#lasercutter

Explore tagged Tumblr posts

Text

Wim Delvoye: Pergola (2011) laser-cut stainless steel

647 notes

·

View notes

Text

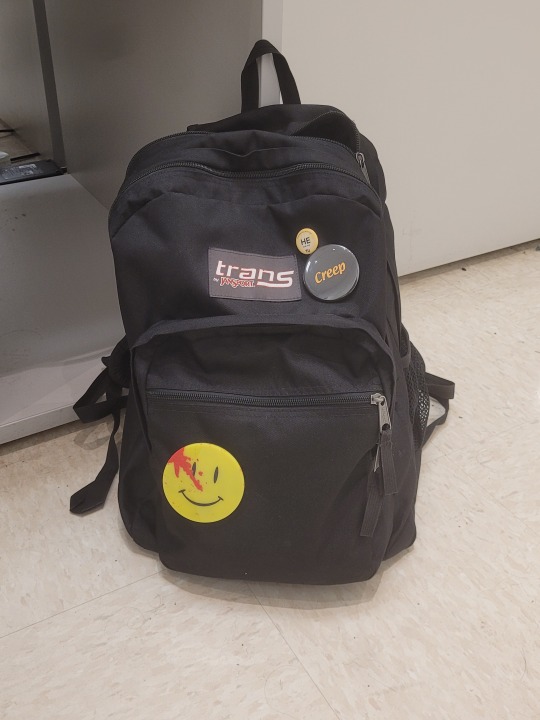

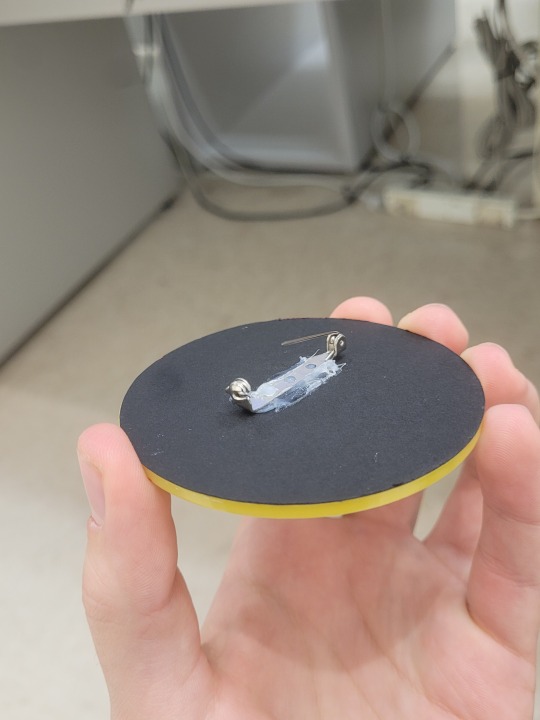

Pin I made from acrylic, paper, and a flat back safety pin. The back of the pin holds up surprisingly well and I'm very happy with the way that it turned out. If I make another, I'll probably add a supporting safety pin so it looks less awkward when worn. I'll also add a thicker card stock to the back so the edges wear away less.

#watchmen#digital art#lasercutter#laser#comics#dc comics#this is the first time I've ever actually posted a serious caption on my tumblr#pee pee poo poo

8 notes

·

View notes

Text

Islamic Mandala Gate DXF GA0058 enables you to make a wonderful and luxurious gate for palaces, villas, or houses, as this design is characterized by the presence of a rich and symmetrical mandala of classic ornaments, with the presence of ornaments distributed surrounding it on both sides

#Designifier#lasercut#lasercutting#laserengraving#acrylic#lasermarking#laserengraved#woodworking#lasercutter#dxfdesign#laserengrave#lasercutwood#crafting#woodcraft#diecut#cncwoodworking#metalfabricationservices

0 notes

Text

Laser Cutting Machine Manufacturers

Winarc is a well-known laser cutting machine manufacturers that provides high precision machines with long lasting performance. Our laser cutting systems are suitable for precisely cutting metals such as stainless steel, mild steel, and aluminum. which feature powerful CNC controls and energy efficient fiber laser technology, are ideal for industries like as fabrication, automotive, and construction.

0 notes

Text

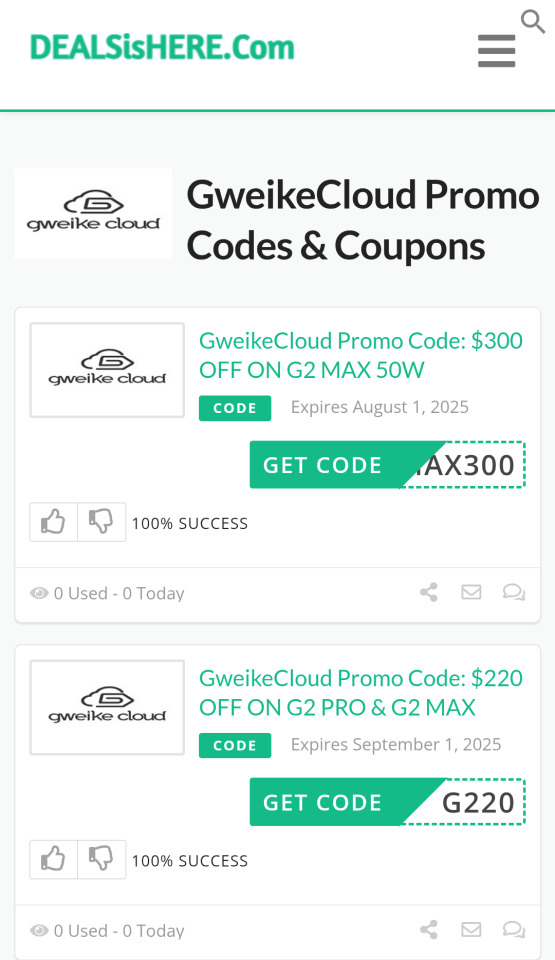

GweikeCloud Promo Codes And Discount Codes - DEALSisHERE.Com

Craft Big. Save Bigger. GweikeCloud Laser Deals Are Here!

Looking to elevate your DIY projects or small business production?

GweikeCloud has some incredible promotions live now:

$300 OFF G2 MAX 50W

$220 OFF G2 PRO & G2 MAX

Exclusive New Year & Mid-Year Coupons

"Craft Love, Grow Business" Deal

These offers are valid until mid to late 2025—don’t miss your chance to upgrade your laser cutting game.

Claim your discount here:

#GweikeCloud #LaserCutter #MakersOfTumblr #DIYLife #CraftTools #PromoCodes #Makerspace #TumblrDeals

0 notes

Text

The laptop stand was cut off by my ACMER P2.😎😎😎

#ACMER#RecordyourlovewithACMER#environment#earthday#laserengraving#lasercutter#laserengravingmachine#lasercuttingmachine#deadpool#phoneholder

1 note

·

View note

Text

Exploring Laser Cutter CNC Machines

In the ever-evolving landscape of manufacturing and fabrication, the laser cutter CNC (Computer Numerical Control) machine stands as a pinnacle of precision and versatility. This sophisticated technology integrates the power of lasers with computer-controlled movements, enabling precise and intricate cuts across various materials with unparalleled accuracy. From intricate designs in arts and crafts to intricate parts in industrial applications, laser cutter CNC machines have redefined the boundaries of what’s possible in modern manufacturing.

The Fusion of Laser Precision and CNC Control

At its core, a laser cutter CNC machine combines two cutting-edge technologies: lasers and CNC control. Lasers emit a highly focused beam of light, capable of delivering intense heat energy to vaporize or melt materials. When coupled with CNC control, which precisely guides the laser across the material according to pre-programmed designs, the result is a level of accuracy and repeatability that surpasses traditional cutting methods.

Versatility Across Materials

One of the most compelling aspects of laser cutter CNC machines is their ability to work with a wide range of materials. Whether it’s wood, acrylic, plastic, metal, leather, fabric, or even certain types of stone, these machines can effortlessly cut through or engrave intricate patterns with remarkable finesse. This versatility makes them indispensable tools across various industries, from aerospace and automotive to jewelry making and signage production.

Applications Across Industries

In the realm of manufacturing, laser cutter CNC machines find extensive use in prototyping, rapid manufacturing, and production of intricate components. In the automotive industry, they are utilized for creating precise gaskets, interior components, and even for trimming composite materials. Similarly, in aerospace, laser cutter CNC machines are instrumental in producing lightweight yet structurally robust components for aircraft and spacecraft.

Artists and designers also harness the power of these machines to bring their creative visions to life. From intricate jewelry designs to elaborate architectural models, the precision and versatility of laser cutter CNC machines enable artists to explore new realms of expression and craftsmanship. Even in education, these machines have found a place, empowering students to learn about design, engineering, and manufacturing processes firsthand.

Precision Engineering and Automation

One of the key advantages of laser cutter CNC machines lies in their ability to automate complex cutting processes with precision and efficiency. Once the design is input into the machine’s software, it can replicate the same cut repeatedly without deviation, ensuring consistency across large production runs. This level of automation not only saves time but also minimizes material wastage, making laser cutter CNC machines an environmentally friendly choice for manufacturing.

Challenges and Considerations

While laser cutter CNC machines offer unmatched precision and versatility, they also present certain challenges. Operating these machines requires specialized training to ensure safety and optimal performance. Additionally, the initial investment and maintenance costs can be substantial, making them more suitable for businesses with high-volume production needs or specialized fabrication requirements.

Furthermore, the choice of laser source, such as CO2 or fiber lasers, and the power output must be carefully considered based on the intended application and the materials being processed. Factors like beam quality, cutting speed, and energy efficiency play crucial roles in determining the suitability of a laser cutter CNC machine for specific tasks.

The Future of Laser Cutter CNC Technology

As technology continues to advance, so too will laser cutter CNC machines. Innovations in laser sources, control systems, and material handling capabilities will further enhance their precision, speed, and versatility. Additionally, advancements in artificial intelligence and machine learning may lead to smarter, more autonomous CNC systems capable of optimizing cutting parameters in real-time for improved efficiency and quality.

In conclusion, laser cutter CNC machines represent a convergence of cutting-edge technologies that have revolutionized the manufacturing and fabrication industries. With their unmatched precision, versatility, and automation capabilities, these machines empower businesses, designers, and creators to push the boundaries of innovation and craftsmanship. As we look to the future, the continued evolution of laser cutter CNC technology promises to unlock even greater possibilities in the world of manufacturing and beyond.

0 notes

Text

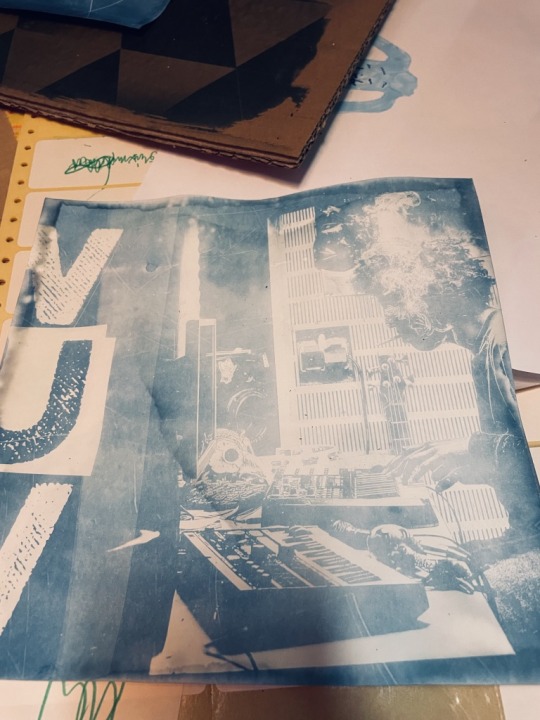

Bringing it too life!!! Laser cutting the pieces of the design on MDF board for creating the physical prototype.

0 notes

Text

Laser Cut Nitinol: Precision Beyond Measure

Introduction

Laser cut Nitinol is a remarkable technological advancement in materials processing. It harnesses the power of laser technology to precisely shape and manipulate Nitinol. This innovative process enables the creation of intricate components and devices and offers a level of precision beyond conventional manufacturing techniques.

In this article, we will delve into the world of laser cut Nitinol and explore its cutting-edge applications, unique characteristics, and profound impact.

The Art of Laser Cutting Nitinol

Laser cutting involves the use of a high-powered laser beam to accurately and cleanly cut through Nitinol sheets, wires, or components. This non-contact process delivers remarkable precision and allows for the creation of complex shapes and patterns with fine detail. Laser cut Nitinol is characterized by its smooth edges, minimal heat-affected zones, and minimal material waste.

Figure 1. Diagram of A Laser Cutter [1]

Unique Characteristics of Laser Cut Nitinol

Laser cutting of nitinol boasts unique traits that set it apart in precision engineering and intricate designs. This specialized process harnesses the power of lasers to shape nitinol with unparalleled accuracy and finesse. Here are some key attributes that distinguish such a product and underpin its exceptional utility in various applications:

Related reading: An Overview Of Nickel-Titanium Alloy

Applications of Laser Cut Nitinol

Laser cut nitinol with its precision and versatility finds diverse applications across industries. This highly adaptable material's contributions span from medical devices to aerospace components, microelectronics, and automotive engineering.

Conclusion

Laser cut Nitinol is a testament to the marriage of advanced technology and cutting-edge materials. Its unparalleled precision, minimal heat impact, and versatility open up a world of possibilities in industries that demand precision and customizability.

As research and development continue to push the boundaries of laser cut Nitinol, it is poised to shape the future of materials engineering, manufacturing, and innovation. Stanford Advanced Materials (SAM) possesses rich experience in manufacturing and supplying top-grade nitinol products. We offer quality nitinol wires, rods, foils, etc. with superelasticity and shape memory effect. Send us an inquiry if you are interested.

Reference:

[1] Laser cutting. (2023, November 8). In Wikipedia. https://en.wikipedia.org/wiki/Laser_cutting

0 notes

Text

With the Oriental Door Ornaments DXF LS0090 digital design, you can make the best decorations in ceilings and Wall art, or partitions between rooms in the home, office, or even shops, cafes, and restaurants. You can create the best classic ornament decorations available through the Oriental Door Ornaments DXF LS0090 vector file, which is available in multiple formats mentioned in the description below, so that you can manufacture wood, metals of all kinds, acrylic, and MDF fiber boards

#Designifier#lasercut#lasercutting#laserengraving#acrylic#lasermarking#laserengraved#woodworking#lasercutter#dxfdesign#laserengrave#lasercutwood#crafting#woodcraft#diecut#cncwoodworking#metalfabricationservices

0 notes

Text

Unlock Precision and Speed with Expert Laser Cutting Machine Manufacturers

Boundless Innovation in Each Cut with the Best Laser Cutting Machine Manufacturers.

Discover our dual-pallet laser cutting machines, engineered for high-speed production and reduced downtime. As reliable Laser Cutting Machine Manufacturers, we ensure that our machines come with simultaneous load/unload features to streamline workflow without sacrificing top cut quality. Optimized nesting software provides precision, burr-free cuts up to 50mm thickness, with no warping or tapering.

Key Performance Features of your most trusted Laser Cutting Machine Manufacturers.

As premier Laser Cutting Machine Manufacturers, we provide high-performance systems for efficiency, accuracy and flexibility. Our machines include a double pallet system, enabling quick job changing with simultaneous loading and unloading to increase throughput.

With micron-grade precision, they are ideal for fine detailing and precise contour cutting. Higher cutting speeds utilizing high-speed fibre lasers and motion control units allow greater productivity for various applications. The capacity to cut multi-materials is assured to deliver clean and precise cuts in mild steel, stainless steel, aluminium, copper and others.

A streamlined, user-friendly interface constantly improved by software updates and user input guarantees usability. Heavy-duty construction delivers vibration-free stability, even in continuous working situations and power-saving fibre lasers reduce long-term operating expenses.

Integrated safety solutions, such as emergency stop functionality and safety enclosures, guarantee safe operation. Available in configurations with different laser powers and table sizes, our equipment fulfils unique workflow needs.

Cut quality is sustained at high velocities with Fly Cut technology and our end-to-end support features technical support, web-based troubleshooting and predictive maintenance software.

Technical Specifications of the best Laser Cutting Machine Manufacturers at a Glance.

The Winarc two-pallet fibre laser sheet cutting machine is designed to deal with an extensive series of sheet sizes with a work length from 3000 mm to 8000 mm and a width from 1500 mm to 3000 mm. It has an axis speed up to 120 meters per minute, yet at the same time achieves a delicate positional accuracy of ±0.03 mm, which is ideal for bulk precision processing.

Driven by Ethercat networking, it provides real-time responsiveness for precise and efficient functioning. The machine accommodates laser powers ranging from 2 kw to 20 kw, with the flexibility to cut materials of different thicknesses. It is also fully integrated with CypNest, Radan and SigmaNest CAD-CAM software to enable precise nesting, seamless programming and optimum material utilization.

Winmaster dual-pallet laser cutting machines are equipped with globally recognized components to ensure maximum durability, accuracy and productivity in demanding industrial environments.

Fibre Laser Source

Brands: Raycus, IPG, Max, Trumpf

These best-in-class sources provide superior beam quality, low maintenance and reliable performance across metals.

CNC Control System

Brands: Cypcut, Eckelmann

User-friendly interfaces paired with high-speed processing allow for responsive and precise control.

Linear Guides & Bearings

Brands: Hiwin, CPC

Engineered for precision motion and long-lasting stability, ensuring high accuracy with every cut.

Servo Motors & Drives

Brand: Yaskawa

Renowned for fast acceleration and pinpoint control, boosting both speed and reliability.

Cooling Unit

Brands: Hanli, Hexacool, S&A

Ensures thermal stability, safeguards core components and extends service life.

Laser Cutting Head

Brands: Precited, Ray tools, WSX, Bochu

Designed for clean, efficient cutting with adaptive focusing and edge sharpness across material types.

0 notes

Text

learned <a lot>

0 notes

Text

Super süße Zuckerstangen Anhänger aus Holz. Perfekt für die Weihnachtsdeko als Geschenkanhänger oder für den Tannenbaum. 🎄😍✨

#ecommerce#small business#stilvrei#handmadebusiness#illustrator#small artist#diy#christmas#candy cane#christmas decoration#woodcut#lasercutter#home decor#handmade#handcrafted#advertising#artists on tumblr#creativity#decor#interior design

0 notes

Text

Neue Hardware - der Atomstack X20 Pro.

0 notes

Text

The Islamic Arabesque Privacy Screen DXF LS0089 is a perfect design for a Masjid window or door, adding style and privacy to the Masjid interior. Inspired by the traditional design of windows seen in Arabic or Islamic architecture, these designs will provide a beautiful addition to your design. You can also create awesome decorations with these Arabic lines-style ornament vector designs in windows, furniture, and doors, among other applications

#Designifier#lasercut#lasercutting#laserengraving#acrylic#lasermarking#laserengraved#woodworking#lasercutter#dxfdesign#laserengrave#lasercutwood#crafting#woodcraft#diecut#cncwoodworking#metalfabrication

0 notes

Text

Best CNC Laser Cutting Machine Manufacturers

We specialize in manufacturing state-of-the-art CNC laser cutting machines manufacturers that cater to diverse industrial needs. Whether you are in the automotive, aerospace, electronics, or signage industry, our machines are designed to meet your specific requirements.

#PlasmaCutting#PlasmaCutter#CNCPlasma#MetalFabrication#WeldingCuttingMachines#CuttingMachines#IndustrialMachines#MetalCutting#ManufacturingTechnology#FabricationIndustry#LaserCutting#CNCMachine#LaserCutter#CuttingTechnology#PrecisionCutting

0 notes