#Advancedprocesscontrol

Explore tagged Tumblr posts

Photo

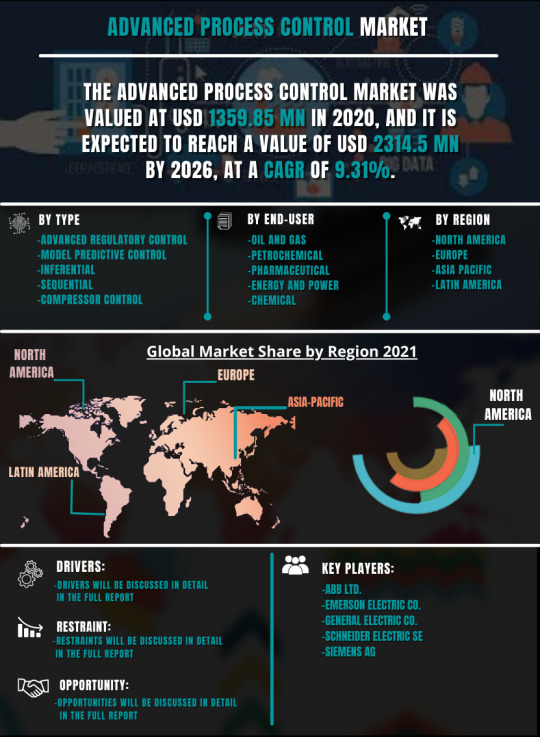

Global Advanced Process Control Market Report 2020 - Market Size, Share, Price, Trend and Forecast The advanced process control market was valued at USD 1359.85 million in 2020, and it is expected to reach a value of USD 2314.5 million by 2026, at a CAGR of 9.31%, over the forecast period, (2021 - 2026). Advanced process controls (APC) are deployed optionally to basic process controls. APCs are added subsequently to address particular performance or economic improvement opportunities in the process.Although the concept of APC has been around for more than three decades, it has only recently gained increased prominence, as factory units across the world are increasingly focusing on process optimization. Please visit for more info:https://bit.ly/38akNxZ

0 notes

Text

Advanced Process Control (APC) Software Market Share Growing Rapidly with Development, Recent Trends, Revenue and Forecast to 2018-2026

Advanced process control, according to control theory, entails the use of a variety of methods and technologies inside an industrial process control system. Improved operational comprehension, higher equipment reliability, enhanced process safety, reduced process settle time, increased production capacity, and lower power usage are just a few of the primary benefits of modern process control software. The benefits listed above are projected to drive demand for advanced process control software in a variety of end-use sectors.

The increasing need for automation solutions across various sectors is one of the primary drivers of growth in the global Advanced Process Control Software Market. Automation technologies are currently being adopted by major businesses in order to make business models as efficient as feasible. Many firms are opting for advanced process control (APC) software solutions to improve the process with basic automation solutions. In addition, the advanced process control (APC) market is expected to grow in the near future due to rising need for innovative software solutions that can foresee component failures, rising demand for energy efficient manufacturing processes, and safety and security concerns.

Read more @ https://cmiaspireblog.blogspot.com/2022/02/advanced-process-control-apc-software.html

#coherentmarketinsights#coherentmarketinsightsreports#Advancedprocesscontrol#Advancedprocesscontrolmarket#InformationTechnology

0 notes

Text

How Advanced Process Control Improves Optimization

If there’s one keyword which concerns every petrochemical plant, it is: optimization. Profit margins are tight, and getting tighter. Increasing need for reliability in petrochemical products means fluctuations in product quality cannot be tolerated, or else a plant risks losing customers or having to reprocess off-spec product. The key to remaining profitable – and growing your operation – is to find ways to optimize without sacrificing safety or quality.

This last point is a particularly sticky one. Too often, in our opinion, do operations take a short-sighted view, sacrificing elements such as mentoring, training, safety, and maintenance for the sake of quick profit boosts. It might improve the quarterly report, but there will be a heavy price paid down the line – sometimes disastrously high, as in cases such as the Deepwater Horizon incident. “Do more with less” is just not working as a management principle in the HPI.

That’s why we at S&D Consulting specialize in advanced process control (APC), automation systems, and real-time optimization. By improving the day-to-day functions of your plant, we can substantially boost your profits and without risking long-term viability.

How Advanced Process Control Improves Your Bottom Line

Fundamentally, advanced process control is about improving a plant’s profitability by maintaining processes at desired operating conditions, while taking process constraints into account in light of the daily changes required for operation. APC and automation are a major component in this, because the applications and automatic system monitoring, and adjustments are what allow these optimizations to occur.

A proper APC implementation begins by getting a full overview of a plant’s operations: beginning with their raw materials, going through the entire system of conversion processes, and looking at the resulting products and\or waste materials. Often, there’s room for optimization just by looking at the inputs and outputs: Could the inputs be acquired more cheaply, or are cheaper substitutes available? Could the waste products be put to productive use, sold, or further refined into something useful? With the knowledge gained via testing and subsequent knowledgeable programming, applications, and configurations, advanced applications are applied that can create optimum operations.

Then, the APC and automation processes begin. Applications, monitoring devices, and control systems are put in place on all major components, backed up by intelligent computer scripting of the tolerances. The APC then watches over the process, making adjustments as needed to keep everything within tolerances, minimize the cost of operation, allow reaching production targets.

This significantly reduces manpower needs, while improving overall product quality, equipment, and systems reliability – yet without sacrificing quality or safety.

0 notes

Photo

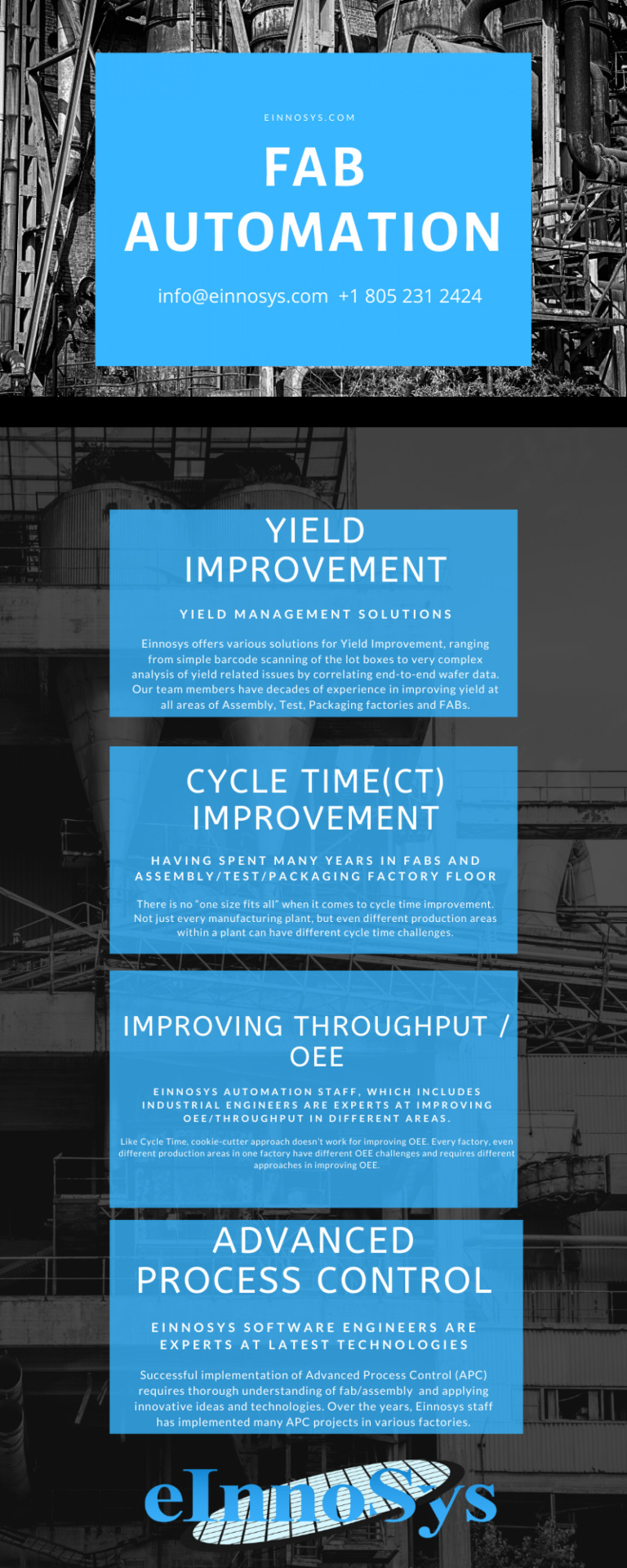

FAB Automation - eInnoSys staff has decades of extensive experience in Fab Automation of varying size and kind – from 4 inch GaAs or another compound semiconductor to 300 mm Silicon fabs as well as Packaging, Test/Assembly factories. Our team members have helped small R&D type fabs with old equipment to most advanced 300mm high volume factories. Download […] Download this infographic.Embed Our Infographic On Your Site!Image Width%px<img src="https://visual.ly/community/Infographics/technology/fab-automation" alt="FAB Automation - An Infographic from uCollect Infographics" width="100%" class="infographic_embedder" /><p class="infographic_attr">Embedded from <a href="http://www.ucollectinfographics.com/fab-automation/" target="_blank">uCollect Infographics</a></p><img src="https://visual.ly/community/Infographics/technology/fab-automation" alt="FAB Automation - An Infographic from uCollect Infographics" width="100%" class="infographic_embedder" /><p class="infographic_attr">Embedded from <a href="http://www.ucollectinfographics.com/fab-automation/" target="_blank">uCollect Infographics</a></p> #AdvancedProcessControl, #CostManagement, #CycleTimeOEEImprovements, #FABAutomation, #FaultDetectionClassification, #SystemsToEaseTroubleshootingComplexIssues, #YieldImprovement

#Advanced Process Control#Cost Management#Cycle Time & OEE Improvements#FAB Automation#Fault Detection & Classification#Systems to ease troubleshooting complex issues#Yield Improvement#Technology

0 notes

Text

process Control

Advanced process control will build a strategy towards functionality for getting desired results. Access Automation is well-expertise for better enhancement of industrial transformational changes by using content management, engineering solutions, infrastructure services, IT outsourcing services, staffing services.

0 notes