#Advantages and Disadvantages of Chemical Engineering

Explore tagged Tumblr posts

Text

A couple notes:

Like there's been some experimental nuclear reactors that don't use water, they use molten salt. But steam keeps getting used for a lot of reasons, primarily:

Molten salt reactors, as well as molten metal cooled reactors, still boil water in most designs. They work on the same principle as a Pressurized Water Reactor: the primary coolant moves heat from the fuel to the secondary coolant while remaining in liquid form, the secondary coolant is water that boils and spins a turbine. In pressurized water reactors the primary coolant is water that's kept at such high pressure it doesn't boil, which has the disadvantage of the reactor pressure vessel needing to be extremely high pressure. Molten metals or salts as primary coolant can remain liquid at temperatures hot enough to serve as the heat source for a steam turbine with little or no pressure. Molten salt fuel also has some potential advantages but again isn't the main working fluid. Some designs may use a gas turbine instead of a steam turbine, using either air or a closed loop of some other gas such as helium.

There are some other advantages steam turbines have that aren't listed.

Heat engines are pretty efficient, actually. They're less efficient than electric motors or fuel cells, but if you want to turn energy from a form that's not already either electricity or a really convenient chemical form that you probably had to manufacture into motion or electricity, a well-designed heat engine tends to be much more efficient than trying to convert heat or light directly into electricity. They're more efficient than most solar panels (around 20% efficient IIRC) and WAY more efficient than thermoelectric generators (<10% efficient IIRC). The reason we use solar panels instead of solar thermal turbines, and RTGs instead of nuclear reactors, on spacecraft is because they have few or no moving parts and/or because they work at small scales.

Heat engines become more efficient the higher temperature the working fluid reaches in the "hot" part of the cycle (and the colder it gets in the cold part of the cycle, but this tends to be limited by the ambient temperature). Gas turbines can reach a higher efficiency than a steam turbine, but only with very high temperatures: steam turbines can still reach pretty good efficiency at relatively low temperature. This is great because while superheated steam is not exactly a benign substance, a turbine that works at, say, 300 degrees celsius is a lot easier to make work from a materials science perspective than one that works at 900 degrees celsius. Not only do materials lose strength at high temperatures but metals under continuous load at high temperature can gradually deform and fail through a process called Creep, and gas turbine blades may need to be manufactured as single crystals, use exotic alloys with ceramic coatings, and so on to have a practical service life. Gas turbines are very high-tech, expensive pieces of equipment.

With that said, the most efficient heat engines usually have multiple stages, cooling the exhaust of one stage with the working fluid of the other. E.g. combined cycle power plants that use the still very hot exhaust from a gas turbine to boil water for a steam turbine. So far I think all of these are chemical-fueled but there are some designs for nuclear ones being considered IIRC. These can reach thermal efficiencies of more than 60%!

Steam turbines can use an arbitrary fuel source, including solid fuels, because you're not trying to run whatever goddawful exhaust it produces through your high precision turbine blades. Gas turbines generally require liquid or gaseous fuels. Union Pacific experimented with making a coal-fired gas turbine locomotive, which was promptly retired because it didn't work. Solid-fueled gas turbines can sort of be done by burning wood gas or coal gas given off by the fuel as it's heated, and amateurs have made "engines" like this using surplus turbocharges (AFAIK none of these produce usable mechanical output power: the turbine just forces more air into the combustion chamber to burn fuel as fast as possible), but that's an extra step and I'm guessing there's a reason coal-fired power plants have continued to use steam turbines.

Internal combustion engine generators: no need to boil water if you're a car engine: just spin the generator instead of wheels! (fun fact: some Electric vehicles have ICE range extension: they're built like an EV, but they have a small gasoline engine included, but it's not connected to the wheels; it just generates power to recharge the batteries)

Additional fun fact: nearly all diesel locomotives work this way, just without the batteries part. Trains need to produce full torque at zero or near zero wheelspeed, and it's impractical to do this with anything but a low-speed switcher/shunter with a purely mechanical powertrain. Diesel-hydraulic transmissions use a torque converter which lets the engine's mechanical advantage effectively change as it "slips" and moves faster than the output shaft IIRC, but these were still pretty much phased out.

nuclear power is impressive until you get up to why. "we use the most precisely engineered machinery ever created to split atoms to release energy" oh yeah how come? "boil water to turn a fan" get the fuck out

73K notes

·

View notes

Text

"How to Select the Right Centrifugal Pump for Your Fluid Handling System"

We pride at AFC in the provision of excellent fluid handling solutions to a multitude of industries. Of all the numerous categories of pumps, perhaps the centrifugal pump is as versatile and common in its deployment in an immeasurable myriad of applications. In this paper, we give you the crux of understanding centrifugal pumps in contrast with other highly reputable pump forms, such as sliding vane and gear pumps in assisting you to better decide on your particular applications.

Learning Centrifugal Pumps

A centrifugal pump is a dynamic pump that transfers fluid motion by an impeller. An impeller is a rotary, curved-vaned device that converts fluid kinetic energy. Fluid kinetic energy is converted to pressure as it leaves the pump casing. The principle used in a centrifugal pump is converting rotational energy into hydrodynamic energy.

Centrifugal Pumps versus Other Pumps

For a better understanding of the advantages and drawbacks of a particular centrifugal pump one may compare it with the two common types of pumps: sliding vane and gear type.

Sliding Vane Pumps

Sliding vane pumps are positive displacement pumps that use vanes that slide in and out of a rotor to produce a pumping action.

Benefits: Very efficient, self-priming, can handle thin fluids.

Disadvantages: Not appropriate for solids-contained fluids or fluids of high viscosity, needs a safety valve.

Gear Pumps

Gear pumps are positive-displacement gear pumps that transport fluid through gears.

Advantages: Can handle fluids of high viscosity, self-priming, less maintenance, flow rate can be regulated.

Disadvantages: Fixed flow rate at constant pressure.

Centrifugal Pumps

Centrifugal pumps possess the following list of advantages and disadvantages:

Advantages:

High flow rate.

Low viscosity fluids.

Less complex design with fewer moving parts.

Less maintenance required.

Adequate for most applications as they are able to pass solids (depending on design).

Drawbacks:

Not self-priming (normally needs priming prior to running).

Poor efficiency with very viscous liquids.

Operation is heavily influenced by fluid viscosity or change in specific gravity.

Applications of Centrifugal Pumps

The flexibility of centrifugal pumps makes them appropriate for very diverse applications in many different industries:

Water and Sewage Treatment: For sewage and water pumping in water treatment plants.

Chemical Industry: To treat solvents, acids, and chemicals.

Oil and Gas: To transport crude oil, petrochemicals, and refined the products.

Agriculture: To use in irrigation and water supply.

HVAC Systems: To transport water in heating and cooling systems.

Food and Beverage: For liquids transfer of food processing plant.

AFC's Commitment to Quality

At AFC, we understand that safety and the efficiency of pumping are two key elements to concentrate on. We therefore stock a complete range of centrifugal pumps from world market leaders. With our skilled teams of engineers, you will be helped into choosing the most suitable pump to suit your application to ensure optimum performance and life. We make it our business to supply solutions with a focus on safety, reliability, and enhanced post-sales support.

Conclusion

Centrifugal pumps are a jack-of-all-trades in the fluid handling world, with some trade-off among cost, maintenance, and flow rate. They're not the ideal choice for every application, but their adaptability, plus their rugged reliability, has won them favor in a broad cross-section of industries. At AFC, we guarantee to provide you with the best in pumping solutions, and our great experience in centrifugal pumps guarantees you of receiving the right pump for your specific application. Contact us today and find out how we can improve your fluid handling operation.

1 note

·

View note

Text

Monel 400: A Comprehensive Guide

Introduction to Monel 400

Monel 400 is a durable nickel-copper alloy recognized for its outstanding corrosion resistance and superior strength. It is widely used in marine, chemical, and aerospace industries due to its outstanding properties. The alloy is composed primarily of nickel (around 67%) and copper (about 23%), with trace amounts of iron, manganese, carbon, and silicon. This unique composition gives Monel 400 superior resistance to harsh environments, making it a preferred choice for various applications.

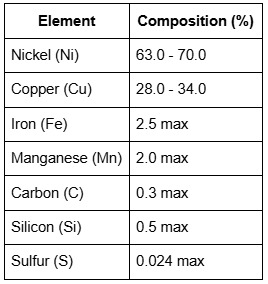

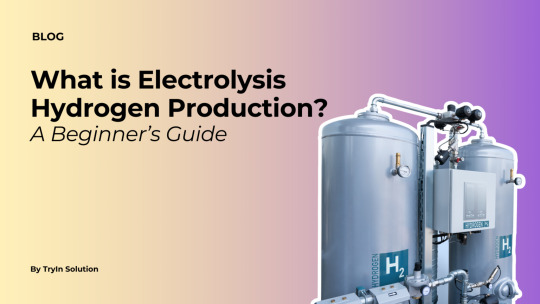

Chemical Composition of Monel 400

The high nickel and copper content makes Monel 400 an excellent choice for extreme environments where high resistance to acids, alkalis, and seawater is required.

Mechanical Properties of Monel 400

These mechanical properties indicate that Monel 400 offers excellent strength and ductility, making it suitable for both high-temperature and cryogenic applications.

Key Characteristics of Monel 400

Corrosion Resistance: Excellent resistance to seawater, hydrofluoric acid, sulfuric acid, and alkaline solutions.

High Strength: Retains strength across a broad temperature range.

Good Ductility: Can be easily fabricated, machined, and welded.

Thermal Stability: Performs well under extreme temperatures.

Magnetic Properties: Slightly magnetic at room temperature.

Applications of Monel 400

Due to its superior properties, Monel 400 is extensively used in:

1. Marine Industry

Shipbuilding

Submarine parts

Heat exchangers

Seawater piping

2. Aerospace Industry

Aircraft fuel tanks

Engine components

Hydraulic lines

3. Chemical Processing Industry

Pumps and valves

Heat exchangers

Chemical storage tanks

4. Oil and Gas Industry

Offshore drilling components

Pipeline systems

Valves and pumps

5. Power Generation

Nuclear and fossil fuel power plants

Boiler feedwater heaters

Advantages of Monel 400

Exceptional corrosion resistance in harsh environments

High tensile strength and durability

Good machinability and weldability

Superior resistance to high-temperature oxidation

Long lifespan and reliability

Disadvantages of Monel 400

Expensive compared to other alloys

Challenging to machine due to high strength and work-hardening nature

Limited availability in some forms and sizes

Monel 400 vs. Other Alloys

Monel 400 vs. Stainless Steel

Monel 400 has superior corrosion resistance in marine and acidic environments.

Stainless steel is generally more affordable and readily accessible.

Monel 400 exhibits better performance in high-temperature applications.

Monel 400 vs. Inconel

Inconel offers better oxidation resistance at extreme temperatures.

Monel 400 is better suited for seawater and acidic conditions.

Inconel is used for aerospace applications due to its high-temperature performance.

Conclusion

Monel 400 is a premium nickel-copper alloy with remarkable corrosion resistance, high strength, and excellent durability. Its widespread use in marine, chemical, and aerospace industries is a testament to its outstanding properties. While it may be more expensive and challenging to machine than other materials, its long-term performance and reliability make it a valuable choice for demanding applications.

Frequently Asked Questions (FAQ)

1. What makes Monel 400 corrosion-resistant?

Monel 400's high nickel and copper content provide exceptional resistance to seawater, acids, and alkaline solutions.

2. Can Monel 400 be welded?

Yes, Monel 400 can be welded using gas tungsten arc welding (GTAW), shielded metal arc welding (SMAW), and gas metal arc welding (GMAW) methods.

3. Is Monel 400 magnetic?

Monel 400 is slightly magnetic at room temperature due to its nickel content.

4. What is the temperature range of Monel 400?

Monel 400 can operate in temperatures ranging from cryogenic levels up to approximately 1000°F (538°C).

5. Is Monel 400 suitable for seawater applications?

Yes, Monel 400 is widely used in marine environments due to its excellent resistance to seawater corrosion.

#ananka#anankafasteners#monel#monelfasteners#articles#blog#monel400#monel500#inconel#inconelfasteners#inconelbolts#manufacturer#fasteners#supplier#mumbai#bolt#tumblr#blog tumblr

0 notes

Text

What is Electrolysis Hydrogen Production? A Beginner’s Guide

As the world transitions toward cleaner energy solutions, hydrogen has emerged as a promising alternative to traditional fossil fuels. One of the most sustainable methods of producing hydrogen is through electrolysis. But what exactly is electrolysis hydrogen production, and why is it important? This beginner’s guide aims to answer these questions and shed light on its potential to revolutionize the energy landscape.

Understanding Electrolysis Hydrogen Production

Electrolysis is a process that uses electricity to split water ( H₂O ) into its basic components: hydrogen ( H₂ ) and oxygen ( O₂ ). When the electricity used comes from renewable energy sources like wind or solar, the hydrogen produced is often referred to as “green hydrogen” due to its minimal environmental impact.

The Basic Process

Electrolyzer: The device used for electrolysis consists of an anode and a cathode submerged in water, separated by an electrolyte.

Electric Current: A direct current (DC) is passed through the water.

Separation: Hydrogen gas collects at the cathode, while oxygen is released at the anode.

This simple yet effective process is at the heart of electrolysis hydrogen production, offering a clean and efficient way to generate hydrogen for various applications.

Why is Electrolysis Hydrogen Production Important?

1. A Cleaner Energy Source

Hydrogen produced via electrolysis emits no greenhouse gases during its use, making it an excellent substitute for fossil fuels in sectors like transportation, manufacturing, and power generation.

2. Energy Storage

Hydrogen acts as a powerful energy carrier, enabling the storage of excess energy generated by renewable sources. This addresses the intermittency issues of solar and wind power.

3. Industrial Applications

Industries like steel production, ammonia manufacturing, and chemical refining benefit from the high purity hydrogen generated through electrolysis.

Types of Electrolyzers Used in Hydrogen Production

1. Alkaline Electrolyzers

How It Works: Uses a liquid alkaline electrolyte, such as potassium hydroxide, to conduct electricity.

Advantages: Proven technology, cost-effective, and scalable.

Disadvantages: Lower efficiency compared to advanced systems.

2. Proton Exchange Membrane (PEM) Electrolyzers

How It Works: Utilizes a solid polymer electrolyte to separate hydrogen and oxygen.

Advantages: Higher efficiency and compact design.

Disadvantages: More expensive due to the use of precious metals like platinum.

3. Solid Oxide Electrolyzers

How It Works: Operates at high temperatures to split water molecules.

Advantages: Extremely efficient, especially when integrated with industrial heat sources.

Disadvantages: Still under development and requires further cost reductions.

Applications of Hydrogen from Electrolysis

1. Clean Transportation

Hydrogen-powered fuel cells are being increasingly used in vehicles, providing a zero-emission alternative to gasoline and diesel engines.

2. Power Generation

Hydrogen can be burned or used in fuel cells to generate electricity, making it a flexible energy source for both grid and off-grid applications.

3. Industrial Uses

In industries requiring high temperatures, such as steelmaking, hydrogen offers a cleaner fuel alternative to coal.

4. Export Potential

Countries investing in electrolysis hydrogen production can export green hydrogen to nations seeking to decarbonize their energy systems.

Challenges in Electrolysis Hydrogen Production

1. High Energy Requirements

Electrolysis requires significant amounts of electricity, making its efficiency directly dependent on the energy source used.

2. Cost Factors

The cost of electrolyzers and renewable energy infrastructure is still relatively high, which impacts the overall affordability of green hydrogen.

3. Scaling Up

While the technology is promising, scaling up to meet global energy demands requires further innovation and investment.

The Future of Electrolysis Hydrogen Production

The global push toward sustainability has positioned electrolysis hydrogen production as a cornerstone of the energy transition. Governments and organizations worldwide are investing in research, infrastructure, and policies to support the adoption of green hydrogen. With advancements in electrolyzer technology and renewable energy integration, the cost of hydrogen production is expected to decrease, making it more accessible across industries.

Why Choose TryIn Solution for Hydrogen Solutions?

At TryIn Solution, we understand the transformative potential of green hydrogen and are dedicated to supporting businesses in adopting sustainable energy practices. From providing cutting-edge technology to offering expert guidance, we help you harness the benefits of electrolysis hydrogen production effectively and efficiently.

Conclusion

Electrolysis hydrogen production is a game-changing technology that promises to redefine how we produce and use energy. By offering a clean, sustainable, and versatile energy source, it addresses some of the most pressing challenges of our time, from reducing carbon emissions to ensuring energy security. As we move toward a greener future, investing in this innovative solution will be pivotal for industries and governments alike.

Explore how TryIn Solution can help you integrate hydrogen solutions into your operations. Contact us today to learn more!

0 notes

Text

Aluminium Welding and Fabrication: The Essential Guide

Aluminium welding is commonly used in many industries including auto manufacturing aerospace industries construction marine industries etc. This material is highly versatile because of its lightweight, high durability, and immunity to corrosion; it is a darling of manufacturers and engineers. In this article, we will analyze the possibility of welding and fabrication of aluminum materials, its advantages and disadvantages, anthe d necessary equipment and methods.

Key Characteristics of Aluminium:

Lightweight: Aluminium is about 1/3 of the density of steel.

Corrosion Resistance: To be more specific, it develops an oxide film to prevent the process of rusting.

High Thermal Conductivity: Aluminium conducts heat and hence it is not very suitable for welding procedures.

Oxide Layer: The surface oxide has a higher melting point than the base metal so exacting methods are necessary.

Common Aluminium Welding Methods:

TIG Welding (Gas Tungsten Arc Welding): Recommended for thin sections due to the accuracy and smoothness of the finish.

MIG Welding (Gas Metal Arc Welding): More appropriate for thicker materials to offer a faster rate of production.

Spot Welding: Primarily used in car manufacturing for fastening thin metals such as sheet metal.

Aluminium Fabrication Explained

Fabrication means the shaping of aluminum by processes such as cutting, bending as well as joining to produce particular parts or systems.

Fabrication Processes:

Cutting: Possible to utilize laser cutting, water jet cutting, or CNC machining if accuracy is necessary.

Bending: Aluminium sheets are bent through the use of press brakes/rollers.

Joining: This may be welding, riveting,g, or bonding together of the parts, that is, the use of adhesives to join the parts.

Finishing: Polishing anodizing, or powder coating of the outside view to improve its look and performance.

Industries Using Aluminium Fabrication:

Aerospace: Things like wings and segments of the fuselage as used in the construction of a plane.

Automotive: Fuel-efficient components for lighter cars.

Construction: Windows, doors, and roofing.

Marine: Items such as hulls of ships and structures of decks.

Benefits of Aluminium Welding and Fabrication

Aluminium is a versatile metal, which cannot be substituted in a multitude of industries and applications. Here are the key advantages:

Lightweight Yet Strong: Offers a high strength-to-weight ratio, reducing structural load.

Corrosion Resistance: Excellent for outdoor and marine applications.

Eco-Friendly: Aluminium is 100% recyclable, reducing environmental impact.

Cost-Effective: Despite higher initial costs, its durability and low maintenance make it economical in the long run.

Future Trends in Aluminium Welding and Fabrication

The industry is evolving with advancements in technology and sustainability efforts:

Automation: Robotic welding and CNC machining increase the accuracy and speed of steel production.

3D Printing: Modern manufacturing techniques such as AM are applied to highly complicated aluminum parts.

Sustainable Practices: Focus on reuse and usage of energy-saving practices and policies.

Advanced Alloys: Higher performance non-heat treatable aluminum alloy-based specific applications.

Essential Tools and Techniques

Aluminum welding and fabrication are as important as any other type of welding, but there is a stark difference in the way it has to be done.

Welding Machines: TIG and MIG welders with a pulse to enable control of the heat intensity.

Filler Materials: Base metal compatible aluminum alloy filler rods or wires.

Protective Equipment: Welding helmets gloves and clothing for safety.

Preparation Tools: Wires for brushing the oxide layer away and chemical products for washing the oxide layer off.

Clamping Systems: To keep the component in a fixed position and minimize its movement during the fabrication.

Challenges in Aluminium Welding and Fabrication

Nonetheless, aluminum holds some advantages, yet it needs expertise and tools to work because of its peculiar characteristics.

Warping and Distortion: A high ability to conduct heat can lead to parts distorting as welds are being made.

Porosity: Aluminium reacts with hydrogen and, therefore, porosity is often observed in welds.

Oxide Removal: The oxide layer has to be removed for better adhesion and this can be done through pre-weld cleaning.

Skill Requirements: Welding of aluminum requires skilled professionals and specific parameters to accomplish excellent work.

Final Thoughts

Aluminum welding and fabrication are integral to modern engineering and manufacturing. From selecting the right welding method to leveraging advanced fabrication techniques, working with aluminum requires expertise and precision. As industries push towards lighter, stronger, and more sustainable solutions, aaluminumcontinues to lead the way.For expert aaluminumwelding and fabrication services, trust DARMIS, a name synonymous with quality and innovation in the field. Visit their website to learn more about their offerings and how they can bring your projects to life.

0 notes

Text

How Do Natural Stone Wall Cladding Tiles Compare to Other Materials?

When it comes to choosing the right material for wall cladding, natural stone tiles stand out as an option that seamlessly blends beauty, durability, and practicality. At The Stone Evolution, we understand the importance of selecting the perfect cladding material for both residential and commercial spaces. In this blog, we will explore how natural stone wall cladding tiles compare to other materials, focusing on their unique advantages and limitations.

Aesthetic Appeal

Compared to artificial materials like concrete or ceramic tiles, natural stone exudes elegance and adds a sense of timelessness to any space. While other materials may imitate the appearance of stone, they often lack the depth and character that come with genuine natural stone. Natural stone wall cladding tiles have an unmatched aesthetic appeal. Each piece is a work of art created by nature, with unique patterns, textures, and colors. Materials like marble, slate, sandstone, and granite offer diverse styles, from rustic and rugged to sleek and modern. Durability and Longevity

Durability is a key factor when selecting cladding materials, and natural stone excels in this regard. Stone cladding is resistant to weathering, UV rays, and wear, making it an excellent choice for both indoor and outdoor applications. Materials like wood and vinyl may warp, fade, or deteriorate over time, especially when exposed to harsh environmental conditions. Natural stone, on the other hand, can last for decades with minimal maintenance, making it a cost-effective investment in the long run.

Versatility in Design

Natural stone wall tiles are versatile and can be used in various settings. Whether you want to create a striking feature wall, enhance the facade of a building, or add texture to an interior space, natural stone can meet your design needs. Other materials, such as brick or plaster, may have limitations in terms of texture and variety. Natural stone tiles can also be cut and finished in various ways to achieve polished, honed, or rough textures, providing endless design possibilities.

Environmental Friendliness

Sustainability is a growing concern for many homeowners and builders. Natural stone is an eco-friendly choice as it is sourced directly from nature without the need for extensive chemical processing. Unlike synthetic materials like PVC or engineered wood, natural stone has a lower environmental impact during production. Additionally, natural stone can be recycled or repurposed, making it a more sustainable option compared to non-recyclable alternatives.

Cost Considerations

While stone wall cladding tiles can be more expensive upfront compared to materials like ceramic or vinyl, their long-term benefits often outweigh the initial investment. Synthetic materials may require frequent replacements or repairs, leading to higher costs over time. The durability of natural stone ensures that you save on maintenance and replacement expenses in the long run. Additionally, the premium appearance of stone can increase the value of your property, making it a worthwhile choice.

Maintenance Requirements

Natural stone cladding requires regular cleaning and occasional sealing to maintain its appearance and durability. While this may seem like a disadvantage compared to low-maintenance materials like plastic panels or aluminum, the effort is minimal and ensures the stone retains its natural beauty for years. With proper care, stone cladding can look as good as new even after decades of use.

Weather Resistance

One of the standout features of natural stone wall cladding is its ability to withstand extreme weather conditions. Materials like vinyl and wood can crack, fade, or warp under prolonged exposure to sunlight, rain, or snow. In contrast, natural stone remains unaffected by temperature fluctuations, moisture, or UV radiation, making it an ideal choice for outdoor applications.

Conclusion

Natural stone wall tiles offer a perfect balance of beauty, durability, and functionality. While synthetic materials may seem more affordable or convenient, they often lack the unique charm, resilience, and environmental benefits of natural stone. Whether you’re renovating your home or designing a commercial space, choosing natural stone wall cladding from The Stone Evolution is a decision that combines aesthetics with long-lasting value.

Explore our wide range of natural stone wall cladding options to find the perfect fit for your project. Let The Stone Evolution help you transform your space into a timeless masterpiece.

0 notes

Text

What Is Melamine Particle Board? Comparison with Plywood and MDF

How Are Melamine Particle Board Manufactured?

Melamine particle board are crafted through a process involving melamine resin, initially an organic compound that undergoes polymerization to become a robust and durable plastic material. Essentially, melamine is a chemical compound derived from an organic base and acts as a trimer of cyanamide.

Melamine Laminate is typically resistant to stain, heat, and fire. It’s moisture and scratch-resistant and can be found in many colors, patterns, sizes, and thicknesses making it ideal for particleboard, plywood, or MDF applications. Melamine is more like small pieces of wood (particleboard) glued and pressed together and covered with a plasticized coating.

Uses of Melamine

The term "melamine" finds extensive application not only in cabinet construction but also in various other industrial sectors unrelated to construction.

For instance, melamine laminate serves as a key material not only in crafting woodworks such as shelves and cabinets but also in the resin utilized for Formica and other laminated countertops commonly found in kitchens.

Moreover, melamine is widely employed in the manufacture of floor tiles. Melamine tile floors offer enhanced glossiness, scratch resistance, reduced susceptibility to staining, and easier maintenance compared to porcelain or stone alternatives. Importantly, they also tend to be more cost-effective.

Given the glossy finish of melamine-coated boards and their ability to resist surface scratches, melamine proves to be an excellent material for the production of whiteboards.

Advantages of Melamine Wood

Melamine engineered products are often more budget-friendly while maintaining reliability.

Melamine boards boast a consistent surface that is highly durable and resistant to scratches, stains, heat, and fire.

The waterproof nature of typical melamine surfaces allows for easy cleaning with soap and water.

Many prefer the absence of wood grain in melamine boards, especially those seeking solid-colored cabinets, as melamine is readily available pre-finished in various colors.

It offers a smooth finish, ready for use with minimal construction waste.

Cutting melamine is relatively straightforward with the right equipment, such as a saw with a scoring unit or CNC routers, which help prevent chipping. Proper material support during cutting reduces the risk of breakage.

Disadvantages of Melamine Board

Melamine boards are prone to bending and warping under heavier loads.

Due to its composite composition, melamine material tends to be heavy.

Melamine boards are manufactured using glues that can emit Volatile Organic Compounds (VOCs), which, according to the United States Environmental Protection Agency, may have adverse health effects in both the short and long term.

Comparing Melamine with Plywood

Melamine board offers distinct advantages when compared to plywood. While plywood board is known for its strength and natural wood grain appearance, melamine board provides a cost-effective alternative with increased durability and moisture resistance. It offers a wide range of attractive finishes, allowing for diverse design options.

Moreover, melamine board demands minimal upkeep and exhibits lower susceptibility to warping or delamination when contrasted with plywood. These attributes have propelled melamine board to become a preferred option in furniture production, especially when factors like durability, cost-effectiveness, and aesthetic appeal are pivotal. Although plywood possesses its own strengths, the benefits of melamine board render it an enticing choice for furniture designers and manufacturers aiming for a versatile and pragmatic material.

Comparing Melamine with MDF

Fiberboards, particularly MDF board (Medium Density Fiberboard), offer a cost-effective option for those looking to outfit modern kitchens, bathrooms, and interior furniture.

This material is composed of numerous wood fibers mixed with wax and resin under high pressure and temperature conditions.

Fiberboards available in the market are classified based on their densities, which are determined by the levels of temperature and pressure during manufacturing. Consequently, HDF (High Density Fiberboard) requires higher levels of pressure and temperature compared to MDF.

In summary, MDF falls in between HDF and particleboard in terms of density, with particleboard having the lowest density and exhibiting larger wood grains.

Comparing Melamine with solid wood, plywood, or fiberboards is a complex task.

Melamine is a popular plastic material widely used by modern cabinet builders. It can be applied as a laminate onto substrates such as plywood or particleboard, or it can be incorporated into the construction of kitchen cabinets, particularly when combined with MDF or particleboard. These substrates, made from wood chips, are used to form High Pressure Laminate (HPL) or Thermally Fused Laminate (TFL). Consequently, direct comparisons between melamine and MDF or particleboard can be challenging.

One of the key advantages of melamine is its durability and high resistance to scratches, along with its extensive range of colors and patterns. This versatility makes melamine fused with plywood arguably one of the most sustainable options for cabinetry.

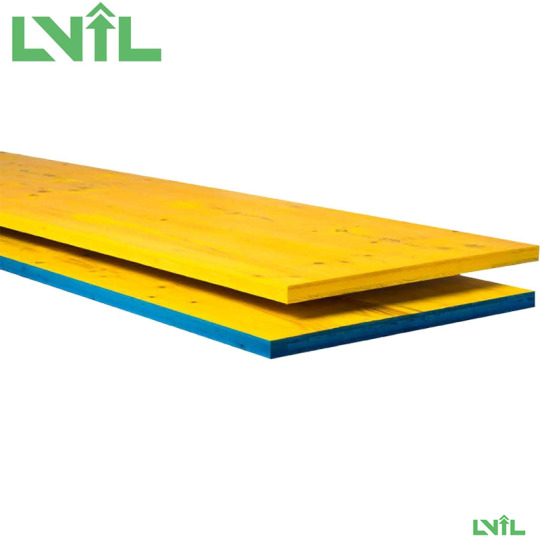

Previous:The Benefits and Safety of LVL Scaffold Planks in Construction

Next:LVL vs. Solid Wood Window Frames: Choosing the Right

0 notes

Text

Car Battery Maintenance Knowledge

As the weather turns cooler and winter approaches, people begin to bundle up and protect themselves from colds. Similarly, with the change of seasons, cars often develop various issues, especially with their batteries. After enduring the summer’s intense heat and heavy rains, the connections on a car’s battery are likely to suffer from oxidation and other faults. The car battery is the primary power source for the vehicle’s electronic systems, and its importance cannot be overstated. With the increasing electrification of modern vehicles, the reliance on the car battery becomes even greater. A lack of battery power can lead to a complete breakdown of the vehicle. Therefore, maintaining and caring for your car’s battery is crucial.

Common Types of Car Batteries

The most common type of car battery is the lead-acid battery, which comes in two varieties: the flooded lead-acid battery and the maintenance-free lead-acid battery. Currently, over 80% of vehicles on the market use maintenance-free lead-acid batteries. Understanding the differences between these two types can help owners make informed decisions about maintenance and replacement.

Flooded Lead-Acid Battery This type of battery consists of plates made of lead and lead oxide, with the electrolyte being a dilute sulfuric acid solution. Its advantages are stable voltage and relatively low cost. However, its disadvantages include low energy density (i.e., it stores less energy per kilogram), shorter lifespan, and the need for frequent maintenance, such as adding distilled water.

Maintenance-Free Lead-Acid Battery Maintenance-free batteries have a significant advantage due to their structure. They consume very little electrolyte, meaning that they rarely need to be topped up during their lifetime. They are also resistant to shock, high temperatures, and self-discharge. The lifespan of these batteries is typically twice that of traditional flooded batteries. Maintenance-free batteries come in two types: one type is filled with electrolyte once at purchase and does not require any further maintenance, while the other type comes sealed from the factory with no possibility of adding fluid.

https://www.sunvoltbat.com/wp-content/uploads/2024/10/03-9.jpg

How to Maintain Your Car Battery

To extend the life of your car’s battery, regular maintenance is essential. Here are some simple yet effective maintenance tips for car owners:

Regularly Check the Battery Terminals The battery terminals are critical for good contact between the battery and the electrical system. Oxidation or poor connections can result in inadequate current flow, leading to engine startup problems. Regularly inspect and clean the terminals to prevent issues.

Avoid Deep Discharge Allowing the battery to discharge too much can severely damage it. Avoid leaving electrical devices on when the engine is off, and try to keep the battery’s charge within a healthy range.

Maintain Proper Electrolyte Levels For flooded lead-acid batteries, ensuring that the electrolyte level is adequate is essential. If the electrolyte level is too low, the plates can become exposed to air, leading to oxidation and sulfation.

Prevent Overheating High temperatures can accelerate chemical reactions inside the battery, causing electrolyte evaporation and potentially damaging the battery. Keep the area around the battery clean and free from excessive heat.

Check Battery Voltage Regularly Use a voltage meter to check the battery’s voltage. If the voltage is low, it could indicate that the battery is not charging properly, and you may need to replace it.

Choose the Right Battery Always select a battery that matches your vehicle’s specifications in terms of voltage and capacity. A mismatched battery could cause early wear and damage to the vehicle’s electrical system.

How to Evaluate the Quality of Dry Batteries

In addition to car batteries, dry batteries used in everyday devices such as remote controls, flashlights, and radios are also important. To ensure you are purchasing high-quality dry batteries, experts recommend three simple steps:

Check the Price Generally, higher-priced dry batteries are of better quality. Avoid purchasing batteries from unlicensed sellers, as they may be substandard and prone to leakage.

Weigh the Battery Higher-quality dry batteries tend to be heavier than low-quality ones. You can weigh the batteries using an electronic scale to make an informed decision.

Inspect the Appearance Good-quality dry batteries will have neat and precise packaging, with clear labels indicating the brand, manufacturer, battery type, voltage, production date, and expiry date. They should also be free from leakage and should have environmentally friendly labels like “mercury-free” or “0% mercury.”

Conclusion

Car batteries are a critical component of modern vehicles. As the level of electronic systems in vehicles continues to rise, the importance of the battery grows even more. Regular maintenance and care will help ensure your battery lasts longer and functions efficiently, keeping your vehicle running smoothly. Similarly, choosing quality dry batteries for everyday use will ensure reliable performance for your household electronics. By paying attention to battery health and maintenance, you can avoid many potential issues and extend the life of both your car and your household devices.

0 notes

Text

Understanding Liquid Cooling Systems in Bikes: A Complete Guide

If you've looked up current bike specs, you may have encountered the phrase "liquid-cooled engine." Because of this technology's effectiveness in controlling engine heat and preserving steady performance has grown in favor. This extensive guide will go deeply into the world of liquid-cooled engine bikes, emphasising their applicability and benefits in India. Whether you're thinking of buying a liquid-cooled bike or already have one, this guide will offer helpful advice.

Understanding Liquid or Water-Cooled Engines in Bikes

Water-cooled engines, sometimes called liquid-cooled engines, control engine temperature using a liquid, usually a blend of coolant and water. This system significantly improves over conventional air-cooled engines by providing better heat management and consistent performance. The coolant mixture, which flows around the engine in a typical 1:1 ratio with water, absorbs heat and avoids overheating.

What is a Liquid-Cooled Engine?

A liquid-cooled engine controls its temperature using a liquid, usually a mixture of water and coolant. This method has significantly developed and provides better heat control than conventional air-cooled engines.

Exploring Closed Circuit Water-Cooled Engines

In India, closed-circuit water cooling systems are a common characteristic of modern liquid-cooled engine bikes. The pressured environment these systems maintain causes the water's boiling point to rise to 110 degrees Celsius. This high boiling point ensures effective and extended cooling by preventing quick evaporation. Radiators and water pumps are two parts of the system that cooperate to dissipate heat efficiently.

Construction and Design of Water-Cooled Engines

The construction of liquid-cooled engines involves several key components:

Water jackets: These openings let coolant circulate and absorb heat within the engine block and cylinder head.

Water Pump: This part keeps the coolant flowing continuously and at a constant temperature.

Radiator: A cooling fan helps dissipate the absorbed heat as the hot coolant passes through the radiator.

Thermostat: This valve maintains ideal thermal conditions by controlling coolant flow in response to engine temperature.

The Function of Coolant in Engines

Coolant, often known as antifreeze, is essential for preventing overheating. It contains chemicals to lubricate moving parts, lowering friction and making operation smoother. Furthermore, coolants lessen the chance of electrolysis, a chemical reaction that can erode metal components and shield metal surfaces from rust.

The Importance of Thermostats in Water-Cooled Engines

Thermostats are essential to keeping the engine's temperature within an ideal range. The thermostat stays closed when the engine is cold, stopping coolant from reaching the radiator. The thermostat opens when the engine heats up, enabling coolant to flow and controlling the engine's temperature. This exact management avoids both overcooling and overheating.

Benefits of Liquid-Cooled Engine Bikes

Liquid-cooled engine bikes offer several advantages, particularly in the Indian context:

Balanced Cooling: In multi-cylinder engines, liquid cooling ensures that each cylinder receives the same amount of cooling, preventing overheating.

Enhanced Fuel Efficiency: These engines run more efficiently and have less chance of damage since they are kept at the ideal temperature.

Enhanced Thermal Efficiency: Engine performance is enhanced when temperatures are controlled.

Decreased Water Loss: Closed systems maintain steady cooling performance by reducing water evaporation.

Drawbacks of Liquid-Cooled Engine Bikes

Although liquid-cooled bikes in India offer many advantages, they also have certain disadvantages:

Increased Costs: The intricate design and extra components raise the cost of production and upkeep.

Complex Design: The complex cooling system requires accurate engineering, which raises production costs.

Liquid-cooled engines are a popular option for riders looking for dependable performance despite these drawbacks.

Comprehensive Bike Insurance Is Essential for Engine Coverage, Among Other Things

In India, the owner must protect their bike with a liquid-cooled engine. Compulsory third-party motor insurance only covers the most basic responsibilities; comprehensive bike insurance covers much more, including engine coverage. Choosing a comprehensive plan, like those provided by SBI General Insurance, guarantees protection against theft, natural disasters, accidents, and other issues.

Comprehensive insurance can cover some engine-related issues, including water intrusion, lubricant leaks, and gearbox damage, in the case of liquid-cooled engine bikes. Purchasing a comprehensive bike insurance policy gives you peace of mind in addition to protecting your bike.

FAQs

Do water-cooled engines require regular maintenance?Yes, regular maintenance is necessary to guarantee that the cooling system operates properly. This includes ensuring the water pump and thermostat are in good working order, monitoring the coolant levels, and looking for leaks.

Is a water-cooling system capable of handling extreme temperatures?Absolutely. Engines that use liquid cooling are built to withstand high temperatures. The right coolant composition ensures optimal performance by preventing freezing in cold weather and boiling in hot weather.

Do water-cooled engines require a specific type of radiator?Yes, radiators used in water-cooled engines are made to absorb heat from the coolant effectively. The radiator must work with the cooling system to allow the engine to cool down as efficiently as possible.

Conclusion

In India, liquid-cooled engine bikes are a significant development in motorcycling technology, providing better heat control and reliable performance. Riders can make more educated selections if they know these systems' advantages and disadvantages and how they operate. Furthermore, it's essential to safeguard your investment with comprehensive bike insurance, like those provided by SBI General Insurance. This insurance offers comprehensive protection for your bike's engine and other parts and basic liability coverage.

By maintaining regular upkeep and choosing the right insurance policy, you can ensure that your liquid-cooled engine bike continues to deliver optimal performance, making every ride a smooth and enjoyable experience.

Source URL- https://www.sbigeneral.in/blog-details/understanding-liquid-cooling-systems-in-bikes

0 notes

Text

A comparison of solid hardwood furniture and engineered wood furniture

Here's a comparison of solid hardwood furniture and engineered wood furniture:

Advantages of Solid Hardwood Furniture:

Durability: Solid hardwood furniture is known for its longevity and ability to withstand daily wear and tear. It can be passed down through generations if properly maintained.

Natural Beauty: Solid hardwood furniture showcases the inherent beauty of wood, including unique grain patterns and colors that synthetic materials cannot replicate.

Versatility: Solid hardwood furniture is very diverse and can adapt to various decorative styles and color schemes.

Sustainability: Solid hardwood furniture is an eco-friendly option as it is made from renewable resources and can be sustainably sourced.

Value Retention: Solid hardwood furniture is a wise investment as it tends to retain its value over time, and may even appreciate in value.

Health Benefits: Solid hardwood furniture is a healthier choice as it is naturally made from wood, improving indoor air quality unlike synthetic materials that can release harmful chemicals into the home.

Customizability: Solid hardwood furniture can be customized to meet personal needs, whether in size, type of wood, or finish.

Easy Maintenance: Solid hardwood furniture is relatively easy to maintain, requiring only regular dusting and occasional polishing.

Timeless Style: Solid hardwood furniture has a timeless, classic style that never goes out of fashion.

Disadvantages of Solid Hardwood Furniture:

High Cost: Solid hardwood furniture can be more expensive, depending on the type of wood used.

Environmental Impact: It may not be the most environmentally friendly option due to the need to cut down trees to obtain solid timber.

Sensitive to Humidity and Climate: Solid hardwood furniture can be affected by humidity and climate, such as expansion or contraction.

Pest Susceptibility: Over time, solid hardwood furniture is more susceptible to pests like termites.

Heavier Weight: Solid hardwood furniture is usually heavier and not as easy to move.

Advantages of Engineered Wood Furniture:

Cost-Effective: Engineered wood furniture is much cheaper than solid hardwood furniture, making it suitable for consumers with a limited budget.

Environmentally Friendly: It uses smaller wood fibers or thin veneers, reducing waste and often sourced from fast-growing, sustainable tree species, making it a more eco-friendly option than some solid hardwoods.

Versatility and Wide Application: Engineered wood can be used for various applications, such as flooring, furniture, and structural components of home construction.

Dimensionally Stable: Due to its laminated structure, engineered wood is more resistant to warping, shrinking, and expanding, especially with changes in humidity and temperature.

Easy Installation: Engineered wood products are easier to install than traditional hardwood, especially for flooring systems.

Pest Resistance: The resin adhesive used in engineered wood is a strong deterrent against termites.

Lightweight: Engineered wood furniture is usually lighter than solid hardwood furniture, making it easier to move.

Disadvantages of Engineered Wood Furniture:

Limited Lifespan: Engineered wood furniture typically has a shorter lifespan than solid hardwood, especially if not properly maintained.

Sensitive to Water: Engineered wood is still susceptible to water damage, especially if the core material is exposed.

Potential Toxic Chemicals: The adhesives used in engineered wood often contain formaldehyde and other toxic chemicals that can off-gas into the indoor environment.

Limited Refinishing Options: Unlike solid hardwood, the thin veneer layer on engineered wood limits how many times it can be refinished.

Poor Weather Resistance: Certain engineered materials can warp when exposed to sunlight for extended periods.

Difficult to Repair: Once damaged, engineered wood furniture is hard to repair and may require replacement.

In summary, solid hardwood and engineered wood furniture each have their own set of advantages and disadvantages. The choice between the two depends on your budget, style preferences, environmental conditions, and the durability and sustainability requirements for your furniture.

0 notes

Text

What is Grinding? The Essential Process for Finishing and Shaping Materials

Grinding is a fundamental process used in various industries to finish and shape materials. It involves the use of abrasive materials or tools to remove material from a surface or object, resulting in a smooth, precise, and high-quality finish. Grinding is an essential process in manufacturing, construction, and other industries, and is used to produce a wide range of products, from consumer goods to aerospace components. In this article, we will explore the concept of grinding, its applications, and the benefits it provides.

What is Grinding?

what is grinding is a process that involves the use of abrasive materials or tools to remove material from a surface or object. The abrasive material or tool is applied to the surface or object, and the friction generated between the two causes the material to be removed. Grinding can be performed using a variety of techniques, including mechanical grinding, chemical grinding, and manual grinding. Each technique has its unique advantages and disadvantages, and the choice of technique depends on the specific needs of the project.

Applications of Grinding

Grinding has a wide range of applications in various industries, including manufacturing, construction, and aerospace. In manufacturing, grinding is used to produce high-precision components, such as engine parts, gearboxes, and satellite components. In construction, grinding is used to finish and shape concrete, stone, and other building materials. In aerospace, grinding is used to produce high-precision components, such as aircraft parts and satellite components. Grinding is also used in other industries, such as automotive, medical, and consumer goods.

Benefits of Grinding

Grinding provides several benefits, including improved surface finishes, increased precision, and enhanced durability. Grinding allows manufacturers to produce high-quality products with precise dimensions and smooth surfaces. It also enables them to improve the durability of their products by removing imperfections and defects. Additionally, grinding can be used to repair and refurbish existing products, reducing waste and extending their lifespan.

Types of Grinding

There are several types of grinding, including surface grinding, cylindrical grinding, internal grinding, and centerless grinding. Surface grinding involves grinding a flat surface, while cylindrical grinding involves grinding a cylindrical or spherical surface. Internal grinding involves grinding an internal surface, such as a hole or bore, while centerless grinding involves grinding a cylindrical part without the use of centers or spindles. Each type of grinding has its unique applications and requirements, and the choice of technique depends on the specific needs of the project.

Grinding Machines and Tools

Grinding machines and tools are designed to perform specific grinding operations. Surface grinders, cylindrical grinders, internal grinders, and centerless grinders are some of the most common types of grinding machines. Grinding tools, such as grinding wheels and abrasive belts, are also used to perform grinding operations. The choice of grinding machine or tool depends on the specific needs of the project, and the type of material being ground.

Safety Precautions and Best Practices

Grinding can be a hazardous process, generating dust, noise, and vibrations that can be harmful to workers and the environment. To minimize these risks, it is essential to follow safety precautions and best practices, including wearing personal protective equipment (PPE), using proper ventilation, and maintaining equipment regularly. Additionally, workers should be trained on the safe operation of grinding machines and tools, and should follow established procedures and guidelines to ensure a safe working environment.

Conclusion

In conclusion, grinding is a fundamental process used in various industries to finish and shape materials. It involves the use of abrasive materials or tools to remove material from a surface or object, resulting in a smooth, precise, and high-quality finish. Grinding provides several benefits, including improved surface finishes, increased precision, and enhanced durability. By understanding the concept of grinding and its applications, manufacturers and industries can produce high-quality products and improve their overall productivity and efficiency.

0 notes

Text

Understanding Engine Oil: Importance, Types, and Maintenance Tips

Engine oil is one of the most crucial components in keeping a vehicle running smoothly. Its primary role is to lubricate the engine's moving parts, reducing friction, preventing wear, and dissipating heat. Without engine oil, the metal components in your engine would quickly degrade, leading to overheating, damage, and ultimately, engine failure. In this blog post, we will explore the importance of engine oil, the different types available, and tips for maintaining your vehicle’s engine oil for optimal performance.

What Is Engine Oil?

Engine oil is a specially formulated lubricant designed to keep the moving parts of an engine functioning properly. It acts as a barrier between metal components, reducing friction and wear caused by continuous movement. In addition to lubrication, engine oil serves other functions, including cooling the engine, cleaning contaminants, and preventing rust and corrosion.

Why Is Engine Oil Important?

The primary purpose of engine oil is to reduce friction between the moving parts of an engine, such as pistons, crankshafts, and valves. This helps prevent wear and tear, ensuring that the engine operates smoothly and efficiently. The oil also serves to:

Lubrication: Engine oil forms a thin film between moving metal parts, preventing direct contact and reducing friction. This helps prevent engine components from grinding against each other, which can lead to severe damage.

Cooling: In an engine, parts like pistons and valves can get extremely hot due to constant friction and combustion. Engine oil absorbs some of this heat and carries it away from critical components, helping to prevent overheating.

Cleaning: Engine oil helps trap dirt, debris, and other contaminants that naturally accumulate inside the engine. It picks up particles such as carbon buildup and metal shavings, which are then filtered out by the oil filter.

Corrosion Prevention: The oil creates a protective layer that prevents moisture and contaminants from coming into direct contact with the metal surfaces inside the engine..

Types of Engine Oil

Not all engine oils are created equal. The type of engine oil you use will depend on your vehicle’s engine design, operating conditions, and manufacturer recommendations.

1. Mineral Oil (Conventional Oil)

Mineral oil is the most basic form of engine oil and is derived from refined crude oil. It is commonly used in older vehicles or those with simpler engine designs. Mineral oils are generally less expensive than synthetic oils but may not offer the same level of protection, especially under extreme conditions.

Advantages:

Cost-effective

Suitable for older engines

Regularly changed, it can perform well under typical driving conditions

Disadvantages:

Breaks down more quickly than synthetic oils

Less effective in extreme temperatures

Requires more frequent oil changes

2. Synthetic Oil

Synthetic oil is artificially created using chemical compounds that are engineered to provide better performance than conventional oils. It is engineered to endure high temperatures, minimize engine wear, and enhance fuel efficiency. Synthetic oils are particularly beneficial for modern vehicles with high-performance engines.

Advantages:

Improved performance in extreme temperatures (both high and low)

Longer oil change intervals

Better lubrication and protection for high-performance engines

Reduces engine sludge and contaminants

Disadvantages:

More expensive than mineral oils

May not be necessary for older or less-demanding engines

3. Semi-Synthetic Oil (Blended Oil)

Semi-synthetic oil is a blend of traditional mineral oil and synthetic oil. It offers a balance between performance and cost, providing some of the benefits of synthetic oil at a lower price point. It is suitable for vehicles that need better performance than conventional oils can offer but don’t require full synthetic oil.

Advantages:

Better performance than conventional oil

More affordable than full synthetic oil

Longer oil change intervals than mineral oil

Disadvantages:

Not as durable as fully synthetic oil

Still may not be suitable for extreme driving conditions

How Often Should You Change Engine Oil?

One of the most common questions vehicle owners have is how often to change the engine oil. The recommended oil change interval can vary based on factors such as the oil type, vehicle age, and driving conditions, but here are some general recommendations:

Conventional Mineral Oil: Typically, it’s recommended to change conventional oil every 3,000 to 5,000 miles.

Synthetic Oil: Full synthetic oils can last longer, with intervals ranging from 7,500 to 10,000 miles.

High-Mileage Oil: For older engines, oil changes may be recommended every 5,000 to 7,500 miles.

However, always refer to your vehicle’s owner’s manual for the manufacturer’s recommended oil change intervals, as newer vehicles may have longer intervals or require specific types of oil.

Signs That Your Engine Oil Needs Changing

There are a few key indicators that it’s time to change your engine oil:

Dirty or Dark Oil: Fresh engine oil is amber in color. If the oil appears dark and gritty, it may be time to replace it.

Unusual Engine Noises: If you hear knocking, ticking, or grinding sounds coming from the engine, it may indicate that the oil isn’t lubricating properly.

Oil Warning Light: Most modern vehicles are equipped with an oil pressure warning light that will illuminate when the oil level is low or when the oil is old and needs to be changed.

Oil Smell: A strong smell of burnt oil could indicate that the oil is degrading and no longer offering adequate protection.

Conclusion

Engine oil is vital to keeping your vehicle running efficiently and preventing costly repairs. By understanding the importance of engine oil, choosing the right type for your vehicle, and adhering to regular maintenance schedules, you can ensure that your engine stays in good condition for years to come.

0 notes

Text

Plywood vs. Particle Board: Which One Should You Use?

Plywood and particle board, They both have their advantages and disadvantages and knowing these differences will help you decide. We'll explore the characteristics, applications, and pricing of plywood, including hardwood plywood and MR plywood, while comparing them with particle boards.

Understanding Plywood

Plywood is a wood product made by gluing sheets of veneer together. This makes the product very sturdy and durable and not as likely to warp or crack as solid wood. There are many different kinds of plywood, one type is hardwood plywood which has hardwood veneers that make it very strong and durable.

Benefits of Plywood

Strength and Durability: The outstanding strength-to-weight ratio of plywood is well-known. It will not warp or crack under a lot of weight, which makes it good for furniture and structural uses.

Versatility: Plywood is very versatile, it can be used for furniture, flooring, cabinetry, etc. Whether building custom plywood furniture or using plywood sheets for wall paneling, it offers great flexibility.

Aesthetic Appeal: With options like plywood sheet white or decorative veneers, plywood can be finished to match various interior styles, enhancing the overall look of your space.

Moisture Resistance: Some plywood like marine plywood is made to withstand moisture and is perfect for a damp surrounding.

Eco-Friendly: Plywood is often considered more environmentally friendly than particle boards because it uses fewer chemicals in its manufacturing process.

Pricing of Plywood

Plywood has different prices according to the type and how thick it is. For example, hardwood plywood is more expensive than regular plywood, but it is of better quality and it will last longer. Plywood sheets usually run from moderately to very expensive, depending on the grade, the finish, etc.

Exploring Particle Board

Particle board, (or particleboard or chipboard) is composed of wood chips sawmill shavings, and even wood dust, mixed with some sort of resin or glue, and pressed and heated to form a board. It is a type of engineered wood and is widely used in furniture.

Benefits of Particle Board

Cost-Effective: One of the best things about particle board is that it is very cheap. It is much cheaper than plywood most of the time and that is why people who are low on money tend to use it a lot.

Smooth Surface: Particle boards are very smooth and it is easy to paint or laminate them so they are good for many types of furniture.

Lightweight: Particle board is lighter than plywood, which can be beneficial when moving or transporting furniture.

Easy to Work With: Particle boards are easier to cut and shape than plywood, and therefore more detailed designs and finishes are possible.

Drawbacks of Particle Board

Lower Strength: The particle board is good for light stuff, but it's not as strong or as durable as plywood. It may sag or break under heavy loads.

Moisture Sensitivity: The particle board isn't as water-resistant as plywood. If it gets wet, it expands and becomes structurally unsound.

Limited Aesthetic Appeal: Particle boards can be finished of course but they are kind of ugly compared to the natural beauty of wood veneers in plywood.

Which One Should You Use?

When to Choose Plywood

If it's durability and versatility you're after, plywood takes the cake. It is especially recommended for:

Furniture Construction: Some strong, durable plywood furniture that can take everyday wear and tear.

Cabinetry: In the construction of kitchen or bathroom cabinets, where moisture resistance and strength are needed.

Structural Applications: If you're doing some construction work with load-bearing stuff.

When to Choose Particle Board

Then again particle board might be the way to go if price and accessibility are important. Consider particle board for:

Budget-Friendly Furniture: For pieces that won’t undergo heavy use, such as occasional tables or decorative shelves.

Lightweight Applications: If mobility is a factor, then the light weight of the particle board is a plus.

Temporary Solutions: For projects where longevity is not a concern, such as DIY furniture for short-term use.

Conclusion

Ultimately, the choice between plywood and particle board depends on your specific needs and budget. Plywood is strong, durable, and beautiful, and should be used for fine furniture, and structural applications. Particle board on the other hand is cheap and can be used on light-duty, less stressful applications.

Before making a decision, consider factors such as plywood price, MR plywood price, and the specific applications you have in mind. Engineered wood and plywood, each have their place in construction and furniture building, but knowing the difference between the two will aid you in selecting the appropriate material for your project.

0 notes

Text

The Ultimate guide to Latest Technology

Introduction

Technology is the reproducible application of knowledge to practical objectives. Tools, machines, software, and systems are all examples of products that can be referred to as technology. In the fields of science, engineering, and everyday life, technology plays a crucial role. Society, culture, the economy, and the environment have all undergone significant shifts as a result of technological advancements. What technology is, what kinds of technology there are, how to use technology responsibly and effectively, and the advantages and disadvantages of technology will all be discussed in this article.

What is technology?

Technology is defined as "a method of accomplishing a task especially using technical processes, methods, or knowledge" by the Merriam-Webster dictionary. “The application of scientific knowledge to the practical goals of human life or, as it is sometimes phrased, to the change and manipulation of the human environment” is another definition of Technology is both a process and a product at the same time. Technology is the tangible or intangible creations made by humans with their skills and knowledge as a product. Technology is the methodical application of knowledge to achieve practical goals.

The information source: Natural sciences like physics, chemistry, and biology, social sciences like psychology, sociology, and economics, and humanities like philosophy, art, and literature can all contribute to technology.

The degree of difficulty: Innovation can go from straightforward (like a stone device) to complex (like a PC).

The level of originality: Technology can be either incremental or radical, such as a new invention that alters the status quo or an improved version of an existing product.

The function and purpose: Technology can be either useful (like a nail-driving hammer) or expressive (like a painting that expresses feelings).

The effects and repercussions: Individuals, groups, organizations, societies, and ecosystems can all benefit or suffer from the effects of technology.

What are some emerging technologies?

In the coming years, some emerging technologies—whether new or existing—have the potential to alter the world. The following are some of the top ten emerging technologies for 2021, as identified by the World Economic Forum

Crops that self-fertilize: These are plants that are able to produce their own nitrogen fertilizer from the air. This makes it less necessary to use synthetic fertilizers, improves the health of the soil, and increases crop yields 1.

Drug manufacturing on demand: Utilizing digital blueprints and chemical reactors, this technology can produce customized drugs on demand, reducing waste, cost, and supply chain issues 1.

Diagnostics using breath sensors: Using non-invasive and portable devices, this technology can analyze the chemical composition of human breath to diagnose a variety of diseases, including COVID-19, diabetes, and cancer.

Built with 3D printing: Using robotic arms and nozzles that deposit layers of concrete, plastic, or other materials, this technology can build houses faster, for less money, and with less impact on the environment1.

These are just a few examples of the new technologies that are currently available. Energy technology, biotechnology, nanotechnology, space technology, and a variety of other emerging technologies are among the many others. You can learn more about these and other emerging technologies from a variety of websites, blogs, courses, podcasts, videos, books, and other sources.

What are some ethical issues related to emerging technologies?

Security and privacy: Personal and sensitive data, such as biometric, genetic, or behavioral data, can be collected, processed, and manipulated in large quantities by emerging technologies like artificial intelligence, biotechnology, or nanotechnology. This can put individuals' and groups' privacy, security, and sovereignty, as well as the stability of nations, in jeopardy. The technology behind facial recognition, for instance, can be utilized for discrimination, profiling, and surveillance. The technology of gene editing can be used to enhance, modify, or weaponize living organisms 2. It is possible to use nanotechnology for espionage, sabotage, or warfare 3.

Responsibility and accountability: Complex and autonomous systems that can act and interact with humans and other systems can be created by emerging technologies like artificial intelligence, biotechnology, or nanotechnology. This may prompt inquiries regarding the moral and legal status of these technologies as well as the accountability and responsibility of their creators, users, and

0 notes

Text

Construction Anchors Market Analysis by 2033 | Global Insight Services

Construction anchors are devices that are used to connect two or more elements of a structure together. There are many different types of construction anchors, each with its own advantages and disadvantages. The most common type of construction anchor is the bolt. Bolts are strong and can be used in a variety of applications, but they are not always the best choice for every situation. Other types of construction anchors include nails, screws, and adhesives.

View The Full Report Here – https://www.globalinsightservices.com/reports/construction-anchors-market/?utm_id=Pranalip

Key Trends

There are a few key trends in construction anchors technology that are worth mentioning.

Firstly, there has been a move towards using more environmentally friendly materials in construction anchors. This is in response to increased awareness of the impact of construction on the environment.

Secondly, there has been an increase in the use of innovative technologies such as 3D printing in construction anchors.

Finally, there has been a trend towards using more sustainable construction methods. This is in response to the increasing cost of traditional construction methods, as well as the negative impact that they can have on the environment.

Key Drivers

The key drivers of the construction anchors market are the growing construction industry, the increasing demand for construction anchors from the oil & gas industry, and the increasing infrastructural development.

The construction industry is growing at a rapid pace owing to the increasing population and urbanization. This is resulting in the increasing demand for construction anchors from the construction industry.

The oil & gas industry is also growing at a rapid pace owing to the increasing demand for oil & gas. This is resulting in the increasing demand for construction anchors from the oil & gas industry.

The infrastructural development is also increasing owing to the growing economy. This is resulting in the increasing demand for construction anchors from the infrastructural development sector.

Unlock Growth Potential in Your Industry – Get Your Sample Report Now –https://www.globalinsightservices.com/request-sample/GIS22599/?utm_id=Pranalip

Restraints & Challenges

There are a few key restraints and challenges in the construction anchors market.

Firstly, the raw materials used to manufacture construction anchors are often in short supply, which can lead to production delays and increased costs.

Secondly, the installation of construction anchors can be time-consuming and require specialized equipment, which can add to the overall cost of the project.

Finally, construction anchors are often used in high-stress applications, which can lead to premature failure if they are not installed correctly.

Market Segments

The construction anchors market is segmented by type, application, and region. By type, the market is classified into metal, chemical, and light-duty anchors. Based on application, it is bifurcated into building construction, civil engineering, and others. Region-wise, the market is segmented into North America, Europe, Asia Pacific, and the Rest of the World.

Key Players

The global construction anchors market includes players such as Stanley Black & Decker Inc, Hilti Corporation, Simpson Manufacturing Co Inc, EJOT Holding GmbH & Co. KG, Misumi Corporation, Ancon Limited, Fosroc Chemicals Private Limited, Unika Co. Ltd, Yuyao City Xintai Hardware Co. Ltd, Fixdex Fastening Technology, and others.

Buy Now@https://www.globalinsightservices.com/checkout/single_user/GIS22599/?utm_id=Pranalip

Research Scope

Scope – Highlights, Trends, Insights. Attractiveness, Forecast

Market Sizing – Product Type, End User, Offering Type, Technology, Region, Country, Others

Market Dynamics – Market Segmentation, Demand and Supply, Bargaining Power of Buyers and Sellers, Drivers, Restraints, Opportunities, Threat Analysis, Impact Analysis, Porters 5 Forces, Ansoff Analysis, Supply Chain

Business Framework – Case Studies, Regulatory Landscape, Pricing, Policies and Regulations, New Product Launches. M&As, Recent Developments

Competitive Landscape – Market Share Analysis, Market Leaders, Emerging Players, Vendor Benchmarking, Developmental Strategy Benchmarking, PESTLE Analysis, Value Chain Analysis

Company Profiles – Overview, Business Segments, Business Performance, Product Offering, Key Developmental Strategies, SWOT Analysis.

With Global Insight Services, you receive:

10-year forecast to help you make strategic decisions

In-depth segmentation which can be customized as per your requirements

Free consultation with lead analyst of the report

Infographic excel data pack, easy to analyze big data

Robust and transparent research methodology

Unmatched data quality and after sales service

Contact Us:

Global Insight Services LLC 16192, Coastal Highway, Lewes DE 19958 E-mail: [email protected] Phone: +1-833-761-1700 Website: https://www.globalinsightservices.com/

About Global Insight Services:

Global Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

0 notes

Text

A Guide to Bamboo Flooring