutting wheels#Cutting wheels#Abrasives#industrial safety equipment suppliers#mro products#lpsis#lpsis mro solutions

0 notes

Text

Discover the Power of Precision with Orkon Abrasives

➡ Achieve Unmatched Cutting and Grinding Performance with these Discs! Are you in search of top-notch cutting and grinding solutions? Look no further!

Orkon is here to provide you with exceptional performance and meet all your requirements. Request our catalogue today in the comment section.

🔧 Our meticulously designed Orkon brand discs are engineered to deliver unparalleled results, ensuring precision and efficiency in every task. Whether you’re working on metal, concrete, or any other material, our discs are tailored to exceed your expectations.

✅ Why Choose Orkon Discs?

🔹 Superior Quality: Our discs are crafted with the utmost precision and the finest materials, guaranteeing durability and longevity.

🔹 Precision Cutting: Experience clean and precise cuts, allowing you to achieve flawless results in your projects.

🔹 Efficient Grinding: Our discs are designed to provide maximum efficiency, saving you time and effort.

🔹 Versatile Applications: From industrial projects to DIY tasks, our discs are versatile and can handle a wide range of applications.

🔹 Customer Satisfaction: We prioritize customer satisfaction and strive to meet your specific requirements.

Request our catalog today in the comment section.

👉 Explore our full range of products and unleash the potential of precision: Website — https://abrasives.onshoretechnical.com

Do you have questions or need assistance? Our dedicated team is just a call or email away:

📞 Call: +966 54 458 0607 | 📧 Email: [email protected]

For quick inquiries, you can also reach us on 📱 WhatsApp Chat Now👉 https://wa.me/966544580607

Join the Orkon revolution and experience precision like never before! 💎

👉 Like 👍 | Share 🔁 | Comment 💬 | Tag your buddies! 🙌

Read the full article here: https://medium.com/@onshoretechnicalmarketing/discover-the-power-of-precision-with-orkon-abrasives-d8692037962b

1 note

·

View note

Text

You have taken the whole of me. I could never accept just a piece of you in return.

#baldur's gate#baldur's gate 3#bg3#lae'zel#bg3edit#gamingedit#videogamewomen#gamingladiesedit#*#MY FOREVER GIRL#i love her i love how she can be rude and abrasive and she knows and isnt ashamed of that part of herself#she's softer on the inside but it doesn't cancel out how fierce she is; it's not like who she is on the surface is all an act

9K notes

·

View notes

Text

https://medium.com/@surfceinternational01/enhancing-surface-preparation-the-role-of-airless-shot-blasting-machines-in-coating-applications-b683674fd276

#AirlessShotBlasting#ShotBlastingMachine#SurfacePreparation#IndustrialCleaning#BlastCleaning#BlastingEquipment#RustRemoval#CoatingRemoval#SurfacePrep#AbrasiveBlasting#MetalPreparation#SteelCleaning#HighPressureBlasting#DustlessBlasting#SurfaceRestoration#Abrasives#CorrosionProtection#HeavyDutyCleaning#IndustrialMachinery#BlastingTechnology

0 notes