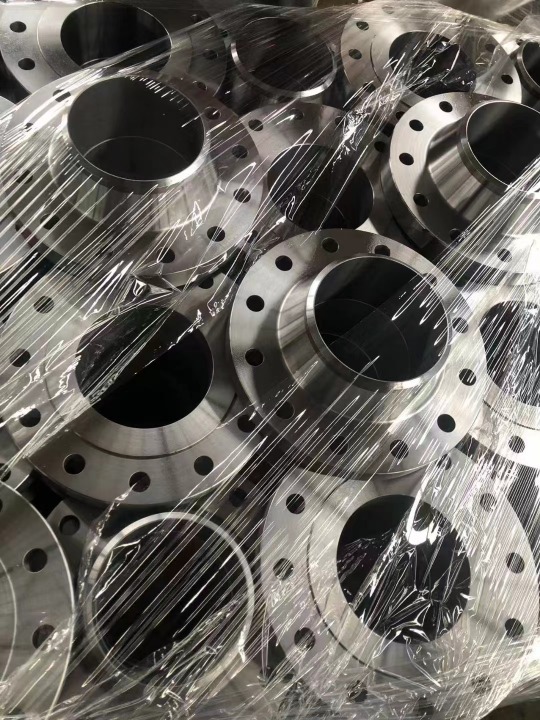

#Duplex 2205 Flanges

Text

Duplex Steel in the Energy Sector: Power Generation and Distribution

Duplex steel, known for its incredible strength and corrosion resistance, has gained a leading position in the power generation and distribution industry because of its corrosion-resistant, durable characteristics. At Jay Steel Corporation, we take pride in being the leading duplex steel products manufacturer, supplier, stockist, and exporter, offering a diverse range of solutions tailored to meet the unique requirements of projects across the globe.

In this blog post, we will delve into the significance of duplex steel in the energy sector, with a focus on power generation and distribution.

Duplex Steel: The Powerhouse Material

Duplex steel, particularly the widely used duplex 2205 grade, is renowned for its exceptional properties that make it ideal for the energy sector. Here are some key reasons why duplex steel is gaining prominence:

Corrosion Resistance:

Duplex steel is highly resistant to corrosion, a crucial feature when power generation and distribution equipment is often exposed to harsh environmental conditions. Whether it's offshore wind farms, chemical plants, or coastal power stations, duplex steel stands strong against the elements.

Strength and Durability:

Power generation processes involve immense mechanical stress. Duplex steel's high tensile strength and superior resistance to cracking make it an ideal choice for critical components such as turbines, heat exchangers, and pressure vessels. This robust material can withstand the intense pressure and temperature variations inherent in power generation, contributing to the longevity of these systems.

Thermal Resistance

The ability of duplex steel to withstand extreme temperatures makes it invaluable in power generation. Whether in traditional coal-fired plants or modern gas turbine facilities, duplex steel maintains its integrity in the face of severe thermal stress. This quality is especially vital in ensuring the safety and efficiency of power generation processes.

Cost-Efficiency:

With longer service life and reduced maintenance requirements, duplex steel provides a cost-effective solution in the long run. This makes it an attractive option for energy companies aiming to optimize their operations.

Duplex Steel in Power Generation

Heat Exchangers: Duplex Steel's corrosion resistance makes it an excellent choice for heat exchangers in power plants. These components are constantly exposed to high temperatures and aggressive fluids, making Duplex Steel a reliable material for extended service life.

Pipelines: Duplex Steel's durability is well-suited for the construction of pipelines that transport oil, gas, or chemicals. These pipelines often traverse challenging environments and require materials that can withstand harsh conditions.

Turbines: In the manufacturing of turbines for power generation, Duplex Steel's strength and resistance to fatigue and stress corrosion cracking make it an optimal choice. This extends the lifespan of turbines and reduces maintenance costs.

Duplex Steel in Power Distribution

Cable and Wire Protection: Power distribution networks involve a vast array of cables and wires that require protection against environmental factors. Duplex steel is often used for cable trays, conduit systems, and enclosures, providing excellent protection against rust and corrosion.

Substation Equipment: Electrical substations are crucial for power distribution, and many of their components are exposed to the elements. Duplex steel is utilized in the construction of substation enclosures, support structures, and busbars, ensuring longevity and reliability.

Transmission Towers: Duplex steel's strength and corrosion resistance make it an excellent choice for transmission towers that carry high-voltage power lines across long distances. These towers are exposed to extreme weather conditions, and duplex steel helps maintain their structural integrity.

Final Words

Duplex Steel plays a vital role in ensuring durability, efficiency, and cost-effectiveness in the energy industry, which is always changing. Jay Steel Corporation has emerged as a trusted global supplier, recognized for its unwavering commitment to quality and excellence. Whether you are looking for a Duplex 2205 Strips Sheet & Plate Supplier, Duplex 2205 wire mesh, round bars, strips, sheet & plates, tube & pipe, fittings, flanges, or fasteners, Jay Steel Corporation offers a comprehensive range of Duplex Steel products to meet the diverse needs of the energy industry. With our presence in countries like Thailand, Singapore, Malaysia, Germany, Russia, France, Nigeria, USA, Saudi Arabia, Kuwait, Qatar, Egypt, Turkey, Oman, Jordan, Bahrain, Russia, Germany, United Kingdom, and Italy, we continue to be the preferred choice for Duplex Steel materials, powering the energy sector into a sustainable and prosperous future.

0 notes

Text

DUPLEX STEEL & ENGINEERING -

Duplex steel and engg. Co. Pvt. Ltd is one of the leading manufacturer of Duplex Steel 2205, Super duplex 2507, pipe, Tube, sheet, plates, flanges, fasteners in India.

DUPLEX STEEL 2205 / UNS S31803PLATES / SHEETS / COIL

Request the latest Duplex Steel 2205 Plates / Sheets / Coil Price List. Please Call +91 98691 88888 or Send an Email to [email protected] for Duplex Steel UNS S31803, 1.4462 Pipe Plates / Sheets / Coil Ready stock information and updated price list.

https://www.unisteelsengg.com

#Duplex Steel 2205 Sheet#Super duplex 2507 Plate#Stainless Steel Pipe#SS Tubes#duplex 2205 pipe#duplex 2205 tube#316 Stainless steel Sheet#Inconel 200 Flanges#Monel 400 Tube Fittings#Nickel Alloy 20 Sheet#Titanium Grade 2 Round Bar#Hastelloy C22 Angle Bar Supplier#Alloy 20 Butt weld Fittings Dealer#Inconel 600 Flanges Exporter in India

2 notes

·

View notes

Text

Duplex S32205 Flanges

In the realm of industrial piping systems, Duplex S32205 flanges are integral components known for their robustness, corrosion resistance, and versatility. These flanges, crafted from a duplex stainless steel alloy, play a crucial role in ensuring secure connections and reliable performance across various industries. This blog delves into the features, applications, and benefits of Duplex S32205 flanges, highlighting their significance in modern engineering and construction projects.

Understanding Duplex S32205 Flanges

Duplex S32205, also known as UNS S32205 or Alloy 2205, is a duplex stainless steel alloy characterized by its dual-phase microstructure of ferrite and austenite. This composition provides Duplex S32205 flanges with superior mechanical properties and resistance to corrosion, making them ideal for demanding applications in aggressive environments.

Key Features of Duplex S32205 Flanges

Corrosion Resistance: Duplex S32205 flanges offer excellent resistance to corrosion, including stress corrosion cracking, pitting, and crevice corrosion. This makes them suitable for use in marine environments, chemical processing plants, and offshore oil and gas platforms.

High Strength: The duplex microstructure imparts high mechanical strength to S32205 flanges, enabling them to withstand high pressures and mechanical loads without deformation or failure. This strength is crucial for maintaining integrity in critical piping systems.

Versatility and Adaptability: These flanges are versatile and adaptable to various applications across industries such as oil and gas, chemical processing, marine, and power generation. They can withstand a wide range of temperatures and corrosive environments, ensuring reliable performance in diverse conditions.

Weldability: Duplex S32205 flanges exhibit good weldability, allowing for ease of fabrication and installation. Proper welding practices ensure the retention of corrosion resistance and mechanical properties during assembly.

Cost-Effectiveness: Despite their superior properties, Duplex S32205 flanges offer a cost-effective solution compared to other high-performance alloys. They provide a balance of performance and affordability in critical industrial applications.

Applications of Duplex S32205 Flanges

Duplex S32205 flanges find widespread use in various industrial sectors for critical applications:

Oil and Gas Industry: Used in pipelines, subsea equipment, and offshore platforms due to their corrosion resistance and strength.

Chemical Processing: Ideal for reactors, storage tanks, and process equipment handling corrosive chemicals and acids.

Marine and Shipbuilding: Employed in ship hulls, desalination plants, and seawater handling equipment for their resistance to chloride corrosion.

Power Generation: Utilized in turbine components, boilers, and heat exchangers where high temperature and pressure resistance are required.

Benefits of Using Duplex S32205 Flanges

Reliability: These flanges ensure reliable performance in critical applications, contributing to operational efficiency and safety.

Durability: Duplex S32205 flanges are known for their durability and longevity, requiring minimal maintenance over their service life.

Environmental Sustainability: The recyclability and sustainability of Duplex S32205 support eco-friendly practices in industrial manufacturing and construction.

Conclusion

Duplex S32205 flanges exemplify strength, corrosion resistance, and versatility, making them indispensable in modern industrial applications. Their ability to withstand harsh environments while maintaining structural integrity ensures optimal performance and longevity in critical infrastructure projects. By understanding their features, applications, and benefits, industries can leverage Duplex S32205 flanges to enhance the efficiency, reliability, and sustainability of their operations.

0 notes

Text

Fully automatic flange CNC lathe

45 years of professional pipe fittings and flange manufacturers and suppliers

Duplex steel S3225 A815 WPS32205

1 note

·

View note

Text

Monel K500 Blind Flanges Exporters

Monel Blind Flanges are manufactured without a bore and used to blank off the ends of piping, Valves and pressure vessel openings. From the standpoint of internal pressure and bolt loading, blind flanges, particularly in the larger sizes, are the most highly stressed flange types. A Blind flange is round plate which has all of the relevant boltholes but no center hole, and because of this feature this flange is used to close off the ends of a piping systems and pressure vessel openings. It also permits easy access to the interior of a line or vessel once it has been sealed and must be reopened.

However, most of these stresses are bending types near the center, and since there is no standard inside diameter, these flanges are suitable for higher pressure temperature applications.

Monel Blind Flanges are used for testing the flow of gas or liquid through a pipeline or vessel. It helps to close the end of piping systems or vessel openings. It allows easy access to the pipeline when there is a requirement to work done inside the line. They are used in high pressure applications available in all grades, materials, size and specifications. Blind pipe flanges are typically provided with a raised face, flat face, or RTJ facing. When a raised face is necessary for blind pipe flanges, the standard height is 1/16" for blind pipe flanges under 400 ( 2.4360)#. For blind pipe flanges of 400 ( 2.4360)# and up, the standard blind pipe flange raised face height is 1/4".

B16.5 ASTM A182 Blind Flange, Fusion Bonded Epoxy Coating, EN 1092-2 PN16 Blind Flange, ASME B16.5 Dual Monel Alloy Blind Flange, ANSI B16.5 Class 150 Flat Face Blind Flange, Monel Alloy Reducing Blind Flange Stockiest.

Standards Specification:

Size : 1/2" to 48"

Specifications : ASTM A182

Rating: 150#, 300#, 600 (2.4640)#, 900#, 1500#, 2500#,

Material & Grade :

Stainless Steel :Grade: 304 (1.4301), 304L (1.4307), 304H (1.4948), 309 (1.4828), 309S, 310, 310S (1.4845) , 316 ( 1.4401), 316H, 316L( 1.4404 /1.4432) , 317, 317L (1.4438), 321 (1.4541), 321 H(1.4878), 347 (1.4550), 347H (1.4961), 904L (1.4539)

Duplex Steel:Grade: 2205 (1.4507)

Super Duplex Steel:Grade: 2507 (UNS S32750) (1.4410) (UNS S32750)

Inconel :Grade: Inconel 600 (2.4640), Inconel 601 (2.4851), Inconel 625 (2.4856), Inconel 718(2.4668)

Incoloy :Grade: Incoloy 800 (2.4958), Incoloy 800H, Incoloy 800HT

Nickel :Grade: Nickel 200, Nickel 201

Titanium :Grade: Gr.1 (3.7025) , Gr.2 (3.7035) , Gr.3:(3.7055) , Gr.5(3.7164/65), Gr. 7(3.7235) , Gr. 11 (3.7225)

Hastalloy :Grade: Hastalloy B2, Hastalloy B3, Hastalloy C22, Hastalloy C276, Hastalloy X.

For More Information

Visit Our Website - http://www.kobsindia.in/monel-blind-flange.html

Contact Us -9819523999

Email Id - [email protected]

4 notes

·

View notes

Text

What are the different grades of SS (stainless) pipes & tubes? How do they differ in terms of properties such as tensile strength and hardness?

Different Grades of Stainless Steel Pipes and Tubes

Stainless steel (SS) is a versatile material known for its corrosion resistance and durability. It's widely used in various industries, including construction, manufacturing, and food processing. The different grades of SS pipes and tubes are categorized based on their chemical composition, which affects their properties like tensile strength, hardness, and corrosion resistance.

Common Grades and Their Properties

Austenitic Stainless Steel: Grades: 304, 316, 316L, 309, 310 Properties: Excellent formability, good weldability, high corrosion resistance, moderate strength. Applications: Food processing, chemical processing, architectural applications.

Ferritic Stainless Steel: Grades: 430, 440A, 440C Properties: Good corrosion resistance, moderate strength, magnetic. Applications: Automotive components, cutlery, surgical instruments.

Martensitic Stainless Steel: Grades: 410, 420, 440A, 440C Properties: High hardness and strength, good wear resistance, magnetic. Applications: Cutlery, surgical instruments, bearings.

Duplex Stainless Steel: Grades: 2205, 2209Properties: Excellent corrosion resistance, high strength, good weldability. Applications: Oil and gas industry, marine applications, chemical processing.

0 notes

Text

What Makes Super Duplex Flanges Stand Out?

Because of their extraordinary blend of strength and resistance to corrosion, Super Duplex flanges, especially those collected of alloys like Super Duplex 2507, stand out. Chemical processing facilities, offshore oil & gas platforms, and maritime requests can all advantage greatly from these flanges' aptitude to endure extremely corrosive circumstances, such as high temperatures and chloride concentrations. When it comes to dependability in harsh circumstances, Super Duplex flanges provide better mechanical qualities than conventional duplex stainless steels. For crucial piping systems where dependability and safety are crucial, their extended integrity preservation lowers maintenance expenses, making them the material of choice.

Summary of Flanges and Fittings for Duplex and Super Duplex Systems

Due to its durability and conflict to corrosion, Duplex 2205 fittings and super duplex pipe fittings manufacturers are vital parts of industrial plumbing systems. These fittings are produced under strict rules by specialized Indian businesses, assuring dependability in difficult circumstances.

Strength and Versatility of Duplex Flanges

Duplex flanges are well known for their power and adaptability. This includes Duplex 2205 flanges. They are widely used in desalination facilities and offshore oil rigs, among other industries that demand resistance to stress corrosion cracking and pitting. Indian producers are excellent at creating these flanges to precise measurements, guaranteeing that they satisfy the rigorous requirements of contemporary industrial operations.

Super Duplex Flanges: Outstanding Results in Tough Conditions

Super Duplex flanges, such Super Duplex 2507 flanges, have better mechanical strength and corrosion resistance than regular duplex alloys. They do best in situations that include a lot of chloride and strong chemicals. India is home to producers who specialize in precisely constructing these flanges for industries where sturdiness and reliability are critical.

High-Temperature Uses for Inconel 625 Pipe Fittings

Because of its strange resistance to oxidation and high temperatures, Inconel 625 pipe fittings are the preferred optimal. Chemical processing, aerospace, and marine engineering are between the industries that use them. The aptitude of Indian producers of Inconel pipe fittings to generate fittings that purpose well and endure harsh environments without cooperating structural integrity is well-known.

Selecting the Correct Vendor: Skill and Knowledge

Quality certifications, manufacture experience, and conformism to international standards are important considerations when selecting dealers for Inconel 625 pipefittings, Duplex 2205 fittings, Super Duplex pipe fittings, and Duplex flanges. Indian creators are distinguished by their devotion to providing goods that content international industrial standards, all the while maintaining modest prices and reliable customer service.

Innovation and a commitment to excellence are driving the ongoing development of the Duplex and Super Duplex fittings and flanges as well as inconel pipe fittings manufacturers in india. Even if you need Inconel 625, Super Duplex 2507, or Duplex 2205 fittings and flanges, Indian sellers offer a complete choice of options designed to tackle the most problematic problems in a variety of global sectors. Customers are certain to obtain goods that not only meet but also surpass prospects for performance, durability, and dependability because to their unwavering commitment to practical advancement.

0 notes

Text

Ultimate hints for excessive-performance composites

If you're looking for top-notch alloy products, Siddhagiri Metals and Tubes has been given you protection. With such a lot of products to be had, in addition to SS 304 tube fittings, Inconel 625 round bars, hastelloy c276 plate, and more, this newsletter may be your go-to useful resource for finding statistics and choosing a product that works nicely approximately. It's a totally effective combination of substances to fit your needs.

Inconel 625 flanges are designed to provide a watertight and durable connection underneath hot temperature rise and corrosive situations. Siddhagiri Metals and Tube gives a choice of Inconel 625 flanges designed to fulfil enterprise needs and specifications.

Hastelloy C276 tube fittings from Siddhagiri Metals and Tubes provide super resistance to pitting, crevice corrosion, and strain corrosion cracking, making them best for important packages in medicine, sewage remedy, and different fields.

Duplex 2205 is a low-rate, bendy duplex stainless steel that is evidence of corrosion in hundreds of conditions.Siddhagiri Metals and Tubes offers a complete line of Duplex 2205 Tube Fittings designed for excessive overall performance and long-term reliability.

Super Duplex 2507 tube fittings are recognized for their robust tensile energy and advanced corrosion resistance below excessive situations. Siddhagiri Metals and Tubes offers a huge variety of Super Duplex 2507 Tube Fittings for bundle necessities in oil and gas, chemical production, and plenty of other industries. Copper-nickel filters are acknowledged for their excessive resistance to saltwater corrosion and fouling, making them an excessive first-class desire for marine and offshore applications. Siddhagiri Metals and Tubes gives fantastic copper-nickel tube fittings which can withstand harsh marine situations.

Selecting the Right High-Performance Alloy Products Selecting precise, high-standard performance alloy products is critical to the success and persistence of your packages.When combining materials such as titanium grade 2 round bar, Monel 400 plate, and chrome steel 304 pipe, the following factors must be kept in mind: Corrosion Resistance All of the above high-performance alloys boast extremely high corrosion resistance properties. do, ensuring overall reliable performance. bad environment Whether you need Inconel 625 Round Bar or Hastelloy C276 flanges, you should not forget that Siddhagiri alloys and tubes offer the trade-off with advanced corrosion resistance.

Mechanical Strength From Monel four hundred spherical bars to Duplex 2205 tube fittings, the mechanical strength of high-normal overall performance alloy merchandise is a key consideration. Siddhagiri Metals and Tubes ensures that all products meet stringent mechanical strength requirements, presenting the sturdiness and reliability wanted for numerous business programmes.

High-performance alloys are engineered to go through excessive temperatures and demanding thermal situations. When deciding on items that include Inconel 625 tube fittings or Super Duplex 2507 tube fittings, it's crucial to test their temperature resistance tendencies to assure maximum typical overall performance in high-temperature applications.

Each excessive-standard overall performance alloy product is designed to fulfil precise commercial enterprise requirements and necessities. Whether you want Hastelloy C276 tube fittings or Titanium Grade 2 plate, Siddhagiri Metals and Tubes assures that each product meets relevant industry necessities, ensuring compatibility and conformity with requirements.

Siddhagiri Metals and Tubes is a reliable and appeared company of high-ordinary overall performance alloy items at the side of Inconel 625 plate, Stainless Steel 304 spherical bar, Hastelloy C276 plate, and masses more. Siddhagiri Metals and Tubes is your one-prevent save for immoderate-performance alloy solutions, emphasising fantastic, dependability, and adherence to business enterprise standards. Siddhagiri Metals and Tubes no longer gives anything short of excellence in excessive-overall performance alloy products.

0 notes

Text

Platinex Piping Solutions has you covered with our top-notch 2205 duplex flanges!

These bad boys are built with superior corrosion resistance, especially for areas with high chloride content like:

Seawater applications

Desalination plants

Chemical processing plants

Here's what makes our 2205 duplex flanges the ultimate choice:

Superior strength & toughness compared to regular stainless steel flanges thanks to chromium, molybdenum, nickel, and nitrogen.

Excellent mechanical properties to handle demanding situations.

Weldability for seamless integration into your piping system.

Don't settle for less! Get a quote for your 2205 duplex flange needs today and experience the Platinex Piping Solutions difference!

www.platinexpiping.com

#platinexpipingsolutions#2205duplexflanges#corrosionresistantflanges#highperformanceflanges#chemicalprocessing#seawaterapplications#desalination#pipingsolutions#industrialpiping

#platinexpipingsolutions#2205duplexflanges#corrosionresistantflanges#highperformanceflanges#chemicalprocessing#seawaterapplications#desalination#pipingsolutions#industrialpiping

0 notes

Text

Stainless Steel Round Bar Manufacturer

Arisa Impex is a Stainless Steel Round Bar Manufacturer in Ahmedabad.

Arisa Impex is a Manufacturer, Exporter, and Supplier of Stainless Steel Products like Stainless Steel Round bar, Wire, Rods, Sheets, Coils, Pipe, Flat Bar, Square Bar, Hexagonal Bar, Angle, Flanges, and Alloy Steel.

Our headquartered in Ahmedabad, Gujarat, India.

We design all our manufactured products, such as stainless steel round bars, according to specified dimensions and desired lengths.

Each product undergoes meticulous manufacturing, testing, and inspection by our expert team to ensure high quality throughout the process.

Stainless Steel Round Bars are essential products crafted from stainless steel materials, known for their strength and corrosion resistance. They come in various grades suited for diverse industries.

Our manufacturing includes round bars made from ferritic, austenitic, and martensitic stainless steel, meeting AISI standards such as 202,303, 304, 304L, 310, 316, 316L, 316Ti, 321, 403, 409, 410, 416, 420, 430, 430F, 430LBN, 431, and 904, as well as duplex grade 2205.

Our company oversees all stages of production, ensuring adherence to proper methods and standards for quality assurance.

Application:

Motor Pump

Marine

Chemical Industries

Food Processing

Construction industries

Arisa Impex is a Stainless Steel Round Bar Manufacturer in Ahmedabad and Supplier of SS Round Bars across India including locations like Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chandigarh, Chhattisgarh, Dadra and Nagar Haveli and Daman and Diu, Delhi, Goa, Gujarat, Haryana, Himachal Pradesh, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Ladakh, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Nagaland, Odisha, Puducherry, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, West Bengal.

For more information about our product catalog, please feel free to reach out to us through the provided contact details.

View Product: Click here

Read the full article

0 notes

Text

Duplex Steel S32205 Flanges Manufacturers in India

Introduction

Duplex Steel S32205, often referred to as Duplex 2205, is a popular duplex stainless steel known for its excellent combination of strength and corrosion resistance. One of the key applications of this alloy is in the manufacture of flanges, which are essential components in piping systems. In this blog, we will delve into the various aspects of Duplex Steel S32205 flanges, including their properties, specifications, advantages, major industry uses, and conclude with a summary of their importance.

Overview

Duplex Steel S32205 flanges are widely used in industries that require reliable and durable connections in piping systems. These flanges are composed of a balanced mixture of austenitic and ferritic stainless steels, which imparts them with high mechanical strength and outstanding resistance to stress corrosion cracking, pitting, and crevice corrosion. The typical composition of Duplex S32205 includes approximately 22% chromium, 5% nickel, and 3% molybdenum, along with nitrogen and other alloying elements.

Specifications

The specifications for Duplex Steel S32205 flanges are as follows:

Grade: Duplex S32205

UNS Number: S32205

Equivalent Standards: ASTM A182, ASTM A240, ASTM A789

Form: Flanges

Size Range: ½” to 24” (nominal bore size)

Pressure Ratings: Class 150 to Class 2500

Types: Weld Neck Flange, Slip-On Flange, Blind Flange, Socket Weld Flange, Threaded Flange, Lap Joint Flange

Dimensions: ANSI/ASME B16.5, ANSI/ASME B16.47, MSS SP-44, API 605, AWWA C207

Corrosion Resistance: Excellent resistance to stress corrosion cracking, pitting, and crevice corrosion

Temperature Range: Suitable for applications ranging from -50°C to 300°C (-58°F to 572°F)

Advantages

High Strength: Duplex S32205 flanges offer higher strength compared to conventional austenitic stainless steels, allowing for lighter and more cost-effective designs.

Corrosion Resistance: The excellent resistance to a wide range of corrosive environments makes these flanges suitable for harsh conditions, including chloride-containing environments.

Cost-Effective: Due to their high strength, Duplex S32205 flanges often require less material, resulting in cost savings.

Improved Toughness: These flanges exhibit superior toughness and ductility compared to ferritic stainless steels.

Long Service Life: The combination of strength and corrosion resistance ensures a longer service life, reducing maintenance costs and downtime.

Major Industry Uses

Oil and Gas Industry: Used extensively in offshore and onshore applications due to their resistance to chloride-induced stress corrosion cracking and high mechanical strength.

Chemical Processing: Ideal for handling aggressive chemicals, acids, and other corrosive substances.

Marine Applications: Excellent for use in seawater environments where high corrosion resistance is crucial.

Petrochemical Industry: Suitable for pipelines and process equipment that handle hydrocarbons and other chemicals.

Power Generation: Used in cooling water systems, flue gas desulfurization units, and other power plant components.

Pulp and Paper Industry: Employed in bleaching and digesting processes due to their resistance to harsh chemicals.

Conclusion

Duplex Steel S32205 flanges are an excellent choice for industries requiring high-strength, corrosion-resistant, and cost-effective piping components. Their balanced composition and superior properties make them suitable for a wide range of applications, ensuring reliable performance in even the most demanding environments. By choosing Duplex S32205 flanges, industries can achieve enhanced durability, reduced maintenance costs, and improved overall efficiency in their operations.

0 notes

Text

Difference between duplex and super duplex stainless steel

The terms "duplex" and "super duplex" are frequently heard when it comes to stainless steel, but what exactly do they mean? Jay Steel Corporation, as a leading duplex and super duplex stainless steel materials manufacturer, supplier, stockist, and exporter in India, is here to shed light on the differences between these two exceptional alloys. We offer an extensive range of products, including super duplex 2507 strips, sheets & plates, duplex 2205 strips, sheets & plates, super duplex 2207 flanges, duplex 2205 round bars, as well as wire mesh, fittings, and fasteners to cater to your diverse project requirements. Furthermore, our commitment to quality and affordability extends to various countries worldwide, making us a trusted name in the global market. If you're in search of a reliable Super Duplex 2507 strips, sheet & plate supplier, Duplex 2205 strips, sheet & plate manufacturer, or any other product among them, you've come to the right place!

In this blog post, we will delve into the difference between duplex and super duplex stainless steel, shedding light on their unique characteristics and applications.

Duplex Stainless Steel

Duplex stainless steel, represented by grades like 2205, is a remarkable material known for its balanced combination of properties from both austenitic and ferritic stainless steel. This alloy contains a significant amount of chromium, which enhances its corrosion resistance, and it also features molybdenum and nitrogen for added strength and durability. Here's a closer look at the key characteristics of duplex stainless steel:

Corrosion Resistance: Duplex stainless steel provides excellent resistance to corrosion, making it suitable for various industrial applications, including chemical processing, water treatment, and offshore oil platforms.

Strength and Toughness: Duplex steel is characterized by high tensile strength and exceptional toughness, allowing it to withstand extreme temperatures and mechanical stress.

Cost-Effective: Its balanced composition and competitive pricing make duplex stainless steel a cost-effective choice for many projects.

Super Duplex Stainless Steel

Super duplex stainless steel, such as grade 2507, takes the attributes of duplex steel to the next level. It offers even higher levels of corrosion resistance and strength, making it ideal for the most demanding applications. Let's explore the unique features of super duplex stainless steel:

Enhanced Corrosion Resistance: Super duplex steel contains higher levels of chromium, molybdenum, and nitrogen, which grant it outstanding resistance to aggressive environments, including those with high chloride content.

Strength and Durability: With a higher alloy content, super duplex steel excels in both mechanical strength and resistance to pitting and crevice corrosion.

Applications: Super duplex stainless steel is used in industries where standard duplex or austenitic stainless steels may fall short. It is found in offshore structures, desalination plants, and chemical processing units.

Comparing Duplex and Super Duplex Stainless Steel

Composition: The primary difference lies in the alloying elements. Super duplex stainless steel contains a higher proportion of chromium, molybdenum, and nitrogen, which contributes to its exceptional corrosion resistance.

Corrosion Resistance: While duplex stainless steel provides good corrosion resistance, super duplex stainless steel excels in hostile environments, making it suitable for more demanding applications.

Strength: Super duplex stainless steel generally has a higher tensile strength and is better equipped to withstand extreme conditions.

Cost: Super duplex stainless steel is typically more expensive than its duplex counterpart due to its superior properties and alloy composition.

Final Words!

The main difference between duplex and super duplex stainless steel lies in their composition and performance characteristics. Duplex stainless steel offers an excellent balance of properties, while super duplex stainless steel elevates those properties to meet the most demanding requirements. Regardless of your project's specific needs, Jay Steel Corporation stands as a reliable source for top-notch materials, ensuring that you can find the perfect stainless steel solution for your applications. Moreover, our commitment to competitive pricing and premium quality ensures that we are the top choice for businesses in Singapore, Malaysia, Nigeria, Thailand, USA, France, Saudi Arabia, Kuwait, Qatar, Egypt, Turkey, Oman, Jordan, Bahrain, Russia, Germany, the United Kingdom, and Italy at the most reasonable in the market!

#super duplex stainless steel#duplex stainless steel#Duplex 2205 Round Bar#Super Duplex 2507 Strips#Sheet & Plate#Duplex 2205 Strips#Duplex 2205 Flanges#Super Duplex 2507 Fasteners

0 notes

Text

Stainless Steel Pipes in Rajasthan

Meghmani Metal Industries is a Manufaturer and Supplier of Stainless Steel Pipes in Rajasthan, India.

Founded in 2011, Meghmani Metal Industries has steadfastly placed emphasis on customer satisfaction and environmental responsibility across all facets of its operations.

Our comprehensive range includes stainless steel plates, coils, bars, pipes, tubes, flanges, valves, fittings, fasteners, channels, and flats.

Stainless Steel Pipes are hollow tubes made primarily from stainless steel, an alloy composed mainly of iron and varying amounts of chromium.

We craft our stainless steel pipes from various grades including Austenitic (e.g., 304, 316), which offer strong corrosion resistance and are non-magnetic; Ferritic (e.g., 409, 430), which are magnetic and durable; and Duplex (e.g., 2205, 2507).

Stainless steel pipes earn renown for their resistance to corrosion, making them suitable for use in aggressive environments where exposure to moisture, chemicals, or salt is common.

They exhibit excellent mechanical properties, including high tensile strength and toughness, which ensure long-term durability and reliability even under extreme conditions.

Stainless steel pipes are easy to clean and sanitize due to their smooth, non-porous surface. This makes them ideal for applications where cleanliness and hygiene are critical.

Stainless steel pipes maintain their strength and integrity at both high and low temperatures, making them suitable for applications ranging from cryogenic conditions to high-temperature industrial processes.

Meghmani Metal Industries is a Manufaturer and Supplier of Stainless Steel Pipes in Rajasthan and places like Ajmer, Alwar, Amer, Barmer, Beawar, Bharatpur, Bhilwara, Bikaner, Bundi, Chittaurgarh, Churu, Dhaulpur, Dungarpur, Ganganagar, Hanumangarh, Jaipur, Jaisalmer, Jalor, Jhalawar, Jhunjhunu, Jodhpur, Kishangarh, Kota, Merta, Nagaur, Nathdwara, Pali, Phalodi, Pushkar, Sawai Madhopur.

Feel free to reach out for further details and inquiries. We're here to assist you.

Read the full article

0 notes

Text

A Comprehensive Guide to Indian Manufacturers of Stainless Steel Pipe Fittings

India has soon become a key source of manufacture, aiding the demands of the global world in outshining stainless steel pipe fittings. Indian producers are known for the high evaluation of their products and low prices, making it possible to compete with other industries worldwide. In this exhaustive article, we will discuss the situation of stainless steel pipe fitting manufacturers in India.

Wide Range of Product Offerings

Stainless steel pipe fitting manufacturers in India attend to a myriad of varying requirements of the industrial sectors through the variety of products that they supply. Indian manufacturers specialize not only in simple things like elbows, tees, and couplings but also in specified goods like duplex tube fittings, nickel super alloy pipe fittings, and Hastelloy C-276 pipe fittings at their disposal, which are their products in various materials and grades.

India turns out fittings from Stainless Steel 304 and Stainless Steel 316 widely. Such offerings feature a long lifespan and excellent corrosion resistance, resulting in diverse applications.

Duplex 2205 fittings and super duplex pipe fittings is also produced by Indian manufacturers which maintains the high strength and corrosion resistance for the industries that require this.

Competitive Pricing and Cost Advantage

The other major advantage and factor that is a source of passion for Indians is the lower cost of production in India compared to the international ones. Via cheaper labor benefits, more efficient production methods, and a good business environment, stainless steel pipe fittings manufacturers in India can now sell high-quality fittings at a low price compared with manufacturers from other countries.

This cost efficiency has actually been the major magnet for buyers who are after reduced sourcing costs while maintaining quality. Indian producers of the products offer lower prices and are also able to provide customised solutions to meet the specific patient’s requirements.

Strong Manufacturing Infrastructure and Skilled Workforce

India has a vibrant manufacturing industry and a workforce that is known for its expertise, which has greatly contributed to the current size that the stainless steel pipe fittings market is today. Ukraine's economy is serviced by a high level-developed network consisting of metal foundries, forging units, and machining plants that allow producing fittings cost-efficiently.

Although stainless steel pipe fittings manufacturers in India have the disadvantage of high wages compared to the cheaper labor in China and Brazil, they are well-versed in a large number of highly skilled professionals with the necessary experience and knowledge to enable them to create high-quality fittings. By this competent staff and modern manufacturing technologies, Indian producers can now offer products that are not only of high quality but also meet standards laid down by countries in the global sphere and satisfy their clients.

Conclusion

With a steady inflow of orders from stainless steel flange manufacturers in India, exporters have become a sought-after yet inexpensive supply source in the world market. Stainless steel flanges manufacturers in India are increasingly assured of the ability to reach the level of growing requirements in the global market with the growing number of world companies. It can not be emphasized enough that the most important thing when shopping for stainless steel pipe fittings, including water connection fittings and water and gas pipes, is choosing a reliable manufacturer of such products as KK Fittings.

0 notes

Text

Calico Metal Alloys LLP is one of the main Manufacturers, Suppliers and Exporters of top notch Duplex 2205, UNS S31803, UNS S32205, UNS S32750, UNS S32760, Duplex 2202, Duplex 2304 pipe, Tube, sheet, plates, Coil, Shim Sheet flanges, fasteners in India at low price.

#ASTM A312 TP 304/304H Stainless Steel#Titanium Grade 1 Pipes & Tubes#Nickel Alloy 200/201#Aluminium Alloy 2014#Copper and Brass Alloys#Duplex Steel 2205#Titanium Alloys#Cobalt Alloys#Silver and Gold Brazing Alloys supplier from Mumbai#India.

0 notes

Text

Pipe Tee | Platinex Piping

About Pipe Tee

Stainless steel pipe tee, carbon steel tees and special grade tees are widely supplied by us to many industries such as power generation, petro chemical, shipbuilding, paper Manufacturing, chemical, pharmaceutical, and fabrication.

When the size of the branch is same as header pipes, equal tee is used and when the branch size is less than that of header size, reduced tee is used. The three sizes of a tee are End x End x Center. So if you want a tee that is 1’’ on both ends and 3/4’’ in the center it would be 1’’ x 1’’ x 3/4’’.

Depending on our customer requirements, we can manufacture and offer straight tees and reducing tees in various grades including 202, 304/304L, 904L, 316/316L, Duplex 2205, Alloy 20, Cupro Nickel, Monel Alloy 400, Inconel Alloy 625, Inconel Alloy 600, Hastelloy Alloy C276, and also in various Aluminium Grades.

The ends may be machined for butt welding, threaded (usually female), or socketed, etc. When the two ends differ in size, the fitting is called a reducing elbow or reducer elbow.

0 notes