#Batch Coding Manual Printing Machine

Explore tagged Tumblr posts

Text

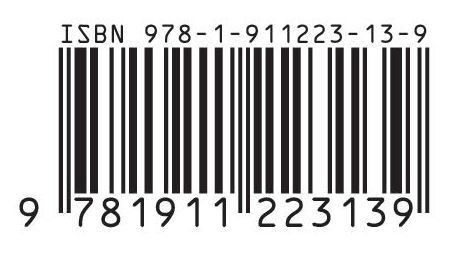

Understanding Barcode Definitions: A Quick Guide 2025

1. What Is a Barcode? Simple Barcode Definitions Explained

In 2025, barcodes continue to play a vital role in modern business operations. To begin, let’s explore the Barcode Definitions in the simplest terms. A barcode is a visual representation of data using parallel lines (in 1D barcodes) or squares and patterns (in 2D barcodes like QR codes). This code is scanned using machines to retrieve the encoded information instantly.

The purpose of Barcode Definitions is to explain what barcodes are and how they enable businesses to streamline tracking, inventory, and point-of-sale systems. Barcodes are now used in retail, healthcare, logistics, catering, and countless other sectors.

2. How Barcodes Work: A Quick Technical Breakdown

Understanding how barcodes function helps bring clarity to Barcode Definitions. Each barcode is designed to hold specific data such as a product ID, location, batch number, or price. A scanner uses light sensors to read the code and instantly translate it into readable data for a computer system.

The scanner decodes the reflected light from the barcode and converts it into digital signals. These signals are matched with backend systems to identify the item or data linked to the code. This makes barcodes a fast and efficient solution for real-time tracking and management.

3. Common Types of Barcodes Used in 2025

When looking at Barcode Definitions, it’s important to know the various types available today:

1D Barcodes (like UPC or EAN): These are linear and used mainly in retail.

2D Barcodes (like QR Codes and Data Matrix): These carry more data in less space.

PDF417: Used in official documents like driving licenses or airline boarding passes.

GS1 Barcodes: Global standards for supply chains and retail.

Each of these fits under the umbrella of modern Barcode Definitions and helps businesses choose the best format for their needs.

4. Importance of Barcodes in Retail, Logistics, and Healthcare

Barcodes play a huge role in various industries. The Barcode Definitions used in retail involve product labeling, price management, and automated checkout systems. In logistics, barcodes help in tracking goods from warehouse to delivery. In healthcare, patient IDs, medication labels, and equipment tags rely on barcodes for accuracy and safety.

These definitions reflect the growing demand for error-free, data-driven systems that barcodes continue to fulfill in 2025.

5. Barcode Definitions in Inventory Management Systems

One of the key applications of Barcode Definitions is in inventory control. Businesses use barcodes to keep accurate track of stock levels, shipments, and usage trends. Barcode systems eliminate manual entry and reduce errors significantly.

For example, catering businesses like Jaffer Bhai’s use barcodes to track ingredient usage, kitchen supplies, and packaging materials. Each item can be tagged, scanned, and updated in real-time, helping with order accuracy and planning.

6. Advantages of Using Barcodes in Modern Business Operations

There are many advantages associated with Barcode Definitions in daily business use:

Speed: Scan hundreds of items in minutes.

Accuracy: Reduce human errors in data entry.

Cost-effective: Affordable to print and implement.

Scalability: Suitable for businesses of all sizes.

These benefits show why Barcode Definitions are essential for businesses that value efficiency and precision in 2025.

7. Barcode vs QR Code: What's the Difference in 2025?

Many people confuse barcodes with QR codes, so understanding their differences is part of clear Barcode Definitions. A barcode (1D) holds limited information and requires line-of-sight scanning. A QR code (2D) can hold more data and can be scanned from any angle, even with mobile phones.

In catering, barcodes might be used to label utensils, while QR codes can direct customers to digital menus or feedback forms. Knowing when to use each format helps businesses make the most of their barcoding systems.

8. Smart Packaging and Barcode Innovation Trends for 2025

Barcode Definitions have evolved with the rise of smart packaging. In 2025, businesses use barcodes combined with cloud systems and mobile apps to manage inventory automatically. Products can be tracked from production to customer delivery using advanced barcode systems.

Smart labels also include features like temperature tracking, expiry alerts, and tamper evidence, making barcode solutions smarter and more secure than ever.

9. How to Implement a Barcode System for Your Business

Implementing barcode systems starts with understanding Barcode Definitions and identifying your tracking needs. Here are basic steps:

Choose the right barcode type for your industry.

Invest in barcode software and printers.

Label all inventory or equipment clearly.

Train staff on how to scan and manage barcoded items.

Connect scanning data to your inventory or POS software.

Once set up, barcodes will begin improving accuracy and accountability immediately.

10. The Future of Barcode Technology: What's Next Beyond 2025?

The Barcode Definitions of the future include integration with AI, IoT (Internet of Things), and blockchain. These technologies will help verify the origin of goods, automate reordering, and improve transparency in the supply chain.

Barcodes will also evolve in design, using invisible ink or nano printing for added security. Mobile apps will continue making barcode scanning easier for businesses and consumers alike.

Call to Action:

Want to implement barcode tracking in your business? Contact AIDC Technologies India today to discover cutting-edge solutions built on reliable Barcode Definitions and smart automation.

#BarcodeDefinitions#BarcodeTechnology2025#SmartInventory#RetailAutomation#BarcodeSystem#InventorySolutions#AIDCIndia

0 notes

Text

4 Must-Have Candy Manufacturing Machines for Efficient Production

If you're a confectioner aiming to scale up candy production or boost efficiency, the right equipment makes all the difference. Whether you're crafting caramels, gummies, hard candies, or chocolate-coated treats, reliable candy manufacturing equipment helps you maintain consistency, reduce waste, and meet demand without compromising quality.

In this guide, we break down the top four machines every candy business needs to streamline operations and produce top-tier confections.

1. Candy Cooker (Batch or Continuous)

No matter your recipe, cooking sugar mixtures to precise temperatures is the foundation of every successful candy. From glucose syrups to fruit purées, proper heat control ensures flavor, texture, and color remain consistent across batches.

Why it matters:Undercooked candy can be sticky or unstable. Overcooked batches may crystalize or burn. The right candy cooker ensures repeatable results every time.

What to look for:

Accurate digital temperature controls

Vacuum cooking options for moisture control (ideal for gummies and soft candies)

Food-grade stainless steel construction

Choose batch cookers for flexibility and small batches, or continuous cookers for high-volume production

Pro Tip: If you manufacture both hard and soft confections, consider a dual-purpose cooker or modular setup.

2. Candy Depositor or Moulding Machine

The candy depositor is where your mixture takes shape — literally. Whether you're filling molds for gummies or forming chewy pieces, this machine ensures portion control and consistent product sizing.

Why it matters: Uniform size and weight ensure better packaging, setting, and quality control — and help keep your ingredient costs predictable.

What to look for:

Interchangeable mold and nozzle designs

Programmable portion sizes

Heated hoppers (prevents premature crystallization)

Compatibility with various consistencies — from viscous syrups to liquid centers

From tabletop depositors for small-batch candy makers to fully automated moulding systems, there’s a solution for every scale.

3. Cooling Tunnel or Cooling Cabinet

Once formed or coated, your candy must cool under controlled conditions. A cooling tunnel or cooling cabinet stabilizes the product, locking in texture and finish.

Why it matters: Improper cooling can cause chocolate bloom, sticky gummies, or deformed shapes. Temperature and humidity control are crucial at this stage.

What to look for:

Adjustable temperature and airflow settings

Multi-tier or conveyor-style layouts for high output

Easy-to-clean design to meet hygiene standards

Humidity control to prevent condensation and spoilage

Cooling is not just a post-production step — it’s a key quality control point in your candy line.

4. Candy Packaging Machine

Great candy deserves great presentation — and protection. Whether you sell retail-ready treats or bulk packs, the right candy wrapping machine or packaging system helps preserve freshness and appeal.

Why it matters: Modern packaging protects against moisture, oxygen, and tampering. It also improves shelf life and retail acceptance.

What to look for:

Packaging formats: flow wrap, pillow pack, twist wrap, jars, sachets

Throughput speed that fits your production needs

Integration with batch coding or expiry date printing

Compact design with food-grade materials

Startups may benefit from semi-automatic packaging machines that allow manual feeding with automated sealing, balancing cost and efficiency.

Final Thoughts: Start Smart with the Right Candy Equipment

These four essential machines — cooker, depositor, cooling system, and packaging unit — form the backbone of any successful candy production line. Whether you're starting small or scaling up, focus on candy production equipment that is:

Scaled to your current output

Built for future expansion

Easy to clean, operate, and maintain

Certified for food safety and hygiene standards

Need Help Choosing Equipment?

At Latini Hohberger Dhimantec, we specialize in high-performance candy and chocolate manufacturing machinery. Our equipment is used by both artisanal producers and global brands — offering modular, durable, and precision-engineered solutions built to grow with your business.

🔗 Explore Candy Equipment at LatiniUSA.com

Source URL: Blogspot.com

0 notes

Text

Bottle Labeling Machine: Complete Guide to Precision Product Labeling

What is a Bottle Labeling Machine?

A bottle labeling machine is an automated or semi-automated system used to apply labels onto bottles of various shapes and sizes—round, flat, oval, or square. These machines are engineered for high accuracy, speed, and uniformity, significantly reducing labor costs and errors associated with manual labeling.

Whether it's a wrap-around label on a soda bottle or a front-and-back label on a shampoo container, these machines handle it all with seamless efficiency.

Types of Bottle Labeling Machines

1. Manual Bottle Labeling Machines

Ideal for small-scale or home-based operations

Hand-cranked or foot-pedal operated

Low investment, minimal automation

2. Semi-Automatic Bottle Labeling Machines

Operator places the bottle, and the machine handles the labeling

Perfect for startups and small to mid-sized businesses

Compatible with wrap-around, single-side, and double-side labels

3. Fully Automatic Bottle Labeling Machines

Bottles are fed and labeled automatically on conveyors

Suitable for high-speed production lines

High output, precise alignment, reduced labor needs

4. Rotary Labeling Machines

Designed for ultra-high-speed lines

Uses a carousel system to label multiple bottles simultaneously

Often used in beverages, pharma, and cosmetics industries

5. Shrink Sleeve Labeling Machines

Applies shrink labels using heat tunnels for 360° branding

Common in juice, soft drinks, and energy drink packaging

Applications of Bottle Labeling Machines

Food & Beverage Industry

Juices, mineral water, milk, sauces, syrups, oils, alcohol

Date coding, branding, and compliance labels

Pharmaceuticals

Tablets, syrups, liquid drugs

Includes batch number, expiry date, and dosage information

Cosmetics & Personal Care

Shampoos, conditioners, lotions, perfumes

Requires visually appealing labels to reflect brand identity

Chemicals and Agro-Products

Fertilizers, pesticides, cleaning products

Requires resistant, long-lasting adhesive labels

Core Features of Advanced Bottle Labeling Machines

1. High Labeling Speed

Capable of labeling 20 to 300 bottles per minute, depending on model and label type.

2. Accuracy and Precision

Label placement tolerance as low as ±1 mm, ensuring professional appearance.

3. Label Sensor System

Automatically detects label gaps and bottle positions to prevent misalignment.

4. Adjustable Conveyor System

Compatible with a wide range of bottle sizes and shapes.

5. Integrated Coding Devices

Allows real-time printing of batch numbers, barcodes, and expiry dates.

6. PLC and Touchscreen Control

Easy programming, operation, and error diagnostics through HMI systems.

Benefits of Using a Bottle Labeling Machine

Enhanced Branding: Professionally applied labels elevate product appeal

Time-Saving: Speeds up production lines exponentially

Reduced Human Error: Increases labeling accuracy and consistency

Compliance Assurance: Meets global labeling standards (FDA, FSSAI, EU)

Versatility: One machine can handle different bottle types and label formats

Low Operational Costs: Cuts labor costs while boosting throughput

0 notes

Text

Top Print and Apply Labeling Systems Manufacturers in the UK: What You Need to Know

In today’s fast-paced manufacturing environment, print and apply labeling systems have become a critical component of efficient packaging and logistics operations. Whether you're in food & beverage, pharmaceuticals, e-commerce, or logistics, choosing the right manufacturer can significantly impact your productivity and compliance. Here’s a complete guide to the top print and apply labeling system manufacturers in the UK and what to consider before making a purchase.

🔹 What Are Print and Apply Labeling Systems?

Print and apply labeling systems are automated machines designed to print labels (with barcodes, batch codes, expiry dates, etc.) and apply them directly onto products, cartons, or pallets. These systems ensure fast, accurate, and reliable labeling, which is essential for inventory tracking, traceability, and supply chain efficiency.

🔹 Benefits of Print & Apply Labeling Machines

Improved Efficiency: Automates the labeling process, reducing manual labor.

Accuracy: Reduces human error and mislabeling.

Scalability: Ideal for high-volume operations.

Compliance: Meets industry regulations (e.g., GS1 standards, FDA, EU directives).

Versatility: Works with different product types, sizes, and surfaces.

🔹 Top UK Print and Apply Labeling System Manufacturers

1. Domino Printing Sciences

One of the leading global players headquartered in the UK, Domino offers high-speed, integrated labeling systems with a focus on traceability, efficiency, and sustainability.

2. Label-Aire Europe

Label-Aire is known for robust and flexible labeling systems that integrate seamlessly into existing production lines. Their UK division offers strong technical support and custom solutions.

3. Logopak UK

Logopak specializes in high-performance print and apply systems for demanding industrial applications. They are a trusted name in food, beverage, and logistics sectors.

4. Advanced Labelling Systems (ALS)

Based in Oxfordshire, ALS provides reliable labeling automation with comprehensive support, including installation, servicing, and training.

5. Herma UK

Herma is known for German engineering with UK-based service. They deliver precision labeling machines with user-friendly interfaces and high output rates.

🔹 Factors to Consider When Choosing a Manufacturer

Speed and Output: Match the labeling speed to your production line requirements.

Print Quality: Look for machines that offer high-resolution printheads.

Maintenance & Support: Choose manufacturers that offer reliable after-sales service in the UK.

Integration Capabilities: Ensure the system integrates with your ERP, WMS, or existing production line.

Labeling Accuracy: Essential for compliance and barcode scanning efficiency.

🔹 Industries That Benefit Most

Food & Beverage: Date codes, nutrition labels, and allergen compliance.

Pharmaceuticals: Serialization and tamper-evident labeling.

Retail & E-Commerce: Inventory tracking and shipping labels.

Logistics: Pallet labeling and warehouse barcoding.

🔹 Final Thoughts

Investing in a print and apply labeling system from a reputable UK manufacturer ensures long-term efficiency, compliance, and productivity. With options ranging from standard to fully customized solutions, UK-based companies are leading the way in innovation and reliability. Take the time to assess your specific needs and choose a manufacturer that offers robust service and industry expertise.

0 notes

Text

Unveiling Efficiency: The Power of Strip Packaging Machines in Modern Manufacturing

In the fast-paced world of modern manufacturing, where precision, efficiency, and safety are paramount, the Strip Packaging Machine stands as a cornerstone of smart automation. Far more than just a piece of equipment, it represents a leap forward in how sensitive products, particularly in the pharmaceutical, food, and even some consumer goods industries, are prepared for market.

At its core, a strip packaging machine meticulously seals individual units of a product—be it tablets, capsules, small candies, or even tiny components—into a continuous strip of flexible material, typically foil, paper, or a laminate. This process offers distinct advantages over traditional bulk packaging methods. Firstly, the individual pouches create a robust barrier against moisture, oxygen, and light, significantly extending shelf life and preserving product integrity. This is critically important for pharmaceuticals, where degradation can impact efficacy, and for food items, where freshness is key to consumer satisfaction.

The precision offered by these machines is unparalleled. Equipped with advanced sensors and often integrated with vision systems, they ensure accurate counting and placement, minimizing waste and guaranteeing that each strip contains the correct number of units. This level of accuracy is vital for dosage control in medication and for maintaining consistent product offerings in consumer goods. Furthermore, the sealing process is highly controlled, often employing heat sealing, which creates a tamper-evident seal. This adds a crucial layer of security, reassuring consumers that the product they are receiving is untouched and safe.

Beyond product preservation and security, the economic benefits of implementing a strip packaging machine are substantial. Its automated nature dramatically reduces the need for manual labor, leading to significant cost savings in the long run. The high throughput capabilities mean that large volumes of product can be processed quickly, meeting market demands efficiently and enabling faster time-to-market. Downtime is minimized thanks to robust engineering and user-friendly interfaces that facilitate quick changeovers for different product sizes or packaging materials. This operational flexibility is a major advantage for companies dealing with diverse product portfolios.

From a regulatory standpoint, particularly in the pharmaceutical sector, strip packaging machines help manufacturers adhere to stringent guidelines for packaging and serialization. The ability to print batch numbers, expiry dates, and even unique serial codes directly onto each pouch ensures traceability and compliance, which are non-negotiable in today's highly regulated environments.

In essence, the strip packaging machine is not just about putting products into packets; it's about optimizing an entire manufacturing process. It's about delivering superior product protection, enhancing consumer safety, boosting operational efficiency, and ensuring regulatory compliance. For any business looking to elevate its packaging standards and gain a competitive edge in today's demanding market, investing in a state-of-the-art strip packaging machine is no longer an option, but a strategic imperative. It's the silent workhorse that ensures your products reach your customers safely, securely, and in perfect condition, every single time.

0 notes

Text

Boosting Traceability with a Modern Batch Coding Machine

In today’s fast-paced manufacturing and packaging industries, traceability is no longer a luxury — it’s a necessity. From pharmaceuticals to food and beverage, and even cosmetics, brands are under increasing pressure to ensure that every product can be tracked from production to delivery. This is where a Batch Coding Machine plays a vital role in streamlining traceability processes and ensuring compliance with regulatory standards.

What Is a Batch Coding Machine?

A Batch Coding Machine is a specialized device used to print essential information such as batch numbers, expiry dates, manufacturing dates, barcodes, and more on product packaging. These details are crucial for product identification, traceability, and regulatory compliance. The machine prints directly onto surfaces such as plastic, glass, metal, cardboard, or flexible packaging materials.

Modern Batch Coding Machines come with advanced features like high-resolution printing, fast speed, automated operation, and the ability to integrate seamlessly into production lines. These features make them indispensable tools for any manufacturer looking to enhance quality control and supply chain management.

Why Traceability Matters More Than Ever

Consumers and regulators demand transparency. Whether it's a bottle of medicine or a carton of milk, knowing where a product came from, when it was made, and which batch it belongs to can be critical. In the case of recalls, accurate traceability allows companies to isolate the affected products quickly, minimizing health risks and financial losses.

Moreover, global standards such as the Food Safety Modernization Act (FSMA) or the EU’s Falsified Medicines Directive require companies to ensure end-to-end traceability. A Batch Coding Machine is essential in meeting these standards by printing accurate and consistent batch information on every unit.

How a Batch Coding Machine Boosts Traceability

A Batch Coding Machine enhances traceability in several significant ways:

1. Consistent and Legible Coding

Modern Batch Coding Machines ensure that every printed code is sharp, clear, and legible. This consistency helps scanners and quality control teams accurately identify products, even in high-volume production environments.

2. Real-Time Data Integration

Today’s Batch Coding Machines can be connected to centralized systems or databases. This integration allows real-time updates to be reflected in the printed codes. Whether it’s a change in the batch number or a new manufacturing date, the machine adjusts automatically, reducing human error and improving traceability.

3. Automation and Speed

In high-speed production lines, manual coding can lead to errors, misprints, or inconsistencies. A modern Batch Coding Machine automates the process, ensuring accuracy while keeping up with production demands. Faster and error-free coding significantly boosts operational efficiency and traceability.

4. Support for Multiple Packaging Types

Manufacturers often use different types of packaging. Whether it’s PET bottles, flexible pouches, cartons, or jars, a Batch Coding Machine is designed to handle a wide range of surfaces and shapes, making it versatile and adaptable for any industry.

Choosing the Right Batch Coding Machine

Selecting the right Batch Coding Machine is crucial for maximizing traceability benefits. Here are a few considerations:

Print Quality and Resolution – Ensure the machine offers high-resolution printing for barcode and QR code readability.

Ease of Integration – The machine should seamlessly fit into your current production line.

Support and Service – Choose a reliable supplier like SH HITECH SOLUTIONS, known for quality equipment and excellent after-sales service.

User-Friendly Interface – A simple control panel helps operators make quick adjustments, reducing downtime.

Real-World Applications

From a small food packaging company to a large pharmaceutical manufacturer, a Batch Coding Machine is essential across industries. For example, a dairy company may use it to print production dates and batch numbers on milk cartons to comply with food safety regulations. Meanwhile, a pharmaceutical brand can use it for secure and precise date and batch marking to meet strict medical standards.

Final Thoughts

Traceability is not just about following regulations — it's about building consumer trust, improving product quality, and protecting your brand. A modern Batch Coding Machine empowers companies to do just that by delivering fast, accurate, and durable coding on every product.

As industries evolve and the demand for transparency grows, investing in the right Batch Coding Machine becomes more critical than ever. With advanced coding technology and support from trusted partners like SH HITECH SOLUTIONS, businesses can ensure flawless traceability from start to finish.

0 notes

Text

How Does an Automatic Pouch Packaging Machine Work?

In today’s fast-paced industrial landscape, packaging plays a crucial role in ensuring product safety, enhancing shelf appeal, and improving overall efficiency. Businesses across various industries rely on Automatic Pouch Packaging Machines to streamline their production lines and maintain product quality. But how do these machines function? Let’s explore the working process of an Automatic Pouch Packaging Machine and why choosing a reliable Automatic Pouch Packaging Machine Manufacturer like Ambika Packaging Solution is essential.

Understanding Automatic Pouch Packaging Machines

An Automatic Pouch Packaging Machine is a high-speed, precision-based equipment designed to fill and seal pouches efficiently. These machines are widely used in industries such as food & beverage, pharmaceuticals, chemicals, cosmetics, and more. By automating the packaging process, businesses can achieve greater consistency, reduce labor costs, and increase productivity.

Step-by-Step Working Process of an Automatic Pouch Packaging Machine

1. Pouch Loading and Feeding

The process starts with pouch loading, where pre-formed pouches are fed into the machine. Some machines come with an automatic feeding system that picks up the pouches from a stack and places them into the designated position for further processing.

2. Pouch Detection and Alignment

Once the pouches are fed into the system, sensors detect their presence and ensure proper alignment. This step is critical to avoid errors such as misaligned sealing or improper filling, which could compromise the packaging quality.

3. Pouch Opening

After alignment, the machine opens the pouch using vacuum suction or mechanical grippers. This step ensures that the pouch is fully open and ready to receive the product without any obstructions.

4. Product Filling

The filling station dispenses the pre-measured product into the open pouch. Different types of filling mechanisms are used depending on the nature of the product:

Auger Fillers – Used for powders like spices, flour, and coffee.

Liquid Fillers – Ideal for juices, oils, and sauces.

Weigh Fillers – Used for granular and solid products like snacks, nuts, and dry fruits.

5. Excess Air Removal (Optional)

In some packaging processes, excess air is removed from the pouch to increase product shelf life and maintain freshness. This is especially important in food packaging.

6. Pouch Sealing

Once the product is filled, the pouch moves to the sealing station. The machine applies heat and pressure to seal the pouch effectively. There are different sealing techniques, such as:

Heat Sealing – Commonly used for plastic and laminated pouches.

Ultrasonic Sealing – Used for delicate packaging materials and provides a strong seal without excessive heat.

7. Coding and Labeling (Optional)

Many Automatic Pouch Packaging Machines integrate a coding system to print batch numbers, manufacturing dates, expiration dates, and barcodes on the pouch. This step ensures compliance with industry regulations and enhances traceability.

8. Pouch Cutting and Discharge

After sealing, the machine cuts the pouch to separate it from the next one (if applicable) and then discharges the finished product onto a conveyor belt or collection area for final inspection and packaging.

9. Quality Check and Sorting

A final quality check ensures that the pouches are properly sealed, labeled, and free from defects. Any defective pouches are rejected automatically to maintain the highest packaging standards.

Benefits of Using an Automatic Pouch Packaging Machine

Increased Efficiency – Automating the packaging process significantly reduces downtime and improves production speed.

Consistent Quality – Ensures uniform filling, sealing, and packaging, eliminating human errors.

Reduced Labor Costs – Minimizes the need for manual intervention, cutting down labor expenses.

Versatility – Can handle a variety of pouch materials, shapes, and sizes.

Enhanced Product Shelf Life – Proper sealing techniques help prevent contamination and spoilage.

Customization Options – Machines can be tailored to suit specific industry requirements.

Choosing the Right Automatic Pouch Packaging Machine Manufacturer

Selecting a reliable Automatic Pouch Packaging Machine Manufacturer is crucial for ensuring durability, efficiency, and quality. Ambika Packaging Solution is a trusted name in the industry, offering state-of-the-art packaging machines tailored to various industrial needs. Here’s why you should choose Ambika Packaging Solution:

Advanced Technology – They use cutting-edge technology to manufacture high-performance packaging machines.

Customization – They provide tailored solutions to meet specific business requirements.

Quality Assurance – Machines undergo rigorous quality checks to ensure reliability and efficiency.

After-Sales Support – Dedicated customer support ensures seamless operation and minimal downtime.

Industry Expertise – Years of experience in the packaging industry make them a preferred choice among businesses.

Conclusion

An Automatic Pouch Packaging Machine is a game-changer for industries looking to enhance efficiency and maintain high packaging standards. By automating the pouch filling and sealing process, businesses can achieve consistent quality, reduce costs, and increase productivity. Choosing a reliable Automatic Pouch Packaging Machine Manufacturer, such as Ambika Packaging Solution, ensures that you get a high-quality machine tailored to your industry needs.

If you’re looking for a trusted partner in packaging automation, Ambika Packaging Solution offers cutting-edge solutions to streamline your packaging operations. Contact them today to learn more about their innovative packaging machines!

#Automatic Pouch Packaging Machine Manufacturer#Packaging Solutions Near Me#Packaging Machine Manufacturer in Haryana#Liquid Packaging Machines Manufacturer

0 notes

Text

Cartoning Machine: A Complete Guide to Automated Packaging

The packaging industry has seen significant advancements in automation, and one such innovation is the cartoning machine. These machines are designed to efficiently pack products into cartons, ensuring speed, accuracy, and consistency in the packaging process. Whether used in the food, pharmaceutical, or cosmetic industry, cartoning machines have become an integral part of modern packaging solutions.

In this blog, we will explore the different types of cartoning machines, their working principles, benefits, applications, and factors to consider when selecting the right one for your business.

What is a Cartoning Machine?

A cartoning machine is an automated system used for erecting, filling, and closing cartons. These machines streamline the packaging process, reducing labor costs and increasing production efficiency. They come in various designs, catering to different product types and packaging needs.

Types of Cartoning Machines

Cartoning machines can be broadly classified into two main categories:

1. Horizontal Cartoning Machines

Horizontal cartoning machines load products into cartons horizontally. They are ideal for products such as:

Bottles

Tubes

Sachets

Pouches

Blister packs

These machines are widely used in industries like pharmaceuticals, food, and cosmetics.

2. Vertical Cartoning Machines

Vertical cartoning machines insert products from the top of the carton. They are suitable for:

Granules

Powders

Small bottles

Vials

These machines are commonly used in the food and pharmaceutical industries for bulk filling applications.

Working Principle of Cartoning Machines

The working of a cartoning machine involves multiple automated steps:

Carton Erection – The machine picks up a flat carton and erects it into shape.

Product Loading – The product is inserted into the carton manually or through an automated system.

Folding & Closing – The machine folds the flaps of the carton and applies adhesives or tuck-in closures.

Sealing & Coding – Some machines integrate coding systems to print batch numbers, expiry dates, or barcodes.

Final Output – The finished cartons are sent for further processing or shipment.

Benefits of Using a Cartoning Machine

Investing in a cartoning machine offers several advantages, including:

1. Increased Efficiency

Automation reduces manual labor, leading to higher production rates and consistency in packaging.

2. Cost Savings

Although the initial investment is high, cartoning machines significantly reduce labor costs and material wastage over time.

3. Improved Product Safety

Secure packaging ensures that products remain intact during transportation and storage, minimizing damage.

4. Customization and Flexibility

Modern cartoning machines offer customization options, allowing businesses to pack a variety of products with different carton sizes and styles.

5. Compliance with Industry Standards

For industries like pharmaceuticals and food, automated packaging ensures compliance with hygiene and safety regulations.

Applications of Cartoning Machines

Cartoning machines are used across multiple industries, including:

1. Pharmaceutical Industry

Packaging of tablets, capsules, syrups, and ointments.

Tamper-proof sealing ensures product integrity.

2. Food Industry

Cereal boxes, snack packs, frozen foods, and ready-to-eat meals.

Maintains freshness and extends shelf life.

3. Cosmetic Industry

Packaging of skincare products, perfumes, and beauty kits.

Enhances product appeal with attractive packaging.

4. Consumer Goods

Packaging of electrical components, household items, and personal care products.

Ensures durability and protection.

Factors to Consider When Choosing a Cartoning Machine

Selecting the right cartoning machine requires careful consideration of various factors:

1. Production Speed

Determine the required output capacity to ensure the machine meets production demands.

2. Carton Size and Type

Ensure the machine can handle the specific carton dimensions and closure methods required for your product.

3. Automation Level

Choose between semi-automatic and fully automatic machines based on budget and operational requirements.

4. Space and Layout Constraints

Assess the available space and ensure the machine fits seamlessly into your production line.

5. Maintenance and Support

Opt for a machine that offers easy maintenance and comes with reliable technical support.

Used Cartoning Machines: A Cost-Effective Solution

For businesses looking for an affordable alternative, purchasing a pre-owned cartoning machine can be a viable option. Buying a cartoning machine from a reliable supplier of used packaging equipment ensures quality while keeping costs low. Many refurbished machines offer similar performance levels as new ones but at a fraction of the cost.

Conclusion

Cartoning machines have revolutionized the packaging industry by enhancing efficiency, reducing costs, and improving product safety. Whether you are in the pharmaceutical, food, or cosmetic industry, investing in the right cartoning machine can significantly boost your production process. By understanding the types, benefits, and factors to consider, businesses can make informed decisions that align with their packaging needs.

If you are looking to optimize your packaging line, consider investing in a high-quality cartoning machine or exploring used packaging equipment options to meet your budget and production goals.

0 notes

Text

gs1 barcode

Understanding GS1 Barcodes: The Standard for Global Product Identification

In today's interconnected world of commerce, efficient product identification and seamless supply chain management are essential for businesses of all sizes. GS1 barcodes serve as the global standard for uniquely identifying products, assets, and locations, ensuring consistency and accuracy across industries worldwide. This article explores the fundamentals of GS1 barcodes, their types, and why they are critical for businesses operating in a global marketplace.

What is GS1?

GS1 (Global Standards One) is a non-profit organization that develops and maintains global standards for supply chains. Established in 1974, GS1 is best known for introducing the Universal Product Code (UPC), the world's first barcode. Today, GS1 standards are used in over 100 countries, enabling businesses to identify, capture, and share information seamlessly.

Key GS1 Functions:

Provide unique identification numbers for products, assets, and locations.

Ensure barcode consistency across global markets.

Facilitate efficient supply chain management and data sharing.

What is a GS1 Barcode?

A GS1 barcode is a machine-readable symbol used to represent a GS1 identification number. This number uniquely identifies products, locations, shipments, or assets in a standardized format, ensuring seamless communication between businesses, retailers, and consumers.

Each GS1 barcode contains:

GTIN (Global Trade Item Number): A unique product identifier.

Company Prefix: A unique code assigned to the brand owner.

Product Code: A unique number for each product variant.

Check Digit: Ensures barcode accuracy during scanning.

Types of GS1 Barcodes

GS1 offers a variety of barcode formats tailored for different uses across industries.

1. UPC (Universal Product Code)

Commonly used in retail stores worldwide.

Contains 12 digits (GTIN-12).

Ideal for point-of-sale (POS) scanning.

2. EAN (European Article Number)

Widely used in Europe and globally.

Contains 13 digits (GTIN-13).

Compatible with retail and POS systems.

3. GS1-128

Used for logistics and shipping labels.

Can encode batch numbers, expiration dates, and other data.

Improves traceability in the supply chain.

4. DataMatrix

A 2D barcode used in healthcare and manufacturing.

Stores large amounts of data in a small space.

Ideal for tracking medical devices and pharmaceuticals.

5. QR Code (Quick Response Code)

Used in marketing, payments, and digital product information.

Can store URLs, text, or serial numbers.

Scannable using smartphones.

6. GS1 Digital Link

Connects physical products to digital content via barcodes.

Enables customers to access product information, promotions, and manuals online.

Why Use GS1 Barcodes?

GS1 barcodes offer several advantages for businesses across different sectors:

Global Recognition: Accepted worldwide in retail, logistics, and healthcare.

Accuracy: Minimize errors during scanning and data entry.

Efficiency: Streamline inventory management and reduce manual processes.

Traceability: Enable end-to-end product tracking across the supply chain.

Transparency: Provide detailed product information to consumers.

Regulatory Compliance: Meet international standards and regulations.

How to Get a GS1 Barcode?

Register with GS1: Start by creating an account with your local GS1 organization.

Obtain a GS1 Company Prefix: This prefix uniquely identifies your brand.

Assign GTINs: Allocate a Global Trade Item Number (GTIN) to each product.

Generate Barcodes: Use GS1-approved tools to create your barcode.

Print and Apply: Ensure high-quality printing for clear scanning.

GS1 in Different Industries

1. Retail:

Accurate product identification at point-of-sale terminals.

Better inventory control and stock management.

2. Healthcare:

Tracking of medical equipment and medications.

Enhancing patient safety with precise identification.

3. Logistics:

Real-time tracking of shipments and parcels.

Better warehouse management and order fulfillment.

4. E-commerce:

Simplify product catalog management.

Ensure compatibility across online marketplaces.

5. Food and Beverage:

Track ingredients and final products through supply chain transparency.

Ensure product authenticity and reduce counterfeiting.

Benefits of GS1 Barcodes

Global Standards Compliance: Recognized worldwide for cross-border trade.

Supply Chain Optimization: Enhances logistics and warehouse efficiency.

Reduced Errors: Lowers the risk of manual data entry mistakes.

Enhanced Customer Trust: Accurate product information boosts credibility.

Cost-Effective: Saves time and resources in manual tracking systems.

Challenges in Implementing GS1 Barcodes

While GS1 barcodes offer numerous advantages, businesses may face challenges:

Initial Setup Costs: Registering and obtaining GS1 licenses may require investment.

Training Needs: Staff must be trained to handle barcode systems efficiently.

Printing Quality: Poor-quality barcode printing can affect scanner accuracy.

The Future of GS1 Barcodes

The GS1 system continues to evolve with advancements in technology:

Integration with IoT (Internet of Things): Enabling smarter supply chain solutions.

Blockchain Technology: Enhancing traceability and data transparency.

AI and Machine Learning: Improving demand forecasting and inventory management.

GS1 Digital Link: Bridging physical products with the digital world through scannable links.

Conclusion

GS1 barcodes are more than just a series of lines and numbers—they represent a global standard for efficiency, traceability, and accuracy. Whether you're a small business or a multinational corporation, adopting GS1 barcodes ensures your products are identified correctly, tracked seamlessly, and meet global compliance standards.

Investing in GS1 barcode standards is not just a business decision; it’s a step towards global competitiveness and customer trust.

0 notes

Text

Packaging Automation Solutions: A Game-Changer for Modern Businesses

Automation is no longer just a buzzword; it’s the lifeblood of industries striving for efficiency and innovation. In the world of packaging, packaging automation solutions are transforming how businesses operate. From small startups to multinational giants, everyone is tapping into the power of automation to streamline processes and boost productivity. Let’s explore what makes these solutions so impactful, and yes, we’ll keep it engaging—because automation doesn’t have to be boring!

What Are Packaging Automation Solutions?

Packaging automation solutions encompass advanced technologies and systems designed to handle various packaging tasks—think filling, sealing, labeling, and palletizing—with minimal human intervention. These solutions use robotics, sensors, and software to deliver precision, speed, and reliability in packaging operations.

Gone are the days of endless manual labor on assembly lines. With packaging automation solutions, businesses can achieve more in less time, ensuring consistent quality while reducing costs.

Why Should Businesses Invest in Packaging Automation Solutions?

Let’s break it down:

Speed: Imagine meeting tight deadlines without breaking a sweat.

Accuracy: Say goodbye to crooked labels and messy seals.

Cost Savings: Less waste and reduced labor costs mean a better bottom line.

Scalability: Whether it’s 100 units or 10,000, automation adapts to your needs.

Happier Teams: Employees can focus on creative, meaningful tasks instead of repetitive grunt work.

The Benefits of Packaging Automation Solutions

1. Supercharged Productivity

With packaging automation solutions, what used to take hours can now be done in minutes. Machines don’t take breaks, and they certainly don’t call in sick. This consistent output ensures you meet production goals, even during peak demand periods.

2. Impeccable Quality Control

Human error is inevitable, but machines? They’re built for precision. Whether it’s filling bottles to the exact milliliter or applying labels perfectly every time, automation ensures your products look and perform their best.

3. Cost Efficiency

While the initial investment might seem steep, the long-term savings are worth it. Automation minimizes waste, optimizes material use, and reduces the need for manual labor. Over time, these savings add up significantly.

4. Enhanced Worker Safety

Let’s face it—packaging tasks can be repetitive and even hazardous. Packaging automation solutions take over the physically demanding jobs, reducing workplace injuries and keeping your team safe.

5. Eco-Friendly Operations

Modern automation systems are designed with sustainability in mind. They optimize resource use, reduce waste, and often integrate with green energy solutions, helping your business stay environmentally responsible.

How Do Packaging Automation Solutions Work?

Step 1: Feeding and Organizing

Products are fed into the system using conveyors and robotic arms. These machines organize and sort items, ensuring a smooth flow through the packaging line.

Step 2: Filling and Sealing

Automated systems precisely measure and fill products into containers, be it liquids, powders, or solids. Once filled, the packages are sealed—tight, secure, and ready to move on.

Step 3: Labeling and Coding

Labels are applied flawlessly, and any necessary information—like barcodes, batch numbers, or expiry dates—is printed with laser-sharp clarity.

Step 4: Quality Checks

AI-powered cameras and sensors inspect every package to ensure it meets quality standards. Defective products are flagged and removed from the line.

Step 5: Palletizing and Shipping

Finally, robotic arms stack the packaged goods onto pallets, optimizing them for storage or transport. Some systems even integrate with logistics software for seamless shipping.

Real-World Success Stories

Case Study 1: A Craft Brewery’s Leap to Automation

A small craft brewery struggling with demand spikes turned to packaging automation solutions. The result? Their production tripled, labor costs halved, and they finally had time to focus on brewing award-winning beers.

Case Study 2: A Global Retailer’s Packaging Overhaul

A retail giant adopted fully automated packaging systems across their distribution centers. Not only did this cut processing times by 60%, but it also reduced packaging waste by 30%, aligning with their sustainability goals.

Challenges in Adopting Packaging Automation Solutions

Initial Costs

Let’s be honest—automation isn’t cheap. Investment if often important as long-term benefits often outweigh the initial expenses.

Skill Gaps

Operating and maintaining automated systems require skilled workers. Investing in training is crucial.

Integration

Adapting new systems to existing operations can be tricky. Partnering with experienced providers ensures a smoother transition.

The Future of Packaging Automation Solutions

The future is bright, and it’s automated! Innovations in AI, machine learning, and IoT are making packaging systems smarter and more adaptable. Picture this: machines that predict maintenance needs, adapt to new packaging designs on the fly, and optimize energy use—all while keeping your operations running smoothly.

Conclusion

Packaging automation solutions are the secret sauce for businesses aiming to stay competitive in today’s fast-paced world. They enhance efficiency, improve quality, and save costs—all while making operations safer and more sustainable. Whether you’re a small startup or a global powerhouse, automation can revolutionize your packaging game. So, what are you waiting for? It’s time to let the robots take the reins—and maybe crack a joke or two along the way!

FAQs

1. What industries benefit the most from packaging automation solutions?

Virtually all industries—from food and beverages to pharmaceuticals, cosmetics, and e-commerce—can benefit from automation.

2. How long does it take to see ROI on automation?

Depending on the scale of implementation, most businesses see ROI within 1-3 years.

3. Is automation suitable for small businesses?

Absolutely! Scalable solutions mean even small businesses can adopt automation without breaking the bank.

4. Do automated systems require a lot of maintenance?

Regular maintenance is necessary but manageable, especially with modern systems designed for durability and self-diagnosis.

5. Can automation help with sustainability?

Yes! Many systems are designed to optimize resources and reduce waste, making your operations greener.

1 note

·

View note

Text

Barcode Definitions 101 | Uses & Guide | AIDC INDIA – 2025

Barcodes play a vital role in today’s business environment. From retail checkout systems to inventory tracking, they have transformed the way data is collected and managed. As we step into 2025, it becomes more important to understand barcode definitions and their role in modern operations. This guide from AIDC Technologies India is designed to simplify everything you need to know about barcodes and their practical uses.

2. What Is a Barcode? A Simple Definition Explained

A barcode is a machine-readable code represented as numbers and parallel lines or squares. Barcode definitions explain how this code is structured and what type of data it holds. Barcodes typically encode product information like SKU, batch number, or manufacturing details. They are scanned using barcode readers, which instantly convert visual patterns into digital data.

3. Types of Barcodes Used in 2025

There are various types of barcodes in use, each with its own format and function. Barcode definitions help identify which format suits a particular industry or task:

1D Barcodes: These are linear barcodes like UPC, EAN, and Code 128, often used in retail and inventory.

2D Barcodes: These include QR codes and Data Matrix codes, used for storing more complex data.

PDF417: A stacked linear barcode used on IDs and transport documents.

Each format has a specific barcode definition and is designed to meet unique requirements based on space, readability, and data needs.

4. How Barcodes Work: From Scanning to Data Collection

The basic process begins with printing a barcode on a label or product. A barcode scanner reads the lines or squares, and decoding software extracts the stored information. Barcode definitions help determine what type of scanner and software are needed to read the code accurately. This simple process eliminates manual entry and ensures fast, reliable data capture across operations.

5. Key Uses of Barcodes in Modern Industries

Barcode definitions are foundational in a wide range of sectors. In retail, barcodes are used for pricing and checkout. In warehouses, they track stock movement and inventory levels. Healthcare uses barcodes for labeling medicine and managing patient records. Logistics companies depend on barcodes for real-time tracking of shipments. The correct use of barcode definitions ensures that the data captured is accurate and usable.

6. AIDC India’s Role in Barcode Solutions

AIDC Technologies India provides complete barcode systems—from labels and scanners to printers and integration software. Our deep understanding of barcode definitions allows us to recommend the right type of barcode solution for your specific industry. We support clients in retail, manufacturing, healthcare, education, and logistics with customized systems that improve data tracking and minimize errors.

7. Benefits of Using Barcodes in Business

Barcodes offer several benefits that go beyond just automation. Proper use of barcode definitions brings improvements in many business areas:

Speed: Barcodes speed up scanning and reduce checkout time.

Accuracy: Minimizes manual errors in data entry.

Inventory Control: Keeps track of stock movement in real time.

Cost Savings: Reduces labor and improves efficiency.

By applying the right barcode definitions, businesses can unlock these advantages more effectively.

8. Barcode Definitions vs QR Codes vs RFID

Understanding how barcode definitions compare to other technologies helps in selecting the best system. Barcodes are simpler and more cost-effective for small to medium-sized operations. QR codes, which are 2D barcodes, can store more data and are often used in mobile marketing or payment systems. RFID, which uses radio waves, allows item tracking without line-of-sight scanning. However, barcode systems remain more accessible and easier to implement.

9. Smart Barcode Scanning Solutions by AIDC India

AIDC India offers barcode scanning devices that are optimized to read all standard barcode definitions. Whether it’s a handheld scanner for retail or an industrial-grade scanner for warehouses, our devices ensure fast, accurate, and error-free data collection. We also provide software tools that integrate these scanners with your inventory or billing systems for seamless workflows.

10. Choosing the Right Barcode System for Your Business

Barcode definitions help businesses choose the right format, printing method, and scanning tools. AIDC India helps you evaluate your operational needs, the volume of data you need to encode, and the environment where scanning takes place. Based on these factors, we recommend and implement barcode systems that align with your goals.

11. Future of Barcodes: Trends to Watch in 2025

As we look ahead, barcode definitions are evolving with technology. Mobile barcode scanning is becoming more popular, especially in e-commerce and delivery services. Smart inventory systems are using AI to analyze barcode data for forecasting and planning. Environment-friendly printing solutions are also emerging. AIDC India stays updated with these trends to provide future-ready barcode solutions for businesses of all sizes.

12. Get Started with Barcode Solutions from AIDC India

Barcodes are a small but powerful part of your business infrastructure. With the right barcode definitions and tools, you can automate operations, reduce costs, and improve customer satisfaction. AIDC Technologies India offers everything you need—from barcode labels and printers to scanners and integration support.

Call to Action: Ready to streamline your operations with smart barcode solutions? Contact AIDC Technologies India today for a free consultation, customized recommendations, and reliable tools that match your business goals.

#BarcodeDefinitions2025#BarcodeGuide#BarcodeUses#AIDCIndiaBarcode#BarcodeTechnology#SmartTrackingSolutions#BarcodeBasics#InventoryManagement#BarcodeScanning#RetailTech2025

0 notes

Text

Sticker Labelling Machine: The Complete Guide to Smart Product Labeling

What is a Sticker Labelling Machine?

A sticker labelling machine is a device that applies pre-printed or blank self-adhesive labels (commonly called "stickers") onto various products like bottles, jars, boxes, and containers. These machines offer precision, speed, and customization for diverse packaging requirements.

They eliminate the inefficiencies of manual labeling and ensure that labels are applied straight, bubble-free, and uniformly across thousands of items daily.

Types of Sticker Labelling Machines

1. Manual Sticker Labelling Machines

Best for small-scale production

Cost-effective and simple to operate

Ideal for startups and cottage industries

2. Semi-Automatic Sticker Labelling Machines

Operator loads the product manually; machine applies the label

Perfect for medium-volume operations

Common in the food, personal care, and small pharmaceutical sectors

3. Automatic Sticker Labelling Machines

Fully automated with conveyor belt integration

High-speed labeling with minimal human intervention

Used for mass production and industrial packaging lines

4. Double Side Sticker Labelling Machines

Labels both the front and back sides of containers simultaneously

Excellent for cosmetics, shampoos, and cleaning products

5. Wrap Around Sticker Labelling Machines

Designed for cylindrical bottles and jars

Applies a full 360° label

6. Top and Bottom Labelling Machines

Apply stickers to top and/or bottom surfaces of flat objects like boxes, trays, and pouches

Industrial Applications of Sticker Labelling Machines

Pharmaceutical Industry

Applies labels with dosage, expiry date, QR codes

Ensures regulatory compliance and barcode readability

Food and Beverage

Bottle and jar labeling for soft drinks, sauces, honey, and oils

Labels withstand refrigeration and moisture exposure

Cosmetic Industry

High-end product labeling for creams, serums, and perfumes

Requires elegant, smudge-free, and durable finishes

Chemical and Pesticide Industry

Labels resistant to harsh chemicals, UV, and abrasion

Logistics and Warehousing

Barcode labels, shipping tags, inventory stickers

Key Features of a Modern Sticker Labelling Machine

1. High-Speed Operation

Capable of labeling 100 to 400 units per minute, depending on model

2. Advanced Sensor Systems

Detects product presence and label gaps for precise placement

3. Touchscreen HMI and PLC Controls

Easy configuration, error detection, and real-time production monitoring

4. Adjustable for Multiple Products

Handles various diameters, shapes, and label sizes

5. Coding and Printing Integration

Supports batch coding, barcodes, QR codes, manufacturing/expiry dates

6. Stainless Steel Construction

Food and pharma-grade SS304/SS316 material ensures hygiene and durability

Advantages of Using Sticker Labelling Machines

Professional Finish: Ensures brand consistency across all units

Enhanced Productivity: Reduces labeling time drastically

Cost Efficiency: Cuts down on labor and label waste

Minimal Downtime: Easy to maintain and calibrate

Customizable: Adapts to various products and packaging formats

Regulatory Compliance: Meets FDA, FSSAI, ISO standards for packaging

0 notes

Text

Choosing the Right Print & Apply Labeling System for Your Industry

In today’s fast-paced industrial landscape, efficiency, accuracy, and compliance are critical factors when it comes to labeling products. Whether you operate in the food and beverage, pharmaceutical, logistics, or manufacturing sector, selecting the right print & apply labeling system is essential to streamline operations, improve traceability, and ensure regulatory compliance. But with numerous options available, how do you choose the right one for your industry? Let’s explore the key factors to consider when making this important decision.

Understanding Print & Apply Labeling Systems

A print & apply labeling system is an automated solution that prints labels on demand and applies them directly to products, cartons, or pallets. These systems are commonly used in industries where high-speed labeling, precision, and traceability are necessary. They integrate with existing production lines and help businesses maintain consistency and compliance with industry regulations.

Key Considerations When Choosing a Print & Apply Labeling System

1. Industry-Specific Requirements

Each industry has unique labeling requirements. Here are some key considerations based on different industries:

Food & Beverage: Compliance with FDA, USDA, and EU regulations, durability in cold or humid environments, and the ability to print expiration dates and batch codes.

Pharmaceutical & Healthcare: Adherence to stringent regulatory requirements such as FDA 21 CFR Part 11, serialization, and tamper-evident labeling.

Logistics & E-commerce: High-speed barcode printing, variable data printing, and integration with warehouse management systems (WMS).

Manufacturing & Automotive: Resistance to harsh conditions, high-speed application, and integration with supply chain tracking systems.

2. Labeling Speed & Throughput

Different industries have varying production speeds. Choosing a system that matches your required throughput is crucial to avoid bottlenecks. High-speed production lines need labeling machines capable of handling fast-paced operations without compromising accuracy.

3. Print Quality & Resolution

Labels often contain essential information such as barcodes, expiration dates, serial numbers, and branding elements. A print & apply system should offer high-resolution printing (e.g., 300 dpi or higher) to ensure clear and legible labels that comply with industry standards.

4. Label Material & Adhesion Requirements

Consider the type of materials used for labels and the surfaces they will be applied to. Some applications require durable, heat-resistant, or moisture-resistant labels. Ensuring the right label material and adhesive type will prevent peeling, smudging, or fading over time.

5. Integration with Existing Systems

Your labeling system should seamlessly integrate with your Enterprise Resource Planning (ERP), Warehouse Management System (WMS), or Manufacturing Execution System (MES) to enable real-time data exchange, automated updates, and reduced manual intervention.

6. Ease of Use & Maintenance

A user-friendly interface, simple software setup, and easy-to-replace consumables contribute to smooth operations. Choose a system that minimizes downtime, has robust technical support, and offers remote diagnostics to ensure continuous operation.

7. Compliance with Industry Regulations

Regulatory compliance is a significant factor in choosing a print & apply system. Verify that the system meets industry-specific standards such as GS1, FDA, EU MDR, ISO, or GHS labeling requirements to ensure global compliance.

8. Scalability & Future-Proofing

As your business grows, your labeling needs may change. Opt for a scalable system that can handle increased production demands and support additional labeling applications such as RFID tags, 2D barcodes, and multi-sided labeling.

Popular Print & Apply Labeling System Technologies

Thermal Transfer Printers: Ideal for long-lasting labels with durable prints, commonly used in logistics, pharmaceuticals, and manufacturing.

Direct Thermal Printers: Best for short-term labels such as shipping labels and perishable goods in food and beverage industries.

RFID Labeling Systems: Used in industries that require advanced tracking and authentication, such as supply chain and retail.

Laser Labeling Systems: Provides high-speed, permanent labeling for industries like automotive and aerospace.

Final Thoughts

Selecting the right print & apply labeling system depends on your industry’s specific needs, regulatory requirements, production speed, and integration capabilities. Investing in a high-quality system will enhance efficiency, ensure compliance, and reduce labeling errors, ultimately leading to improved operational performance.

By carefully evaluating the factors mentioned above, you can choose a print & apply labeling solution that aligns with your business goals, streamlines workflows, and provides long-term value. If you’re unsure about which system best fits your needs, consulting with an expert in labeling automation can help you make an informed decision.

Ready to upgrade your labeling process? Explore the latest print & apply labeling systems designed to optimize efficiency and accuracy in your industry!

0 notes

Link

Batch Printing Machine, Batch Code Machine and Batch Coding Machine, Batch Code Printing Machine Manufacturer, Batch Print, Batch Code Machine. Our Winder Rewinder Machines for Inkjet Printing & Batch Printing are widely used by all Printer Manufacturers all over the world. Our Winding Rewinding Machines give efficient prompt printing an all types of laminates like, Foil, Paper, LDPE, HDPE, PVC, Automatic Batch Coding Machine, Automatic Batch Printing Machine etc. The Batch Coding application for Winder Rewinder Machine is coupled beautifully & synchronized well.

#Batch Printing Machine#Batch Printing Machine Manufacturer#Batch Coding Machine#Batch Coding Machine Manufacturer#Batch Code Machine#Automatic Batch Coding Machine#Automatic Batch Printing Machine#Automatic Carton Batch Printing Machine#Batch Coding Machines#Batch Coding Manual Printing Machine

1 note

·

View note

Link

Slitting Rewinding Machine for Batch Printing Coding, Slitting Machines, Slitter Rewinder Machine for Industry specific Batch Printing, Batch Printing, Slitter Rewinder Machine, Doctoring Rewinding Machine, Batch Coding Machine, Packaging Machine, Printing Machine, Fabric Folding Machine, Cantilever design-balancing body for easy loading and unloading of parent / rewound reel. Movable unwind stage for Edge guiding System (Hydraulic Web Aligner).Mechanical 1.5 / 2.5 Kg. Optional Magnetic powder brake with tension controller & Torque control potentiometer. Provision for incorporating Inkjet Printing System with Hot air ink drying. The Model is specially designed for correcting badly wounded reels for inspection & doctoring operation. It is great substitute to online coding / batching operation

http://www.windingrewindingmachine.com/slitting-rewinding-machine-for-batch-printing-coding.php

#batch coding machine#batch printing machine#slitter machine manufacturer#winder Rewinder machine#Winding Rewinding Machine Manufacturer#slitter Rewinder#slitting rewinding machine#motor winding machine price#date printing machine#manual batch coding machine#Bopp tape slitting machine#batch printing machine price#rewinding machine price#paper winding machine#digital batch coding machine

1 note

·

View note

Link

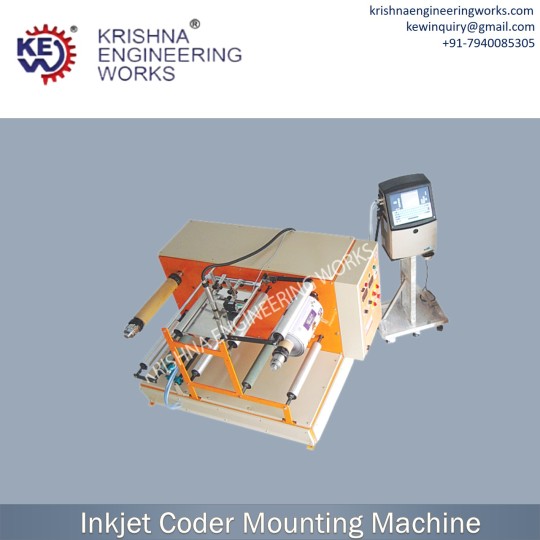

Inkjet Coder Mounting Machine manufacturers, suppliers, and exporters in Inkjet Coder Mounting Machine, in any paper, film, and foil conversing industries, the Winder/Rewinder (Doctor Machine) is used widely for online printing of Mfg. Dt., Exp. Dt. B. No. etc. using Inkjet printer or other contact coding machines from Roll to Roll at high speeds & then these printed roll are used in various packaging machines. For more information:

Website: krishnaengineeringworks.com

Email: [email protected]

Contact Us: +91-7940085305

#Inkjet Coder Mounting Machine#inkjet batch code printer#batch coder mini printer#batch printing machine#batch coding machine#manual batch coding machine#automatic batch coding machine#batch printer machine#batch coding printing machine

1 note

·

View note