#Aluminium Gravity Die Casting

Text

Aluminium Actuator Housing, Manufacturer, Supplier, Sangli, India

We are Manufacturer, Supplier, Exporter of Aluminium Actuator Housing, Aluminium Casting For Electrical Products from Sangli, Maharashtra, India.

Aluminium Actuator Housing, Aluminium Casting For Electrical Products, Aluminium Gravity Die Castings, Machined Components, Gravity Die Casting, Aluminium Gravity Die Casting, Aluminium Casting, Pressure Die Casting, Aluminium Pressure Die Casting, Manufacturer, Supplier, Exporter, Sangli, Asia, Mumbai, Thane, Navi Mumbai, Pune, Nashik, Aurangabad, Ratnagiri, Nagpur, Ahmednagar, Akola, Amravati, Chandrapur, Dhule, Jalgaon, Raigad, Satara, Belgaum, Kolhapur, Belgaon, Maharashtra, India.

#Aluminium Actuator Housing#Aluminium Casting For Electrical Products#Aluminium Gravity Die Castings#Machined Components#Gravity Die Casting#Aluminium Gravity Die Casting#Aluminium Casting#Pressure Die Casting

0 notes

Text

CNC Machining and Milling manufacturer copmany in Rajkot, Gujarat, India

Briva Enterprises in India is situated in Rajkot, Gujarat. The foundation year of this organization is 2018 and its business manages CNC Machines, its machine devices as well as robotization. It gives the best cnc plasma reducing machine cost in India. The area it has a place with is private. This organization has a ton of involvement throughout the long term and has succeeded around here of assembling CNC across numerous countries all over the planet. The branch in India like some other branch has gotten a high level in the main CNC organizations in India and this organization has acquired a great deal of prevalence on the planet market.

#aluminium gravity die casting industry in rajkot#gujarat#india#cnc turning#cnc machining#cncmachiningmillingmanufacturing#india.#manufacturer#cncmachiningandmilling

0 notes

Text

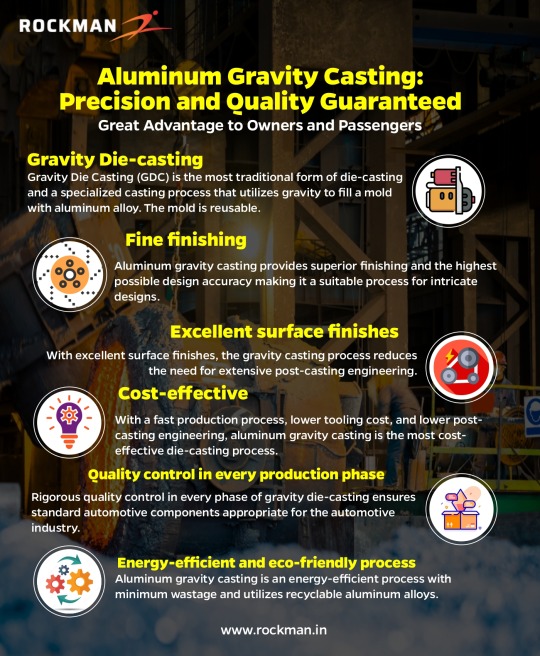

Aluminum Gravity Casting: Precision and Quality Guaranteed

Gravity Die-casting

Gravity Die Casting (GDC) is the most traditional form of die-casting and a specialized casting process that utilizes gravity to fill a mold with aluminum alloy. The mold is reusable.

Advantages of aluminum gravity casting

Fine finishing

Aluminum gravity casting provides superior finishing and the highest possible design accuracy making it a suitable process for intricate designs.

Excellent surface finishes

With excellent surface finishes, the gravity casting process reduces the need for extensive post-casting engineering.

Cost-effective

With a fast production process, lower tooling cost, and lower post-casting engineering, aluminum gravity casting is the most cost-effective die-casting process.

Quality control in every production phase

Rigorous quality control in every phase of gravity die-casting ensures standard automotive components appropriate for the automotive industry.

Energy-efficient and eco-friendly process

Aluminum gravity casting is an energy-efficient process with minimum wastage and utilizes recyclable aluminum alloys.

For more information on gravity casting and aluminum die-casting visit: https://www.rockman.in/

#Aluminum gravity casting#Alloy wheels for passenger cars#Aluminium die casting#die casting parts#High Pressure Die Casting suppliers in india#Aluminium casting#Aluminium Die cast#Aluminium die casting parts suppliers in india

0 notes

Link

1 note

·

View note

Text

2023 Honda CBR650R

Model updates: Honda’s versatile middleweight sports bike was the best-selling sports bike in Europe in 2021. It continues to carve out a strong following thanks to its unmistakeable CBR look and rich specification including 41mm Showa Separate Function Big Piston USD forks, high-revving four-cylinder engine, HSTC, assist/slipper clutch, under seat USB Type-C socket and LCD display. For 23YM, visual updates further heighten the appeal.

- Introduction

Honda’s fully faired CBR650F, launched in 2014 alongside the naked CB650F, provided a healthy slice of four-cylinder middleweight performance, very much at the sporty end of the ‘sports touring’ spectrum. Five years later, the CBR650F became the CBR650R, the upgrade from ‘F’ to ‘R’ indicating an even more potent shot of sporty ability designed to be explored, used and enjoyed on the street.

In the process of its transformation the CBR650R became, deliberately, a rare breed: a four-cylinder sports bike that provides similar pleasure, enjoyment and adrenaline to an RR machine, yet with enough practicality – and sensible running costs – to make it a viable option as day-to-day transport in addition to weekend fun.

It’s a direction that’s been well received. In 2021, the CBR650R was the best-selling sports bike in Europe. The 21YM version continued the development curve with user-driven detail improvements and a major upgrade for the front suspension.

For 23YM the CBR650R gains aesthetic updates to both colour options that further enhance its road presence and desirability.

- Model Overview

The CB650R received a significant refresh for 21YM. The major news was application of 41mm Showa Separate Function Big Piston (SSF-BP) USD forks – high quality suspension that really elevates the bike’s handling ability.

EURO5 compliance for the engine was achieved with no loss of top end power; other detail improvements included improved visibility for the LCD display and USB Type-C charging socket under the seat. The headlight reflectors, side panels and rear mudguard were all also updated.

The 23YM CBR650R will be available in two colour options:

Mat Gunpowder Black Metallic with new black engine and cam covers, blue highlights and red shock spring

Grand Prix Red with new black engine and cam covers, black belly pan and front mudguard and red Honda logo and shock spring

- Key Features

3.1 Chassis

- 41mm Showa Separate Function Big Piston (SFF-BP) USD forks

- Four-piston, radial-mount front brake calipers and floating discs

- 120/70-ZR17 and 180/55-ZR17 front and rear tyres

The steel diamond frame uses pressed swingarm pivot plates and twin elliptical spars with a rigidity balance specifically tuned (stiffer around the headstock and more flexible in the spar sections) to deliver balanced handling characteristics, with high levels of rider feedback. Rake is set at 25.5° with trail of 101mm and wheelbase of 1,450mm. Kerb weight is 208kg.

Showa’s 41mm Separate Function Big Piston (SFF-BP) USD forks offer high-quality reaction. A pressure separation damper in one fork tube and spring mechanism in the other deliver high damping performance and lighter weight. Together with the use of a larger sized piston the result is increased feel, bump absorption and control. Adjustable for 10-stage spring preload, the single-tube monoshock (with its spring now finished in red) operates directly on the curvaceous gravity die-cast aluminium swingarm.

Four-piston radial-mount front brake calipers work 310mm wave-pattern floating discs, and are paired with a single-piston rear caliper and 240mm disc. The ABS is a two-channel system.

Cast aluminium wheels mount 120/70-ZR17 and 180/55-ZR17 front and rear tyres.

3.2 Styling & equipment

- Minimal panels and rear mudguard/number plate mount

- LCD display easy to read

- USB Type-C socket under the seat

- New visual updates or both colours including new all black engine cases and cam cover

With its four-cylinder power unit clearly on display the CBR650R’s wrapping ramps up pure sporting appeal; dual LED headlights emit an uncompromising stare, and the upper and lower fairings blend muscularity with slim lines and angles.

The seat unit, too is compact and truncates the rear of the machine, adding to the hard-edged sense of purpose. Trim side panels accentuate the minimalism, as does the steel rear mudguard/number plate mount.

The aggressive riding position starts with clip-on handlebars that mount beneath the top yoke, matched to rear set footpegs. There’s also a USB Type-C socket located under the seat, for easy charging of a mobile device. Seat height is set at 810mm.

Stylish, easy-to-read LCD instruments include Shift-Up, Gear Position and Peak Hold indicators.

For 23YM, both colour options receive visual updates including new all black engine and cam covers. The Mat Gunpowder Black Metallic features new blue highlights on the tank, tail and fairing, and a new red shock spring. The Grand Prix Red features a new black front mudguard and a new black belly pan that features a bold red Honda logo that chimes neatly with the new red fork spring.

3.3 Engine

- 70kW peak power, 63Nm peak torque with 35kW A2 licence option

- Honda Selectable Torque Control (HSTC)

- Assist/slipper clutch

The 649cc, DOHC 16-valve engine is tuned to create the purest, most enjoyable mid-sized four-cylinder performance possible, with the classically fast ‘pick-up’ through the rev range and hard-hitting, high-revving top-end for which Honda’s in-line’s fours are renowned. Peak power of 70kW arrives @ 12,000rpm with peak torque @ 63Nm delivered at 9,500 rpm. A 35kW option is available for A2 licence holders.

Direct cam actuation makes for a compact cylinder head; bore and stroke is set at 67mm x 46mm with compression ratio of 11.6:1. Iridium spark plugs are employed and twin air ducts – either side of the fuel tank – feed the airbox and produce a throaty intake roar.

Asymmetric piston skirts minimise bore contact and reduce friction. Ferrous spines on the outer surface of the cylinder sleeves reduce oil consumption (and friction) with improved heat transfer and a silent SV cam chain reduces frictional losses by using a Vanadium coating on its pins. Internal water channelling from cylinder head to cylinders does away with most of the exterior hoses.

The engine uses a compact internal architecture, stacked six-speed gearbox and starter layout with the cylinders canted forward 30°. An assist/slipper clutch eases upshifts while managing rear-wheel lock up under hard braking and rapid downshifts. Honda Selectable Torque Control (HSTC) manages rear wheel traction; it can be turned off should the rider choose.

Fuel consumption of 20.4km/l (WMTC mode) gives a range of over 300km from the 15.4L

fuel tank. EURO5 compliance required revisions to the ECU, cam lobes, intake timing, exhaust pipe, catalyser and silencer, as well as the addition of a crank pulsar.

- Accessories

A range of Genuine Honda Accessories are available for the CBR650R, both available as individual items and grouped in packs, that are ready to bolt straight on to the bike:

The Sport Pack enhances the dynamism and sportiness of the motorcycle by featuring the following accessories:

- Quickshifter

- Colour matched Rear Seat Cowl

- Smoke High Wind Screen

- Tank Pad

The Comfort Pack has been designed to increase rider comfort and features:

- Clear High Wind Screen

- Grip Heaters & Attachment

The Travel Pack includes all the parts necessary to maximize the carrying capacity of the CBR650R and features

- Tank Bag & Attachment

- Rear Seat Bag & Attachment

The line-up is completed with Wheel Stripes available in different colours. All the accessories featured in packs can also be purchased individually.

- Technical Specifications

ENGINE

Type

Liquid-cooled 4-stroke 16-valve DOHC inline-4 cylinder

Engine Displacement (cm³)

649cc

Bore x Stroke (mm)

67.0mm x 46.0mm

Compression Ratio

11.6:1

Max. Power Output

70kW/12,000rpm

Max. Torque

63Nm/9,500rpm

Oil Capacity

2.7L

Noise Level (dB)

Lwot - 80

Lurban - 76

FUEL SYSTEM

Carburation

PGM-FI electronic fuel injection

Fuel Tank Capacity

15.4L

Fuel Consumption

20.4km/litre

ELECTRICAL SYSTEM

Starter

Electric

Battery Capacity

12V/8.6AH

ACG Output

370W

DRIVETRAIN

Clutch Type

Wet, multiplate disc

Transmission Type

6-speed

Final Drive

Chain

FRAME

Type

Steel diamond

CHASSIS

Dimensions (LxWxH)

2120 x 750 x 1,150mm

Wheelbase

1450mm

Caster Angle

25.5°

Trail

101mm

Seat Height

810mm

Ground Clearance

130mm

Kerb Weight

208kg

Turning radius

SUSPENSION

Type Front

41mm Showa Separate Function front Fork Big Piston (SFF-BP) USD forks

Type Rear

Monoshock damper with 10 stage adjustable preload, 43.5mm stroke

WHEELS

Rim Size Front

Hollow section 6-spoke cast aluminium

Rim Size Rear

Hollow section 6-spoke cast aluminium

Tyres Front

120/70ZR17 M/C (58W)

Tyres Rear

180/55ZR17 M/C (73W)

BRAKES

ABS System Type

2 channel; hydraulic dual disc 310mm front, hydraulic disc 240mm rear

INSTRUMENTS & ELECTRICS

Instruments

Digital speedometer, digital bar graph tachometer, dual trip meter, digital bar graph fuel gauge, gear position and upshift indicator, digital clock

Headlight

LED

Taillight

LED

# Please note that the figures provided are results obtained by Honda under standardised testing conditions prescribed by WMTC. Tests are conducted on a rolling road using a standard version of the vehicle with only one rider and no additional optional equipment. Actual fuel consumption may vary depending on how you ride, how you maintain your vehicle, weather, road conditions, tire pressure, installation of accessories, cargo, rider and passenger weight, and other factors.

For more Honda Motorcycles UK news check out our dedicated page Honda Motorcycles UK News

or head to the official Honda Motorcycles UK website honda.co.uk/motorcycles.html

Read the full article

2 notes

·

View notes

Text

Aluminium Pressure Die Casting Tool Design in Pune | India

Advance Technologies is one of the best manufacturers of Aluminium Pressure Die Casting Tool Design in Pune, India. Aluminium pressure die casting tool produces thin-walled parts with a small machining allowance. Aluminium Gravity Die Casting is Low mold cost and long mold life. Our company provides trustable aluminium pressure die casting tool design tools. Contact Us: +91 9552593936 Visit Us: http://www.advancetechnologies.co/aluminium-pressure-die-Casting-tool-design.html

0 notes

Text

Alu Die Casting

Aluminium die casting manufacturer in China (GC Precision Mold Co., Ltd ). has over 20 years of practical experience in custom aluminum die casting manufacturing. We offer efficient, excellent aluminum die casting services with the most economic solutions. We offer state-of-the-art production technology for custom die casting products.We are committed to produce high quality die casting products in aluminum, zinc, magnesium, providing total customer satisfaction and delivering Chinese made value, competitively and quickly. Most of our products are exported to USA, Canada, and Germany, France, Italy, Finland, Switzerland, Norway in western Europe.To support varieties customers needs we have high pressure die casting machines from 120 tonnages to 1650 Tonnages and Gravity casting we can produce part weight up to 50 kg. We look forward to servicing your custom aluminum die casting needs.

Custom aluminum die casting

1 note

·

View note

Text

Elevating Production Excellence: Your Trusted Partner in Aluminium Die Casting in China

Welcome to GC Precision Mold Co., Ltd, a leading aluminium die casting company in China with about two decades of palms-on experience in crafting tailor made aluminium die casting answers. Our journey is described by productive, impeccable services and economically viable alternatives, environment new benchmarks on the globe of die casting. With reducing-edge output technological innovation, an unwavering determination to top quality, in addition to a determination to shopper fulfillment, we stand to be a beacon of Chinese production excellence.

Mastering the Artwork of Aluminium Die Casting

Having a legacy spanning in excess of 20 years, GC Precision Mildew Co., Ltd has carved a distinct segment like a outstanding aluminium die casting manufacturer in China. Our prowess lies within our ability to rework aluminium into intricate, specific components that meet up with the highest market benchmarks. From conception to manufacturing, we provide a seamless journey, guaranteeing that your die casting needs are fulfilled with utmost professionalism and finesse.

Striving for Excellence in Every Aspect

We choose satisfaction inside our condition-of-the-artwork production technological innovation, a testament to our unwavering dedication to excellent. Every die casting merchandise that bears the GC Precision Mold Co., Ltd mark embodies the essence of precision, sturdiness, and trustworthiness. Our journey is underscored by a relentless pursuit of excellence, setting a benchmark for custom die casting methods.

A Global Footprint, Pushed by Benefit

At GC Precision Mold Co., Ltd, we transcend borders with our impeccable die casting choices. A good portion of our goods finds its strategy to esteemed China die casting Places in Western Europe, including the United states, Canada, Germany, France, Italy, Finland, Switzerland, and Norway. This world attain can be a testament to our determination to delivering Chinese-created benefit that is both of those competitive and prompt.

Empowering Prospects: Our Abilities

Our abilities really are a testament to our devotion to cater to numerous consumer wants. We boast significant-tension die casting machines ranging from one hundred twenty tonnages to 1650 tonnages, empowering us to provide solutions that span a wide spectrum of needs. Also, our prowess extends to gravity casting, enabling us to generate components with weights of around fifty kg. This assorted range of capabilities positions us as your trustworthy associate for all points related to aluminium die casting in China.

A Future of Collaboration and Excellence

As we stage into the long run, GC Precision Mildew Co., Ltd envisions a journey marked by collaboration, innovation, in addition to a relentless pursuit of excellence. We are not just a producer; we're your companions in pushing the boundaries of aluminium die casting. Irrespective of whether it's intricate components, intricate patterns, or massive-scale productions, we've been poised to generally be the cornerstone of your aluminium die casting journey.

Companion With all the Pioneers

At GC Precision Mildew Co., Ltd, we invite you to affix us from the pursuit of producing excellence. Whether It is China die casting, die casting in China, or aluminium die casting China, we stand as your trustworthy, modern, and committed lover. Alongside one another, let us condition a future exactly where aluminium transforms into precision and prospects, setting new benchmarks in the realm of die casting.

1 note

·

View note

Text

0 notes

Text

Alu Die Casting

Aluminium die casting manufacturer in China (GC Precision Mold Co., Ltd ). has over 20 years of practical experience in custom aluminum die casting manufacturing. We offer efficient, excellent aluminum die casting services with the most economic solutions. We offer state-of-the-art production technology for custom die casting products. We are committed to produce high quality die casting products in aluminum, zinc, magnesium, providing total customer satisfaction and delivering Chinese made value, competitively and quickly. Most of our products are exported to USA, Canada, and Germany, France, Italy, Finland, Switzerland, Norway in western Europe. To support varieties customers needs we have high pressure die casting machines from 120 tonnages to 1650 Tonnages and Gravity casting we can produce part weight up to 50 kg. We look forward to servicing your custom aluminum die casting needs.

Aluminum die Casting manufacturer

1 note

·

View note

Text

Which is the best plastic die maker in Thane?

Swastik Industries is the best Aluminium casting and plastic Die maker in Thane and Mumbai, Also offers Investment casting dies, Injection moulding dies, rubber dies, PVC dies, Gravity dies, plastic dies, and more.

https://swastikindustriesindia.com/services

0 notes

Text

Aluminium Butterfly Valves Body, Aluminium Valve Body, Manufacturer

We are Manufacturer, Supplier, Exporter of Aluminium Butterfly Valves Body, Aluminium Valve Body from Sangli, Maharashtra, India.

Aluminium Butterfly Valves Body, Aluminium Valve Body, Aluminium Gravity Die Castings, Machined Components. Gravity Die Casting, Aluminium Gravity Die Casting, Aluminium Casting, GDC Supplier, Pressure Die Casting, Aluminium Pressure Die Casting, PDC Supplier, Manufacturer, Supplier, Exporter, Sangli, Asia, Mumbai, Thane, Navi Mumbai, Pune, Nashik, Aurangabad, Ratnagiri, Nagpur, Ahmednagar, Akola, Amravati, Chandrapur, Dhule, Jalgaon, Raigad, Satara, Belgaum, Kolhapur, Belgaon, Maharashtra, India.

0 notes

Text

Casting Manufacturer Industry in Rajkot, Gujarat, India, Die Casting Manufacturer,

Aluminium die casting industry in Rajkot,Gujarat, India,

Our company offers a comprehensive suite of manufacturing solutions, including die casting services. With a focus on precision, efficiency, and quality, we cater to diverse industries and provide tailored solutions to meet specific project needs. Casting Manufacturer Industry in Rajkot, Gujarat, India,

Milling Die Casting Services From the Aluminium Gravity Die Casting Manufacturing Industries In Rajkot

Our Milling Alluminium Gravity Die Casting Manufacturing services leverage state-of-the-art equipment and advanced technology to deliver high-precision parts with tight tolerances. Key highlights of our machining services include:

Advanced Equipment: We utilize modern Die casting Service material machines with multi-axis capabilities, enabling us to perform a wide range of machining operations with speed and accuracy.

Die Casting Manufacturer,

Aluminium die casting industry in Rajkot,Gujarat, India,

#india#gujarat#aluminium die casting industry in rajkot#aluminium casting manufacturer company in rajkot#aluminium gravity die casting industry in rajkot#diecasting#Diecastingmanufacturer#Diecastingmanufacturerindustryinrajkotgujarat#manufacturer

0 notes

Text

The necessary Die Casting Process Is Followed As Per The Order Volume and Quality Finishing

High Pressure Die Casting (HPDC) Process

In high pressure die casting process, the molten metal is injected into the steel mold at high pressure. This is a common process for manufacturing non-ferrous metal parts with metals such as aluminium alloys with low melting points.

Low Pressure Die Casting (LPDC) Process

In the low pressure die casting process, the molten metal is injected into the steel mold at low pressure, normally around 0.7 bar. This is different from HDPC as the pressure of the system remains much lower than HDPC. This process of die casting ensures low porosity.

Gravity die casting (GDC) Process

This is the most traditional die casting process. In this process, the molten metal is allowed to settle into the mold in absence of any external pressure. This is often used for light alloy die casting like aluminium die casting.

For more information on different die casting processes visit https://www.rockman.in

0 notes

Link

According to HTF Market Intelligence, the Global Aluminium Gravity Die Casting (GDC) Alloy Wheels market to witness a CAGR of 6.40% during forecast period of 2023-2029. The Aluminium Gravity Die Casting (GDC) Alloy Wheels market size is estimated to increase by USD 1.3 Billion at a CAGR of 6.40% from 2023 to 2029.

0 notes

Text

Metal Casting Market Size, Share & Segment by Raw Material, by End-User, by Form , by Modification type , by Function, by Regions & Global Market Forecast 2022-2028

The research focuses on the market's major key market participants and their entire portfolio. It helps the reader understand the methods and collaborations that businesses use to compete in the market. The detailed analysis delves into the Metal Casting Market industry at a granular level. Knowing the global revenue of manufacturers, the global price of manufacturers, and the global sales of manufacturers over the projection period allows the reader to identify the manufacturers' footprints. Extensive research has been conducted by dedicated analysts and researchers to provide current and future market scenarios. They have given the readers a comprehensive picture by providing an in-depth review that is accurate and reliable.

Book Your Free Sample Report @ https://www.snsinsider.com/sample-request/1909

The study employs a SWOT analysis to examine the market's leading competitors' strengths and weaknesses. The researcher thoroughly examines the Metal Casting market size, share, trends, overall earnings, gross revenue, and profit margin in order to accurately estimate market trends and provide professional insights to investors. This research looks at past and projected sales and revenue. Understanding the categories aids in determining the importance of various market growth variables.

Market Segmentation:

By Material Type

Cast Iron

Aluminium

Stainless Steel

Zinc

Magnesium

Carbon Steel

High Steel Alloy

Others

By Process Type

Sand Casting

Die Casting

Shell Mold Casting

Gravity Casting

Vacuum Casting

Investment Casting

Others

By End-use

Automotive & Transportation

Building & Construction

Mining

Equipment & Machine

Consumer Goods

Others

Market Segmentation

This section of the report includes information on profit forecasts as well as market share for each country and sub-region. The market has been segmented by product type and application, according to the Metal Casting market study. Each segment is rated according to its market share and rate of growth. In addition, the researchers looked into potential areas that could pay off for manufacturers in the coming years. Geographic research provides precise value and volume forecasts, allowing market participants to gain an overall understanding of the industry.

COVID-19 Impact Analysis

As a result of the COVID-19 epidemic, customer behavior in all sectors of society has changed. In order to respond to changing market supplies, industries will need to rethink their strategies. This research looks into the impact of COVID-19 on the Metal Casting market and will assist you in developing your business in accordance with the new industry standards.

Competitive Outlook

The research delves into the top market players' business overviews, expansion plans, and strategies. In its statistical analysis of the global Metal Casting market, it includes CAGR, revenue, volume, market share, and other key figures. It contains a large number of global market intelligence studies.

Buy This Exclusive Report @ https://www.snsinsider.com/checkout/1909

Table Of Contents

1. Introduction

1.1 Market Definition

1.2 Scope

1.3 Research Assumptions

2. Research Methodology

3. Market Dynamics

3.1 Drivers

3.2 Restraints

3.3 Opportunities

3.4 Challenges

4. Impact Analysis

4.1 COVID 19 Impact Analysis

4.2 Impact Of Ukraine-Russia War

5. Value Chain Analysis

6. Porter’s 5 Forces Model

7. PEST Analysis

8.Global Metal Casting Market Segment, By Material Type

8.1 Cast Iron

8.2 Aluminium

8.3 Stainless Steel

8.4 Zinc

8.5 Magnesium

8.6 Carbon Steel

8.7 High Steel Alloy

8.8 Others

9.Global Metal Casting Market Segment, By Process Type

9.1 Sand Casting

9.2 Die Casting

9.3 Shell Mold Casting

9.4 Gravity Casting

9.5 Vacuum Casting

9.6 Investment Casting

Contact US:

Akash Anand

Manager- Business Development

SNS insider PVT LTD

USA: +1-415-230-0044

www.snsinsider.com

Mail - [email protected]

0 notes