#Automatic loading systems for trailers and loading docks

Explore tagged Tumblr posts

Text

Revolutionizing Spain’s Industries: Automation & Sustainable Energy

Spain’s industrial sector is rapidly evolving with cutting-edge technology and sustainable solutions. Two game-changing innovations—Automatic Loading Systems For Trailers And Loading Docks and Alternative Fuel Installations For Cement And Gasification Plants—are shaping a more efficient and eco-friendly future.

Streamlining Logistics with Automation- Industries are embracing automatic loading systems to optimize supply chain operations. These advanced systems enhance loading efficiency, reduce labor costs, and minimize downtime. By ensuring seamless material movement, businesses can improve productivity and safety while meeting high-demand logistics requirements.

Sustainable Energy for Cement & Gasification Plants- The shift towards alternative fuel installations is reducing Spain’s carbon footprint. Cement and gasification plants, traditionally reliant on fossil fuels, are integrating alternative energy sources such as biomass, waste-derived fuels, and hydrogen-based solutions. This transition not only helps in lowering CO₂ emissions but also enhances cost efficiency and long-term sustainability.

With automation streamlining logistics and alternative fuels driving sustainability, Spain’s industries are setting benchmarks for a cleaner, smarter future.

Website: http://seconcomponents.com/en/

#Automatic Loading Systems For Trailers And Loading Docks#Alternative Fuel Installations For Cement And Gasification Plants

0 notes

Text

Energy-Efficient Heating Options for Large Industrial Spaces in 2025

Among the most reliable options for energy-efficient heating in 2025 are indirect-fired heaters. These systems are ideal for indoor environments where open flame or exhaust fumes cannot be tolerated. With sealed combustion chambers and remote thermostat compatibility, indirect-fired heaters significantly reduce heat loss and maximize fuel usage. They’re often used in food processing plants, jobsite trailers, and other enclosed industrial environments. Cantherm’s indirect-fired heaters for industrial spaces exemplify the best in this class, providing clean air and consistent warmth with low emissions and CSA-certified safety. As more facilities opt for controlled and clean heat, these systems remain a top choice for safe industrial heating.

Radiant Tube Heaters Improve Efficiency with Targeted Heat

Facilities that prioritize focused, localized heat benefit from the energy-saving design of radiant tube heaters. Instead of heating air much of which can escape in tall or drafty buildings radiant systems warm surfaces and people directly. This makes them ideal for settings like loading docks, workshops, and garages where maintaining constant ambient air temperature isn’t practical. By delivering warmth exactly where it’s needed, radiant heaters reduce energy consumption and operational costs. While they don’t replace primary heating systems in larger buildings, they are a powerful supplementary option in targeted heating zones.

High-Efficiency Unit Heaters Now Offer Smart Controls and Better Fuel Management

Today’s most energy efficient warehouse heaters feature modulating burners, electronically commutated (EC) motors, and compatibility with building management systems. These technologies allow unit heaters to automatically adjust output based on real-time temperature demands, ensuring that energy isn’t wasted through unnecessary cycles. In facilities with high ceilings and varied layouts, modern unit heaters help maintain consistent temperatures without overheating unoccupied areas. Building automation adds an extra layer of control, letting managers monitor fuel use, schedule run times, and optimize performance with ease.

Hybrid Systems Combine Heating and Ventilation for Air Quality and Efficiency

More industrial buildings are investing in hybrid systems that combine heat delivery with advanced ventilation technology. These setups use integrated HRVs or makeup air systems to maintain healthy indoor air quality while efficiently distributing heat. Especially in facilities with high occupancy, chemicals, or airborne contaminants, maintaining fresh air is just as important as temperature control. By combining heating and ventilation into a single strategy, businesses can reduce the need for multiple systems while gaining better control over their indoor environment. Cantherm’s climate control systems support these hybrid solutions, offering both comfort and compliance in one efficient package.

Portable Heating Units Provide Versatility for Temporary and Zoned Needs

Industrial heating needs are not always permanent. Temporary structures, renovations, or remote locations often require flexible solutions that can be deployed quickly and moved as necessary. Portable industrial heaters meet this need, especially those that are CSA-approved and built for rugged use. Whether warming a construction site or a temporary operations hub, Cantherm’s portable heating systems Canada lineup includes powerful and reliable indirect-fired models that offer impressive thermal output, fuel efficiency, and on-site versatility. Their ease of setup and safety certifications make them a dependable choice across industries.

Energy Efficiency is the New Standard for Commercial Heating in 2025

The market for commercial space heaters has evolved beyond just output power. In 2025, energy efficiency, safety compliance, and smart automation define the leading edge. As building codes tighten and energy prices climb, the cost of inefficient systems becomes too great to ignore. That’s why choosing systems with optimized fuel consumption and smart integration is no longer optional it’s essential for financial and operational sustainability. Cantherm’s product lines, including the latest in large warehouse heating solutions, are built to address these realities with precision and performance in mind.

Solutions Tailored for Industrial Scale and Unique Heating Needs

Every industrial facility has unique heating challenges, from irregular floor plans to ventilation requirements and ceiling heights. That’s why the best heater for large industrial space is never one-size-fits-all. Custom solutions that consider building layout, insulation quality, air circulation, and fuel availability provide the best return on investment. Cantherm’s in-depth understanding of industrial needs ensures that every client is matched with a heating system that delivers results not just heat. Whether you’re retrofitting an old plant or setting up a new warehouse, their team will help you assess, select, and implement the right equipment for long-term efficiency and comfort.

Why Energy-Efficient Heating is a Game-Changer for Industrial Sites

The shift toward energy efficient industrial heating solutions is more than a trend it’s an industry-wide necessity. Lower emissions, reduced fuel usage, and smarter temperature control all contribute to reduced overhead costs and a smaller carbon footprint. Forward-thinking facility managers are already adopting new technologies to ensure long-term compliance and competitiveness. With Cantherm’s range of heating options from indirect fired heaters to portable units and hybrid systems industrial spaces across Canada are better equipped to face the challenges of tomorrow.

Conclusion

As 2025 progresses, industrial operations need heating systems that combine efficiency, safety, and adaptability.��Cantherm Distributors continues to lead in this space by offering premium, reliable solutions tailored to the demands of warehouses, job sites, and manufacturing plants. Whether you’re looking for radiant, indirect-fired, or portable options, choosing energy-efficient heating is not just good businessit’s the smart way forward.

0 notes

Text

Best Practices for Operating Dock Levellers Safely and Effectively

Ensuring safe and efficient operations in loading bays is a priority for any business handling goods. At Maini Materials Movement, we understand that while dock levellers are critical for seamless logistics, they can pose risks if not managed properly. By adopting best practices, you can minimize hazards, boost productivity, and protect your workforce. Here’s a comprehensive guide to operating these systems safely and effectively.

1. Prioritize Comprehensive Staff Training

The foundation of safe operations lies in well-trained staff. Employees must be thoroughly educated on the correct use of equipment, including how to operate levellers and follow safety protocols. Training should cover startup procedures, load handling, and troubleshooting common issues. Regular refresher courses reinforce these skills and keep workers updated on best practices. Maini Materials Movement advocates for a safety-first culture, encouraging employees to report potential hazards immediately. This proactive approach prevents accidents and fosters accountability across the team.

2. Match Equipment to Trailer Heights

Loading bays often handle vehicles of varying sizes, and not all trailers align perfectly with standard platforms. A typical leveller operates within a 300mm range above and below the dock height. However, if your facility frequently services trucks with significantly different floor heights, consider investing in equipment with an extended range. This ensures smooth transitions between trailers and docks, reducing strain on both workers and machinery. Properly matched equipment enhances efficiency and minimizes the risk of damage or injury during loading and unloading.

3. Optimize for Manual Handling Equipment

The type of manual handling tools used in your facility—such as hand pallet trucks or electric pallet trucks—directly impacts safe operations. Hand pallet trucks require a gentle slope, typically no more than 3%, while electric models can handle up to 5%. Steeper gradients force workers to exert excessive effort, increasing the likelihood of injuries and slowing operations. Selecting a leveller with an appropriate gradient for your equipment ensures smoother workflows and protects workers from unnecessary strain, contributing to long-term operational efficiency.

4. Prevent Slips, Trips, and Falls

Loading areas are prone to slips, trips, and falls, especially when debris, spills, or obstructions accumulate. Regular cleaning of the leveller and surrounding areas is essential to maintain a safe environment. High-visibility markings guide workers and drivers, while anti-slip surfaces provide extra traction. Properly maintained dock seals and shelters shield the area from weather-related hazards, such as rain or snow, which can create slippery conditions. Additionally, installing dock lights improves visibility during early morning or late-night operations, further reducing risks.

5. Establish Robust Emergency Procedures

Preparedness is critical for handling unexpected situations. Clear guidelines should outline steps to take in case of equipment malfunction, ensuring staff can respond swiftly and safely. Levellers equipped with advanced safety features, like automatic stops, offer an extra layer of protection. These systems can secure the platform if a truck moves unexpectedly while a forklift is in use, preventing potentially dangerous incidents. Regular drills and accessible emergency protocols empower workers to act confidently, minimizing downtime and risks during critical moments.

6. Conduct Regular Maintenance Checks

Routine maintenance is vital to keep equipment in peak condition. Schedule regular inspections to identify wear and tear, such as damaged hinges or hydraulic issues, before they escalate into safety hazards. Lubricate moving parts, check electrical systems, and verify that safety features are functioning correctly. A well-maintained leveller not only operates more efficiently but also extends its lifespan, saving costs in the long run. Maini Materials Movement recommends partnering with experts for professional servicing to ensure compliance with industry standards.

7. Foster Continuous Improvement

Safety and efficiency are ongoing commitments. Encourage feedback from operators to identify areas for improvement, such as workflow bottlenecks or recurring hazards. Stay informed about advancements in loading bay technology, such as energy-efficient levellers or smart sensors, to enhance operations. By regularly evaluating and updating your practices, you can maintain a safe, productive environment that adapts to evolving business needs.

Final Thoughts

Operating dock levellers safely and effectively requires a proactive approach, from training staff to selecting the right equipment. By implementing these best practices, businesses can reduce risks, improve efficiency, and create a safer workplace. Maini Materials Movement is committed to supporting companies in optimizing their loading bay operations with reliable solutions and expert guidance. Embrace these strategies to ensure your facility runs smoothly and your team stays protected.

0 notes

Text

The Future of Trailer Manufacturing: Trends to Watch in 2025

The trailer manufacturing industry is undergoing significant changes, with new technologies and innovations reshaping how trailers are designed, produced, and used. As we move into 2025, there are several key trends that trailer manufacturers, businesses, and consumers alike should be aware of. In this blog, we’ll explore the cutting-edge developments that are set to redefine the future of trailer manufacturing.

1. Sustainability and Eco-Friendly Materials

As the global push toward sustainability grows, trailer manufacturers are increasingly focusing on using eco-friendly materials and adopting energy-efficient practices. By 2025, we expect to see a rise in the use of lightweight, recyclable materials such as aluminum and composites. These materials not only help reduce the overall weight of the trailer, which improves fuel efficiency, but they also contribute to lowering carbon footprints during production.

Moreover, manufacturers are looking into sustainable coatings and finishes that reduce environmental impact while maintaining durability and protection against the elements. In addition, trailer manufacturers may start adopting more sustainable manufacturing processes, reducing energy consumption and waste.

2. Electric and Hybrid Trailers

The transportation industry is shifting towards electric and hybrid vehicles, and trailers are no exception. While electric trucks have been gaining traction, electric and hybrid trailers are in the early stages of development. In 2025, we could see the introduction of electric trailers designed to work alongside electric trucks, enabling a more sustainable and efficient transport ecosystem.

These electric trailers could feature integrated battery systems that help reduce the energy consumption of both the trailer and the vehicle towing it. This move toward electrification could drastically change how trailers are powered and reduce the overall environmental impact of freight transportation.

3. Smart Trailers with IoT Integration

The Internet of Things (IoT) is revolutionizing industries worldwide, and trailer manufacturing is no exception. Smart trailers equipped with IoT sensors and connected technologies are becoming more common. These trailers will be able to track real-time data such as temperature, load weight, tire pressure, and even location.

By 2025, we can expect to see trailers that automatically alert fleet managers about maintenance issues, optimize routes for fuel efficiency, and even monitor cargo conditions to ensure that perishable goods are kept at the correct temperature. This connectivity will make trailers safer, more efficient, and more reliable, ultimately lowering operational costs for businesses.

4. Autonomous Trailers

Autonomous vehicles are already being tested on the roads, and trailers are set to follow suit. While fully autonomous trucks are still in development, trailers that can operate autonomously in certain situations are on the horizon. By 2025, we may see trailers that can automatically dock themselves to a truck, maneuver in parking lots, or even perform autonomous driving tasks when connected to a fully autonomous vehicle.

Autonomous trailers could revolutionize logistics, reducing human error, improving safety, and enhancing efficiency in warehouse operations and long-haul transportation. The integration of AI and machine learning into trailer manufacturing could make autonomous hauling a reality sooner than we expect.

5. Improved Safety Features

Safety continues to be a top priority in trailer manufacturing, and advancements in technology are enabling manufacturers to implement new safety features. By 2025, trailers will likely be equipped with more advanced braking systems, collision avoidance systems, and lane-keeping assist features. These technologies will help prevent accidents caused by human error and improve safety for both truck drivers and other road users.

Additionally, trailers may be designed with enhanced lighting systems, including LED lights that improve visibility and increase safety, especially during nighttime driving or in poor weather conditions.

6. Customization and Specialized Designs

Every industry has unique needs when it comes to trailers, from refrigerated units for transporting food to flatbeds for construction equipment. In 2025, customization and specialized trailer designs will continue to be a major trend, as manufacturers cater to specific industries with tailored solutions.

3D printing and advanced manufacturing techniques are likely to play a larger role in this trend, allowing for more cost-effective and quicker production of custom trailers that meet the precise needs of businesses. Whether it’s a trailer designed for a specific type of cargo or one that features specialized technology, the demand for personalized trailers will continue to rise.

7. Increased Automation in Manufacturing

Automation in manufacturing processes is already a key trend, and by 2025, it will be more prevalent in the trailer manufacturing industry. From automated welding and assembly lines to robotic painting and testing, automation will help streamline the production process, reduce human error, and lower costs.

Furthermore, 3D printing and additive manufacturing technologies are expected to play an increasingly important role in trailer production. These technologies will allow manufacturers to produce complex parts more efficiently, reduce material waste, and even create custom parts on-demand.

8. Enhanced Durability and Longevity

As manufacturers strive to meet the demands of more challenging terrains, long-haul trips, and increased load capacities, trailers in 2025 will be designed with enhanced durability in mind. Improved materials, like high-strength steel and advanced polymers, will ensure that trailers can withstand harsh environments without compromising their performance.

Additionally, trailer manufacturers will focus on reducing wear and tear by integrating self-lubricating components, rust-resistant coatings, and better suspension systems. These upgrades will increase the lifespan of trailers, which is particularly important for businesses that rely on trailers for long-term use.

Shiraa UAE is a leading manufacturer and supplier of high-quality trailers in the UAE, offering a wide range of solutions including flatbed, lowboy, tanker, refrigerated, dump, and container chassis trailers. They also provide custom-designed trailers to meet specific business needs. Known for their durability, safety, and adherence to international standards, Shiraa ensures reliable transportation equipment for industries such as construction, logistics, and heavy machinery. Their trailers are built with advanced technology and materials to provide long-lasting performance, backed by excellent after-sales support and maintenance services.

1 note

·

View note

Text

Enhance Your Boating Experience with an Automatic Boat Loading System

For avid boaters, the process of loading and unloading a boat can sometimes be a time-consuming and frustrating task. Thankfully, advancements in technology have made it easier than ever with the introduction of boat-loading systems. Whether you're a novice or an experienced boater, investing in an automatic boat loading system can significantly improve your boating experience.

An automatic boat loading system simplifies the process by automatically guiding your boat onto the trailer with minimal effort. This system ensures that your boat is perfectly aligned and securely fastened, reducing the risk of damage during loading. It's particularly beneficial when you're dealing with strong currents, high winds, or tricky launch sites, where manual loading might prove difficult.

At Load My Boat, we specialize in providing high-quality boat loading systems that are designed for maximum efficiency and ease of use. Our automatic boat loading system is engineered to offer a smooth, reliable, and safe loading experience every time, giving you peace of mind and saving you valuable time at the dock.

Whether you're looking to upgrade your current system or invest in one for the first time, our boat-loading systems provide the convenience and safety you need. Say goodbye to the hassle of manual loading and enjoy more time on the water with an advanced automatic boat loading system from Load My Boat! Visit our website to learn more about our products and accessories.

0 notes

Text

Space habitat reports – Mar.28.2024

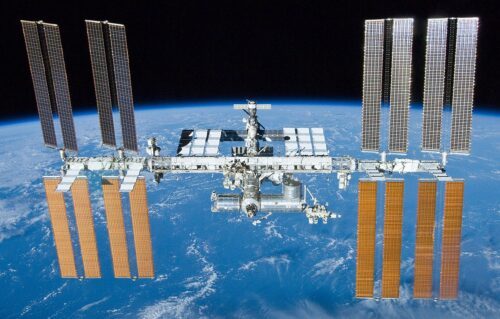

Here is this week's selection of videos and news items about space habitats, living in space, and space settlement. https://youtu.be/uWnmc1C_UOc ** Expedition 70 NASA's SpaceX 30th Commercial Resupply Services Docking Part 2 - March 23, 2024 - NASA Video Loaded with scientific experiments and supplies, an unpiloted SpaceX Dragon cargo ship automatically docked to the International Space Station’s space-facing port of the Harmony module March 23. The SpaceX resupply craft launched from NASA’s Kennedy Space Center in Florida March 21 as part of the company’s 30th commercial resupply mission for the agency and will remain at the station for one month. https://youtu.be/xRh8yByGnU8 ** Expedition 70/71Soyuz MS-25 Launch, Docking Highlights - March 25, 2024 - NASA Video NASA astronaut Tracy Dyson, Roscosmos cosmonaut Oleg Novitskiy, and Belarus spaceflight participant Marina Vasileyskaya launched on the Soyuz MS-25 spacecraft atop a Soyuz 2.1a rocket from the Baikonur Cosmodrome in Kazakhstan on March 23. Following a thirty-four orbit rendezvous, the trio docked to the Prichal module of the International Space Station, opened up the hatch of the Soyuz MS-25 spacecraft and floated aboard the International Space Station March 25. https://youtu.be/TJyCDVj0trU ** First Belarusian in space and crewmates enter space station after Soyuz docking - VideoFromSpace Belarusian astronaut Marina Vasilevskaya, NASA's Tracy C. Dyson and Roscomos' Oleg Novitskiy completed ingress on the International Space Station shortly after docking on March 25, 2024. https://youtu.be/Vbmh85ZT4lY ** Expedition 70 Astronaut Mike Barratt Talks with KGW TV Portland Oregon - NASA Video Aboard the International Space Station, Expedition 70 Flight Engineer Mike Barratt of NASA discussed life and work aboard the orbital outpost during an in-flight interview March 26 with KGW-TV, Portland. Barratt is in the midst of a long-duration mission living and working aboard the microgravity laboratory to advance scientific knowledge and demonstrate new technologies for future human and robotic exploration flights as part of NASA’s Moon and Mars exploration approach, including lunar missions through NASA’s Artemis program. https://youtu.be/-bLmuFdWxOA ** Expedition 70 Station Crew Talks with Women in Aerospace Engineering Conference - March 28, 2024 - NASA Video Aboard the International Space Station, Expedition 70 Flight Engineers Jeanette Epps and Tracy Dyson of NASA discussed life and work aboard the orbital outpost during an in-flight interview March 28 with attendees of the Women in Aerospace Engineering Conference at Georgia Tech University. Epps and Dyson are in the midst of a long-duration mission living and working aboard the microgravity laboratory to advance scientific knowledge and demonstrate new technologies for future human and robotic exploration flights as part of NASA’s Moon and Mars exploration approach, including lunar missions through NASA’s Artemis program. https://youtu.be/a0ceZIJg3wU ** NLRA 2024-6: In-space Production Applications: Advanced Materials and Manufacturing - ISS National Lab On March 21, 2024, the ISS National Lab held a webinar to discuss ISS National Lab Research Announcement (NLRA) 2024-6 soliciting proposals focused on flight investigations that seek to demonstrate space-based manufacturing and advanced materials activities on the ISS. https://youtu.be/bJ9y9K0fWrU ** Gateway - Lunar Space Station Trailer - NASA Johnson The Gateway space station will be humanity's first space station to orbit the Moon in support of the Artemis missions to return humans to the lunar surface for scientific discovery and chart a path for the first human missions to Mars and beyond. https://youtu.be/iLqu4sS4iR4 ** Blue Origin - Orbital Reef project: NASA Sees Progress on Blue Origin’s Orbital Reef Life Support System | NASA - Mar.20.2024 A @NASA-funded commercial space station, @blueorigin's Orbital Reef, recently completed testing milestones for its critical life support system as part of the agency’s efforts for new destinations in low Earth orbit. The four milestones are part of a NASA Space Act Agreement… pic.twitter.com/bCypsQE78P — NASA Space Operations (@NASASpaceOps) March 20, 2024 ** Introducing our Haven-1 aluminum primary structure, made in . - VAST - VAST Our Haven-1 aluminum primary structure manufacturing is underway. Designed, manufactured, and tested in house in the . https://youtu.be/wgW1hjdrfFU ** The Space Café Podcast #103: Building for New Frontiers: How Space Architecture Shapes Our Future in the Cosmos with space architect Georgi Petrov - SpaceWatch.Global Space Architecture is not just about creating structures; it’s about envisioning a sustainable future for humanity in space. In the latest #SpaceCafePodcast, Markus dives into a thought-provoking conversation with Georgi Petrov, a visionary at the forefront of designing habitats beyond Earth. https://www.buzzsprout.com/1915816/14777125-georgi-petrov-architecting-new-worlds-conversations-on-designing-for-space-habitation.mp3 ** Every Space Station Size Comparison | The Evolution of Space Station 3D - REAL SPACE(Hat tip Bob Zimmerman) https://youtu.be/qJNQ4aIwIKM ** TIMELAPSE: Retrieval of ETCS PM : External Thermal Control System Pump Module from SpX-30 trunk - ISS Above 20x TIMELAPSE: Retrieval of ETCS PM : External Thermal Control System Pump Module from SpX-30 trunk https://youtu.be/Sxvtk41rArc ** Other news and articles: - NASA Astronaut Loral O’Hara, Expedition 70 Science Highlights | NASA - Mar.28.2024 - Station Crew Expands to Ten, Begins Working Together | Space Station/NASA - Mar.26.2024 - Drilling for water ice on Mars: How close are we to making it happen? | Space.com - Mar.24.2024 - What We Can Create on Mars | Robert Zubrin/Quillette - Mar.19.2024 ** Highlight: Quebec - Newfoundland Sea Ice - Mar 25, 2024 17:05 EDT - ISS Above https://youtu.be/SNslBmyBWuo ** Highlight: LA - AL - TN - Mar 24, 2024 - 18:58 CDT - ISS Above https://youtu.be/5TZbeYMNfLw ** Live Video from the International Space Station (Official NASA Stream) - NASA Watch live video from the International Space Station, including inside views when the crew aboard the space station is on duty. Views of Earth are also streamed from an external camera located outside of the space station. During periods of signal loss due to handover between communications satellites, a blue screen is displayed. The space station orbits Earth about 250 miles (425 kilometers) above the surface. An international partnership of five space agencies from 15 countries operates the station, and it has been continuously occupied since November 2000. It's a microgravity laboratory where science, research, and human innovation make way for new technologies and research breakthroughs not possible on Earth. More: https://go.nasa.gov/3CkVtC8 Did you know you can spot the station without a telescope? It looks like a fast-moving star, but you have to know when to look up. Sign up for text messages or email alerts to let you know when (and where) to spot the station and wave to the crew: https://spotthestation.nasa.gov https://www.youtube.com/live/xAieE-QtOeM?feature=share ====

ISS after undocking of STS-132 === Amazon Ads === Lego Ideas International Space Station 21321 Toy Blocks, Present, Space, Boys, Girls, Ages 16 and Up ==== Outpost in Orbit: A Pictorial & Verbal History of the Space Station Read the full article

0 notes

Text

The Unique Advantages of Hydraulic Dock Levelers

In the bustling world of logistics and supply chain management, efficiency and safety are paramount. One technology that plays a crucial role in ensuring smooth operations is the hydraulic dock leveler.

While dock levelers in general are used to bridge the height gap between a loading dock and a trailer, hydraulic dock levelers offer unique advantages that set them apart from other types of levelers.

Precision Control and Smooth Operation:

One of the standout features of hydraulic dock levelers is their precision control and smooth operation. Unlike mechanical levelers that rely on spring or chain mechanisms, hydraulic levelers use fluid power to achieve controlled movement. For more equipment from Aurotoshi, please click on Industrial automation.

This results in a gradual and steady raising or lowering of the platform, allowing for precise adjustments to match the height of the trailer. This level of control minimizes the risk of abrupt movements that could lead to accidents or damage to goods.

Adaptability to Various Heights:

Modern warehouses and distribution centers handle a wide variety of vehicles with different heights. Hydraulic dock levelers are known for their adaptability to various trailer heights. Here is our one of the best equipment: High speed doors

They can be easily adjusted to accommodate everything from smaller delivery trucks to large container trailers. This versatility ensures that loading and unloading processes remain efficient regardless of the type of vehicle being serviced.

Reduced Maintenance and Longer Lifespan:

Hydraulic dock levelers are engineered for durability and reduced maintenance. The fluid power system is designed to operate smoothly with fewer mechanical components prone to wear and tear.

This translates to lower maintenance costs and longer lifespan compared to mechanical alternatives. The robust construction of hydraulic dock levelers also contributes to their ability to withstand heavy loads and constant usage, making them a cost-effective long-term investment.

Enhanced Safety Features:

Safety is a paramount concern in any loading dock environment. Hydraulic dock levelers are equipped with advanced safety features that contribute to accident prevention. Many models have automatic lip extension, which ensures that the lip of the leveler is properly positioned on the trailer bed before any loading or unloading begins.

Additionally, hydraulic levelers often have smooth transition plates that prevent tripping hazards for workers and the smooth movement of material handling equipment.

Energy Efficiency:

Hydraulic dock levelers are designed with energy efficiency in mind. Traditional mechanical levelers rely on springs or chains that need a considerable amount of force to operate, often leading to increased energy consumption.

On the other hand, hydraulic systems require less energy to achieve the same level of movement, resulting in reduced energy costs over time. Some models even feature power-saving modes that further optimize energy usage.

Weather Resilience:

Loading and unloading operations continue regardless of weather conditions. Hydraulic dock levelers are built to withstand various environmental challenges. They are less susceptible to temperature fluctuations compared to mechanical alternatives, which can become less effective in extreme cold or heat.

The hydraulic fluid in these levelers maintains consistent performance regardless of external temperatures, ensuring reliable operation year-round.

Conclusion:

In the realm of loading dock equipment, hydraulic dock levelers stand out for their precision, adaptability, safety features, energy efficiency, and durability. Their ability to smoothly and safely bridge the gap between loading docks and trailers makes them an indispensable tool for modern supply chain management.

As businesses strive for efficiency and safety in their operations, opting for hydraulic dock levelers can provide a unique set of advantages that contribute to streamlined logistics and increased productivity.

0 notes

Text

Delivering to Amazon … the Lotus Terminals Solution!

Is there anyone who has not heard of Amazon? As of 2023, Amazon has become the world’s largest online retailer and marketplace, smart speaker provider, cloud computing service, live-streaming service, and Internet company. In fact, in 2021, it surpassed Walmart as the world’s largest retailer outside of China. More people around the globe order goods and services through Amazon than any other company. Amazon has become a global business force that cannot be ignored.

As we all know, Amazon produces few actual goods themselves but uses Amazon.com as an e-commerce platform to link a diverse set of merchants with buyers. Logistical challenges arise from the need to connect such disparate merchants with the global customer base.

To deal with this, Amazon has created an extensive supply chain consisting of cross-dock centres, fulfillment centres, sortation centres and delivery stations. These all serve a specific purpose, but it is likely the fulfillment centres that serve the most important one. Fulfillment centres, offering a service called Fulfillment by Amazon (FBA), move products. A fulfillment centre does have shelves for storing goods, but the purpose of a fulfillment centre is shipping orders, not storage. Fulfillment centres worker’s process inbound inventory, pick products to fill orders, pack and label packages, and ship orders to customers. They serve as a supply chain link between manufacturing and the end consumer.

Amazon fulfillment centres have a somewhat unique delivery system to deal with the volume of goods arriving on a near constant basis. Normally, delivering to a standard warehouse or fulfillment centre simply requires contacting the receiver and making a delivery appointment that works for both the receiver and the carrier. It is a much more complicated process to do the same with an Amazon Warehouse.

As is the norm, carriers do need to make sure [we] have an accurate actual address for delivery. However, it is important to note that Amazon fulfillment centres are defined by a location code. For example, the code for the Amazon fulfillment centre in Nisku, Alberta is YEG1 and YVR1 for the centre in Delta, BC. Once you have established the Amazon fulfillment centre where the delivery needs to occur, a delivery appointment must be made. All Amazon delivery appointments must be made through Amazon Carrier Central. To make an appointment, you will need the Destination FC (e.g., YEG1), freight type (truck load or less than truck load), load type (floor loaded or palletized), if the freight is clampable, the carrier trailer number, requested deliver date, pro number (which is the FBA #), vendor (original customer), pallet count and carton and unit count. Once you have completed this, Amazon will confirm the order has been entered correctly.

It is important to note that even though an appointment has been booked, it is NOT confirmed. An Amazon fulfillment centre delivery appointment is not confirmed until an automatically generated email is received. While it is possible the email will confirm the exact delivery you requested, it is unlikely. The email will likely be for an appointment as close as possible to the one requested.

For this reason, ideally carriers book themselves. With our experience delivering to Amazon, we can assist and support merchant vendors, third-party sellers and freight forwarders and carriers with making their delivery appointment assuring the freight arrives on time, reducing costs and increasing profits. Lotus Terminals is your solution to your Amazon problems!

Ready to talk to us about your Amazon freight needs? Contact us today at [email protected] and let’s get moving!

0 notes

Text

How It’s Made Index(S21~S30)

How It’s Made是由 Discovery Channel 制作一款王牌节目,又被翻译为制造的原理或造物小百科, 本片从2001年推出至今,涵盖了几乎所有的制造技术 ,非常适合机械专业和对此感兴趣的同学。希望大家享受这趟制造的艺术之旅!

第二十一季推出时间为2013-04-04至2013-08-01

S21E01 Rubber Gloves; Soap Carvings; Aircraft Cabinets; Motorcycle Brake Locks 橡胶手套,肥皂雕刻,飞机木柜,摩托车制动锁

本集看点:极其舒适的橡胶手套制作过程;

S21E02 Powder Horns; Handcrafted Molds; Perogies; Inner Tubes 粉角,手工模具,饺子,内胎

S21E03 Lace; Antique Frame Replicas; Orchids; Unicycle Wheel Hubs 蕾丝,古董架复制品,兰花,独轮车轮毂

S21E04 External Hard Drives; Frozen Shrimp; Thai Rice Boxes; Paper Towel 外置硬盘,冷冻虾,泰国米箱,纸巾

本集看点:硬核的西部数据移动硬盘组装制程;

S21E05 Tea; Roof Finials; Artificial Flowers; Alloy Wheels 茶,屋顶饰物,人造花,合金轮毂

S21E06 Gel Caps; Playground Spring Riders; Frozen Pancakes; Natural Rubber 胶囊,摇摇玩具,冷冻煎饼,天然橡胶

S21E07 Paper Umbrellas; Coal; Aircraft Seats; Urns 纸伞,煤,飞机座椅,瓮

S21E08 Aluminum Canoes;Wood Bowls;Wheelchair Accessible Vans;Marimbas 铝独木舟,木碗,残疾人改装车,木琴

S21E09 Indy Car Seats; Paper Flowers; Stand-by Generators; 赛车座椅,纸花,备用发电机

S21E10 Knee Replacements; Leaf Springs; Lavender; Rivets and Rivet Tools 膝关节置换,钢板弹簧,薰衣草,铆钉和铆钉的工具

本集看点:另外一种大型弹簧结构;铆钉的工作原理;

S21E11 Cast Iron Stoves; Ultralight Aircraft; Snow Groomers; Rubber Bands 铸铁炉具,超轻型飞机,推雪车,橡皮筋

S21E12 Barber Chairs; Sewage Pumps; Bimini Boat Tops; Diesel Filters 理发椅,污水泵,比米尼游乐船,柴油过滤器

S21E13 Car Tires; Silk; Art Conservation; Scuba Tanks 汽车轮胎,丝绸,艺术保护,潜水氧气瓶

本集看点:铝合金终极冲压教程;

本季资源链接:

magnet:?xt=urn:btih:8e3c0ca289825ca99cbb7699dcbaf926aeb42265&dn

第二十二季推出时间为2013-10-10至2014-01-16

S22E01 Electric Stand-Up Vehicles; Frozen Fruit; Beer Coasters; Forged Door Handles 电动站立车,冰冻水果,啤酒杯垫,锻造门把手

本集看点:专业铁匠;

S22E02 Rock Crushers;Fabric Lampshades;Cake Sprinkles;Steam Irons 岩石破碎机,织物灯罩,蛋糕彩条,蒸汽熨斗

S22E03 Indy Steering Wheels;Mixed Salad;Wind Turbines 印地赛车方向盘,什锦沙拉,风力涡轮机

S22E04 Blast Doors; Lipstick; Artificial Palm Trees; Brass Plaques 防爆门,口红,人造棕榈树,黄铜牌匾

S22E05 Carbon Fiber; Antique Frame Restoration; Railcar Movers; Hood Ornaments 碳纤维,古董保存架,有轨机车,车头装饰品

S22E06 Sawhorses and Toolboxes;Sorbet Pops;School Buses 史丹利工具箱,便携汁冰糕,校车

S22E07 Sanders;Solid Terrain Models;Stucco;High-Speed Roll-up Doors 抛光机,固体地形模型,水泥,高速卷门

S22E08 Pressed Glass;Pickup Truck Caps;Alpaca Yarn;Utility Knives 压制玻璃,敞蓬小型载货卡车,羊驼纱线,工具刀

S22E09 Body Casting; Downdraft Stoves; Compression Garments; Electric Motorcycles 身体模型,气流炉灶,长袜,电动摩托车

S22E10 Sidecars;Frozen French Toast;Refrigerator Compressors;Superchargers 摩托侧箱,冷冻法式土司,冰箱压缩机,增压器

S22E11 Custom Knee Braces;Air Conditioners;Window Films;Motorcycle Exhaust 定制膝盖支撑,空调,窗户贴膜,摩托车排气管

S22E12 Solid State Drives;Eye Shadow;Limousines;Dead Blow Hammers 固态硬盘,眼���,豪华加长轿车,香槟锤

本集看点:先进半导体制程制作的硬盘;

S22E13 Dragster Tires; Icing; Floating Docks; Spiral Pipes 赛车轮胎,冰淇淋,飘浮船坞,螺旋管

本季资源链接:

magnet:?xt=urn:btih:c1ddbd38f95041c1482295587ae0c59e19416937&dn

第二十三季推出时间为2014-04-03至2014-07-03

S23E01 Motion Sensors; Belt Loaders; Pheasant Breeding; Diving Helmets 运动传感器,带式装载机,野鸡养殖,潜水头盔

本集看点:先进半导体制程制作的传感器芯片;

S23E02 Rawhide Lampshades; Chocolate Chip Cookies; MRI Scanners 皮灯罩,巧克力饼干,核磁共振成像扫描仪

S23E03 Noise Barrier Walls; Front-Load Washers; Bourbon; Flexible Circuit 声音屏障墙,滚筒洗衣机,威士忌,柔性电路板(FPC)

本集看点:柔性电路板是如何加工的;

S23E04 Railway Bridge Ties; Membrane Filters; Hydraulic Post Drivers; Bi-Planes 铁路桥梁枕木,膜过滤器,桩机,四翼飞机

S23E05 Hospital Laundry; Brass Instrument Restoration; Horse Replicas; Excavation 医院洗衣,铜管乐器修复,马复制品,挖掘机挖斗

本集看点: 用玻璃纤维制作空心复制品;巨厚钢板的激光切割,折弯与焊接;

S23E06 Ceramic Fireplaces; Synthetic Corks; Parking Garage Floor Slabs 陶瓷壁炉,合成软木塞,车库楼板

本集看点: 多种塑胶粒子组合的连续注塑;

S23E07 Oil Pressure Sensors; Printing; Equipment Simulators; Head & Neck Restraints 油压传感器,大型印刷,设备模拟器,护颈

本集看点: 打金线制程;

S23E08 Mobile Concert Stages; Mascara; Continuous Miners; Wood Gift Boxes 移动音乐会舞台,睫毛膏,挖煤机,木制礼品盒

S23E09 NASCAR Car Bodies; Hurley Sticks; Tube Amplifiers; Thermal Coffee Pots 纳斯卡跑车车身,赫尔利球球棒,声音放大器,热咖啡壶

S23E10 Electric Vehicle Charging Stations; Grappa; Lunar Rover Replicas 电动汽车充电站; 格拉巴酒; 月球车复制品

S23E11 Slate Tiles; Hot Dog Carts; Garage Door Openers; Bicycle Seats 板岩瓷砖;热狗车; 车库门开启器; 自行车座椅

S23E12 Racing Leathers; Evaporative Cooling Towers; Rocking Chairs; Wire Wheels 赛车皮革;蒸发��却塔; 摇椅; 钢丝轮

本集看点: 滚丝螺纹工艺;

S23E13 Mountain Bikes; Rice; Lever Action Rifles 山地自行车;大米;杠杆动作步枪

S23E14 Shark Week Edition: Surfboards; Diving Regulators; SCUBA Tanks; Water Skis 回收冲浪板; 潜水调节器; 潜水氧气瓶; 滑水板

S23E15 300th Episode - Shark Week Edition: Sails; Reef Aquariums; Oceanographic Buoys; Folding Kayaks 风帆; 珊瑚礁水族馆; 海洋浮标; 折叠皮划艇

本季资源链接:

magnet:?xt=urn:btih:33139d133183e8bf6e6dfec6684ca9f07bec0982&dn

第二十四季推出时间为2014-09-25至2015-01-15

S24E01 Saunas; Wheelchair Lifts; Dioramas 桑拿; 轮椅升降机; 立体模型

S24E02 Oil Lamps; Chocolate Mints; Underfloor Heating; Pillows ��灯; 巧克力薄荷糖; 地板采暖; 枕头

S24E03 Upright Pianos; Flags; Wet/Dry Vacuums; Medieval Axes 立式钢琴; 旗帜; 湿式/干式吸尘器; 中世纪斧头

S24E04 Skeletal Replicas; Ice Buckets; Dining Chairs; Inground Pools 骨骼复制品; 冰桶; 餐椅; 地下游泳池

S24E05 Automatic Sliding Doors; Gin; Firearms Restoration 自动推拉门; 杜松子酒; 枪械修复

S24E06 Scuba Lights; Sandals; Race Car Simulators; Fibreglass Doors 潜水灯;凉鞋;赛车模拟器; 玻璃钢门

S24E07 Wood Windows; Cashmere Fabric; Plastic Recycling; Architectural Glass 木窗; 羊绒面料; 塑料回收; 建筑玻璃

S24E08 Gas Barbecues; Mattress Pads; Ear Prostheses 燃气烧烤炉; 床垫; 耳假体

S24E09 Recycled Skateboards; Braided Pastry; Construction Trailers; Vises 回收滑板; 编织糕点; 施工拖车; 虎钳

S24E10 Plasma Gems; Special Effects Snow; Piano Restoration 等离子宝石; 特效雪; 钢琴修复

S24E11 3-Wheel Electric Bikes; Skin Cream; Patio Heaters; Wood Wheels 三轮电动自行车; 润肤霜; 天井取暖器; 木轮

S24E12 Old West Holsters; Underwater Video Housings; Soy Beverages; Pet Nail Trimmers 老西部皮套; 水下视频外壳; 大豆饮料; 宠物指甲修剪器

S24E13 Wood Garage Doors; Sand and Salt Spreaders; Animatronic Dinosaurs 木车库门; 沙子和盐撒布机; 电子动画恐龙

本季资源链接:

magnet:?xt=urn:btih:0a4eda224bbaf24666bb12c13bf1cd5732bf51fd&dn

第二十��季推出时间为2015-04-02至2015-07-02

S25E01 Grammy Awards; Bicycle Lights; Above-Ground Pools; Foldable Solar Panels 格莱美奖; 自行车灯; 地上游泳池; 可折叠太阳能电池板

S25E02 Led Stage Lights; Apple Cider; Chemical Tank Trailers; Ornate Stone Floor LED舞台灯; 苹果酒; 化学品罐拖车; 华丽的石地板

S25E03 Fishing Line; Industrial Mixers; Natural Baking Soda; and Tow Trucks 钓鱼线; 工业搅拌机; 天然小苏打; 拖车

S25E04 Storage Sheds; Industrial Fans; Parchment Paper; and Climbing Walls 储藏棚; 工业风扇;羊皮纸;攀岩墙

S25E05 Precast Concrete Walls; 3D Printers; Telescopic Cranes; Kerosene Lamp Burners 预制混凝土墙; 3D 打印机; 伸缩式起重机; 煤油灯燃烧器

S25E06 Car Headlamps; Directional Drills; Pet Combs; and Stained Glass Restoration 汽车大灯; 定向钻; 宠物梳子; 彩色玻璃修复

S25E07 Handcrafted Skis; Septic Tanks; Hydroformed Chassis Parts; Aquarium Windows 手工制作的滑雪板; 化粪池; 液压成型底盘零件; 水族馆窗户

S25E08 Zip Line Brakes; Silk Fiber Lamps; Round Balers; Comfort Shoes 拉链线制动器; 丝纤维灯; 圆形打包机; 舒适鞋

S25E09 Armored Vehicles; Tension Fabric Buildings; Rowers; Sculpture Enlargements 装甲车; 张力织物建筑; 划船者; 雕塑放大

S25E10 Mountain Bike Suspensions; Surgical Sutures; Grain Dryers; and Frying Pans 山地自行车悬架; 手术缝合; 谷物烘干机; 煎锅

S25E11 Downhill Ski Bindings; Immersion Washers; Mining Ventilation; Pencil Sharpeners 速降滑雪绑定; 浸入式垫圈; 矿用通风; 卷笔刀

S25E12 Gingerbread Houses; Livestock Trailers; Hangar Doors; and Toy Figurines 姜饼屋; 牲畜拖车; 机库门; 玩具公仔

S25E13 Traffic Signal Poles; Coffee Filters; and Chainsaw Mining Machines; 交通信号杆; 咖啡过滤器; 链锯采矿机;

本季资源链接:

magnet:?xt=urn:btih:78ae318559e0477f5bb1db0abb0fcfa841e491be&dn

第二十六季推出时间为2015-09-10至2015-12-17

S26E01 Time-Delay Locks; Brownies; Pallet Dispensers; and Crystal Chandeliers 延时锁; 布朗尼; 托盘分配器; 水晶吊灯

S26E02 Bead Wire; Mini Pepperoni; Irrigation Sprinklers; and Leather Gloves 珠线; 迷你意大利辣香肠; 灌溉喷头; 皮手套

S26E03 Mouth-Blown Window Glass; Water Pumps; Sake; Tweezers 口吹窗玻璃; 水泵; 清酒; 镊���

S26E04 Statue Restoration; Tripods; Polish Sausages; Welding Guns 雕像修复; 三脚架; 波兰香肠; 焊枪

S26E05 Champagne; ATMs; Marine Turbochargers; 香槟酒; 自动取款机; 船用涡轮增压器;

S26E06 Sharpening Steels; Bladder Pumps; Ironing Boards; and Kayak Paddles 磨刀钢; 膀胱泵; 烫衣板; 皮划艇桨

S26E07 Champagne Hoods; Pneumatic Systems; Espresso Machines; Pizza Ovens 香槟罩; 气动系统; 浓缩咖啡机; 比萨烤箱

S26E08 Stile & Rail Doors, Steam Cleaners, Hand-Held Pizzas, and Power Brushes 轨道门;蒸汽清洁器;手持比萨饼;电动刷

S26E09 Industrial Casters; Wedding Cakes; THz Spectrometers; Racing Catamarans 工业脚轮; 婚礼蛋糕; 太赫兹光谱仪; 竞速双体船

S26E10 Ceramic Grills, Pneumatic Punchers, Water Jet Fountains, Wooden Surfboards 陶瓷烤架、气动打孔机、喷水喷泉、木制冲浪板

S26E11 Vibrating Mining Screens; Whoopie Pies; Utility Poles; Roller Conveyors 振动采矿筛; 百日咳派; 电线杆; 滚筒输送机

本集看点:电线杆也内卷;

S26E12 Exercise Bikes; Cornish Pasties; Pasta Makers; Slate Products 健身车; 康沃尔馅饼; 面食制造商; 板岩产品

S26E13 Channel Signs, Wetsuits, and Aluminum Aircraft 航道标志;潜水服;铝制飞机

本季资源链接:

magnet:?xt=urn:btih:85892a96e09b0d9f596d98bcd450aeb870a6af3d&dn

第二十七季推出时间为2016-05-19至2016-08-15

S27E01 CNC Assembly Machines; Lemon Tarts; Miniature War Figures 数控组装机; 柠檬馅饼; 微型战争人物

S27E02 Chemical Tank Pressure Vents; Candy Wafers; Food Trucks; Traditional Ropes 化学品罐压力通风口; 糖果晶圆; 食品卡车; 传统绳索

S27E03 Graphene; Worlds Smallest Car; Force Testers; Composite Cans 石墨烯; 世界上最小的汽车; 力测试仪; 复合罐

本集看点:单层的石墨烯是如何分离出来的;

S27E04 LED tubes; chocolate peanut butter bars; robotic medication dispensers. LED灯管;巧克力花生酱棒;机器人配药器

S27E05 Commercial drones; aquarium fish; runway cleaners. 商用无人机; 观赏鱼; 跑道清洁工

S27E06 Wooden Matches, Tillage Machines, Telescopic Gangways 木火柴、耕地机、伸缩式舷梯

S27E07 Mosquito Coils, Solar-Assist Tricycles, Palm Oil, Fiberglass Chopper Guns 蚊香���太阳能辅助三轮车、棕榈油、玻璃纤维斩波枪

S27E08 Wood Toys, Retro Toasters, Laboratory Furnaces, Aerogel 木制玩具、复古烤面包机、实验室炉、气凝胶

S27E09 Combination Squares, Farmed Shrimp, Ball Valves and String Trimmers 组合方形、养殖虾、球阀和切线器

S27E10 Chinese-style Furniture, Electrical Switches, Thai Fish Sauce, Cappers 中式家具、电器开关、泰式鱼露、压盖机

S27E11 Mortars and pestles; bowling lane conditioners; crematories 研钵和研杵; 保龄球道调节器; 火葬场

S27E12 Race Car Oil Tanks; Plaster Mouldings; Lemongrass Oil 赛车油箱; 石膏线条; 柠檬草油

S27E13 Coconut Charcoal; Dial Indicators; Wet Downdraft Tables; Bassoon Reeds 椰子炭; 表盘指示器; 湿式下吸台; 巴松管簧片

本季资源链接:

magnet:?xt=urn:btih:5289719d3944f98f2c2d425cd79b0487aec36fc7&dn

第二十八季推出时间为2016-08-22至2016-11-03

S28E01 Classic Car Gauges; Chocolate Marble Cake; Ghillie Kettles 经典汽车仪表; 巧克力大理石蛋糕; 吉利水壶

S28E02 Pasta Dies; Blueberries; Composting Toilets; Surge Arresters 面食模具; 蓝莓; 堆肥厕所; 避雷器

S28E03 Angle Grinders; Berry Baskets; Omnidirectional Speakers 角磨机; 浆果篮; 全向扬声器

S28E04 Cartridge Blades; Chocolate Banana Loaves; Vending 墨盒刀片; 巧克力香蕉面包; 自动售货机

S28E05 Ultra-Thin Glass; Pallet Dismantlers; Cupcakes; Stainless Steel 超薄玻璃; 托盘拆卸器; 纸杯蛋糕; 不锈钢

本集看点: 溢流熔融法制作的柔性超薄玻璃(应该是康宁);

S28E06 Potash; Leather Bracelets; Wild Rice; Hex Key L Wrenches 钾肥; 皮革手链; 野米; 六角扳手 L

S28E07 Nail Files; Birch Canoes; Boat Hardtops; High Voltage Circuit 指甲锉; 桦木独木舟; 船硬顶; 高压电路

S28E08 Macarons; Pine Needle Baskets; Micrometers 马卡龙; 松针篮; 千分尺

S28E09 Endoscopes; Megaphones; Uranium 内窥镜; 扩音器; 铀

S28E10 Hollow Disk Pumps; Palm Sugar; Yachts 空心圆盘泵; 棕榈糖; 游艇

S28E11 Abalone Collagen; Digital-to-Analog Converters; Embosssed 鲍鱼胶原蛋白; 数模转换器; 压花

S28E12 Thai Barbecues; Diving Masks & Fins; Bassoons 泰式烧烤; 潜水面罩和脚蹼; 巴松管

S28E13 Wooden Utensils; Transport Refrigeration Units; Moccasins 木制餐具; 运输制冷装置; 莫卡辛鞋

本季资源链接:

magnet:?xt=urn:btih:6b3298e03c0e32ede5bc1b81e13a315adae86528&dn

第二十九季推出时间为2017-06-22至2017-09-24

S29E01 Skateboard Wheels; Baklava & Galaktoboureko; CO2 滑板轮;千层酥皮奶冻玉米糕 ;二氧化碳

S29E02 Nuno Felt; Drum Crushers; Kimchi; Parquet Floors 努诺毡;鼓式破碎机;泡菜;镶木地板

S29E03 Wood Watches; Steel Bicycles; Raw Pet Food; Replica Police 木表; 钢制自行车; 生宠物食品; 复制警察

S29E04 Thermoplastic Fire Helmets; Basketry Sculptures; Coffee 热塑性消防头盔; 篮子雕塑; 咖啡

S29E05 Office Chairs; Vinobrew; Reconditioned Sander Drums 办公椅; 酒酿; 翻新砂光鼓

S29E06 Fireplace Bellows; Calissons; Diving Watercraft 壁炉波纹管; 卡利松; 潜水艇

S29E07 Artist Brushes; DEF Tank Heaters; Game Tables; Art Glass 艺术家画笔; DEF 储罐加热器; 游戏桌; 艺术玻璃

S29E08 Flying Water Bikes; Throttle Position Sensors; Cinnamon 飞行水上自行车; 油门位置传感器; 肉桂

S29E09 Foosball Tables; Marseille Soap; Laguiole Pocket Knives 桌上足球桌; 马赛皂; 拉吉奥小折刀

S29E10 Berets; Pastis; Stationary Bikes 贝雷帽; 意大利面食; 固定自行车

S29E11 Bistro Sets; Letterpress Printing; Bamboo Lights; Asphalt 小酒馆套餐; 凸版印刷; 竹灯; 沥青压车

S29E12 Technological Corks; Zinc Gutters; Traditional Ham; Chisteras 技术软木塞; 锌天沟; 传统火腿; 奇斯特拉斯游戏手臂

S29E13 Pentanque Ball; Biologic Medicines; Asphalt Pavers; Basques 滚球; 生物药物; 沥青摊铺机; 巴斯克鞋

本期看点:空心半铁球焊接,再两步CNC制作出完美球形;

本季资源链接:

magnet:?xt=urn:btih:971ec4ef1ce447538e18d1305ec2f8103daee29d&dn

第三十季推出时间为 2017-09-11至2017-12-18

S30E01 Leather Basketballs; Flood Gates; Wood Panel Canvases; Shoelaces 皮革篮球; 防洪闸; 木板画布; 鞋带

S30E02 Power Steering Pumps; Asian Bowl Meals; Walking Canes 动力转向泵; 亚洲碗餐; 手杖

S30E03 Plant Oil Extractors; Custom Chandeliers; Power Trainers; Coffee Pods 植物油提取器; 定制吊灯; 力量训练器; 咖啡包

S30E04 Witness Samples; Pressure Washers; Bee Hives; Cast Iron Cookers 见证样品; 压力垫圈; 蜂箱; 铸铁炊具

S30E05 Leather Sculptures; Travel Hot Plates; Ochre; Hurdy Gurdies 皮革雕塑; 旅行热板; 赭石;赫迪·古尔迪斯

S30E06 Spiral Stairs; Pita Bread; Exhaust Headers; Molded Limestone Artwork 螺旋楼梯; 皮塔饼; 排气集管; 模压石灰石艺术品

S30E07 Recycled Skateboard Guitars; Solar Street Lights; Dolls 回收的滑板吉他; 太阳能路灯; 娃娃

S30E08 Glass Sculptures; Racing Pulley Systems; Inductors; Medicine Balls 玻璃雕塑; 赛车滑轮系统; 电感器; 药丸

S30E09 Fish Rubbings; Clay Shooting Machines; Almonds; High-End Motorcycles 鱼拓片; 粘土射击机; 杏仁; 高端摩托车

S30E10 Throttle Bodies; Limestone Fireplace Mantels; Candied Fruit & Fruit Jellies; Linen Ukulele 节气门体; 石灰石壁炉架; 蜜饯和果冻; 亚麻尤克里里

S30E11 Rubber Balls; Motion Chairs; Montreal Smoked Meat; Motorized Scooters 橡胶球; 运动椅; 蒙特利尔熏肉; 电动滑板车

S30E12 Aerospace Fasteners; Cactus Pear Puree; Lab Reactors 航空紧固件; 仙人掌梨泥; 实验室反应器

S30E13 Wall Beds; Sundae Cups; Digital Paintings; Badminton Rackets 壁床; 圣代杯; 数字绘画; 羽毛球拍

本季资源链接:

magnet:?xt=urn:btih:cc865a515b621051b71e833bd62e466fc45949d3&dn

3 notes

·

View notes

Text

Enhance Trailer Loading with Cargofloor Spare Parts and Advanced Automation

Maintaining operational efficiency in logistics requires robust systems and high-quality components. Spare Parts For Cargofloor Moving Floor System play a crucial role in ensuring seamless cargo movement within trailers. The Cargofloor system is widely known for its reliability and performance in transporting goods, but regular maintenance with genuine spare parts ensures its long-term durability and efficiency. These parts, ranging from hydraulic components to specialized floor slats, are designed to withstand the demands of heavy-duty applications, reducing downtime and increasing productivity.

In addition to reliable systems, advanced automatic loading systems for trailers and loading docks are transforming logistics operations. These systems are engineered to streamline loading and unloading processes, minimizing manual labor and maximizing speed. Whether handling bulk cargo or palletized goods, automatic systems offer a versatile and safe solution for high-volume operations. They reduce risks associated with manual handling, optimize space usage, and significantly cut down turnaround times at loading docks.

Combining the reliability of spare parts for Cargofloor moving floor systems with the efficiency of Automatic Loading Systems For Trailers And Loading Docks creates a seamless operational synergy. Businesses that invest in these solutions can expect improved workflow, reduced costs, and enhanced safety standards.

When choosing these systems and spare parts, always opt for trusted suppliers to ensure quality and performance. This investment not only supports operational excellence but also helps businesses stay ahead in today’s competitive logistics landscape.

Website- http://seconcomponents.com/en/

#automation of pallet/skid loading into trailers and loading docks.#Automatic Loading Systems For Trailers And Loading Docks#Spare Parts For Cargofloor Moving Floor System

0 notes

Text

Energy-Efficient Heating Options for Large Industrial Spaces in 2025

Among the most reliable options for energy-efficient heating in 2025 are indirect-fired heaters. These systems are ideal for indoor environments where open flame or exhaust fumes cannot be tolerated. With sealed combustion chambers and remote thermostat compatibility, indirect-fired heaters significantly reduce heat loss and maximize fuel usage. They’re often used in food processing plants, jobsite trailers, and other enclosed industrial environments. Cantherm’s indirect-fired heaters for industrial spaces exemplify the best in this class, providing clean air and consistent warmth with low emissions and CSA-certified safety. As more facilities opt for controlled and clean heat, these systems remain a top choice for safe industrial heating.

Radiant Tube Heaters Improve Efficiency with Targeted Heat

Facilities that prioritize focused, localized heat benefit from the energy-saving design of radiant tube heaters. Instead of heating air much of which can escape in tall or drafty buildings radiant systems warm surfaces and people directly. This makes them ideal for settings like loading docks, workshops, and garages where maintaining constant ambient air temperature isn’t practical. By delivering warmth exactly where it’s needed, radiant heaters reduce energy consumption and operational costs. While they don’t replace primary heating systems in larger buildings, they are a powerful supplementary option in targeted heating zones.

High-Efficiency Unit Heaters Now Offer Smart Controls and Better Fuel Management

Today’s most energy efficient warehouse heaters feature modulating burners, electronically commutated (EC) motors, and compatibility with building management systems. These technologies allow unit heaters to automatically adjust output based on real-time temperature demands, ensuring that energy isn’t wasted through unnecessary cycles. In facilities with high ceilings and varied layouts, modern unit heaters help maintain consistent temperatures without overheating unoccupied areas. Building automation adds an extra layer of control, letting managers monitor fuel use, schedule run times, and optimize performance with ease.

Hybrid Systems Combine Heating and Ventilation for Air Quality and Efficiency

More industrial buildings are investing in hybrid systems that combine heat delivery with advanced ventilation technology. These setups use integrated HRVs or makeup air systems to maintain healthy indoor air quality while efficiently distributing heat. Especially in facilities with high occupancy, chemicals, or airborne contaminants, maintaining fresh air is just as important as temperature control. By combining heating and ventilation into a single strategy, businesses can reduce the need for multiple systems while gaining better control over their indoor environment. Cantherm’s climate control systems support these hybrid solutions, offering both comfort and compliance in one efficient package.

Portable Heating Units Provide Versatility for Temporary and Zoned Needs

Industrial heating needs are not always permanent. Temporary structures, renovations, or remote locations often require flexible solutions that can be deployed quickly and moved as necessary. Portable industrial heaters meet this need, especially those that are CSA-approved and built for rugged use. Whether warming a construction site or a temporary operations hub, Cantherm’s portable heating systems Canada lineup includes powerful and reliable indirect-fired models that offer impressive thermal output, fuel efficiency, and on-site versatility. Their ease of setup and safety certifications make them a dependable choice across industries.

Energy Efficiency is the New Standard for Commercial Heating in 2025

The market for commercial space heaters has evolved beyond just output power. In 2025, energy efficiency, safety compliance, and smart automation define the leading edge. As building codes tighten and energy prices climb, the cost of inefficient systems becomes too great to ignore. That’s why choosing systems with optimized fuel consumption and smart integration is no longer optional it’s essential for financial and operational sustainability. Cantherm’s product lines, including the latest in large warehouse heating solutions, are built to address these realities with precision and performance in mind.

Solutions Tailored for Industrial Scale and Unique Heating Needs

Every industrial facility has unique heating challenges, from irregular floor plans to ventilation requirements and ceiling heights. That’s why the best heater for large industrial space is never one-size-fits-all. Custom solutions that consider building layout, insulation quality, air circulation, and fuel availability provide the best return on investment. Cantherm’s in-depth understanding of industrial needs ensures that every client is matched with a heating system that delivers results not just heat. Whether you’re retrofitting an old plant or setting up a new warehouse, their team will help you assess, select, and implement the right equipment for long-term efficiency and comfort.

Why Energy-Efficient Heating is a Game-Changer for Industrial Sites

The shift toward energy efficient industrial heating solutions is more than a trend it’s an industry-wide necessity. Lower emissions, reduced fuel usage, and smarter temperature control all contribute to reduced overhead costs and a smaller carbon footprint. Forward-thinking facility managers are already adopting new technologies to ensure long-term compliance and competitiveness. With Cantherm’s range of heating options from indirect fired heaters to portable units and hybrid systems industrial spaces across Canada are better equipped to face the challenges of tomorrow.

Conclusion

As 2025 progresses, industrial operations need heating systems that combine efficiency, safety, and adaptability. Cantherm Distributors continues to lead in this space by offering premium, reliable solutions tailored to the demands of warehouses, job sites, and manufacturing plants. Whether you’re looking for radiant, indirect-fired, or portable options, choosing energy-efficient heating is not just good businessit’s the smart way forward.

0 notes

Text

The Critical Role of Dock Levellers in Efficient Material Handling

In the fast-paced world of logistics and warehousing, efficiency is everything. Every second saved in loading and unloading goods translates to cost savings and improved productivity. One unsung hero in this process is the dock leveller, a vital piece of equipment that bridges the gap between a warehouse dock and a vehicle, ensuring smooth and safe material handling. At Maini Material Movements, a trusted name in material handling solutions, we understand how critical dock levelers are to streamlining operations. In this blog, we’ll explore why dock levelers are indispensable, their benefits, and how they transform warehouse efficiency.

Why Dock Levelers Are Essential

Warehouses and distribution centers handle thousands of shipments daily, and any bottleneck at the loading dock can ripple through the supply chain. Dock levelers address this by enabling faster, safer, and more efficient material handling. They’re particularly crucial in industries like manufacturing, retail, and e-commerce, where high throughput is non-negotiable. Let’s break down the key reasons dock levelers play a critical role in operations.

1. Enhanced Safety for Workers and Equipment

Safety is paramount in material handling, and uneven dock-to-truck transitions pose significant risks. Workers can trip, and forklifts may tip or drop loads when navigating gaps or height differences. A dock leveler eliminates these hazards by creating a smooth, level surface. Maini Material Movements’ dock levelers are engineered with robust materials and safety features like non-slip surfaces and automatic shut-off systems, reducing the risk of accidents. This not only protects workers but also prevents damage to goods and equipment, saving costs on repairs and downtime.

2. Increased Operational Efficiency

Time is money in warehousing, and dock levelers drastically cut loading and unloading times. By providing a stable platform, they allow forklifts to move goods directly into trucks without manual adjustments or makeshift ramps. This speed is critical during peak seasons when warehouses face high demand. For example, a well-installed dock leveler can reduce loading time by up to 50%, enabling more shipments per day. Maini Material Movements offers hydraulic and mechanical dock levelers tailored to different throughput needs, ensuring maximum efficiency for any operation.

3. Versatility Across Vehicle Types

Trucks and trailers come in various sizes and heights, creating a challenge for fixed docks. Dock levelers solve this by adjusting dynamically to match each vehicle’s bed height. Whether it’s a low-bed delivery van or a high-bed container truck, a dock leveler ensures compatibility. This versatility minimizes delays caused by mismatched equipment and keeps operations running smoothly. Maini Material Movements designs its levelers with adjustable ranges to accommodate diverse fleets, making them ideal for warehouses serving multiple clients.

4. Durability for Long-Term Performance

Warehouses operate under tough conditions, with heavy loads and constant use testing equipment durability. A high-quality dock leveler is built to withstand these demands, offering years of reliable service with minimal maintenance. Maini Material Movements uses premium materials and advanced engineering to produce levelers that resist wear, corrosion, and extreme weather, ensuring consistent performance even in high-traffic docks. This durability translates to lower replacement costs and uninterrupted operations.

5. Energy Efficiency and Environmental Benefits

Modern dock levelers contribute to sustainability by improving energy efficiency. For instance, hydraulic dock levelers from Maini Material Movements are designed to maintain a tight seal between the warehouse and truck, preventing air leaks in climate-controlled facilities. This reduces energy loss from heating or cooling, lowering utility bills and carbon footprints. Additionally, faster loading times mean trucks spend less time idling, further cutting emissions. These benefits align with the growing emphasis on green logistics practices.

Choosing the Right Dock Leveler

Selecting a dock leveler depends on your warehouse’s needs—factors like load capacity, dock height, and traffic volume play a role. Hydraulic levelers are ideal for high-frequency docks due to their ease of use and automation, while mechanical ones suit smaller operations with lower budgets. Maini Material Movements offers expert guidance to match businesses with the right solution, ensuring optimal performance and ROI.

Final Thoughts

Dock levelers may seem like a small component in the grand scheme of warehousing, but their impact on efficiency, safety, and cost savings is immense. By bridging the gap between docks and vehicles, they streamline material handling and keep operations running like clockwork. Maini Material Movements’ expertly crafted dock levelers elevate this impact, offering durability, versatility, and energy efficiency tailored to modern logistics. Invest in a quality dock leveler, and watch your warehouse transform into a hub of productivity and precision.

0 notes

Text

Truck Loading Conveyors manufacturers

Truck Loading Conveyors manufacturers

Raj Conveyors are the leading Truck Loading/Unloading Conveyors manufacturers. Our offered Loading Conveyors System is very cost effective, easy to maintain and saves considerable floor space. These are used to load carton boxes & Bags into trucks and containers. Were the loading deck is not available. Can be used in different industries were bags and boxes are used extecively for packing.

Movable

Easy to handle

Can achieve different heights for stacking of bags

Please Contact Us for Our Technical Broucher

Dock less Loading Conveyors

Dockless loading conveyors is quite welcome to automatiCally load or unload goods in and out of trailers/vans/truck/containers in warehouse,harbor,airport,dock,etc.it solves the problems of no shipping docks when loading or unloading.the mechanized operation largely increases work efficiency,relieves labor intensity and also reduces cost for modern enterprises in a side range of applications.it facilitates goods handing work and also provides advantages to advanced production,modernized mangement and safe operation.

Bags Loading & Unloading Conveyors

These types of conveyors are used for loading and unloading of 50, 100kg bags both jutte and carton boxes. This conveyors is having huge demand in soya plants, sugar mills & flour mills for storing activities.

#Warehouse Conveyor manufacturers#Flexible Gravity Conveyor manufacturers#Spiral Chutes conveyors manufacturers#Spiral gravity Roller Conveyors manufacturers#Truck Loading Conveyors manufacturers#Telescopic Belt Conveyors manufacturers

0 notes

Text

Effortless Loading with an Automatic Front Boat Loader

If you're tired of the hassle of loading and unloading your boat, the Automatic Front Boat Loader is the game-changing solution you’ve been waiting for. This innovative tool makes loading boats onto trailers simple, fast, and stress-free. With just the press of a button, your boat will be securely loaded without the need for any physical effort. It eliminates the need for complex manual adjustments or additional help at the dock, saving you valuable time.

For those who are passionate about boating, investing in automatic systems can significantly enhance your experience. With automatic load boats, you can ensure safe and efficient transportation, protecting your investment. These systems work seamlessly with various boat types and sizes, making them versatile for all kinds of boating adventures.

Designed with durability and convenience in mind, an automatic front boat loader takes the stress out of what used to be a challenging part of boating. It's especially helpful for solo boaters or those who prefer to handle their boats independently. You can now load and secure your boat in minutes, giving you more time to enjoy the water.

Whether you're an experienced boater or a newcomer to the water, an automatic front boat loader offers peace of mind and a more enjoyable boating experience. Embrace the convenience and elevate your boating lifestyle today!

0 notes

Text

Top Conveyor Manufacturers and Suppliers in India

Raj Conveyors is the Top Conveyor Manufacturers and Suppliers which are specialized in solution concept Design, Supply and installation of conveyors. We give solutions meeting the needs of companies throughout the country. We are based in hyderabad. Our products are known for their high quality, dependability, durability and timely delivery.

The products includes

Telescopic Conveyor manufacturers: Raj Conveyors are the Telescopic Conveyor manufacturers Telescopic Container, Truck Loading Conveyors is an automatic loading & unloading equipment which can extend directly into containers / trucks / trailers / vehicles. It is widely used in logistics shipping and receiving distribution centers, ports, docks, stations, airports and warehouses. Involving industries of post, home appliances, food, tobacco and light industry. It saves time of walking back and forth to make the loose loading work more efficient and less intensive.

Warehouse/ Logistic Conveyor manufacturers: Raj Conveyors are the Warehouse/Logistics Conveyors manufacturers which are used to convey products which have defined shape, like, throughout the facility and to another warehouse nearby if needed. These apparatus can either be operated manually, by gravity, or by a motor. Conveyors could also help improve warehouse operations by organizing transportation processes and minimizing human errors.

Speedy Delivery

Minimized Risks

Increased Productivity

Flexible Gravity Conveyor manufacturers: Raj Conveyors are the Flexible Gravity Conveyors manufacturers. Highly mobile, extremely flexible conveyor can be moved, stretched out and positioned in minutes. Simply wheel it out and expand it straight or around bends to suit your needs. When finished just close the unit up and store away. These machines can be used on their own or to supplement existing installations in stores, warehouses or assembly lines.

Load Bearing capacity: 25-30 kgs per Item

Zero Power requirements

Zero maintenance

Completely flexible

Faster loading & unloading of truck

Spiral Chutes manufacturers: Raj Conveyors are the Spiral Chutes manufacturers which are used to bridge relatively large height differences in confined spaces with the option of several feeds, arranged opposite or one above the other.

Spiral chutes are developed, designed and manufactured individually according to your specific needs. The conveying height and direction can be varied by a modular design, and the coil diameter and pitch as well as the dimensions of the inputs and outputs are variable. The active sliding surface is pressed three-dimensionally with gentle transitions for particularly smooth and noiseless transport of packaged goods.

Spiral Roller Conveyors manufacturers: Raj Conveyors are the Spiral Roller Conveyors manufacturers. The Spirals can convey full and empty cartons, cases, trays, totes and all sorts of packaged goods in a continuous flow. Loads are conveyed reliably on our proprietary slat type belts, depending on the product size. The slats are overlapping and provide an efficient and safe conveying surface at speeds up to 200 FPM. It can convey the goods in both directions and with a single drive.

These spiral conveyors can save the space

Truck Loading Conveyors manufacturers: Raj Conveyors are the Truck Loading/Unloading Conveyors manufacturers. Our offered Loading Conveyor System is very cost effective, easy to maintain and saves considerable floor space. These are used to load carton boxes & Bags into trucks and containers. Where the loading deck is not available. Can be used in different industries where bags and boxes are used extensively for packing.

Movable

Easy to handle

Can achieve different heights for stacking of bags

#Telescopic Conveyor manufacturers#Warehouse Conveyor manufacturers#Logistic Conveyor manufacturers#Flexible Gravity Conveyor manufacturers#Spiral Chutes manufacturers#Spiral Roller Conveyors manufacturers

0 notes