#Aluminum gravity casting

Text

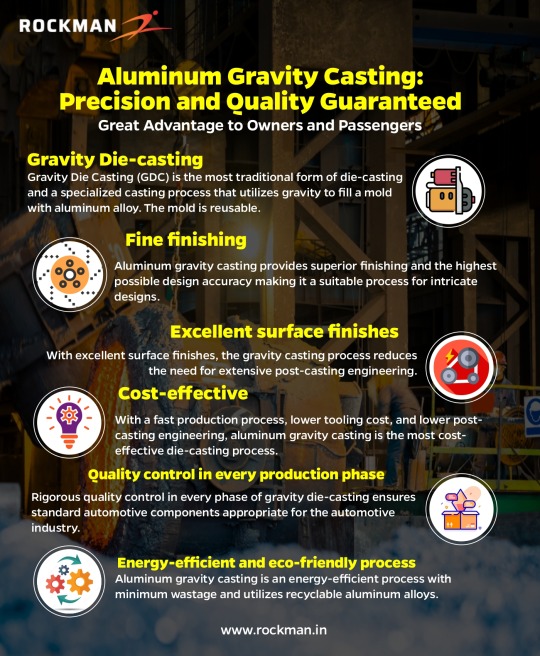

Aluminum Gravity Casting: Precision and Quality Guaranteed

Gravity Die-casting

Gravity Die Casting (GDC) is the most traditional form of die-casting and a specialized casting process that utilizes gravity to fill a mold with aluminum alloy. The mold is reusable.

Advantages of aluminum gravity casting

Fine finishing

Aluminum gravity casting provides superior finishing and the highest possible design accuracy making it a suitable process for intricate designs.

Excellent surface finishes

With excellent surface finishes, the gravity casting process reduces the need for extensive post-casting engineering.

Cost-effective

With a fast production process, lower tooling cost, and lower post-casting engineering, aluminum gravity casting is the most cost-effective die-casting process.

Quality control in every production phase

Rigorous quality control in every phase of gravity die-casting ensures standard automotive components appropriate for the automotive industry.

Energy-efficient and eco-friendly process

Aluminum gravity casting is an energy-efficient process with minimum wastage and utilizes recyclable aluminum alloys.

For more information on gravity casting and aluminum die-casting visit: https://www.rockman.in/

#Aluminum gravity casting#Alloy wheels for passenger cars#Aluminium die casting#die casting parts#High Pressure Die Casting suppliers in india#Aluminium casting#Aluminium Die cast#Aluminium die casting parts suppliers in india

0 notes

Photo

Old school Bob jobTwin cylinder 74 CI engine

Pre 1940 leaf spring front end

Flanders handlebars

Aluminum fuel tanks

This 1947 Indian Chief is an old-school bob-job built up from the best-looking Indian parts. The engine, gearbox and frame date from the postwar era, with a plunger frame and the upgraded 74 CI Chief motor with standard 3-speed gearbox, hand shift and foot clutch. The machine has been modified with a pre-1940 leaf-spring front end and a pair of cast aluminum tanks from the 1930s. It’s all been assembled as a period postwar bob-job, which was the hot setup for many motorcyclists in the era, with as much sheet metal as possible discarded for a massive weight reduction, a bobbed rear fender, cowhorn Flanders handlebars and a solo seat completing the style.

The stance in this instance is long and low, with a prewar vibe given the leaf-spring forks, although the plunger rear suspension gives a more comfortable ride. The inspiration for the bob-job (now called simply ‘bobber’) began even before the advent of Class C racing in the mid-1930s, all the way back to the mid-1920s, with the California Cut Down style, which used the same formula for increased performance: ditch weight, open the pipes, raise the handlebars, lower the center of gravity. The Cut Down style was the original American custom motorcycle style, and the first widely-replicated custom look from any region.

The Cut Down saw its peak with the Harley-Davidson JDH, and a few were even commercially produced by independent motorcycle shops, with instructions on shortening/lowering the ‘J’ frame published in magazines like Popular Mechanics. With the introduction of Class C production racing in 1936, the style was given a new life as the bob-job, as riders customized their street machines to look more like race bikes. This 1947 Indian Chief Bobber is exactly such a machine, modified to look like a racer, but fully street-legal. It’s as old school as it gets, and Indian bob-jobs are much less common than Harley-Davidson customs in the early postwar era, making this bike very rare.

16 notes

·

View notes

Text

10 Different Types of Casting Process Used in Manufacturing

The article aims to discuss the various kinds of casting processes that are used globally in the manufacturing industry for producing quality products.

There has been a notable increase in the industrial products. That should not be a problem, because there are several kinds of metal casting services. With the help of these services, complex products can be effortlessly manufactured.

In order for the firm or company to choose the right or specific kind of casting manufacturing process, they need to first know the different types of casting processes that are used in the manufacturing industry.

Each of the casting process methods comes with its own benefits and flaws. A brief overview of various types of casting processes has been provided in the article.

What is the casting process?

The casting process is a method where the metal parts are produced according to the specific needs of the clients. It is done by pouring the molten metal into a mould. Then once it has been poured, hardened, and cooled, the desired shapes are designed.

So, casting helps industries achieve their goal of having the metal pieces according to their shapes, ideal for mass production. Besides, there are several kinds of casting that can immensely help to satisfy the user requirements.

What are the different types of Casting Processes?

There are different kinds of casting processes that can be used according to the needs of the user.

Sand Casting Process

The sand casting is a simple process of casting that helps cast ferrous or non-ferrous metal alloys. This method is mostly used for the production of metals that find applications in the automobiles like the engines, cylinders, and crankshafts.

The mould is produced from silica-based substances that can be naturally bonded. Then it is used to produce a mould surface that is smooth. The mould surface consists of two parts namely, cope (the upper half) and drag (the lower half).

Then the molten metal is poured into the desired pattern. Then it is left to harden so that it can form the final shape. The excess metal is removed in the final metal casting product.

Gravity Die Casting

This method is also called permanent mould casting. Here the metal and the metal alloys are fabricated using the moulds that come reusable. They can be steel, graphite, and the like. The metal casting process can be used to make items like gears, pipe fittings, wheels, and so on.

The molten metal is directly poured into the mould cavity. This happens when there is an influence of gravity, where the die is angled to adjust the filling. Then, the molten metal is let to cool down so that it can solidify inside the mould.

This method uses the mould from the bottom up, which enables it to have a greater casting rate than sand casting. But it can be somewhat costly than most methods.

Pressure Die Casting

There are two types of die casting, namely low-pressure die casting and high-pressure die casting. Low-pressure die casting is used for the production of large components. The high-pressure die casting is used in the production of geometrical shapes that need very high precision.

Some examples would be nonferrous metals like zinc, tin, copper, and aluminum.

Investment Casting

This type of casting is also known as lost-wax casting. Here the metals are produced by using the wax pattern of the metal. Then a refractory material and a binding agent are used. This is done so that the exact shape is obtained, and the molten metal can be poured into the mould.

It is a labour-intensive process that is expensive as well. This method is used to produce several products like gears, bicycle trunks, moto discs, and blasting machine replacements.

Plaster Casting

The casting process makes use of the mould that contains ‘Plaster of Paris.’ Here, the plaster is allowed to cool and then the metal is let to dissolve in the contents, due to the limited thermal conductivity.

This helps achieve high precision. The method is used to produce cross-section pieces that are narrow & need to fit in small gaps. It helps in the production of small castings that contain small amounts of castings of 45 kgs.

Centrifugal Casting

This kind of casting is called roto casting where cylindrical objects are produced for industrial applications. It is done with the help of the centrifugal forces. Here the metal is poured into the spinning die of the metal casting.

Then at high pressure with the help of the centrifugal forces, the molten metal is shaped inside the die. Because the spinning happens constantly, the metal that is in molten form takes the shape of the centrifugal casting.

Examples can include bush bearings, clutch plates, piston rings, and cylinder liners.

Lost-Foam Casting

This method is almost the same as the investment casting. However, the pattern is made of foam, and not from wax. When the design of the metal has been produced, the casing is coated with a refractory ceramic.

Then the molten metal is poured into the mould. The method is used to produce alloy steel, carbon steel, alloy cast iron, and ferrous alloys.

Vacuum Casting

This kind of casting method happens under a vacuum pressure of 100 bar. This is done to help the exhaust gas from the mould. Besides, it helps remove the bubbles and air pockets, when the molten metal is poured inside a vacuum chamber.

Then the metal is cured in a heating chamber. The products formed are commonly used in the automotive, aerospace, electronics, marine, and telecommunications.

Squeezing Casting

In this casting method, the high pressure is used for preventing shrinkage. But due to the specialised tooling requirements, it can’t be used for large production. Some products include space frame joints, aluminum front steering knuckles, chassis frames, and brackets.

Continuous Casting

In this type of casting the production of metals profiles comes infused having a constant cross-section. It is mainly used for the production of steel bars. Besides, it can be also used for semi-continuous casting.

The molten metal allows a solid metal surface to form on the liquid metal. The solidification of the metal happens from the outside. Then the remaining strands of the metal can be taken away from the mould.

Conclusion

This is it. These were some of the most popular casting methods that are used in the market. Each method has its own pros & cons. From the above article, it becomes obvious that choosing the appropriate casting method is critical for producing sublime products. With so many different types of casting methods metal components can be produced. It becomes crucial that the right kind of casting method is used to produce quality goods.

0 notes

Text

Die Casting - An Insight into the Intricate Metal Forming Process

Die casting is a metal forming process where molten metal is injected at high pressure into steel molds or dies. Due to the high pressures involved, it results in products with very tight tolerances and precise dimensional specifications. This helps produce intricate components with complex internal passages in high volumes, at competitive costs compared to other manufacturing processes.

History and Applications

It is a relatively old manufacturing technology that was first developed in the late 18th century for producing metal buttons and thimbles. Over the years, advancements in metal alloys and casting equipment led to expanding applications of it, especially for zinc and aluminum. Today, commonly die cast metals include aluminum, zinc, magnesium, copper and tin-based alloys. Major industries using die cast components include automotive, industrial equipment, electronics, hardware, and household appliances. Common applications are engine parts, transmission components, housings, casings, and covers for electronics, tools, and consumer goods. It accounts for over 60% of all aluminum cast parts produced globally.

Different Methods

There are two main casting methods in use today - hot chamber and cold chamber Die Casting . Hot chamber machines maintain molten metal at a high temperature inside a holding furnace. Cold chamber machines solidify molten metal in a shot sleeve before injecting it into the die under pressure. Within these, there are further variants depending on the type of filling method - gravity, low/high pressure, and squeeze casting. Hot chamber casting is preferred for zinc and tin-based alloys, while aluminum alloys are commonly cold chamber die cast. Each method has merits suited for certain alloy compositions and part sizes/thicknesses.

Process Steps

The key steps involved in casting are:

1. Preparation of die and mold cavity

2. Melting and alloying of metal

3. Metal conditioning and transfer

4. Shot delivery into the die cavity

5. solidification under applied pressure and cooling

6. Die opening and part ejection

7. Finishing of cast parts

The die or mold containing the cavity of desired part shape is first prepared using tool steels. Molten metal at 700-800°C is transferred and conditioned in the shot sleeve of the Die Casting machine. On trigger, a shot of melt is injected rapidly into the die cavity under very high pressures of 600-1500 kg/sq cm before solidifying. Accurate temperature control is vital to obtain quality castings.

Design Considerations for Die Cast Parts

Designing die cast parts requires careful planning to ensure production feasibility, dimensional accuracy, and assembly/performance needs. Key factors considered are part size/weight limitations, wall thickness variations and thick/thin sections, draft angles, gates and risers placement, machining/finishing requirements post casting, functional lives under service loads/temperatures, and surface finish needs. Finite element analysis involving thermo-mechanical simulations is often used at the design stage to validate castability. Functional designs help achieve dimensional consistency and elimination of defects in high volume production.

Get more insights on Die Casting

Vaagisha brings over three years of expertise as a content editor in the market research domain. Originally a creative writer, she discovered her passion for editing, combining her flair for writing with a meticulous eye for detail. Her ability to craft and refine compelling content makes her an invaluable asset in delivering polished and engaging write-ups.

(LinkedIn: https://www.linkedin.com/in/vaagisha-singh-8080b91)

#Die Casting#Metal Casting#Precision Manufacturing#Aluminum Casting#Zinc Casting#Casting Process#Industrial Casting#Mold Casting

0 notes

Text

Aluminium Pressure Die Casting Tool Design in Pune | India

Advance Technologies is one of the best manufacturers of Aluminium Pressure Die Casting Tool Design in Pune, India. Aluminium pressure die casting tool produces thin-walled parts with a small machining allowance. Aluminium Gravity Die Casting is Low mold cost and long mold life. Our company provides trustable aluminium pressure die casting tool design tools. Contact Us: +91 9552593936 Visit Us: http://www.advancetechnologies.co/aluminium-pressure-die-Casting-tool-design.html

0 notes

Text

0 notes

Photo

New Post has been published on https://www.vividracing.com/blog/best-brake-kit-for-the-bmw-m3-e9x-1m-why-you-need-to-upgrade/

Best Brake Kit for the BMW M3 E9X / 1M - Why You Need To Upgrade!

EBC Brakes Racing 6-Piston Apollo Big Brake Kit: A Game Changer for BMW M3 E9x and BMW 1M

Controlling the power of a S65 is no easy task. The E9x is BMW’s answer to American muscle, and somewhere they didn’t deliver it was with the brakes. The braking system is one of the most critical components for any performance vehicle, and for those who drive a BMW M3 E9x or BMW 1M, this holds especially true. These legendary platforms are known for their thrilling driving characteristics and mental lap times, but their stock brakes often leave faster lap times or confident canyon runs to the 911s. Let’s dive into the new EBC Brakes Racing 6-Piston Apollo Big Brake Kit—a revolutionary upgrade that promises to elevate the braking performance of these iconic BMWs.

If you want to check out the price or shop any of these EBC BBKs, they’re available at Vivid Racing!

EBC Brakes = Unmatched Stopping Power

The EBC Brakes Racing 6-Piston Apollo Big Brake Kit is a comprehensive solution designed to transform the braking capabilities of the BMW M3 E9x series and the BMW 1M. This kit includes 6-piston front calipers, 380mm fully floating two-piece rotors, front Bluestuff™ NDX pads, front braided lines, and all necessary fluid and fixtures. Engineered in the UK, the Apollo Big Brake Kit offers a significant leap forward in braking performance, catering to both spirited road driving and demanding track conditions. Let’s keep in mind the four major factors of this brake kit:

– 6-piston calipers

– 380mm floating two-piece rotors

– Performance pads

– Braided lines

The combination of these big four is truly what makes this brake kit the ultimate package. Any one of these upgrades to the stock brake kit is a noticeable change, but why not embody all four? Some would even say this kit is overkill… but who doesn’t want to bring a Gatlin gun to a knife fight? We talking about brakes here!

What makes this the best big brake kit for the BMW E9x or 1M?

Apollo-Series 6-Piston Calipers:

The lightweight yet robust aluminum 6-piston calipers are a standout feature of this kit. The two-piece bolted design incorporates high-tensile 12.9-grade steel bolts for enhanced caliper stiffness, as proven by computer FEA analysis. Machined from heat-treated low-pressure castings, these calipers offer superior strength compared to conventional gravity cast calipers. High-temperature fluid seals and full boot-type dust seals provide maximum protection against road grime and debris, ensuring longevity and reliability.

Fully-Floating Two-Piece Rotors:

The 380x36mm fully-floating rotors are designed to withstand extreme heat and reduce stress, extending rotor life and minimizing the risk of cracking. The drive bobbins, machined from a single piece of stainless steel, offer maximum strength and corrosion resistance. The rotors feature 48 directional internal curved vanes for improved cooling, and the unique ‘Swept Groove’ slot design ensures effective evacuation of braking dust and gases.

Bluestuff™ NDX Performance Brake Pads:

The Bluestuff™ NDX pads, included in every kit, combine excellent cold bite with the ability to perform well in short spells of track or race conditions. These pads are now road legal in most markets, making them an ideal choice for enthusiasts who demand high performance on both the street and the track.

Stainless Steel Braided Brake Lines:

The kit’s stainless-steel braided brake lines prevent the ‘ballooning’ phenomenon common with OE rubber lines, providing greater precision and feel under braking. This feature ensures a more consistent and responsive brake pedal feel.

Super DOT 4 Brake Fluid:

Each kit includes 1 liter of BF307+ Super DOT 4 brake fluid, boasting a 310°C boiling point—significantly higher than standard DOT 5.1 fluid. This high boiling point ensures exceptional endurance, allowing drivers to push their vehicles hard without experiencing brake fade due to fluid boiling.

Check out EBC Brakes – Brake Fluid

A Must-Have Upgrade for Enthusiasts

For BMW M3 E9x and BMW 1M owners looking to enhance their vehicle’s braking performance, the EBC Brakes Racing 6-Piston Apollo Big Brake Kit is an essential upgrade. Whether you’re tackling a twisty mountain road or hitting the track, this kit provides the stopping power and reliability needed to match the high-performance capabilities of these legendary cars.

By investing in the Apollo Big Brake Kit, drivers can enjoy a firmer, more responsive brake pedal feel, and significantly extended periods of hard driving without the onset of brake fade. This makes it a game changer for any enthusiast looking to get the most out of their BMW M3 E9x or BMW 1M.

For more information and to order the EBC Brakes Racing 6-Piston Apollo Big Brake Kit, visit Vivid Racing. Experience the ultimate in braking performance and take your driving to the next level.

Let us help!

As always, if you have any questions regarding upgrades for your vehicle or this EBC Brake Kit specifically, we are enthusiasts who truly believe in supplying fellow enthusiasts with the best mods to meet your driving goals! We have almost 12,000 reviews and a 4.6/5 review on Google to prove it 😏

You can chat with us – HERE (Live Chat). We’ll get back to you like, spooky fast.

Reach out to us at [email protected] or give us a call at (480) 966-3040 📞 and we’ll be happy to help with your questions or be a shoulder to cry on.

0 notes

Text

Sculptural Metal Forms: Exploring the Intersection of Art and Material Mastery

In the realm of artistic expression, sculptural metal forms stand as bold declarations of creativity and craftsmanship. From the sinuous curves of abstract sculptures to the imposing presence of monumental installations, these forms captivate and inspire with their dynamic interplay of shape, texture, and light. Rooted in the ancient tradition of metalworking yet constantly evolving with contemporary sensibilities, sculptural metal forms invite us to explore the limitless possibilities of material manipulation and artistic vision.

At the core of sculptural metal forms lies the transformative process of shaping and sculpting metal into expressive and evocative shapes. Whether through traditional techniques such as forging, casting, and welding, or cutting-edge methods like plasma cutting and CNC machining, artists harness the inherent properties of metal—its strength, ductility, and reflective qualities—to create works that defy gravity and challenge perception. Each form is a testament to the artist's mastery of their medium, as well as their ability to evoke emotion and provoke thought through the language of form and space.

One of the most compelling aspects of sculptural metal forms is their ability to transcend the constraints of materiality and take on a life of their own. Whether rendered in bronze, steel, aluminum, or copper, these forms possess a vitality and presence that belies their inanimate nature, inviting viewers to engage with them on a visceral and emotional level. They exist in a state of dynamic tension, poised between stillness and movement, solidity and ethereality, inviting us to contemplate the mysteries of existence and the nature of reality itself.

Moreover, sculptural metal forms often serve as vessels for exploring complex themes and ideas, from the relationship between humanity and nature to the interconnectedness of the cosmos. Whether inspired by the organic forms of the natural world, the geometric patterns of sacred geometry, or the chaos and complexity of the modern urban landscape, these works offer a rich tapestry of meaning and symbolism for viewers to unravel and interpret. They serve as mirrors to our innermost thoughts and emotions, reflecting back to us our own hopes, fears, and aspirations.

In recent years, sculptural metal forms have found new relevance and resonance in the realm of public art and urban design. From iconic landmarks and monumental sculptures to temporary installations and immersive experiences, these forms enrich the built environment and foster a sense of place and identity in communities around the world. They serve as catalysts for social interaction and cultural exchange, bringing people together in shared spaces to celebrate, contemplate, and connect with one another and the world around them.

In conclusion, sculptural metal forms represent a convergence of artistry, craftsmanship, and imagination. Through their mastery of material and form, artists create works that transcend the limitations of their medium, inviting us to explore the boundless possibilities of the human creative spirit. Whether celebrating the beauty of the natural world, reflecting on the complexities of the human condition, or envisioning bold new futures, sculptural metal forms continue to inspire and uplift us with their timeless beauty and enduring significance.

0 notes

Text

Aluminium sand casting, Aluminium gravity die casting industry in Rajkot, Gujarat, India

Aluminum Die Casting Service

Suitability for Hot-Chamber Die Casting: Aluminum alloys are primarily used in die casting Service due to their relatively high melting point compared to other metals used in Alluminium Die casting.Service In Rajkot

Material Costs: Aluminum die casting alloys typically offer a good balance between

performance and cost-effectiveness.

Indirect Material Costs: These alloys may require additional post-processing depending on the desired surface finish or specific part requirements.

Structural Properties: Aluminum alloys provide lightweight solutions with good strength and dimensional stability, making them suitable for complex parts.

Strength: Aluminum die casting alloys offer sufficient strength for various applications.

Weight: Aluminum alloys are lightweight, which is advantageous for parts that require reduced weight.

Surface Finish: They provide good surface finishes suitable for a wide range of applications without additional treatments.

Machinability: Aluminum alloys are generally easy to machine, allowing for additional machining operations if necessary.

Aluminium sand casting Aluminium gravity die casting industry in Rajkot, Gujarat, India

#aluminium gravity die casting industry in rajkot#aluminium casting manufacturer company in rajkot#india#gujarat#aluminium die casting industry in rajkot#manufacturer#india.#aluminium sand casting

0 notes

Text

Deluxe Free Fall-Single Pendulum Apparatus

Deluxe Free Fall-Single Pendulum Apparatus is designed for qualitative and quantitative study of free falling bodies experiments (acceleration due to gravity) with a measurement up to 160 cm of free-fall distance.It is mainly made of an aluminum alloy with a yellow scale. A steel ball is suspended with an electromagnet, which when turned off, plummets toward the catching net, which is fixed on the cast-iron base and tripod at the lower end of the vertical rod.Acceleration of the free fall motion of the steel ball is captured by moveable photogates and recorded by the digital timer (download).

The vertical rod is fixed on a solid tripod base and can be easily adjusted to true vertical by means of the leveling bolts on the tripod base and the included plumbline.

Deluxe Free Fall-Single Pendulum Apparatus includes Free Fall apparatus and accessories, photogates, 18mm steel ball, plumbline, pendulum, cables and plugs, and instructions.Required by not included: Digital Timer with Photogates(download).

The vertical rod is fixed on a solid tripod base and can be easily adjusted to true vertical by means of the leveling bolts on the tripod base and the included plumbline.

Deluxe Free Fall-Single Pendulum Apparatus includes Free Fall apparatus and accessories, photogates, 18mm steel ball, plumbline, pendulum, cables and plugs, and instructions.Required by not included: Digital Timer with Photogates(download).

#FORCES & MOTION#FREE FALL#GRAVITY#MECHANICES#teaching apparatus#educational equipments#technical training equipments#lab supplies

0 notes

Text

Rotar-70 GDC Parts, Aluminum Gravity Die Casting Components, GDC Parts, Manufacturer India

We are Leading Manufacturer of Rotar-70 GDC Parts, Aluminum Gravity Die Casting Components, GDC Parts from Kolhapur, Maharashtra, India.

0 notes

Text

Die Casting Process: A Strong Support To Next Generation Automotive

A versatile manufacturing process

With lots of advantages and manufacturing excellence, the die casting process is known for its versatility and ability to manufacture intricate automotive components.

Die-casting processes

Die-casting experts like Rockman have established themselves as pioneering die-casting companies with facilities for all three kinds of die-casting processes.

Gravity Die Casting

Low-Pressure Die Casting

High-Pressure Die Casting

Aluminum alloy die-casting

Rockman is the market leader in aluminum alloy die-casting. They have established a modern infrastructure for die casting process and supply international standard aluminum die-cast components to the automotive manufacturers and OEMs in the automotive industry.

Quality control in aluminum die-casting

Quality control is a primary requirement in auto parts manufacturing and supply. In aluminum die-casting several parameters are maintained before marketing a product. Manufacturers like Rockman with international repute never compromise in this matter.

For more details on die-casting process visit: https://rockman.com

0 notes

Text

What is an Injection Molding Machine? Get to know everything about it!

Injection molding is an important industrial technique. Although it is somewhat similar to die casting, but the raw material used in this case are different. Die casting uses metals that melt at extremely high temperatures, whereas injection molding mostly uses glasses, elastomers, and most frequently thermoplastic and thermosetting polymers. Nevertheless, this process is commonly used to create thermoplastic materials. In this method, raw materials are heated to a certain temperature and then injected under pressure into the mould cavity without changing their composition.

What are the main parts of injection molding machine?

The material hopper, barrel, an injection ram/rotating screw type plunger, heating element (heater), adjustable pattern, ejectors, and a mould inside mould cavity are the key components of an injection molding machine.

Injection molding machines typically operate horizontally. A barrel is part of an injection molding machine (cylindrical pipe). At one end of the barrel, there is a hopper. Inside the barrel is a revolving screw or hydraulic ram powered by an electric motor that provides force. The barrel has a heating element (warmer) attached to it that is used to melt the molding compound when it exits the hopper.

Mold cavity linked to the barrel's opposite side. During the entire production process, a movable pattern is used and the mould is situated inside the mould cavity. Typically, copper, aluminum, and tool steels are used to make mould. Distinct types of material moulds have different life cycles. This can be chosen based on your needs.

How does the injection moulding machine works?

Extrusion and injection molding both function similarly, as implied by their names. Using a feeding apparatus, molding material and raw materials are poured into the hopper. Following that, the molding material falls into the cylinder (barrel) as depicted in the diagram due to gravity. The material is melted using a circumferential heater that is mounted on the barrel. When molding compound in powder form enters the barrel from the hopper, it begins to melt, and a revolving screw or hydraulic ram applies pressure to advance the compound into the mould.

In this split mould, which is attached to the other side of the barrel, molten plastic material is pumped into a closed mould. The revolving screw constantly advances the molding material. The hydraulic system exerts pressure. Normal injection pressure ranges from 100 to 150 MPa. Following injection, pressure is exerted for a while or held in place with some force.

The pieces produced when the entire procedure is complete are appropriately cooled. The mould is then opened, and a few ejectors are utilized to remove the part properly and damage-free. The portion mould is reopened after removal. This process is very fast and automatically repeated. Here, it is simple to make pieces with complex shapes. The injection molding process may produce 12–16,000 components every cycle.

The Procedure

- The process parameter fluctuates based on the circumstances and demands.

- The components made with this method typically weigh between 100 and 500 g.

- A single part's cycle time ranges from 5 to 60 seconds, depending on how the item is made.

- The heating range for molding material is 150 to 350 degrees Celsius.

- The molding machine has an injection capacity of 12,000 to 2.2 106 mm3.

- 100 to 150 MPa is the injection pressure.

- From 0.1 to 8.0 MN is the locking force.

What are the advantages of Injection molding machine?

- The fundamental benefit of this method is that intricately shaped components with thin walls (5–15 mm) may be molded with ease and retrieved from the die without being harmed.

- Injection-molded components offer good dimensional tolerance.

- The main benefit of this method is that it produces far less scrap than certain other methods.

- Investment cast iron and intricately machined pieces compete with parts produced through the Injection Moulding Method.

- In comparison to other procedures, this process has a high production rate.

What are the various types of injection molding machines?

Following are the different types of injection molding machines. Have a look:

Hydraulic Injection Molding Machine

Hydraulic injection molding machine were the only types of machine at start. It is the oldest one in the industry. Following are the benefits of this machine-

1. Economical price

These machines cost far less at the base level than comparable models.

2. Cheap parts

If a machine component needs to be replaced because it has been damaged or has reached the end of its useful life, the replacement parts are less expensive and more readily available.

3. Robust components

The machine's hydraulic components are longer-lasting and more resistant to deterioration.

4. Easy to use and maintain

High-pressure clamping forces are typically simple to adjust on hydraulic injection devices.

5. Powerful

The gripping force on hydraulic molding machines is outstanding.

Electric Injection Molding Machines

In the 1980s, electric injection molding machines were made available and soon gained popularity in the high precision plastic parts production sector. The positioning accuracy of today's full electric servo drive injection molding machines is exceptionally precise (of 0.0001 in), but at a very high cost.

1. Less idle time

There is no possibility of oil leaking. Additionally, since no oil is used, there is no need to replace filters, which lowers consumable costs.

2. Efficiency while using energy

Electric Injection Molding Machines only consume energy when they are in use, thus their output is limited to what is necessary to support the load.

3. Fast procedure

Since these machines are digitally controlled, the procedure can be completely repeated without any oversight.

4. Highly reproducible

The injection device can be accurately controlled, the molding conditions can be stabilized, the injection control (such as pressure and speed) can be regulated in fine units, and there is a highly accurate control and monitoring system. It can handle challenging tasks like multi-stage hydraulic system extension and control the extension.

Injection Molding Machine Price

There are various types of machines. The Injection Molding Machine Price will also vary according to the complexity of the machine.

Costs for large industrial injection molding equipment can range from $50,000 to $200,000 or more. Additionally, the facilities needed to operate, maintain, and monitor these equipment are more demanding and call for expert staff.

Who are the best injection molding machine manufacturers?

There are many Injection Molding Machine Manufacturers in India; however, some of them offer the exception quality products that last longer. Here is the list of some trusted manufacturer in India-

Milacron

Yizumi Injection Molding Machine

Primex Plastics Pvt. Ltd

Windsor Machines Limited

Haitian

Hikon

ENGEL Global

Indo-MIM

Micro Plastic

Kruger

Vikas Industries

Jagmohan PlaMech Pvt. Ltd

Neelgiri Machinery

These are some of the leading manufacturers offering the best quality Injection Molding Products. If you are looking for someone in your region, you can try to search on Google and write Injection Molding Machine near me. This way, you will find the list of top-rated manufacturers offering top-notch services in your area.

Types of products made with injection molding machine

There are various types of products that can be made with injection molding machines.

Some of them are listed below-

Toys

Plastic bottles

Machinery and automotive components

Household products like molded closures, containers, etc.

Healthcare industry

Agricultural products

Conclusion

Injection moulding may appear to be a complicated procedure, yet it is the most popular manufacturing technique because it can manufacture a wide range of everyday things quickly and effectively. One of the most economical methods for producing both working prototypes and finished goods is injection molding.

#Injection Molding Machine#molding material#raw materials#injection molding process#Injection-molded components#Injection Moulding Method.#hydraulic molding machines#Injection Molding Machine Price#Injection Molding Machine Manufacturers#Injection Molding Products

0 notes

Text

Alu Die Casting

Aluminium die casting manufacturer in China (GC Precision Mold Co., Ltd ). has over 20 years of practical experience in custom aluminum die casting manufacturing. We offer efficient, excellent aluminum die casting services with the most economic solutions. We offer state-of-the-art production technology for custom die casting products.We are committed to produce high quality die casting products in aluminum, zinc, magnesium, providing total customer satisfaction and delivering Chinese made value, competitively and quickly. Most of our products are exported to USA, Canada, and Germany, France, Italy, Finland, Switzerland, Norway in western Europe.To support varieties customers needs we have high pressure die casting machines from 120 tonnages to 1650 Tonnages and Gravity casting we can produce part weight up to 50 kg. We look forward to servicing your custom aluminum die casting needs.

Custom aluminum die casting

1 note

·

View note

Video

youtube

Focus on the aluminum gravity casting process. The casting don't any de...

1 note

·

View note

Text

Band Saws in Slovakia

A band saw is a type of metal cutting machine that has a rotating blade with teeth on one edge. This tool is used primarily to cut curves in stock, but it can also be used to make custom cuts for production work. It is typically operated by hand, although some models allow for automated feeds. There are many different types of band saws available, including gravity-feed, semi-automatic, and automatic cutters. Some types are more suitable for industrial applications, while others are designed for home use. Check their site to know more details pásové píly.

In the world of woodworking, a band saw is one of the most versatile and powerful tools a woodworker can have. Whether you are looking to make precise curves or angled cuts, a quality band saw can help you get the job done with little effort. However, if you’re new to using this tool, there are many factors to consider before making your purchase. First, determine what you will be cutting on your saw to better choose the right model for your needs.

The type of wood you’ll be cutting will also influence your choice of a band saw, as some have a larger throat capacity than others to accommodate a wider range of blade widths. The type of work you’ll be doing will also play a role in how much power you’ll need from your band saw, as some have a more powerful motor that can handle bigger loads.

You’ll also need to take into account the price and features of the saw you’re considering. Some models have extras such as a LED work light or adjustable front handle to reduce fatigue during long woodcutting sessions, while others have dust ports and miter gauges to streamline your work. Lastly, you’ll want to consider the construction of your band saw, with some models being made from aluminum die-cast and others from cast iron.

The Cosen brand is one of the world's leading manufacturers of metal cutting machinery, offering more than 140 models of vertical, horizontal, miter-cutting, NC & CNC automatic and customized band saws. The company is based in the Czech Republic and employs more than 150 people. Its machines are used around the globe, with customers ranging from small metal shops to multinational corporations. Cosen offers a wide range of saws for different industries, with capacities from 200 to 3200 mm. The company's products are known for their high efficiency, accuracy, and reliability.

MILWAUKEE is a global leader in cordless power tools, and the band saw category is no exception. The M18 FUEL(tm) Deep Cut and Compact Dual-Trigger Band Saws provide the fastest cutting speed, largest capacity, and highest durability in their class. Both saws feature MILWAUKEE's innovative battery technology and the new Industry 4.0 Sawing Performance & Health Prognosis app.

Slovakia is a small central European nation that shook off decades of Soviet domination in 1993. The country has largely supported Ukraine since Russia invaded the neighboring country more than 18 months ago, with Slovakia the second NATO member to agree to give its fleet of Soviet-era MiG fighter jets to Kyiv. But the support has eroded public trust in liberal democracy and Western organizations.

The country's early parliamentary elections on Sept. 30 are expected to yield a victory for populist former Prime Minister Robert Fico, who has campaigned on a hardline anti-Russia message. Fico will have the opportunity to reverse Slovakia's military and political support for Ukraine if he returns to power. Michalovce is located near the border with Ukraine and serves as a key checkpoint for both migrants and freight. It has been a point of friction between Ukraine and the EU, with Ukrainian grain undercutting local markets.

1 note

·

View note