Text

The Value of Advanced NDT Techniques in Tube Inspection

Ensuring the optimal performance and safety of industrial equipment is a top priority across various sectors. One critical aspect of maintaining such performance is through Tube Inspection Services from RVS QUALITY CERTIFICATIONS PVT LTD. These services are indispensable for industries that rely on the efficient functioning of tubes, such as in heat exchangers, boilers, and condensers. Here, we explore the importance of Inspection Services and how they contribute to the overall health of industrial systems.

Preventive Maintenance e Precision

Inspection Services are fundamental to preventive maintenance strategies. By regularly inspecting tubes, potential issues can be identified before they lead to significant failures or costly downtime. This proactive approach not only enhances the longevity of the equipment but also ensures that it operates at peak efficiency. Regular inspections help detect early signs of wear and tear, corrosion, and other forms of degradation, allowing for timely interventions that can prevent more severe damage.

Advanced Inspection Techniques

The effectiveness of Inspection Services is greatly enhanced by advanced non-destructive testing (NDT) methods. Techniques such as eddy current testing, ultrasonic testing, and remote visual inspection are commonly employed to assess the condition of tubes without causing any damage. Inspectors with NDT Level 2 Certification Courses from RVS QUALITY CERTIFICATIONS PVT LTD are trained to use these advanced methods to accurately identify defects, including cracks, pitting, and wall thinning. This high level of precision ensures that even the smallest issues are detected, enabling precise maintenance planning and execution.

Optimizing System Efficiency

The performance of systems that rely on tubes, such as heat exchangers and boilers, directly impacts the overall efficiency of industrial operations. Any compromise in the integrity of these tubes can lead to reduced heat transfer efficiency, increased energy consumption, and higher operational costs. By employing comprehensive Inspection Services, organizations can maintain optimal system performance. These inspections help ensure that the tubes are free from blockages, corrosion, and other issues that could impede their functionality, thereby sustaining efficient and cost-effective operations.

Safety and Compliance

Ensuring the safety of industrial operations is paramount, and Inspection Services play a crucial role in this regard. Faulty tubes can lead to catastrophic failures, posing serious risks to personnel and equipment. Regular inspections help mitigate these risks by identifying and addressing potential issues before they escalate. Furthermore, industries are often required to comply with stringent safety and regulatory standards. Third-party Third-Party Inspection Services from RVS QUALITY CERTIFICATIONS PVT LTD provide an additional layer of assurance, validating that the equipment meets all necessary compliance requirements. This external validation not only enhances safety but also boosts the organization's credibility and reliability.

Cost-Effective Maintenance

While some may view Inspection Services as an added expense, they are, in fact, a cost-effective maintenance strategy. Early detection of issues through regular inspections can prevent costly repairs, extensive downtime, and loss of productivity. The ability to plan maintenance activities based on accurate inspection data allows organizations to allocate resources more efficiently and avoid unexpected breakdowns. In the long run, the investment in Inspection Services pays off by reducing the total cost of ownership and maximizing the return on investment for industrial equipment.

Training and Expertise

The effectiveness of Inspection Services is highly dependent on the expertise of the inspectors. Professionals trained through NDT Certification Courses possess the necessary skills and knowledge to perform thorough and accurate inspections. Their expertise ensures that all potential issues are identified and appropriately addressed. Continuous training and certification updates are essential to keep inspectors abreast of the latest advancements in inspection technologies and methodologies, thereby maintaining high standards of service quality.

In conclusion, Inspection Services are essential for ensuring the optimal performance, safety, and efficiency of industrial systems. By incorporating advanced non-destructive testing techniques and leveraging the expertise of certified professionals, organizations can proactively manage the health of their equipment. Regular inspections help prevent costly failures, ensure compliance with safety standards, and enhance overall operational efficiency. For industries striving to maintain high-performance standards and minimize risks, investing in Inspection Services is a prudent and necessary decision.

0 notes

Text

The Power of Precision: Exploring the Benefits of PAUT in NDT

In the realm of industrial inspections, the demand for accuracy and efficiency has never been higher. Phased Array Ultrasonic Testing (PAUT) stands out as a revolutionary method that fulfills these requirements, offering unparalleled precision and speed. As an integral part of Non Destructive Testing, PAUT is widely used across various industries to ensure the integrity and reliability of critical components. Here, we delve into the intricacies of PAUT and its benefits.

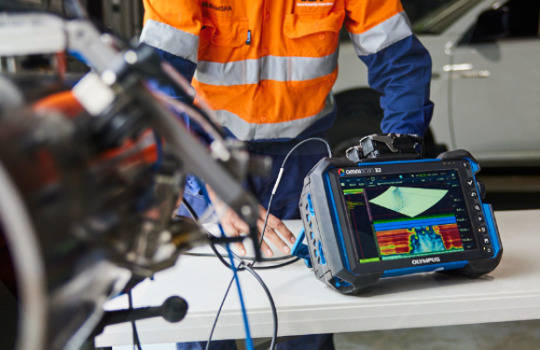

PAUT is an advanced method of ultrasonic testing that uses multiple elements and electronic time delays to create beams of sound waves. These beams can be steered, focused, and scanned, providing detailed images of internal structures. Unlike conventional ultrasonic testing, which uses a single transducer to send and receive sound waves, PAUT employs an array of transducers. This allows for simultaneous collection of data from multiple angles, resulting in more comprehensive and accurate inspections.

As part of a broader suite of Non Destructive Testing Services, PAUT plays a crucial role in ensuring the safety and reliability of industrial components. Nondestructive testing (NDT) from RVS QUALITY CERTIFICATIONS PVT LTD encompasses various techniques used to evaluate the properties of a material, component, or system without causing damage. PAUT's advanced capabilities enhance the overall effectiveness of NDT services, providing detailed and reliable data that support maintenance and quality assurance programs.

Applications Across Industries

The versatility of PAUT makes it suitable for a wide range of applications. It is commonly used in the aerospace, automotive, and power generation industries for inspecting critical components such as welds, turbine blades, and composite materials. PAUT's ability to detect minute defects and irregularities ensures that even the smallest flaws are identified before they become critical issues. This level of precision is essential for maintaining safety and performance standards in high-stakes environments.

Efficiency and Accuracy Combined

One of the standout features of PAUT is its efficiency. The ability to steer and focus sound waves electronically means that inspections can be performed more quickly compared to traditional methods. This not only reduces downtime but also increases the number of inspections that can be completed within a given timeframe. Additionally, the detailed images produced by PAUT provide a clearer understanding of the inspected material's condition, allowing for more accurate assessments and decision-making.

Enhanced Tube Inspections

A specific area where PAUT excels is in Tube Inspection Services. Tubes, often found in heat exchangers and boilers, are prone to various types of degradation such as corrosion and cracking. PAUT's ability to inspect from multiple angles simultaneously makes it particularly effective for tube inspections. It can detect flaws that may be missed by conventional methods, ensuring that tubes are thoroughly evaluated for any signs of wear or damage. This comprehensive approach helps prevent failures and extends the lifespan of critical equipment.

Advancing with Technology

The continuous evolution of technology has significantly impacted PAUT. Advances in digital signal processing and software have improved the resolution and clarity of the images produced. Portable PAUT equipment from RVS QUALITY CERTIFICATIONS PVT LTD has made it possible to conduct inspections in challenging environments, further expanding its applicability. These technological advancements ensure that PAUT remains at the forefront of nondestructive testing techniques, providing industries with cutting-edge solutions for maintaining safety and quality.

In conclusion, PAUT is a powerful tool that combines precision and efficiency to deliver superior inspection results. Its ability to provide detailed images from multiple angles makes it invaluable for identifying defects and ensuring the integrity of critical components. As a key component of Non Destructive Testing, PAUT supports industries in maintaining high standards of safety and performance. Whether it's for welds, turbine blades, or Tube Inspection Service, PAUT continues to set the standard for advanced nondestructive testing methodologies.

0 notes

Text

Boosting Business Credibility: The Key Benefits of Third Party Inspection Services

In today's competitive business environment, ensuring the quality and reliability of your products and services is paramount. One effective way to achieve this is through Third-Party Inspection Services from RVS QUALITY CERTIFICATIONS PVT LTD. These services provide an unbiased assessment of your products, processes, and systems, offering several significant advantages. Here, we explore four critical benefits of utilizing Third Party Inspection Services and how they can enhance your organization's performance and credibility.

Enhanced Credibility and Trust

Engaging in Third Party Inspection Services significantly boosts your organization's credibility and trustworthiness. When an independent entity evaluates your products or services, it assures your clients, stakeholders, and regulatory bodies of your commitment to maintaining high standards. This independent verification is particularly valuable in industries where compliance with stringent regulations and standards is crucial. Clients are more likely to trust a company that proactively seeks external validation of its quality and safety measures, ultimately leading to stronger business relationships and increased customer loyalty.

Improved Quality Control

One of the primary benefits of Third Party Inspection Services is the enhancement of quality control processes. By incorporating external expertise, your organization gains access to specialized knowledge and advanced inspection techniques that may not be available in-house. For instance, Phased Array and TOFD Training from RVS QUALITY CERTIFICATIONS PVT LTD equips inspectors with the skills to use sophisticated ultrasonic testing methods, ensuring precise and reliable results. This expertise leads to early detection of potential issues, reducing the likelihood of defects or failures in your products. Consequently, you can implement corrective actions promptly, maintaining consistent quality and reducing costs associated with rework or recalls.

Cost Efficiency and Risk Mitigation

Utilizing Third Party Inspection Services can lead to significant cost savings and risk mitigation. Independent inspections help identify potential problems before they escalate into costly issues. Early detection and resolution of defects prevent expensive recalls, production delays, and legal liabilities. Moreover, third-party inspectors often bring a fresh perspective, identifying areas for improvement that may have been overlooked internally. By addressing these areas proactively, your organization can optimize processes, enhance efficiency, and minimize waste, leading to long-term cost savings. Additionally, third-party inspections serve as a safeguard against non-compliance penalties and potential reputational damage, further protecting your bottom line.

Access to Advanced Technologies

Another critical advantage of Third Party Inspection Services is the access to advanced technologies that can significantly enhance the accuracy and efficiency of inspections. For example, Infrared Thermography Services from RVS QUALITY CERTIFICATIONS PVT LTD utilize thermal imaging to detect anomalies and potential issues in electrical systems, mechanical equipment, and building structures. This non-invasive technique allows for comprehensive assessments without disrupting operations, providing valuable insights into areas that may be challenging to inspect using conventional methods. By leveraging such cutting-edge technologies, Third Party Inspection Services can deliver more accurate and detailed results, enabling your organization to make informed decisions and maintain optimal performance.

In conclusion, Third Party Inspection Services offer numerous benefits that can greatly enhance your organization's quality, credibility, and efficiency. By incorporating independent assessments into your quality control processes, you can ensure compliance with industry standards, reduce costs, and mitigate risks. Additionally, access to advanced technologies and specialized knowledge further strengthens your ability to maintain high-quality standards and improve overall performance. For businesses striving to excel in today's competitive landscape, Third Party Inspection Services are an invaluable resource that fosters trust, reliability, and long-term success.

0 notes

Text

Seeing the Unseen: How Infrared Thermography Services Can Save You Time and Money

In the modern world, maintaining efficiency and reducing costs are paramount for businesses across various industries. One powerful tool that has emerged to help achieve these goals is infrared thermography. Infrared Thermography Services are revolutionizing how companies manage maintenance, detect issues, and ensure safety. At RVS Quality Certifications Pvt Ltd., we understand the value of advanced diagnostic tools and offer comprehensive training and consultancy services to help you harness these technologies.

Understanding Infrared Thermography

Infrared thermography is a non-invasive, non-contact method of detecting heat patterns and temperatures on surfaces. By using infrared cameras, technicians can visualize and measure thermal energy emitted by objects. This technology allows for the identification of anomalies that might indicate underlying problems, such as electrical faults, mechanical failures, or insulation deficiencies.

Employing Infrared Thermography provides significant advantages over traditional inspection methods. It enables the detection of issues before they become critical, allowing for preventive maintenance and reducing the likelihood of unexpected downtime. This proactive approach can save businesses substantial amounts of time and money by avoiding costly repairs and ensuring optimal operational efficiency.

Applications Across Industries

Infrared thermography is versatile and applicable in various industries, including manufacturing, construction, energy, and automotive. In manufacturing, it helps in monitoring equipment conditions, detecting overheating components, and ensuring the integrity of electrical systems. In construction, it is used for inspecting building envelopes, identifying moisture intrusion, and verifying insulation performance.

For energy companies, infrared thermography is essential in monitoring power lines, transformers, and substations. It aids in detecting hot spots that could indicate potential failures, thereby preventing power outages. In the automotive industry, it is used for quality control and ensuring the safety of electrical systems in vehicles.

Training and Certification

To effectively utilize infrared thermography, proper training and certification are crucial. At RVS Quality Certifications Pvt Ltd., we offer NDT Level 2 Certification Courses that equip professionals with the necessary skills and knowledge to perform accurate and reliable thermographic inspections. Our courses cover the principles of thermography, equipment handling, data analysis, and report generation.

Achieving NDT Level 2 certification signifies a high level of competence in non-destructive testing methods, including infrared thermography. This certification not only enhances the skill set of professionals but also increases their value in the job market. Companies benefit from having certified personnel who can conduct thorough inspections and contribute to improved maintenance strategies.

Enhancing Safety and Reliability

One of the primary benefits of infrared thermography is its contribution to safety. By identifying potential issues early, businesses can mitigate risks and prevent accidents. For example, detecting overheating electrical components can prevent fires, while identifying structural weaknesses can avoid catastrophic failures in buildings and machinery.

RVS Quality Certifications Pvt Ltd. emphasizes the importance of Non Destructive Testing Services in maintaining safety and reliability. Our comprehensive training ensures that professionals are equipped to perform accurate assessments, thereby contributing to safer work environments and more reliable operations.

Cost Savings and Efficiency

Implementing infrared thermography can lead to significant cost savings. By identifying problems before they escalate, businesses can plan maintenance activities more effectively, reduce unplanned downtime, and extend the lifespan of equipment. This proactive approach minimizes the need for emergency repairs, which are often more expensive and disruptive.

For industries that rely heavily on the integrity of their equipment, such as energy and manufacturing, the cost savings from avoiding major failures are substantial. Additionally, by optimizing maintenance schedules and reducing downtime, companies can enhance their overall productivity and operational efficiency.

Specialized Services for Specific Needs

In addition to general applications, infrared thermography is also valuable for specialized inspections. For instance, Tube Inspection Services utilize infrared technology to assess the condition of tubes in boilers, heat exchangers, and other critical equipment. This type of inspection can detect issues such as blockages, corrosion, and leaks, which can significantly impact the performance and safety of the equipment.

#Infrared Thermography Services#NDT Level 2 Certification Courses#Non Destructive Testing Services#Tube Inspection Services

0 notes

Text

RVS Quality Certifications Pvt Ltd. offers a comprehensive suite of services, including Infrared Thermography Services, that can significantly benefit your operations. Here are six key advantages of these services. Third-Party Inspection Services offer an impartial assessment of your products, processes, and systems. RVS provides these services to ensure compliance with industry standards and regulatory requirements.

#third party inspection services#Infrared Thermography Services#Tube Inspection Services#Phased Array Ultrasonic Testing#Phased Array and TOFD Training

0 notes

Text

RVS Quality Certifications Pvt Ltd stands at the forefront of providing comprehensive inspection and training solutions, earning an esteemed reputation for its unparalleled expertise and commitment to quality.

#third party inspection services#Infrared Thermography Services#Phased Array Ultrasonic Testing#Tube Inspection Services#Phased Array and TOFD Training

0 notes

Text

Top 5 Benefits Of Non Destructive Testing

In the realm of non-destructive testing (NDT), technological advancements continue to revolutionize inspection methodologies, paving the way for superior results and enhanced efficiency. Among these innovations, Phased Array Ultrasonic Testing stands out as a game-changer, offering unparalleled benefits for various industrial applications. As a leading authority in ISO certification and quality assurance, RVS Quality Certifications Pvt Ltd., one of the prominent Non Destructive Testing Services providers, is committed to highlighting the advantages of PAUT for businesses seeking excellence in inspection processes. Let's explore the top five benefits of Such testing:

Enhanced Inspection Capabilities: Such testing represents a significant leap forward in inspection capabilities, allowing for comprehensive assessment of materials and components with precision and accuracy. Unlike conventional ultrasonic testing methods, which utilize single-element transducers, PAUT employs multiple elements that can be electronically controlled to steer and focus the ultrasonic beam. This dynamic beam control enables inspectors to tailor the inspection angle, focal depth, and beam size, facilitating thorough examination of complex geometries, curved surfaces, and composite materials.

Improved Detection of Defects: One of the primary advantages of Such testing is its superior defect detection capabilities. By manipulating the ultrasonic beam's characteristics, such as angle, focal depth, and frequency, inspectors can optimize the inspection process to detect defects of varying sizes, orientations, and depths within the material. Whether conducting tube inspections, weld examinations, or structural integrity assessments, PAUT enhances flaw detection sensitivity, thereby minimizing the risk of undetected defects and ensuring the integrity of critical components. We also offer Infrared Thermography Services and NDT Level 2 Certification Courses which are important for organizations in a variety of sectors, assisting with the maintenance of buildings and equipment by identifying abnormalities that may suggest possible problems.

Time and Cost Savings: PAUT offers significant time and cost savings compared to traditional ultrasonic testing methods. The ability to perform multiple scans simultaneously and in real-time streamlines the inspection process, reducing downtime and expediting decision-making. Moreover, the versatility of PAUT allows inspectors to inspect larger areas or multiple components in a single scan, eliminating the need for repetitive testing and minimizing labor and equipment costs. As a result, businesses can achieve greater operational efficiency and cost-effectiveness while maintaining high standards of quality and safety.

Versatile Applications and Training Opportunities: PAUT's versatility extends beyond traditional inspection applications, encompassing a wide range of industries and sectors, including aerospace, automotive, energy, and manufacturing. As the demand for PAUT expertise continues to grow, there is a corresponding need for comprehensive Phased Array and TOFD Training programs to equip professionals with the necessary skills and knowledge. RVS Quality Certifications Pvt Ltd. offers industry-leading training courses in Phased Array and TOFD, designed to empower inspectors, engineers, and technicians with proficiency in advanced ultrasonic testing techniques, ensuring compliance with industry standards and regulations.

Enhanced Data Visualization and Analysis: Such testing provides enhanced data visualization and analysis capabilities, empowering inspectors to extract valuable insights from inspection data with unprecedented clarity and detail. Advanced imaging techniques, such as sectorial scanning, C-scan imaging, and 3D visualization, allow for comprehensive mapping of defects and material properties in real-time. This wealth of information enables stakeholders to make informed decisions regarding asset integrity, maintenance strategies, and risk mitigation measures, ultimately enhancing operational reliability and performance.

In conclusion,

Such testing represents a paradigm shift in non-destructive testing methodologies, offering unparalleled benefits in terms of inspection capabilities, defect detection, efficiency, and data analysis. As a trusted provider of Tube Inspection Services, Ultrasonic Testing Services and ISO certification training and consultancy, RVS Quality Certifications Pvt Ltd. recognizes the transformative potential of PAUT in enhancing quality assurance and asset integrity across diverse industries. Embrace the future of inspection technology with Such testing and elevate your organization's commitment to excellence and reliability.

0 notes

Text

Third-Party Inspection Services | Borescope Inspection Services

Enter Third-Party Inspection Services, the beacon of objectivity and expertise in quality assessment. In collaboration with RVS Quality Certifications Pvt. Ltd., let's explore the profound benefits of third-party inspections and their transformative impact on businesses.

Know More: Borescope Inspection Services

#third party inspection services#rebound hammer testing services#titanium alloys#non destructive testing services

0 notes

Text

Eddy Current Training Courses | NDT STANDARD REFERENCE BLOCKS /NDT FLAW SPECIMENS

Enter Eddy Current Testing (ECT), a cutting-edge non-destructive testing (NDT) technique revered for its ability to detect flaws and anomalies with remarkable precision. Amidst this backdrop, the necessity for proficient Eddy Current Training Courses has never been more vital. Join us as we delve into the realm of the invisible and uncover five compelling reasons to invest in Eddy Current Training.

Know More: NDT STANDARD REFERENCE BLOCKS /NDT FLAW SPECIMENS

#titanium alloys#eddy current training courses#NDT STANDARD REFERENCE BLOCKS /NDT FLAW SPECIMENS#third party inspection services

0 notes

Text

Non Destructive Testing Services | Forging Consultants

As a renowned ISO certification training and consulting firm, RVS Quality Certifications Pvt. Ltd. understands the significance of Non Destructive Testing Services in maintaining high standards of quality and safety. Let's explore three hidden advantages of non-destructive testing methods and why they are essential for industries today.

Read More: Forging Consultants

0 notes

Text

Rebound Hammer Testing Services | Titanium Alloys

In the dynamic realm of quality assurance, precision and reliability are paramount. At RVS Quality Certifications Pvt. Ltd., we take pride in delivering unrivalled Rebound Hammer Testing Services that not only meet but exceed industry standards.

Visit: Titanium Alloys

0 notes

Text

Titanium Alloys

RVS Quality Certifications Pvt. Ltd. is a leading company specializing in Titanium Alloys. Renowned for its commitment to excellence, It is at the forefront of providing high-quality titanium alloy solutions for diverse industries. With a focus on precision engineering and advanced metallurgy, the company ensures superior strength, corrosion resistance, and lightweight properties in its alloys. They dedicated to meeting stringent quality standards, offering innovative solutions, and fostering client satisfaction. As a trusted name in the industry, RVS Quality Certifications Pvt. Ltd. continues to be a reliable partner for those seeking top-notch titanium alloy products for various applications.

#Titanium Alloys#Third-Party Inspection Services#Eddy Current Training Courses#Rebound Hammer Testing Services#Non Destructive Testing Services#NDT Equipment Supply Services#Forging Consultants

1 note

·

View note