#Aluminum Components Manufacturers in India

Text

Top 6 Aluminum Parts Manufacturers in India

Explore the Versatility of Aluminum Parts in Modern Manufacturing, Where Its Lightweight Construction, Corrosion Resistance, High Strength-to-Weight Ratio, Malleability, and Exceptional Thermal and Electrical Conductivity Make It a Preferred Choice Across Industries Like Aerospace, Automotive, Construction, Electronics, and Packaging. Discover how Aluminum Contributes to Improved Performance, Efficiency, and Reliability in Diverse Applications. Additionally, Learn About the Top Aluminum Parts Manufacturers in India, Including Meck Industries, Cooper Corp, GM Hi-Tech, Kavya Metal, RK Industrial Components, and Lamda Components Pvt. Ltd., Renowned for Their Precision Engineering and High-Quality Products.

Read More: Top 6 Aluminum Parts Manufacturers in India

#Aluminum Parts Manufacturers in India#Aluminum Components Manufacturers in India#Top Aluminum Parts Manufacturers in India#Best Aluminum Parts Manufacturers in India#Top Aluminum Components Manufacturers in India#Best Aluminum Components Manufacturers in India

0 notes

Text

EV Aluminum Components Making EVs More Comfortable and Safer

Lightweight

Aluminum is lightweight and strong. It’s an ideal metal for EV components reducing the weight of the vehicle and extending the battery life. The EV aluminum components have enabled EV manufacturers to introduce lighter versions of two-wheelers and four-wheelers.

Enhanced safety

The high strength-to-weight ratio of aluminum improves the safety parameters to a great extent. The component manufacturers like Rockman as well as the auto makers ensure that EVs meet stringent safety standards.

Design flexibility

EV aluminum components can be customized to any extent. High malleability and trusted die-casting processes allow for complex designs of various components improving vehicle efficiency and augmenting aerodynamics. Rockman supplies customizable components to the automotive manufacturers and OEMs.

Durability

High strength-to-weight ratio and corrosion resistivity make every EV unit durable. The use of aluminum die-cast components also reduces the maintenance costs remarkably.

For more information on EV aluminum components visit: https://rockman.com

#EV aluminum components#aluminium die casting#die casting process#Rockman supplies#auto parts manufacturers in india

0 notes

Text

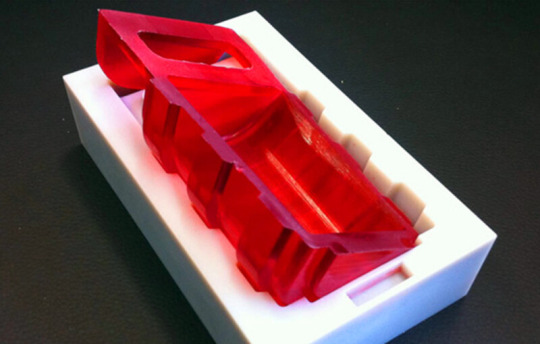

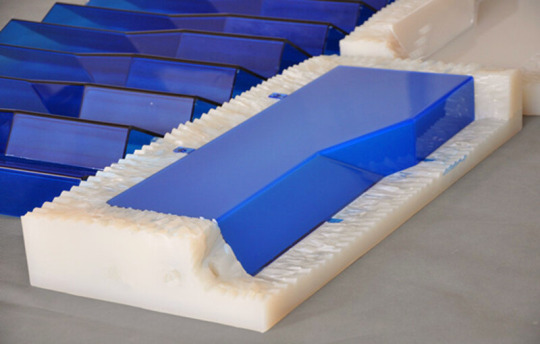

Working of Vacuum Casting and Its Multiple Uses

To make complicated components, a liquid substance is sucked into a silicone mold under vacuum. This method is known as vacuum casting. Rubber and plastic are examples of elastomers that are utilized as liquid materials in vacuum casting.

Since polyurethane resin, a kind of elastomer is employed as the casting medium, vacuum casting is also frequently referred to as polyurethane casting or urethane casting. When producing plastic components, vacuum casting is a more cost-effective method than injection molding because of its reduced manufacturing costs.

For batch manufacturing and other low-volume production tasks, vacuum casting is a great method of production. Vacuum casting is widely utilized in India's manufacturing of industrial electronics, FMCG, and consumer goods.

How do you work with vacuum casting?

Injection molding, in which cast material is poured into molds to create items, and vacuum casting services are very comparable processes. The kinds of molds used in injection molding and vacuum casting differ from one another.

Molds for injection molding might be formed of steel, aluminum, or other materials. Silicone molds are utilized in vacuum casting, nevertheless. This significantly lowers the mold-making cost because silicone is more affordable and has better durability.

Polyurethane is the most often utilized casting material in this procedure. The qualities of various polyurethanes vary, including good shock and temperature resistance, elasticity, flexibility, and structural stiffness. Thus, different polyurethanes may be employed depending on the kind of product being created.

Vacuum casting uses

Making complicated and sophisticated goods may be accomplished more cost-effectively and efficiently with vacuum casting as opposed to the conventional injection molding method.

Due to its efficient production process, vacuum casting finds widespread application in the fabrication of commercial items. The following are a few industries that employ vacuum casting:

Manufacturing of consumer goods

Vacuum casting is a more effective method of producing consumer goods including combs, hair brushes, makeup packaging, sunglasses, pens, and other stationery.

Industry of Food and Beverages

Vacuum casting is used to create food and beverage containers, bottles, cans, mugs, and glasses. Due to the process's great efficiency and ability to produce goods quickly, vacuum casting is widely utilized in various industries where rapid manufacture is essential.

Advanced industry

Excellent heat and shock resistance is a feature of polyurethanes. Therefore, the recommended production procedure for creating electrical device housings is vacuum casting by Vacuum Casting Manufacturer using polyurethanes.

Follow our Facebook and Twitter for more information about our product.

#vacuum casting#vacuum casting services#Explore vacuum casting#Vacuum Casting Services China#Vacuum Casting Manufacturer#Vacuum Casting supplier

2 notes

·

View notes

Text

Excellence in Non-Ferrous Forging & Casting in India

Non-ferrous forging and casting have emerged as critical processes in the manufacturing landscape, contributing significantly to India's industrial prowess. With a focus on metals like aluminum, copper, brass, and bronze, the country's expertise in non-ferrous forging and casting has reached new heights. Let's explore the excellence that India brings to these essential metallurgical processes.

Non-ferrous forging in India is marked by precision and skill, as manufacturers leverage advanced techniques to shape metals into components with superior mechanical properties. The forging process involves applying heat and pressure to mold metals into desired forms, enhancing their strength and durability. Indian forging facilities are equipped with state-of-the-art technology, ensuring the production of high-quality components that meet international standards.

Casting, another integral part of non-ferrous metal processing, is equally impressive in India. Foundries across the country use advanced casting methods to create intricate and complex shapes from molten non-ferrous metals. The attention to detail in the casting process is evident in the precision components that are vital to various industries.

Industries such as automotive, aerospace, and electronics in India benefit significantly from the excellence in non-ferrous forging and casting. The automotive sector, for instance, relies on these processes for manufacturing engine components, transmission parts, and lightweight structural elements. The use of non-ferrous metals contributes to fuel efficiency and sustainability, aligning with global trends.

In the aerospace industry, where precision and reliability are paramount, non-ferrous forging and casting play a crucial role. Components like aircraft engine parts and structural elements are crafted with meticulous attention to detail, ensuring the highest standards of performance and safety.

The electronics industry in India also reaps the rewards of non-ferrous forging and casting. The superior thermal conductivity of non-ferrous metals makes them ideal for applications such as heat sinks and connectors. The corrosion resistance of these metals ensures the longevity of electronic components in various environments.

As India continues to position itself as a global manufacturing hub, the excellence in non-ferrous forging and casting becomes a cornerstone of its industrial success. The commitment to quality, technological advancement, and sustainability places India at the forefront of non-ferrous metallurgy, contributing to the growth and competitiveness of its industries on the world stage. The journey of excellence in non-ferrous forging and casting in India is undoubtedly a testament to the nation's capabilities in shaping the future of manufacturing.

2 notes

·

View notes

Text

What types of metal can be processed using Jugmug roll forming machines

Jugmug Roll Forming machines are versatile and can process a wide variety of metals, making them suitable for numerous applications across different industries. The types of metals that can be effectively processed using Jugmug roll forming technology include:

1. Steel

Cold Rolled Steel: This is the most common material used in roll forming due to its excellent formability and strength. It is often used for producing structural components, framing, and various profiles.

Hot Rolled Steel: Suitable for applications requiring thicker materials, hot rolled steel can also be processed, though it may require specific adjustments in the roll forming setup.

2. Stainless Steel

Stainless steel is highly valued for its corrosion resistance and aesthetic appeal. Jugmug machines can form stainless steel into complex shapes for applications in construction, automotive, and kitchenware.

3. Aluminum

Aluminum is lightweight and has excellent corrosion resistance, making it ideal for applications in the automotive and aerospace industries. Jugmug's roll forming machines manufacturers in India can handle various aluminum alloys to create intricate profiles.

4. Galvanized Steel

This type of steel is coated with zinc to prevent rusting, making it suitable for outdoor applications. Jugmug machines are capable of processing galvanized steel efficiently, which is commonly used in roofing and siding.

5. Pre-Painted and Coated Steel

Jugmug can process pre-painted or coated steel sheets, allowing manufacturers to produce finished products without additional painting or coating steps. This is particularly useful in the construction industry for aesthetic applications.

6. Copper

Copper is used in electrical applications due to its excellent conductivity. Jugmug’s roll forming technology allows for the production of copper profiles that meet specific electrical requirements.

Factors Influencing Metal Processing

The ability to process these metals effectively depends on several factors:

Formability: The inherent properties of the metal determine how easily it can be shaped without cracking or deforming.

Springback: Different metals exhibit varying degrees of springback after bending, which must be accounted for during the design of the roll forming process.

Minimum Bend Radius: Each metal type has a specific minimum bend radius that must be adhered to in order to prevent damage during processing.

Conclusion

Jugmug Roll Forming machines are capable of processing a diverse range of metals including steel, stainless steel, aluminum, galvanized steel, pre-painted steel, copper, lead, and titanium. This versatility makes them suitable for various industries such as construction, automotive, HVAC, and more. The technology employed by Jugmug ensures high precision and efficiency while accommodating the unique characteristics of each metal type.

#roll forming machine#roll forming industries india#roll forming machine in india#roll forming machine suppliers

0 notes

Text

Perforated Sheets 101: A Comprehensive Guide to Types and Uses

Perforated sheets, characterized by their array of holes punched through a sheet of material, have become integral in a wide array of industries. From architecture to engineering, these versatile materials offer a mixture of functionality and aesthetic appeal. This article delves into the various applications of perforated sheets and highlights their numerous benefits.

Understanding Perforated Sheets

Perforated sheets are flat materials that have been punched or drilled with a pattern of holes. These sheets can be made from various materials, including metals (such as steel, aluminum, or stainless steel), plastics, and even some composites. The process of perforation involves creating a pattern of holes in a sheet, which can vary in size, shape, and spacing. These patterns are designed based on the intended application, whether it be for ventilation, filtration, or decorative purposes.

Key Characteristics of Perforated Sheets

Perforated sheets are most commonly made from metals due to their strength and durability, but they can also be made from plastics or other materials. The holes in perforated sheets can be arranged in different patterns, such as round, square, rectangular, or custom shapes. The spacing between holes and their size can also be adjusted based on the functional or aesthetic needs. While the thickness of the sheet material can vary, influencing its strength and durability, thicker sheets are generally more robust and suitable for heavier applications. Perforated sheets can have painted, anodized, or galvanised finishes to enhance their appearance and protect them from corrosion or other environmental factors.

Benefits of Perforated Sheets

The design possibilities with perforated sheets are nearly limitless. They can be customised to create intricate patterns that serve as visual focal points or subtle accents in various applications. The holes in perforated sheets can also be tailored to specific needs, such as improving airflow, reducing weight, and facilitating drainage. They are typically made from robust materials, which means they can withstand harsh environmental conditions and mechanical stress, making them ideal for both indoor and outdoor applications.

Applications Across Industries

Architecture and Design: Perforated sheets have found a significant place in architectural design due to their aesthetic and functional properties. They are commonly used in facades, ceilings, and partitions.

Industrial and Manufacturing: In the industrial sector, perforated sheets are essential for various applications such as screens, filters, and protective covers. They are used in machinery to separate materials, facilitate airflow, and provide a barrier that protects sensitive components.

Environmental and Safety Applications: Perforated sheets are also utilized in environmental management and safety applications. For instance, they are used in water treatment facilities as filters to remove debris and contaminants.

Consumer Products: Beyond industrial uses, the uses of perforated sheets are found in everyday consumer products. From kitchen appliances like range hoods to decorative items such as lamps and screens, these sheets offer both functionality and style.

Conclusion

Perforated sheets are more than just functional components; they are a versatile material that blends practicality with aesthetic appeal. Their applications span across industries, demonstrating their broad utility and importance. Whether for their design flexibility or their practical benefits, perforated sheets continue to be a valuable material in numerous fields. Visit Fine Perforators, one of the biggest perforated sheet manufacturers in India, to find the best Perforated sheets that cater your specific needs.

Source: https://www.linkedin.com/pulse/perforated-sheets-101-comprehensive-guide-types-uses-fine-perforators-5j2vc/

0 notes

Text

Top Aluminium Die Casting Manufacturer & Supplier in India | BQMP

BQMP is a top aluminum die casting manufacturer and supplier in India, offering high-quality die cast components and custom solutions for diverse industries. Explore our premium Aluminum casting services to meet your specific needs.

0 notes

Text

Figuring out Round Bars' Superiority: An All-Inclusive Guide

Introduction:

Nova Steel Corporation is leading Round Bar Manufacturer in India. Round bars, the unsung heroes of the industrial world, have a significant impact on modern infrastructure and innovation. Despite their simple appearance, round bars are essential components in a variety of industries, including construction, manufacturing, automotive, and aerospace. In this comprehensive tutorial, we will look at the fundamentals of round bars, including their applications, properties, and why they are such important components in engineering and design.

Understanding Round Bars:

Round bars, often called rods or solid bars, are cylindrical metal bars with a circular cross section. They are fabricated from different materials, including steel, stainless steel round bar, High Nickel Alloy Round Bars, XM19/Nitronic Round Bar, LF2 Round Bar, and Alloy Steel 4340 Round Bar, each offering unique properties suited for specific applications. Round bars are manufactured through processes such as hot rolling, cold drawing, or machining, ensuring precise dimensions and consistent quality.

Applications Across Industries:

The versatility of round bars renders them indispensable across a myriad of industries:

1. Construction: Round bars are fundamental components of construction projects; they are used to fabricate building and bridge frameworks, create support beams, and reinforce concrete structures.

2. Manufacturing: Round bars are used in the manufacturing industry to make shafts, axles, fasteners, and precision components for machinery, equipment, and tools.

3. Automotive and Aerospace: Because of their strength, endurance, and resistance to corrosion, round bars are widely used in the automotive and aerospace industries for the fabrication of engine parts, chassis components, landing gear, and structural elements.

4. Energy Sector: Round bars are used in the energy industry to manufacture pipelines, drill rods, and components for power production and transmission equipment.

Key Characteristics:

Several key characteristics make round bars indispensable in engineering and construction:

1. Strength and Durability: Round bars provide structural integrity and endurance because of their great tensile strength and resilience, which allows them to handle large loads and harsh environments.

2. Machinability: Round bars are easily machined and built into unique components, allowing for precision shape and dimensional accuracy to fulfill design specifications.

3. Corrosion Resistance: Because of their superior corrosion resistance, materials such as aluminum and stainless steel are a good choice for outdoor and marine applications where exposure to severe conditions and moisture is common.

4. Thermal Conductivity: Round bars conduct heat well, making them ideal for applications that require heat transmission or dissipation, such as heat exchangers and thermal management systems.

Best Round Bar Manufacturer

Nova Steel Corporation is leading Round Bar Supplier in India. We have substantial expertise in the manufacturing and supplying of all sorts of Round Bars. We are Best Round Bar Manufacturers. Personnel with the necessary qualifications and a wealth of experience handling different kinds of Pipe Fittings and other products supervise the whole manufacturing process.

Finally, round bars represent the pinnacle of versatility, strength, and dependability in the field of engineering and building. From towering skyscrapers to precise machinery, round bars are the foundation of modern infrastructure and innovations, representing human ingenuity and perfection. As technology advances and businesses evolve, the importance of round bars will grow, influencing the landscapes of tomorrow and beyond.

0 notes

Text

Forging Company in India: Pioneering Excellence in Metal Fabrication

Forging has been a crucial process in metal fabrication, significantly contributing to various industries, including automotive, aerospace, and construction. In India, the forging industry has witnessed substantial growth, with companies like Happy Forging Ltd. (HFL) leading the way. HFL, a renowned forging company in India, has set benchmarks in quality, innovation, and customer satisfaction. This blog delves into the forging process, its significance, and how HFL has become a pioneer in this field.

What is Forging?

Forging is a manufacturing process where metal is shaped using compressive forces. This process enhances the metal's structural integrity, making it stronger and more durable. There are different types of forging, including open-die forging, closed-die forging, and rolled-ring forging, each serving specific purposes and industries.

Types of Forging

Open-Die Forging: This method involves deforming a metal piece between multiple dies that do not enclose the metal entirely. It is used for large, simple-shaped components.

Closed-Die Forging: Also known as impression-die forging, this process involves metal being placed in a die resembling a mold, which is then hammered or pressed. It is ideal for more complex shapes.

Rolled-Ring Forging: This type involves creating a seamless ring by piercing a hole in a thick, round piece of metal and then rolling it into a thin ring. It is commonly used in the production of bearings and gears.

Importance of Forging in Metal Fabrication

Forging plays a pivotal role in metal fabrication due to several reasons:

Enhanced Strength: The forging process aligns the metal's grain structure, resulting in improved strength and durability.

Superior Quality: Forged components exhibit better mechanical properties and can withstand high stress and load conditions.

Cost-Effective Production: Forging reduces material wastage, making it a cost-effective method for producing high-quality metal parts.

Versatility: The process is adaptable for various metals, including steel, aluminum, and titanium, catering to diverse industrial needs.

HFL: A Leader in Forging Excellence

Happy Forging Ltd. (HFL) stands out as a forging company in India due to its commitment to quality, innovation, and customer satisfaction. Established with the vision of providing top-notch forging solutions, HFL has continuously evolved, embracing advanced technologies and processes.

Advanced Technology and Infrastructure

HFL boasts state-of-the-art infrastructure, equipped with advanced forging presses, automated systems, and quality control laboratories. The company's focus on technological advancements ensures precision, efficiency, and consistency in its forging processes. By integrating modern techniques, HFL has achieved remarkable milestones in production and quality standards.

Skilled Workforce and Expertise

One of HFL's core strengths lies in its skilled workforce and expertise. The company employs a team of experienced engineers, technicians, and craftsmen who are proficient in various forging techniques. Continuous training and development programs ensure that the team stays updated with the latest industry trends and practices.

Commitment to Quality

Quality is paramount at HFL. The company adheres to stringent quality control measures at every stage of the forging process, from raw material selection to final inspection. By implementing rigorous testing protocols, HFL guarantees that its products meet international quality standards, ensuring reliability and durability.

Applications of Forged Products

Forged products find applications across numerous industries, each benefiting from the unique advantages of forged components.

Automotive Industry

In the automotive sector, forged parts are integral to vehicle performance and safety. Components such as crankshafts, connecting rods, and gears are commonly forged to withstand high stress and ensure longevity.

Aerospace Industry

The aerospace industry demands components that can endure extreme conditions and maintain structural integrity. Forged products like turbine blades, aircraft fittings, and landing gear are critical for aircraft performance and safety.

Construction and Heavy Machinery

Forged components are essential in construction and heavy machinery due to their robustness and reliability. Excavator arms, bulldozer blades, and crane hooks are examples of forged parts that enhance the durability and efficiency of construction equipment.

List Of Top Companies in the Forging Sector in India

India is home to several leading forging companies, each contributing significantly to various industries through their high-quality forged products and innovative techniques. Here are some of the main companies in the forging sector in India:

1. Bharat Forge Ltd.

Bharat Forge Ltd. is one of the largest forging companies in India and the world. Headquartered in Pune, the company is a part of the Kalyani Group and specializes in manufacturing a wide range of high-performance, critical components for automotive, power, oil and gas, construction, and mining industries. Bharat Forge is renowned for its advanced technology, research and development capabilities, and global footprint.

2. Mahindra Forgings

Mahindra Forgings, a subsidiary of Mahindra CIE, is a prominent player in the Indian forging industry. The company produces a variety of forged components for the automotive industry, including crankshafts, camshafts, and connecting rods. With a strong focus on innovation and sustainability, Mahindra Forgings has established itself as a reliable supplier to leading automobile manufacturers worldwide.

3. Happy Forging Ltd. (HFL)

Happy Forging Ltd. (HFL) is a leading forging company in India known for its commitment to quality, innovation, and customer satisfaction. HFL offers a diverse range of forged products for various industries, including automotive, aerospace, and construction.

The company's state-of-the-art infrastructure, skilled workforce, and stringent quality control measures ensure the production of high-quality forged components.

4. Ramkrishna Forgings Limited

Ramkrishna Forgings Limited is a well-established forging company based in Kolkata. The company specializes in manufacturing forged and machined components for the automotive, railway, mining, and oil and gas industries. With a strong emphasis on technological advancements and customer-centric solutions, Ramkrishna Forgings has become a trusted name in the forging sector.

Future Prospects and Innovations

Looking ahead, Forging Companies aims to further strengthen its position as a leading forgings company across the globe by exploring new markets and investing in research and development. The company plans to introduce innovative forging techniques and expand its product portfolio to cater to emerging industry demands. Companies like HFL are committed to excellence and innovation, positioning them for continued growth and success in the forging industry.

Conclusion

Forging is a vital process in metal fabrication, offering numerous benefits such as enhanced strength, superior quality, and cost-effective production. Happy Forging Ltd. (HFL) exemplifies excellence in this field, with its advanced technology, skilled workforce, and unwavering commitment to quality. As a pioneering forgings company in India, HFL continues to set benchmarks, driving innovation and customer satisfaction.

0 notes

Text

Inside the Manufacturing Process: How Bicycle Brakes Are Made

One of a bike's most important parts for maintaining rider safety and control is the brake system. We at S.K. Aggarwal & CO are proud to be among the top manufacturers of leading bicycle brake parts in India. Situated in Ludhiana, a center for high-quality bicycle production, we are committed to creating brakes that surpass industry standards in terms of functionality, robustness, and security. We show you how we make premium bicycle brakes by taking you inside our manufacturing facility in this blog.

Step 1: Design and Engineering

Careful engineering and design serve as the foundation for the production process. Whether they are disc brakes, V-brakes, or other forms of brakes, our team of professionals is dedicated to designing brake systems that provide the best possible performance. Every component is designed with precision and dependability using sophisticated CAD tools. We take into account elements like heat dissipation, weight distribution, and material choice to create brakes that function superbly in a variety of circumstances.

Step 2: Material Selection

Selecting the proper materials is essential to producing bicycle brakes that are long-lasting and efficient. Being the top producers of bicycle brakes in Ludhiana, we employ premium components like composites, stainless steel, and aluminum alloys. These materials have been selected due to their strength, low weight, and ability to withstand corrosion and wear. To ensure long-lasting performance, our brake rotors, for instance, are made of hardened stainless steel that can tolerate severe friction and heat.

Step 3: Component Fabrication

Once the design and materials are finalized, the next step is component fabrication. This involves various processes, including:

Step 4: Assembly

In the assembly stage, individual components are brought together to form a complete brake system. This requires careful attention to detail to ensure each part fits perfectly. For instance, when assembling disc brakes, the calipers must align precisely with the rotors to provide optimal braking force. As a bicycle brakes manufacturer Ludhiana, our assembly process includes the following steps:

Cutting and Shaping: Raw materials are shaped into the precise pieces required for the brake system using CNC machines and precision cutting tools. This covers brake pads, calipers, rotors, and brake levers.

Machining: To ensure a flawless fit, these components are machined to precise specifications using high-precision CNC equipment. The smooth and responsive braking action that riders depend on is only possible with this level of precision.

Heat Treatment: To improve their hardness and wear resistance, some parts, including rotors, are subjected to heat treatment. To obtain the required mechanical qualities, this method entails heating the metal to a high temperature and quickly cooling it down.

Sub-Assembly: Individual smaller parts, including calipers and brake levers, are constructed first. This entails fastening nuts, springs, and additional tiny components.

Final Assembly: The entire brake unit is then formed by combining the sub-assemblies. Every assembly is examined by our knowledgeable specialists to ensure correct alignment, tension, and movement.

Lubrication: To guarantee smooth operation and stop wear, moving parts are greased. For the brakes to continue working as intended over time, this procedure is essential.

Step 5: Quality Control and Testing

An essential component of our production process is quality control. We follow strict quality standards as one of the top producers of bicycle brake parts in India to make sure every brake system satisfies safety and performance requirements. Our procedure for quality control consists of:

Visual Inspection: Every brake is examined visually to check for flaws such as surface abnormalities, cracks, and misalignments.

Performance Testing: Brake performance is evaluated by measuring stopping power, modulation, and heat dissipation. To make sure the brakes will function dependably in a variety of situations, this testing replicates real-world circumstances.

Testing for Durability: Brakes are put through extensive wear and fatigue tests to make sure they can handle repeated use. This involves conducting repeated brake tests to assess the components' resilience under load.

Step 6: Finishing and Packaging

The final stage is where the brakes go after passing quality control. Protective coatings, like anodizing for aluminum components, are applied to components to improve their resistance to corrosion and give them a sleek look. Lastly, to avoid damage while delivery, the brakes are properly packed. Being the best bicycle brakes manufacturers in Ludhiana, we guarantee that our goods arrive to clients' locations in flawless shape and are prepared for installation.

Conclusion

Bicycle brakes are made using a process that combines precision craftsmanship, premium materials, and cutting-edge engineering. We at S.K. Aggarwal & CO are dedicated to creating brake systems that give riders the performance and safety they require. Every stage of our production process, from design to quality assurance, demonstrates our commitment to being the top producer of bicycle brakes in Ludhiana, India.

We continue to provide brake systems that are the industry standard for performance and safety in the cycling sector by putting an emphasis on innovation and quality. Our brakes are made to provide you with the assurance and control you require on every ride, whatever of your skill level.

#bicycle brakes manufacturer in india#bicycle disc brakes in ludhiana#bicycle brakes manufacturer ludhiana#bicycle v brakes in india#bicycle disc brakes in india#bicycle disc brakes in punjab#bicycle brakes manufacturer in punjab#bicycle v brakes in ludhiana#best bicycle brakes manufacturers in ludhiana#best bicycle brakes manufacturers in punjab

0 notes

Text

Advanced Ceramics Market - The Biggest Trends to watch out for 2024-2030

Advanced Ceramics Industry Overview

The global advanced ceramics market size was estimated at USD 107.00 billion in 2023 and is projected to grow at a CAGR of 4.2% from 2024 to 2030.

Increasing demand for advanced ceramics in various industries, coupled with growth in the medical and telecom sectors, is expected to drive market expansion. Advanced ceramics, also known as technical ceramics, possess improved magnetic, optical, thermal, and electrical conductivity. End-users can reduce their production and energy costs by utilizing advanced ceramics that provide high efficiency to end products. Asia Pacific is a leading market for advanced ceramics in the world in terms of their consumption.

Gather more insights about the market drivers, restrains and growth of the Advanced Ceramics Market

The rise in demand for advanced ceramics in the U.S. can be attributed to an increasing preference for lightweight materials across various industries. The production and consumption of these materials and components for the electrical and electronics sectors have been on the rise due to the growing need for uninterrupted connectivity. Furthermore, flourishing electric vehicle (EVs) and defense sectors have also contributed to market growth.

For instance, in 2023, under the National Defense Authorization Act of the U.S., the country authorized USD 32.6 billion for Navy shipbuilding, an increase of USD 4.70 billion. Also, in April 2023, the EPA announced new and stricter environmental rules for light- and medium-duty vehicles. The rules are expected to apply to vehicles manufactured from 2027 to 2032, covering greenhouse gases (GHG) and other pollutants, including ozone, nitrogen oxides, particulate matter, and carbon monoxide.

Advanced Ceramics Market Segmentation

Grand View Research has segmented the global advanced ceramics market report based on material, product, application, end-use, and region:

Material Outlook (Revenue, USD Million, 2018 - 2030)

Alumina

Titanate

Zirconate

Ferrite

Aluminum Nitride

Silicon Carbide

Silicon Nitride

Product Outlook (Revenue, USD Million, 2018 - 2030)

Monolithic

Ceramic Coatings

Ceramic Matrix Composites (CMCs)

Application Outlook (Revenue, USD Million, 2018 - 2030)

Electric Equipment

Catalyst Supports

Electronic Devices

Wear Parts

Engine Parts

Filters

Bioceramic

Others

End-use Outlook (Revenue, USD Million, 2018 - 2030)

Electric & Electronics

Automotive

Machinery

Environmental

Medical

Others

Regional Outlook (Revenue, USD Million, 2018 - 2030)

North America

US

Europe

Germany

UK

Asia Pacific

China

India

Central & South America

Brazil

Middle East and Africa

Saudi Arabia

Browse through Grand View Research's Advanced Interior Materials Industry Research Reports.

The KSA cement market size was estimated at USD 3.99 billion in 2023 and is projected to grow at a CAGR of 7.0% from 2024 to 2030.

The global linear slides market size was estimated at USD 2.73 billion in 2023 and is expected to grow at a CAGR of 6.6% from 2024 to 2030.

Key Advanced Ceramics Company Insights

Some of the key players operating in the market include Kyocera Corp. and CoorsTek.

Kyocera Corp. is a multinational electronics and ceramics manufacturer based in Japan. Its advanced ceramics division offers a wide range of products, including cutting tools, industrial components, and electronic devices. Kyocera's advanced ceramics are known for their high quality, durability, and performance, making them a preferred choice in industries, such as automotive, aerospace, and medical

CoorsTek is a privately owned manufacturer of technical ceramics based in the U.S. It produces a diverse range of advanced ceramic products, including components for semiconductor manufacturing, medical devices, and industrial equipment

Nexceris and Admatec are some of the emerging market participants in the advanced ceramics market.

Nexceris is an advanced materials company dedicated to developing innovative ceramic technologies for energy, environmental, and industrial applications. Headquartered in the U.S., Nexceris specializes in the design and manufacture of ceramic-based products including solid oxide fuel cells, gas sensors, and catalysts. Leveraging its expertise in materials science and engineering, Nexceris aims to address critical challenges in clean energy and environmental sustainability

Key Advanced Ceramics Companies:

The following are the leading companies in the advanced ceramics market. These companies collectively hold the largest market share and dictate industry trends.

3M

AGC Ceramics Co., Ltd.

CeramTec GmbH

CoorsTek Inc.

Elan Technology

KYOCERA Corporation

Morgan Advanced Materials

Murata Manufacturing Co., Ltd.

Nishimura Advanced Ceramics Co., Ltd.

Ortech Advanced Ceramics

Saint-Gobain

Recent Developments

In February 2023, MO SCI Corp., completed the acquisition of 3M's advanced materials business. This strategic move encompasses the transfer of more than 350 specialized pieces of equipment and associated intellectual property. By the fourth quarter of 2023, all acquired assets, including equipment and technology, will be fully integrated and operational at MO SCI Corp.'s headquarters in Rolla, Missouri

In June 2022, CoorsTek allocated more than USD 50 million towards the establishment of a cutting-edge advanced materials manufacturing campus spanning 230,000 square feet. This strategic investment aims to drive further innovation across multiple markets. The expansion represents a substantial commitment by CoorsTek to enhance its Benton facility, marking a pivotal milestone in the company's ongoing long-term investment strategy in Arkansas

Order a free sample PDF of the Advanced Ceramics Market Intelligence Study, published by Grand View Research.

0 notes

Text

A sand casting company specializes in producing metal components using the sand casting process. They create custom molds from sand to cast complex parts in various metals, including aluminum and steel. These companies cater to industries like automotive, aerospace, and machinery, providing high-quality, cost-effective solutions for manufacturing needs.

0 notes

Photo

Are you looking for the best quality tool steel, die steel, and mold steel suppliers for your engineering work in India?

As one of India’s leading special steel suppliers, #ViratSpecialSteels can supply the following industries requirement of steel practically off-the-shelf.

Virat Special Steels Pvt. Ltd., is one of India’s top Tool Steel, Die Steel suppliers, and Mold Steel Stuckists. This company provides special steel of every kind in sizes and shapes (flat, round, or bars) per customer requirements. Based in #Gurgaon (Haryana) & #Ludhiana (Punjab) India.

Forging Industry - Forging is a process in which metal is being shaped using compressive forces with a Hammer or a press. Forging are classified into Cold forging, warm forging or hot forging. Mainly material used: Din 1.2714(DB6), DIN 1.2344(H13), DIN 1.2343(H11).

Pressure Die Casting – Die casting is performed by forcing molten metal under high pressure into a mold cavity & the cavity (mold cavity) is manufacture by using two hardened tool steel dies & perform similar to an injection mold. Mainly material used: Hot die steel i.e. DIN 1.2344(H13), DIN 1.2343(H11), and DIN 1.2581(H21).

Aluminum Extrusions - In Extrusion process material is pushed through a die to the desired cross section & in this manufacturing process it creates very complex cross section. The parts are being formed with an excellent surface finish. Mainly material used: - Hot die steels i.e. DIN 1.2344 (H13) grade.

Automotive Industry - Automotive industry are wide range of companies is mainly involved in manufacturing, design, development, of motor vehicles. Mainly material used: - Din 1.2714(DB6), DIN 40NiCrMo84(EN24), DIN 3343(M2), 16Mncr5, 20Mncr5.

Plastic industry - Polymer materials are manufactures in plastic industry and offers services to aerospace, building, construction, electronics, packaging and transportation. Mainly material used: - DIN 2738 (P20+ Ni), DIN 2311(P20).

Railways - They are involves mainly in manufacturing railways components i.e. Railway gear holder, Railway bogie cast parts, Railways axles, railways Sets of pins, Ground lever frame, adjustable crank, Compressor pistons, Compressor bearings. Mainly material used:-Din 1.2714(DB6), DIN 1.2344(H13), DIN 1.2343 (H11), DIN 40NiCrMo84(EN24), 20NiCrMo5(EN353).

Oil & Gas - Oil & Gas they supply more than 60 percent of our nation’s energy. Natural gas also helps generate the electricity that powers our daily lives.

They also have a fully equipped quality assurance and process examination facility that conducts tests such as hardness and analyses of grain structure.

Find us:

Website: https://www.viratsteels.com/

Email us: [email protected]

Call Us Now: +91-9814021775

#viratspecialsteels#viratsteelsindia#viratsteels#2714steel#h13steel#din2714#din2738#db6steel#din2344#diesteel#mouldsteel#mouldsteelstockist#tool steels#toolsteelsupplier#delhincr#gurugram#ludhiana#gurgaon#pune#india#forging#metalworking#steel#alloy steel#cold work steel#high speed steel#hot work steel#manufacturing#construction#iso9001

3 notes

·

View notes

Text

ONEMOLD: Leading the Way as a Plastic Injection Mould Maker

Whether is the product an automobile component, medical device, consumer electronic, or a packaging solution Injection Mould Maker has emerged to be the backbone of most industries in the manufacturing world today. ONEMOLD is the leading plastic injection mold maker that has revolutionized the way business production and design meet. But what makes ONEMOLD so unique? Accuracy Enters the Mould Space Precision Engineering

The success behind ONEMOLD is its quality in being accurately precise. INJECTION MOLDING APPLIES HIGH REQUIREMENTS as regards strict tolerances more complex and high-performance plastic parts have demanding requirements for exact allowances. ONEMOLD employs the use of state-of-the-art machinery, advanced CAD/CAM systems in every single mold, which indicates the highest standards are applied. Engineers work on very meticulous analysis of every project to fulfill even the toughest requirements.

Address: 28, 2nd floor, Ujagar Estate, Deonar.

State: Maharashtra

City: Mumbai

Country/Region: India

Zip: 400088

28, Ujagar Industrial Estate, Mumbai, INDIA

Every Industry Receives Customization

ONEMOLD understands that no two industries are alike. And, hence, with every industry in which they work, ONEMOLD provides specifically tailored solutions. Be it the automotive industry requiring that parts be sturdier or thermally resistant; or if it is the medical field requiring cleanroom-compliant moulds, ONEMOLD develops the customised solution tailor-made to specific requirements. Their expertise in mould manufacturing means versatility that leaves many rivals in the mould-making business in the dust.

One-stop shop from ONEMOLD:

ONEMOLD is not a molding company it is total project support at all stages right from design consultation to post-production services. The company makes sure that it gives total support to the customer at every stage of the process. The engineers at ONEMOLD have close coordination with the clients. It is these engineers who bond closely to ensure that the end product, as delivered by them, meets the client’s goals concerning design, functionality, and production efficiency. In this way, it is easier for clients to save costs, enhance the quality of their products, and bring timelines closer in manufacturing processes.

Injection Moulding Process at ONEMOLD

Prototype and Design

The ONEMOLD injection moulding process first begins with the design and prototyping phase. The company works with clients and an advanced 3D modeling software of their team to come up with a precise design of the desired component. Prototypes are then carried out to test the form, fit, and function before switching to full-scale production. This is a critical step for the early identification of possible flaws in the design, which saves time and money in the long run.

Mould Manufacturing

When the design is ready, ONEMOLD goes into manufacturing the mould. This is the magic part. Made from high-grade steel or aluminum, the moulds are precision machined according to the specifications of the project. ONEMOULD uses the most advanced CNC machining and EDM (electrical discharge machining) systems to produce some of the most accurately and durably built moulds in the business.

After preparing the molds, this is when the actual process of injection molding begins. ONEMOLD uses high-performance injection molding machines compatible with a range of thermoplastic materials. These machines inject hot melted plastic under pressure into the mold so that the final product will not have any flaw of whatsoever and will be just what is desired.

Why Choose ONEMOLD?

Quality Assurance

The operations of ONEMOLD have founded quality. They undergo severe and rigid quality control processes, therefore sending each mould and finished product to strict examinations. This way, it can always be relied upon by businesses to source highly performing products from ONEMOLD.

Sustainability

With awareness of the environment growing by the day, sustainability is a high priority for ONEMOLD. The production stream is kept as sustainable as possible, reducing waste and energy utilization as much as possible. This has a lot of positive effects on the environment besides reducing cost, which they pass down to their customers.

Global Reach

ONEMOLD’s reputation is huge both in its home market as well as all across the world where it has been making waves. The company has clients from around the world and makes efforts to give them the kind of Houseware Mould solutions that they need in order to remain competitive in this global marketplace. Be you a local startup or a multinational, ONEMOLD has the expertise and resources that could help fulfill your needs.

Conclusion:

Being a plastic injection mould maker, ONEMOLD is your first choice business partner in whatever sector. Having covered factors such as precision engineering, quality, and customer satisfaction, ONEMOLD has never been more established in the plastic injection moulding world. In a world where plastic injection moulding is threatened by such strong competition, the very choice of ONEMOLD means innovation, reliability, and excellence in every mould it creates for you.

0 notes

Text

Top Aluminium Die Casting Manufacturer & Supplier in India | BQMP

BQMP is a top aluminum die casting manufacturer and supplier in India, offering high-quality die cast components and custom solutions for diverse industries. Specializing in aluminum product design and manufacturing, we provide comprehensive services from concept to production, ensuring innovative and high-performance products tailored to your specific needs.

#marketing#business#Aluminium Die Casting Manufacturer#Aluminium Die Casting#Die Casting Manufacturer & Supplier in India

0 notes

Text

Wire Harness Manufacturers in India: Bhagyadeep Cables

In today's fast-evolving industries, efficient and reliable electrical connections are crucial for ensuring smooth operations across various applications. Wire harnesses play an integral role in this, providing a streamlined and organized way to bundle wires and cables that transmit electrical power and signals. Among the leading players in this domain is Bhagyadeep Cables, a prominent wire harness manufacturer in India known for its high-quality products and innovative solutions tailored to meet diverse industry needs.

The Importance of Wire Harnesses

Wire harnesses are essential components in many industries, including automotive, aerospace, electronics, telecommunications, healthcare, and more. They offer several advantages, such as:

Space Optimization: Wire harnesses bundle multiple wires into a single unit, reducing clutter and saving space.

Enhanced Safety: By securing and organizing wires, harnesses help prevent short circuits, electrical fires, and other hazards.

Improved Performance: Wire harnesses ensure stable and efficient electrical connections, minimizing signal interference and power loss.

Simplified Installation and Maintenance: Pre-assembled wire harnesses make installation and maintenance quicker and more straightforward, reducing downtime.

Bhagyadeep Cables: Leading the Way in Wire Harness Manufacturing

Bhagyadeep Cables has established itself as a leader in wire harness manufacturing by delivering superior quality products that adhere to global standards. The company provides a comprehensive range of wire harness solutions designed to cater to various applications and industries.

Key Features of Bhagyadeep Cables' Wire Harnesses

Customization to Meet Unique Requirements: Bhagyadeep Cables understands that each industry has unique demands. Therefore, the company offers fully customized wire harness solutions, engineered to specific dimensions, configurations, and material requirements to match client needs precisely.

Top-Quality Materials and Components: The company uses high-grade materials, such as copper, aluminum, and specialized insulating materials, to ensure optimal conductivity, durability, and resistance to environmental factors like heat, moisture, and chemicals.

Advanced Manufacturing Processes: Bhagyadeep Cables employs cutting-edge manufacturing technologies and automated processes to produce wire harnesses that meet the highest standards of precision, consistency, and reliability.

Stringent Quality Control: Quality is paramount at Bhagyadeep Cables. Every wire harness undergoes rigorous quality checks, including continuity testing, insulation resistance testing, and pull force testing, to ensure flawless performance and safety.

Compliance with International Standards: The wire harnesses manufactured by Bhagyadeep Cables comply with global standards, such as ISO, UL, and RoHS, guaranteeing quality, safety, and environmental responsibility.

Industries Served by Bhagyadeep Cables

Bhagyadeep Cables caters to a wide range of industries that rely on reliable and efficient wire harness solutions:

Automotive Industry: Wire harnesses are essential in vehicles for transmitting signals and power to various components, such as engines, lighting systems, infotainment systems, and safety features. Bhagyadeep Cables provides robust and durable automotive wire harnesses that withstand the rigors of on-road and off-road conditions.

Industrial Equipment: For machinery and industrial automation, wire harnesses are crucial for connecting various control units, sensors, and actuators. Bhagyadeep Cables designs harnesses that support seamless communication and power flow, enhancing equipment efficiency and reliability.

Telecommunications and Data Centers: In telecommunications and data centers, wire harnesses are used to manage data and power cables efficiently, ensuring optimal performance and minimizing interference. Bhagyadeep Cables offers custom wire harness solutions that meet the specific requirements of high-speed data transmission.

Consumer Electronics: For devices like household appliances, audio systems, and personal gadgets, wire harnesses provide the necessary connections for internal circuitry, enhancing product performance and longevity.

Medical Devices: Wire harnesses play a critical role in medical equipment, where reliability and safety are paramount. Bhagyadeep Cables manufactures specialized wire harnesses that meet the stringent quality and safety standards required in the healthcare sector.

Why Choose Bhagyadeep Cables for Wire Harness Solutions?

Expertise and Experience: With years of experience in the cable and wire harness industry, Bhagyadeep Cables brings a wealth of knowledge and expertise to every project, ensuring reliable and efficient solutions.

Innovation-Driven Approach: Bhagyadeep Cables invests in continuous research and development to stay at the forefront of technological advancements and offer innovative wire harness solutions that cater to emerging industry trends.

Customer-Centric Focus: The company prides itself on its customer-centric approach, working closely with clients to understand their specific needs and deliver solutions that exceed expectations.

Competitive Pricing and On-Time Delivery: By optimizing its manufacturing processes, Bhagyadeep Cables offers high-quality wire harnesses at competitive prices while ensuring timely delivery.

Conclusion

As one of the leading wire harness manufacturers in India, Bhagyadeep Cables is committed to providing top-notch, reliable, and customized solutions for various industries. With a focus on quality, innovation, and customer satisfaction, the company continues to set new benchmarks in the wire harness manufacturing sector. For businesses looking for a trusted partner in wire harness solutions, Bhagyadeep Cables stands as a reliable choice, ensuring excellence in every connection.

0 notes