#AntiCorrosionBolts

Explore tagged Tumblr posts

Text

The Ultimate Guide to Saltwater Resistant Fasteners for Marine Applications

Marine environments pose some of the toughest conditions for fasteners due to continuous exposure to saltwater, high humidity, and fluctuating temperatures. Select the right fastener is essential to ensure long-term durability, safety, and reliable performance. In this guide, we cover everything you need to know about marine-grade fasteners, saltwater-resistant options, and anti-corrosion marine bolts.

What Are Marine Grade Fasteners?

Marine-grade fasteners are specifically engineered to resist the harsh and corrosive conditions found in marine and coastal environments. These fasteners are manufactured using specialized materials and protective coatings designed to withstand:

Constant exposure to saltwater

UV rays

High humidity

Temperature extremes

Physical stress from waves and vibrations

Their corrosion-resistant properties make them ideal for use in boats, docks, offshore rigs, naval structures, and coastal construction.

Why Standard Fasteners Fail in Marine Environments

Regular carbon steel or even mild steel fasteners corrode quickly in marine settings due to:

Saltwater exposure, which accelerates oxidation

Electrochemical reactions between different metals (galvanic corrosion)

Crevice corrosion, especially in tight joints

Pitting corrosion, common in chloride-rich environments

Top Materials Used in Marine Grade Fasteners

1. Stainless Steel (304, 316, 316L)

316 and 316L Stainless Steel

The most commonly used stainless steel fasteners for marine applications are made from 316 and 316L stainless steel.

These alloys contain molybdenum, which greatly enhances resistance to chlorides and saltwater corrosion.

304 Stainless Steel

Less corrosion-resistant than 316 but still suitable for mildly marine environments

Not recommended for full immersion or high-salinity conditions

2. Silicon Bronze

Excellent resistance to saltwater corrosion

Commonly used in boat building, especially below the waterline

Offers good strength and ductility

3. Monel (Alloy 400)

A nickel-copper alloy highly regarded for its superior resistance to corrosion in marine and seawater environments.

Highly resistant to pitting and stress corrosion cracking

Commonly used in marine hardware, pumps, and propeller shafts

4. Titanium

Immune to saltwater corrosion and marine biofouling

Lightweight, high strength, and extremely durable

Widely used in high-performance yachts, submarines, and advanced marine defense systems.

5. Coated Fasteners (Hot-Dip Galvanized, PTFE, or Zinc Coated)

More economical than stainless or bronze

Coatings provide temporary corrosion protection

Not ideal for submerged or highly saline conditions

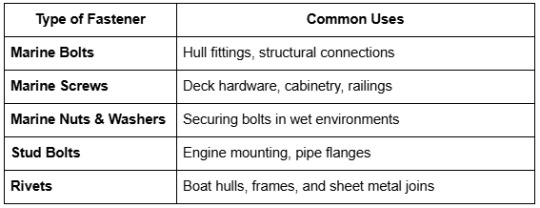

Types of Fasteners for Marine Applications

Anti-Corrosion Marine Bolts: Features to Consider

When selecting anti-corrosion marine bolts, consider the following features:

Material Compatibility: Avoid galvanic corrosion by using the same metal or a compatible combination.

Thread Type: Use coarse threads for soft materials such as wood or fiberglass, and fine threads for fastening into metal.

Sealants & Washers: Use neoprene or rubber washers to seal joints and prevent crevice corrosion.

Coatings: PTFE, Xylan, or hot-dip galvanizing enhance surface corrosion resistance.

Applications of Marine Grade Fasteners

Boat Building & Repair

Shipyards and Dry Docks

Coastal Construction

Marine Engines and Equipment

Offshore Oil Rigs

Underwater Structures

Marinas, Piers & Docks

Maintenance Tips for Marine Fasteners

Regular Inspections: Check for rust, loosening, or damage, especially after storms or long voyages.

Cleaning: Rinse with fresh water after saltwater exposure to remove chlorides.

Protective Coatings: Reapply anti-corrosion sprays or sealants periodically.

Avoid Mixed Metals: Prevent galvanic corrosion by using uniform metals or isolation washers.

Choosing the Right Supplier for Marine Fasteners

Look for suppliers with:

Experience in marine hardware manufacturing

Certifications like ISO 9001, ASTM, or ASME

Custom fabrication options

Inventory of stainless, bronze, Monel, and titanium fasteners

Global shipping and corrosion-resistant packaging

Conclusion

When it comes to marine applications, choosing the right fastener can make the difference between long-term performance and early failure. Marine grade fasteners made from materials like 316 stainless steel, Monel, or silicon bronze are specifically engineered to resist the aggressive environment of saltwater, high humidity, and UV exposure. Whether you're constructing a dock, maintaining a yacht, or installing offshore equipment, investing in saltwater resistant, anti-corrosion marine fasteners ensures safety, durability, and peace of mind.

FAQs

1. What are marine-grade fasteners?

Marine-grade fasteners are specialized bolts, screws, and nuts designed to resist corrosion and degradation in marine environments.

2. Is stainless steel 316 good for saltwater?

Yes, 316 stainless steel is alloyed with molybdenum, enhancing its resistance to chloride induced corrosion and making it well-suited for saltwater environments.

3. Can galvanized bolts be used in saltwater?

Hot-dip galvanized bolts offer temporary protection but are not ideal for long-term immersion in saltwater environments.

4. Which fasteners are best for underwater use?

Titanium, Monel, and silicon bronze fasteners are best for submerged and underwater use due to their superior corrosion resistance.

5. Where can I buy marine fasteners in bulk?

You can source high-quality marine fasteners from certified manufacturers like Ananka Fasteners, which specializes in corrosion-resistant, marine-grade hardware.

#MarineGradeFasteners#SaltwaterResistantFasteners#AntiCorrosionBolts#StainlessSteelFasteners#MarineFasteners#MarineHardware#CorrosionResistantFasteners#MarineBoltsAndNuts#MarineWashers#Ananka#Bolt#Articles#Blog#anankafasteners#manufacturer#fasteners#tumblr blog#tumblr#supplier

0 notes