#ultrasonic testing

Explore tagged Tumblr posts

Text

Ensuring Weld Quality: Advanced Ultrasonic Testing Methods

In the world of welding, ensuring the quality and integrity of welds is crucial. One of the most effective ways to inspect welds is through ultrasonic testing, which uses high-frequency sound waves to detect imperfections. This blog explores advanced ultrasonic testing methods for welding inspection, highlighting their benefits and applications in the UK.

Introduction to Ultrasonic Testing

Ultrasonic testing for welding involves high-frequency sound waves to detect flaws in welds. This non-destructive testing (NDT) method effectively identifies internal and surface defects without damaging the material.

Why Ultrasonic Testing for Welding?

Accuracy: Provides precise detection of internal flaws.

Non-Destructive: Does not damage the material being inspected.

Versatility: Suitable for a wide range of materials and thicknesses.

Advanced Ultrasonic Testing Techniques

Advanced ultrasonic testing techniques have revolutionised the NDT industry, providing unprecedented levels of accuracy and efficiency. Below are some of the most advanced testing techniques used in the industry:

1. Phased Array Ultrasonic Testing (PAUT)

PAUT is an advanced technique that uses different ultrasonic elements and electronic time delays to create a sweeping beam. This method provides a detailed image of the weld, allowing for precise identification of defects.

Benefits:

High-resolution and detailed images

Faster inspection times

Improved defect characterisation

2. Time-of-Flight Diffraction (TOFD)

TOFD is another complex ultrasonic testing method that uses the time taken by sound waves to travel and diffract around defects to detect and size flaws accurately.

Benefits:

High accuracy in defect sizing

Effective for detecting both surface and subsurface defects

Reduced operator dependency

3. Automated Ultrasonic Testing (AUT)

AUT involves automated systems that perform ultrasonic inspections. This method enhances the consistency and repeatability of inspections, making it ideal for large-scale projects.

Benefits:

Consistent and repeatable results

Increased inspection speed

Reduced human error

Applications of Ultrasonic Testing in the UK

Ultrasonic testing is widely used in the UK across different industries to provide safety and integrity to critical infrastructure. Here are some key applications of ultrasonic testing in the UK.

1. Oil and Gas Industry

In the UK, the oil and gas industry rely heavily on ultrasonic testing for welding to ensure the integrity of pipelines and other critical infrastructure. PAUT and TOFD are commonly used to inspect welds in pipelines, ensuring they are free from defects that could lead to failures.

2. Aerospace Industry

The aerospace industry requires the highest levels of safety and reliability. Ultrasonic testing methods are used extensively to inspect welds in aircraft components, ensuring they meet strict safety standards.

3. Construction and Infrastructure

Ultrasonic testing plays a crucial role in the construction industry, particularly for inspecting welds in bridges, buildings, and other structures.

Advantages of Advanced Ultrasonic Testing Methods

Check out the advantages of advanced ultrasonic testing methods over traditional approaches.

1. Enhanced Accuracy

Advanced ultrasonic testing methods provide higher accuracy in detecting and sizing defects than traditional methods.

2. Increased Efficiency

Automated and advanced techniques like PAUT and AUT significantly reduce inspection times while maintaining high levels of accuracy.

3. Comprehensive Reporting

These methods offer detailed and comprehensive reporting, providing clear images and data that can be used for further analysis and decision-making.

Conclusion

Adopting advanced ultrasonic testing for welding is essential for industries aiming to maintain high quality and safety standards.

Investing in these advanced techniques enhances inspection reliability and ensures compliance with stringent safety regulations. By leveraging the benefits of advanced ultrasonic testing, industries can achieve greater efficiency, accuracy, and overall project success.

9 notes

·

View notes

Text

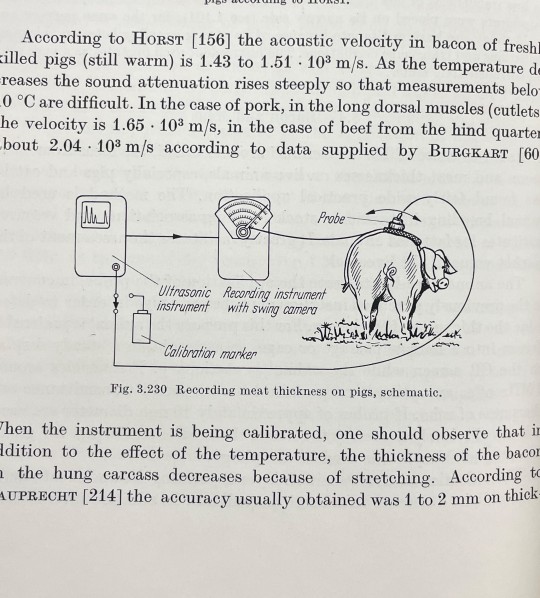

This illustration of an ultrasonic reading device to measure the fat in pigs for bacon is JUST SO WIERD.

Ultrasonic testing of materials, 1969.

41 notes

·

View notes

Text

Ultrasonic inspection involves the propagation of high-frequency sound waves through a material to identify internal flaws & irregularities. Read More!

9 notes

·

View notes

Text

Best Ultrasonic Testing Training Institute in Delhi NCR & Faridabad | A to Z NDT Training

If you want to make a good career in the field of non-destructive testing (NDT) and are looking for valuable skills to acquire, ultrasonic testing (UT) is one of the most valuable skills you can acquire. For North Indians living in Delhi NCR and Faridabad, A to Z NDT Training is a renowned ultrasonic testing training institute in Delhi NCR and Faridabad that provides thorough courses comprising theory and practice classes.

Why Choose Ultrasonic Testing Training?

Ultrasonic testing is most commonly utilized in almost all of the oil & gas, aerospace, construction, and manufacturing industries. It is utilized to identify internal material and structural flaws without any damage. Since companies are becoming increasingly quality- and safety-oriented, the need for UT certified technicians is always increasing.

By using ultrasonic testing training in Delhi NCR, you will be capable of becoming eligible for multiple professional opportunities in India and globally. A to Z NDT Training programs are properly designed in a way through which the students are able to receive the advantage of the most contemporary methodology and industry demand-based certification.

About A to Z NDT Training

A to Z NDT Training is one of the leading names among the training centers for NDT training that has been known to provide quality ultrasonic testing training certification in Delhi NCR as well as in Faridabad. The institute has very experienced trainers, new infrastructure, and course material as per international standards like ASNT (American Society for Nondestructive Testing).

No matter whether you are a working engineer or a student, A to Z NDT Training makes sure that you get the best quality of training.

Courses Covered in Delhi NCR

One of the best ultrasonic testing training centers in Delhi NCR, A to Z NDT Training offers all levels of UT training:

1. UT Level I Training: Covers fundamentals, equipment setup and calibration, and flaw detection methods.

2. UT Level II Training: Provides higher level training in result interpretation, code requirements, and flaw characterization in greater detail.

3. Customized Workshops: Employee development training modules industry-specific as required.

A to Z NDT Training ultrasonic testing training certification in Delhi NCR is sought after by big industries, because of which you are unique compared to others in your career life in the competitive job market.

Ultrasonic Testing Training in Faridabad

For professionals and students in Faridabad, A to Z NDT Training also includes a full ultrasonic testing training center in Faridabad. The center is well managed to provide space for theoretical training as well as practical sessions in an industrial environment.

Courses provided are:

Ultrasonic Testing Training in Faridabad: For fresh as well as experienced professionals.

Ultrasonic Testing Training Certification in Faridabad: Authentic certification with placements at international and national level.

Ultrasonic Testing Training Training Training in Faridabad: Extremely intensive skill-enhancement programs to raise your level.

USP of A to Z NDT Training

Trained Instructors: Master NDT trainers with high levels of real-time experience.

Hands-on Practice: Hands-on training on advanced UT machines.

1. Easy Batches: Working professionals can opt for weekday batches in addition to weekend batches.

2. Reasonable Prices: Low-cost training with easy installment facility.

3. 100% Placement Support: The institute has a good industry reputation, and candidates are guaranteed high-paying jobs after certification.

Ultrasonic Testing Certification: Accelerate Your Career

In the present competitive job market, a certification in ultrasonic testing training in Delhi NCR or Faridabad can become a magic wand. Industries are particularly eager to recruit certified NDT professionals who can deliver safety, compliance, and reliability for operations.

The A to Z NDT Training certifications not only beautify your resume but also prove your quality and accuracy approach.

Sign Up Today

If you are so interested in becoming an ultrasonic tester, do not let it pass away. If you want to look for an ultrasonic testing training institute in Delhi NCR or an ultrasonic testing centre in Faridabad, A to Z NDT Training is the ideal training institute to embark on your NDT journey.

Call A to Z NDT Training today for more details about course material, upcoming batches, and admissions. Invest in your tomorrow with training that matters.

0 notes

Text

0 notes

Text

Ultrasonic Testing in Pune: Comprehensive NDT Inspection Services by Integrated NDE

When it comes to ensuring the integrity and safety of materials and structures, ultrasonic testing stands out as one of the most reliable methods. Integrated NDE, a leading NDE company in Pune, offers state-of-the-art ultrasonic testing services designed to meet the stringent demands of various industries.

What is Ultrasonic Testing?

Ultrasonic testing (UT) is a form of Non-Destructive Testing (NDT) that utilizes high-frequency sound waves to detect flaws, measure thickness, and evaluate material properties without causing damage. This method is particularly effective for inspecting welds, castings, and forgings, making it a critical component of any comprehensive NDT inspection process.

Why Choose Ultrasonic Testing?

Ultrasonic testing is highly accurate and versatile, capable of detecting both surface and subsurface defects. It is widely used in industries such as construction, manufacturing, and aerospace, where safety and precision are paramount.

At Integrated NDE, we employ advanced ultrasonic NDT techniques and equipment, including ultrasonic thickness testers, to provide detailed assessments of materials. Our team of experts ensures that every inspection is carried out with the utmost precision, delivering reliable results that help you maintain the highest standards of quality and safety.

NDT Testing Services Near You

For businesses in Pune and the surrounding areas, finding reliable NDT testing near me is crucial. Integrated NDE offers a wide range of non-destructive testing (NDT) services, including ultrasonic testing. Our ultrasonic testing services near me are designed to meet the needs of industries looking for accurate, efficient, and cost-effective solutions.

Benefits of Choosing Integrated NDE

Local Expertise: As a leading NDE company in Pune, we understand the specific needs of our clients and provide tailored solutions to meet those needs.

Advanced Equipment: We use the latest technology in ultrasonic NDT, ensuring precise and reliable results.

Comprehensive Services: From ultrasonic testing to other forms of NDT inspection, we offer a full suite of services to cover all your non-destructive testing needs.

Conclusion

For businesses in Pune seeking reliable and accurate ultrasonic testing services, Integrated NDE is the go-to solution. With our expert team, advanced equipment, and commitment to quality, we ensure that your materials and structures meet the highest safety standards. Contact us today to learn more about how our ultrasonic testing and other NDT services can benefit your operations.

#nde company#ndt inspection#ndt testing near me#non destructive testing near me#ultrasonic testing#ultrasonic testing in pune#ultrasonic testing ndt#ultrasonic thickness tester#ultrasonic ndt#ultrasonic testing services near me

0 notes

Text

NDT equipment in UAE

Non-Destructive Testing (NDT) equipment is essential in various industries, including oil and gas, aerospace, manufacturing, and construction, to ensure the integrity and reliability of materials and structures without causing any damage. Here’s a comprehensive overview of NDT equipment available in the UAE

https://incorworld.com/products/

0 notes

Text

Integrated NDE Solution in Pune: Leading the Way in Ultrasonic Testing and NDT Services

In the realm of industrial quality assurance, ensuring the structural integrity and reliability of materials and components is paramount. Integrated NDE Solutions in Pune stands at the forefront of this crucial sector, offering state-of-the-art Non-Destructive Testing (NDT) services, with a particular emphasis on Ultrasonic Testing. This article delves into the intricacies of Ultrasonic Testing, explores the comprehensive range of NDT services provided by Integrated NDE Solution in Pune, and underscores the pivotal role they play in various industries.

What is Ultrasonic Testing?

Ultrasonic Testing (UT) is a highly advanced and versatile NDT method used to detect internal flaws, measure material thickness, and evaluate the properties of materials without causing any damage. This technique employs high-frequency sound waves that penetrate the material and reflect back, providing detailed insights into the material's integrity.

How Ultrasonic Testing Works

The process involves transmitting ultrasonic pulses into the material using a transducer. When these pulses encounter a boundary, such as a flaw or the back wall of the material, they reflect back to the transducer. The time it takes for the echoes to return is measured and analyzed to determine the presence, location, and size of any defects.

Benefits of Ultrasonic Testing

Accuracy: UT offers precise measurements and can detect very small flaws.

Depth Penetration: It is capable of inspecting thick materials.

Versatility: Suitable for a wide range of materials, including metals, plastics, and composites.

Safety: Non-hazardous and safe for operators.

Real-Time Results: Immediate feedback allows for on-the-spot decision-making.

Integrated NDE Solution in Pune: Your Partner in Quality Assurance

Integrated NDE Solution in Pune is a premier provider of NDT services, renowned for its expertise, cutting-edge technology, and commitment to quality. Their Ultrasonic Testing services are second to none, ensuring that clients receive the most reliable and accurate results.

Comprehensive NDT Services Offered

Ultrasonic Testing (UT)

Radiographic Testing (RT)

Magnetic Particle Testing (MPT)

Liquid Penetrant Testing (LPT)

Eddy Current Testing (ECT)

Visual Inspection (VI)

Industries Served

Integrated NDE Solution in Pune caters to a broad spectrum of industries, including:

Aerospace: Ensuring the safety and reliability of aircraft components.

Automotive: Inspecting parts to prevent failures and ensure quality.

Construction: Verifying the integrity of structures and materials.

Oil and Gas: Inspecting pipelines and equipment to prevent leaks and failures.

Power Generation: Ensuring the reliability of critical infrastructure.

Advancements in Ultrasonic Testing Technology

Integrated NDE Solution in Pune continuously invests in the latest ultrasonic testing technology to enhance their service offerings. Some of the cutting-edge advancements include:

Phased Array Ultrasonic Testing (PAUT): This technology uses multiple transducers to create a detailed image of the material's interior, allowing for more accurate flaw detection.

Time of Flight Diffraction (TOFD): TOFD is a highly accurate method for measuring the size and location of flaws, particularly in welds.

Automated Ultrasonic Testing (AUT): Automation increases inspection speed and consistency, making it ideal for large-scale inspections.

The Importance of Certified Technicians

The accuracy and reliability of Ultrasonic Testing heavily depend on the skill and expertise of the technicians performing the inspections. Integrated NDE Solution in Pune employs certified technicians who undergo rigorous training and continuous professional development. Their expertise ensures that clients receive the highest quality of service.

Commitment to Quality and Safety

Integrated NDE Solution in Pune places a strong emphasis on quality and safety. Their adherence to international standards and best practices ensures that all inspections are performed with the utmost precision and reliability. This commitment to excellence has earned them a stellar reputation in the industry.

Customer-Centric Approach

At Integrated NDE Solution in Pune, customer satisfaction is paramount. They work closely with clients to understand their specific needs and tailor their services accordingly. Whether it's a small-scale inspection or a large industrial project, they provide personalized solutions that meet the highest standards of quality and reliability.

Why Choose Integrated NDE Solution in Pune?

Expertise: Extensive experience and technical know-how in NDT services.

Technology: Utilization of the latest and most advanced testing equipment.

Quality: Commitment to providing accurate and reliable results.

Customer Service: Focus on building long-term relationships through excellent service.

Compliance: Adherence to all relevant industry standards and regulations.

Conclusion

In an industry where precision and reliability are non-negotiable, Integrated NDE Solution in Pune stands out as a leader in Ultrasonic Testing and NDT services. Their dedication to quality, use of advanced technology, and customer-centric approach makes them the go-to choice for businesses across various sectors. By partnering with Integrated NDE Solution, companies can ensure the integrity and safety of their materials and components, safeguarding their operations and reputation.

Integrated NDE Solution in Pune continues to pave the way for innovation and excellence in Non-Destructive Testing. Their Ultrasonic Testing services not only detect flaws and defects but also provide invaluable insights that drive improvements in quality and safety. For businesses seeking the highest standards of NDT services, Integrated NDE Solution in Pune is the trusted partner that delivers results.

1 note

·

View note

Text

A More Specific Hearing Poll

Put on OVER THE EAR headphones, turn off background noises if possible, and go to this link.

https://mynoise.net/NoiseMachines/ultrasonicNoiseGenerator.php

Press play, press "Z" to turn the noise to zero, and then test the sliders individually.

36 notes

·

View notes

Text

The Power of Precision: Exploring the Benefits of PAUT in NDT

In the realm of industrial inspections, the demand for accuracy and efficiency has never been higher. Phased Array Ultrasonic Testing (PAUT) stands out as a revolutionary method that fulfills these requirements, offering unparalleled precision and speed. As an integral part of Non Destructive Testing, PAUT is widely used across various industries to ensure the integrity and reliability of critical components. Here, we delve into the intricacies of PAUT and its benefits.

PAUT is an advanced method of ultrasonic testing that uses multiple elements and electronic time delays to create beams of sound waves. These beams can be steered, focused, and scanned, providing detailed images of internal structures. Unlike conventional ultrasonic testing, which uses a single transducer to send and receive sound waves, PAUT employs an array of transducers. This allows for simultaneous collection of data from multiple angles, resulting in more comprehensive and accurate inspections.

As part of a broader suite of Non Destructive Testing Services, PAUT plays a crucial role in ensuring the safety and reliability of industrial components. Nondestructive testing (NDT) from RVS QUALITY CERTIFICATIONS PVT LTD encompasses various techniques used to evaluate the properties of a material, component, or system without causing damage. PAUT's advanced capabilities enhance the overall effectiveness of NDT services, providing detailed and reliable data that support maintenance and quality assurance programs.

Applications Across Industries

The versatility of PAUT makes it suitable for a wide range of applications. It is commonly used in the aerospace, automotive, and power generation industries for inspecting critical components such as welds, turbine blades, and composite materials. PAUT's ability to detect minute defects and irregularities ensures that even the smallest flaws are identified before they become critical issues. This level of precision is essential for maintaining safety and performance standards in high-stakes environments.

Efficiency and Accuracy Combined

One of the standout features of PAUT is its efficiency. The ability to steer and focus sound waves electronically means that inspections can be performed more quickly compared to traditional methods. This not only reduces downtime but also increases the number of inspections that can be completed within a given timeframe. Additionally, the detailed images produced by PAUT provide a clearer understanding of the inspected material's condition, allowing for more accurate assessments and decision-making.

Enhanced Tube Inspections

A specific area where PAUT excels is in Tube Inspection Services. Tubes, often found in heat exchangers and boilers, are prone to various types of degradation such as corrosion and cracking. PAUT's ability to inspect from multiple angles simultaneously makes it particularly effective for tube inspections. It can detect flaws that may be missed by conventional methods, ensuring that tubes are thoroughly evaluated for any signs of wear or damage. This comprehensive approach helps prevent failures and extends the lifespan of critical equipment.

Advancing with Technology

The continuous evolution of technology has significantly impacted PAUT. Advances in digital signal processing and software have improved the resolution and clarity of the images produced. Portable PAUT equipment from RVS QUALITY CERTIFICATIONS PVT LTD has made it possible to conduct inspections in challenging environments, further expanding its applicability. These technological advancements ensure that PAUT remains at the forefront of nondestructive testing techniques, providing industries with cutting-edge solutions for maintaining safety and quality.

In conclusion, PAUT is a powerful tool that combines precision and efficiency to deliver superior inspection results. Its ability to provide detailed images from multiple angles makes it invaluable for identifying defects and ensuring the integrity of critical components. As a key component of Non Destructive Testing, PAUT supports industries in maintaining high standards of safety and performance. Whether it's for welds, turbine blades, or Tube Inspection Service, PAUT continues to set the standard for advanced nondestructive testing methodologies.

5 notes

·

View notes

Text

youtube

#hardness tester#portable hardness tester#uci hardness tester#ultrasonic hardness tester#leeb hardness tester#hardness#portable hardness testing machine#Youtube

1 note

·

View note

Text

Services offered by well -measurement companies in Northern Georgia

If you are considering buying or selling a house with a well in North Georgia, it is necessary to understand the importance of tests of water level and the services provided by the well measurement companies. These services play an important role in ensuring protection, reliability and stability in the water supply.

Why the water level tests well is important

Well -watt testing is important for both home builders and suppliers. For those who buy a house with a well, a well -measured company tested a complete test and provides a detailed report that can give you confidence in the protection and reliability of water supply. This information is important to make an informed decision and to ensure that your new house has a reliable water source. For domestic suppliers, newer water quality reports and maintenance registers can trust potential buyers and make your property more desirable. Before you behave your property, you can complete a complete water testing and well inspection, help identify and correct any problem, and make sure your well is safe and reliable.

Well measured services provided by companies

Accurate measurement of the water levels

Companies such as Pinnacle Well Measuring Solution use condition -Eart -art echoostorm and sound wave techniques to provide accurate and reliable data on the water levels well. This advanced technology ensures that the measurements are accurate and non-invasive, reduce the risk of pollution and retain the quality of the water supply.

Contaminated warranty test

One of the biggest benefits of using a professional well measurement company is a guarantee of contaminated testing. Methods for non-Gussti of Pinnacle ensure that no physical or biological contaminated materials enter the water supply during the test process. This means that your well is clean and chemically free, which is the maximum benefit of your natural water source.

Comprehensive report

After completing the tests, well -measured companies provide a detailed and comprehensive report that gives you complete information on the position and performance of your well. These reports can be invaluable for both buyers and suppliers, as they give a clear picture of wells and any problems.

Regular Monitoring

For ongoing peace of mind, many companies offer regular monitoring services to ensure that your well continues to perform optimally. This can be especially important in North Georgia, where seasonal changes and other factors can cause fluctuations in water levels. Regular monitoring allows any changes in water level or quality to be detected early, so corrective measures can be taken promptly.

Customized Solutions

Well measurement companies in North Georgia understand the unique needs of their clients and provide customized solutions to meet those needs. Whether you are buying or selling a home with a well, these companies can tailor their services to ensure that your well water levels are accurately tracked and managed.

Benefits for Homebuyers and Sellers

For Homebuyers

When buying a home with a well, having a well measurement company conduct thorough tests and provide detailed reports can give you confidence in the safety and reliability of the water supply. This information is crucial for making an informed decision and ensuring that your new home has a dependable source of water.

For Home Sellers

For those selling a home with a well, having recent water quality reports and maintenance records can instill confidence in potential buyers and make your property more desirable. Completing a thorough water test and well inspection prior to listing your property can help identify and correct any issues, ensuring that your well water is safe and reliable.

Conclusion

In North Georgia, where well water is a vital resource for many residents, the services offered by well measurement companies are essential for ensuring the safety, reliability, and sustainability of this valuable resource. Whether you are buying or selling a home with a well, these companies provide the expertise and technology needed to accurately assess and manage well water levels. By choosing a reputable well measurement company, you can have peace of mind knowing that your well water is in good hands.

#north georgia well level testing#buying a home with a well#well water level sensor#selling a home with a well#well depth gauge#portable ultrasonic level sensor#company that measures well water levels

0 notes

Text

Ultrasonic Non Destructive Testing Equipment Market to Rise on Safety Demand

The Global Ultrasonic Non Destructive Testing Equipment Market is estimated to be valued at USD 936.6 Mn in 2025 and is expected to exhibit a CAGR of 7% over the forecast period 2025 to 2032.

The ultrasonic non destructive testing (NDT) equipment market centers on specialized instruments that employ high-frequency sound waves to detect internal flaws, cracks, and inconsistencies in metals, composites, and weld joints without impairing the tested component. These products range from portable flaw detectors and thickness gauges to phased array and immersion scanners, all designed to deliver rapid, real-time feedback on structural integrity. Ultrasonic Non Destructive Testing Equipment Market Insights include non-invasiveness, high sensitivity to micro-defects, minimal downtime, and reduced maintenance costs. As industries such as oil and gas, aerospace, automotive, power generation, and construction strive to meet stringent safety regulations and quality control standards, the need for reliable inspection tools has grown. Technological enhancements—including digital signal processing, touchscreen interfaces, and wireless connectivity—have further broadened application scope, enabling remote monitoring and predictive maintenance. With rising infrastructure investments and an aging global asset base demanding frequent inspections, ultrasonic NDT equipment has become integral to risk mitigation and business growth strategies. Get more insights on,Ultrasonic Non Destructive Testing Equipment Market

#Coherent Market Insights#Ultrasonic Non Destructive Testing Equipment#Ultrasonic Non Destructive Testing Equipment Market#Ultrasonic Non Destructive Testing Equipment Market Insights#Thickness gauges

0 notes

Text

Ultrasonic tests play a pivotal role in ensuring the structural integrity of materials without causing harm. Here are a few ultrasonic terminologies. Read More!

#non-destructive testing#ndt techniques#ndt technique#ndt methods#ndt#ndt testing#ultrasonic inspection#ultrasonic testing

6 notes

·

View notes

Text

Reliable Portable Ultrasonic Flaw Detector for NDT

A portable ultrasonic flaw detector is an essential non-destructive testing (NDT) tool for detecting internal defects in materials like metal, composites, and welds. Designed for precision and ease of use, it provides accurate flaw detection in industrial applications, including aerospace, automotive, and manufacturing. This lightweight, handheld device offers real-time analysis, high-resolution imaging, and advanced signal processing. With superior portability and durability, it ensures efficient on-site inspections. Whether for routine checks or critical assessments, a portable ultrasonic flaw detector enhances safety, quality control, and compliance with industry standards, reducing downtime and maintenance costs.

0 notes

Text

Comprehensive Crane Inspections in Perth: Ensuring Safety and Efficiency with Cossack Inspections

NDT inspection services Perth is a vital process in various industries, particularly when it comes to ensuring the safety, integrity, and reliability of equipment, structures, and materials. Cossack Inspections in Perth is a leader in providing high-quality NDT inspection services tailored to meet the needs of businesses in sectors such as construction, manufacturing, oil and gas, and mining.

NDT involves the use of advanced techniques to evaluate the properties of materials, components, or structures without causing any damage. This is crucial for detecting hidden defects, assessing the condition of critical assets, and ensuring that products and infrastructure meet required safety and performance standards.

0 notes