#Advanced NDT

Explore tagged Tumblr posts

Text

Cutech is one of the world’s leading providers of Non-Destructive Testing, Inspection and Advisory services to the Oil & Gas, Petrochemical, Defence and General Engineering Industries. We provides non-destructive testing, auditing, and inspection related services in Singapore and worldwide. Cutech offers a combination of basic and innovative inspection service, distinguishing itself as an advanced NDT provider.

0 notes

Text

Ensuring Weld Quality: Advanced Ultrasonic Testing Methods

In the world of welding, ensuring the quality and integrity of welds is crucial. One of the most effective ways to inspect welds is through ultrasonic testing, which uses high-frequency sound waves to detect imperfections. This blog explores advanced ultrasonic testing methods for welding inspection, highlighting their benefits and applications in the UK.

Introduction to Ultrasonic Testing

Ultrasonic testing for welding involves high-frequency sound waves to detect flaws in welds. This non-destructive testing (NDT) method effectively identifies internal and surface defects without damaging the material.

Why Ultrasonic Testing for Welding?

Accuracy: Provides precise detection of internal flaws.

Non-Destructive: Does not damage the material being inspected.

Versatility: Suitable for a wide range of materials and thicknesses.

Advanced Ultrasonic Testing Techniques

Advanced ultrasonic testing techniques have revolutionised the NDT industry, providing unprecedented levels of accuracy and efficiency. Below are some of the most advanced testing techniques used in the industry:

1. Phased Array Ultrasonic Testing (PAUT)

PAUT is an advanced technique that uses different ultrasonic elements and electronic time delays to create a sweeping beam. This method provides a detailed image of the weld, allowing for precise identification of defects.

Benefits:

High-resolution and detailed images

Faster inspection times

Improved defect characterisation

2. Time-of-Flight Diffraction (TOFD)

TOFD is another complex ultrasonic testing method that uses the time taken by sound waves to travel and diffract around defects to detect and size flaws accurately.

Benefits:

High accuracy in defect sizing

Effective for detecting both surface and subsurface defects

Reduced operator dependency

3. Automated Ultrasonic Testing (AUT)

AUT involves automated systems that perform ultrasonic inspections. This method enhances the consistency and repeatability of inspections, making it ideal for large-scale projects.

Benefits:

Consistent and repeatable results

Increased inspection speed

Reduced human error

Applications of Ultrasonic Testing in the UK

Ultrasonic testing is widely used in the UK across different industries to provide safety and integrity to critical infrastructure. Here are some key applications of ultrasonic testing in the UK.

1. Oil and Gas Industry

In the UK, the oil and gas industry rely heavily on ultrasonic testing for welding to ensure the integrity of pipelines and other critical infrastructure. PAUT and TOFD are commonly used to inspect welds in pipelines, ensuring they are free from defects that could lead to failures.

2. Aerospace Industry

The aerospace industry requires the highest levels of safety and reliability. Ultrasonic testing methods are used extensively to inspect welds in aircraft components, ensuring they meet strict safety standards.

3. Construction and Infrastructure

Ultrasonic testing plays a crucial role in the construction industry, particularly for inspecting welds in bridges, buildings, and other structures.

Advantages of Advanced Ultrasonic Testing Methods

Check out the advantages of advanced ultrasonic testing methods over traditional approaches.

1. Enhanced Accuracy

Advanced ultrasonic testing methods provide higher accuracy in detecting and sizing defects than traditional methods.

2. Increased Efficiency

Automated and advanced techniques like PAUT and AUT significantly reduce inspection times while maintaining high levels of accuracy.

3. Comprehensive Reporting

These methods offer detailed and comprehensive reporting, providing clear images and data that can be used for further analysis and decision-making.

Conclusion

Adopting advanced ultrasonic testing for welding is essential for industries aiming to maintain high quality and safety standards.

Investing in these advanced techniques enhances inspection reliability and ensures compliance with stringent safety regulations. By leveraging the benefits of advanced ultrasonic testing, industries can achieve greater efficiency, accuracy, and overall project success.

9 notes

·

View notes

Text

The Power of Precision: Exploring the Benefits of PAUT in NDT

In the realm of industrial inspections, the demand for accuracy and efficiency has never been higher. Phased Array Ultrasonic Testing (PAUT) stands out as a revolutionary method that fulfills these requirements, offering unparalleled precision and speed. As an integral part of Non Destructive Testing, PAUT is widely used across various industries to ensure the integrity and reliability of critical components. Here, we delve into the intricacies of PAUT and its benefits.

PAUT is an advanced method of ultrasonic testing that uses multiple elements and electronic time delays to create beams of sound waves. These beams can be steered, focused, and scanned, providing detailed images of internal structures. Unlike conventional ultrasonic testing, which uses a single transducer to send and receive sound waves, PAUT employs an array of transducers. This allows for simultaneous collection of data from multiple angles, resulting in more comprehensive and accurate inspections.

As part of a broader suite of Non Destructive Testing Services, PAUT plays a crucial role in ensuring the safety and reliability of industrial components. Nondestructive testing (NDT) from RVS QUALITY CERTIFICATIONS PVT LTD encompasses various techniques used to evaluate the properties of a material, component, or system without causing damage. PAUT's advanced capabilities enhance the overall effectiveness of NDT services, providing detailed and reliable data that support maintenance and quality assurance programs.

Applications Across Industries

The versatility of PAUT makes it suitable for a wide range of applications. It is commonly used in the aerospace, automotive, and power generation industries for inspecting critical components such as welds, turbine blades, and composite materials. PAUT's ability to detect minute defects and irregularities ensures that even the smallest flaws are identified before they become critical issues. This level of precision is essential for maintaining safety and performance standards in high-stakes environments.

Efficiency and Accuracy Combined

One of the standout features of PAUT is its efficiency. The ability to steer and focus sound waves electronically means that inspections can be performed more quickly compared to traditional methods. This not only reduces downtime but also increases the number of inspections that can be completed within a given timeframe. Additionally, the detailed images produced by PAUT provide a clearer understanding of the inspected material's condition, allowing for more accurate assessments and decision-making.

Enhanced Tube Inspections

A specific area where PAUT excels is in Tube Inspection Services. Tubes, often found in heat exchangers and boilers, are prone to various types of degradation such as corrosion and cracking. PAUT's ability to inspect from multiple angles simultaneously makes it particularly effective for tube inspections. It can detect flaws that may be missed by conventional methods, ensuring that tubes are thoroughly evaluated for any signs of wear or damage. This comprehensive approach helps prevent failures and extends the lifespan of critical equipment.

Advancing with Technology

The continuous evolution of technology has significantly impacted PAUT. Advances in digital signal processing and software have improved the resolution and clarity of the images produced. Portable PAUT equipment from RVS QUALITY CERTIFICATIONS PVT LTD has made it possible to conduct inspections in challenging environments, further expanding its applicability. These technological advancements ensure that PAUT remains at the forefront of nondestructive testing techniques, providing industries with cutting-edge solutions for maintaining safety and quality.

In conclusion, PAUT is a powerful tool that combines precision and efficiency to deliver superior inspection results. Its ability to provide detailed images from multiple angles makes it invaluable for identifying defects and ensuring the integrity of critical components. As a key component of Non Destructive Testing, PAUT supports industries in maintaining high standards of safety and performance. Whether it's for welds, turbine blades, or Tube Inspection Service, PAUT continues to set the standard for advanced nondestructive testing methodologies.

5 notes

·

View notes

Text

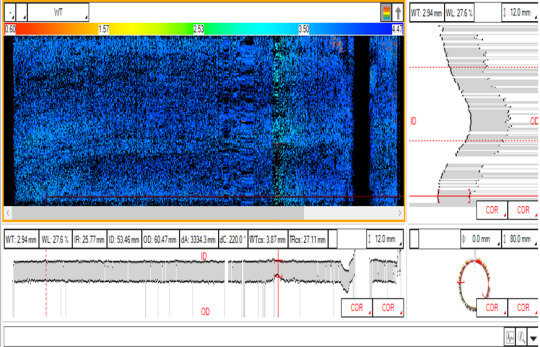

Inspection of Boiler Bank Tubes | Internal Rotary Inspection System (IRIS)

Are you unable to carry out the Inspection of Boiler Bank tubes?

Are you regularly carrying out Capital Investment by purchasing tubes rather than finding only the defective Bank Tubes?

Here is the solution for inspection of Boiler Bank Tubes –

In case of Boiler Bank Tubes, only the Front Column of Tubes are available for Inspection for Thickness Testing externally there is no other way to check the rest of the Tubes. Thus, we have only 5 % of the Tubes available while we miss out on an inspection of the rest of the 95% of the tubes.

RFET was done previously to ascertain the condition of the rest of the 95% of the tubes but due to the limitation of the technique it is also not a right testing method. Then we tried IRIS on these tubes and got amazing results.

HOW IT WORKS –

Because IRIS is an ultrasonic technique, it requires a couplant. In this case, water. Tubes under test must therefore first be flooded to use this technique. IRIS relies on a transducer to generate an ultrasonic pulse parallel to the axis of the tube under test. It also relies on a rotating mirror that directs the ultrasonic wave into the tube wall.

The mirror is driven by a small turbine powered by the pressure of water pumped into the tube. Part of the ultrasonic wave is reflected by the inner diameter (ID) wall, while the rest is reflected by the outer diameter (OD) wall of the tube. Because the ultrasonic velocity of the tube’s material is known, it is possible to assess the thickness of the wall by calculating the difference in times of flight between the two diameters. As the probe is pulled, the spinning motion of the mirror results in a helical scan path.

A critical aspect of IRIS is ensuring that the mirror is at the centre of the tube. An off-centre ultrasonic pulse yields a distorted scan image because of the different ID and OD wall sound paths. That’s why our IRIS kits are equipped with centring devices helping operators keep the system centred.

About IRC Engineering Pvt. Ltd.

IRC is one of the fastest growing Testing and Inspection company in India. We at IRC provide Liquid Penetrant Testing, Non-Destructive Testing, Destructive Testing, Advanced NDT, Third Party Inspection, Condenser Testing, Electrical Testing, Residual Life Assessment of Power Plant, O&M Services, Fitness For Service, Civil Testing and Training services.

Our website - https://ircengg.com/

2 notes

·

View notes

Text

Types of Visual Inspection

Introduction

The history of inspection is a narrative of human ingenuity and the quest for quality assurance across diverse domains.

In ancient times, civilizations such as the Egyptians and Greeks employed visual inspection techniques to assess the structural integrity of monumental constructions like the pyramids and temples.

As industrialization burgeoned, especially during the Renaissance and the subsequent periods, the need for more sophisticated methods became apparent.

This led to the gradual emergence of Non-destructive Testing (NDT), a revolutionary approach that allowed scrutiny without compromising the integrity of the materials.

In the Oil and Gas Industry, where safety and reliability are paramount, NDT testing took center stage.

The exploration of Ultrasonic Testing brought forth a method relying on sound waves, enabling inspectors to delve into the hidden intricacies of materials, identifying flaws that might escape visual scrutiny.

Simultaneously, Magnetic Particle Testing became a pivotal tool, particularly in assessing the integrity of metallic components crucial to the industry.

The Scaffolding that supports the modern industrial landscape, both figuratively and literally, further underscores the need for rigorous inspection.

Complemented by Advanced NDT Techniques, visual inspection ensures that the scaffolding itself, a linchpin in construction and maintenance, meets stringent safety standards.

This historical journey, from ancient Visual Inspections to the contemporary amalgamation of ultrasonic and magnetic particle testing, represents a testament to the evolution of inspection practices — a narrative driven by the relentless pursuit of precision, reliability, and safety in the intricate tapestry of engineering.

What is Visual Inspection?

Visual inspection is a method in Non-destructive Testing (NDT), that relies on the human eye to assess the surface conditions of materials, structures, and components.

This method involves a structured methodology to ensure comprehensive scrutiny.

Operators conducting Visual Inspections follow a systematic approach, beginning with thorough planning and preparation.

What are the benefits of Visual Inspection?

The advantages of Visual Inspection include the following:

Cost-Effective

Visual Inspection is often more economical compared to advanced methods like ultrasonic testing, magnetic particle testing, and Liquid Penetrant Testing.

Real-Time Adaptability

Visual inspection allows for immediate on-site assessments, contributing to real-time decision-making during the inspection process.

Versatility

Applicable to a wide range of materials and structures, making it a versatile choice for diverse industries.

Integrating Automation

Visual Inspection automation enhances efficiency by automating repetitive tasks and ensuring consistent and thorough inspections.

Conclusion

Visual Inspection remains a foundational and enduring method in non-destructive testing (NDT).

As we witness the integration of automation, AI, and robotics, particularly in visual inspection automation and Drone Inspection, the landscape of NDT is evolving.

These advancements enhance efficiency, safety, and accuracy, especially in inaccessible or adverse conditions.

The incorporation of AI in NDT, coupled with Visual Testing and drone inspection, emphasizes the transformative nature of these technologies.

Visual inspection's simplicity, accessibility, and role as the initial step in identifying defects ensure its continued relevance, complementing Advanced NDT Methods applied by professionals and technicians in the field.

#ndt testing#ndt techniques#visual inspection#visual inspection techniques#visual inspection methods#visual inspection benefits

2 notes

·

View notes

Text

Beyond Basics: Exploring the Future of Advanced NDT Services

Advanced NDT services are transforming industrial inspection with smarter, faster, and more accurate techniques. From phased array ultrasonic testing to cutting-edge NDT inspection, these non-destructive testing services ensure asset reliability without compromising safety. As industries demand higher precision, NDT technologies evolve to deliver deeper insights and data-driven decisions. Embrace the future with advanced NDT services designed for complex challenges and critical operations.

0 notes

Text

🚀 Elevating Safety in the Skies 🚁

At Best NDT Inspection, we understand that the aerospace industries demand nothing less than perfection. From aircraft structures to precision-engineered components, our advanced non-destructive testing solutions help ensure every part meets the highest safety and quality standards.

🛰️ Fly safe, fly smart — with Best NDT Inspection. 📍 Learn more at: https://www.bestndtinspection.com/

#AerospaceIndustries#NDTInspection#BestNDTInspection#AerospaceTesting#AviationSafety#QualityControl#FlyWithConfidence

0 notes

Text

Mesta Inc is the best manufacturer of Fabricated Pipe Spools. Mesta Inc is a trusted leader in the engineering and manufacturing of fabricated pipe spools, delivering high-precision solutions tailored to meet the needs of complex piping systems in various industries including oil and gas, power, chemical, and water treatment. With advanced fabrication facilities and a skilled team, Mesta Inc specializes in producing fabricated pipe spools that meet international quality standards and client specifications. These spools are prefabricated sections of piping that include pipes, flanges, elbows, tees, and other fittings, assembled and welded in a controlled environment to ensure accuracy, reduce on-site labor, and speed up project timelines. Mesta Inc uses high-grade materials like carbon steel, stainless steel, and alloy steel to ensure strength, corrosion resistance, and durability under high pressure and extreme temperatures. Each fabricated pipe spool is subjected to rigorous testing including hydro testing, NDT, and dimensional inspection to guarantee leak-proof performance and long-term reliability. Known for on-time delivery and attention to detail, Mesta Inc supports both large-scale and small-scale projects with customized solutions that enhance system integrity and installation efficiency. Whether for new installations or maintenance operations, Mesta Inc’s fabricated pipe spools offer a dependable and cost-effective choice that meets the highest standards of safety, performance, and quality assurance.

0 notes

Text

Top Reasons to Choose a Material Testing Lab in Ajman for Your Construction Projects | +971 554747210

As the UAE continues to invest heavily in infrastructure, real estate, and urban development, the emirate of Ajman has emerged as a promising hub for construction growth. Whether you are developing residential towers, commercial complexes, or civil infrastructure, ensuring the quality, safety, and compliance of materials used in construction is critical. This is where a Material Testing Lab in Ajman plays a pivotal role.

Material testing labs are essential partners in the construction lifecycle, from pre-construction material verification to post-construction quality assurance. In this article, we will explore the top reasons to choose a material testing lab in Ajman and how it can enhance the success of your construction projects.

What Is a Material Testing Lab?

A Material Testing Lab is a specialized facility that conducts scientific evaluations of construction materials such as concrete, steel, soil, aggregates, asphalt, and more. These labs perform physical, mechanical, chemical, and environmental testing to ensure materials meet specific industry standards and project requirements.

In Ajman, many of these labs are ISO/IEC 17025 accredited, equipped with modern testing equipment, and staffed by qualified technicians, making them a trusted resource for developers, contractors, and government authorities.

1. Ensure Compliance with UAE Building Regulations

One of the primary reasons to use a material testing lab in Ajman is to ensure compliance with both local and international building codes and standards. The UAE has strict regulations set by:

Ajman Municipality

Ministry of Infrastructure Development

ESMA (Emirates Authority for Standardization and Metrology)

Dubai Central Laboratory for inter-emirate standards

Material testing labs validate that the materials you use conform to these codes, reducing the risk of legal penalties, project delays, or rework.

2. Guarantee Structural Integrity and Safety

Testing construction materials before and during a project helps ensure that every component—whether it’s concrete, steel reinforcement, or soil foundation—can withstand intended loads and environmental conditions.

Typical tests include:

Compressive strength of concrete

Tensile and yield strength of steel

Soil bearing capacity and compaction

Moisture content and slump testing

Aggregate durability and gradation

Using a certified Material Testing Lab in Ajman helps confirm that your materials meet the safety margins essential for long-term durability and structural stability.

3. Access to State-of-the-Art Testing Facilities

Ajman’s top testing labs are outfitted with advanced laboratory equipment capable of conducting a wide range of tests efficiently and accurately. Some of the high-tech tools include:

Universal testing machines (UTM)

Sieve shakers for aggregates

Soil triaxial and consolidation testers

XRF/XRD analyzers for chemical composition

NDT equipment (Ultrasonic, Radiographic, Rebound Hammer)

These facilities ensure fast turnaround times and precise results, enabling timely decision-making for ongoing construction.

4. Support for Sustainable Building Practices

As the UAE pushes for more eco-friendly and sustainable construction, material testing labs in Ajman play a key role in verifying green compliance.

They conduct tests that help with:

Recyclability of materials

Thermal insulation performance

VOC (Volatile Organic Compound) content in paints and sealants

Durability of alternative and sustainable materials

This supports LEED certification and other green building standards, which are increasingly important for government and private-sector projects.

5. Enhance Cost-Efficiency and Avoid Rework

Material failures during or after construction can lead to expensive repairs, delays, and reputational damage. Engaging a reputable Material Testing Lab in Ajman reduces this risk by identifying flaws early.

Whether it’s detecting substandard steel, improperly mixed concrete, or soil unsuitable for foundations, early testing saves money and improves resource management. Accurate lab data also helps optimize material usage, avoiding over-design or waste.

6. Experienced Technicians and Engineering Support

Most Ajman-based labs employ certified material engineers, lab technicians, and QA professionals with deep industry experience. These experts don’t just perform tests—they interpret results, offer actionable insights, and can even provide consulting on material selection and remediation.

This technical support is especially beneficial in complex projects involving unusual load conditions, challenging soil profiles, or custom material specifications.

7. On-Site Testing and Field Services

To minimize disruptions and speed up decision-making, many material testing labs in Ajman offer on-site testing and sampling services. These include:

Core sampling of concrete

Field density tests for soil compaction

On-site concrete slump and temperature tests

Rebound hammer and ultrasonic pulse velocity for structural integrity

Mobile labs and field teams allow testing to happen in real-time, right where it matters most—on your construction site.

8. Third-Party Quality Assurance and Certification

Government agencies, real estate developers, and large infrastructure investors increasingly demand third-party verification of material quality. Using an independent Material Testing Lab in Ajman enhances your project's credibility and transparency.

These labs provide:

Third-party inspection reports

Material compliance certificates

Batch-wise testing documentation

Final project QA/QC sign-offs

Such documentation is invaluable for regulatory audits, investor reporting, and project handovers.

9. Comprehensive Testing Across All Project Phases

From feasibility studies and site preparation to structural development and finishing stages, Ajman’s testing labs support every phase of construction:

Project Phase

Key Testing Services

Pre-Construction

Soil testing, geotechnical analysis, water table assessment

Structural Development

Concrete strength, steel quality, welding inspection

Interior Finishing

Adhesive performance, tile bonding, VOC emission testing

Handover & Certification

NDT inspection, final QA/QC validation, sustainability audits

This full-spectrum support ensures you never compromise on quality.

10. Strategic Location for Northern Emirates Projects

For developers working in Sharjah, Ras Al Khaimah, Umm Al Quwain, and even parts of Dubai, Ajman’s geographic location makes it a convenient and efficient choice for material testing. The shorter logistics chain translates to faster sample delivery, quick report generation, and better project coordination.

Conclusion

Choosing a reliable Material Testing Lab in Ajman is a smart decision for any construction stakeholder—be it contractors, developers, consultants, or government authorities. From ensuring compliance and structural safety to reducing costs and supporting sustainability, these labs provide the expertise and accuracy needed to deliver high-quality construction outcomes.

#material testing lab#material testing#material testing laboratory#testing lab near me#testing lab uae

0 notes

Text

Get high quality container loading inspection service at best price throughout Asia from RAQC Services. We are committed to maintain in depth expertise, advancement in NDT & continual improvement of our quality system. We guarantee to beat any factory in Asia within 48 hours. Book a container loading inspection services today!

0 notes

Text

Houston Division Manager with Arctic Testing & Inspection

Job title: Houston Division Manager with Arctic Testing & Inspection Company: ASRC Industrial Job description: : asrcindustrial.com/careers/ About Company Arctic Testing and Inspection (ATI) offers a wide-range of comprehensive advanced non…-destructive testing (NDT) and inspection services for the energy, infrastructure, manufacturing and aerospace industries. ATI… Expected salary: Location:…

0 notes

Text

Affordable ASNT Training and course | TryIn Solution

Get industry-recognized ASNT training and certification at budget-friendly prices with TryIn Solution. Our courses combine expert instruction with flexible learning options to help you advance your NDT career affordably. To learn more, visit www.tryinsolution.com today.

0 notes

Text

Best Concrete Testing Equipment Manufacturer in Delhi – Barket Hitech Engineering

Introduction

In the field of construction and civil engineering, ensuring the quality and durability of concrete structures is essential. For accurate and reliable testing, high-quality concrete testing equipment is required. If you’re looking for the best concrete testing equipment manufacturer in Delhi, Barket Hitech Engineering is a trusted name. With a commitment to innovation, precision, and durability, we provide a wide range of advanced concrete testing instruments.

Delhi has witnessed rapid growth in infrastructure projects, making concrete testing equipment a crucial component in the construction industry. Testing ensures compliance with national and international standards, improving the lifespan and safety of buildings, bridges, and roads. Barket Hitech Engineering stands out as a leading supplier of concrete testing machines in India, offering solutions that cater to builders, contractors, and testing laboratories.

What is Concrete Testing Equipment?

Concrete testing equipment is used to assess the strength, durability, and composition of concrete. These tools help in determining whether concrete meets the required standards and specifications for safe construction.

Types of Concrete Testing Equipment

Compression Testing Machines – Measure the compressive strength of concrete cubes and cylinders. This is one of the most critical tests in civil engineering to ensure that concrete structures can withstand applied loads.

Rebound Hammer (Schmidt Hammer) – Evaluates the surface hardness of concrete. It is a non-destructive test widely used for assessing existing structures.

Slump Test Apparatus – Determines the workability and consistency of fresh concrete. This helps in ensuring the right mix design before concrete is poured.

Concrete Permeability Testing Machine – Measures the water permeability of hardened concrete. Lower permeability indicates better durability of concrete structures.

Cement & Mortar Testing Equipment – Includes vicat apparatus, flow table, and setting time testers, all of which are essential in testing the properties of cement before it is used in construction.

Non-Destructive Testing (NDT) Equipment – Used for assessing concrete strength without damaging the structure. These include ultrasonic pulse velocity tests and penetration resistance tests.

Importance of Concrete Testing in Construction

Concrete testing is crucial for ensuring the safety, durability, and compliance of structures with industry standards. Poor-quality concrete can lead to structural failures, resulting in costly repairs and safety hazards. Some benefits of concrete testing include:

Ensuring Structural Integrity – By testing the strength and durability, engineers can verify if the concrete meets the design specifications.

Compliance with Regulations – Concrete must meet BIS, ASTM, and ISO standards for safety and performance.

Cost Savings – Early detection of concrete quality issues helps prevent expensive repairs and failures.

Environmental Sustainability – Proper testing ensures the optimal use of materials, reducing waste and promoting sustainable construction.

Why Choose Barket Hitech Engineering for Concrete Testing Equipment?

Advanced Technology & Precision Engineering

We manufacture state-of-the-art concrete testing machines that offer high precision, durability, and user-friendly operation. Our machines are designed using the latest technological advancements to provide accurate and reliable results.

Wide Range of Testing Equipment

Our product line includes compression testing machines, slump test apparatus, rebound hammers, permeability testers, and more to meet all concrete quality assessment needs. We provide testing solutions for laboratories, construction sites, and research institutions.

High Durability & Low Maintenance

All our concrete testing equipment is built using high-grade materials to ensure long-lasting performance with minimal maintenance. We focus on robust design to withstand heavy usage.

Reliable After-Sales Support & Spare Parts Availability

We provide installation services, spare parts, and regular maintenance support, ensuring that your concrete testing equipment operates efficiently. Our team of experts is always available to assist with troubleshooting and repairs.

Compliance with Industry Standards

Our products conform to BIS, ASTM, and ISO standards, ensuring accurate and reliable concrete testing results. We prioritize quality control to guarantee the highest level of product reliability.

Conclusion

Investing in high-quality concrete testing equipment is essential for ensuring safe and durable construction projects. Choosing the right manufacturer, such as Barket Hitech Engineering, ensures accuracy, reliability, and long-term efficiency.

For the best concrete testing equipment supplier in Delhi NCR, contact Barket Hitech Engineering today and get customized solutions for your construction testing needs!

0 notes

Text

Silver Oak College of Aviation Technology (SOCAT): Aerospace Engineering College in Gujarat

In the rapidly evolving landscape of aerospace and aviation, Silver Oak College of Aviation Technology (SOCAT) in Ahmedabad, Gujarat, stands out as a beacon of excellence. As a constituent college of Silver Oak University, SOCAT is dedicated to producing industry-ready professionals equipped with the knowledge and skills required to excel in the dynamic aviation sector. With a comprehensive curriculum, state-of-the-art facilities, and a commitment to practical training, SOCAT is shaping the future of aerospace engineering education in Gujarat. It is widely recognized as a top Aerospace Engineering College in Gujarat, attracting students from across the country.

Comprehensive Programs Tailored for the Aviation Industry

SOCAT offers a diverse range of programs designed to cater to various facets of the aviation industry, reinforcing its reputation as a leading Aerospace Engineering College in Gujarat:

Aircraft Maintenance Engineering (AME) License Course: This program focuses on the maintenance and troubleshooting of aircraft, ensuring that graduates are well-versed in the technical aspects of aviation safety and performance.

AME with B.Tech in Aeronautical/Aerospace Engineering: A unique four-year integrated program that combines the practical aspects of aircraft maintenance with the theoretical foundations of aeronautical and aerospace engineering. This dual qualification enhances employability both in India and internationally.

Cabin Crew & Airport Management: Designed for those aspiring to be part of the glamorous and fast-paced world of aviation hospitality and airport operations, this course provides insights into customer service, safety protocols, and airport logistics.

BBA and MBA in Aviation Management: These programs delve into the business and managerial aspects of the aviation industry, covering topics like human resources, marketing, airport security, and passenger forecasting.

State-of-the-Art Infrastructure and Facilities

As a prominent Aerospace Engineering College in Gujarat, SOCAT prides itself on its advanced infrastructure that mirrors real-world aviation environments:

Avionics Lab: Equipped with electrical systems, instrument systems, and radio navigation tools, this lab provides hands-on experience in aircraft electronics.

Mechanical Lab: Featuring airframe and jet engine components, students gain practical knowledge of aircraft structures and propulsion systems.

General Engineering Workshop: A space where students can hone their skills in various engineering disciplines relevant to aviation.

Composite, Battery & NDT Shop: These facilities focus on the maintenance and testing of composite materials and batteries, essential for modern aircraft.

Wind Tunnel Setup: Allows students to study aerodynamics and understand airflow patterns over aircraft surfaces.

Mock Aircraft Cabin and Live Airport Environment: Provides a realistic setting for students to practice and understand cabin crew operations and airport management.

Industry Collaborations and Practical Training

Understanding the importance of real-world experience, SOCAT has established partnerships with leading aviation companies, further solidifying its position as a top Aerospace Engineering College in Gujarat:

AAR Indamer Collaboration: Through this partnership, students undergo 300 hours of practical training on real aircraft, including the Airbus A320 fleet maintained for major airlines like IndiGo. This hands-on experience ensures that graduates are industry-ready and familiar with contemporary aviation technologies.

Eligibility Criteria and Admissions

SOCAT maintains clear eligibility criteria to ensure that students are well-prepared for their chosen programs:

AME License Course: Candidates must have completed 12th grade with Physics, Chemistry, and Mathematics or hold a diploma in engineering. A general medical test and color blindness test are also required.

AME with B.Tech: Applicants should have passed 12th grade with at least 45% marks in PCM or possess a diploma in engineering. Medical fitness and color vision tests are mandatory.

Cabin Crew & Airport Management: Open to those who have completed 10+2 or a diploma in any stream, aged between 17 to 24 years, with specific height and appearance criteria.

BBA Aviation Management: Requires completion of 12th grade or a three-year diploma from a recognized board or university.

MBA Aviation Management: Applicants must hold a graduate degree from a recognized university.

Why Choose SOCAT for Aerospace Engineering in Gujarat?

When searching for the best Aerospace Engineering College in Gujarat, SOCAT clearly emerges as a top contender for several compelling reasons:

DGCA Approval: SOCAT is approved by the Directorate General of Civil Aviation, Government of India, ensuring adherence to national aviation education standards.

Integrated Learning Approach: The combination of theoretical knowledge with practical training ensures that students are well-equipped to meet industry demands.

Experienced Faculty: A team of seasoned professionals and educators guide students through the complexities of aviation and aerospace engineering.

Placement Opportunities: SOCAT's strong industry connections facilitate placements in top aviation companies, airlines, and maintenance organizations.

Modern Infrastructure: With facilities that replicate real-world aviation environments, students gain invaluable hands-on experience.

Conclusion

Silver Oak College of Aviation Technology (SOCAT) is more than just an educational institution; it's a launchpad for aspiring aviation professionals. By offering a blend of rigorous academic programs, practical training, and industry exposure, SOCAT ensures that its graduates are not only knowledgeable but also ready to take on the challenges of the global aviation industry. For those passionate about aerospace engineering and seeking a comprehensive education in Gujarat, SOCAT is the destination of choice and a leading Aerospace Engineering College in Gujarat.

If you're looking to build your career at a reputed Aerospace Engineering College in Gujarat, look no further than SOCAT.

For more information and admissions, visit socat.silveroakuni.ac.in.

#AerospaceEngineeringCollegeinGujarat #AeronauticalEngineeringCollegeGujarat #AeronauticalEngineeringCollege #AerospaceCollegeinGujarat #AerospaceEngineering

#Aerospace Engineering College in Gujarat#Aeronautical Engineering College Gujarat#Aeronautical Engineering College#Aerospace College in Gujarat#Aerospace Engineering

0 notes

Text

Inside the Weld: How Phased Array Ultrasonic Testing Is Redefining NDT

Phased Array Ultrasonic Testing (PAUT) is revolutionizing non-destructive testing with its ability to detect minute flaws deep inside welds. Unlike conventional methods, PAUT inspection provides real-time, high-resolution imaging, ensuring superior accuracy and safety. This advanced PAUT testing technique is ideal for critical industries like oil & gas, aerospace, and power. With the power of phased array ultrasound, technicians can pinpoint defects with unmatched precision, making PAUT a game-changer in structural integrity and asset reliability.

0 notes

Text

🌍 Fueling Safety in the Oil & Gas Industries 🛢️

At Best NDT Inspection, we understand the high stakes and extreme environments of the oil & gas industries. Our advanced NDT solutions are designed to detect flaws before they become failures — ensuring your operations stay safe, efficient, and compliant.

🔍 From ultrasonic testing to radiographic inspection, we help protect pipelines, pressure vessels, rigs, and refineries with precision and reliability.

📍 Based in Singapore, trusted globally. Visit 👉 www.bestndtinspection.com

#OilAndGasIndustry#NDTServices#BestNDTInspection#IndustrialSafety#NDTInspectionSingapore#PipelineIntegrity#OilAndGasSafety

0 notes